Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81results about How to "Reduce the amount of sanding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

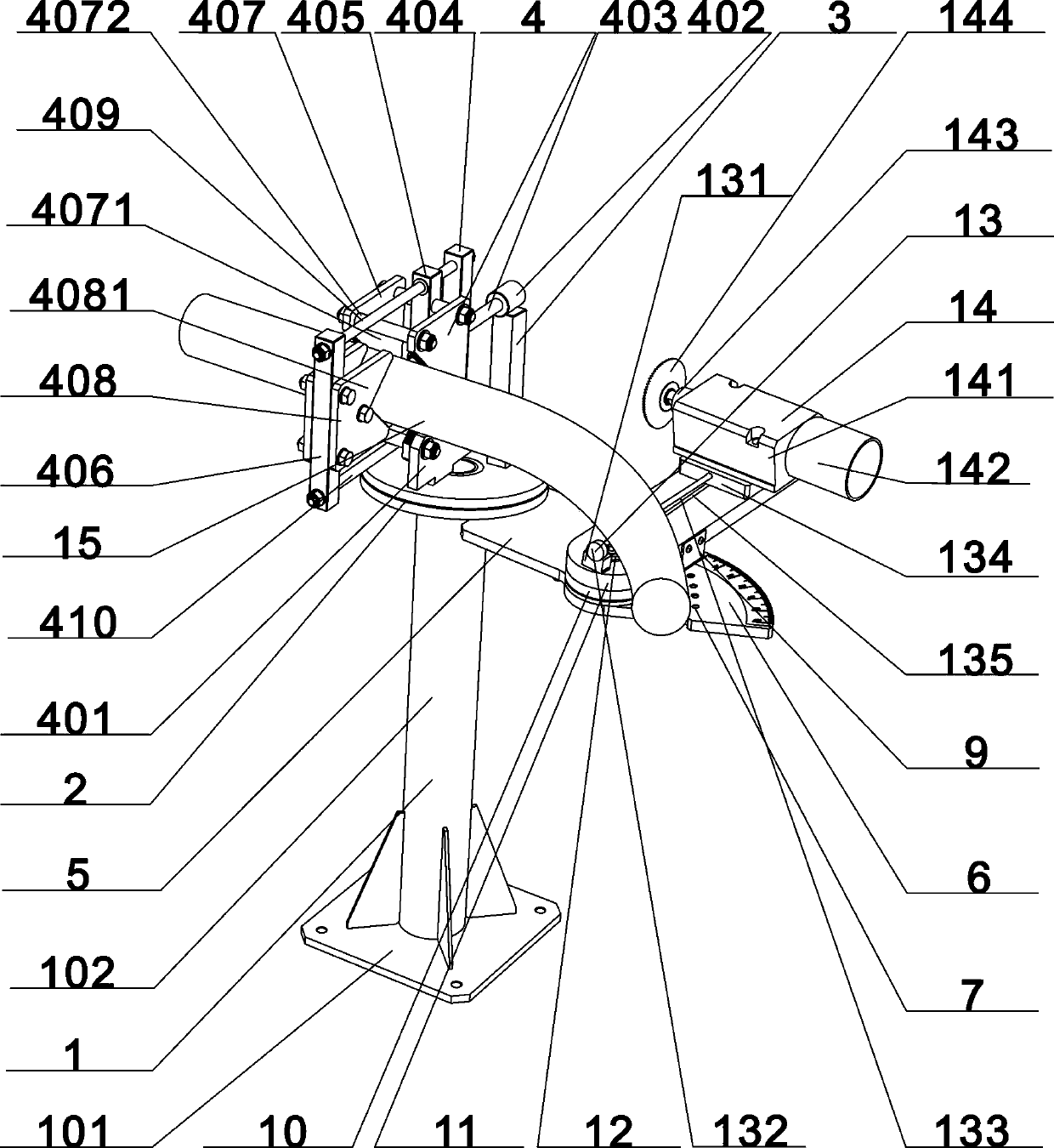

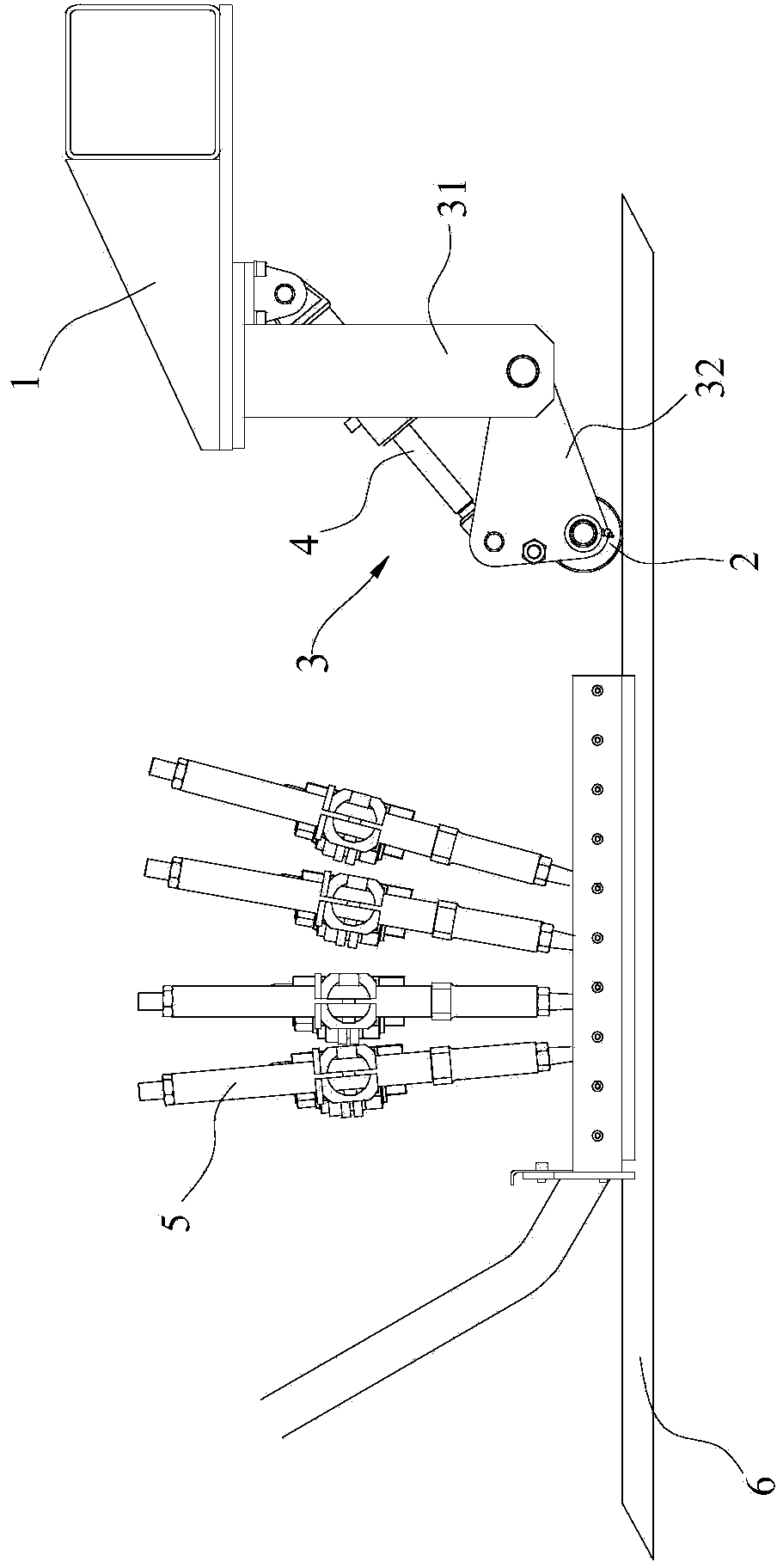

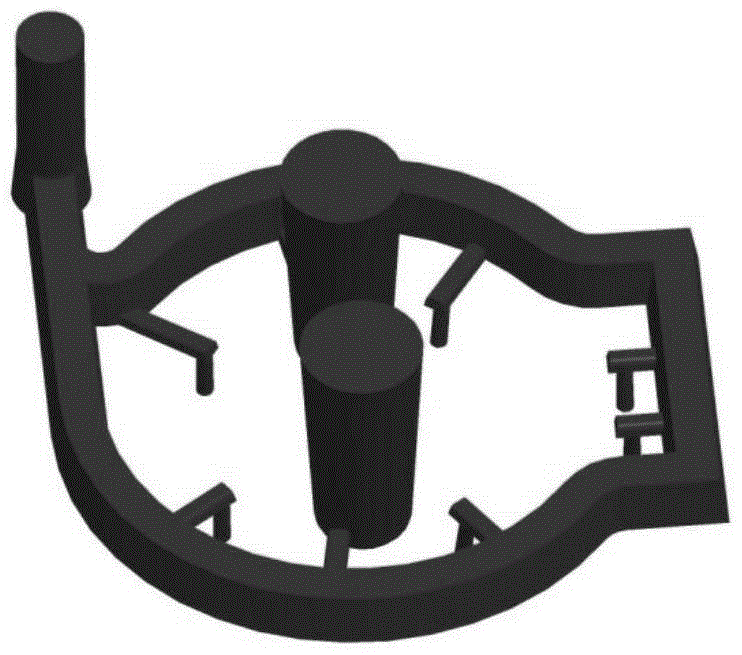

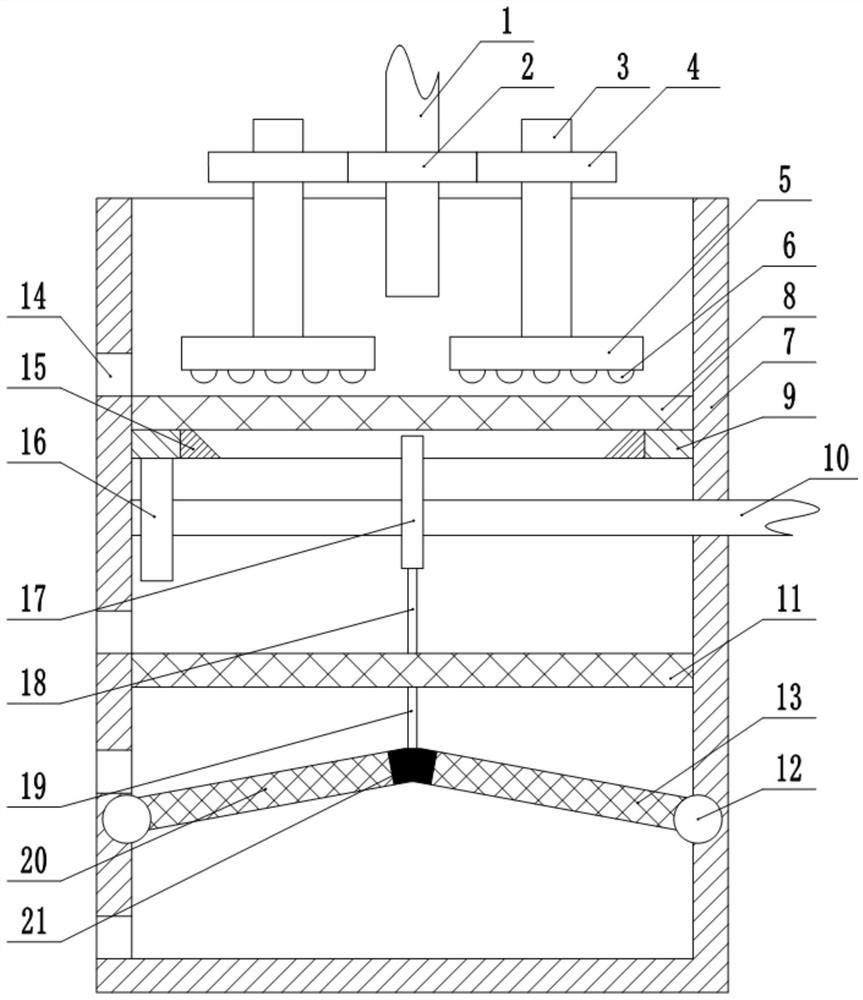

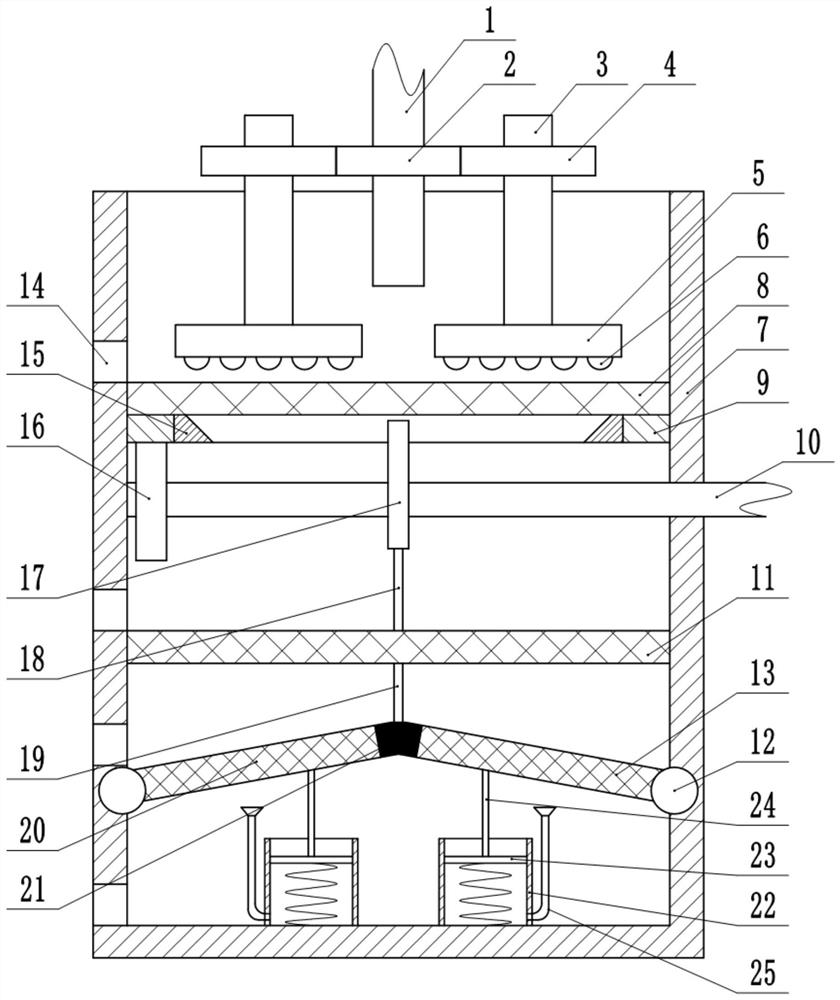

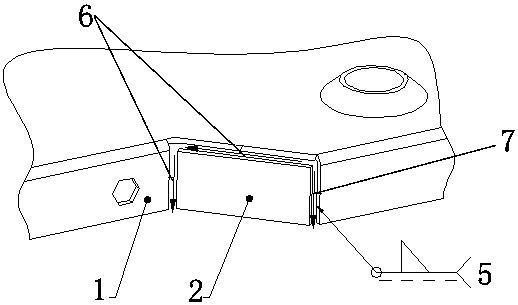

Automatic bead welding equipment of saddle-shaped pipe joint surface with conical table and welding method thereof

InactiveCN101804493AAchieve horizontal displacementConsistent weld beadWelding accessoriesEngineeringLinkage concept

The invention relates to automatic bead welding equipment of a saddle-shaped pipe joint surface with a conical table and a welding method thereof, belonging to the technical field of automatic welding equipment and welding methods. The equipment comprises a station regulating device, an automatic welding gun manipulator, a laser positioner and an electrical control device. When the equipment works, the electrical control device controls the station regulating device and the automatic welding gun manipulator to be dynamically matched to complete the bead welding of an anti-corrosive layer of the saddle-shaped pipe joint surface with the conical table. The invention has the advantages that the electrical control device controls five-shaft linkage so that the end surface of the bead welding position of a workpiece is in a horizontal state; due to the adoption of a hot wire TIG (Tungsten Inert Gas) welding process and a horizontal continuous welding, the automatic bead welding equipment has good welding quality; the automatic bead welding equipment completely realizes automatic welding, reduces the polishing quantity of the bead welding surface and improves the utilization rate of a welding material; and voltage is added between a wire-feeding conducting nozzle and the workpiece through adopting a hot wire technique so that current flows through a welding wire between the wire-feeding conducting nozzle and the workpiece to heat the welding wire, and then the absorption of the welding wire for the heat quantity of an electric arc is reduced, thereby improving the welding efficiency.

Owner:CHINA FIRST HEAVY IND +1

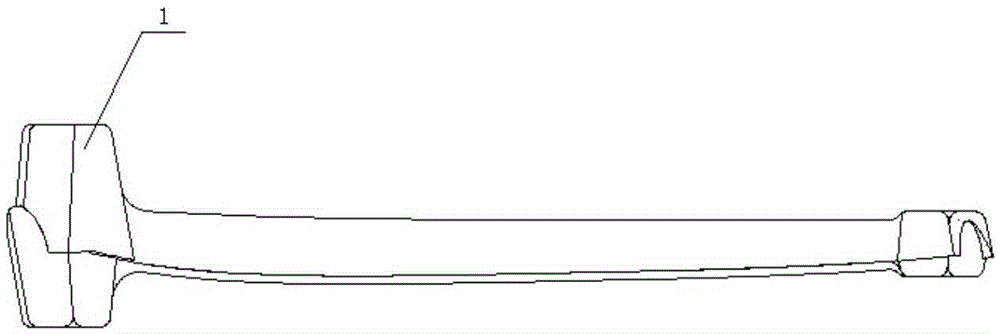

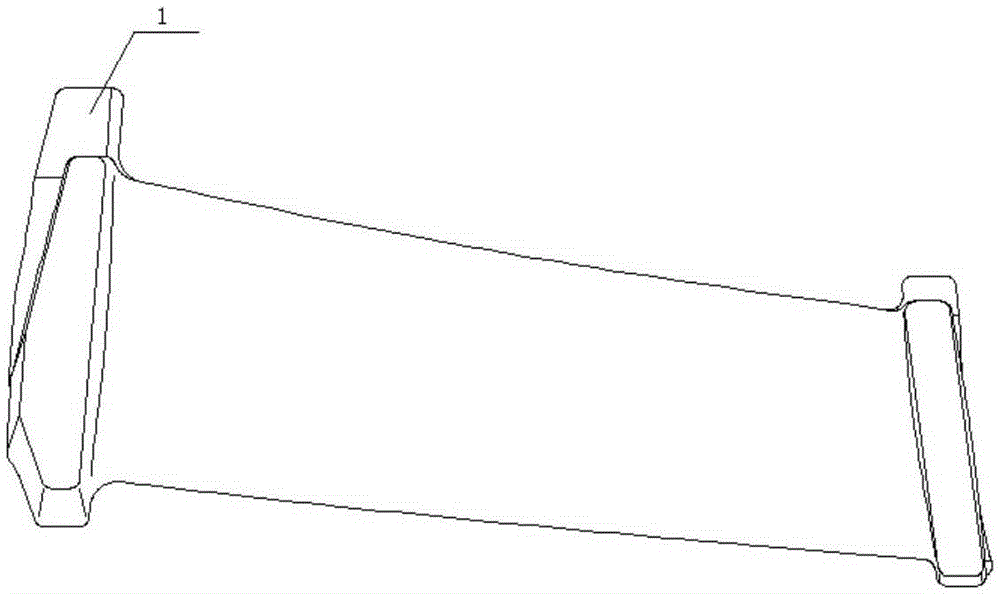

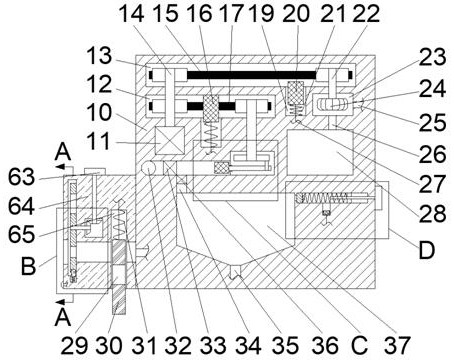

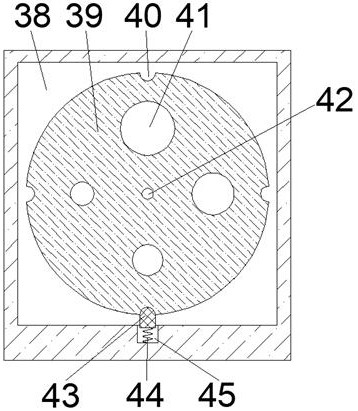

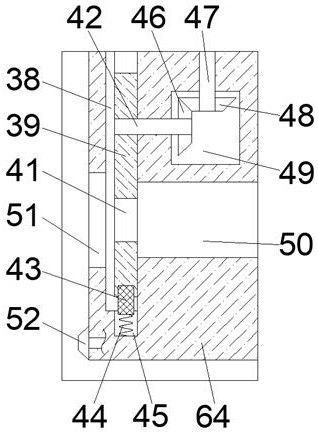

Titanium alloy elbow cutting machine

PendingCN110899827ASimple structural designHigh degree of automationPrecision positioning equipmentFeeding apparatusCircular discStraight tube

The invention belongs to the technical field of cutting of petrochemical engineering pipeline titanium alloy elbows and discloses a titanium alloy elbow cutting machine. The cutting machine is characterized in that a connecting plate is fixedly arranged at a lower part of a right side of a supporting disc, an index plate is fixedly connected with a right side of the connecting plate, pin holes areevenly formed around scales of the index plate at equal intervals, fixing pins penetrate through the left side, close to a front end, of the rotating plate, the pin holes are used for fixing the index plate and the rotating plate, an index alignment plate is fixedly arranged on the right side, close to the front end, of the rotating plate, a rotating chassis is fixed to the center of the front end of the index plate, a lead screw adjusting device is fixedly arranged at the transverse position of an upper portion of the rotating plate, and a cutting device is fixedly arranged on an upper portion of a movable sliding block of a lead screw adjusting device. The cutting machine is advantaged in that flatness of a cutting end face of a titanium alloy bent pipe is greatly improved, the grindingamount of the cutting end face of the titanium alloy bent pipe is reduced, and thereby working efficiency of welding of the titanium alloy bent pipe and a straight pipe is improved.

Owner:HENAN XINKAIYUAN PETROCHEM PIPELINE

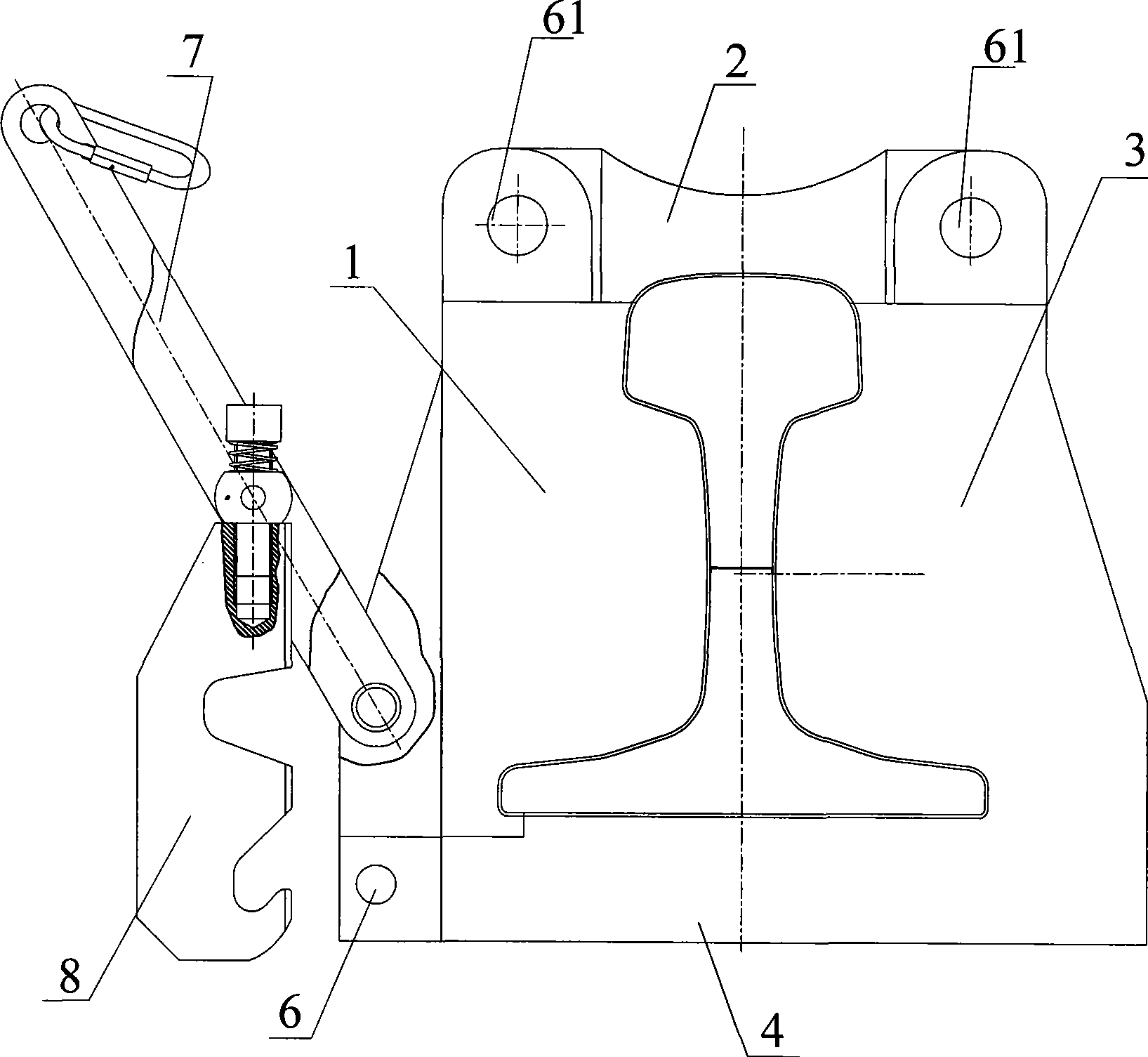

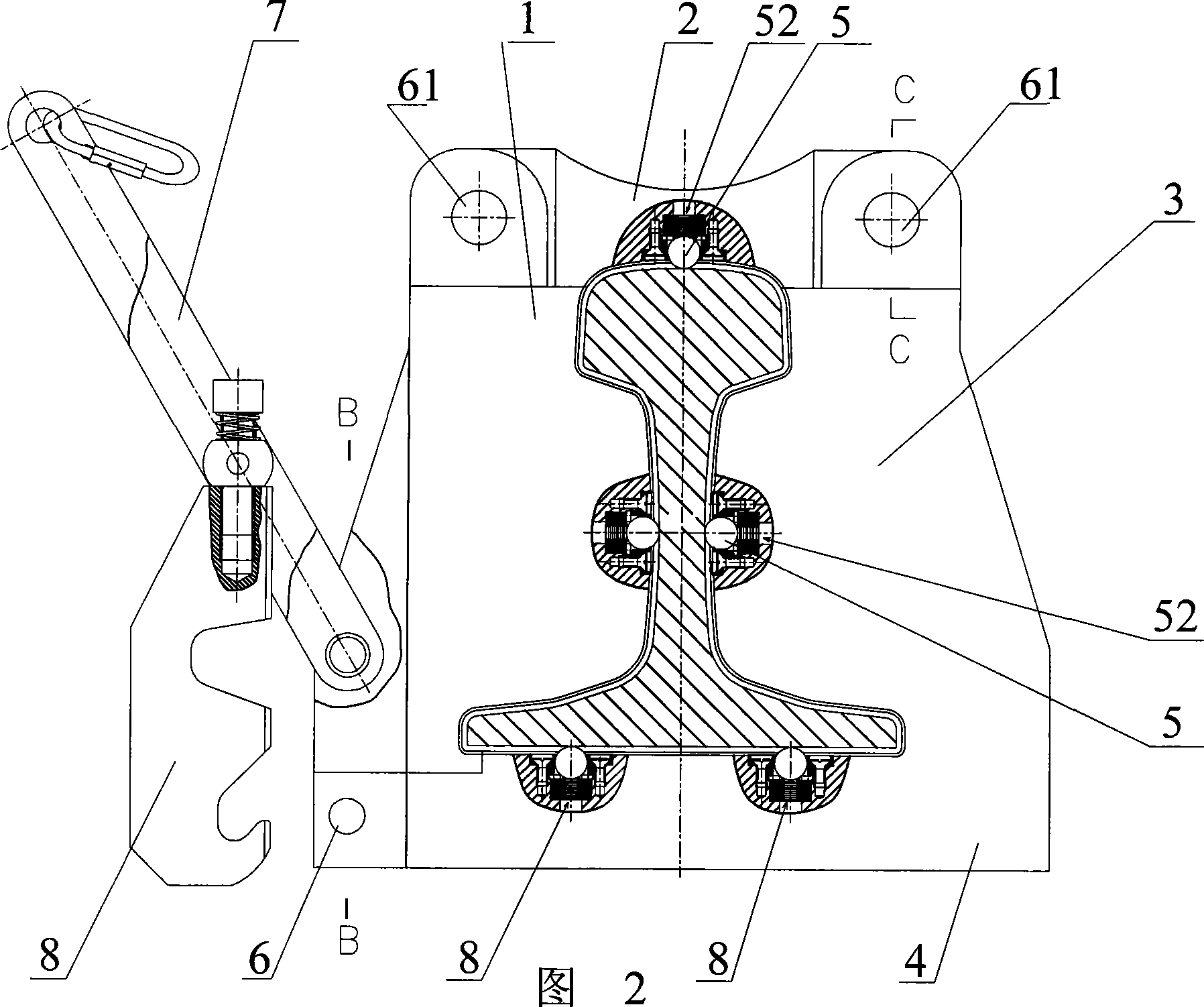

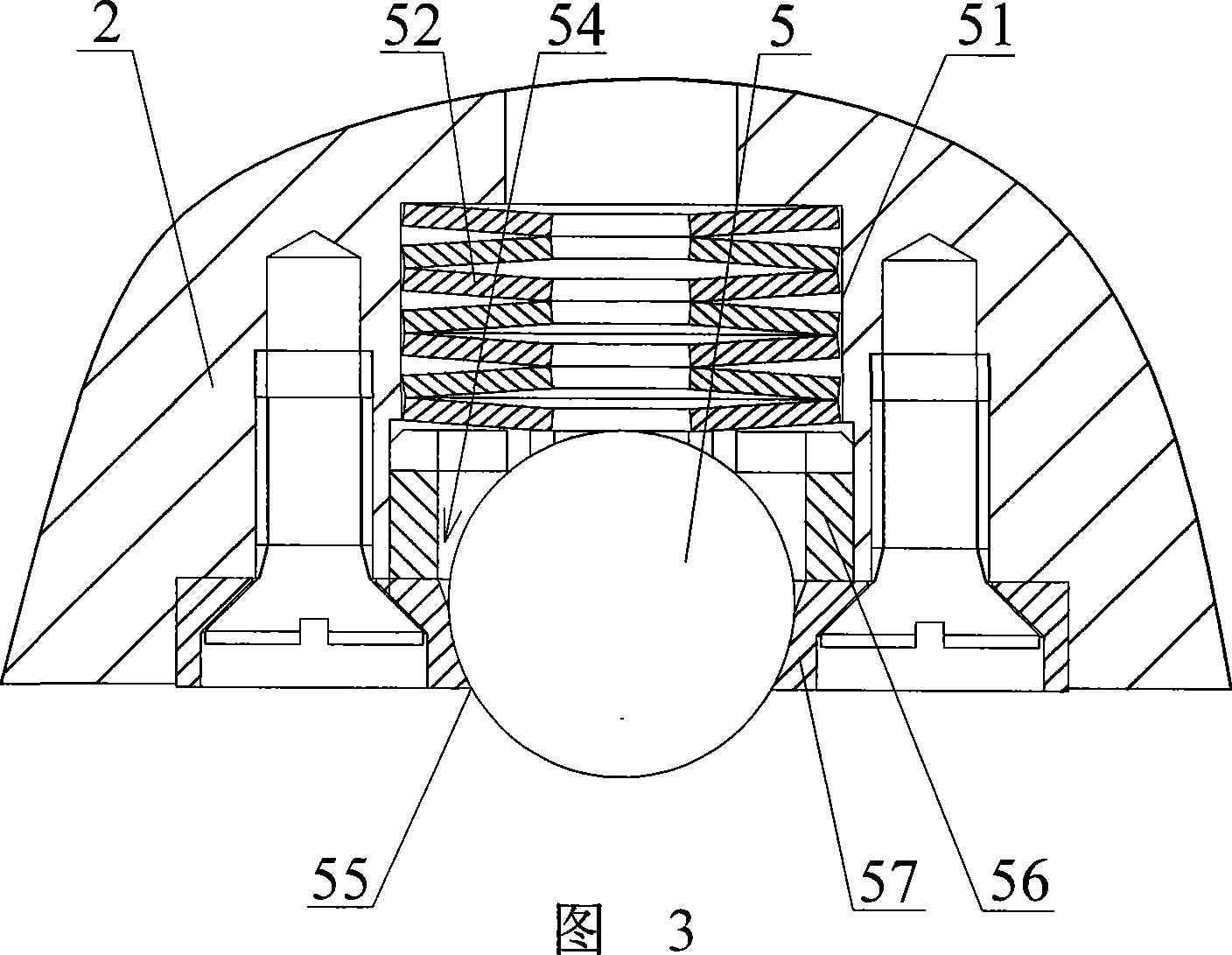

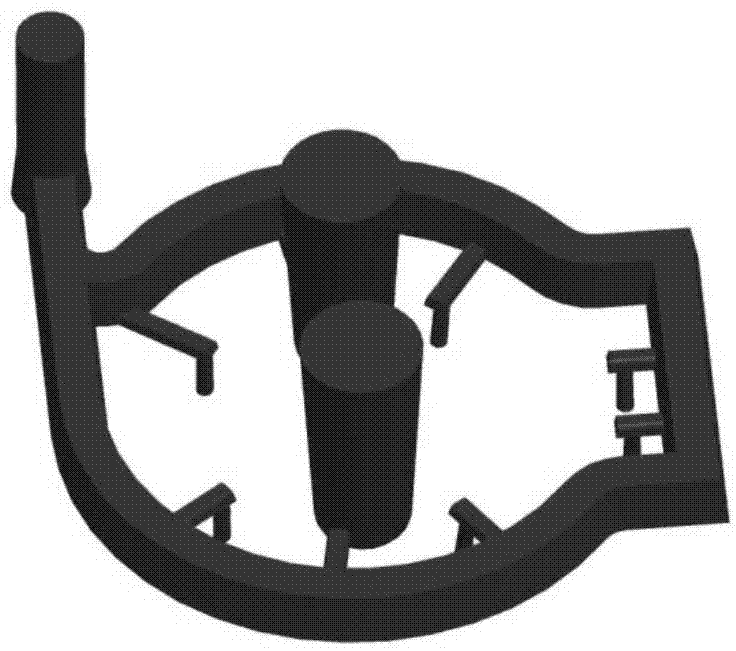

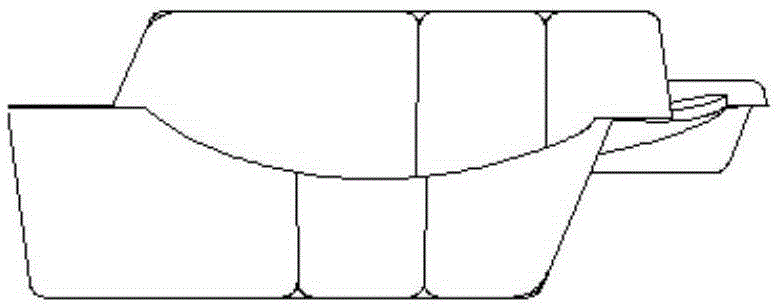

Tumour-pulling knife for removing steel rail welding beading

ActiveCN101428360AExtended service lifeWon't scratchWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismBody positions

The invention relates to a cutting tool, in particular to a knob removing tool used for removing rail welding beading. The invention provides the technical scheme that the knob removing tool for removing welding beading comprises a plurality of cutter bodies and locking mechanisms, which are connected end to end in sequence; wherein, the cutter bodies are mutually hinged end to end in sequence, or at least two adjacent cutter bodies therein are connected into an integrated body, and the other cutter bodies are mutually hinged; wherein, the locking mechanisms which are mutually matched and connected are arranged on the cutter bodies positioned at the front end and the rear end; cutting edges are arranged on the cutter bodies, after the cutter bodies positioned at the front end and at the rear end are mutually connected and locked, a section shape of the rail consists of the cutting edges of the cutter bodies, and the cutter bodies after locking comprise a left cutter body, a top cutter body, a right cutter body and a bottom cutter body. The knob removing tool is characterized in that a mounting hole is formed in the top cutter body, and a positioning component is mounted in the mounting hole, which is partially higher than the cutting edge of the top cutter body. The knob removing tool has the advantages that the main body of the rail can be not damaged in the knob removing process, the polishing quantity for workers is reduced, and the service life can be also prolonged.

Owner:CHANGZHOU RUITAI ENG MASCH CO LTD +1

Method for casting air cylinder cover of diesel engine for chiller-free ship

ActiveCN103480804AEasy to operate on siteReduce the amount of sandingFoundry mouldsFoundry coresChillerEngineering

The invention discloses a method for casting an air cylinder cover of a diesel engine for a chiller-free ship. The method comprises the following steps: calculating main hot spots of a casting piece at first; arranging insulation risers at the two large hot spot parts of the top surface of the casting piece; designing an inner pouring gate at the small hot spot part of the top surface of the casting piece for achieving feeding and exhausting in a solidification process and forming a top-down temperature gradient; finally solidifying molten metal in the risers. The method is simple, convenient, reliable and suitable for casting the air cylinder cover of the diesel engine for the ship.

Owner:CSIC NO 12 RES INST

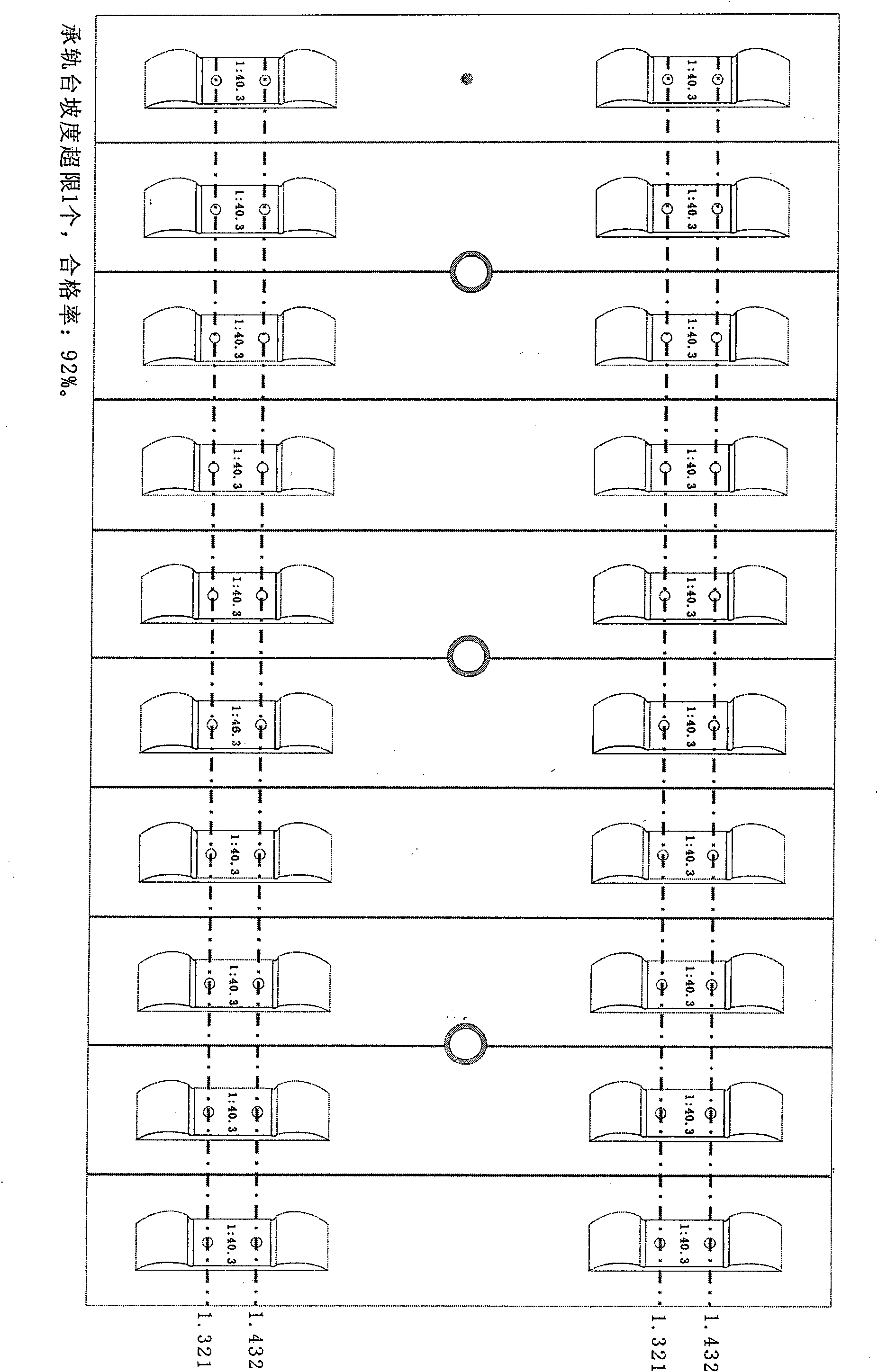

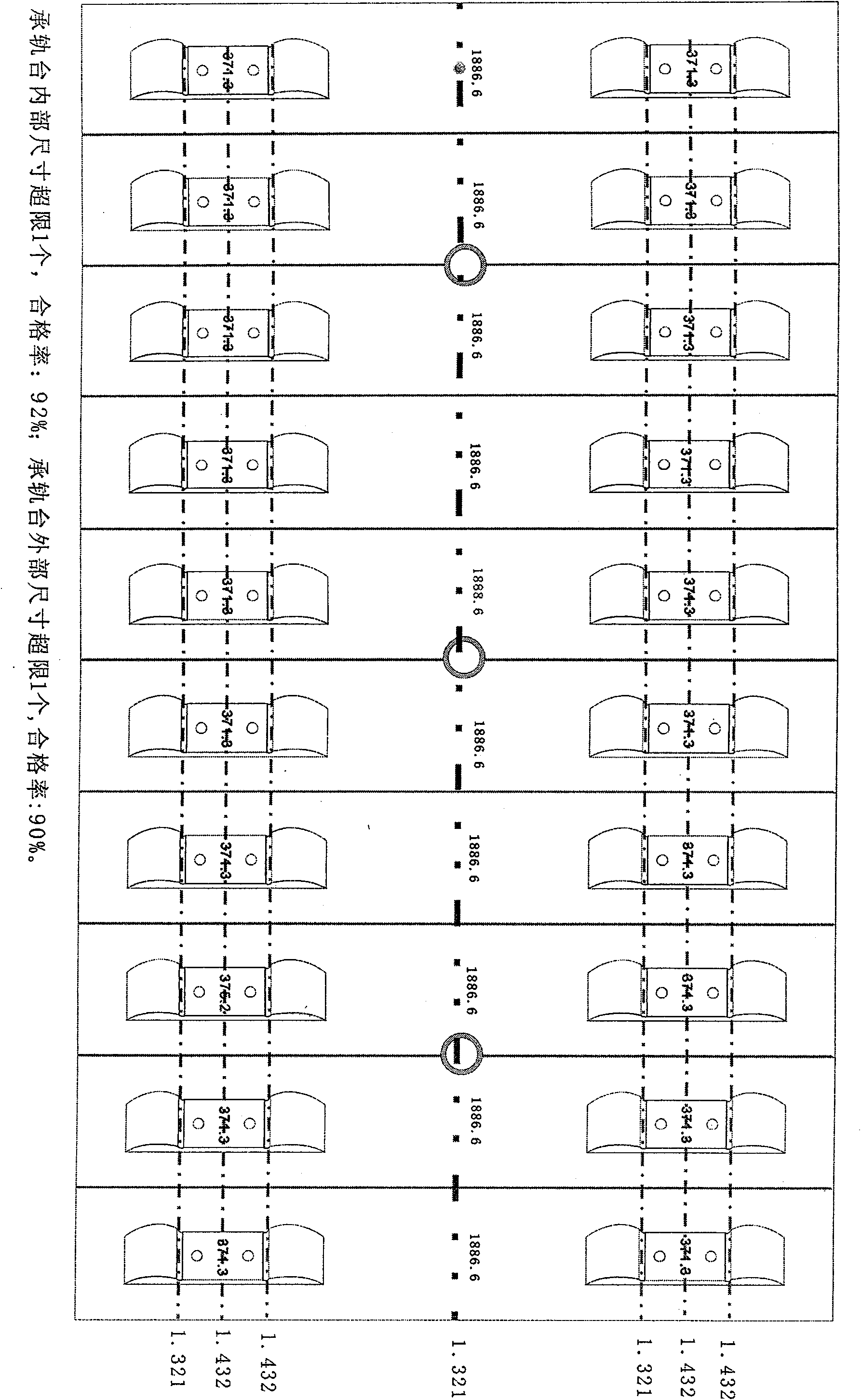

Detection method used for manufacturing CRTS II type track slabs

The invention relates to the field of CRTS II type track slab manufacture, in particular to a detection method for manufacturing CRTS II type track slabs, which solves the problem that the traditional detection system cannot achieve detection real-time or reflect integral track supporting mesa. (1) TK1, TK2 and KUS1 angular magnets are utilized to perform tension beam height and plane adjustment measurement and cylinder adjustment measurement; (2) a tray mould fine tuning fixture, combined with a precision angle concave sphere-prism, finely tunes a mould; (3) an arch mould detection fixture, combined with the precision angle concave sphere-prism, detects the mould; and (4) a platform track slab detection fixture, combined with the precision angle concave sphere-prism, detects a finished product slab and a blank slab. The detection method provides corresponding measurement guarantee for the slabs from a slab field to the processes of construction, prefabrication and polishing, improves the production efficiency of the slab field and saves huge polishing cost; and the system has simple use, can analyze data in real time and can meet the requirements of timeliness and precision.

Owner:CHINA RAILWAY 12TH BUREAU GRP +3

Preparation method for TA17 titanium alloy plate

InactiveCN106944492AAdjustable performanceGuaranteed billet rolling temperatureMetal rolling arrangementsHeating furnaceTitanium alloy

The invention discloses a preparation method for a TA17 titanium alloy plate. The preparation method comprises the following steps that a TA17 plate blank is put into a heating furnace to be heated; the titanium plate is separated from an upper stainless steel base plate and a lower stainless steel base plate; the plate blank is subjected to the first heating number of rolling; after the first heating number of rolling, slitting blanking is conducted according to the width needed by the finished plate in the length direction; the second heating number of rolling is conducted; and the plate blank is subjected to slitting blanking in the length direction. According to the preparation method, the principle that the structure heredity formed through machining under high temperature can be changed under the same temperature is used, the TA17 cogging rolling temperature is ensured, the obvious cracking phenomena of the TA17 titanium alloy plate due to temperature drop in a traditional process are reduced, meanwhile, later polishing quantity is reduced, the upper base plate and the lower plate can be used repeatedly, and cost is reduced.

Owner:天津皕劼同创精密钛铸造有限公司

Aqueous magnetic slurry and preparation method thereof

InactiveCN102134440AReduce the dosage ratioReduce generationMagnetic paintsPolyurea/polyurethane coatingsEmulsionMechanical stability

The invention discloses aqueous magnetic slurry and a preparation method thereof. The magnetic slurry comprises the following component in part by weight: 50 to 80 parts of magnetic powder, 1 to 10 parts of carbon black, 1 to 10 parts of wetting and dispersing agent, 10 to 60 parts of binder, 0 to 10 parts of curing agent and 50 to 200 parts of water. The binder is a mixture of a water soluble binder and an emulsion binder, wherein the weight ratio of the water soluble binder to the emulsion binder is 1:5.5 to 1:20. The slurry has high flowability, improves the water resistance of the coating, reduces air bubbles and improves the spreading appearance of the coating. In the invention, due to the adoption of the two-step preparation method, the requirement of a formula system on the mechanical stability of the emulsion binder is lowered, the selection range of the binder is enlarged, the sanding amount of the slurry is reduced, the production efficiency of the slurry is improved, the air bubble content in the slurry is lowered, and the production cost is reduced.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

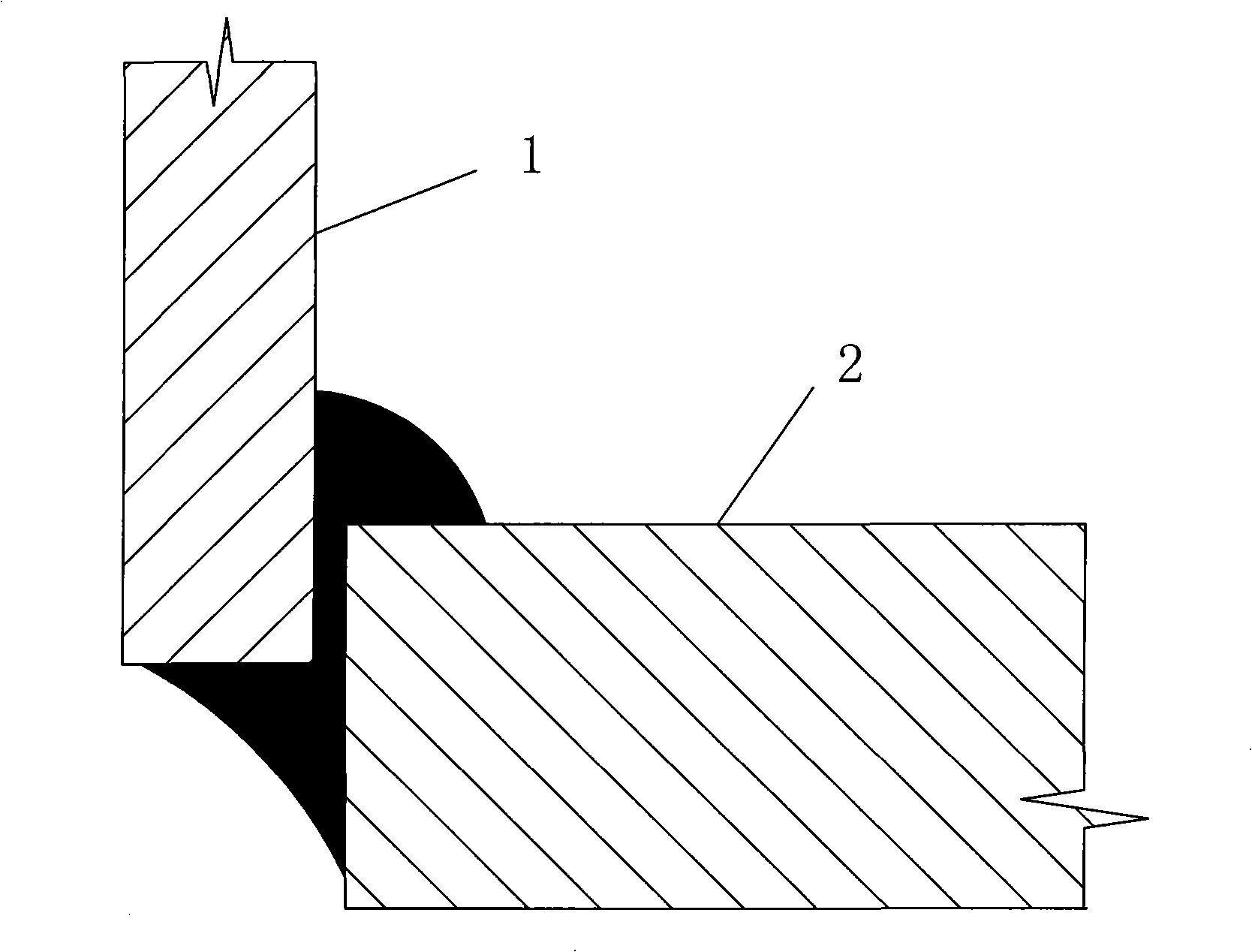

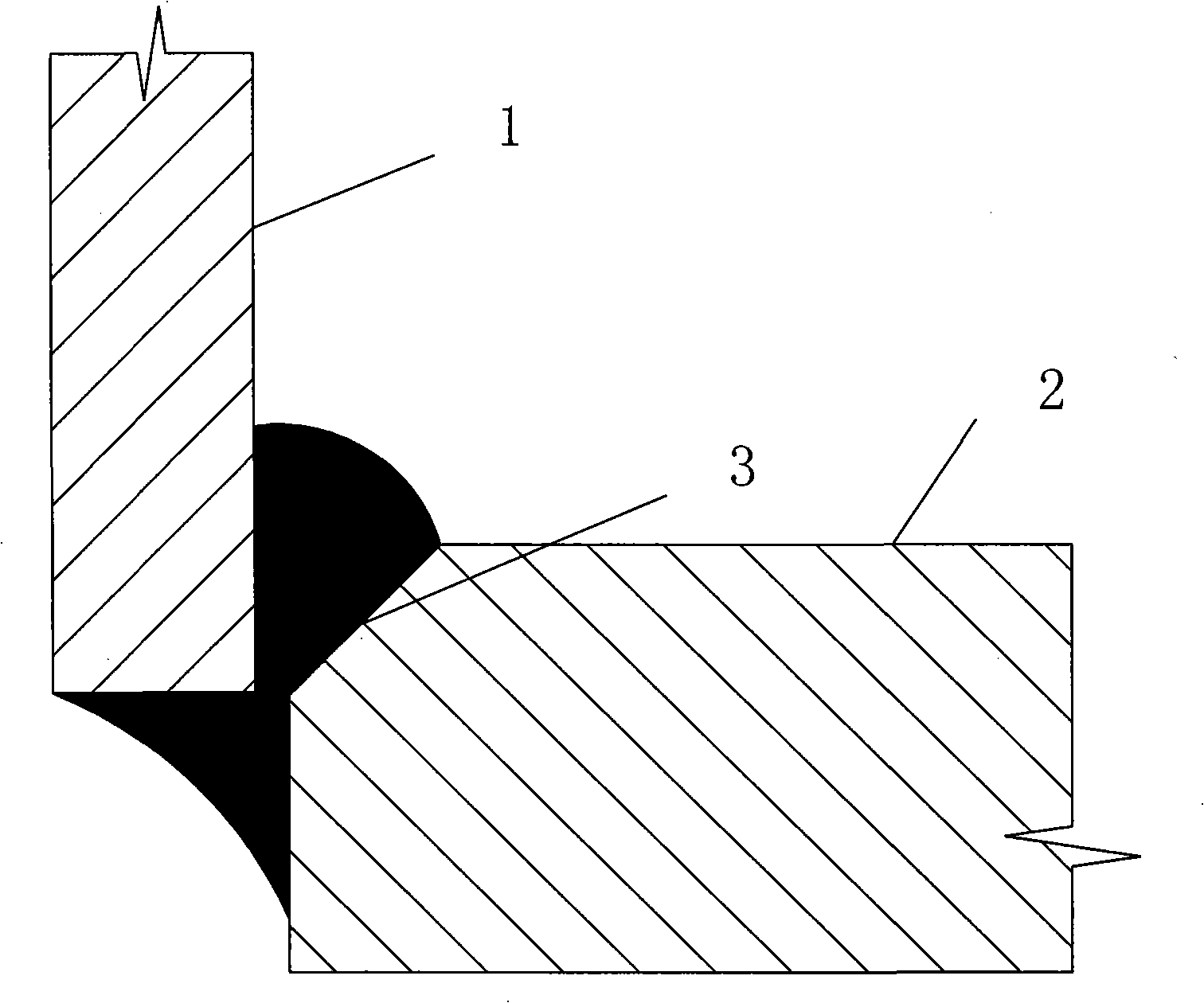

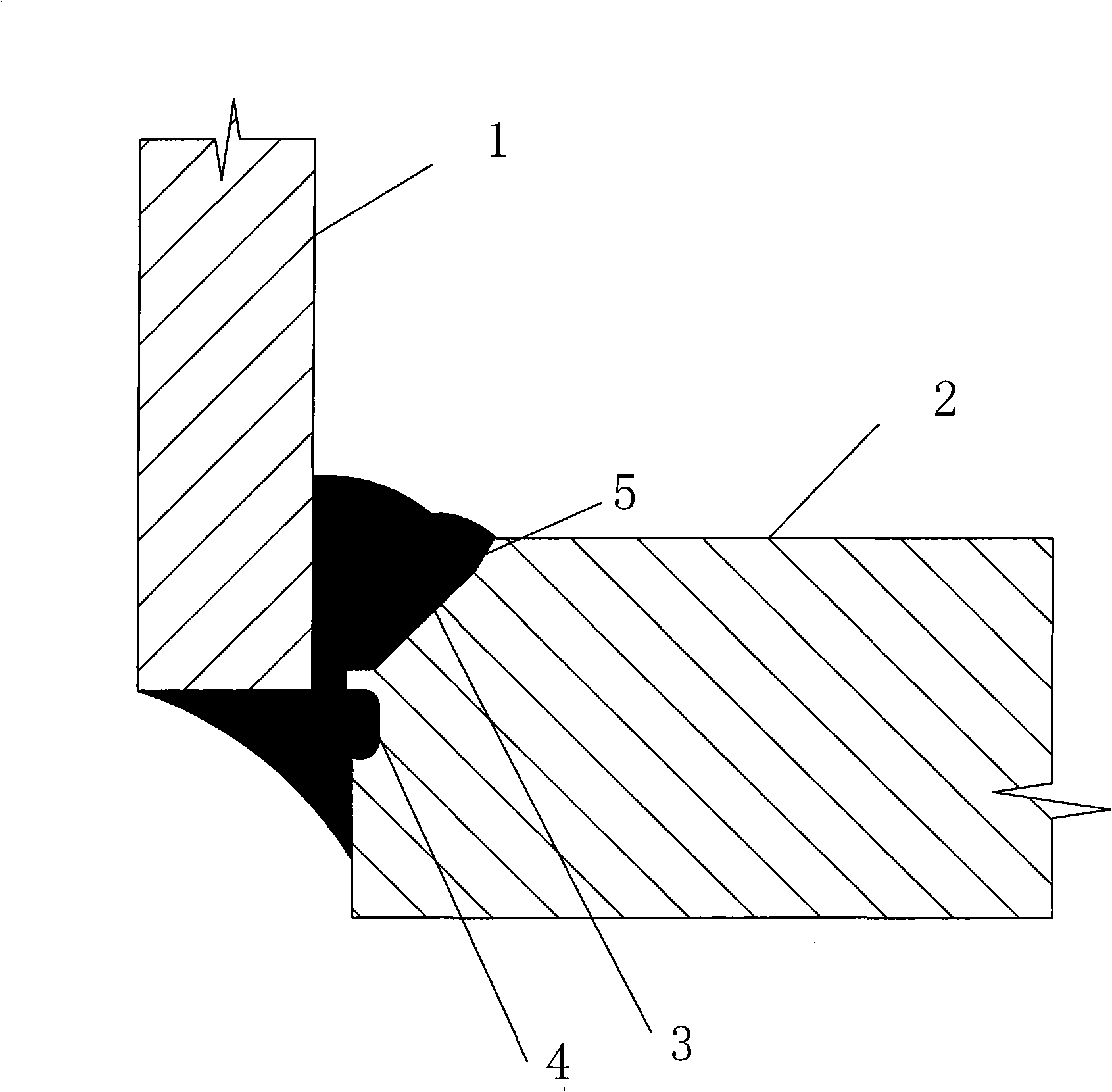

Plane welding flange divided edge structure

InactiveCN101259570AReduce welding distortionSpot welding is firmWorkpiece edge portionsEdge surfaceLap joint

The invention relates to a plane welding flange groove structure, the inner edge surface of a flange is lap-jointed with the outer wall of the end part of a steel pipe, the flange is divided into a lap joint section and an exposed section along the thickness direction, the flange is provided with a circumferential groove along the lap joint section, an annular slot is arranged on the exposed section, and an interval exists between the annular slot and the bottom part of the circumferential groove. The invention provides the plane welding flange groove structure with the firm point welding, full-penetration weld and good welding quality.

Owner:ZHEJIANG SHENGDA STEEL TOWER +2

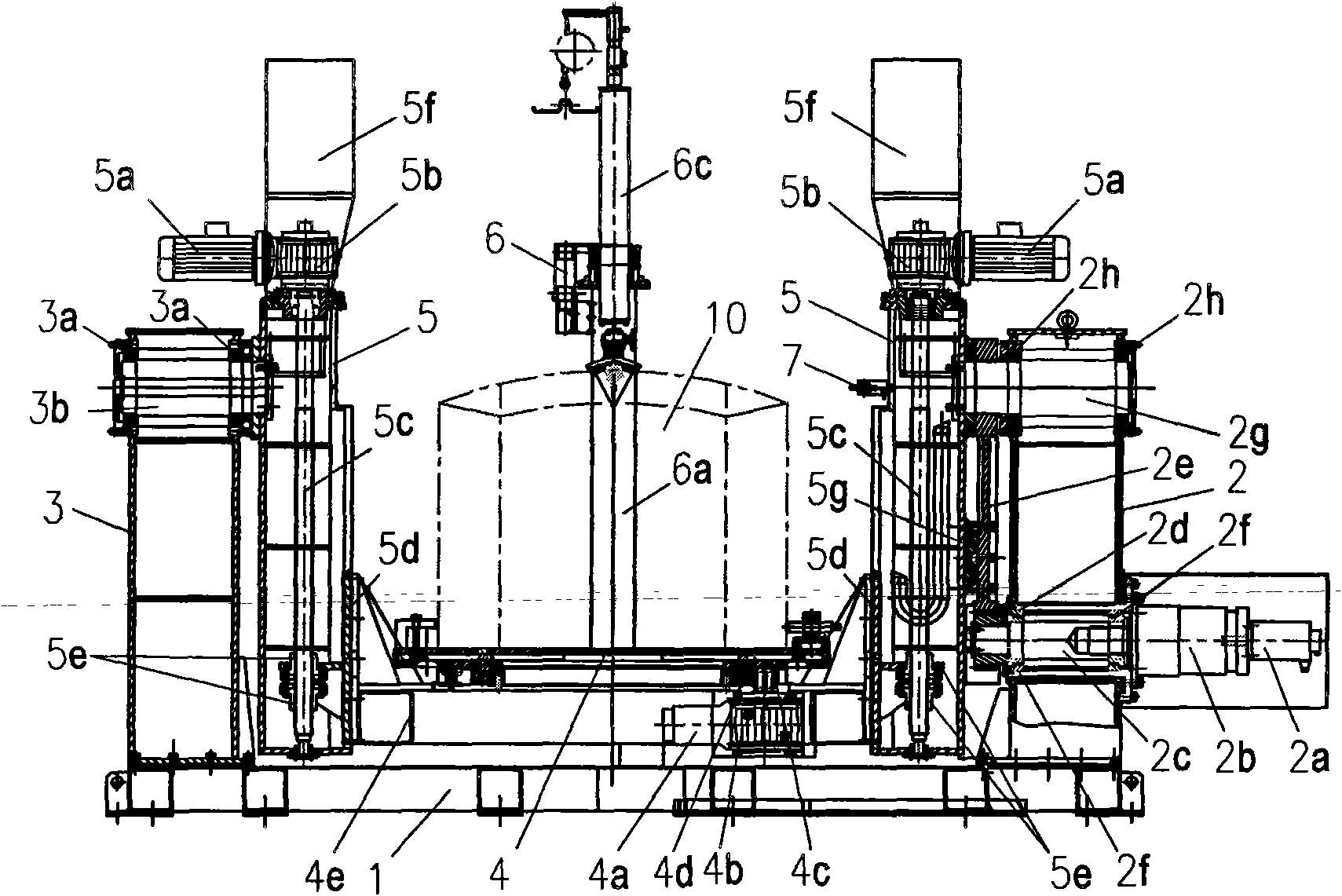

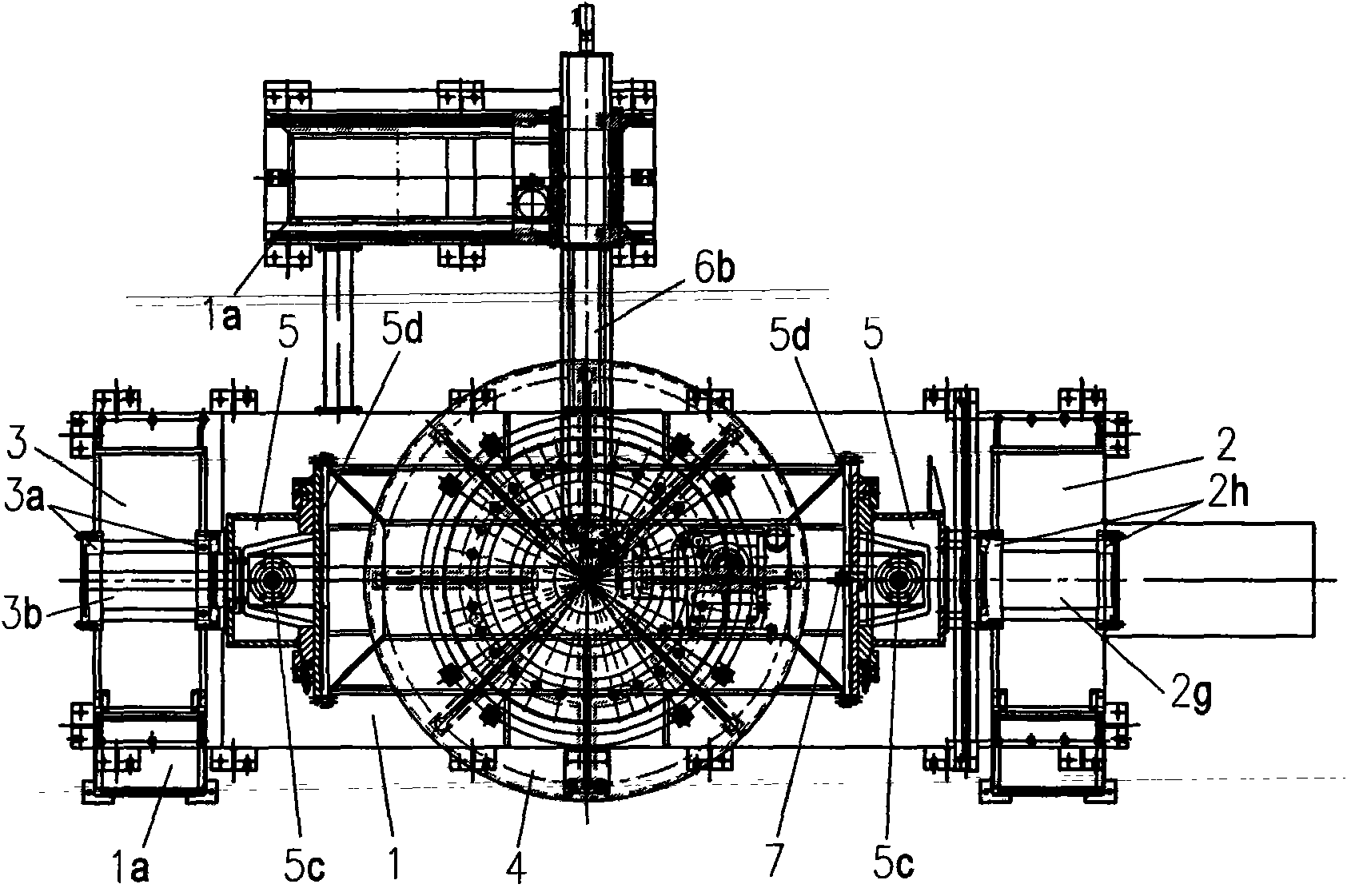

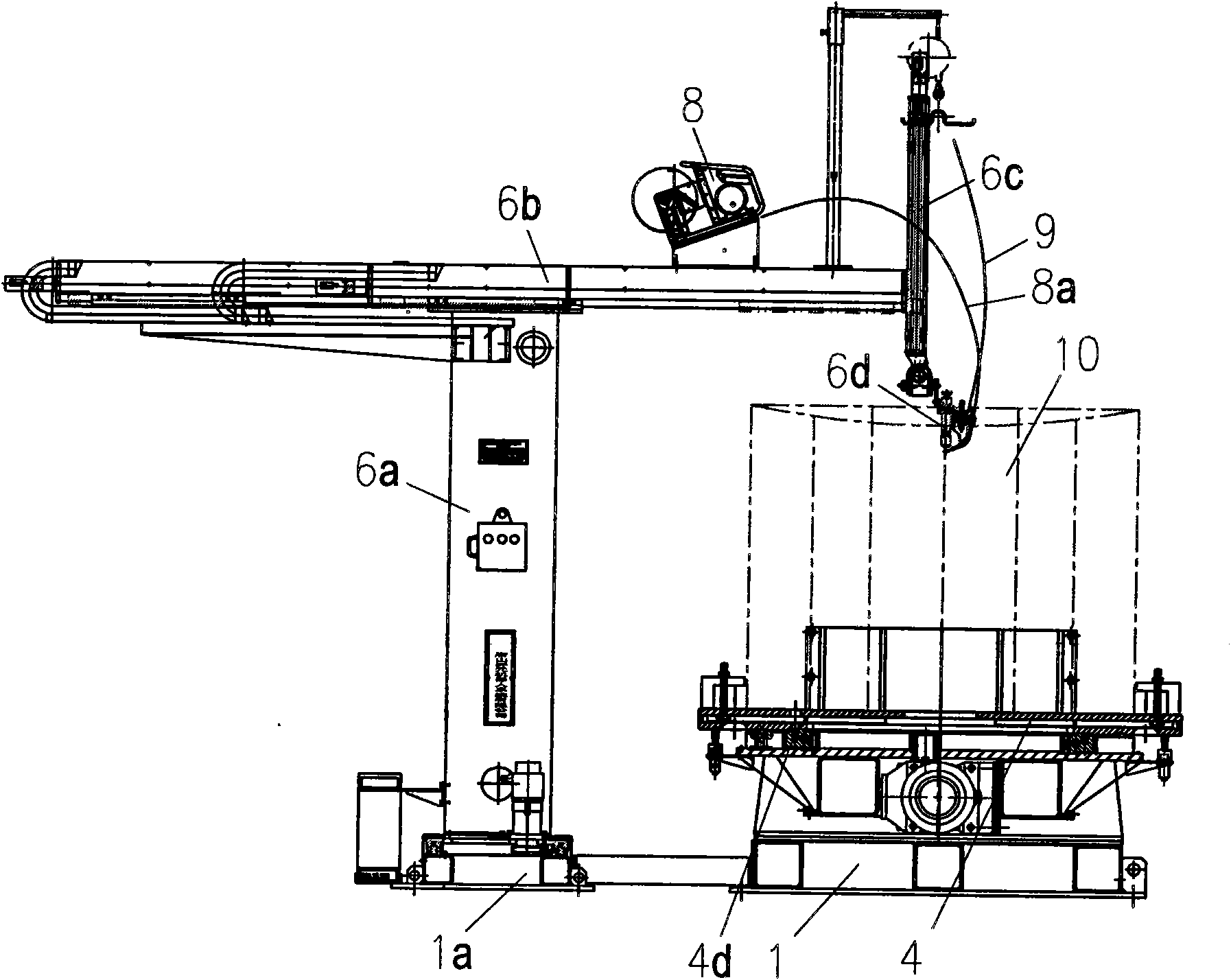

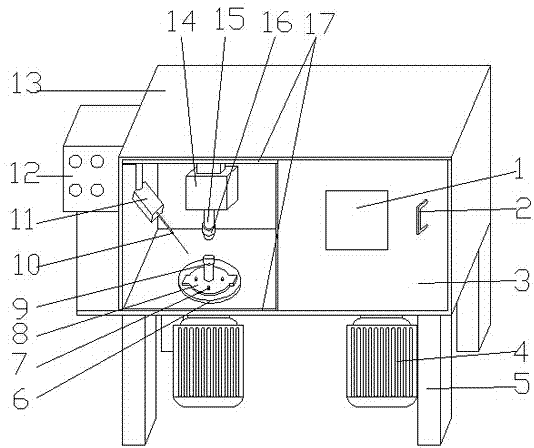

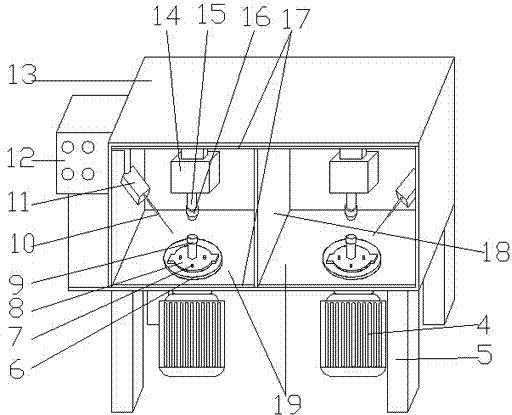

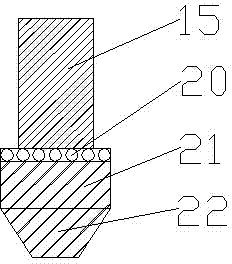

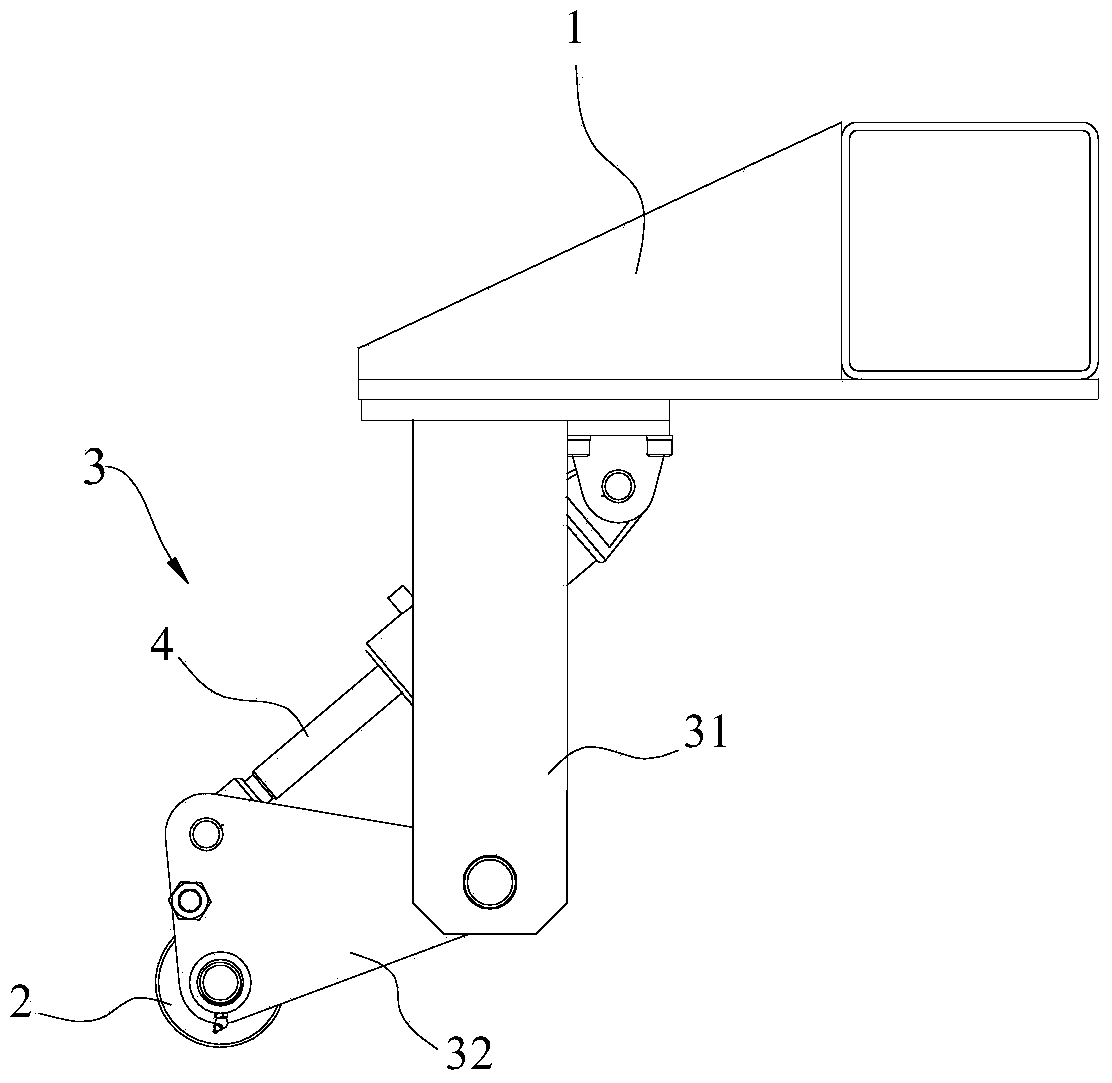

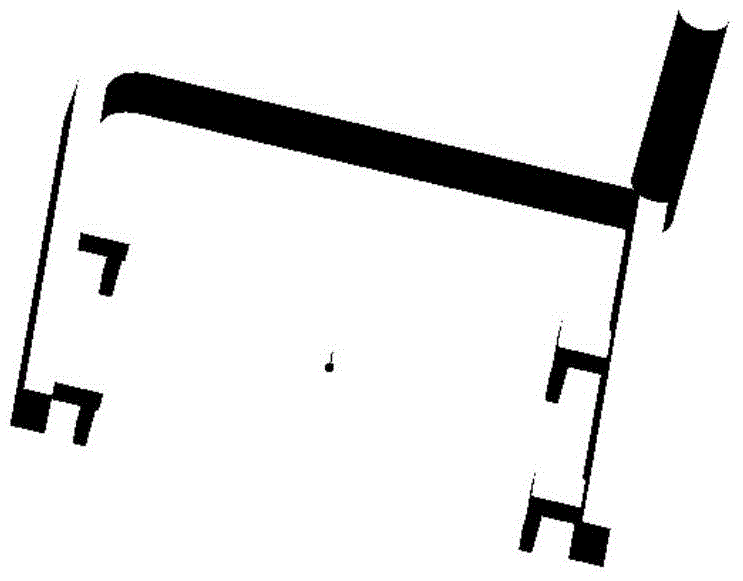

Vertical type double-station steel pipe fitting rotation automatic welding machine tool

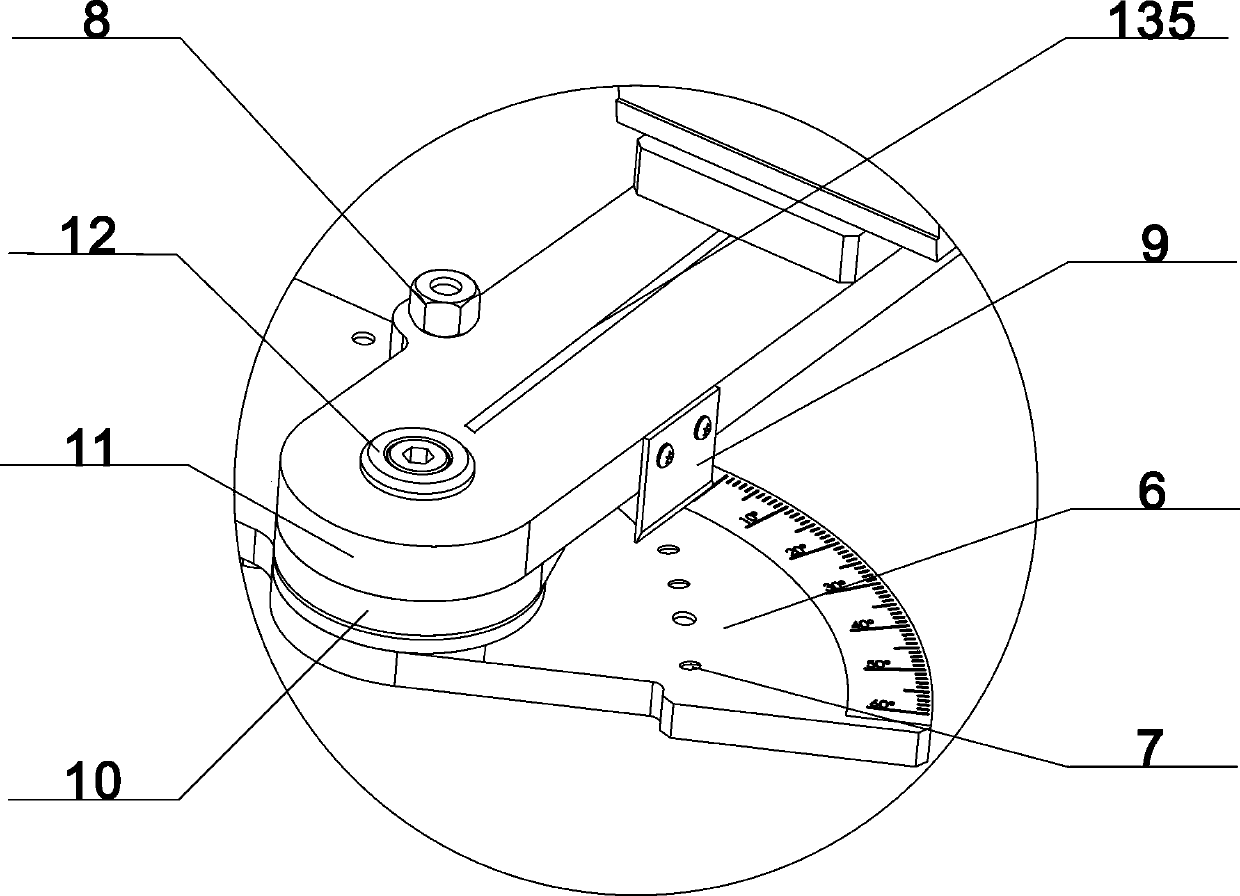

ActiveCN104259701AGuaranteed verticalityLow technical proficiency requiredWelding/cutting auxillary devicesAuxillary welding devicesCircular discPipe fitting

The invention discloses a vertical type double-station steel pipe fitting rotation automatic welding machine tool and belongs to the field of automatic welding machine tools. The vertical type double-station steel pipe fitting rotation automatic welding machine tool comprises a body, automatic welding devices and an electric control device; the body comprises two identical welding chambers; identical automatic welding devices are arranged inside the welding chambers; the automatic welding devices comprise welding devices, vertical correction clamping devices and rotation devices; the welding devices comprise welding wire feeding devices and welding guns; the vertical correction clamping devices comprise air cylinder fixing bases, air cylinders and rotary compression heads; the rotary compression heads comprise cylinders, bearings and bosses; the rotation devices comprise motors, rotary discs, bearing discs and positioning core columns; the electric control device respectively controls the welding devices, the vertical correction clamping devices and the rotation devices. The vertical type double-station steel pipe fitting rotation automatic welding machine tool has the advantages of guaranteeing the perpendicularity of a steel pipe and a pipe base, enabling peripheral weld to be uniform and smooth, improving the welding quality and the product yield, enhancing the welded junction soundness and improving the production efficiency due to a double-station welding mode.

Owner:上海铂宝集团股份有限公司

Efficient manufacturing method of flattened bamboo laminated material

InactiveCN109159224AIncrease profitReduce process complexityWood compressionWood treatment detailsHardnessMechanical property

The invention discloses an efficient manufacturing method of a flattened bamboo laminated material. Under the action of the high temperature steam with the temperature of 120-200 DEG C, the bamboo material is rapidly heated to the softening temperature, after softening, the bamboo material is pressurized progressively by a steam tank built-in press or an external press, and the bamboo material orarc-shaped bamboo material with saw seams is flattened, the flattened bamboo board with high hardness and wide width is used as a raw material, and after drying, finalization, fine planing, sizing, blank assembly and hot pressing, the flattened bamboo laminated material with various blank structures and sizes is obtained. By performing high temperature steam softening on the bamboo material and reducing the processes of bamboo material inner wall notching or nail tooth rolling, the mechanical properties of the flattened bamboo laminated material are improved, the sanding amount of the flattened bamboo board is reduced, and the utilization ratio of the bamboo material is increased. The bamboo material softening treatment at high temperature and the continuous flattening process can reduce the complexity of bamboo processing and improve the production efficiency.

Owner:NANJING FORESTRY UNIV

Weld joint force applying device and method using same for improving form and performance of weld joint

The invention discloses a weld joint force applying device and a method using the weld joint force applying device for improving the form and performance of a weld joint, and the weld joint force applying device is applied to the field of welded pipe machining. In the process of submerged-arc welding, a force applying block in the weld joint force applying device applies force on the weld joint which is still in a liquid state or semi-solid state stage, so that plastic deformation happens on the liquid state or semi-solid state weld joint according to the surface shape of the force applying block to generate a liquid forging effect, the interior of the weld joint after forging and pressing is even and compact, defects possibly existing in the weld joint are eliminated, impacting energy of a weld joint center and a heat effect area is improved, the form of the weld joint can be controlled, and weld joint polishing amount is reduced. The weld joint force applying device and the method well solve the problems that the weld joint form of a submerged-arc welded pipe is difficult to control, and critical defects may happen on the weld joint and can be widely applied to a submerged-arc welded pipe production line.

Owner:番禺珠江钢管(珠海)有限公司

Forming method of large-concentration-ratio upset forging components made of titanium alloy

ActiveCN105328112APromote aggregationImprove coaxialityMetal-working apparatusEngine componentsConcentration ratioElliptic cylinder

The invention aims at solving the problem that upset forging rods with large concentration ratio are difficult to obtain by an upset forging manner in the prior art, and provides a forming method of large-concentration-ratio upset forging components made of titanium alloy. The method comprises the following steps of: taking a bar material made of the titanium alloy, heating the bar material, and placing one end of the bar material in a forging die; performing forging with a forging machine till the ratio of the diameter of the large end of the deforming part of the bar material in the die to the diameter of the small end of the deforming part of the bar material is 1.1-1.5 and the large end and the part which does not deform form a bending angle of R30-R50; performing forging seven times so as to obtain an upset forging component with large concentration ratio. According to the method, the bar material made of the titanium alloy is used as a starting material, through seven times of upset forging, a titanium-alloy upset forging blank with a large end in a parallelogram cylinder shape, a rhombic cylinder shape, a cylindrical shape, or an elliptic cylinder shape and the like is formed, and the maximum concentration ratio reaches 7.1. Through the adoption of the method, the coaxiality of forging blanks and the surface quality of the forging blanks are improved; the grinding amount in subsequent procedures is reduced, and the qualification rate of final forgings is increased; the production efficiency is improved; the production cost is reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Process for producing pre-tensioned and pre-stressed concrete pile mold

The invention relates to a process for producing a pre-tensioned and pre-stressed concrete pile mold and is applicable to production of pre-stressed and pre-tensioned concrete tubular piles. The process comprises the following steps of: firstly, preparing components, namely a matchboard, a tubular wall, longitudinal bars, annular bars, links, bolts, an end plate, an end connecting plate and running wheels; secondly, sequentially connecting all components, performing spot welding on all components into a whole, and thus obtaining half steel molds; and finally, combining the molds and performing finish machining. The process has the advantages that: the produced whole steel mold is small in cavity size error and good in straightness; the produced tubular pile or square pile is good in straightness; the smoothness of appearance is good, the whole longitudinal rigidity is good, and annular strength is improved; the whole coaxiality is ensured; and steel, processes and materials are saved, and the quality of produced products is higher.

Owner:JIANGSU HAI HENG BUILDING MATERIAL MACHINERY CO LTD

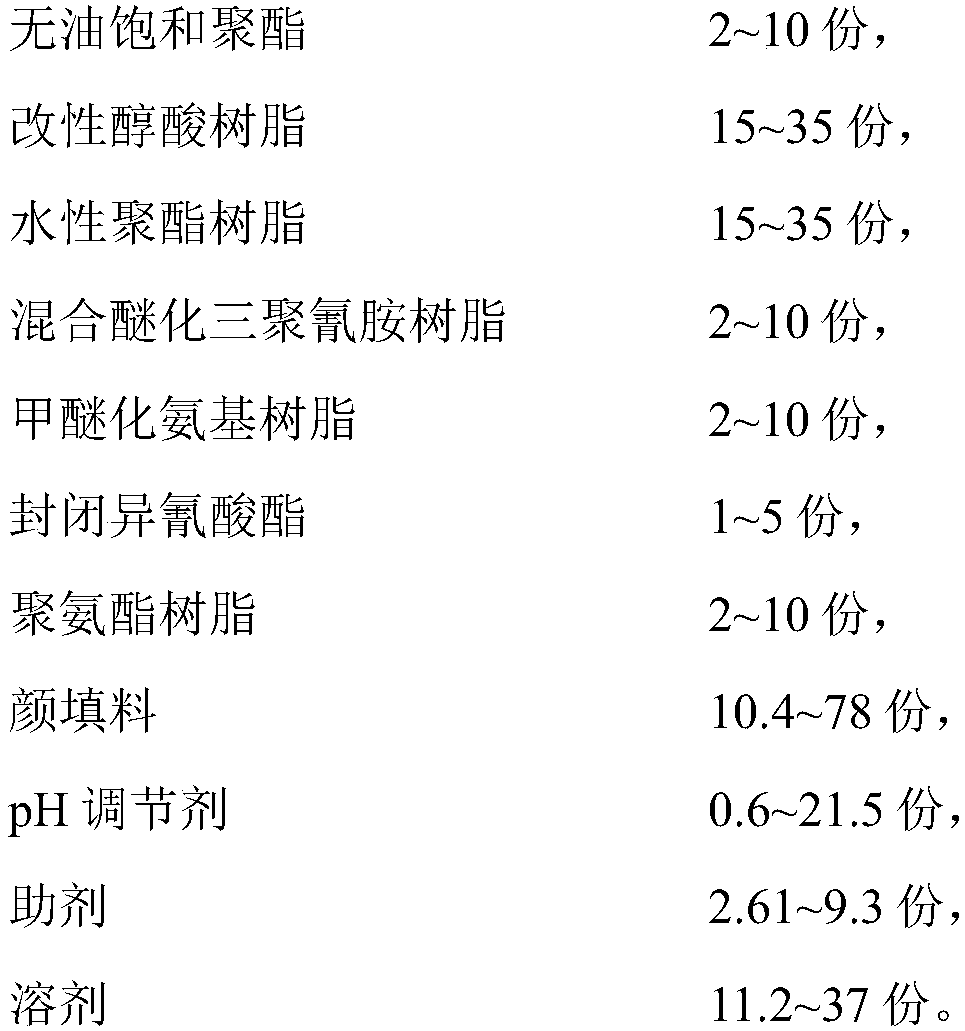

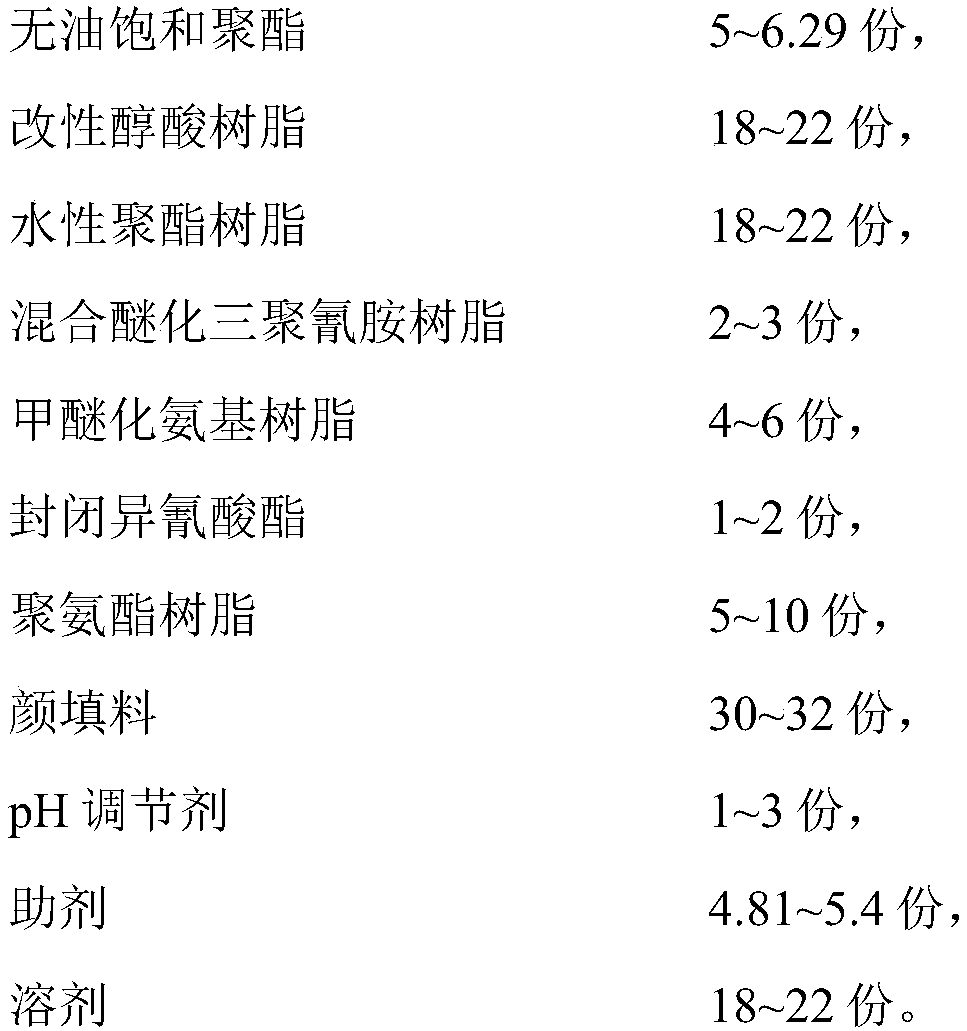

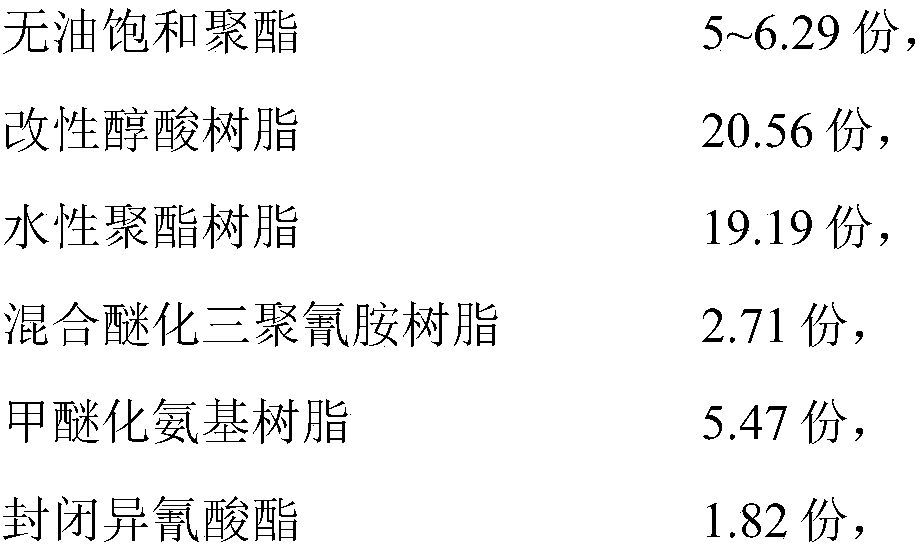

Water-based middle coating high in stone-chip resistance, preparation method and application

InactiveCN109135522ACushion the shockImprove cohesionPolyurea/polyurethane coatingsPolyester coatingsWater basedPolyester resin

The invention discloses water-based middle coating high in stone-chip resistance. The water-based middle coating is prepared from, by weight, 2-10 parts of oil-free saturated polyester, 15-35 parts ofmodified alkyd resin, 15-35 parts of water-based polyester resin, 2-10 parts of mixed etherified melamine resin, 2-10 parts of methylated amino resin, 1-5 parts of blocked isocyanate, 2-10 parts of polyurethane resin, 10.4-78 parts of pigment and filler, 0.6-21.5 parts of pH regulating agent, 2.61-9.3 parts of additive and 11.2-37 parts of solvent. The coating film gloss of the water-based middlecoating high in stone-chip resistance is effectively controlled to be about 75, and the gloss of the original formula is up to 85; the stone-chip resistant effect of original middle coating is judgedas Class 5 according to the Great Wall standards, and the original middle has the phenomenon that a steel plate is exposed; the stone-chip resistant effect of the water-based middle coating high in stone-chip resistance can reach Class 7, and the phenomenon that the steel plate is exposed does not occur.

Owner:LANGFANG NIPPON PAINT

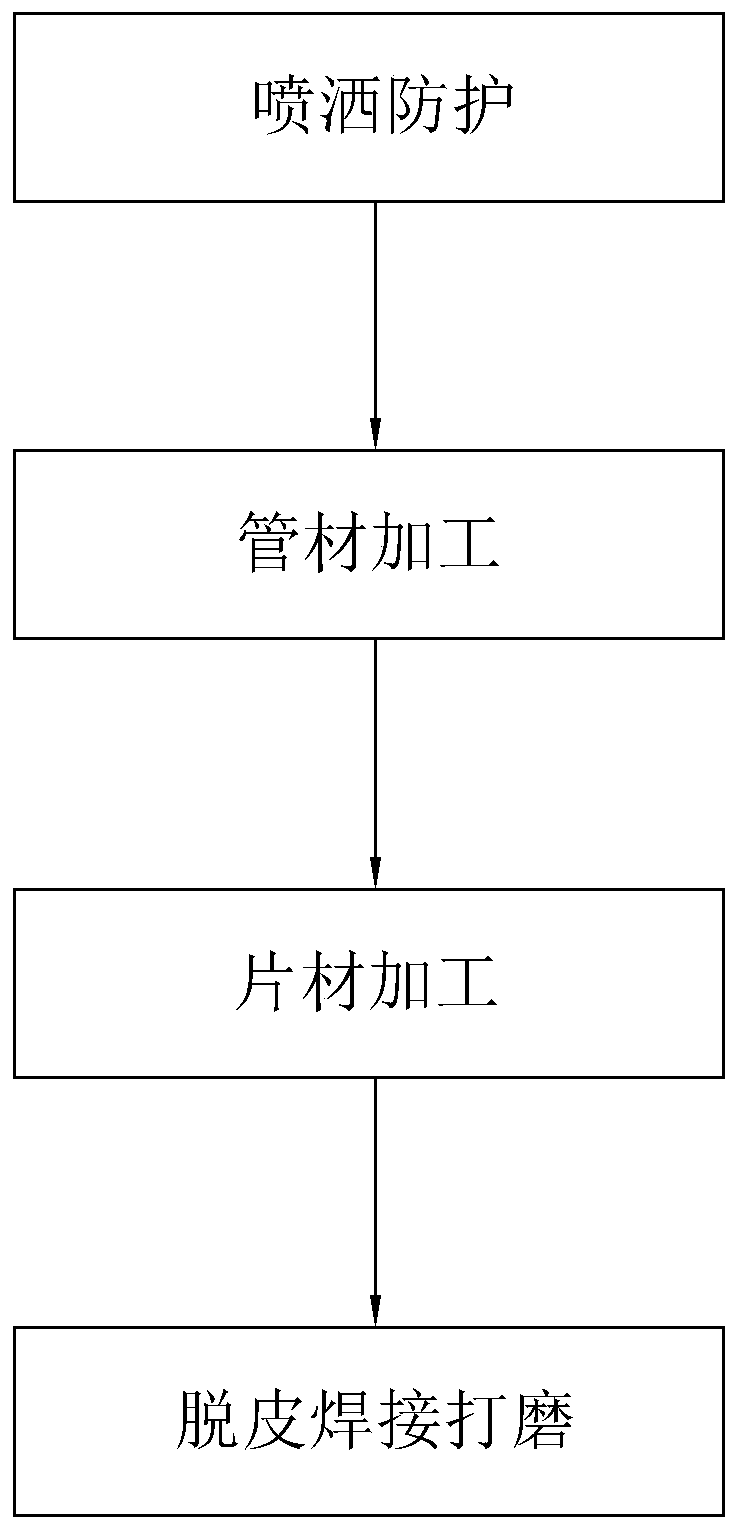

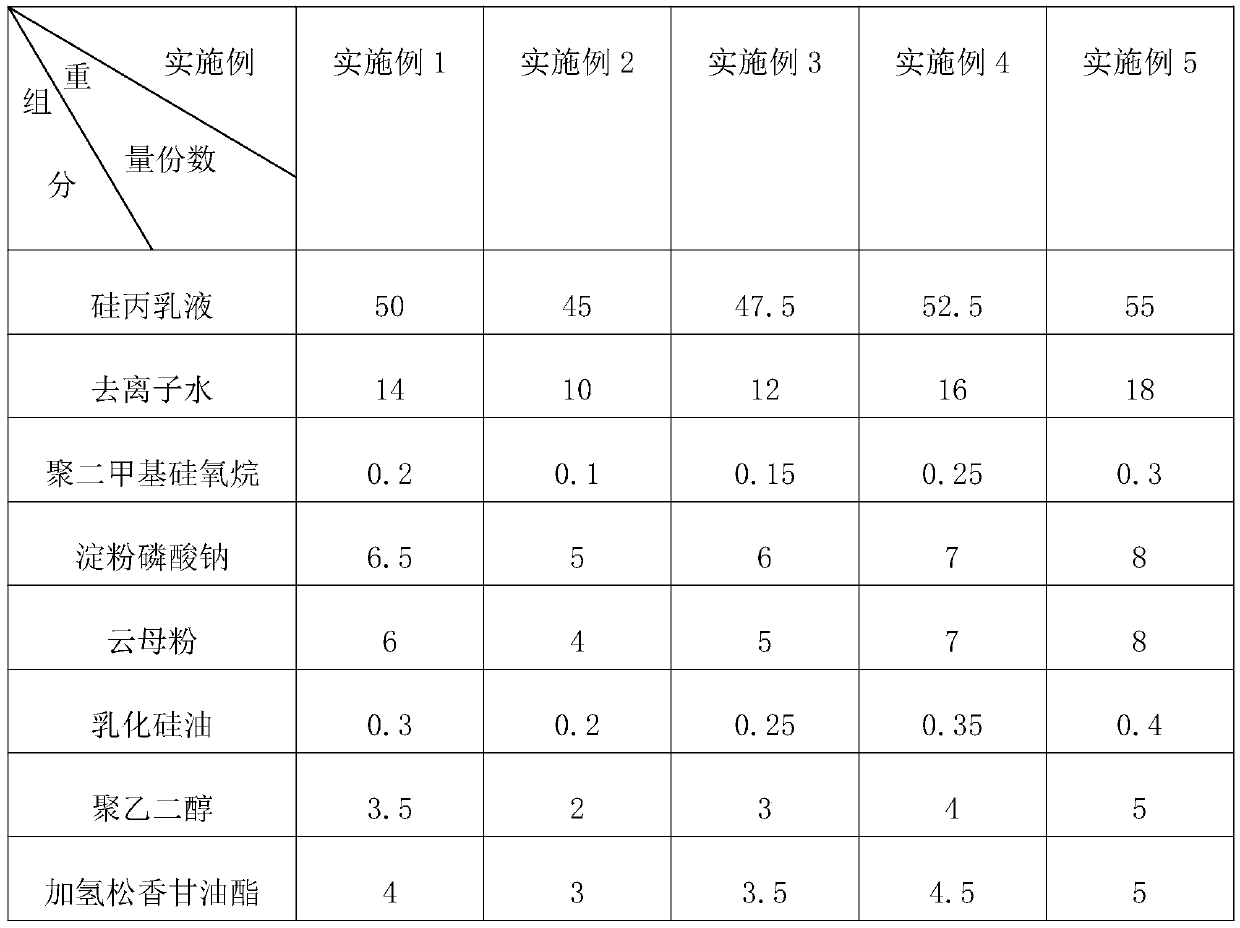

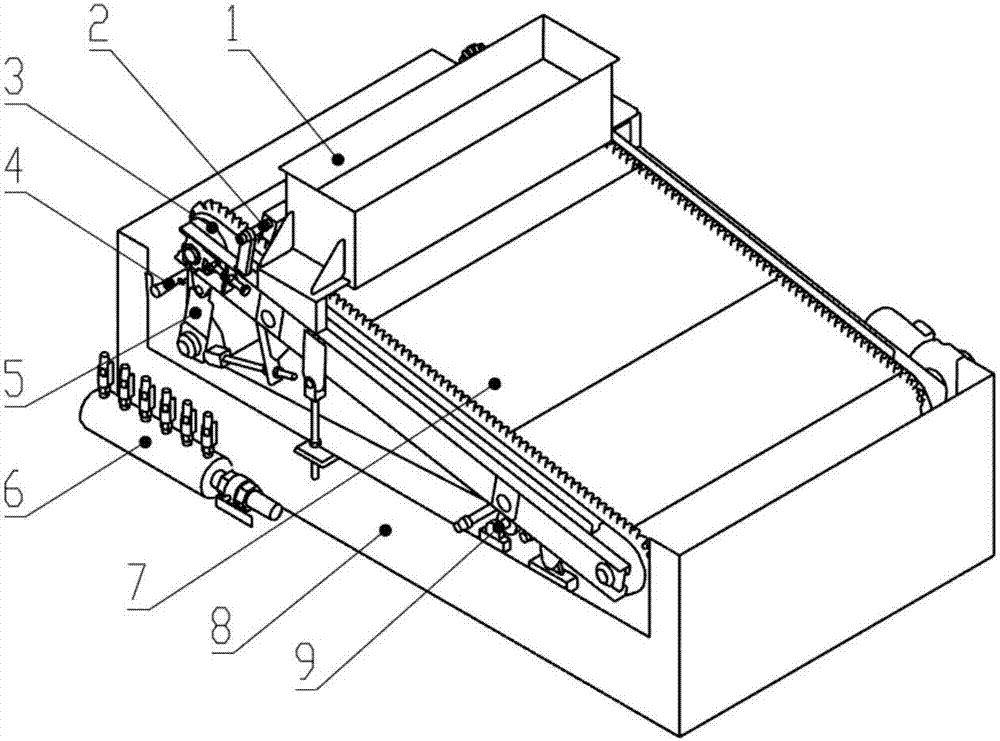

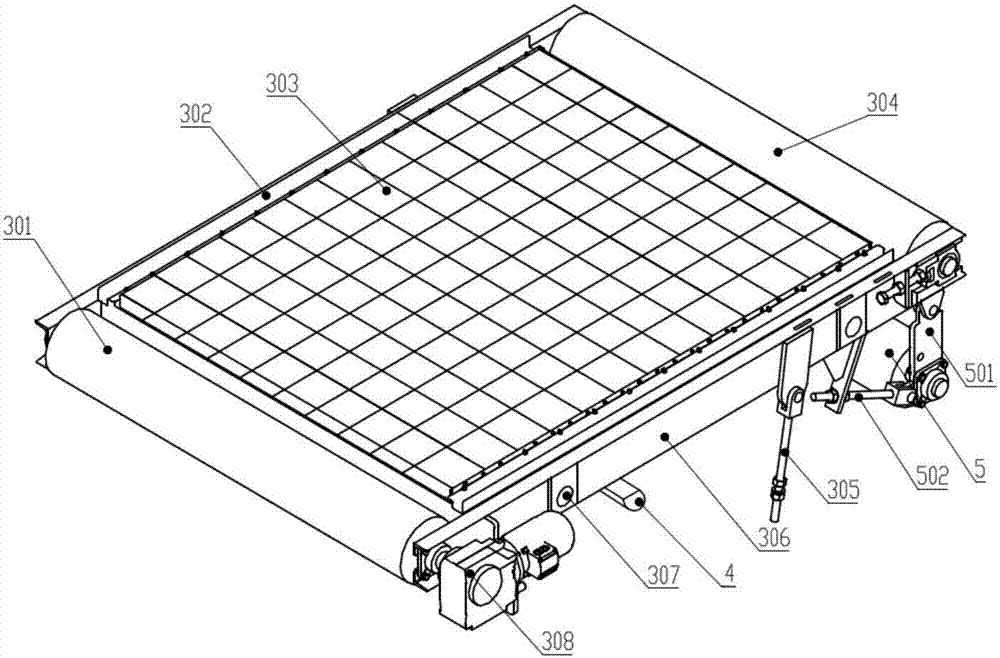

Machining process of showing stand

The invention discloses a machining process of a showing stand, relates to the technical field of metal products, and solves the problem that the overall production efficiency and the percent of passof pipes and sheets are greatly reduced due to the fact that the surfaces of the pipes and the sheets are easily scratched in the machining process. The machining process of the showing stand comprises the following steps: step 1, spraying protection; step 2, pipe processing; step 3, sheet processing; and 4, peeling, welding and polishing. A protective liquid in the step 1 is prepared from the following components in parts by weight: 45-55 parts of silicone acrylic emulsion, 10-18 parts of deionized water, 0.1-0.3 parts of a leveling agent, 5-8 parts of a thickening agent, 4-8 parts of a wear-resistant filler, 0.2-0.4 parts of a defoaming agent, 2-5 parts of polyethylene glycol, and 3-5 parts of hydrogenated rosin glyceride. According to the machining process of the showing stand, the surfaces of the pipes and the sheets are not prone to being scratched in the application process, and therefore high production efficiency and high percent of pass are achieved.

Owner:上海明勤金属制品有限公司

Flat belt magnetic separator

ActiveCN106890726AAvoid accidental damageAdd correction functionMagnetic separationMagnetic separatorEngineering

The invention provides a flat belt magnetic separator. The flat belt magnetic separator comprises a distribution mechanism, an ore washing mechanism, a sorting mechanism, an ore unloading mechanism, a tensioning mechanism, a water separation mechanism, a conveying belt, a bracket collecting tank and a support roller. The flat belt magnetic separator can quickly and conveniently adjust the operation speed of the conveying belt and the optimal working angle of a magnetic system through manual operation under the condition of not using external force; and through multilevel unloading and ore washing, the equipment achieves the optimal sorting effect and efficiency on pulps with different concentrations. The flat belt magnetic separator is simple in structure, flat and regular in magnetic system, continuous and sable in magnetic field and not influenced by the external, and prolongs the service life of the conveying belt.

Owner:LONGI MAGNET CO LTD

Assembly method for fillet welded joint at vertical positions of thin plates

InactiveCN110681954AReduce distortionEasy to assembleWelding/cutting auxillary devicesArc welding apparatusFillet weldThin slab

The invention discloses an assembly method for a fillet welded joint at the vertical positions of thin plates, and belongs to the technical field of metal welding. According to the assembly method forthe fillet welded joint at the vertical positions of the thin plates, the two to-be-welded thin plates are firstly fixed; and the to-be welded positions are welded by adopting a vertical downward locating welding process. The vertical downward locating welding process is adopted, the locating welding length and the locating welding distance are shortened, the vertical downward locating welding length ranges from 15 mm to 20 mm, and the locating welding distance of two adjacent positions ranges from 100 mm to 150 mm; meanwhile, due to the adoption of vertical downward locating welding, the size of a weld leg of locating welding can be effectively controlled to be smaller than or equal to 3 mm, and it is guaranteed that the convexity degree of the welded joint of locating welding is in an inward concave type; the situation that during welding covering and locating welding of the normal filler welded joint, the normal filler welded joint is formed and is too convex at the locating welding position is avoided, welded joint forming of the normal filler welded joint at the locating welding position is improved, and the grinding quantity is effectively reduced; and meanwhile, the weldingspeed and welding efficiency are high, and thin plate deformation caused by locating welding can be reduced.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Storage-tank transverse-seam automatic welding rendering two-sides forming welding method

InactiveCN101396757ASave human effortReduce labor intensityArc welding apparatusEngineeringSurface shape

An automatic welding backing double-side shaping welding method for transverse joints of a storage tank comprises edge preparation, assembling and back cleaning, and is characterized in that a welding fluid is used for protecting the back surface when welding is carried out after assembling. The welding method guarantees backing (root) welding back surface shaping (double-side shaping), cancels carbon arc air gouging, and reduces more than 80% of grinding wheel polishing, thereby not only economizing on manpower, reducing the labor intensity of operators, saving 50.6% of labor cost, but also eliminating the inhalation of powdered carbon by carbon arc air gouging workers, reducing the air pollution, and simultaneously saving carbon rods, welding materials filling at air gouging rooting parts and grinding wheel sheets polished by grinding wheels, and guaranteeing the welding quality. The average radiographic inspection first-time qualification rate of transverse joints of two storage tank is 98.2%.

Owner:CHINA GASOLINEEUM JILIN CHEM ENG & CONSTR

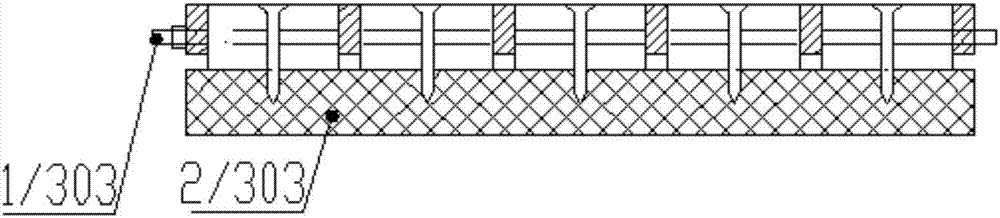

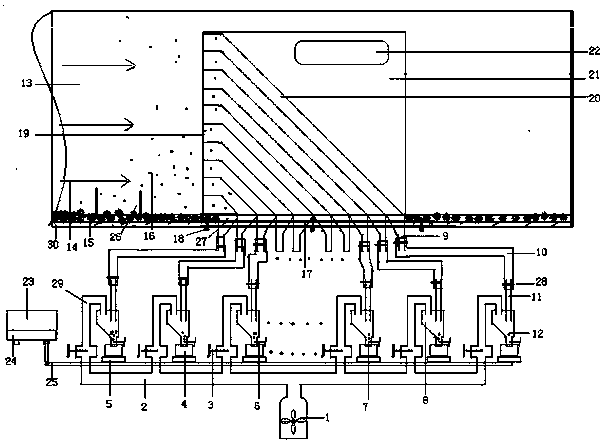

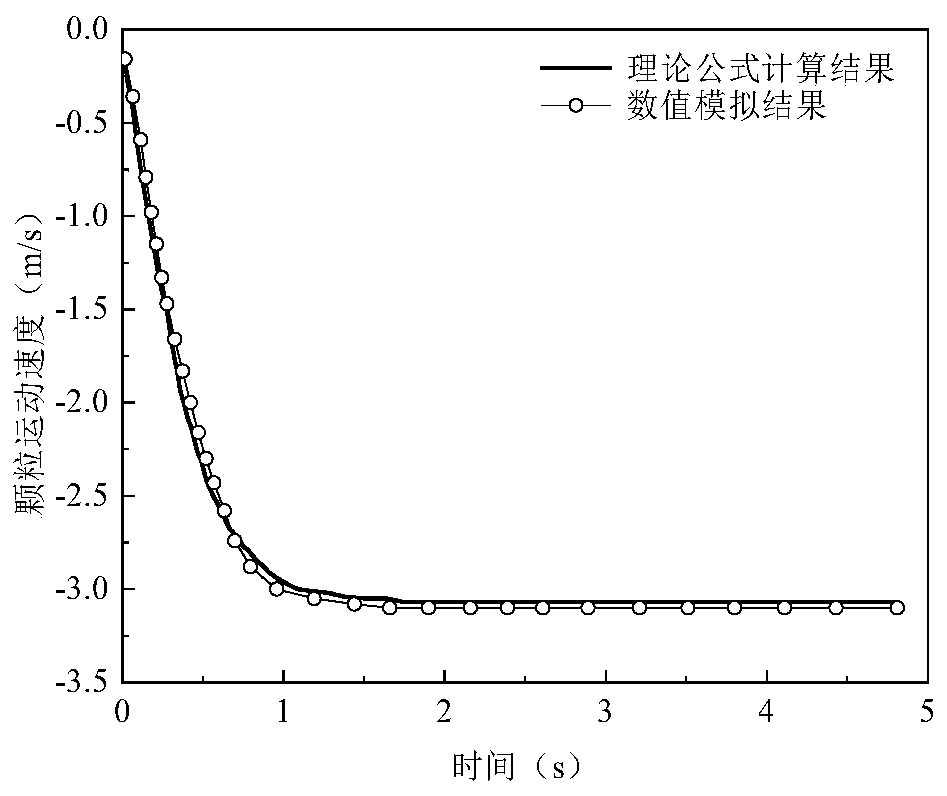

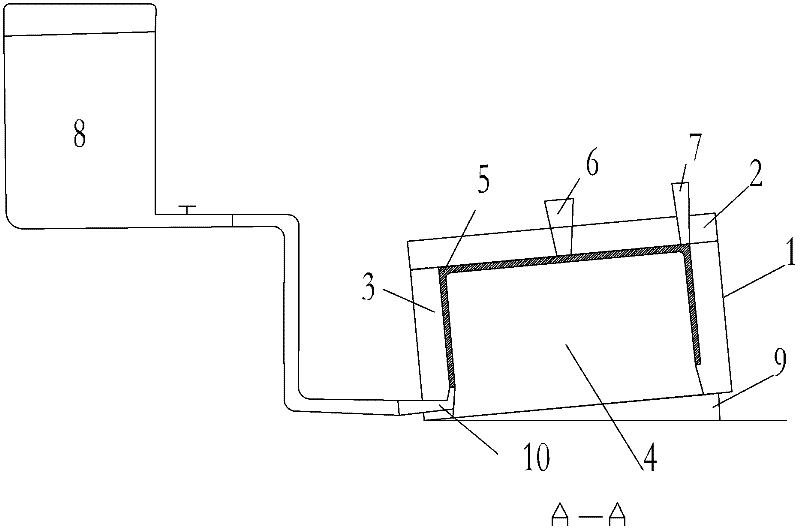

Air-exhaust-type wind-sand flow gradient high sand-collecting rate device for wind-sand environment wind tunnel

The invention relates to an air-exhaust-type wind-sand flow gradient high sand-collecting rate device for a wind-sand environment wind tunnel. The air-exhaust-type wind-sand flow gradient high sand-collecting rate device is characterized in that a sand dust gradient collector is provided with wind-sand flow sand inlets, gradient channels communicate with the wind-sand flow sand inlets, collector placing openings are connected with the gradient channels, air-exhaust connecting pipes are mounted on gradient leaking nozzles exposed out of the collector placing openings correspondingly, the gradient leaking nozzles are perpendicular to the bed surface downwards and are connected with the air-exhaust connecting pipes, the air-exhaust connecting pipes are connected with wind-sand flow air-exhaust branch pipes, wind-sand flow separating tanks of the respective channels sleeve outlets of the wind-sand flow air-exhaust branch pipes, the wind-sand flow separating tanks communicate with weighingbottles, high-precision weighing sensors are placed at the bottoms of the weighing bottles, and the sand delivery amounts in the weighing bottles are measured by the high-precision weighing sensors. According to the air-exhaust-type wind-sand flow gradient high sand-collecting rate device, the measured sand delivery amounts are precise and errorless, and data support is provided for disclosing thechange law that a wind-sand flow passes through a flow field and for researching the relation between the wind speed and a soil structure as well as the relation between the soil water content and soil wind erosion.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

High-water-level disaster-caused control method for sedimentation sections at the confluence of main-tributary streams by regulating sediment with marginal bank erratic boulders under high-intensity sediment from tributary streams

ActiveCN109797707AExtend the arrival timeReduced supply strengthClimate change adaptationStream regulationCarrying capacityHigh intensity

The invention provides a high-water-level disaster-caused control method for sedimentation sections at the confluence of main-tributary streams by regulating sediment with marginal bank erratic boulders under high-intensity sediment from tributary streams. The high-water-level disaster-caused control method includes the steps of (1) selecting a main stream at the confluence of main-tributary streams requiring sediment regulation by the marginal bank erratic boulders as a target reach, wherein the target reach is a steep-gentle connection reach, a gully bed slope of an upper reach of the steep-gentle connection reach is greater than that of a lower reach, and a gully bed slope of a tributary stream at the confluence of main-tributary streams is greater than that of the upper reach of the steep-gentle connection reach; (2) surveying a position of a sediment accumulation body of the target reach at the confluence of main-tributary streams; (3) subjecting the erratic boulders to staggeredarrangement on a left marginal bank and a right marginal bank of the upper reach of the target reach, wherein the erratic boulders at the highest reach are positioned at the confluence of main-tributary streams and the upper reach of the sediment accumulation body at the confluence of main-tributary streams of the target reach. The high-water-level disaster-caused control method can improve the flood carrying capacity of the sedimentation sections at the confluence of main-tributary streams of mountain rivers under the high-intensity sediment from tributary streams.

Owner:SICHUAN UNIV

Mould and method for casting quartz crucibles

The invention discloses a mould for casting quartz crucibles, which comprises a mould main body. The mould main body comprises a mould cover, a periphery side wall and a mould core arranged in the mould cover and the periphery side wall. A crucible casting area is formed among the mould cover, the periphery side wall and the mould core, an open hole communicated with the crucible casting area is arranged on the mould cover, and a casting port communicated with the crucible casting area is arranged on the periphery side wall. The invention further discloses a method using the mould to cast crucibles, which comprises the following steps of feeding quartz slurry into a vacuum casting tank to be vacuumed, communicating the vacuum casting tank with the casting port of the mould, and connecting a funnel with the open hole on the mould cover. Thus, the quartz slurry can fill the whole crucible casting area through the casting port, and then the mould is placed horizontally to be formed. The mould and the method can reduce forming time of crucibles and improve percent of pass of the crucibles.

Owner:徐州协鑫太阳能材料有限公司

Method of reducing hydraulic system power of multi layer hot press and practical appts

InactiveCN1833842AShorten closing timeShorten pressurization timeWood working apparatusFlat articlesProduction lineEnergy consumption

A method for decreasing the power of hydraulic system for multi-layer hydraulic press used to produce raw boards features that the hydraulic oil source for board loading and unloading machines is introduced to the closing and pressing procedures of hot press, resulting in high closing and pressing speed, low capacity of hydraulic system, and low energy consumption.

Owner:ZHENJIANG ZHONGFOMA MACHINERY

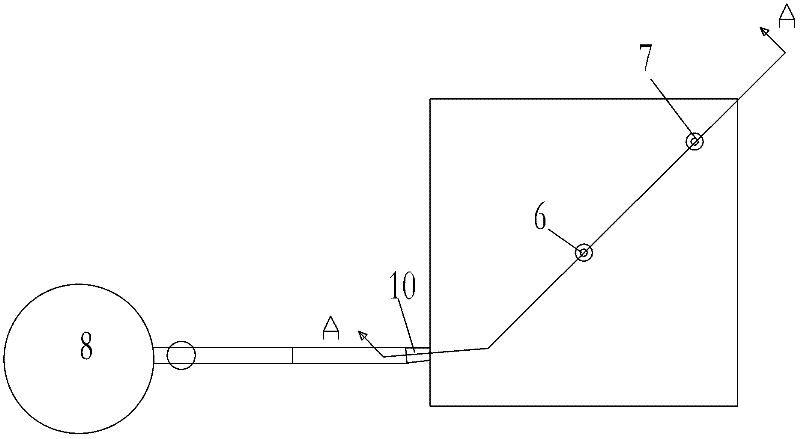

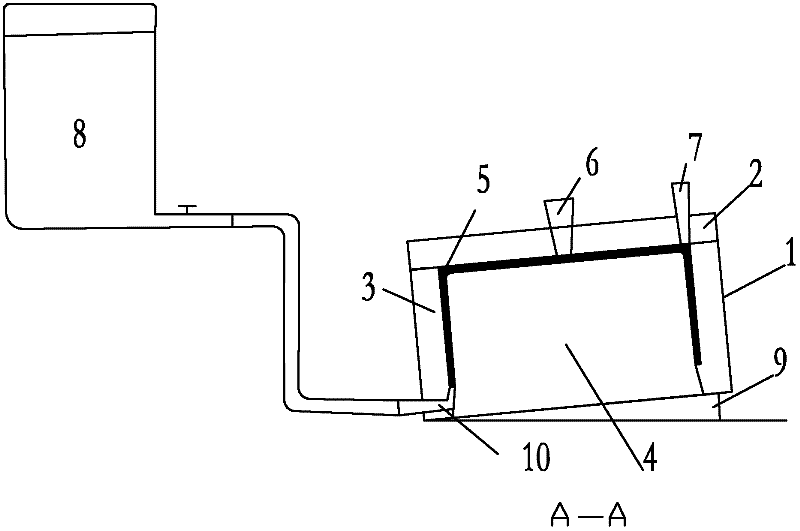

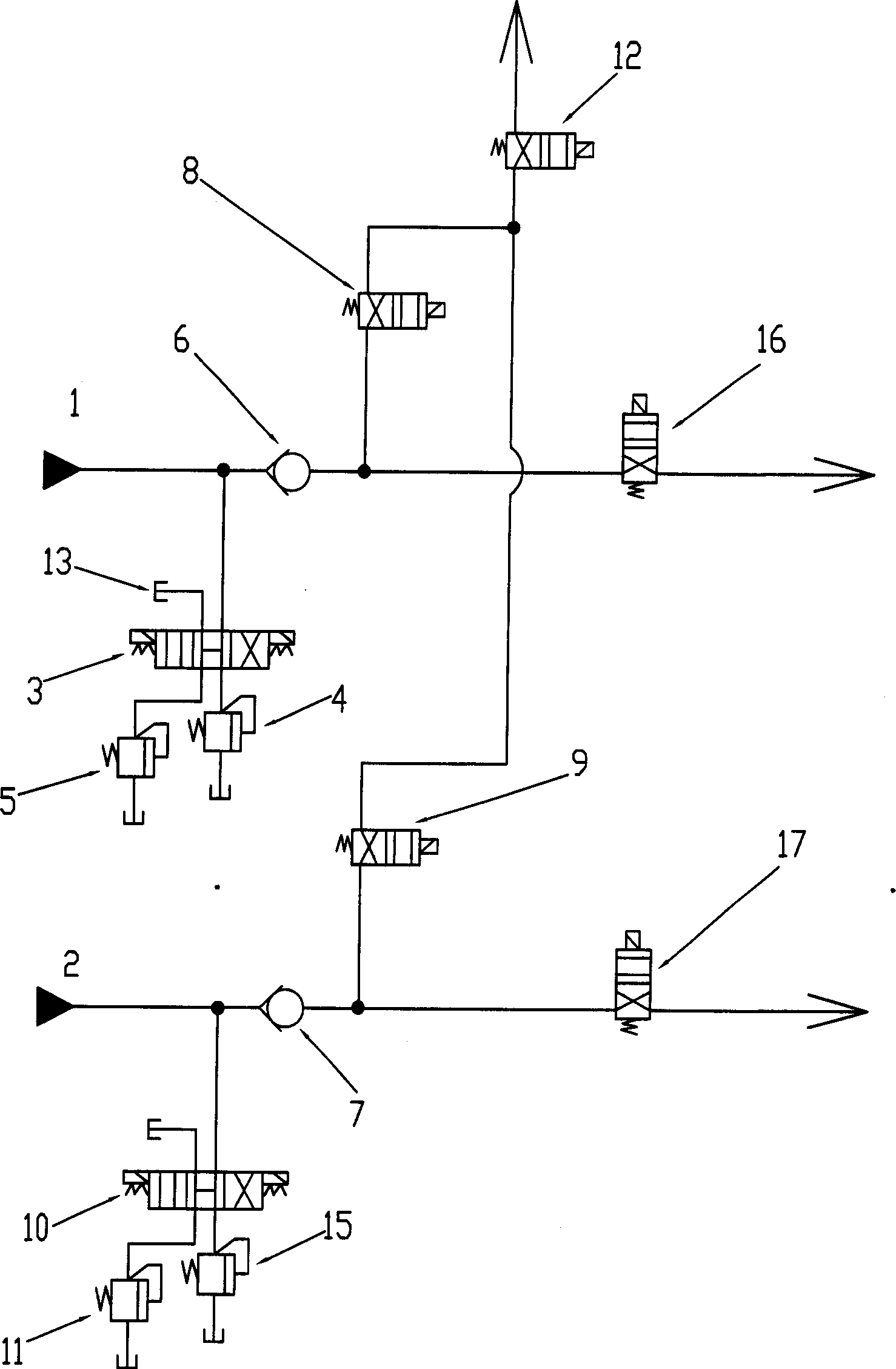

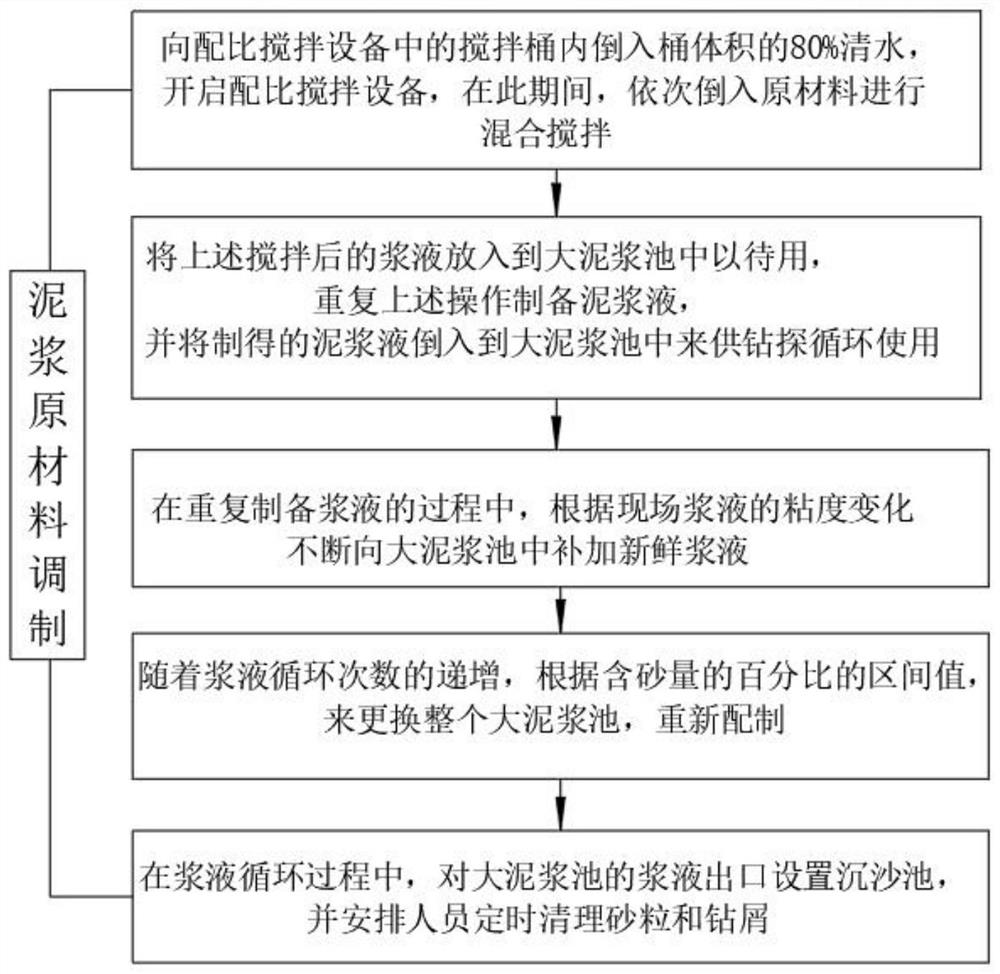

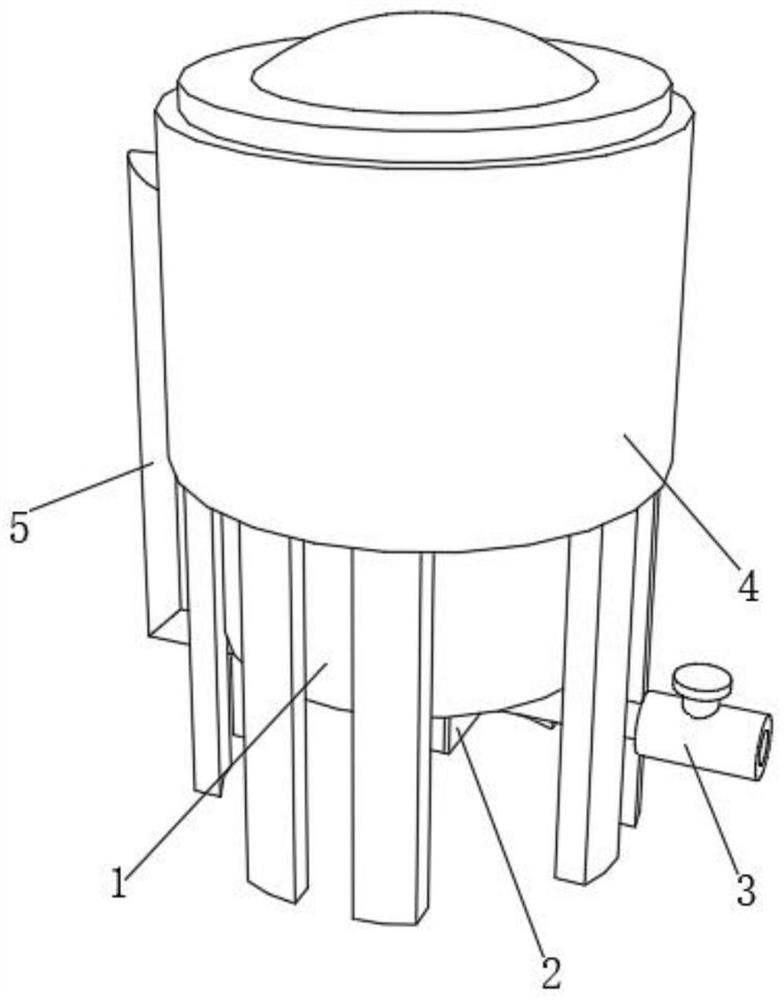

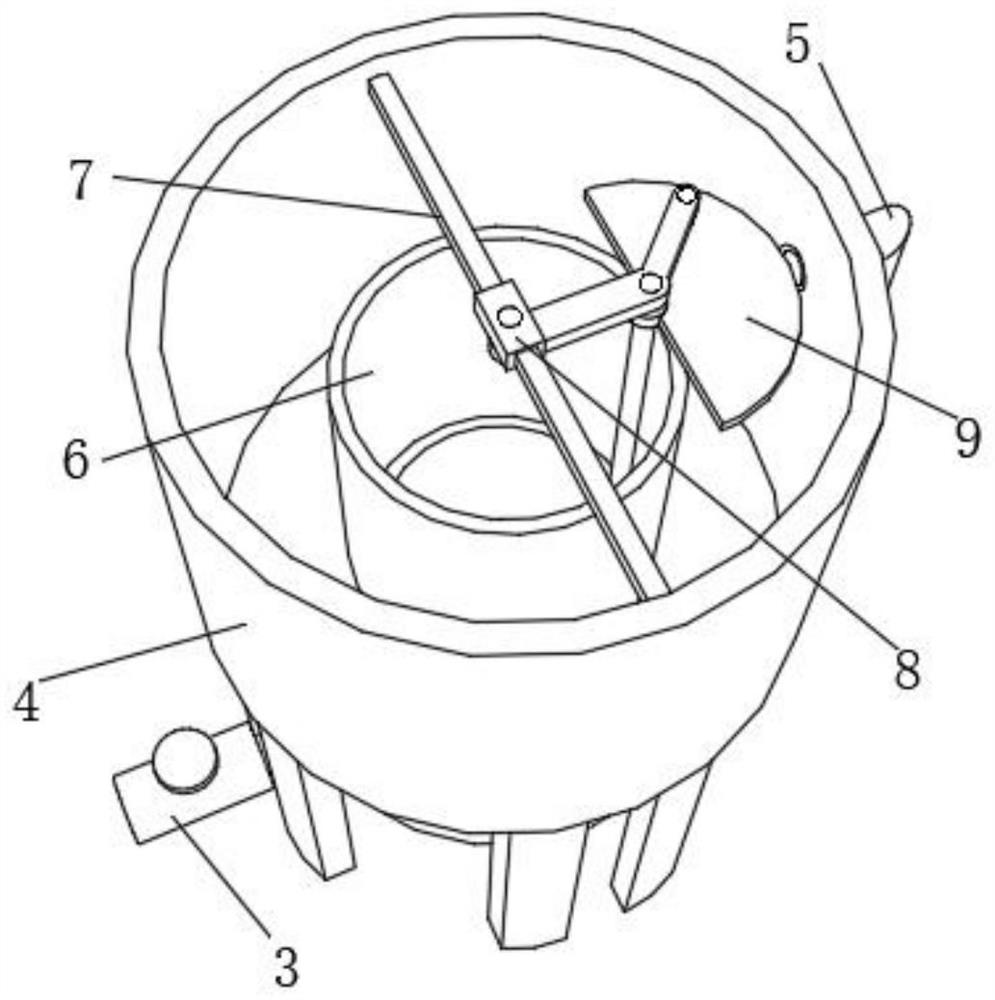

Drilling mud formula and automatic mud circulation purification device

PendingCN114687686ALow turning resistanceHigh turning resistanceConstructionsFlushingCellulosePlant Gums

The invention discloses a drilling mud formula and an automatic mud circulation purification device, and relates to the technical field of drilling mud. The mud specifically comprises mud raw materials, and the mud raw materials comprise, by weight, 1000 parts of clear water, 20 parts of bentonite, 4 parts of polyacrylamide, 4 parts of vegetable gelatin, 6 parts of potassium humate, 3 parts of sodium carboxymethyl cellulose, 3 parts of ferrochrome sodium lignin sulfonate, 4 parts of sodium carbonate, 4 parts of barite fine powder, 3 parts of dry sawdust, 4 parts of asbestos and 5 parts of polyacrylamide flocculant. The high-quality bentonite is selected, so that the slurry has the advantages of low relative density, low viscosity, small sand amount, small water loss, thin mud cake, strong stability, strong wall fixing capability, small rotation resistance of a drilling tool, high drilling rate, high slurry making capability and the like; the viscosity of the slurry can be increased by using sodium carboxymethyl cellulose, so that a thin film is formed on the surface of the soil layer to prevent the hole wall from peeling off, and the effect of reducing the water loss is achieved.

Owner:山东省地质矿产勘查开发局第五地质大队

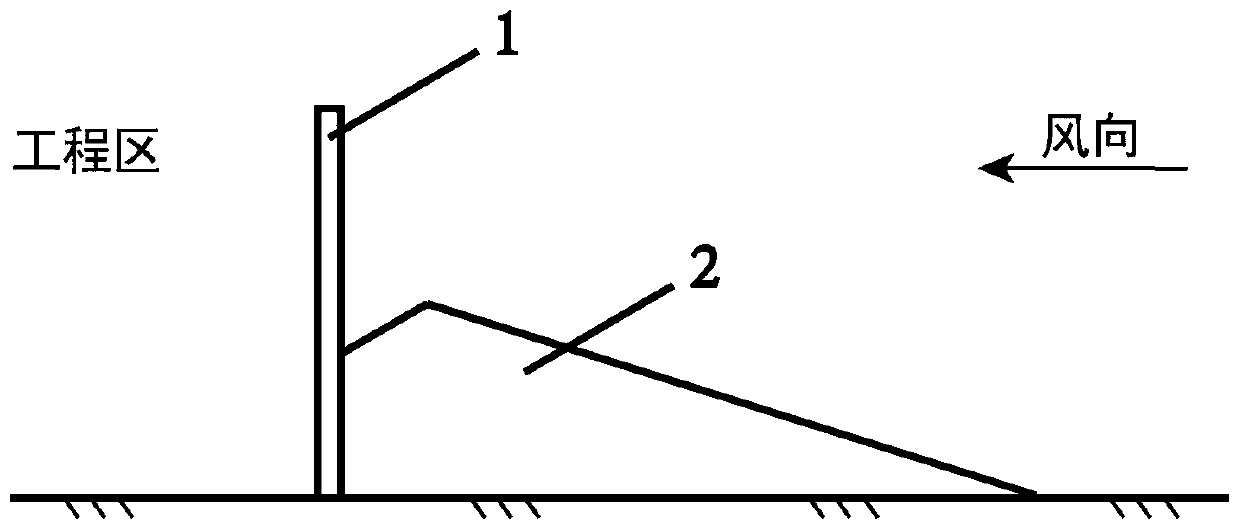

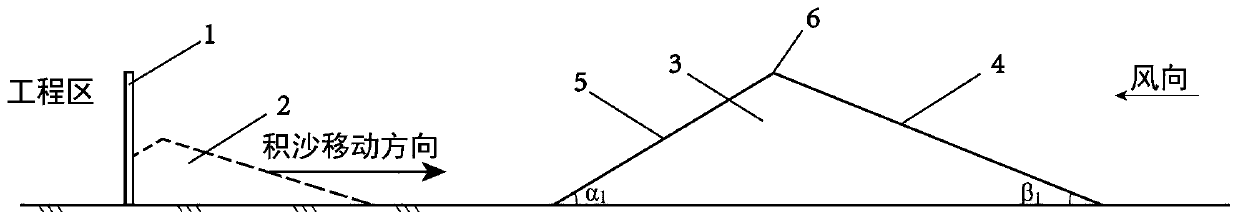

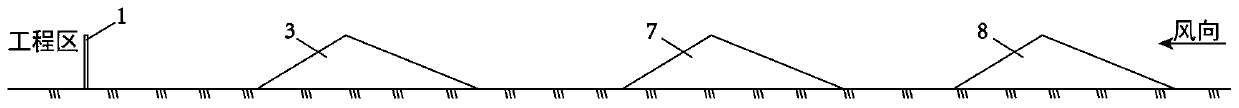

Sand blocking fence accumulated sand removal method, sand guide embankment structure and sand storm protection system

ActiveCN111074801ASolve the problem of sand cleaningReduce the amount of sandingProtective constructionFencingSoil scienceSand storm

The invention relates to the field of sand storm prevention and control, and discloses a sand blocking fence accumulated sand removal method, a sand guide embankment structure and a sand storm prevention system. The accumulated sand removal method comprises the following steps: accumulated sands are transferred before the accumulated sand height on the outer side of a sand blocking fence reaches apreset height; and at least one sand guide embankment is constructed on the outer side of the sand blocking fence by utilizing the transferred accumulated sands, wherein the sand guide embankment andthe sand blocking fence are arranged in parallel. The sand blocking fence accumulated sand removal method, the sand guide embankment structure and the sand storm protection system solve the accumulated sand removal problem of the sand blocking fence by using the accumulated sands for constructing the sand guide embankment on the outer side of the sand blocking fence, and converts the accumulatedsands, which are difficult to treat originally, into the sand guide embankment on site in order to meet the principle of adapting to local conditions; and the sand guide embankment has a good sand guide and protection effect, so the sand protection effect is achieved, the sand coming amount of the sand blocking fence can be effectively reduced, and therefore the effect of protecting the sand blocking fence and an engineering area is achieved.

Owner:SHANGHAI ELECTRICGROUP CORP +1

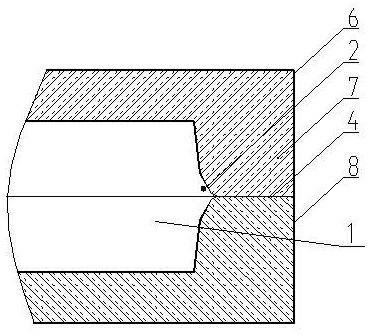

A casting method for a cylinder head of a marine diesel engine without cooling iron

ActiveCN103480804BReduce the amount of sandingImprove surface accuracyFoundry mouldsFoundry coresCylinder headMetallurgy

The invention discloses a method for casting an air cylinder cover of a diesel engine for a chiller-free ship. The method comprises the following steps: calculating main hot spots of a casting piece at first; arranging insulation risers at the two large hot spot parts of the top surface of the casting piece; designing an inner pouring gate at the small hot spot part of the top surface of the casting piece for achieving feeding and exhausting in a solidification process and forming a top-down temperature gradient; finally solidifying molten metal in the risers. The method is simple, convenient, reliable and suitable for casting the air cylinder cover of the diesel engine for the ship.

Owner:CSIC NO 12 RES INST

Casting model

ActiveCN102601303AImprove appearance qualityReduce drapesFoundry moulding apparatusHigh volume manufacturingEngineering

The invention relates to a casting model, which is characterized in that: the bottom of the casting model, which is in contact with a model bottom plate, is provided with an embedded lug boss, and the lug boss is embedded into the model bottom plate; the lug boss and the upper plane of the model bottom plate form a parting surface, and the corner of the parting surface on the lug boss is provided with an inclined surface with a slope of 60 degrees; and the length of the bottom side of the inclined surface is 1.5mm, and a joint of the inclined surface and the parting surface is provided with an R1.5 fillet. Under the premise of unaffecting the size and the configuration of a casting, the model and the model bottom plate are designed into an embedded mode; and the corner of the parting surface is provided with the inclined surface with the slope of 60 degrees, and the inclined surface is a manually controllable large-slope flash. The structure is simple, the use is convenient, and sand burning, sharp corner and local tire falling phenomena are improved. The appearance quality of castings is improved, the fins, flashes and burrs of the castings are obviously reduced, the grinding amount can be reduced by over 80%, the production efficiency is increased by about 25%, the labor intensity of workers is greatly reduced, and the casting model is especially suitable for mass production on the crankshaft casting molding line.

Owner:TIANRUN IND TECH CO LTD

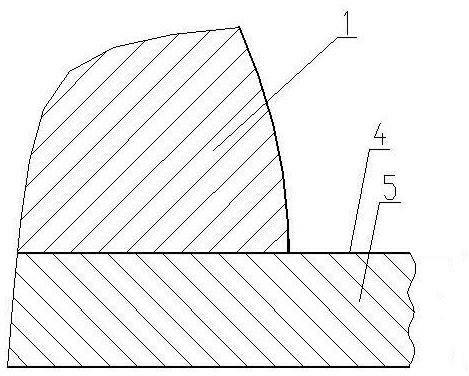

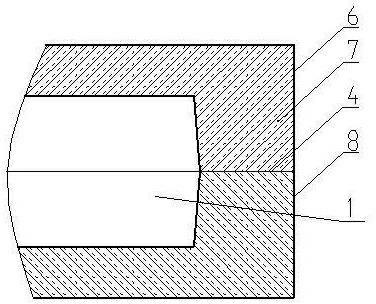

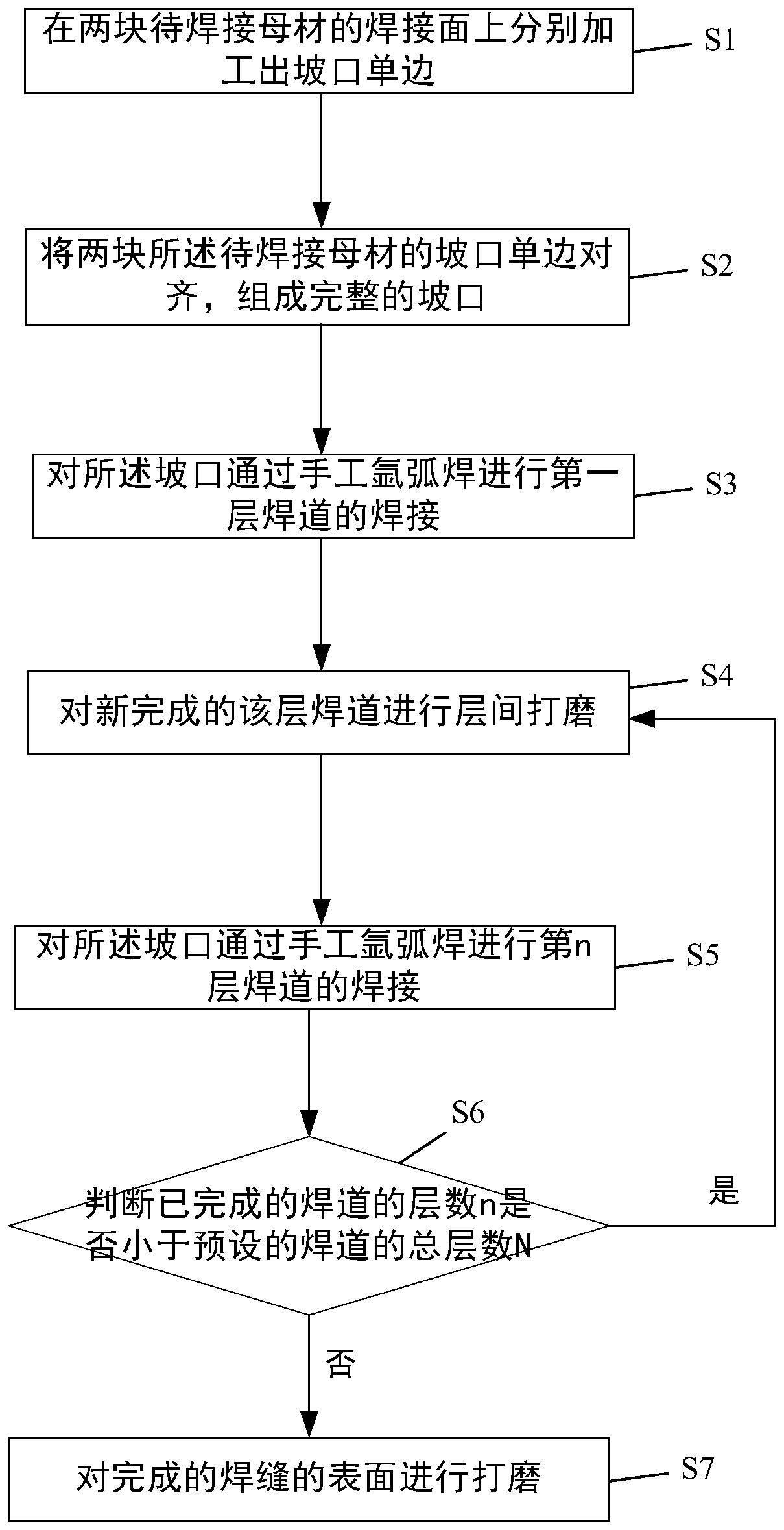

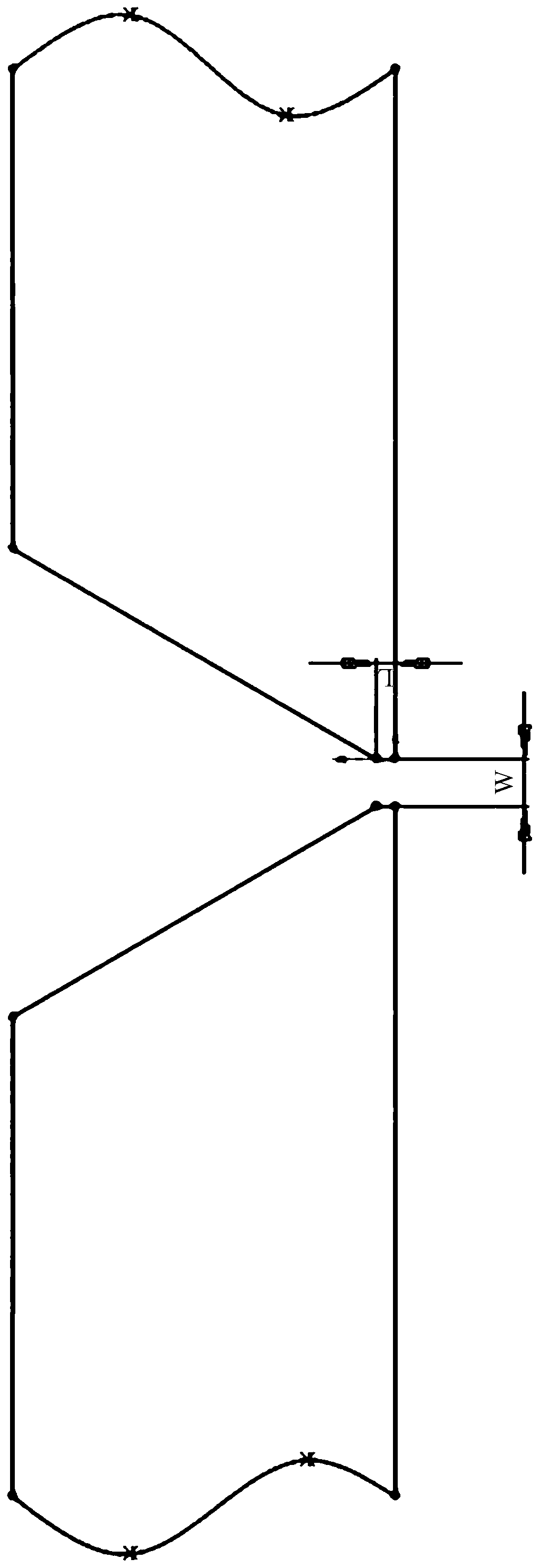

Handmade argon arc welding process capable of eliminating defects of incomplete fusion of weld joints of hastelloy

ActiveCN110877139AEliminate unfused defectsQuality improvementArc welding apparatusWelding/cutting media/materialsStructural engineeringProcess engineering

The invention provides a handmade argon arc welding process capable of eliminating defects of incomplete fusion of weld joints of hastelloy. By setting the welding process parameters of each layer ofweld pass, the defects of incomplete fusion between passes, between layers and of the side wall of the hastelloy are effectively eliminated, and the quality of weld joints is improved; and through thewelding process, grounding is hardly needed between passes, only grinding between layers is needed, thus the grinding workload is greatly reduced, and the welding efficiency is improved.

Owner:上海电气核电集团有限公司

Sand screening equipment for house construction

The invention belongs to the field of house construction, in particular to sand screening equipment for house construction. The sand screening equipment comprises a machine frame, wherein a screeningbox is fixed to the machine frame; the upper end of the screening box is opened; a rotating sieve, a sliding sieve and a swinging sieve are sequentially arranged in the screening box from top to bottom; the pore sizes of sieve holes of the rotating sieve, the sliding sieve and the swinging sieve are sequentially reduced; the rotating sieve is rotatably connected to the inner wall of the screeningbox; a plurality of grinding shafts are rotatably connected to the machine frame, and grinding discs are fixed to the lower ends of the grinding shafts; the sliding sieve is vertically connected to the inner wall of the screening box in a sliding manner, and a first connecting rod is fixed to the upper end of the sliding sieve; the swinging sieve comprises a first half sieve and a second half sieve, and the first half sieve and the second half sieve are separately hinged to the opposite two sides of the inner wall of the screening box, and an elastic band is fixedly connected between the opposite ends of the first half sieve and the second half sieve; and a second connecting rod is fixed between the elastic band and the sliding sieve. By adopting the scheme, the problem that graded screening on sand is inconveniently performed can be solved.

Owner:台州和源建设有限公司

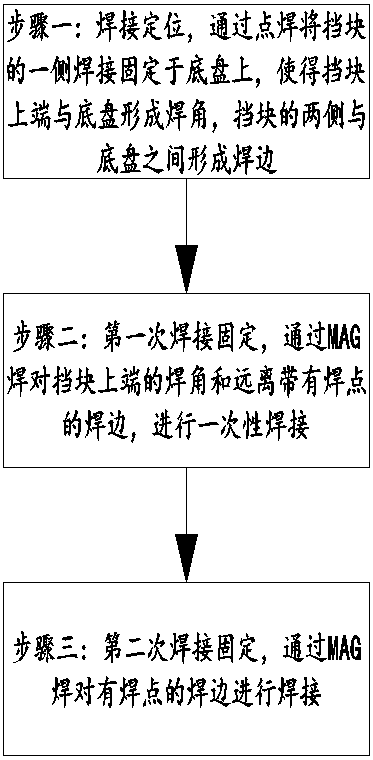

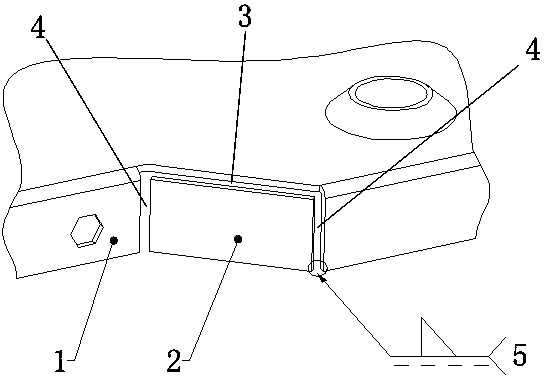

Air conditioner chassis sheet metal part and welding method thereof

ActiveCN110695498AEfficient weldingSolve Welding FormingArc welding apparatusMaterials scienceWelding process

The invention relates to the technical field of welding of air conditioner sheet metal parts, in particular to a welding method for an air conditioner chassis sheet metal part. The welding method forthe air conditioner chassis sheet metal part comprises the following steps that (1) welding positioning is carried out, specifically, one side of a stop block is welded and fixed to a chassis throughspot welding, so that the upper end of the stop block and the chassis form a positioning weld fillet, and weld toes are formed between the two sides of the stop block and the chassis; (2) primary welding fixing is carried out, specifically, the positioning weld fillet at the upper end of the stop block and the weld toe far away from a welding spot are welded at a time through MAG welding; and (3)secondary welding fixing is carried out, specifically, the welding toe with the welding spot is welded through MAG welding. The welding method for the air conditioner chassis sheet metal part has theadvantages that the standardized operation of a welding process is realized, meanwhile, the problem of the quality abnormality caused by the welding variable of the welding process can be solved, andthe welding quality and the production efficiency are greatly improved.

Owner:CHANGSHA GREE HVAC EQUIP CO LTD +1

Sandblasting device with adjustable nozzle size and dust reduction function

InactiveCN111975652AAvoid surface damageWide applicabilityBlast gunsUsing liquid separation agentAbrasive blastingWorking environment

The invention discloses a sandblasting device with adjustable nozzle size and dust reduction function. The device comprises a main box, wherein a sandblasting box is fixedly connected to the lower endof the right end surface of the main box, the sandblasting box is internally provided with a sand nozzle with an opening to the left, the right end wall of the sand nozzle is connected with a caliberturntable cavity, and the lower end wall of the caliber turntable cavity is connected with a positioning slider cavity. The size of the blasting caliber can be changed by rotating a caliber knob in the device, which makes the device more applicable. At the same time, when blasting smaller parts, the amount of sand required is reduced to reduce the cost of blasting and allow smaller parts to be subjected to more detailed blasting treatment, thereby avoiding surface damage caused by the parts being impacted by excessive sand, achieving the effect of reducing dust through the water mist generated by the water mist nozzle, and improving the working environment during sandblasting.

Owner:温州类帕机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com