Forming method of large-concentration-ratio upset forging components made of titanium alloy

A technology of titanium alloy top and aggregation ratio, which is applied in the direction of engine components, metal processing equipment, mechanical equipment, etc., can solve problems such as difficult upsetting aggregation, improve coaxiality and surface quality, reduce grinding amount, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

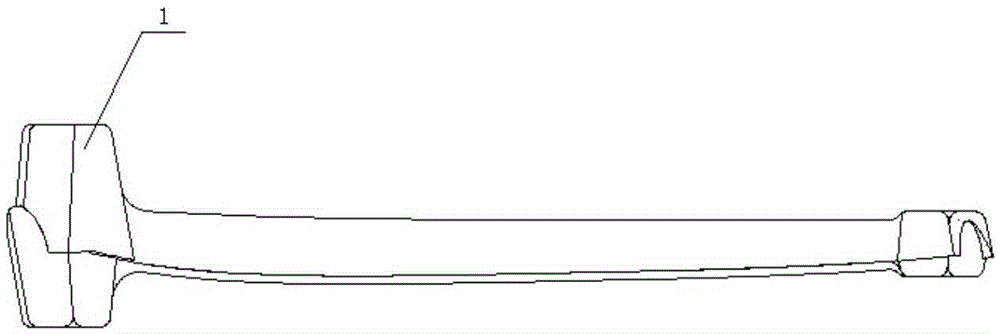

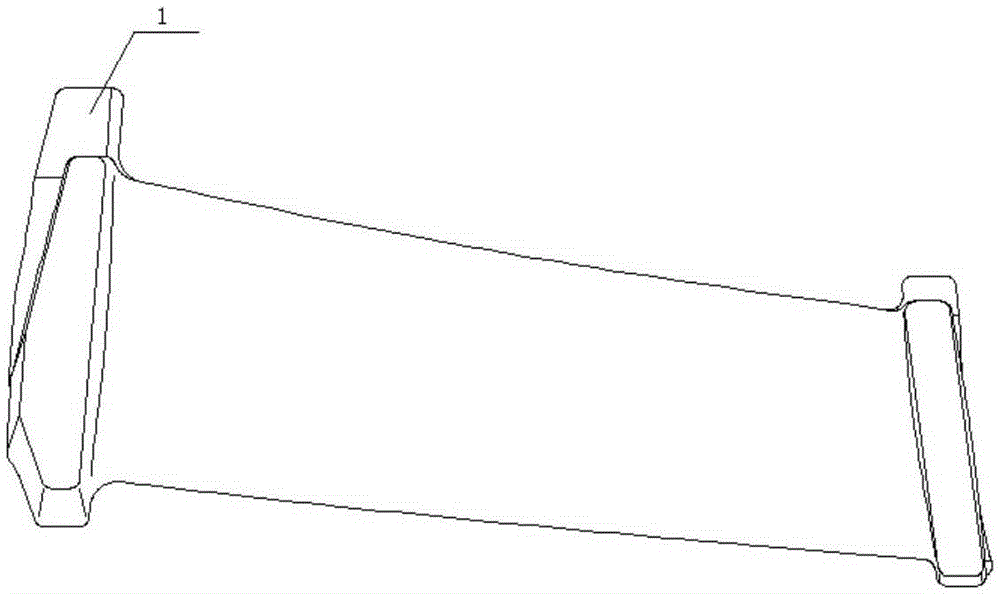

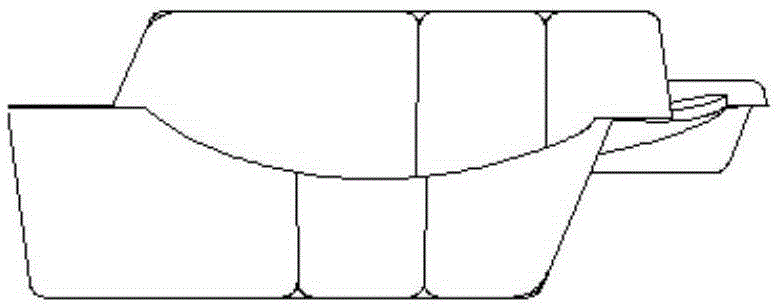

[0031] Pre-cast an aero-engine blade, such as Figure 1~3 It can be seen from the figure that due to the large difference between the two ends of the blade, it is necessary to use a rod-type forging blank with a large aggregation ratio; moreover, the shape of the side plate 1 of the blade is complicated, and it is difficult to fill the mold with a disc-shaped forging blank Therefore, it is necessary to prepare a rod-type forging blank with a large aggregation ratio whose thick end is a parallelogram flat cylinder.

[0032] The preparation method of the large aggregate ratio rod forging blank whose thick end is a parallelogram flat cylinder is as follows:

[0033] 1. Take a titanium alloy bar, the ratio of the diameter to the length of the bar is 7, heat the bar to 950-1000°C, put one end into a forging die, the die is a truncated cone with one end open, and the open end is The thick end of the cone; forging with a pressure of 6000kN on the forging machine until the diameter r...

Embodiment 2

[0042]1. Take a titanium alloy bar. The ratio of diameter to length of the bar is 9. After heating the bar to 900-950°C, put one end into a forging die. The die is a truncated cone with one end open, and the open end is The thick end of the cone; forging with a pressure of 5000kN on a forging machine until the diameter ratio of the large end and small end of the deformed part of the bar in the die is 1.1, and the large end and the undeformed part form an R40 bending angle;

[0043] 2. After heating the forging billet of the first forging to 900-950°C, put the deformed end into the second forging die. The die is a frustum with one end open, and the open end is the thick end of the frustum; use a pressure of 5000kN on the forging machine Carry out forging until the diameter ratio of the big end and the small end of the deformed part of the forging billet in the die is 1.1, and the big end and the undeformed part form an R40 bend;

[0044] 3. After heating the forging billet of t...

Embodiment 3

[0050] 1. Take a titanium alloy bar. The ratio of diameter to length of the bar is 5. After heating the bar to 900-950°C, put one end into a forging die. The die is a truncated cone with one end open, and the open end is The thick end of the cone; forging with a pressure of 7000kN on the forging machine until the diameter ratio of the big end and the small end of the deformed part of the bar in the die is 1.3, and the large end and the undeformed part form an R50 bending angle;

[0051] 2. After heating the forging billet of the first forging to 900-950°C, put the deformed end into the second forging die. The die is a frustum with one end open, and the open end is the thick end of the frustum; use a pressure of 7000kN on the forging machine Carry out forging until the diameter ratio of the big end and the small end of the deformed part of the forging billet in the die is 1.3, and the big end and the undeformed part form an R50 bend;

[0052] 3. After heating the forging billet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com