Airflow assisted internal conical surface distributed electrostatic spinning nozzle

An electrospinning and inner cone technology, which is applied in textiles and papermaking, filament/thread forming, spinneret assembly, etc., can solve the problems of limiting the output of melt electrospinning, and achieve fiber refinement and High-efficiency spinning, reduced processing difficulty, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

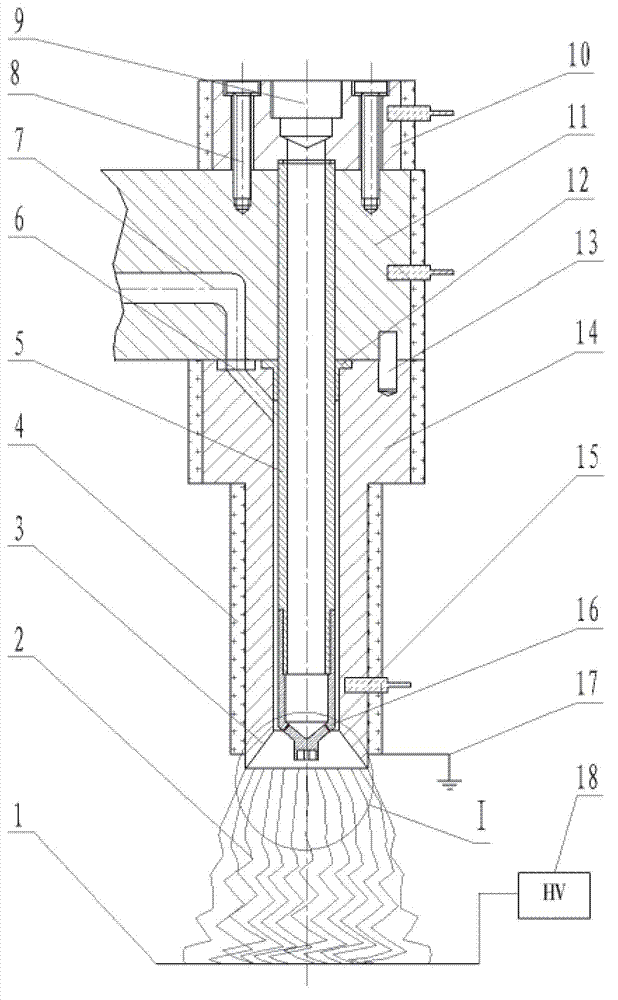

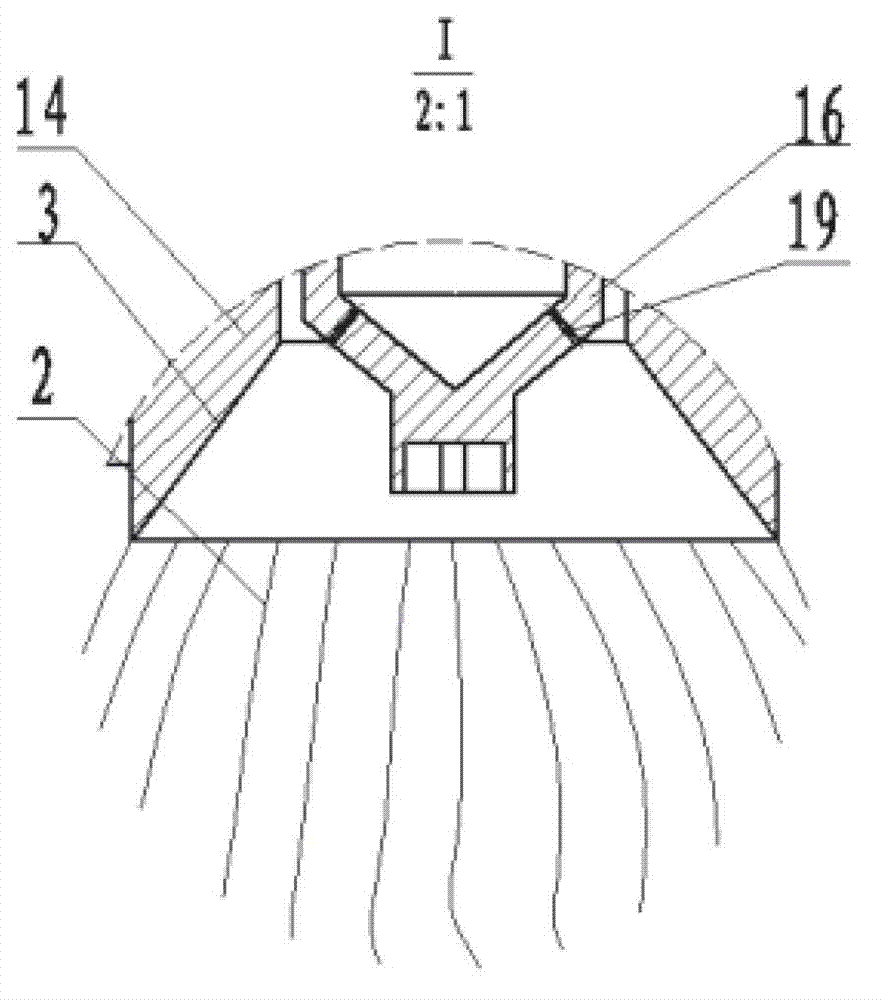

[0023] Air flow assisted inner cone split flow electrostatic spinning nozzle of the present invention such as figure 1 and figure 2 As shown, it mainly includes receiving plate 1, electric heating device 4, airflow guiding column 5, screw 8, air interface block 10, diverter plate 11, flow blocking block 12, inner cone nozzle body 14, nozzle body positioning pin 13, Temperature sensor 15, air flow nozzle 16, grounding electrode 17, high-voltage electrostatic generator 18, receiving plate 1 is fixed on the below that has certain distance with inner cone surface nozzle body 14, and inner cone surface nozzle body 14 passes nozzle body locating pin 13 and The splitter plate 11 is positioned and fixedly connected, the spinning medium inlet 6 and the splitter plate flow channel 7 are connected, the splitter plate 11 and the air interface block 10 are connected by screws 8, and the air flow guide column 5 passes through the flow blocking block 12 and the inner cone nozzle body 14 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com