Tumour-pulling knife for removing steel rail welding beading

A technology for pushing tumor knives and welding tumors, which is applied in the field of tumor pushing knives, which can solve the problems of insufficient cutting, different cutting amount, and damage of tumor pushing knives, etc., and achieve the effects of prolonging service life, uniform cutting amount, and reducing grinding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific drawings and embodiments.

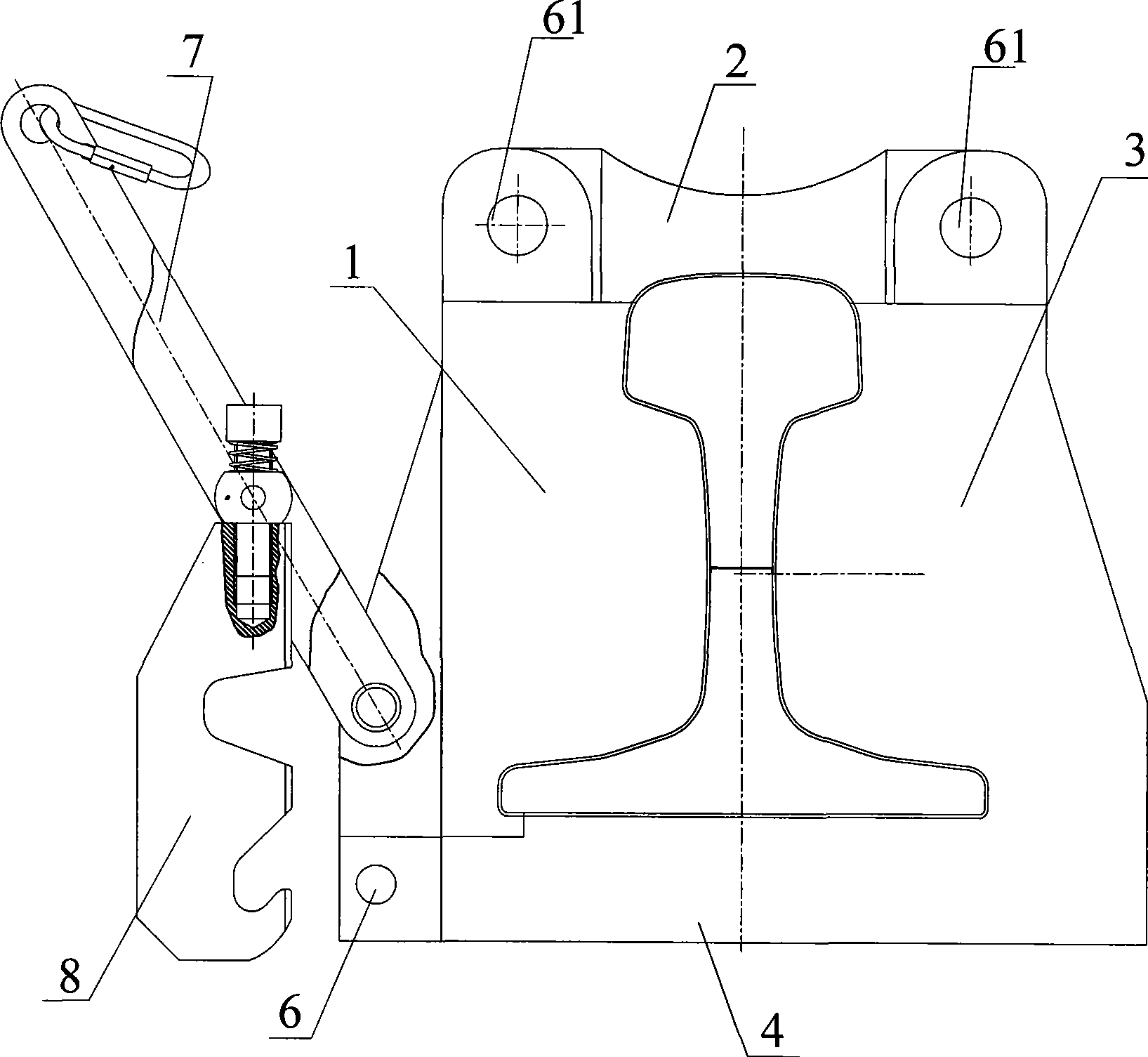

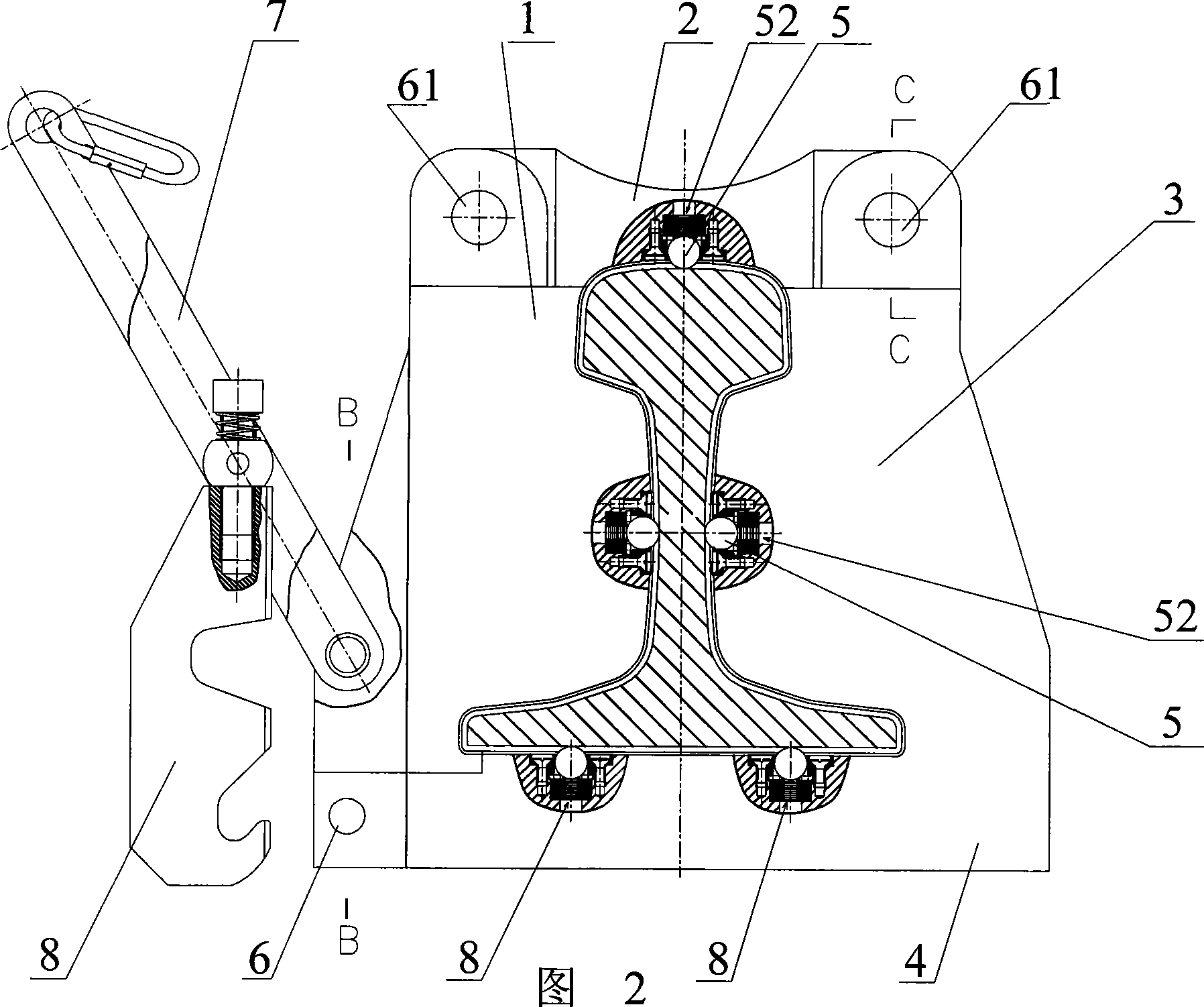

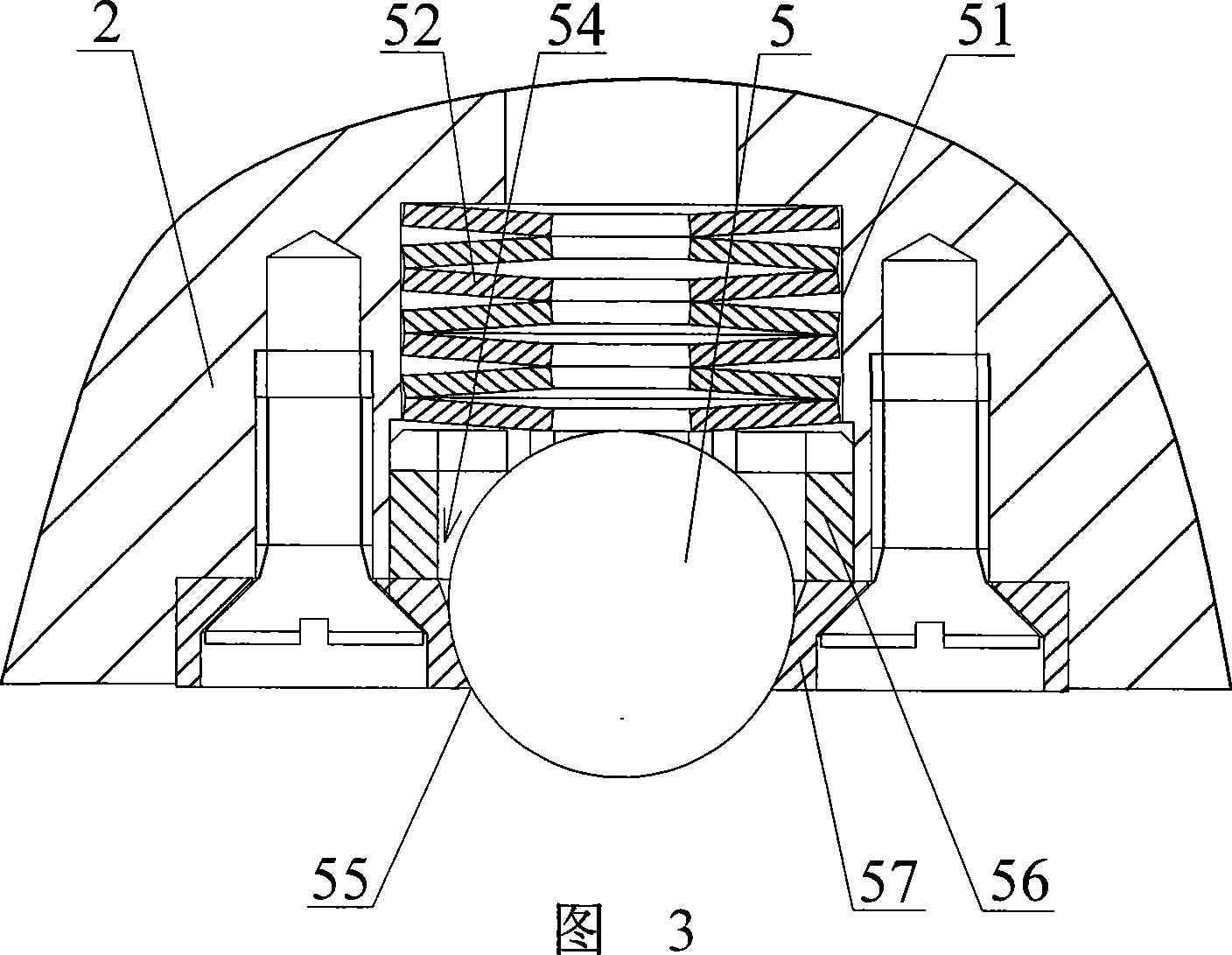

[0028] figure 1 , 2, and 4 show that in the tumor pushing knife, the right side knife body 3 and the bottom knife body 4 are integrated, the top knife body 2 and the right side knife body 3, the top knife body 2 and the left side knife body The body 1, the bottom cutter body 4 and the right cutter body 3 are hinged to each other by pin shafts 61 respectively, and the bottom cutter body 4 and the left cutter body 1 are connected to each other by a locking mechanism. Wherein the bottom cutter body 4 and the left side cutter body 1 are provided with a locking mechanism, so that the bottom cutter body 4 and the left side cutter body 1 are mutually connected and locked; After the side cutter bodies 1 are connected and locked together, the cutting edges of all the cutter bodies constitute the cross-sectional shape of the rail. Please refer to Figs. 7, 9 and 11 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com