Mould and method for casting quartz crucibles

A casting molding, quartz crucible technology, applied in the field of quartz ceramic processing, can solve the problems of reduced strength at grinding, poor exhaust, long casting molding time, etc., to achieve product quality assurance, reduce molding time, and shorten molding time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

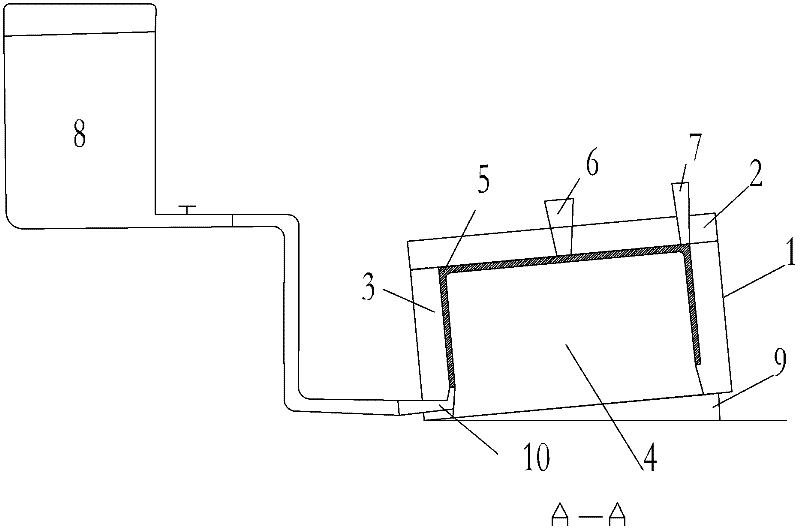

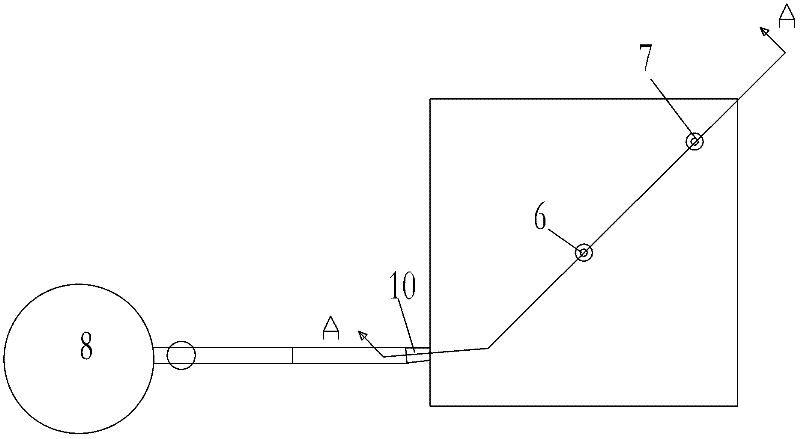

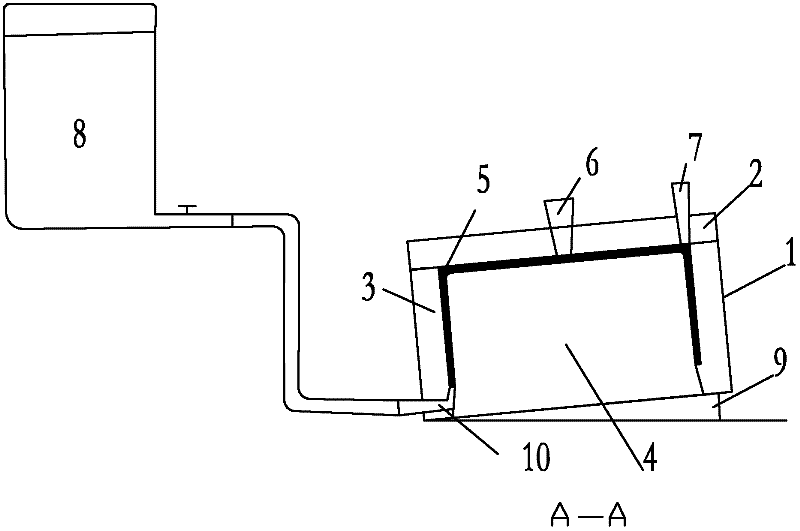

[0038] 1. Prepare quartz slurry, vacuum pouring tank, plaster mold body and pouring platform (one corner of the pouring platform is 5 degrees higher than the opposite corner to the ground, that is, a bracket).

[0039] 2. Put the quartz slurry into the vacuum pouring tank and vacuumize for 50 minutes.

[0040] 3. Assemble the main body of the gypsum mold, and add a funnel with a height of 20cm to the grout filling hole on the mold cover and the exhaust grout filling hole.

[0041] 4. Put the combined gypsum mold body on the pouring platform, pay attention to place the direction of the pouring port on the corner of the bottom of the pouring platform (that is, the lowest point of the crucible pouring forming area), and place the direction of the exhaust port at the height of the pouring platform ( That is, the highest point in the casting area of the crucible).

[0042] 5. Lift the vacuumed slurry and the vacuum pouring tank to the pouring platform, which is higher than the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com