Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about How to "Reduce smoke loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of environmental-protection plant energy particle fuel

InactiveCN101892108AReduce pollutionMeet the requirements of energy saving and emission reductionBiofuelsSolid fuelsEnergy particleSolid fuel

The invention relates to a production process of an environmental-protection plant energy particle fuel, which is characterized by collecting combustible plant materials as raw materials and then sequentially processing the raw materials by the following steps of: (1) pulverizing: the raw materials are pulverized into powdery particle materials with the particle size less than 2 mm; (2) drying: the pulverized materials are dried so that the water content of the materials is 12%-20% by drying; and (3) extrusion molding: extrusion molding is carried out to the dried materials so that the materials form a solid particle fuel with the density of 1.0-1.4 g / cm<3> through extrusion molding. The invention can be used for processing various combustible plant materials comprising agricultural or forestall wastes and the like into high-efficiency combustible solid fuel particles, thereby solving the problem of considerably increased agricultural (forestall) wastes at present, also relieving the current situation of increasing energy shortage at present and being beneficial to environmental protection and energy saving.

Owner:福建泰和生物质能源科技有限公司 +2

Online monitoring method for flue gas temperature of hearth outlet of power station boiler

InactiveCN101806626AGood for the economyIncrease the effective caliberRadiation pyrometryPower stationFlue gas

The invention discloses an online monitoring method for the flue gas temperature of a hearth outlet of a power boiler, comprising the steps of: placing a plurality of targets at a vertical section near a smokestack of a boiler for sensing the temperature; installing a near infrared imaging device on the side wall of a horizontal flue of the boiler for collecting the radiation energy of the targets; carrying out communication by the near infrared imaging device with a computer through a serial port and RS232, sending the collected radiation energy of the targets to the computer, calculating by the computer to obtain temperature data of the targets; and then sending the temperature data of the targets to a host computer for processing, and converting the temperature to the flue gas temperature of the position of the targets. The invention has the advantages that the average temperature at the section of the hearth outlet, the average temperature of the upper / lower and left / right side, and the highest / the lowest temperature can be continuously monitored, the distribution curve of the temperature of the section can be drawn, and a plurality of alarm functions are set; and the invention is beneficial to the safe and economic operation of a boil with a large capacity and high parameters.

Owner:四川东脑电气工程有限公司

Superfine coal dust oxygen-enriched combustion technology and system

InactiveCN103234198AIncrease burnoutAlleviate the problem of slagging on the heating surfaceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTrappingFlue gas

The invention discloses a superfine coal dust oxygen-enriched combustion technology and system in the technical field of energy conservation and emission reduction. The technology comprises the following steps of: preparing superfine coal dust with an average particle size of less than 20 microns, and burning in an oxygen-enriched environment with overall concentration kept at 27-35% (v / v); extracting part of the hot flue gas in a flue at the rear part of a deduster; and circularly preparing superfine coal dust by taking the extracted flue gas and oxygen as combustion-supporting mediums again. According to the technology and system disclosed by the invention, the superfine coal dust is applied to the oxygen-enriched combustion technology, and the advantages of the two are effectively combined to realize an effect of using advantages and bypassing disadvantages; and the superfine coal dust oxygen-enriched combustion technology finishes efficient trapping of CO2 and is a new coal dust combustion technology with good combustion property and better pollutant discharge performance, and surely becomes an emerging technology for pollutant cooperative removal deserving vigorous promotion.

Owner:SHANGHAI JIAO TONG UNIV

Oxygen-enriched combustion transformation method and device for garbage incineration grate furnace

InactiveCN104100979ABurn fullyAdjustable temperatureIndirect carbon-dioxide mitigationIncinerator apparatusBaghouseEngineering

The invention discloses an oxygen-enriched combustion transformation method for a garbage incineration grate furnace. The method comprises the steps that an oxygen injecting step is added before the primary air of a combustion section, namely, oxygen obtained by gasifying and pressure regulating is injected into a primary air pipeline of the combustion section, so the air is fully mixed with the normal air of the combustion section and is then injected into a hearth; injection of normal secondary air is stopped, a draught fan behind a cloth bag deduster is connected with a secondary fan by a pipeline, so circulated smoke is guided into a secondary air pipeline by the secondary draught fan, and is injected into the hearth by a secondary air opening. The invention discloses a corresponding oxygen-enriched combustion device. The excess air coefficient is reduced, the flame temperature in the furnace is improved, the combustion condition is optimized, the generation of pollutants such as dioxin is effectively inhibited, the efficient, stable and safe operation of the incineration equipment is ensured, the smoke exhaust is reduced, the smoke heat loss and output of the draught fan are reduced, the combustion efficiency is improved, and the investment and operation cost of smoke purifying equipment are favorably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

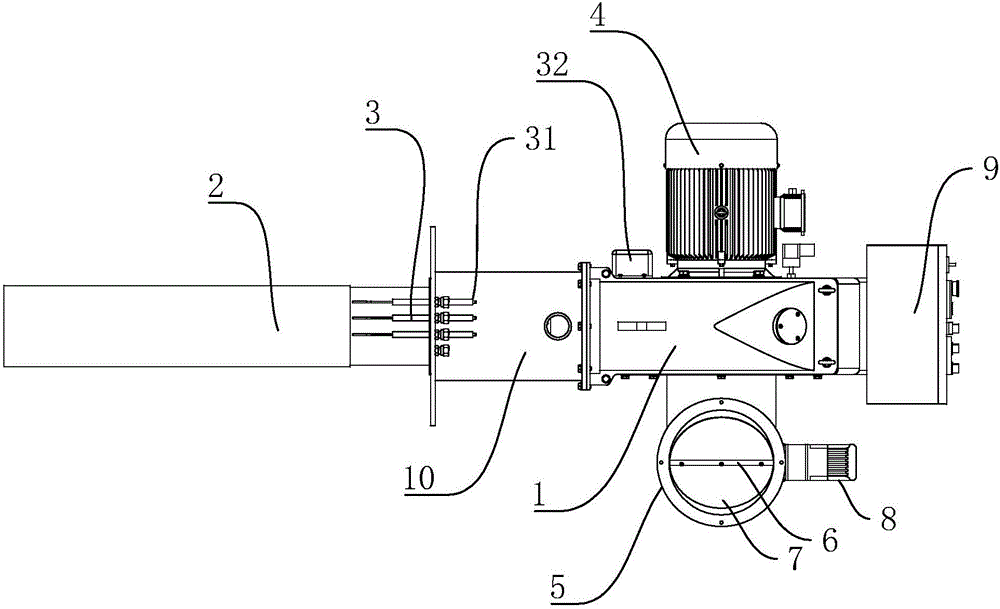

Low-nitrogen burner

The invention discloses a low-nitrogen burner. According to the technical scheme, the low-nitrogen burner is characterized in that a mixer of the low-nitrogen burner comprises a barrel and a gas inlet, wherein an inner barrel and burning-supporting air swirling pieces arranged on the inner wall of the inner barrel are arranged at the gas inlet front end inside the barrel; an air inlet barrel located on the back side of the burning-supporting air swirling pieces in the air inlet direction is arranged at one end, close to the gas inlet back side, of the inner barrel; the air inlet barrel, the inner barrel and the inner wall of the barrel are connected in a sealed manner to form a gas sub-cavity; inclined flow guiding holes are formed in the air inlet barrel; a primary swirling impeller is arranged in the position, located on the air inlet back side of the inner barrel, inside the barrel; and the primary swirling impeller and the air inlet barrel form a primary mixing chamber. Through the arrangement, gas is ejected via the gas sub-cavity from the inclined flow guiding holes, the ejected gas can form multiple single, short and powerful gas flows, air flows sent by a fan pass through the burning-supporting air swirling pieces to form short and powerful rotating air flows, and the rotating air flows are circular and impact the multiple single gas flows, so that the air and the gas of the primary mixed gas reach the air-fuel ratio in the complete burning theory.

Owner:BEIJING SHENKEBOSI THERMAL ENERGY ENG TECH CO LTD

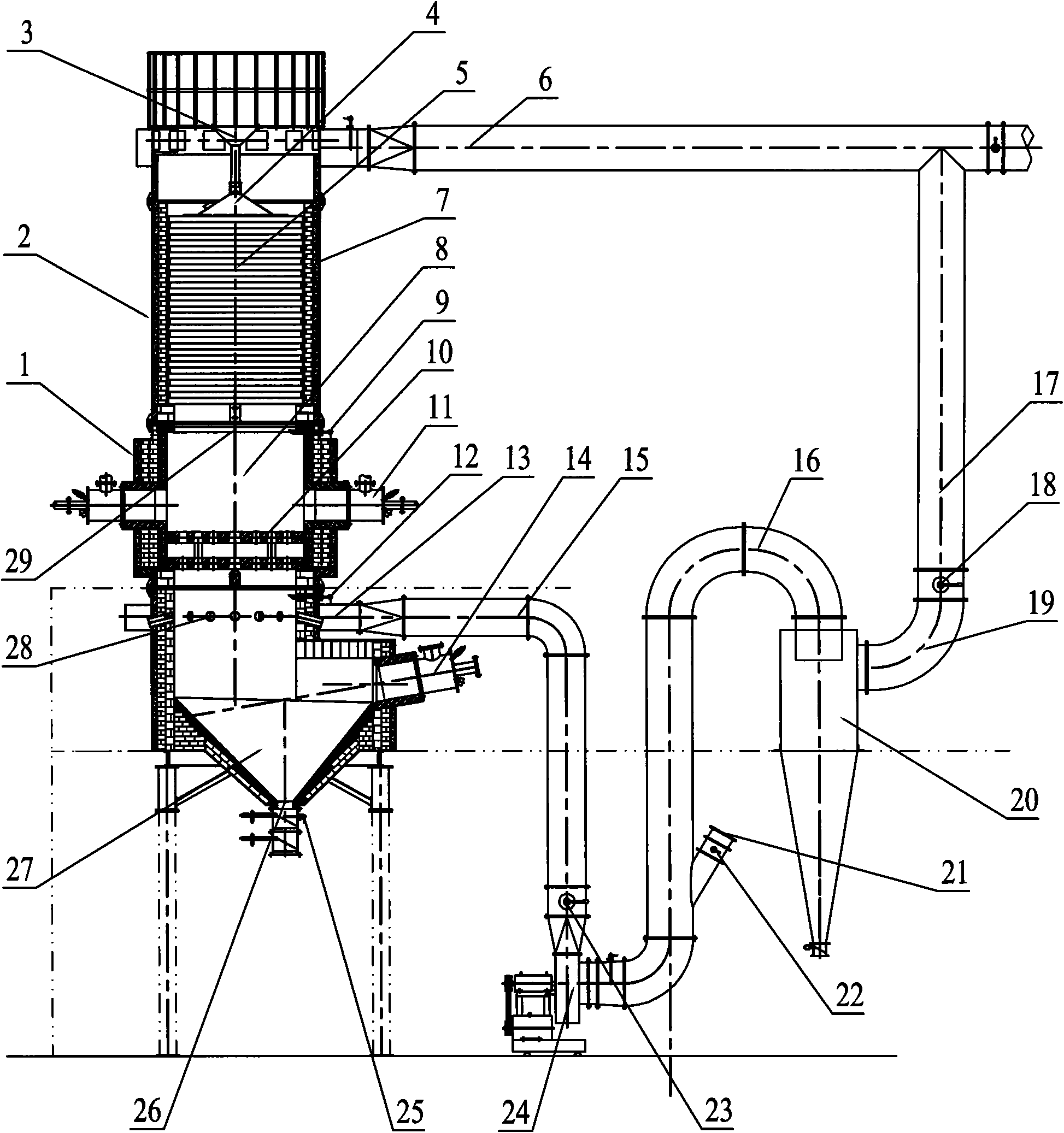

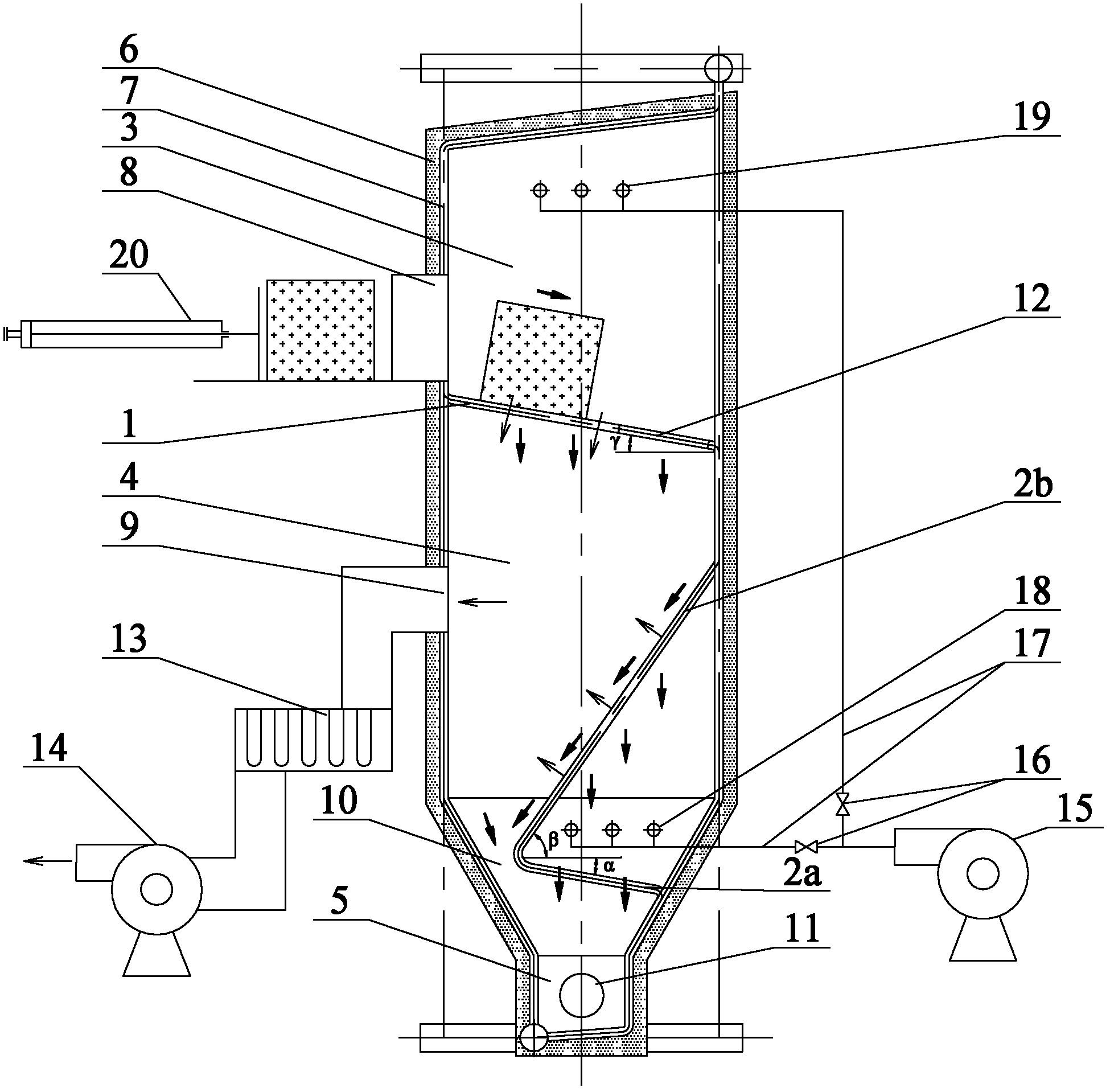

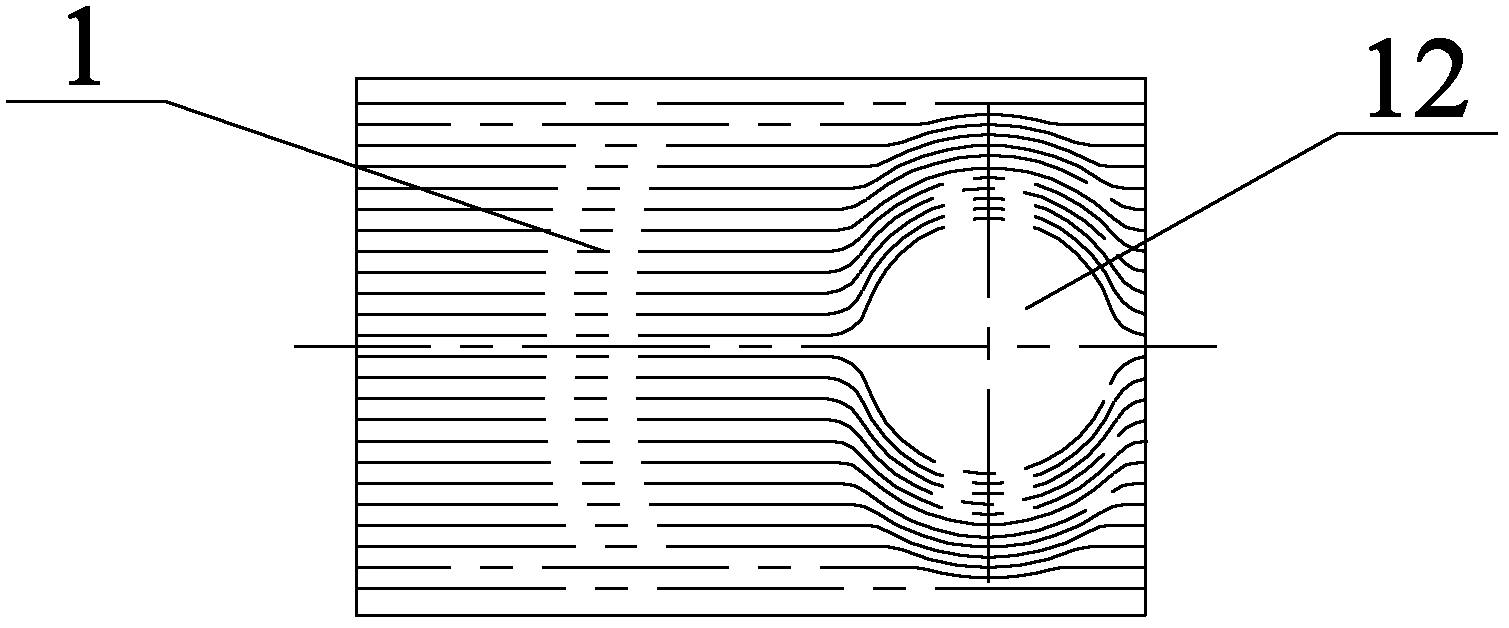

Waste molding sand or core sand regenerating equipment

InactiveCN101862808ATake advantage ofFull heat exchangeMould handling/dressing devicesConvection heatHeat energy

The invention relates to waste molding (core) sand regenerating equipment. The regenerating equipment comprises a fluidizing roasting furnace, wherein the fluidizing roasting furnace is provided with a roasting feeding hole, a roasting discharging hole, an air inlet passage and an air outlet passage. The regenerating equipment is characterized in that the waste molding sand or core sand regenerating equipment also comprises a sand separating heating device; the sand separating heating device is arranged above the fluidizing roasting furnace and comprises a sand separating heating chamber, a sand separating heating beam and a sand separating cone, wherein the sand separating heating beam and the sand separating cone are arranged in the sand separating heating chamber; the top and the bottom of the sand separating heating chamber are provided with openings; the sand separating cone is arranged on the opening at the top of the sand separating heating chamber and fixed at the top of the sand separating heating beam; a sand discharging hopper is arranged above the sand separating heating chamber, and communicated with the sand separating cone; and the opening at the bottom of the sand separating heating chamber is communicated with the roasting material inlet of the fluidizing roasting furnace. The invention has skillful and reasonable structure, skillfully combines a convection heat exchange technology and a boiling and fluidizing heating technology, sufficiently utilizes the heat energy, and enhances the heat efficiency and the treating capability of the equipment.

Owner:WUXI XINAN FOUNDARY MACHINERY

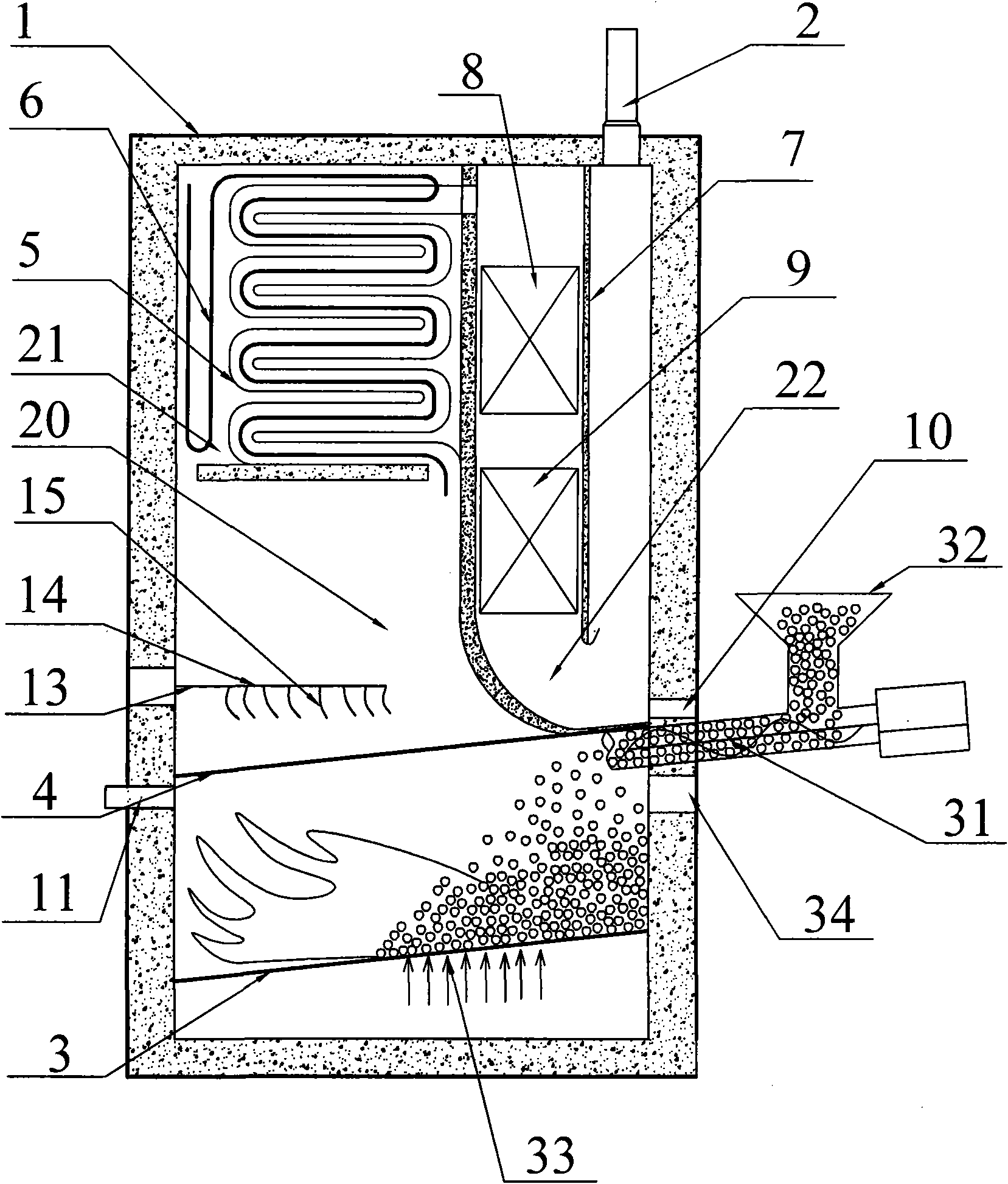

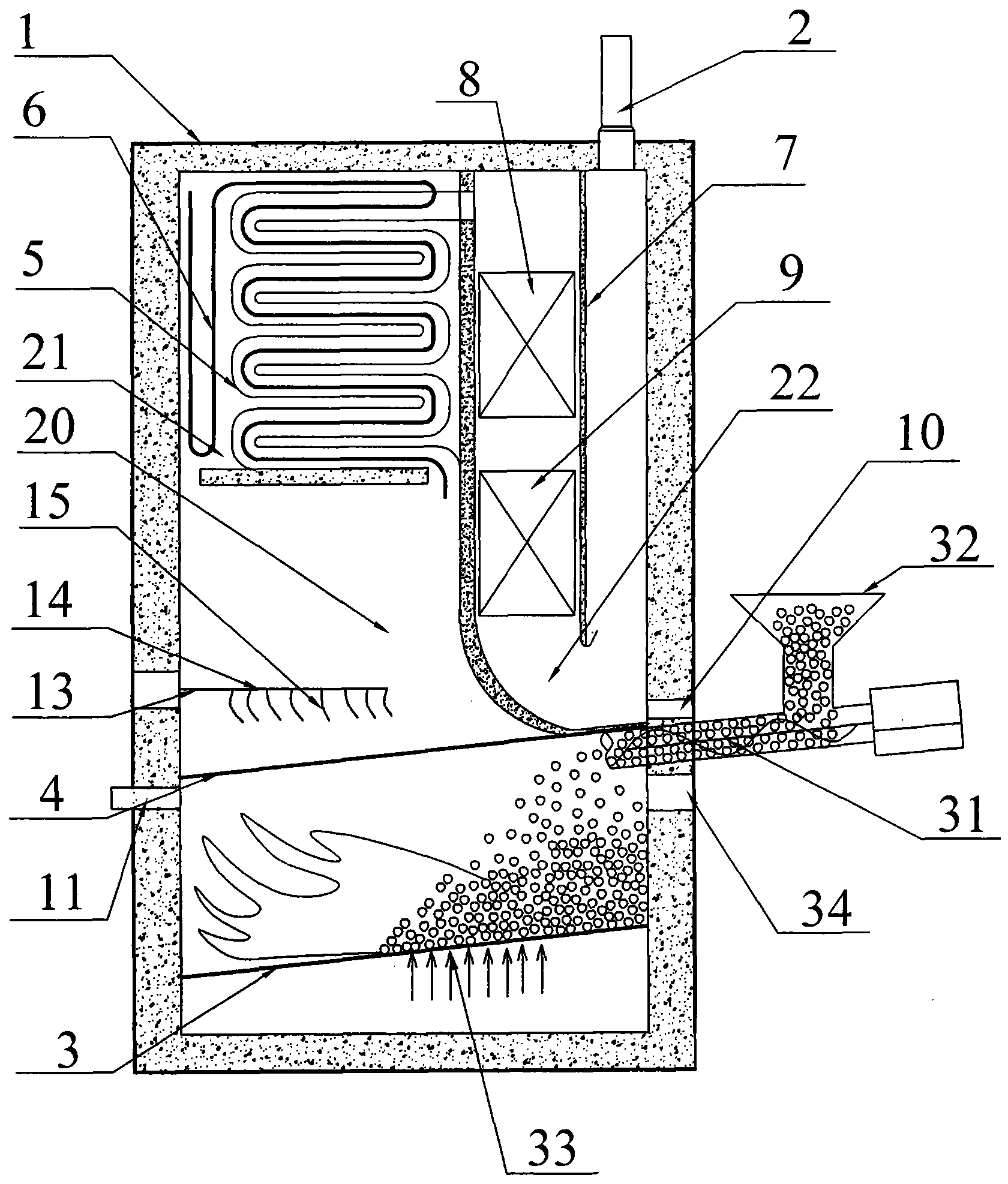

Biomass fuel combustion device

ActiveCN101839475ASlight disturbancePromote combustionDouble grateSolid fuel combustionCombustion chamberPollutant emissions

The invention discloses a biomass fuel combustion device, and provides a biomass fuel combustion device which has the advantages of high combustion efficiency and less pollutant discharge. The biomass fuel combustion device of the invention comprises a vertical combustion furnace (1), wherein a smoke discharging channel (2) is arranged on the vertical combustion furnace (1); a combustion chamber (20) and a heat exchange chamber (21) are arranged in the vertical combustion furnace (1); an upper grate (3) and a lower grate (4) are arranged in the combustion chamber (20); the combustion chamber (20) is provided with a feeding device which is positioned on the side wall of the vertical combustion furnace (1) and is communicated with the combustion chamber (20); a primary air inlet (33), a secondary air inlet (34) and a tertiary air inlet device are respectively arranged in the corresponding positions of the vertical combustion furnace (1); a smoke pipe (5) and a hot water pipe (6) are arranged in the heat exchange chamber (21); and the smoke pipe (5) is respectively communicated with the combustion chamber (20) and the smoke discharging channel (2) through gas flow. The invention can be widely applied to the field of boilers.

Owner:湖南兆丰新能源技术有限公司

Heating furnace visual combustion control system and method based on multi-parameter detection

ActiveCN107152695AEmission reductionImprove combustion efficiencyDirect carbon-dioxide mitigationCombustion regulationLoop controlCO analyzer

The invention discloses a heating furnace visual combustion control system based on multi-parameter detection. The system comprises a CO analyzer for online precise detection of the content of CO in smoke, an O2 analyzer used for online detection of the content of O2 in a hearth, a visual monitoring device, a pressure sensor, a frequency converter, an induced draft fan, a driver, an air door baffle and a DCS control system, wherein the DCS control system is in closed-loop control connection with the CO analyzer, the O2 analyzer and the pressure sensor and controls the driver and the frequency converter according to the set control system safety adjusting threshold value, and the combustion state of the heating furnace is optimized and adjusted; the visual monitoring device displays the combustion state of a nozzle in the heating furnace, the combustion efficiency is estimated, the temperature uniformity and longitudinal temperature gradient of the hearth are calculated, and a control method of the heating furnace visual combustion control system is further disclosed. The multi-parameter visual combustion control method is adopted, the heating furnace is constantly in a theory close combustion state, the combustion efficiency is improved, the device running efficiency is improved, pollutant emission is reduced, and especially emission of CO2 and NOx is reduced.

Owner:HEFEI RUISHI MEASUREMENT & CONTROL ENG TECH

Method for improving measurement accuracy of oxygen content in boiler flue gas

InactiveCN103018279AAccurate healthHigh measurement accuracyMaterial analysis by electric/magnetic meansCombustionFlue gas

The invention discloses a method for improving measurement accuracy of the oxygen content in boiler flue gas and belongs to the technical field of online gas content measurement. According to the technical scheme, the method comprises the steps of establishing a space-time fusion model of the system for measuring the oxygen content of the flue gas; preprocessing the data of an oxygen quantity signal acquired by a zirconia oxygen indicator according to a data consistency testing principle; realizing the fusion of space and time of the oxygen quantity signal through a Kalman filtering fusion algorithm; and finally, calculating the boiler combustion efficiency and smoke outlet loss according to the fused oxygen quantity signal. The method has the beneficial effects that the data fusion technology is used for online measurement of the oxygen content of the flue gas in a heat-engine plant, the method is easy and convenient to calculate and high in reliability, the redundant or complementary information of the oxygen quantity sensor in space or time can be reflected, a measurement result which is more accurate than the arithmetic mean value of limited sensors is obtained, and the operating conditions of the unit can be accurately reflected.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Industrial furnace with high-temperature low-oxygen air burner

InactiveCN1337547AImprove energy utilizationReduce smoke lossCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberIndustrial furnace

The present invention relates to an industrial furnace with high-temp. low-oxygen air burner, which is characterized by that the two ends of furnace cavity are respectively equipped with a high-temp.low-oxygen air burner. Said burner is formed from combustion chamber, combustion chamber end cover which is set at end hole of combustion chamber, possesses a circular through hole in its centre and is formed into a ring channel at end portion of the combustion chamber and cover plate positioned on the end cover of combustion chamber. Said burner can make oxygen being in high-temp. air obtain dilution by means of returned fume and convert it into low-oxygen air, and make the fuel combust under the condition of low-oxygen air, and its oxygen concentration is less than 15%. It not only effectively reduce NOx discharge, but also its discharge temp. only is 150-200 deg.C. so as to attain the goal of saving energy and protecting environment.

Owner:TSINGHUA UNIV

Machine group performance optimization operation management method

InactiveCN1655164AChanges in the concept of economic operationImprove economySpecial data processing applications

This invention puts forward an intelligent unit performance optimized operation management method of a computer, which obtains the unit operation parameter via a boiler control system, obtains the carbon volume in the ash of the boiler from a test device, gets related parameters of factory electricity consumption from an electric transcription system to store real time operation data in a data base server of a central process computer and compute a set of economic targets under the current operation situation to provide the optimum economic operation parameter taking the least cost of electricity as the searching target. Advantage: combining the several single parameters to a comprehensive target expressing the set operation integral effect and directly combining with the profit target of the enterprise to save energy for the generation enterprises.

Owner:NANJING GUOTAI ELECTRIC POWER TECH DEV

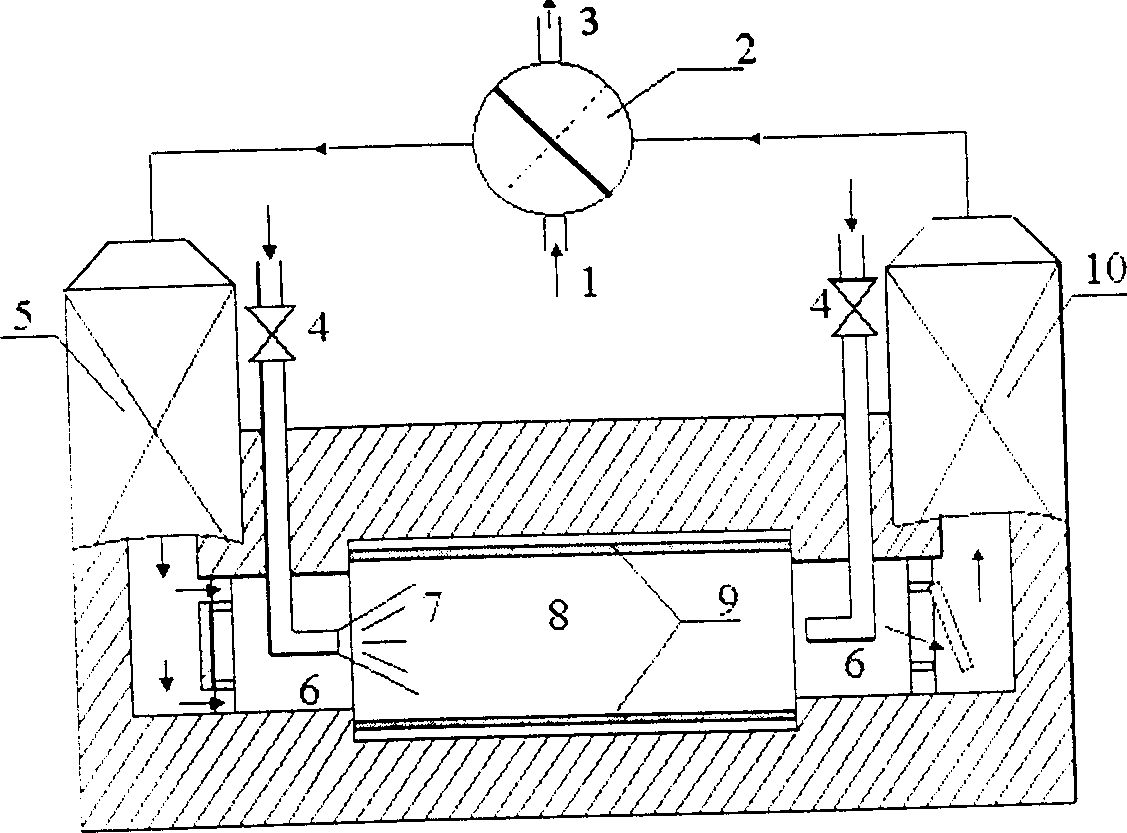

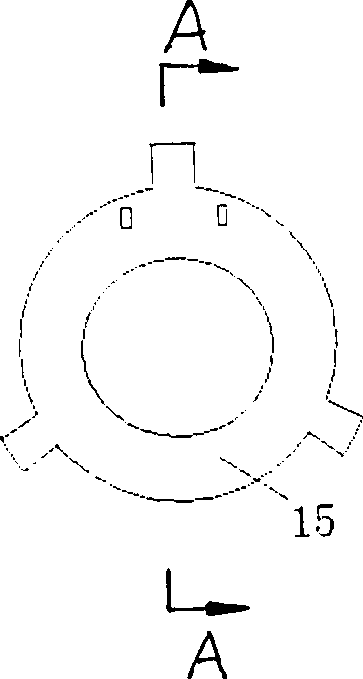

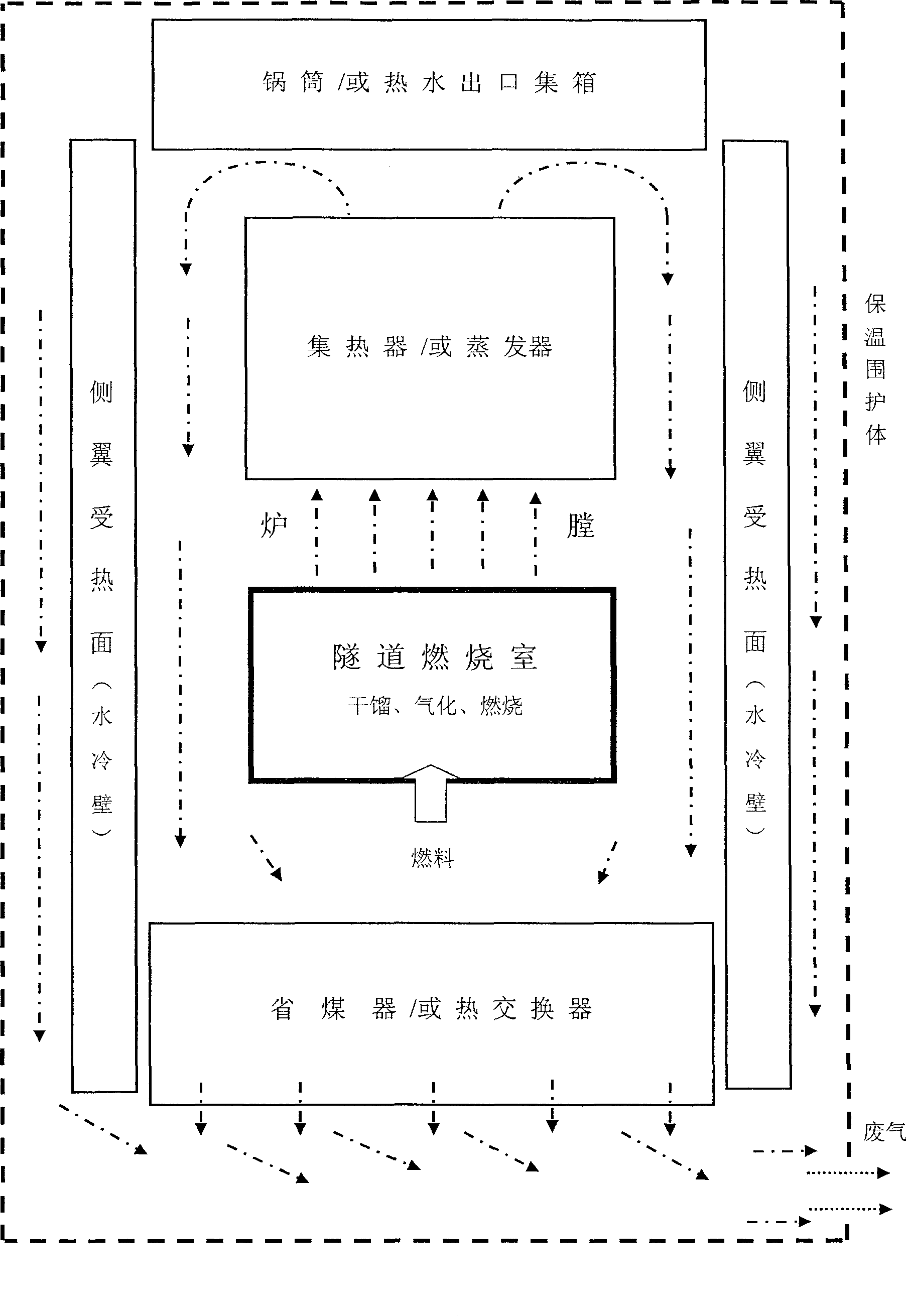

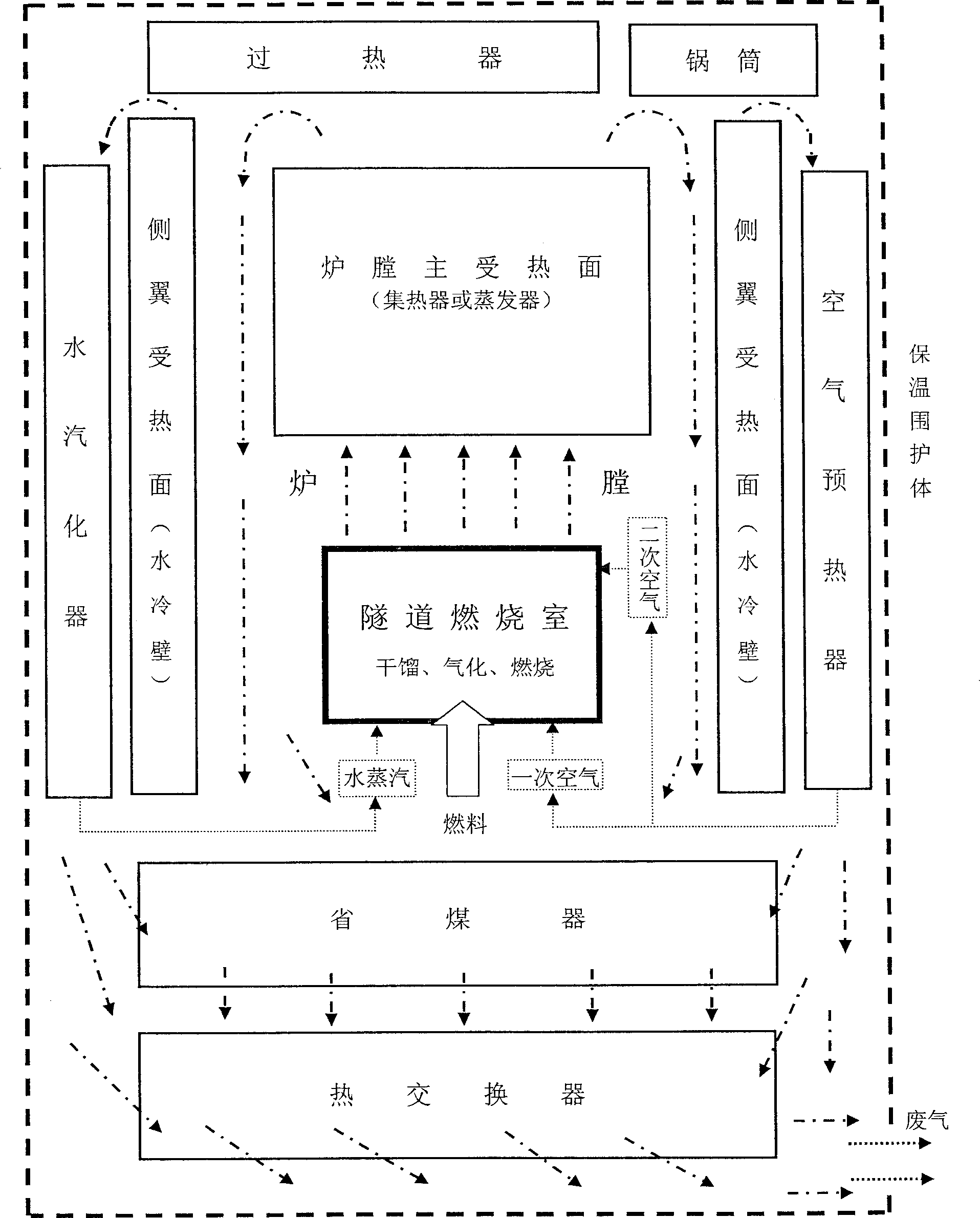

Tunnel combustion chamber and its constructed smoke dust less fuel coal and biomass equipment

InactiveCN1904479ARaise the gradePrevent escapeCasings/liningsNon-combustible gases/liquids supplyResource depletionCombustion chamber

The tunnel combustion chamber and its constitute of burning coal and organism without smoke and dust relate to boiler, furnace and aerify equipment whose fuel is coal and organism. The tunnel combustion chamber has wide fuel scope. It can carry out the cleanness combustion of the smoke raw coal, the spread coal, the organism, the type coal and the biologic coal. It applies the biologic fuels reasonably and has high thermal efficiency. It realizes the large-scale and mechanical burning. The invention resolves the problem of pollution atmosphere environment by coal burning device. It makes the equipments the cleanness combustion when burning the coals. The small equipment doesn't need air blast and induced air and it can burn. And it doesn't need the ash handling equipment to protect the environment. The invention sends the vapour to the tunnel combustion chamber. It is used to restrain the smoke and translate to the gas fuel. It carries out cleanness combustion when realizes the increase the combustion value of the fuels. It lowers the resources depletion and relief the energy strain. It creates a condition for pushing economy social overall coordination sustained developing.

Owner:周开根

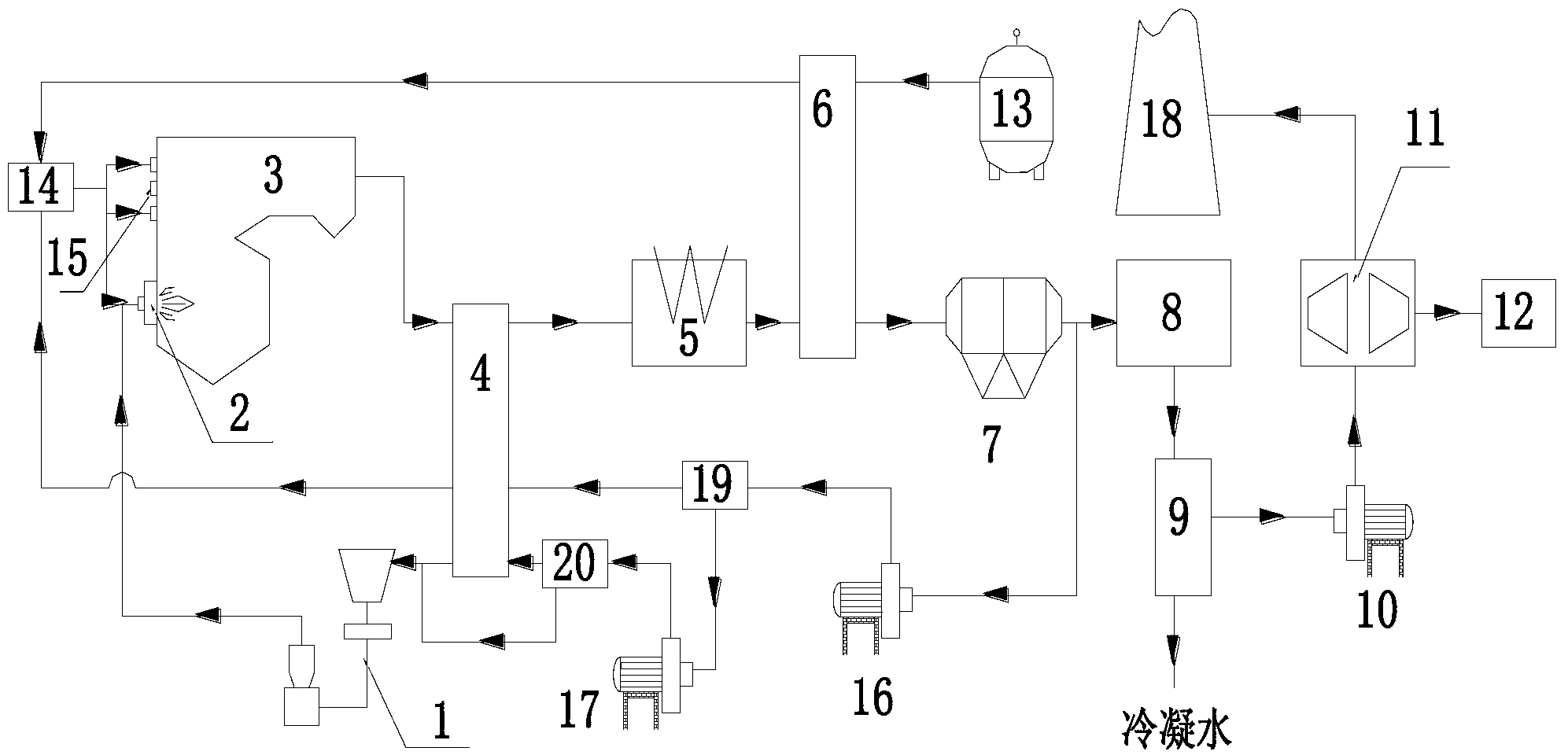

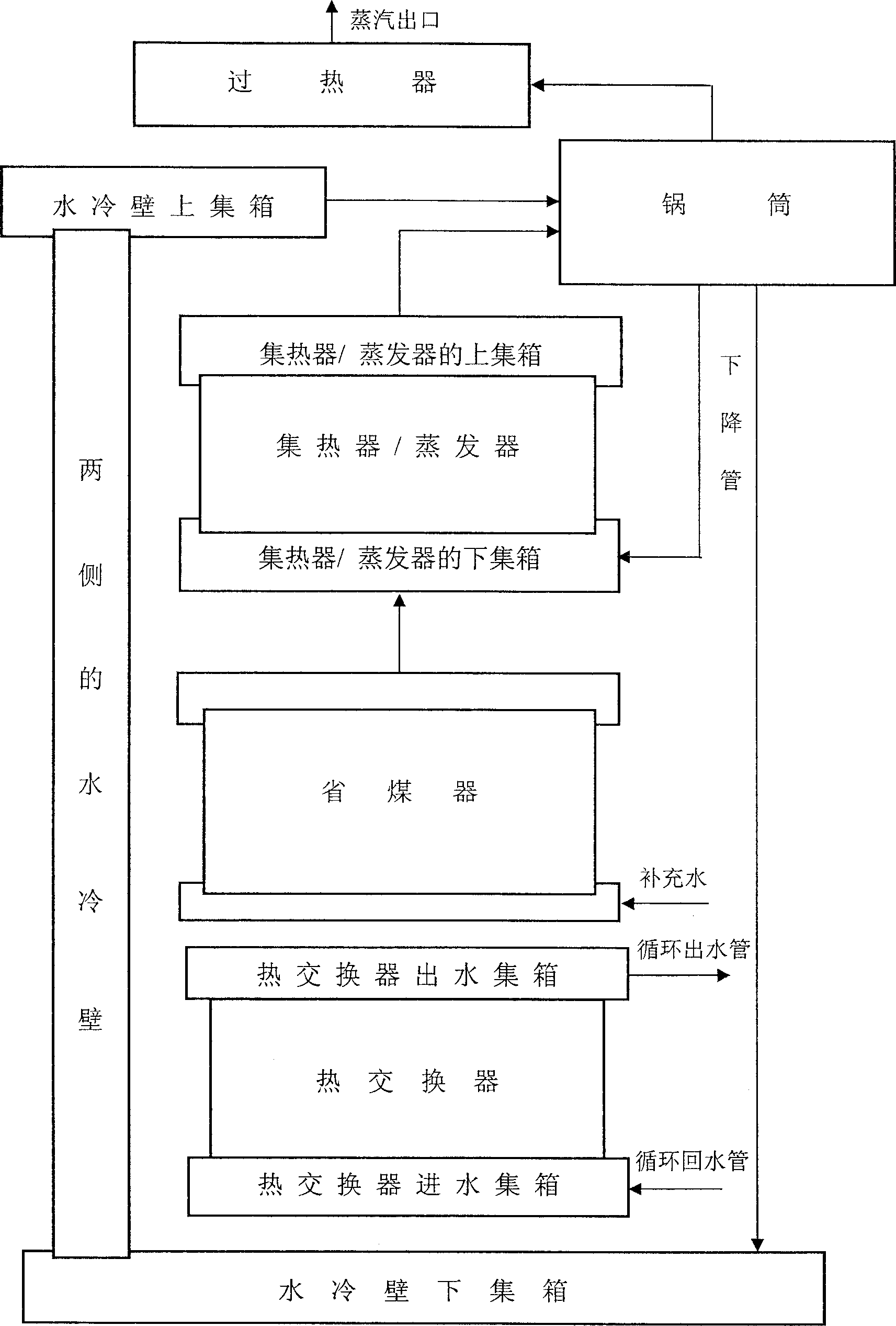

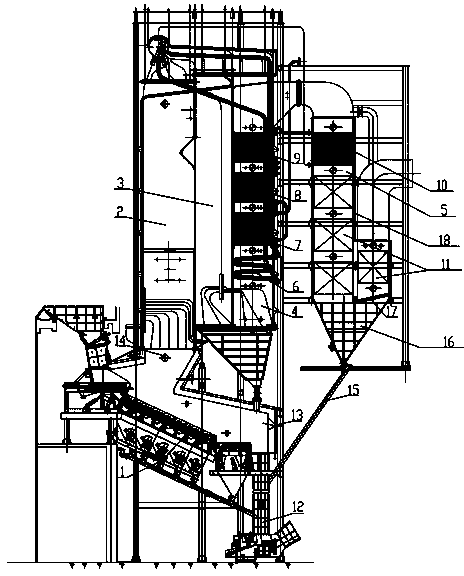

Brown coal pre-drying-air preheating-waste heat utilization composite coal-fired power generation system

InactiveCN103277155AIncrease energy densityStable combustionCombustion processSteam useAir preheaterPower generation system

The invention discloses a brown coal pre-drying-air preheating-waste heat utilization composite coal-fired power generation system, and belongs to the power station energy-saving field. The system is mainly characterized in that a brown coal drying system is connected with a steam turbine regenerative system and an air preheating system, a smoke heat-setting water system is connected with the steam turbine regenerative system and the air preheating system, the steam turbine regenerative system is connected with a steam turbine generating device, the air preheating system is connected between the brown coal drying system and a boiler rear smoke channel, then whole-course heating of air is finished, and brown coal can be directly burned for power generation after being dried. Energy density of the brown coal is increased, boiler efficiency is improved, heat and moisture in dried tail gas are recycled, temperature of air in an inlet of an air pre-heater is increased, meanwhile, a smoke-water heat exchanger arranged in a hearth division smoke channel recycles smoke heat, coal consumption of a unit is expected to be greatly reduced, and therefore the efficient, energy-saving, water-saving and emission-reducing effects are achieved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

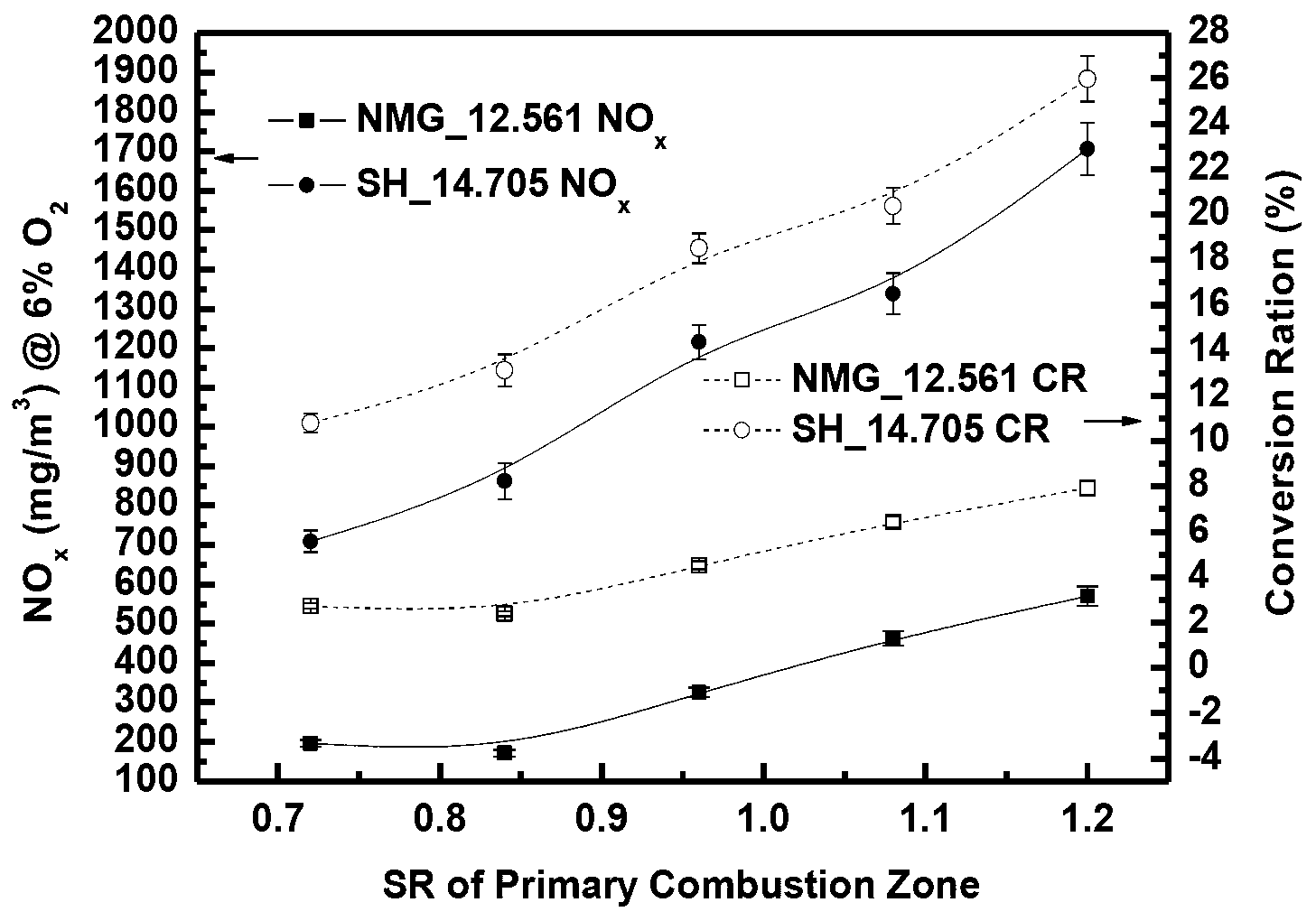

Combustion system and combustion method for retarding slagging and contamination of high-alkali coal boiler for combustion

ActiveCN105299626AImprove efficiencyLong runIndirect carbon-dioxide mitigationCombustion apparatusCombustion systemEngineering

The invention provides a combustion system for retarding slagging and contamination of a high-alkali coal boiler for combustion. An outlet of a dry type electric precipitator is connected with a circulating fan through a smoke recycling pipeline, a pipeline behind the circulating fan and a primary air pipeline are both connected with a recycling pipeline, an ash bin is connected with an ash conveyer, one end of a circulating-ash-containing smoke and air mixing pipeline is connected with the recycling pipeline and the ash conveyer, and the other end of the circulating-ash-containing smoke and air mixing pipeline. The invention also provides a combustion method for retarding slagging and contamination of high-alkali coal boiler for combustion, the mixed airflow of low-temperature circulating smoke, part of primary air and flying ash are sent into a hearth in a layered manner from side boiler walls at four corners of the boiler, and a protection gas film of a wall attaching stream is formed nearby the boiler wall, so that the recycling of smoke and flying ash can be realized. According to the system and the method, the adjustment of the combustion condition of coal dust is facilitated, and the adaptability of the boiler to the coals can be enhanced, so that contamination and slagging of the heat exchange surface of the hearth can be inhibited, the heat exchange capability is changed correspondingly, the smoke discharging loss is reduced, and the boiler efficiency is effectively improved.

Owner:SHANGHAI POWER EQUIP RES INST +1

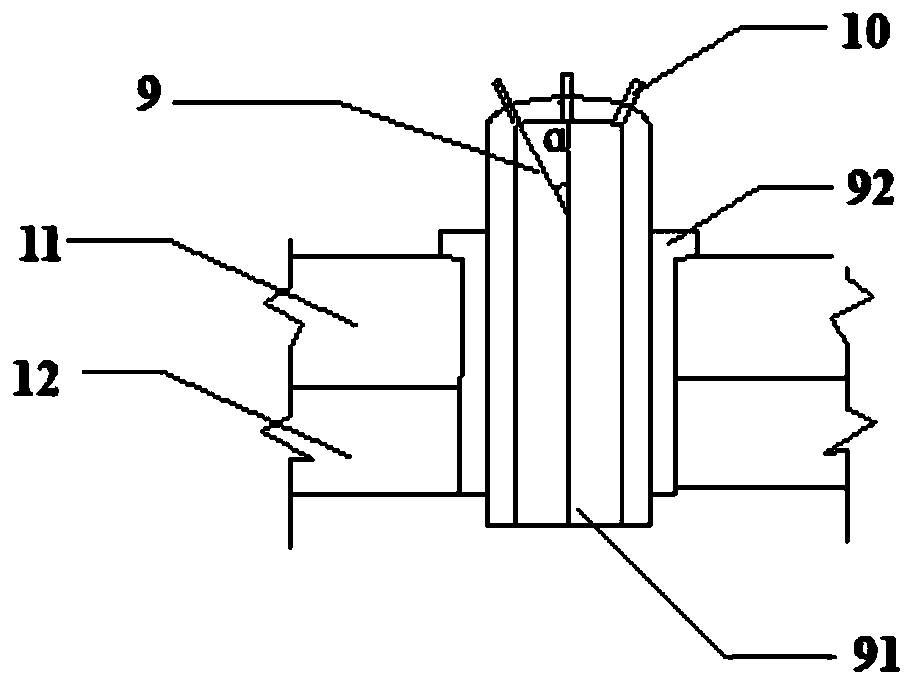

Magnetic wheel radial sealing device of rotary air preheater

ActiveCN109059036AExtended service lifeSmooth movementCombustion processHeat exhanger sealing arrangementAir preheaterEngineering

The invention discloses a magnetic wheel radial sealing device of a rotary air preheater, and belongs to the field of power plant boiler equipment. The device comprises a fan-shaped plate, a rotor, magnetic sealing wheels and rotating rods; the fan-shaped plate is arranged at the outer periphery of the rotor; the surface, towards the rotor, of the fan-shaped plate is a magnetic surface; the rotorcomprises cabin separation plates arranged among all cabins of the rotor; the ends, near the fan-shaped plate, of all the cabin separation plates are hinged with the rotating rods; and the magnetic sealing wheels capable of absorbing the magnetic surface are arranged at one ends of all the rotating rods. The device has the characteristics of simple structure, convenience to install and maintain, high heat deformation adaptability of the rotor and low wear degree of sealing pieces, and can effectively achieve the purposes of reducing radial air leakage of the rotary air preheater and improvingthe operation efficiency of the air preheater.

Owner:HUAZHONG UNIV OF SCI & TECH

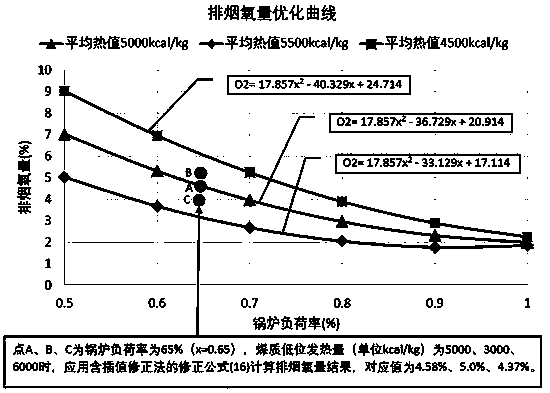

Combustion optimization method based on coal quality on-line monitoring

ActiveCN110848733ASolve the problem of difficult real-time measurement of coal qualitySolve the problem of difficult real-time measurementForecastingCombustion regulationAir volumeCombustor

Owner:NANJING SCIYON AUTOMATION GRP

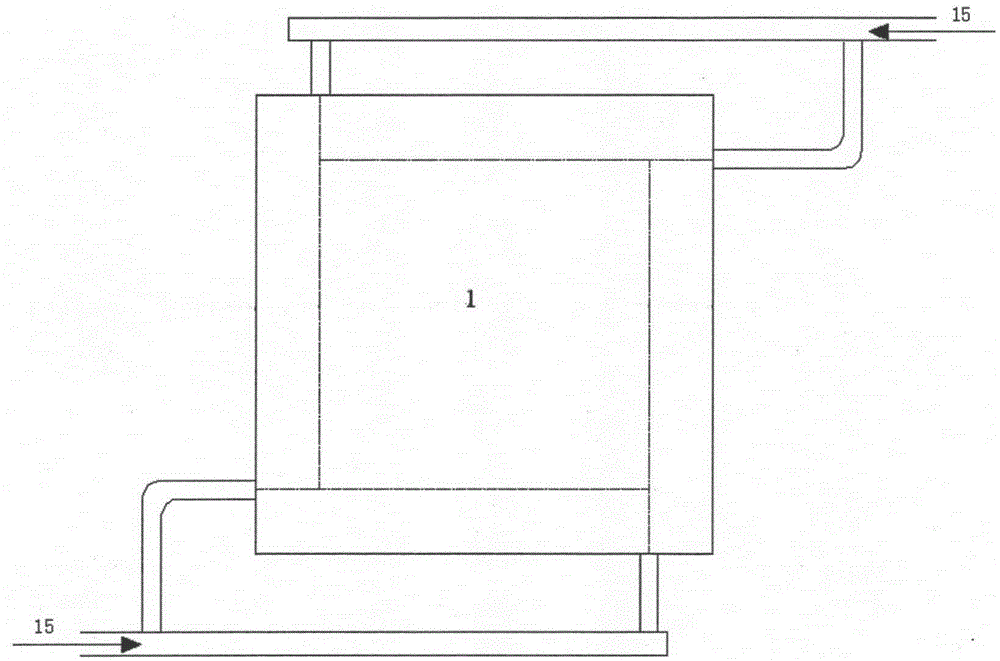

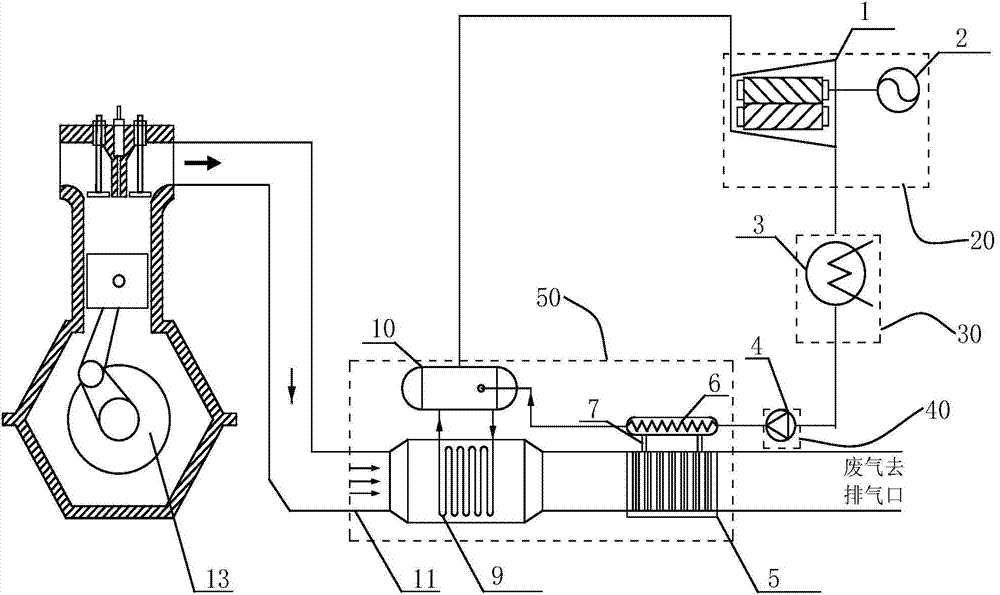

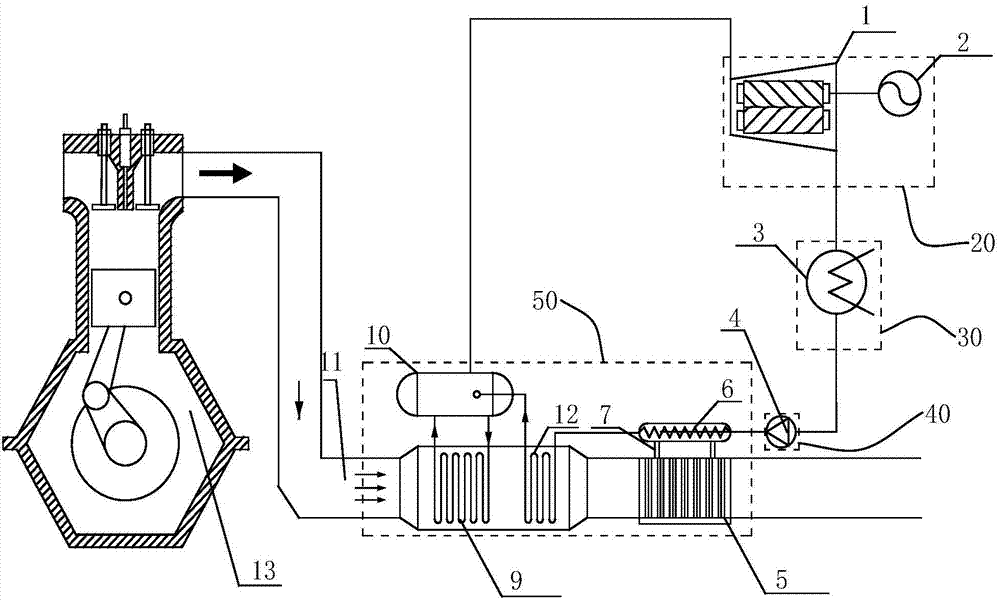

Organic Rankine cycle power generation system using waste heat of engine exhaust

ActiveCN104712402AImprove waste heat utilization efficiencyReduce smoke lossInternal combustion piston enginesExhaust apparatusOrganic Rankine cycleFlue gas

The invention provides an organic Rankine cycle power generation system using waste heat of engine exhaust. The organic Rankine cycle power generation system comprises an engine, an expansion working section, a condensation section, a boosting section and a heat-absorbing section. An organic working medium is circulated among the expansion working section, the condensation section, the boosting section and the heat-absorbing section through pipelines. The expansion working section comprises an expansion power machine and a power generating device connected with the expansion power machine. The heat-absorbing section comprises a steam pocket, a heat-absorbing part, a heat-releasing part, an ascending pipe, a descending pipe and an evaporator. The heat-releasing part is connected with the heat-absorbing part through the ascending pipe and the descending pipe. The heat-absorbing part and the evaporator are all arranged inside an engine exhaust smoke channel. The steam pocket is connected with the evaporator. A closed loop is formed by connecting of the expansion power machine, the condensation section, the boosting section, the heat-releasing part and the steam pocket in a series mode through the pipelines. According to the organic Rankine cycle power generation system using the waste heat of the engine exhaust, the flue gas loss is lowered, so that the waste heat utilization efficiency of smoke gas is improved, the Rankine cycle efficiency is improved, and the problem of acid dew corrosion is effectively avoided.

Owner:SHANGHAI FUBO ENVIRONMENTAL PROTECTION EQUIP

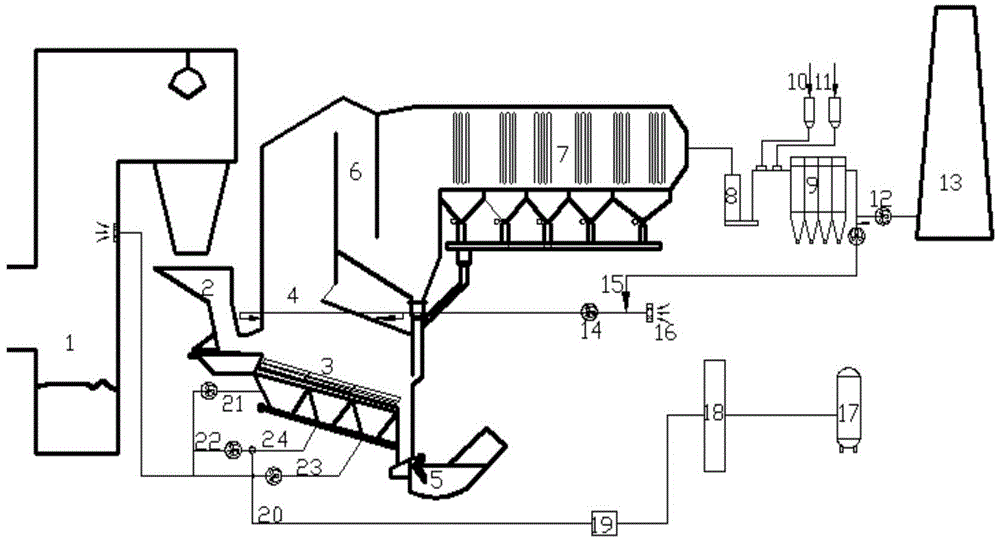

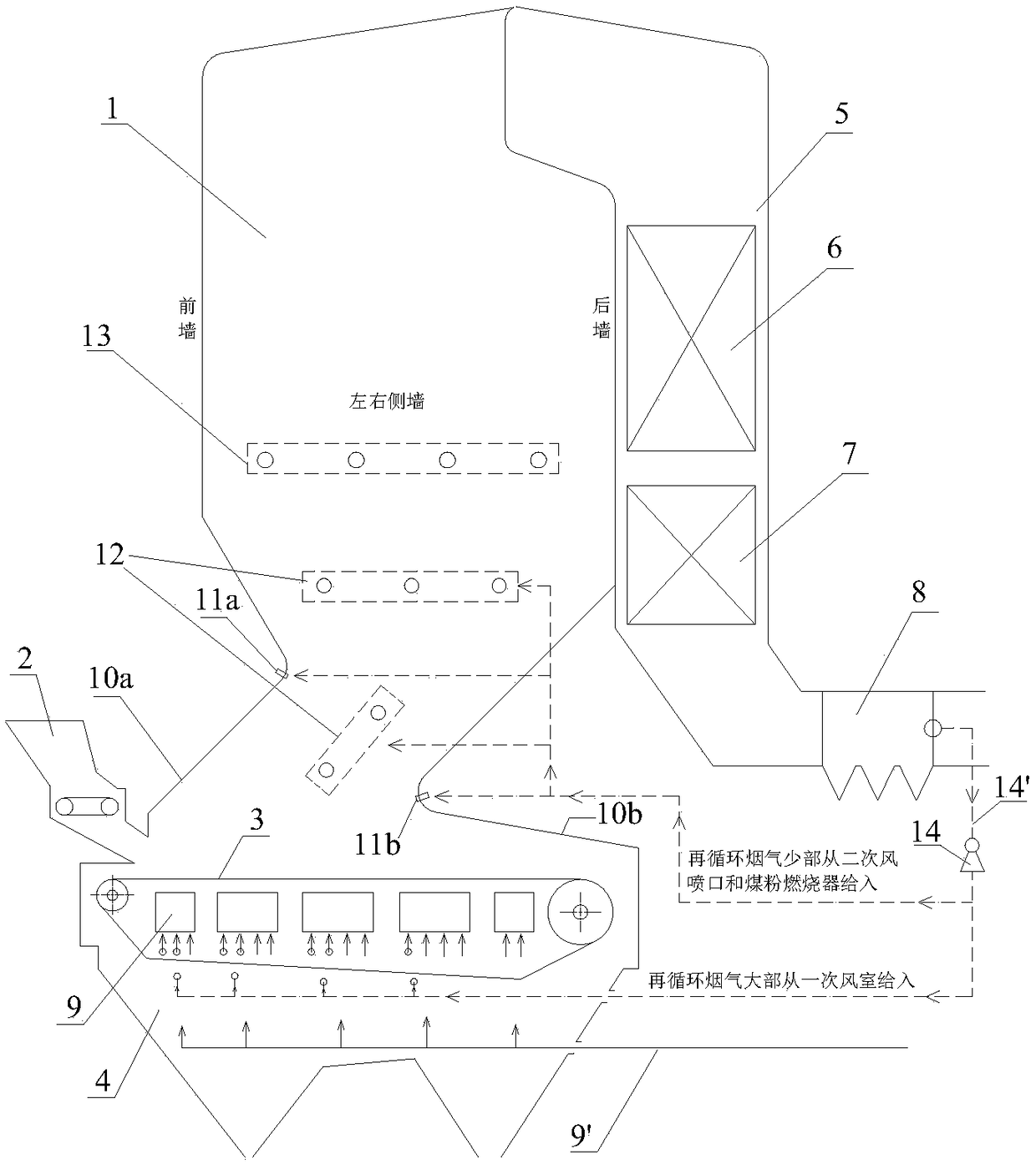

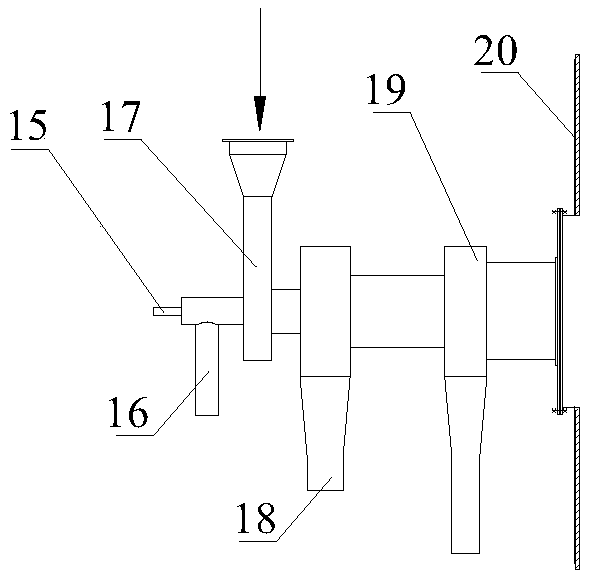

Efficient low NOx chain grate furnace coupled with swirling pulverized coal combustion and enhanced flue gas recirculation

InactiveCN108895430ALow burn shareGood for burnoutSolid fuel combustionAir/fuel supply for combustionLow nitrogenSlag

The invention discloses a high-efficiency low-NOx chain grate furnace coupled with swirling pulverized coal combustion and enhanced flue gas recycling, By reducing the fraction of combustion in gratezone, A low NOx swirl pulverize coal burner and a burned-out air are arrange on that left and right side walls, and an enhanced flue gas recirculation is constructed (i. E., flue gas recirculation isintroduce from a primary air chamber at the lower part of the grate, a front and rear arch secondary air burner and a swirl burner respectively), Deep-air staged low-nitrogen combustion conditions including horizontal staging and suspension staging and enhanced flue gas recirculation low-nitrogen combustion conditions are formed to significantly inhibit NOx formation. A low NOx swirl pulverize coal burner is added to increase that combustion fraction of the suspension combustion zone, Flue gas temperature level and hot air utilization ratio can reduce exhaust gas loss and increase fly ash burnout. In addition, reasonable distribution of flue gas in grate combustion zone and reduction of combustion share can help to improve slag burnout rate, thus achieving the effect of significantly improving boiler thermal efficiency.

Owner:NINGBO UNIV +1

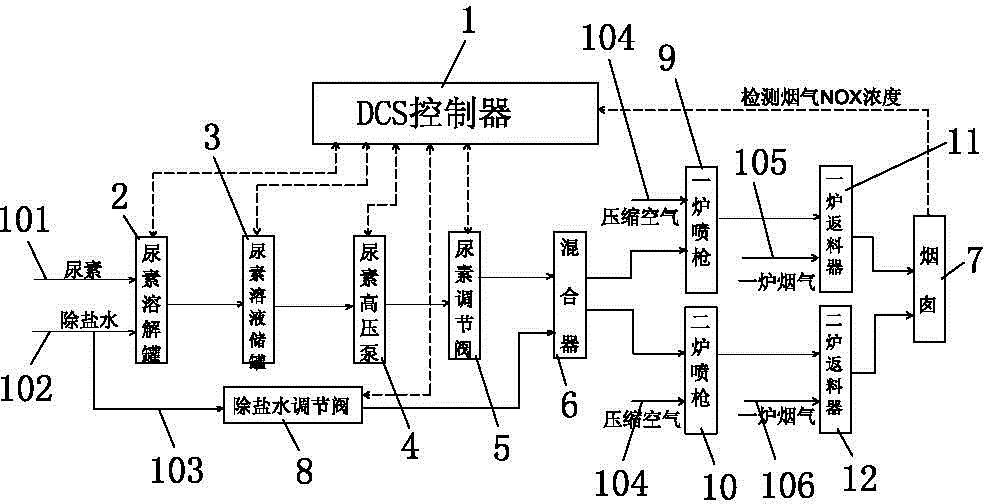

Denitration system

ActiveCN104437064AGood denitrification effectImprove denitrification efficiencyDispersed particle separationThermodynamicsFlue gas

The invention relates to the technical field of papermaking flue gas denitration and in particular relates to a denitration system. The denitration system comprises a DCS controller, a urea dissolving tank, a urea solution storage tank, a urea high-pressure pump, a urea regulation valve, a mixer, a spray gun, a return feeder and a chimney, wherein the urea dissolving tank, the urea solution storage tank, the urea high-pressure pump, the urea regulation valve, the mixer, a spray gun, the return feeder and the chimney are sequentially connected with one another; the DCS controller is respectively connected with the urea dissolving tank, the urea solution storage tank, the urea high-pressure pump and the urea regulation valve in a controlling mode; the chimney is internally provided with an oxynitride concentration detection circuit, the oxynitride concentration detection circuit is used for acquiring a concentration signal of oxynitride in flue gas of the chimney in real time and sending the concentration signal of the oxynitride in the flue gas of the chimney to the DCS controller, and the DCS controller is used for controlling the chimney to discharge the flue gas according to the concentration signal of the oxynitride in the flue gas of the chimney. The denitration system has the advantages of ideal denitration effect, high denitration efficiency, small loss in flue gas discharge of a boiler, and low production cost.

Owner:东莞理文造纸厂有限公司

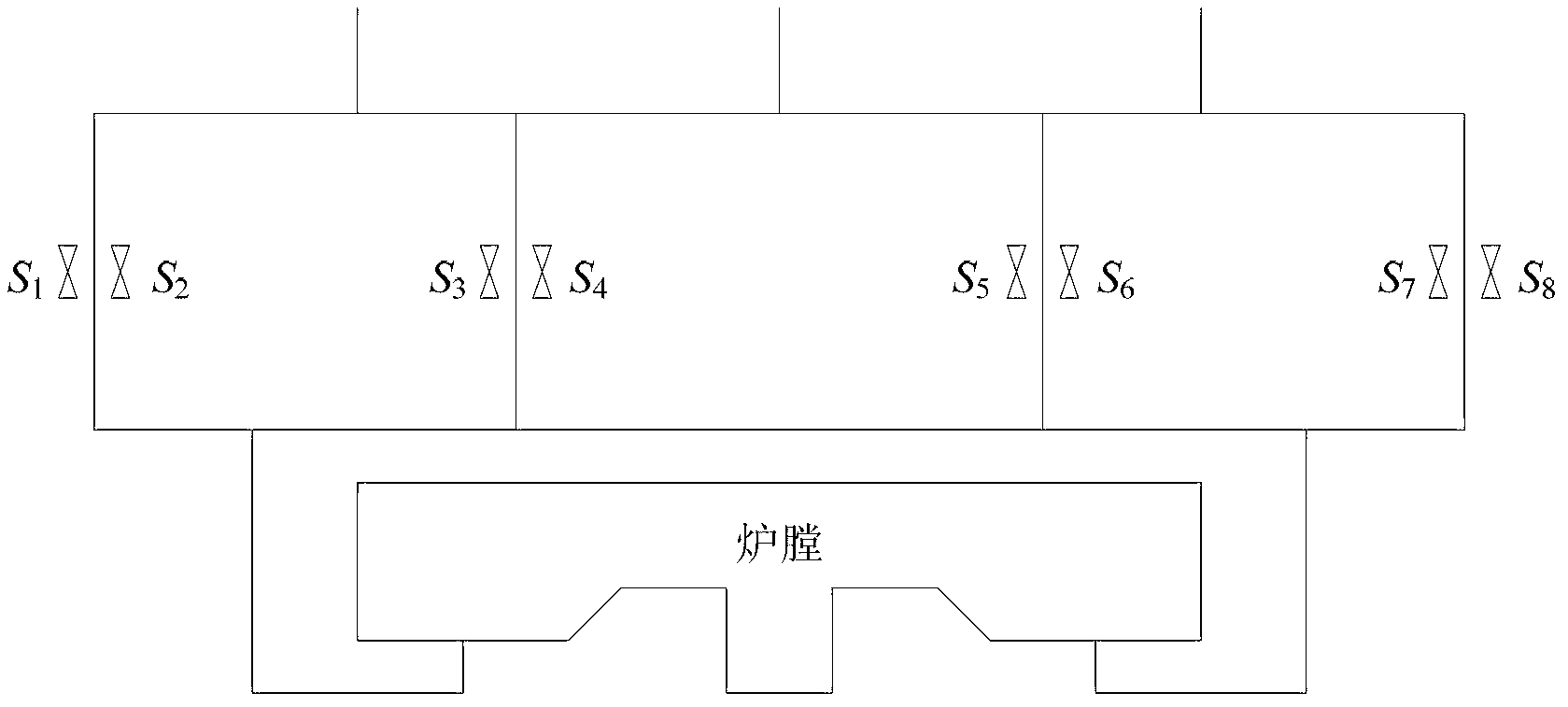

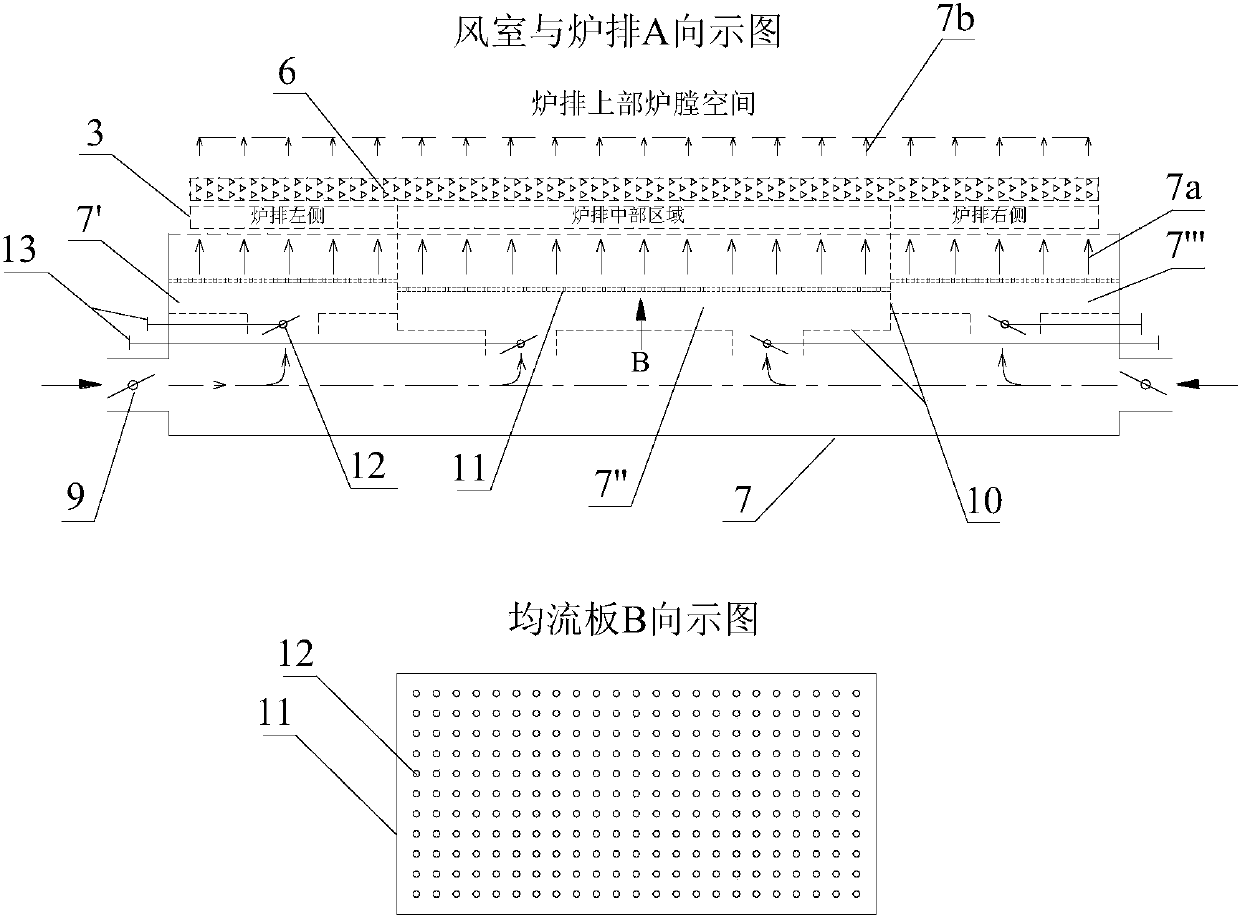

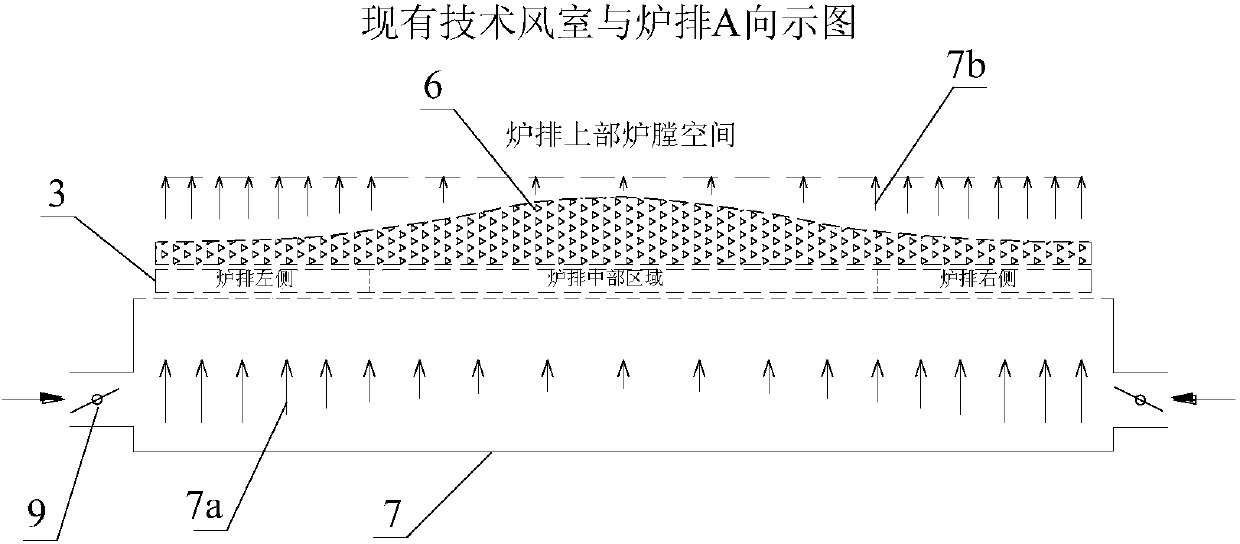

Low-NO<x> efficient chain grate furnace with function of distributing air by area in width direction of grate

InactiveCN107869728AStrong penetrating powerGood diffusion combustion effectDamper arrangementSolid fuel combustionCombustionAir volume

The invention discloses a low-NO<x> efficient chain grate furnace with a function of distributing air by area in the width direction of a grate. On the basis that air enters from the two sides of theposition below the grate, a primary air chamber is divided into a grate left air chamber body, a grate middle air chamber body and a grate right air chamber body by subarea partition plates in the width direction of the grate, the grate left air chamber body, the grate middle air chamber body and the grate right air chamber body are three transverse small air chamber bodies, inlets of all the transverse small air chamber bodies are provided with adjustable air doors, flow equalization plates are arranged in the transverse small air chamber bodies, and accordingly, the condition for distributing the air by area in the width direction of the grate is built. The effect that based on the existing technology, air supply of the middle of a coal seam is strengthened, and air supply of the two sides of the coal seam is appropriately reduced, thus, primary air is relatively uniformly distributed in the width direction of the grate, the situation that the air pressure, the air volume and the airflow penetrating power of all the areas of the coal seam are consistent with the air / coal diffusive combustion condition is achieved, surplus escaped air above the coal seam is little and uniform, accordingly, the problem that when NO<x> discharge is controlled through low-oxygen combustion, coal is stacked in the middle of the grate, and as a result, the burnout effect is poor is solved, the efficient low-oxygen combustion condition of the grate areas is built, and the effects of being good in burnout, low in smoke exhaust loss and small in NO<x> generation amount are achieved.

Owner:NINGBO UNIV

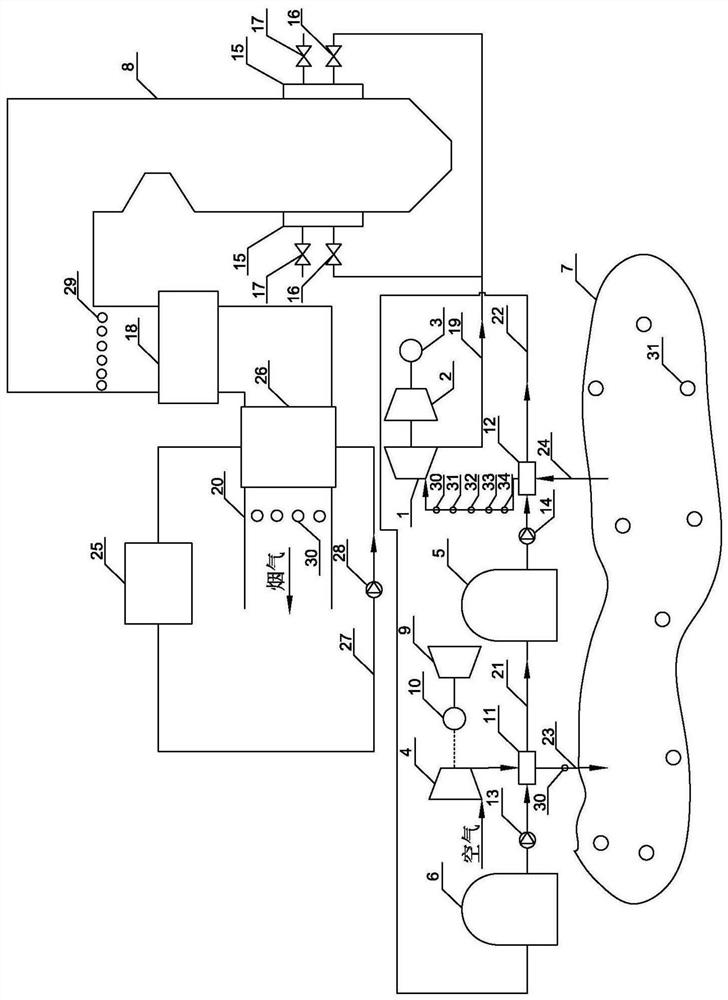

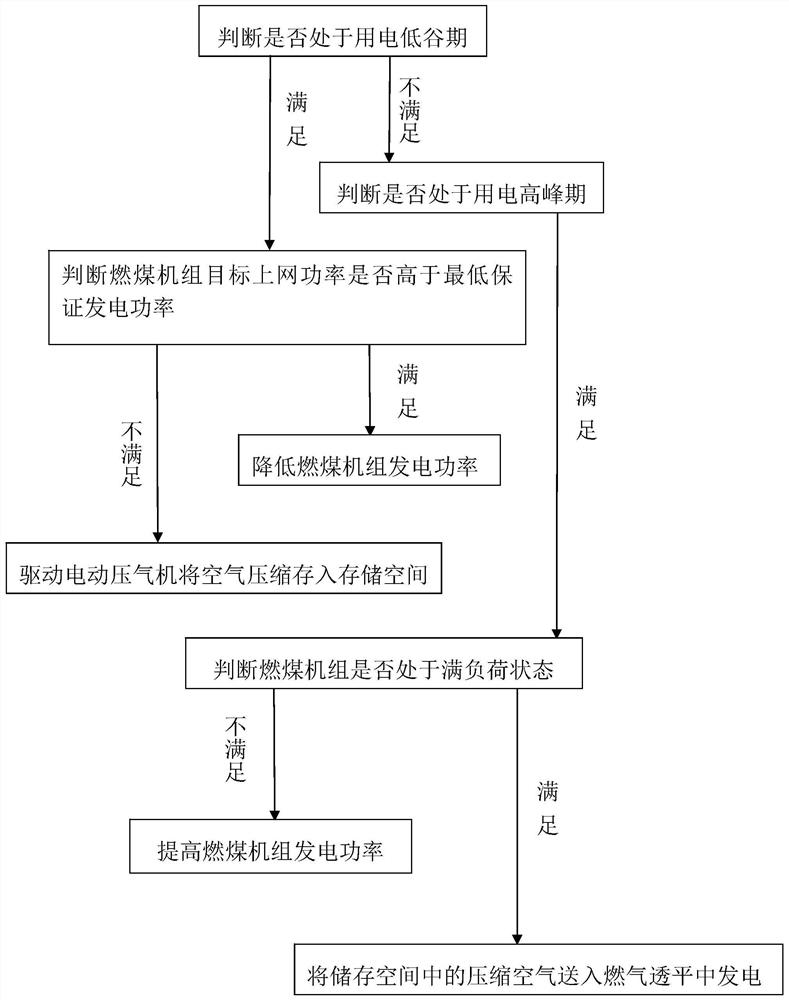

Peak regulation power generation system and method coupled with compressed air energy storage

ActiveCN113202574AIncrease power generationReduce internet powerPumpsSteam engine plantsNatural gas consumptionAir compression

The invention discloses a peak regulation power generation system and method coupled with compressed air energy storage. With the development and utilization of large-scale renewable energy sources, the peak-valley difference of a power grid is increasingly increased, and the bearing capacity is also limited. According to the technical scheme, when the power grid is in a power consumption valley period, air is compressed through power generated by a coal-fired unit and then stored in a storage space, and on the premise that it is guaranteed that the actual generation power of the coal-fired unit is higher than the minimum guaranteed generation power, the on-grid power of the coal-fired unit is effectively reduced; and when the power grid is in a power consumption peak period, the compressed air in the storage space is fed into a gas turbine for power generation, so that the power consumption of a main compressor is reduced, the on-grid power of the gas turbine is improved, and the natural gas consumption is reduced. According to the peak regulation power generation system and method coupled with compressed air energy storage, support can be provided for peak load shifting of the power grid, so that the renewable energy consumption capability is improved, and the usage amount of high-grade energy such as natural gas can be reduced on the premise that the on-grid power of the system meets the power grid adjustment requirement.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Furnace for combined combustion of methane of garbage leachate and garbage

ActiveCN103471103AImprove combustion efficiencyIncrease contact surfaceIncinerator apparatusSteam boilersCombustion chamberThermodynamics

The invention relates to a furnace for combined combustion of methane of garbage leachate and garbage and belongs to the technical field of combustion equipment. The furnace comprises a steel frame, a furnace grate, a furnace chamber and a tail flue pipe. The furnace chamber is connected with the tail flue pipe, the furnace chamber is made up of a hearth, a combustion chamber and three flue pipes, the furnace grate is arranged on the lower part of the furnace chamber, and a slag and ash discharging device is arranged below the furnace grate. The furnace is characterized in that a methane burner of the garbage leachate is mounted on a side wall of the lower part of the hearth above the furnace grate, and superheaters are arranged in the three flue pipes and the tail flue pipe. Considering the features of various fuels, the methane of the garbage leachate and garbage are burned mixedly, and accordingly the furnace is an energy-saving and environment-friendly comprehensive furnace.

Owner:WAI MING ENVIRONMENTAL PROTECTION EQUIP

Bottom-blowing pure oxygen enhanced type plasma gasification melting furnace

PendingCN110425541AHigh melting temperatureImprove melting effectIndirect carbon-dioxide mitigationIncinerator apparatusCombustionCentral oxygen supply

The invention discloses a bottom-blowing pure oxygen enhanced type plasma gasification melting furnace. The bottom-blowing pure oxygen enhanced type plasma gasification melting furnace comprises a furnace body, wherein a drying area, a pyrolysis area and a melting area are sequentially arranged in the furnace body from top to bottom, the diameter of a lower hearth is smaller than that of an upperhearth, a dangerous waste material inlet is formed in the drying area of the hearth, the upper hearth and the lower hearth are connected through a conical structure, and two plasma torches are symmetrically arranged on the lower hearth. A cylindrical central oxygen supply pipe is arranged at the bottom of the melting area at the bottom of the furnace body and is fixed on refractory bricks and heatpreservation bricks through a protective sleeve pipe and can be detached and replaced conveniently; pure oxygen is sprayed into the central oxygen supply pipe to provide the required oxygen amount ofresidual carbon with incomplete pyrolysis gasification reaction; the heat generated by combustion of the residual carbon can be supplied to the gasification of the carbonaceous substance; the meltingeffect and the combustion efficiency of the plasma furnace are improved; and meanwhile, the temperature of the hearth can be increased faster and higher.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

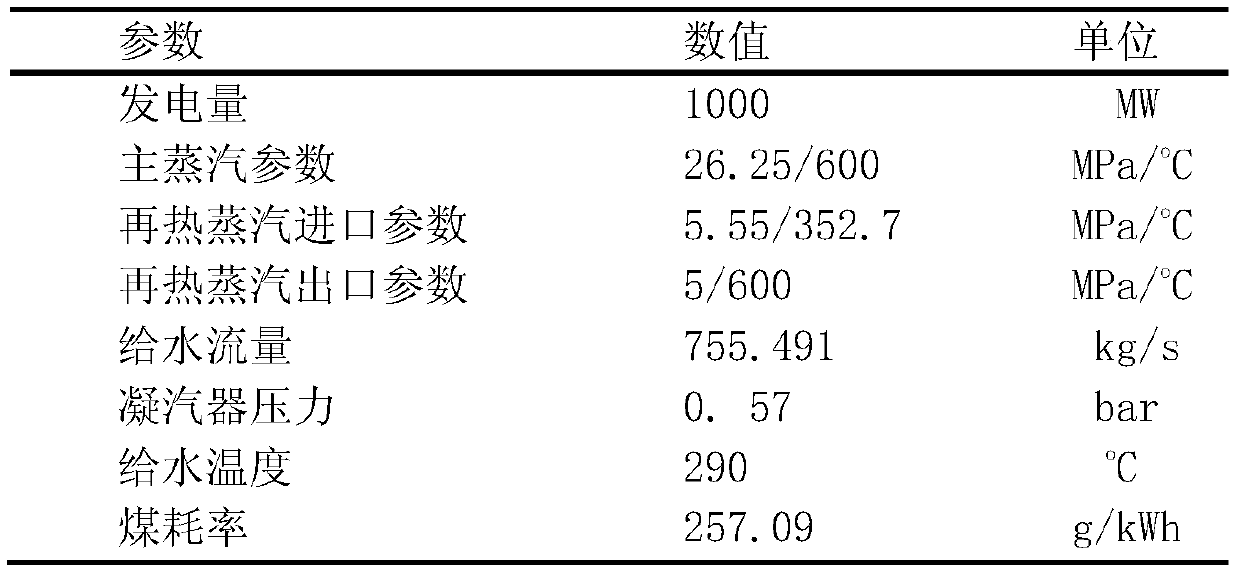

Improved efficient recuperative coal-based supercritical CO2 secondary reheating power generation system

PendingCN109372600ALower exhaust gas temperatureReduce smoke lossSteam engine plantsFeed-water heatersAir preheaterEngineering

The invention relates to an improved efficient recuperative coal-based supercritical CO2 secondary reheating power generation system. The system comprises a carbon dioxide high-pressure turbine, a carbon dioxide middle-pressure turbine, a carbon dioxide low-pressure turbine, a high-temperature recuperative heater, a low-temperature recuperative heater, a re-compressor, a main compressor, a condenser, a coal-fired boiler air preheater, an air preheater smoke bypass high-temperature heat exchanger, an air preheater smoke bypass low-temperature heat exchanger, a boiler primary reheater, a boilersecondary reheater and a smoke heat exchanger cold side bypass. According to the system, a secondary reheat carbon dioxide power generation system is arranged, the circulation heat efficiency can be improved by 0.3%; a recuperative heating system for heating the carbon dioxide through the smoke is arranged, on one hand, the smoke discharge loss is reduced, the efficiency of a boiler is improved by0.5%, and on the other hand, irreversible heat exchange loss of heat transfer of the recuperative heater is reduced, and the heat efficiency of the circulating power generation can be improved by about 0.15%. By means of the system, the circulation efficiency of an existing coal-based supercritical carbon dioxide power generation system can be integrally improved by about 1% or above.

Owner:THERMAL POWER TECH RES INST OF CHINA DATANG CORP SCI & TECH RES INST

Clean combustion poly-generation process system for clean coal

InactiveCN107726306AImprove operating economySolve the use problemFluidized bed combustionCombustion technology mitigationProcess systemsSlag

The invention relates to a clean combustion poly-generation process system for clean coal. The process system comprises a circulating fluidized bed power generation system, a clean coal production system and a fly ash aggregate manufacturing system; the clean coal production system uses screen underflow coal powder screened by raw coal used by the circulating fluidized bed power generation systemthrough a screening device as raw material, then an additive is added and mixed, forming and drying are carried out, drying uses flue gas waste heat in the circulating fluidized bed power generation system, finally, the clean coal is produced through a medium-temperature pyrolysis furnace, and the middle-temperature pyrolysis furnace utilizes hot smoke in the circulating fluidized bed power generation system; and the fly ash aggregate manufacturing system uses ash of a dust remover in the circulating fluidized bed power generation system as raw material, then circulating fluidized bed furnaceslag and a aggregate additive are coordinated to be subjected to mixing and granulating, fly ash aggregate is prepared by sintering in a aggregate sintering machine, and the aggregate sintering machine uses raw gas generated by dry distillation of the pyrolysis furnace in the clean coal production system. The clean combustion poly-generation process system is mainly applied to the aspect of wastegas waste heat utilization in a power generation process of a thermal power plant.

Owner:SHANXI UNIV +1

Vertical U-shaped gasification heating equipment

ActiveCN111780410AImprove heat transfer effectEffectively adjust working conditionsChemical industryStorage heatersIndustrial gasThermodynamics

The invention relates to vertical U-shaped gasification heating equipment. The equipment comprises a shell, a bottom water pool arranged in the shell and a heat source unit and a heated unit arrangedin the shell side by side, wherein the bottoms of the heat source unit and the heated unit are located in the bottom water pool, the heat source unit comprises a combustion mechanism and an injectionguide mechanism which are arranged up and down respectively, a fluid inlet and a fluid outlet are formed in the side face of the shell, the heated unit communicates with the fluid inlet and the fluidoutlet, and a smoke exhaust unit is arranged above the heated unit. Compared with the prior art, the equipment can be used for heating industrial gas or industrial liquid, is wide in application range, increases a heat exchange rate, improves an energy utilization rate, and has a peak regulation effect, so that the equipment is higher in working usability, economical and convenient.

Owner:SHANGHAI UNIV OF ENG SCI

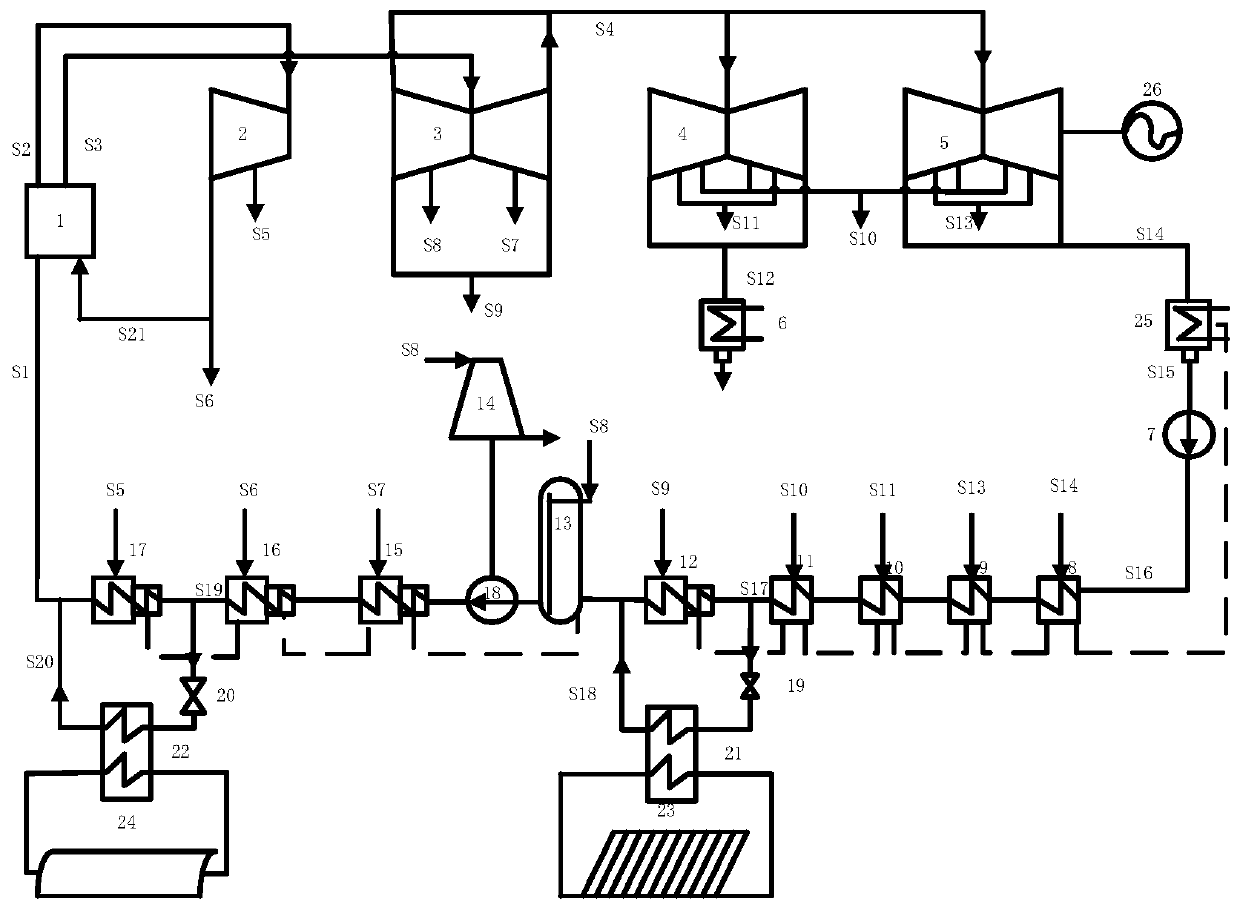

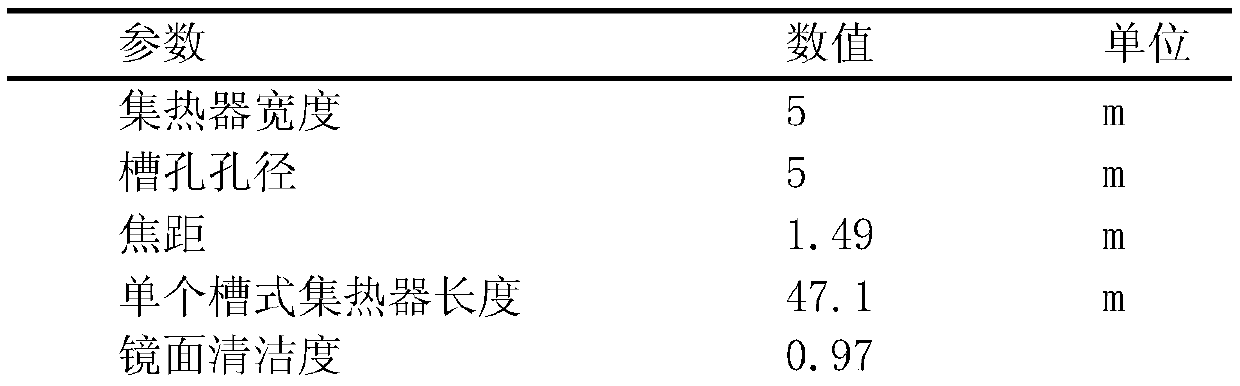

Graded solar assisted coal-fired power generation system

InactiveCN110080959AStrong complementarityRealize cascade utilizationFrom solar energySteam useEngineeringHigh pressure

The invention puts forward a graded solar assisted coal-fired power generation system. Different kinds of solar collectors are coupled with different sections of heaters according to different heat collecting grades of the solar collectors, a flat plate vacuum tube heat collecting system (ET) is connected in parallel to a part of medium pressure heaters, a groove type solar heating system (PT) isconnected in parallel to a part of high pressure heaters, solar heat is utilized to replace the high quality steam extracted from a steam turbine of a coal-fired power station to heat feedwater, and the saved extracted steam can continue to do work in the steam turbine. The complementation and comprehensive gradient utilization of solar energy and conventional thermal power coal-fired units are realized, the steam extraction capacity of high pressure cylinders and intermediate pressure cylinders in the steam turbine is reduced, partial coal-fired consumption is reduced, the cost is reduced, and the graded solar assisted coal-fired power generation system has good economy.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Industrial furnace with high-temperature low-oxygen air burner

InactiveCN1126907CDegree of great dilutionLarge entrainment effectCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCombustor

The present invention relates to an industrial furnace with high-temp. low-oxygen air burner, which is characterized by that the two ends of furnace cavity are respectively equipped with a high-temp.low-oxygen air burner. Said burner is formed from combustion chamber, combustion chamber end cover which is set at end hole of combustion chamber, possesses a circular through hole in its centre and is formed into a ring channel at end portion of the combustion chamber and cover plate positioned on the end cover of combustion chamber. Said burner can make oxygen being in high-temp. air obtain dilution by means of returned fume and convert it into low-oxygen air, and make the fuel combust under the condition of low-oxygen air, and its oxygen concentration is less than 15%. It not only effectively reduce NOx discharge, but also its discharge temp. only is 150-200 deg.C. so as to attain the goal of saving energy and protecting environment.

Owner:TSINGHUA UNIV

Novel pulverized coal boiler low-nitrogen combustion system

PendingCN110454774AGuaranteed operating economyReduce NOxCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow nitrogenModel selection

The invention discloses a novel pulverized coal boiler low-nitrogen combustion system. The novel pulverized coal boiler low-nitrogen combustion system comprises a coal fine coal mill, an efficient low-nitrogen combustion device with wall attaching wind, a heating face with a catalyst spraying layer, a catalyst with CO catalytic oxidation effect, an online O2 measuring device, an online CO measuring device, an online NOx measuring device, an industrial control machine and the like. On the basis of coal fine low-nitrogen combustion theory combining air / fuel depth graded combustion low-temperature, low-oxygen and long staying time and full-hearth large-space low heat load section balance combustion, through large-hearth model selection design, the low-nitrogen combustion system with the wallattaching wind, economic coal fine fineness, powder making system coordination, wind smoke system cooperation and other new technilogy devices, in combination with ultra-fine coal fine, wind powder conveying precise control, depth air graded low-oxygen combustion process optimized regulation technology and hearth outlet CO catalytic oxidation technology, systematicness and full-process low-nitrogen combustion of the coal fine combustion are achieved, and finally boiler high-efficiency ultra-low NOx emission targets can be achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Biomass combustion equipment with double fire grates

ActiveCN102425785AAvoid overheating damageGuaranteed safety and reliabilitySolid fuel combustionCombustion apparatusCombustion chamberSlag

The invention discloses a biomass combustion equipment with double fire grates, and the biomass combustion equipment comprises a feeding device, a feeding hole, a smoke outlet, a furnace wall, a water cooling wall and fire grates, wherein the fire grates comprise an upper fire grate and a lower fire grate; the upper fire grate and the lower fire grate divide a combustion chamber into a main combustion chamber and an auxiliary combustion chamber; the upper fire grate and the lower fire grate are both formed by bending and extending rear-wall water cooling wall pipes; a forward-bending section and a backward-bending section are respectively formed on the lower fire grate and are finally collected on the rear-wall water cooling wall; the upper fire grate is finally collected on a front-wall water cooling wall; and the rear section pipe rack of the upper fire grate is bent to form a macropore for falling slag. The biomass combustion equipment has the advantages that a water-cooling double fire grate structure is adopted, the temperature of the fire grates is lower, the fire grates have small possibility of being deformed and damaged, and the combustion efficiency is high; even if the fire grates are coked, the normal operation of combustion is not influenced; the combustion chamber is in a negative pressure state, the leaked air of the feeding hole and a slag discharging hole is used for combustion, the field is clean, the smoke discharging excess air coefficient is low, and the smoke discharging loss is small.

Owner:TAIYUAN BOILER GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com