Tunnel combustion chamber and its constructed smoke dust less fuel coal and biomass equipment

A combustion chamber and biomass technology, which is applied in the fields of kilns, gasification equipment and boilers, can solve problems such as insufficient measures to eliminate smoke and dust, pollution of the atmospheric environment by coal-fired equipment, and inability to achieve clean combustion, and achieve easy burning of embers. , Improve the quality and contact the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

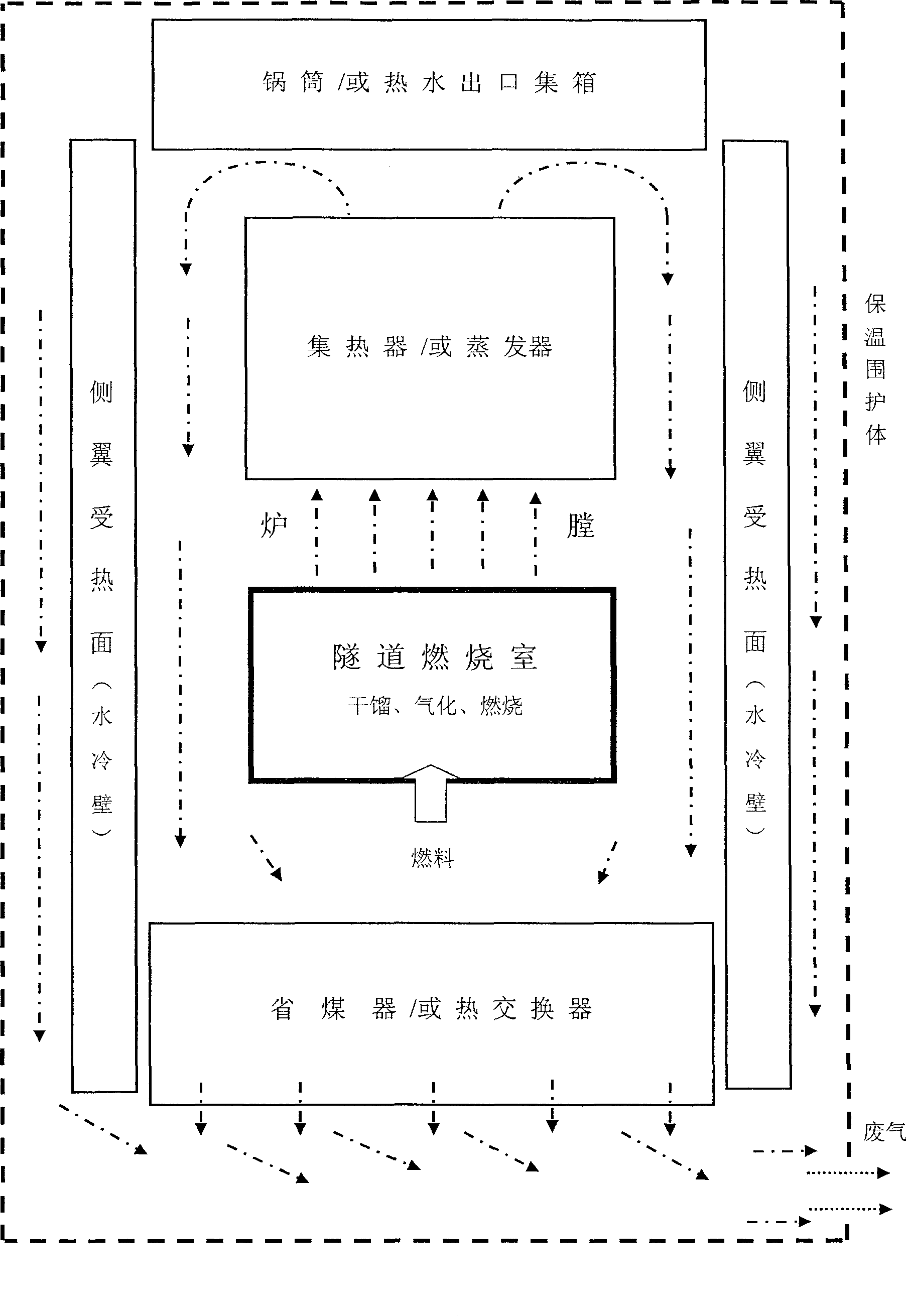

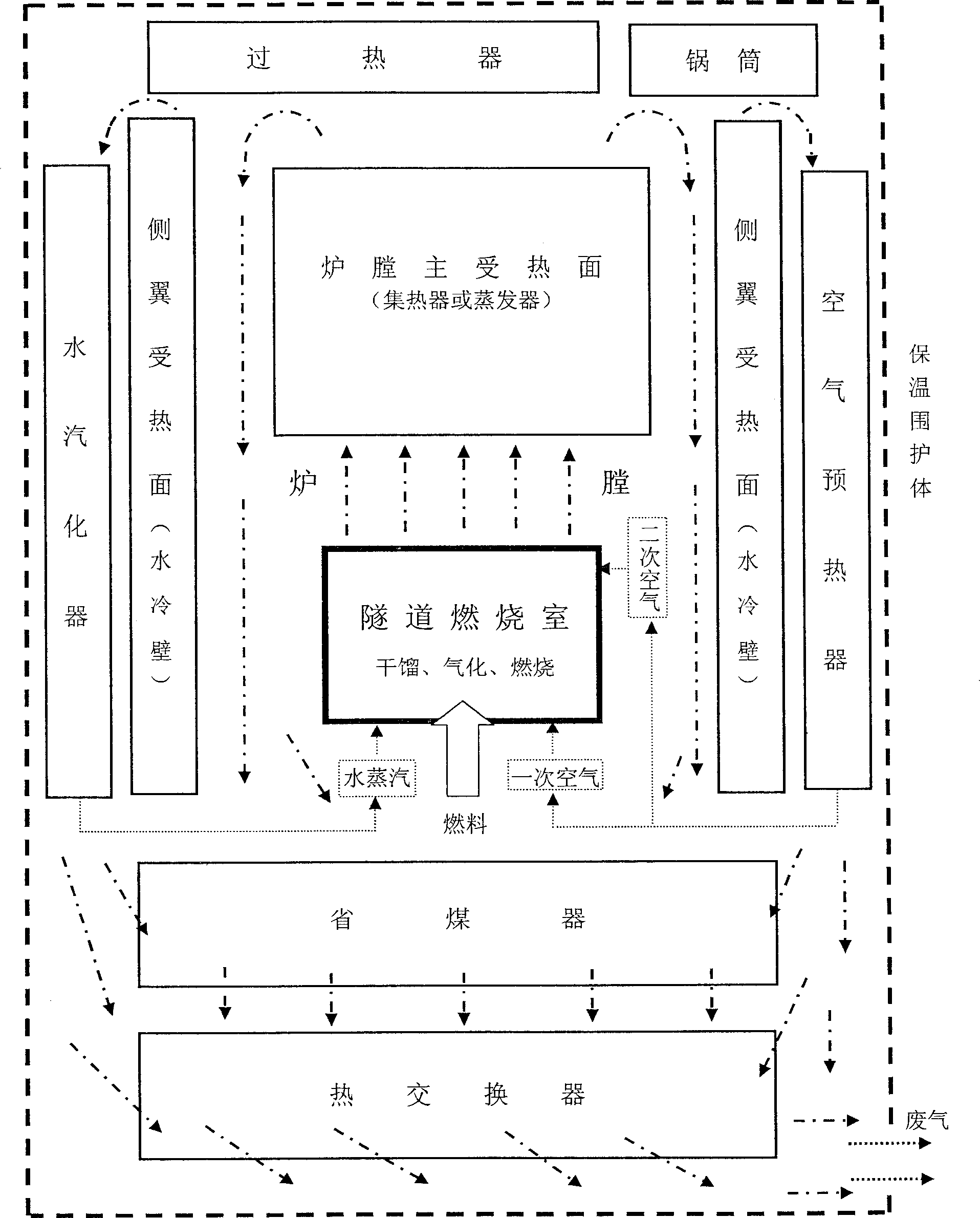

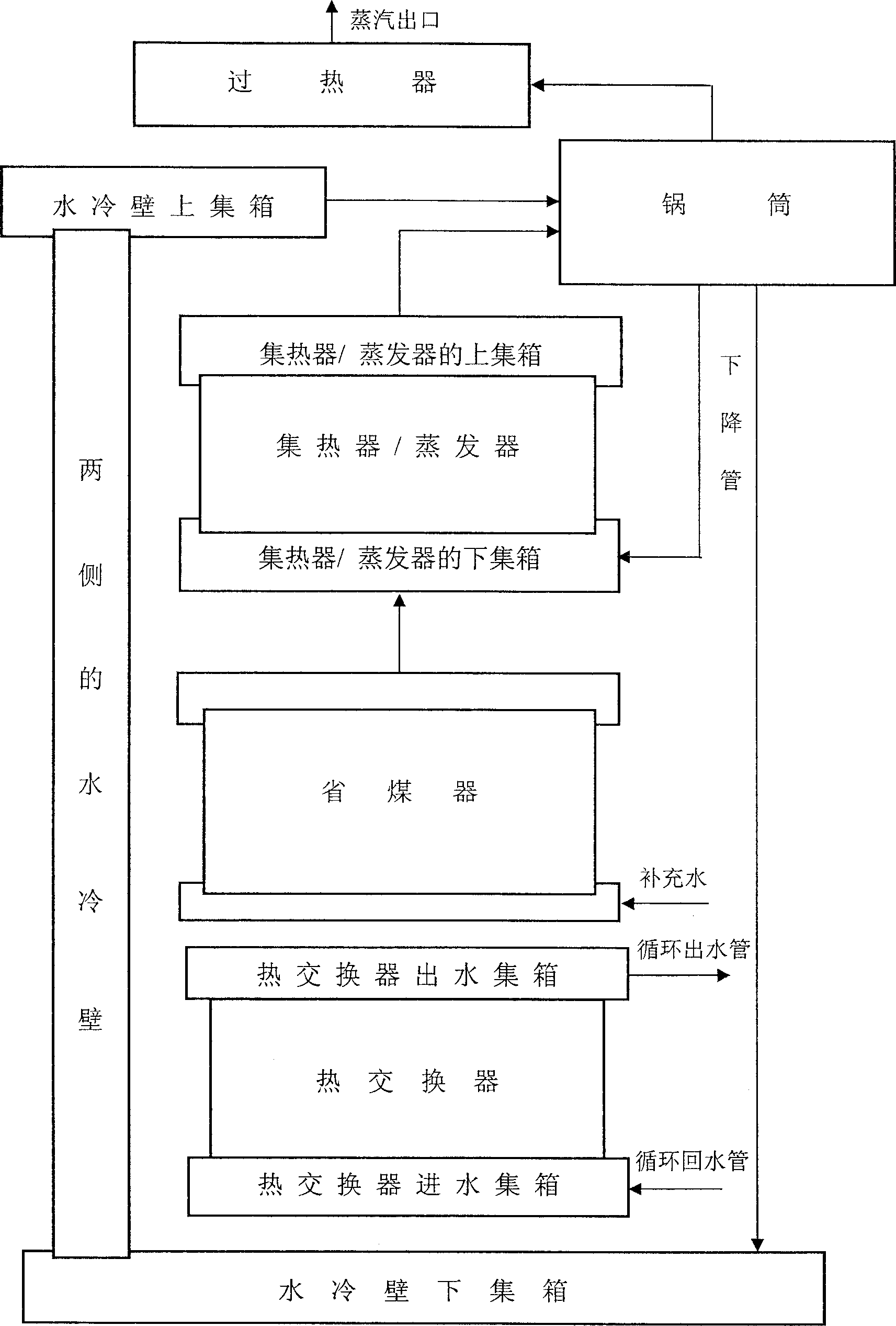

[0057] figure 1 The shown embodiment is the basic composition of the equipment of the present invention and the schematic diagram of the flue gas flow. The equipment mainly consists of a tunnel combustion chamber, a furnace, a heat collector / or evaporator, a drum or a hot water outlet header, a water wall, and an economizer. Or heat exchanger, heat preservation enclosure, fuel burns in the tunnel combustion chamber, the heat generated is transferred to the heating surface in the furnace by radiation heat transfer and convective heat transfer, and above the tunnel combustion chamber, the heat energy is transferred by the tunnel combustion chamber The radiant roof radiates heat energy of infrared wavelengths to the heat collector / or evaporator, and above the tunnel combustion chamber, there are two types of flame airflow ejected from the secondary combustion port of the tunnel combustion chamber roof for radiation heat transfer and convective heat transfer. The heat is transferr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com