Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Reduce rolling costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superhigh-strength high-toughness steel plate for ocean engineering and production method thereof

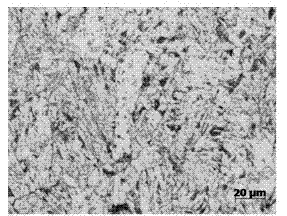

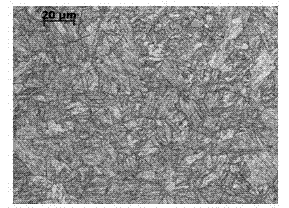

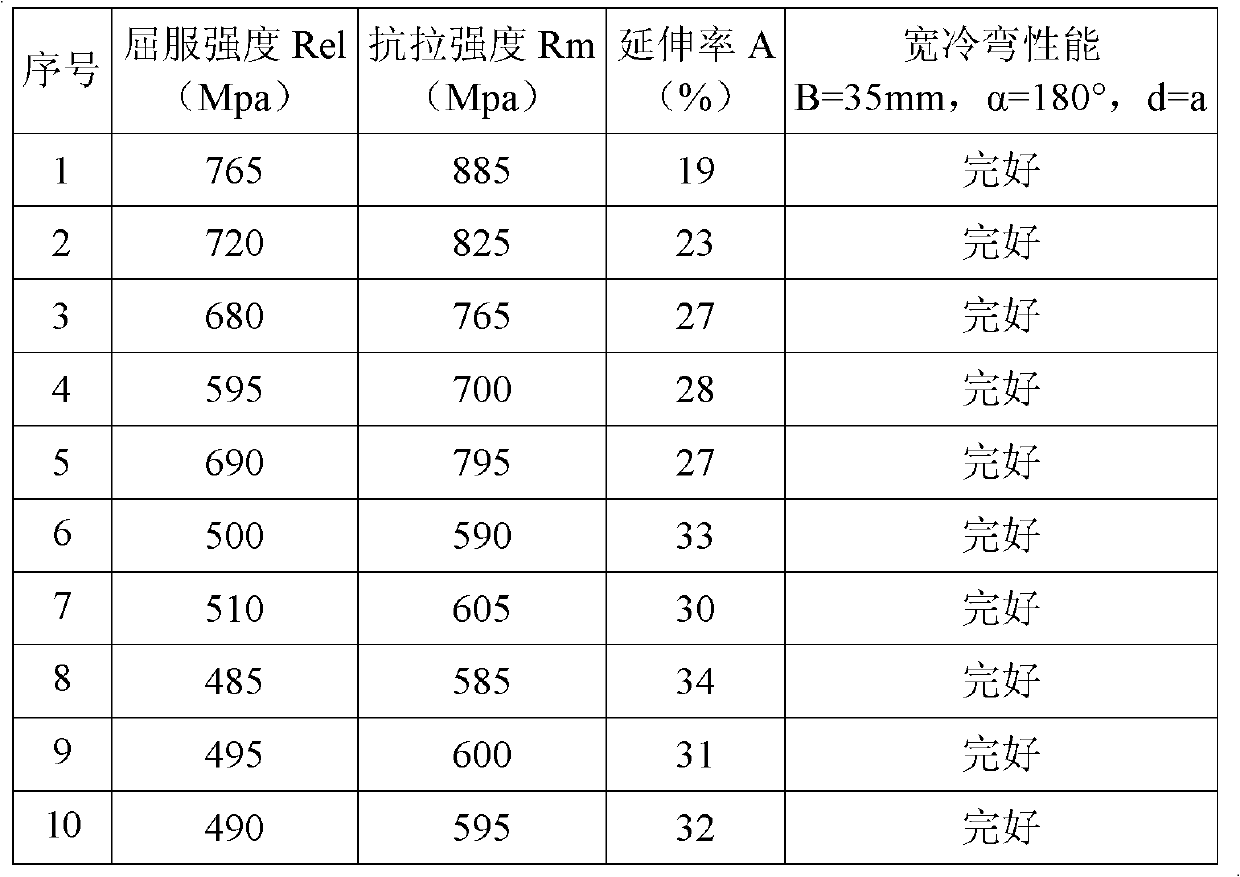

The invention discloses a superhigh-strength high-toughness steel plate for ocean engineering and a manufacturing method thereof. The superhigh-strength high-toughness steel plate comprises the following chemical components in percentage by weight: 0.06-0.10% of C, 0.20-0.40% of Si, 1.10-1.65% of Mn, at most 0.010% of P, at most 0.0020% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.60-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.60% of Cu, 0.40-0.60% of Mo, 0.020-0.040% of Alt, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting in a converter, rolling on a Steckel reversing mill, and finally carrying out hardening and tempering heat treatment by a TMCP (thermomechanical rolling process) technique. The steel plate has favorable properties: the tensile strength is 770-840 MPa, the yield strength is 710-800 MPa, the elongation percentage is 16-19%, the -40 DEG C low-temperature lateral impact and low-temperature ageing impact properties are greater than or equal to 90J, and the cold bending resistance is qualified; and thus, the steel plate has the advantages of ultrahigh strength, excellent low-temperature impact and low-temperature ageing impact properties, and stable production technique.

Owner:NANJING IRON & STEEL CO LTD

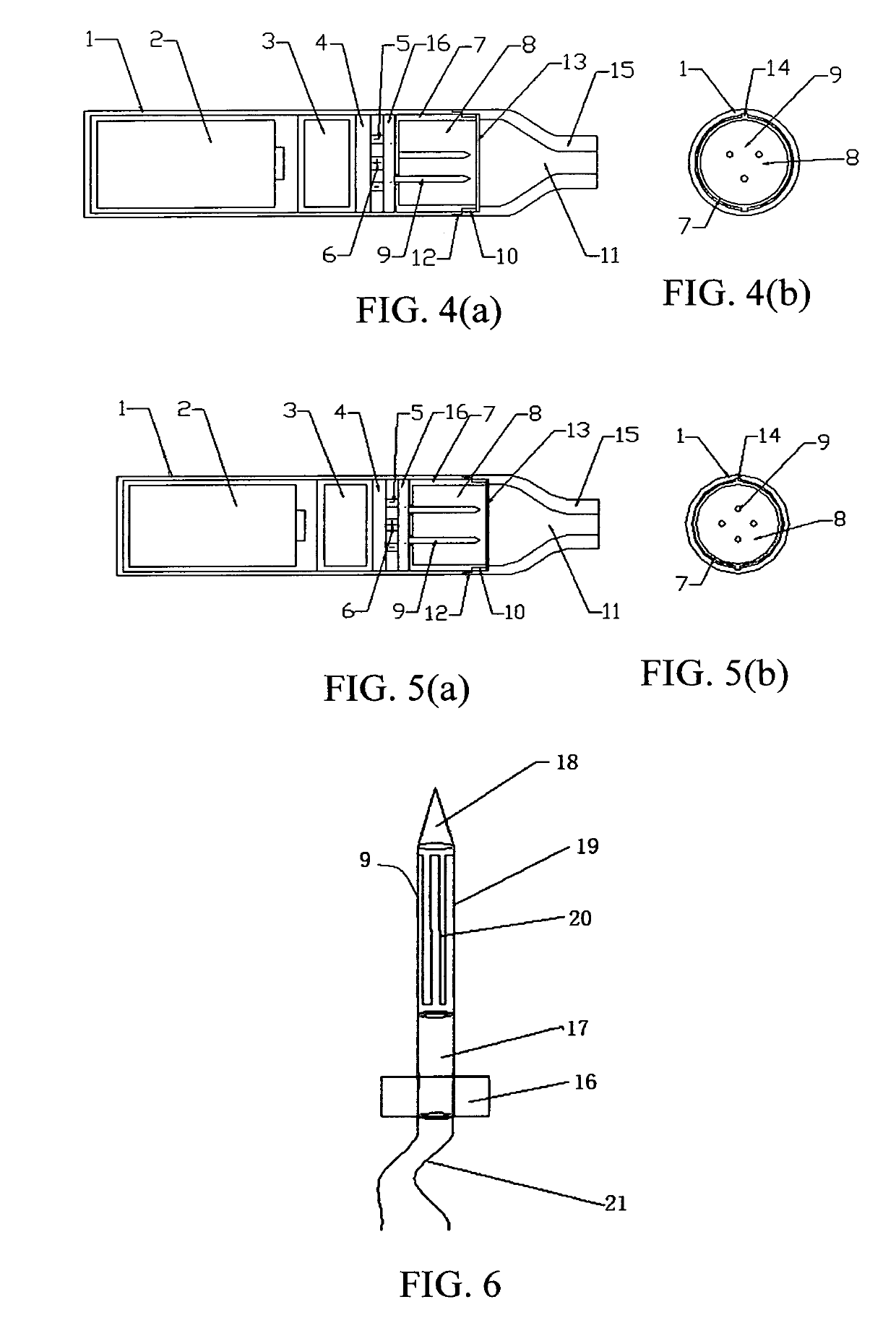

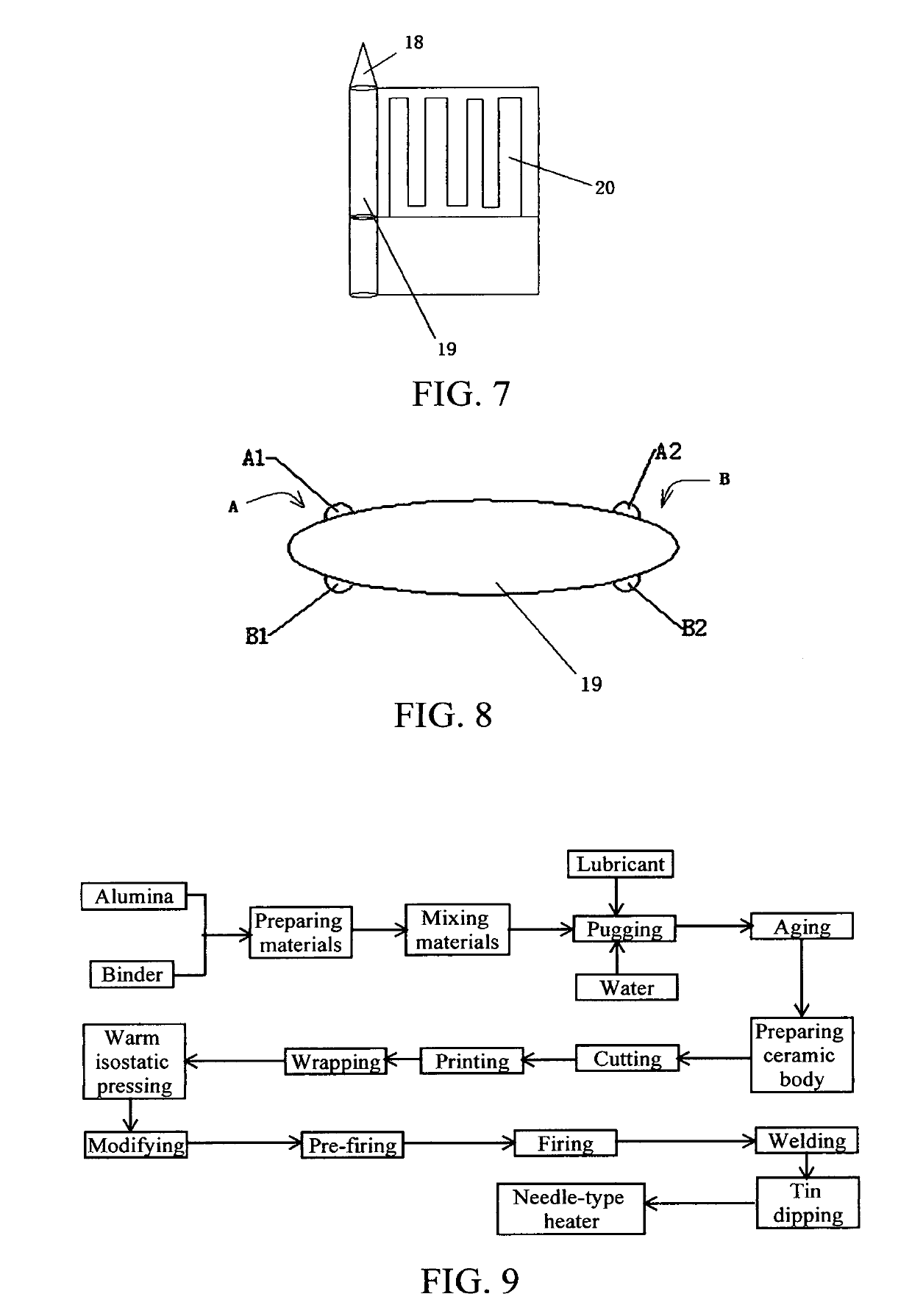

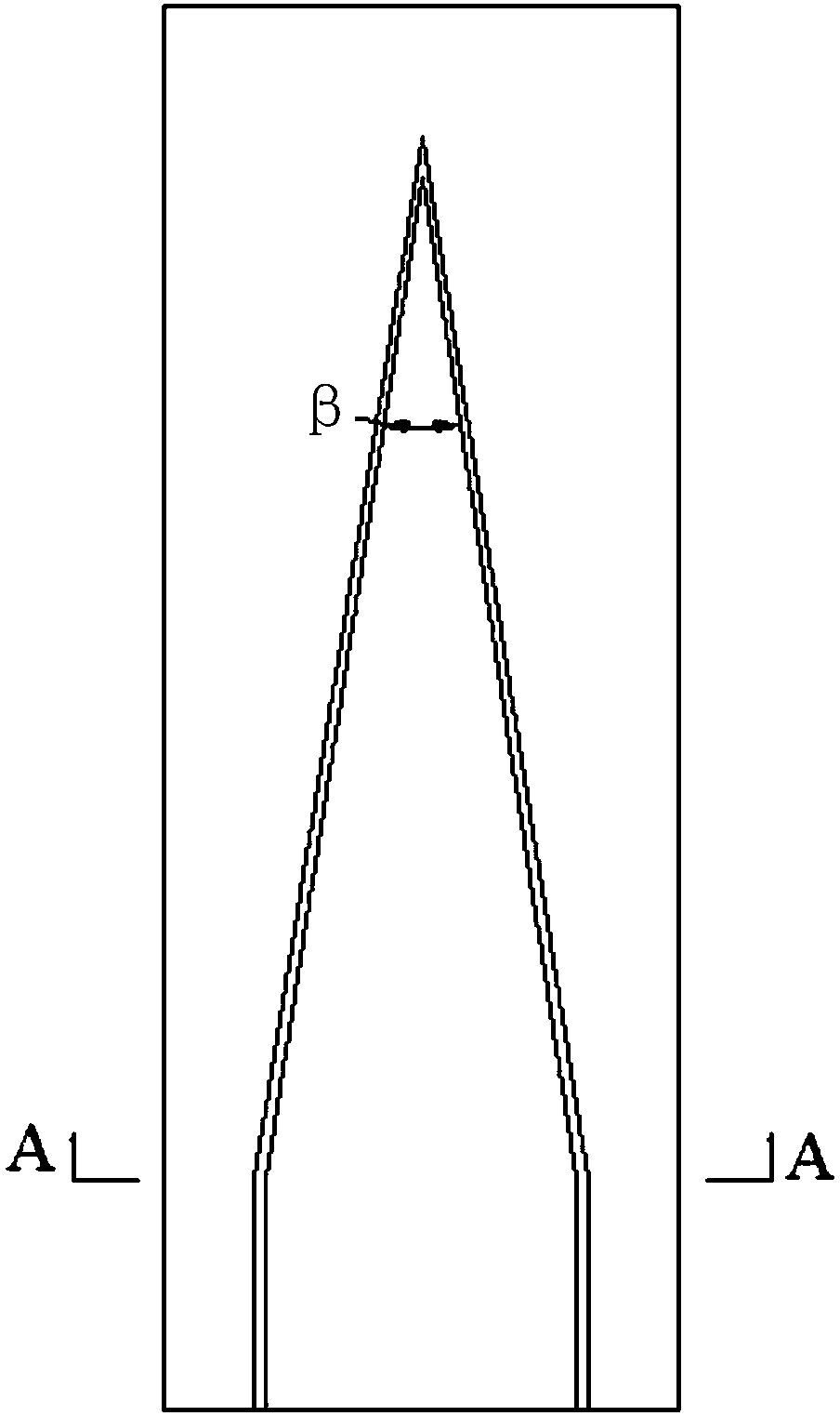

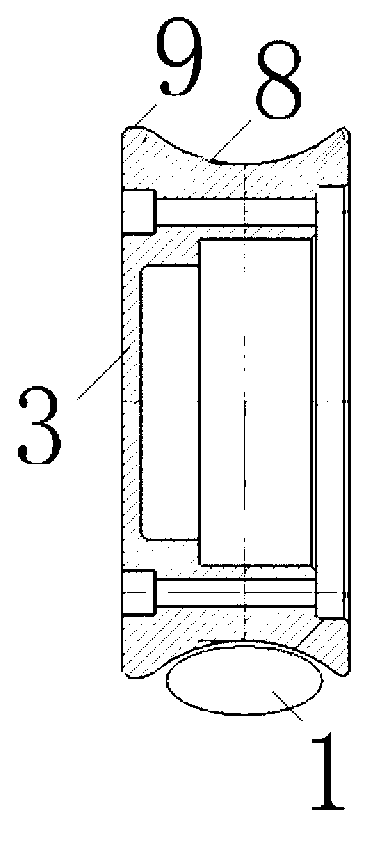

Needle-type heater, production method of needle-type heater, and electrically heated cigarette with needle-type heater

ActiveUS20190320719A1Easy to insertEasy to replaceTobacco treatmentCigar manufactureEngineeringMethods of production

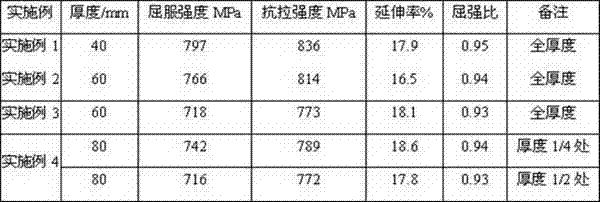

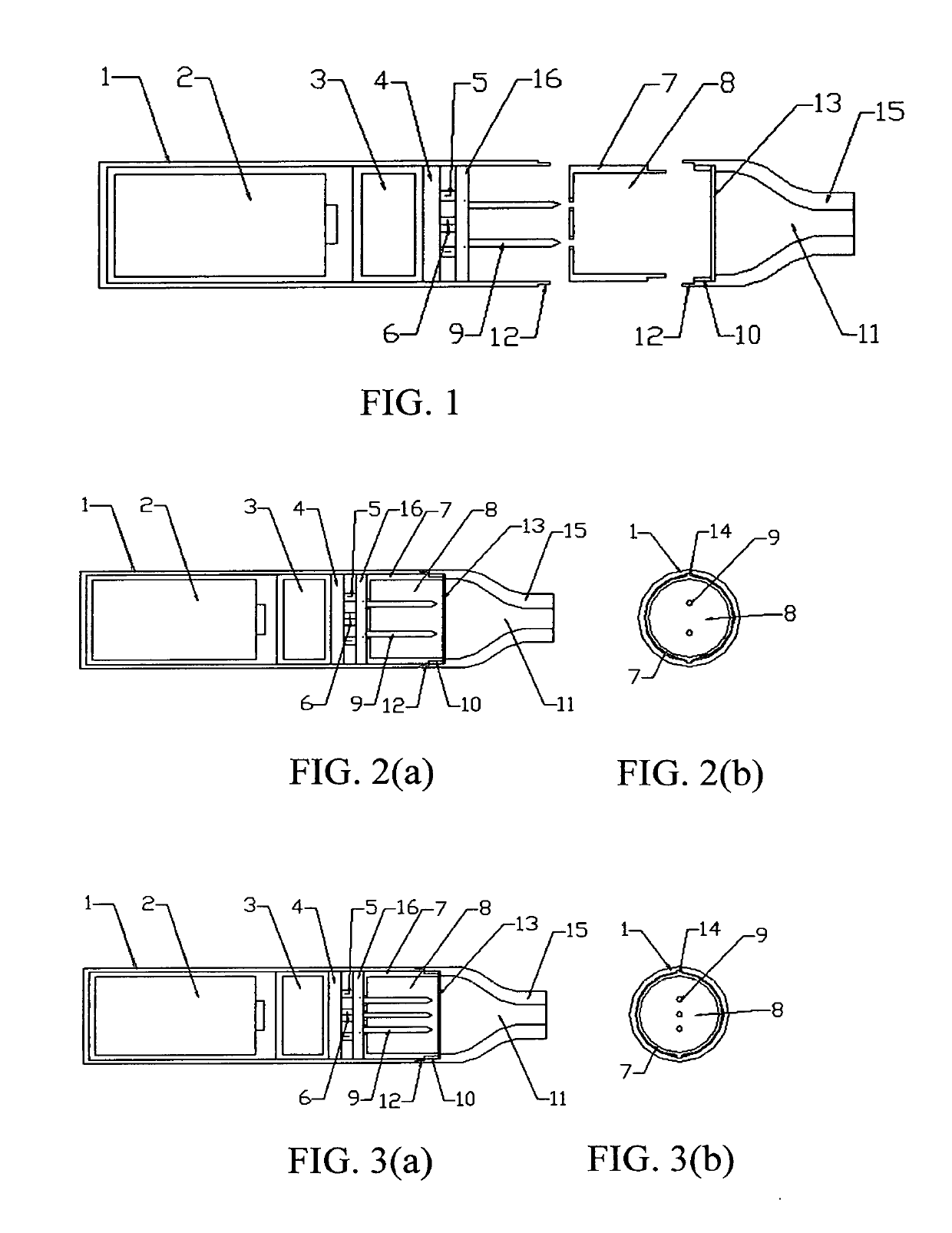

A needle-type heater (9) includes a needle-shaped heating body and a heating element (20), wherein: the needle-shaped heating body includes a tapered cap (18) and a heater substrate (19) connected with a bottom of the tapered cap (18); and the heating element (20) is attached to the heater substrate (19) in a way of coated printing. A production method of the needle-type heater (9) and an electrically heated cigarette with the needle-type heater (9) are also provided. The needle-type heater (9) can fully heat a tobacco product, and the tobacco product is easier to be inserted into a heating cavity (8), so that it is convenient to replace the tobacco product and use.

Owner:HUBEI CHINA TOBACCO IND

Preparation method for reducing scales generated on surfaces of hot-rolled steel plates

InactiveCN101947557ALower the furnace temperatureReduce the number of spawnsTemperature control deviceWork treatment devicesChemical compositionSheet steel

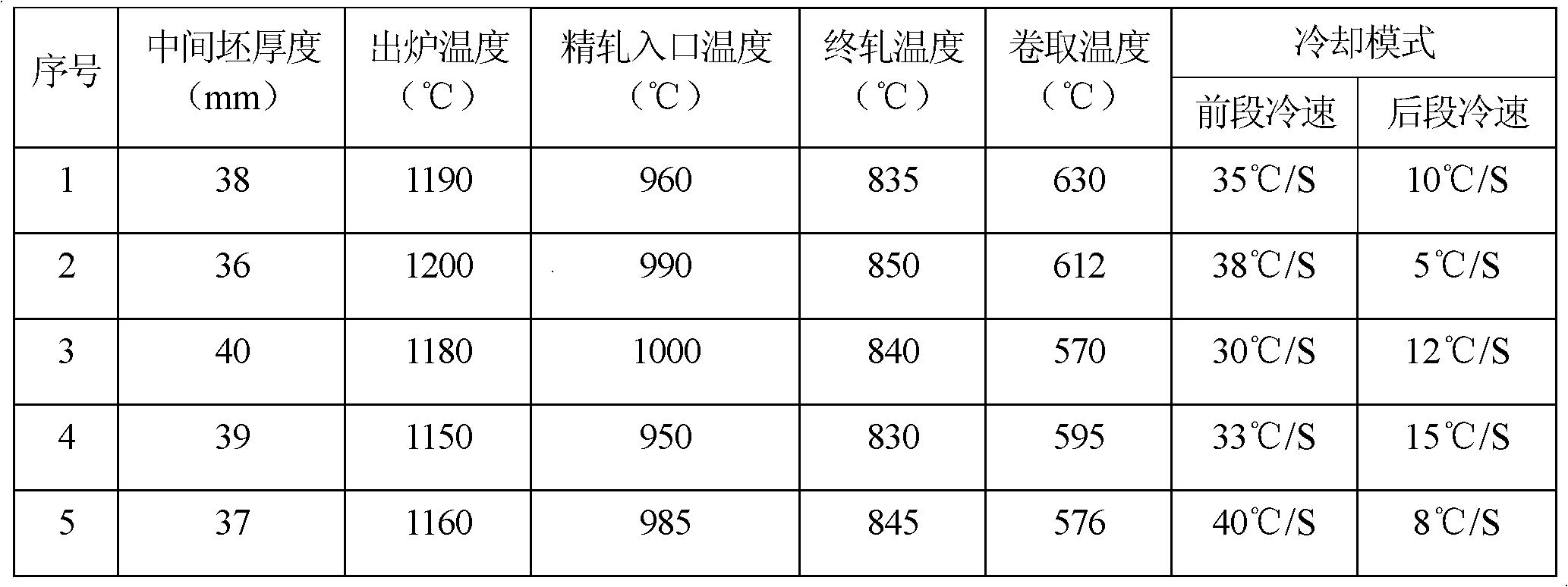

The invention belongs to the technical field of hot-rolled strips and relates to a method for controlling the surface quality of hot-rolled steel plates, namely a preparation method for reducing scales generated on the surfaces of the hot-rolled steel plates. The chemical components of the steel in the method have wider application range and are especially suitable for the hot-rolled steel platescontaining such microalloying elements as Nb, V, Mn and Si. The hot-rolled steel plates have the following chemical components by weight: not less than 0.05% and not more than 0.20% of C, not more than 0.70% of Si, not less than 0.20% and not more than 2.00% of Mn, not less than 0.02% and not more than 0.10% of Nb, not less than 0.03% and not more than 0.15% of V, not more than 0.12% of Ti, not more than 0.040% of P, not more than 0.030% of S and the balance Fe and inevitable impurities. The control method dispenses with improvement of existing equipment, is simple and controllable in processconditions, realizes the aim of reducing the scales by controlling the slab tapping temperature, the finish rolling, initial rolling and final rolling temperature, the coiling temperature and the cooling method and has the advantages of low energy consumption, low cost and wide applicable scope.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

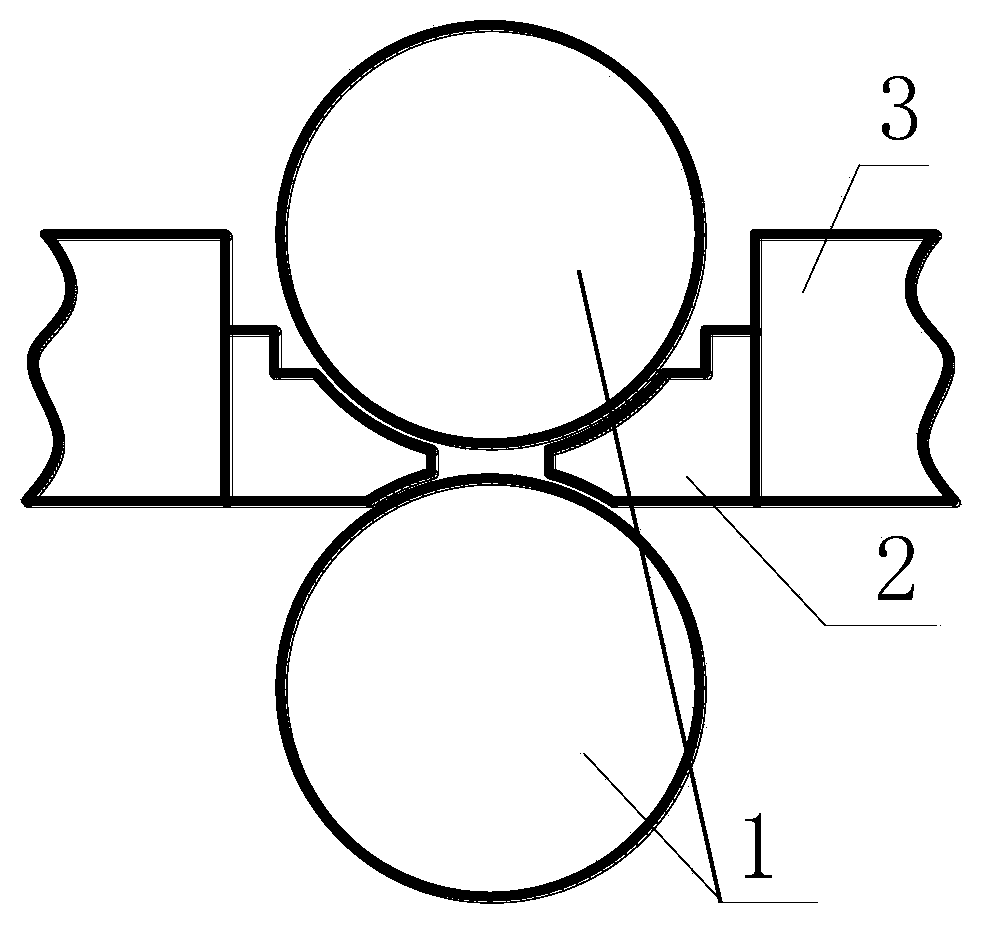

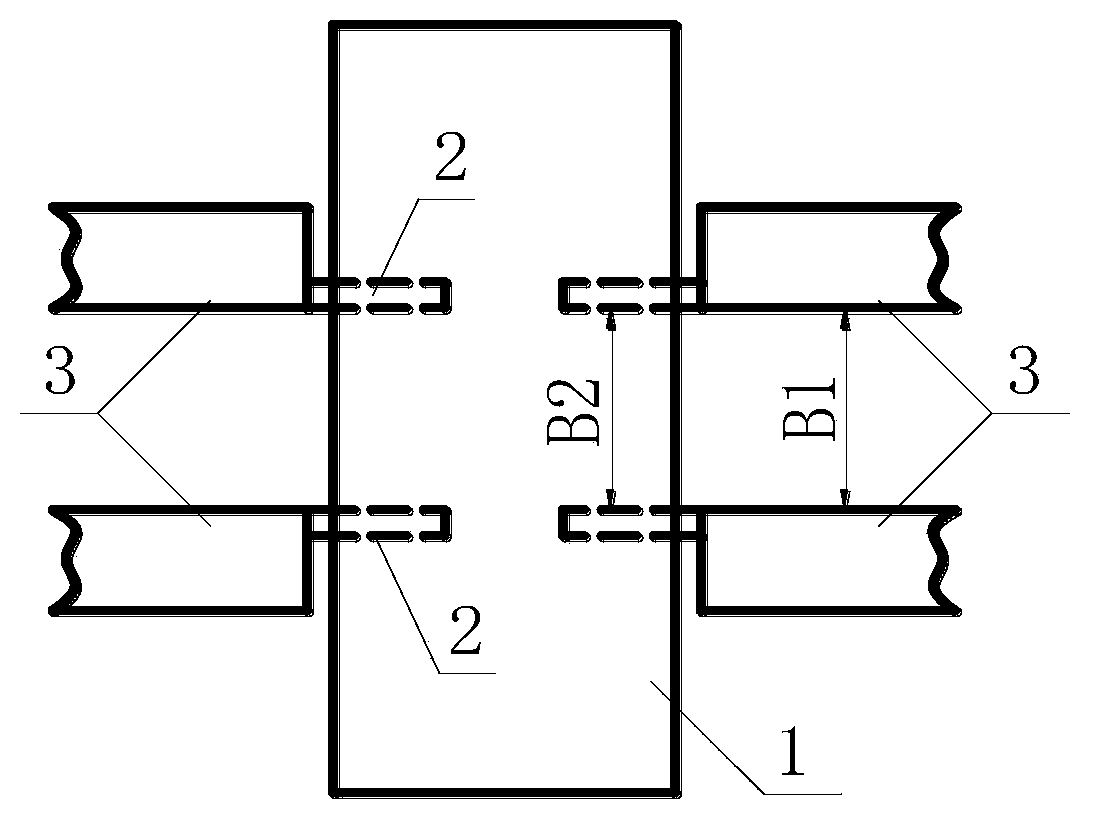

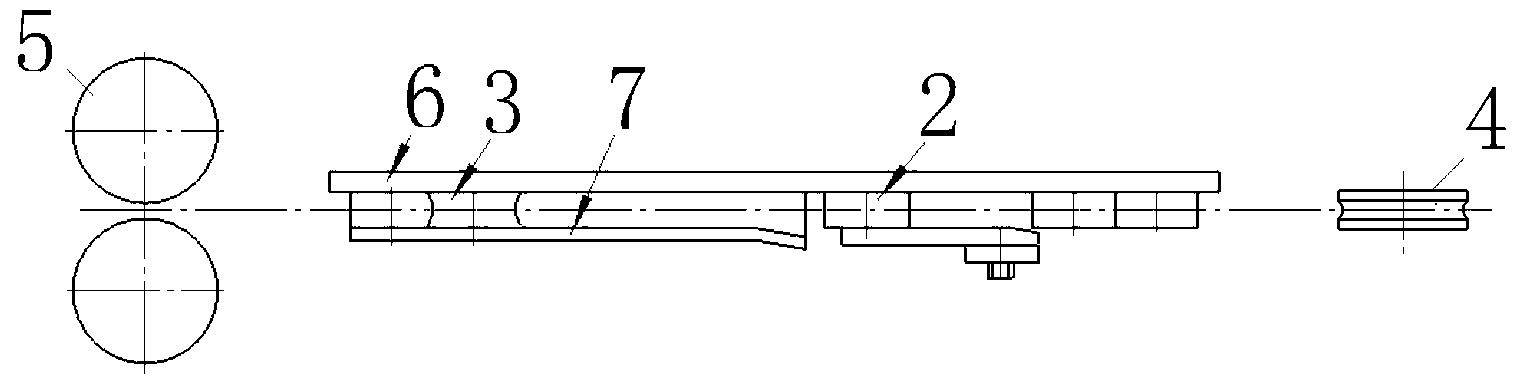

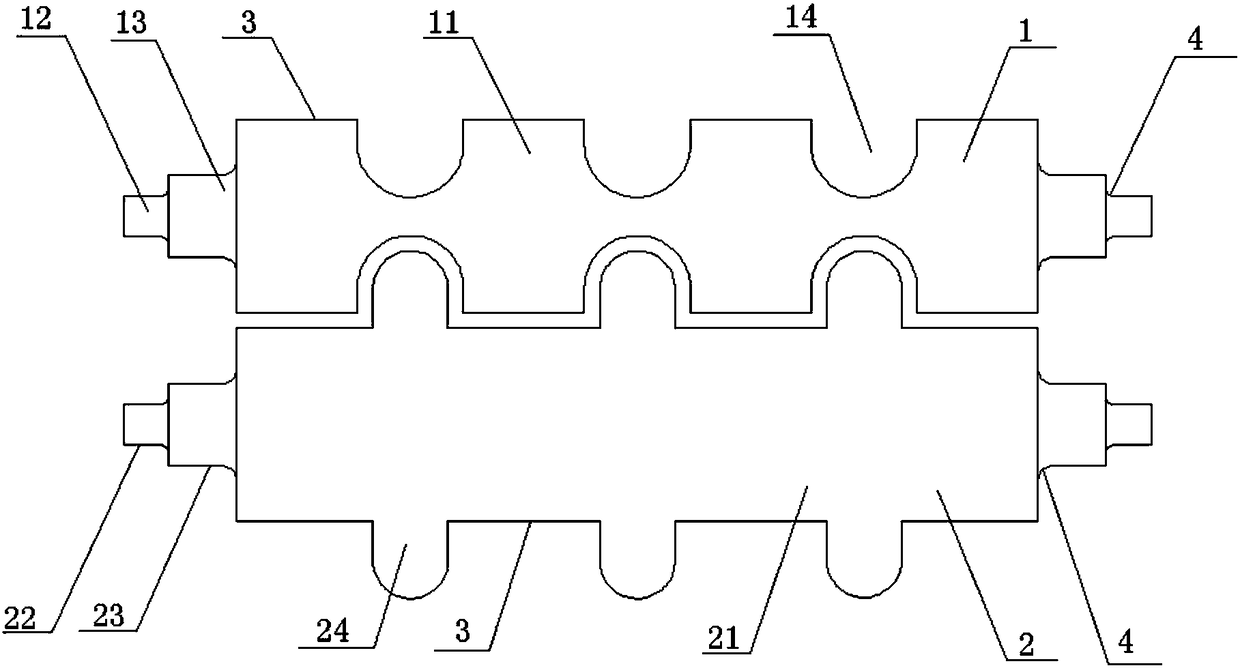

Two-roller reversible mill roller device and technology using continuous casting round billets for carrying out rolling production

ActiveCN103801560AIncrease the amount of steelImprove rolling yieldRollsMetal rolling arrangementsOne passMetallurgy

The invention discloses a two-roller reversible mill roller device and technology using continuous casting round billets for carrying out rolling production. Four types of hole patterns including a transition hole pattern, a supporting hole pattern, a before-finished-product hole pattern and a finished product hole pattern are designed on a pair of rollers. The rolling technology comprises the steps of using the transition hole pattern (1) for rolling the continuous casting round billets, and turning over steel after rolling is accomplished, wherein the rolling reduction ranges from 40 mm to 90 mm per pass; using the supporting hole pattern for continuously rolling the drum-shaped rolled pieces obtained in the previous step to obtain rectangular or square rolled pieces which have regular shapes, and turning over the steel after rolling is accomplished, wherein the rolling reduction ranges from 40 mm 90 mm per pass; using the before-finished-product hole pattern (3) for rolling the rolled pieces to obtain rectangular or oval rolled pieces with reserved rolling reduction and reserved broadening quantity, and turning over the steel billets after rolling is accomplished, wherein the rolling reduction ranges from 20 mm to 90 mm per pass; using the finished product hole pattern for rolling one pass to obtain rolled pieces which are high in dimensional accuracy and product quality, wherein the rolling reduction of square or rectangular steel finished products ranges from 40 mm to 60 mm per pass, and the nominal rolling reduction of round steel ranges from 10 mm to 40 mm per pass.

Owner:HUATIAN ENG & TECH CORP MCC

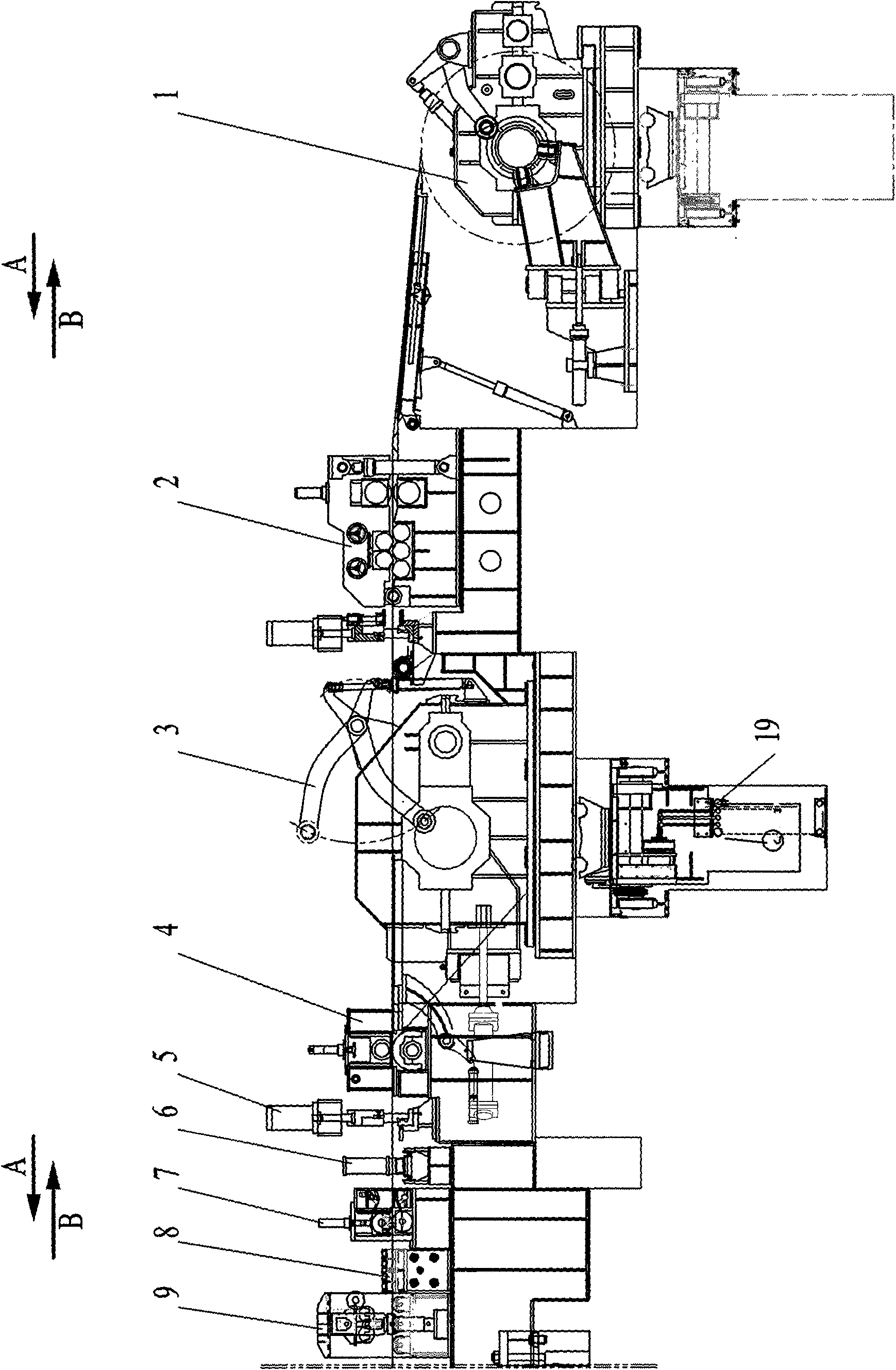

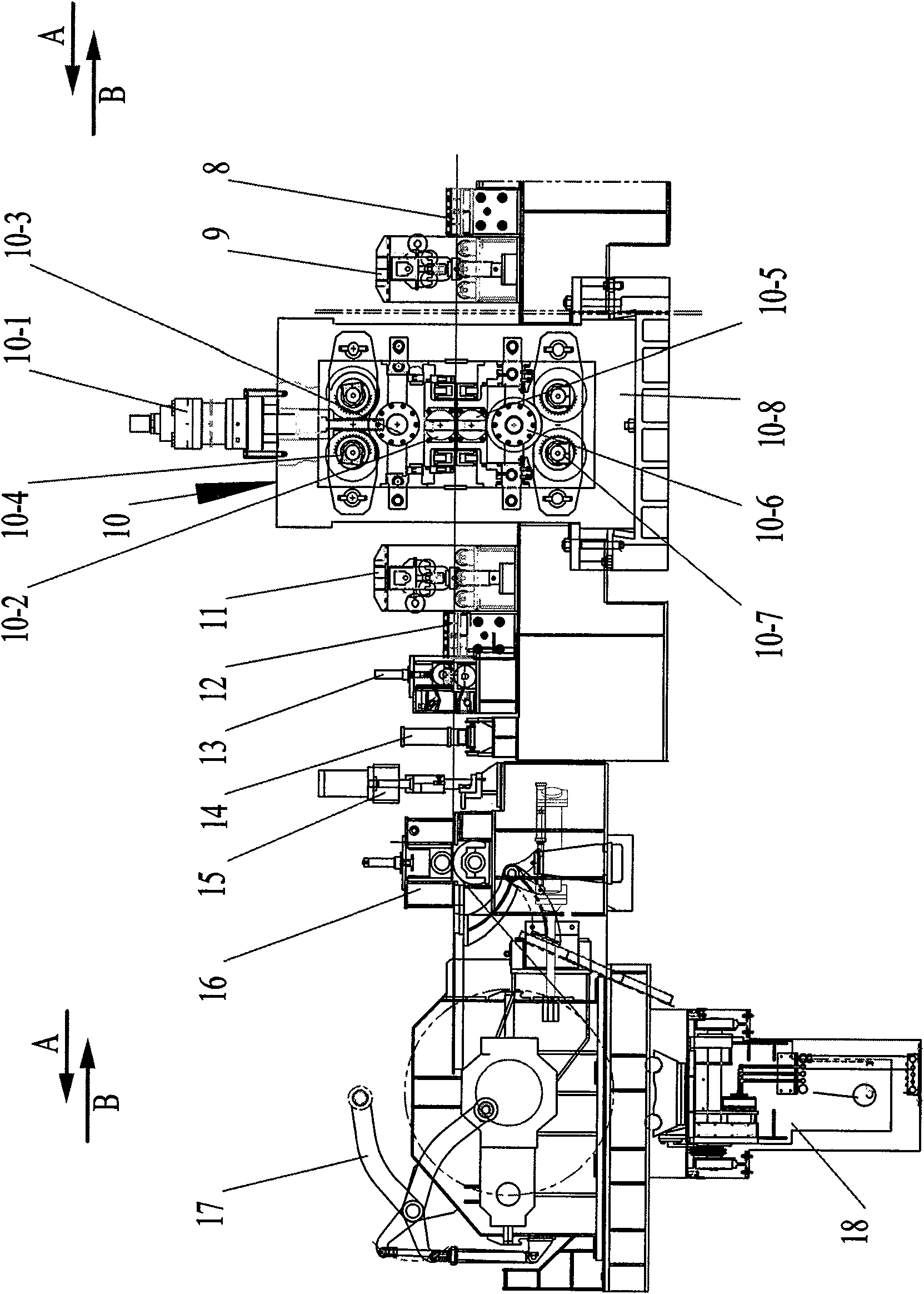

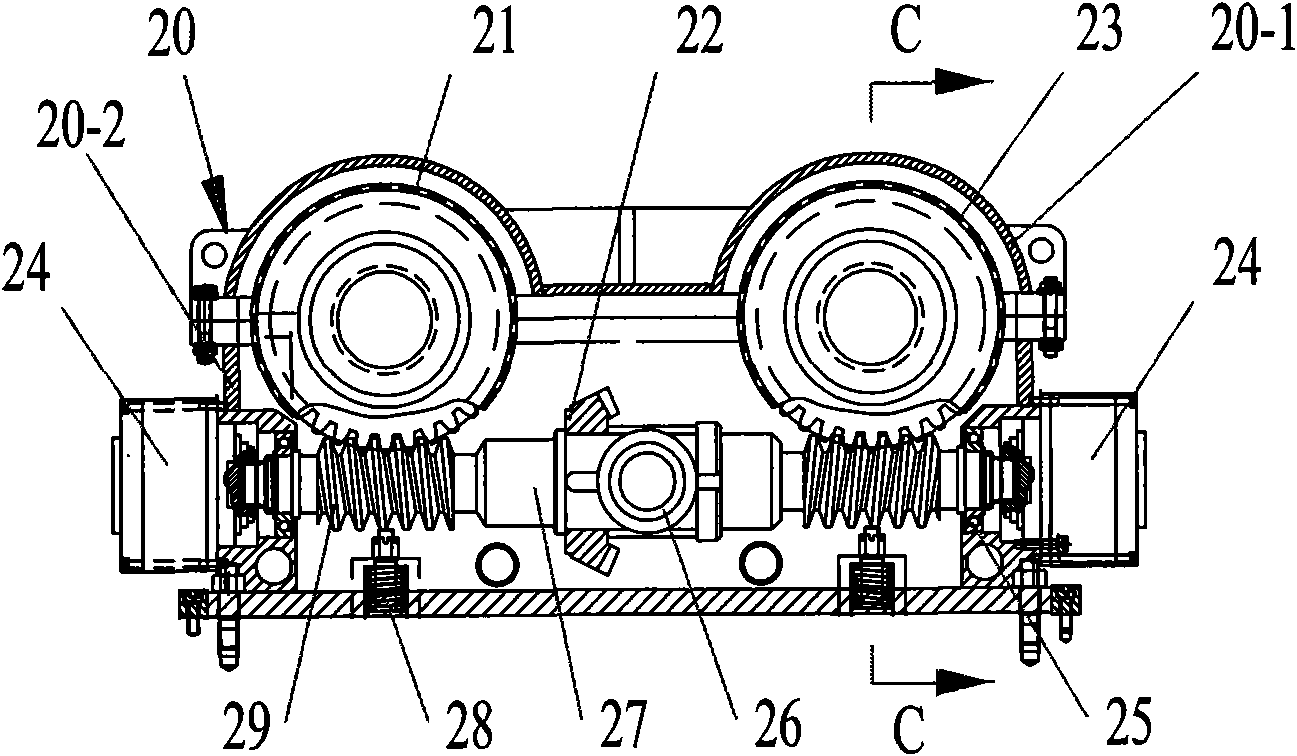

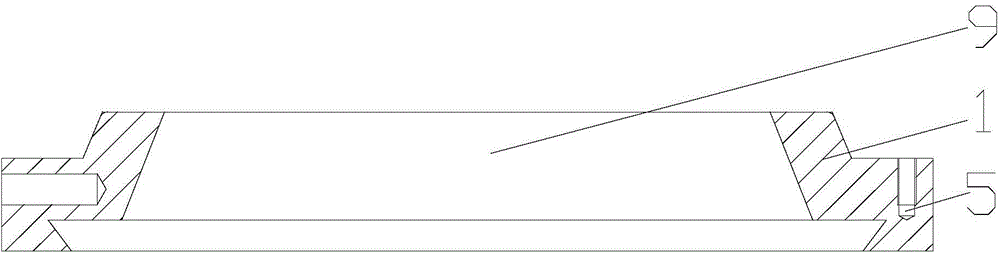

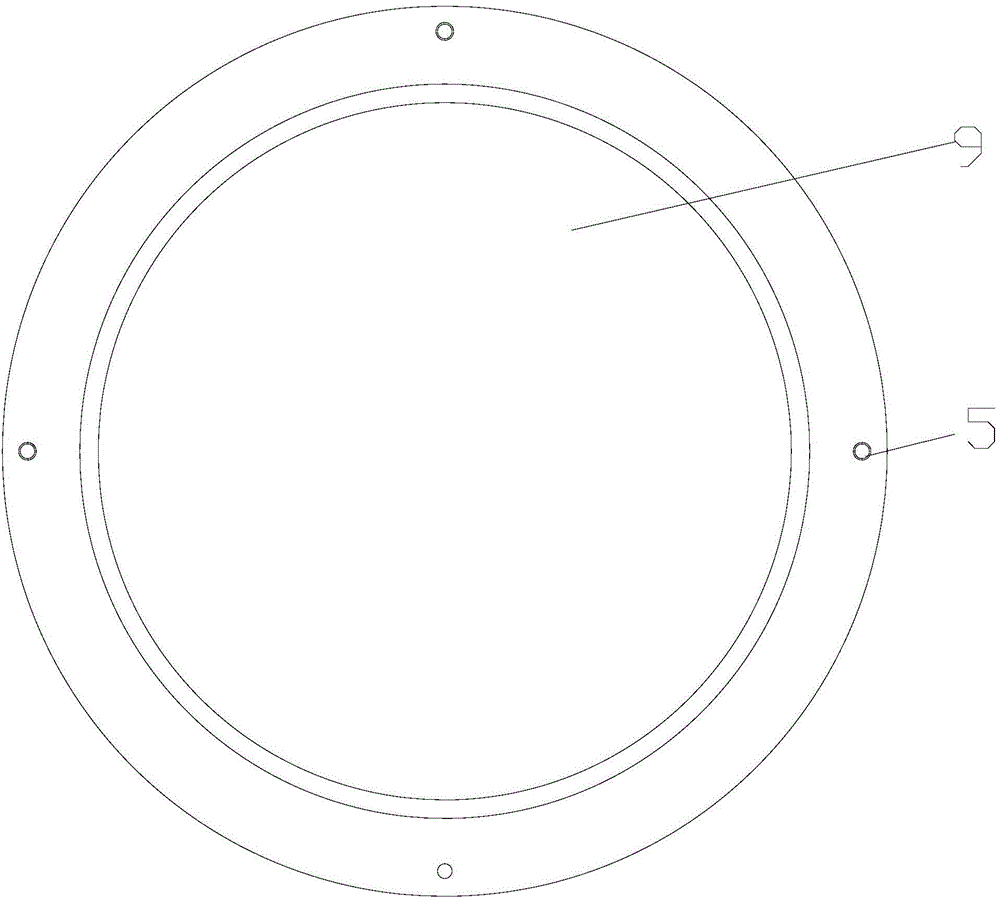

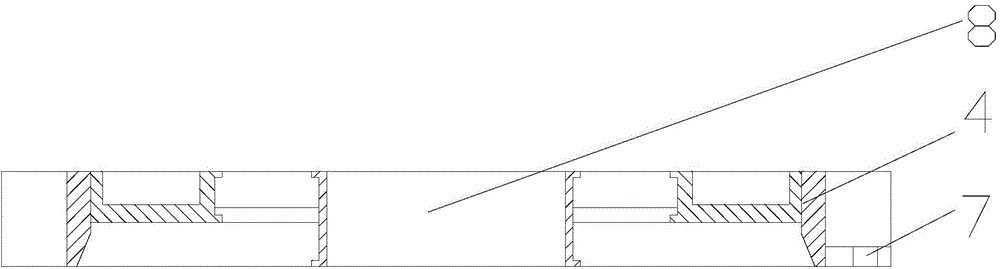

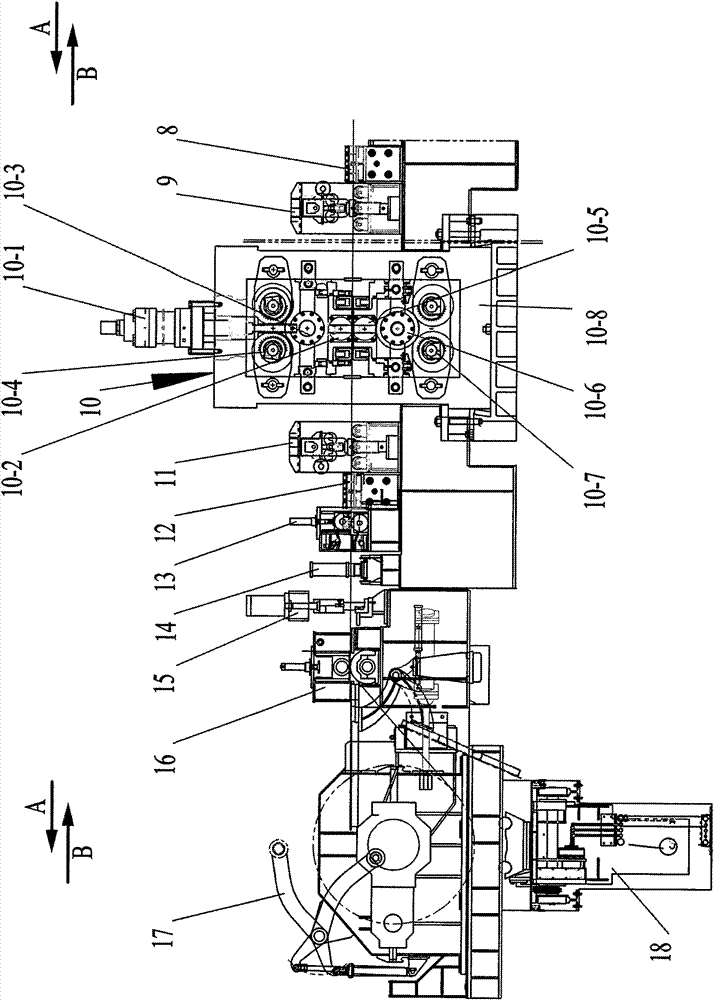

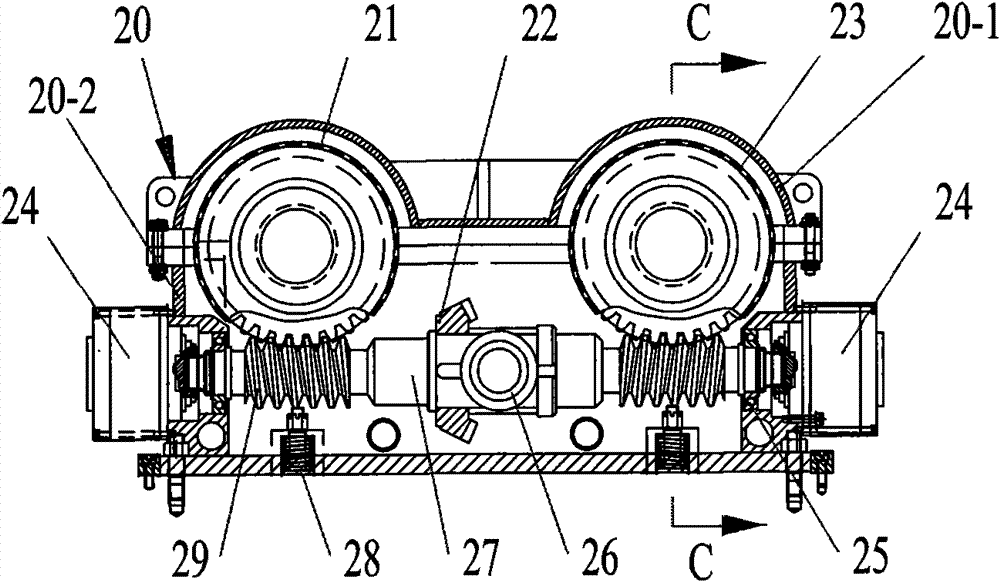

Reversible cold-rolling equipment and production method thereof

InactiveCN101817016ASatisfy the bite conditionNo possibility of skewMetal rolling stand detailsRolling mill drivesLow speedWork roll

The invention discloses reversible cold-rolling equipment, which comprises a main rolling mill, and a front tension device (9), a front alignment device (8), a rear tension device (11) and a rear alignment device (12) positioned on front and rear sides of the main rolling mill. The middle roll of the eight-roll rolling mill is a transmission roll, the transmission side of two lower supporting rolls (10-7) is provided with a lower rolling wire adjusting device connected with an eccentric shaft thereof, and the lower rolling wire adjusting device comprises a box body (20), a driving mechanism and two sets of worm gear transmission mechanisms placed in the box body. The invention also discloses a production method for the reversible cold-rolling equipment, which comprises working roll opening adjustment before rolling, low-speed direct bite of a to-be-rolled strip steel head, high-speed rolling operation and tensioned low-speed rolling operation of a to-be-rolled strip steel tail. The method can meet the bite condition of the rolling mill, realizes a reversible cold-rolling process without leading strip, has high rolling stability and high production efficiency, and is particularly suitable for reversibly cold-rolling thin specification strip steels.

Owner:唐山一重机械制造有限公司 +2

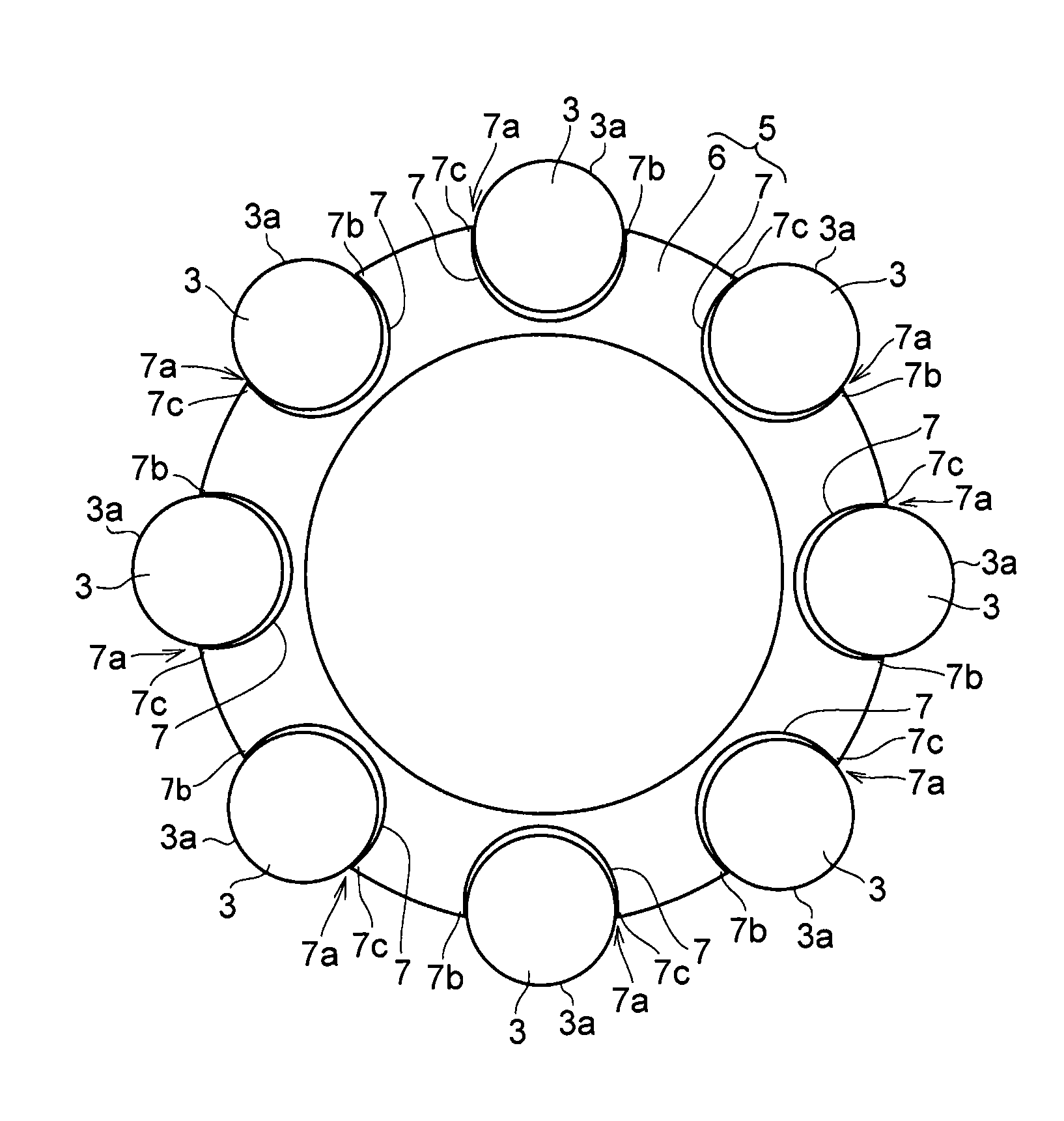

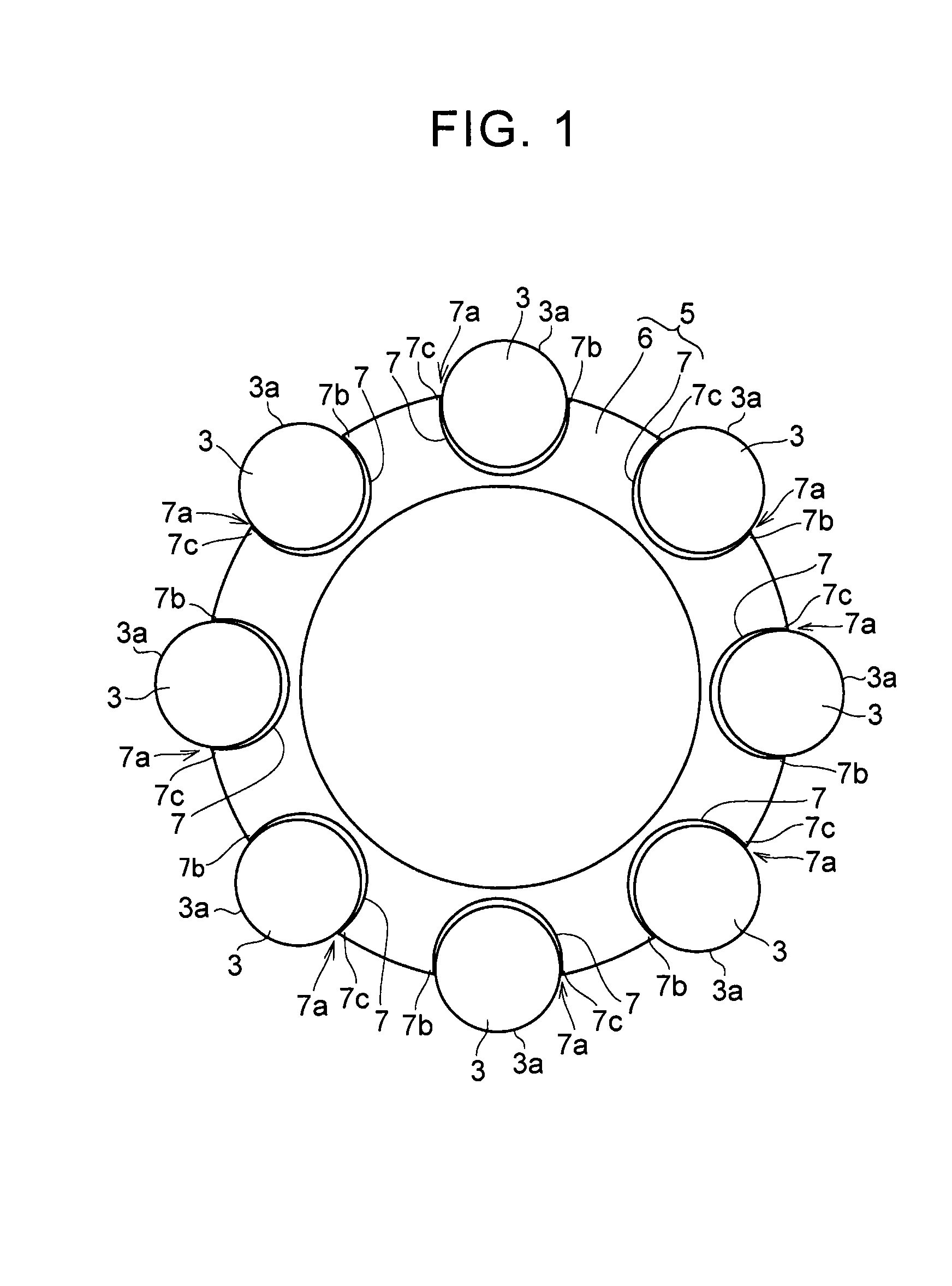

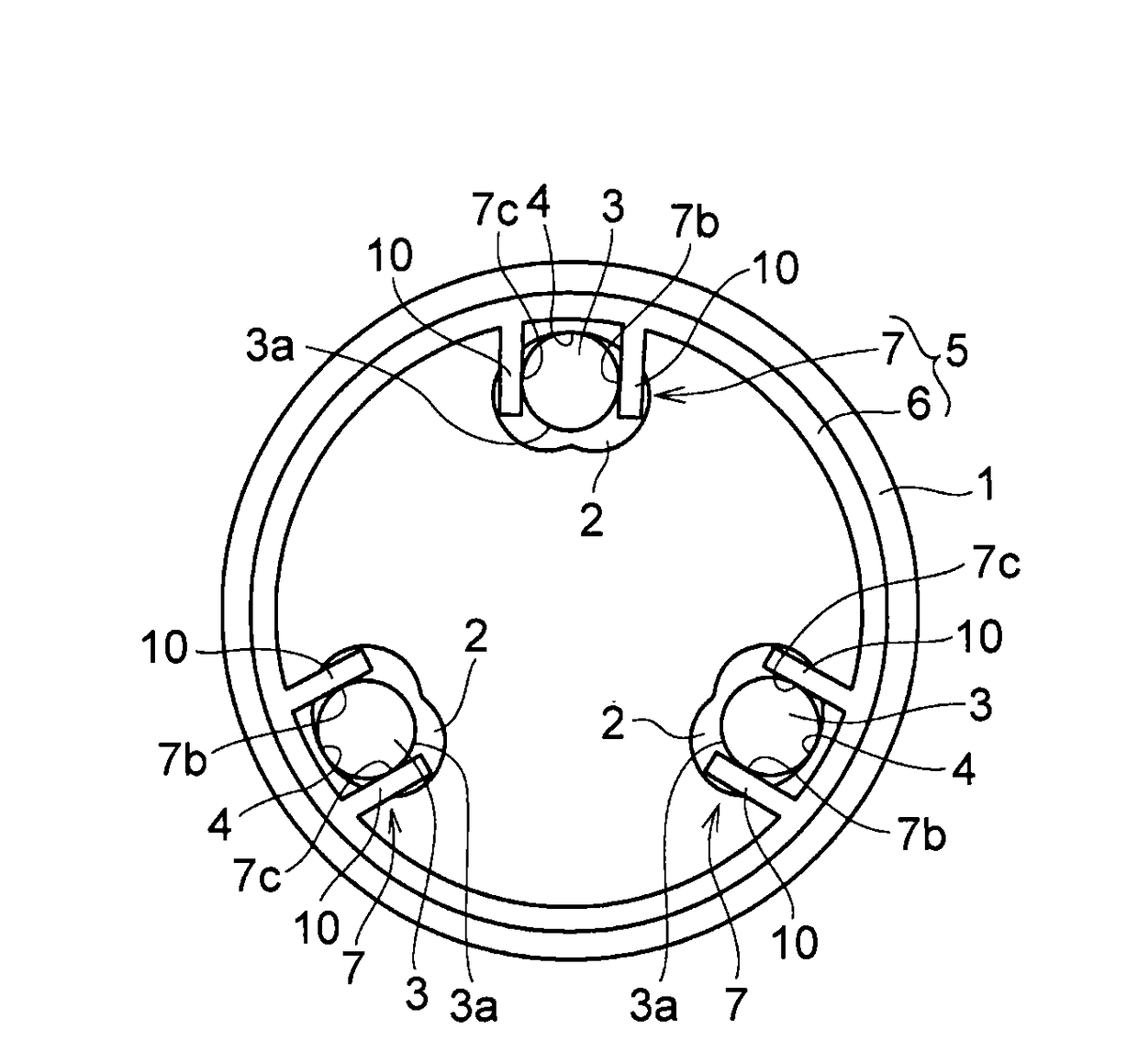

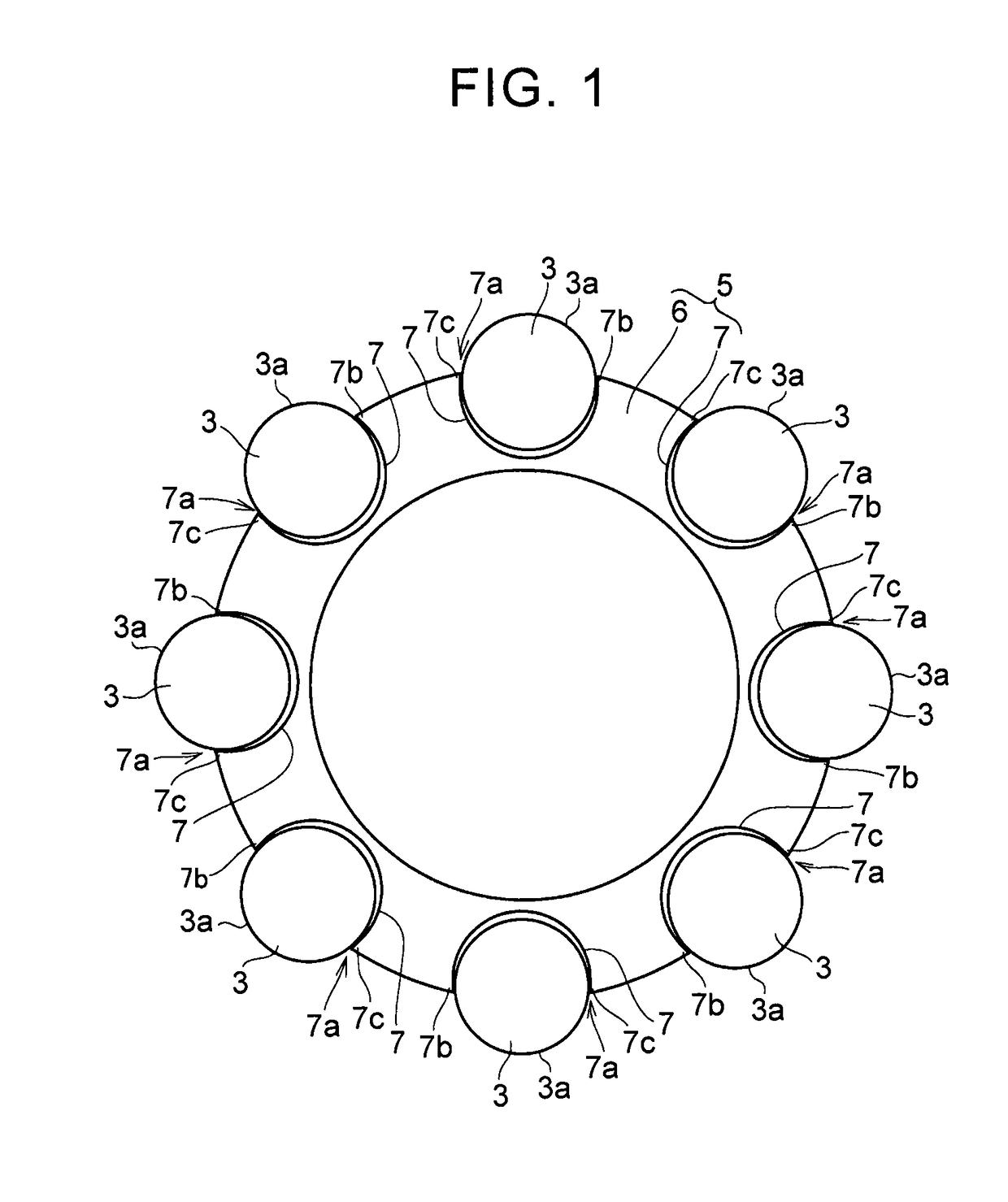

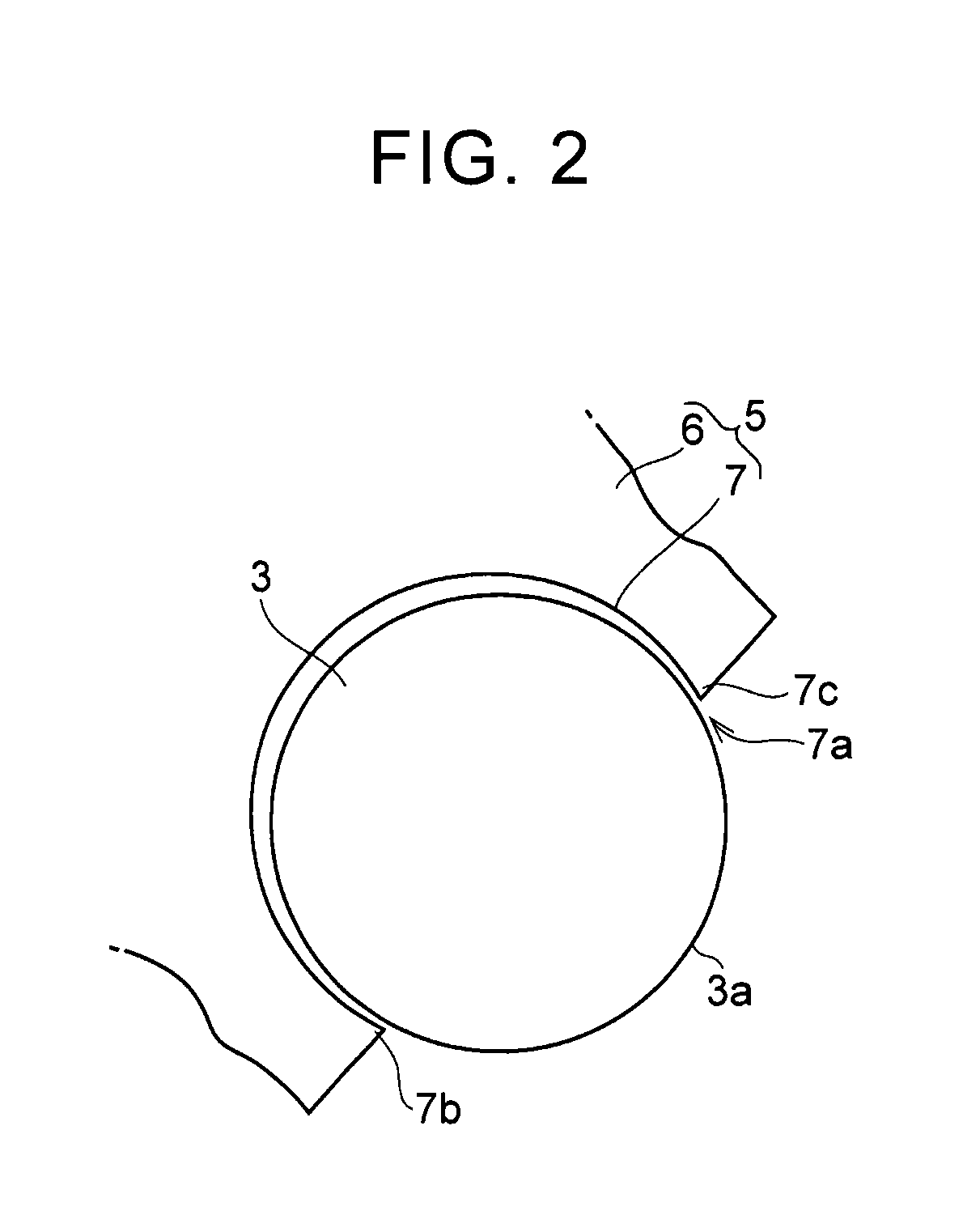

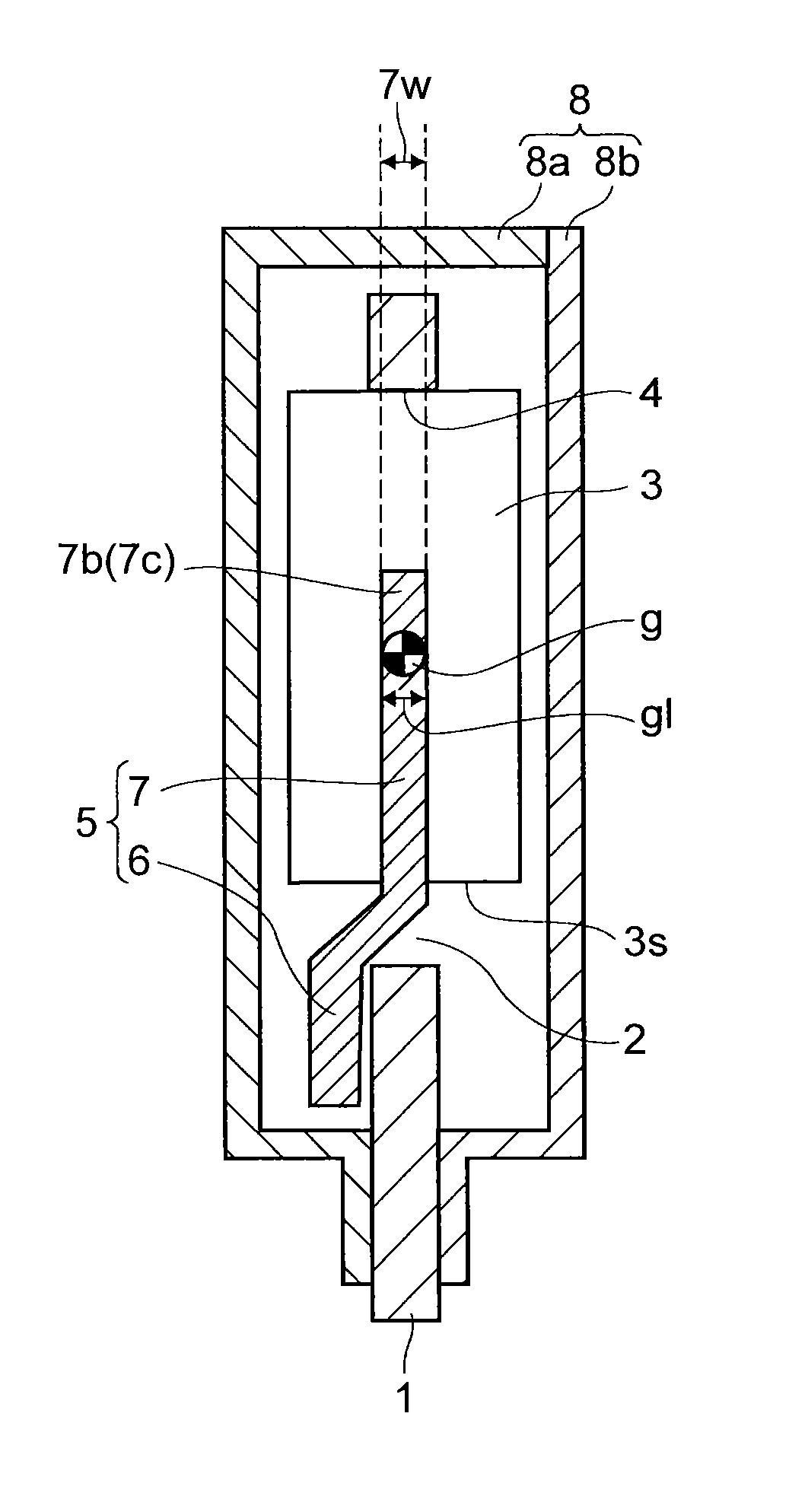

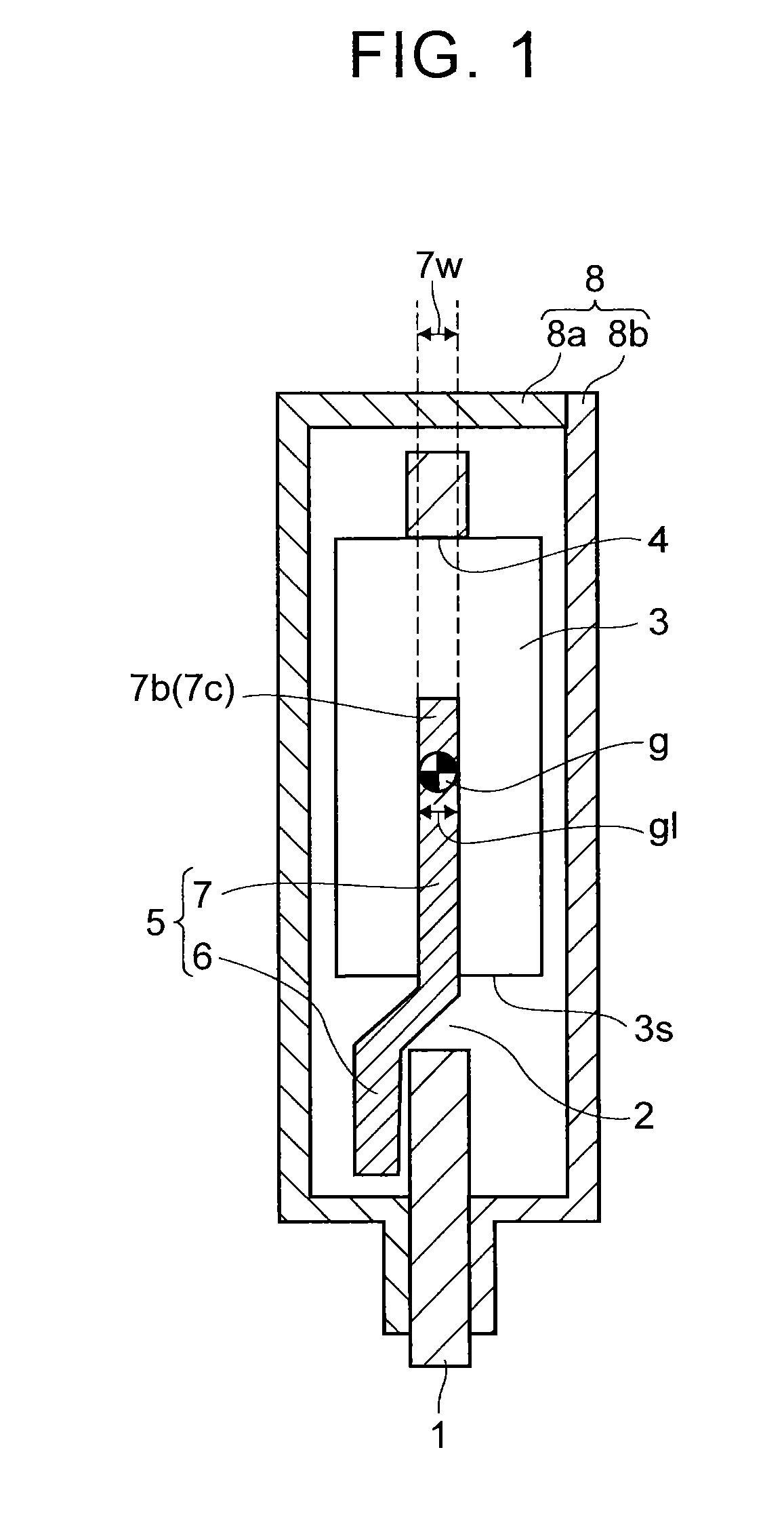

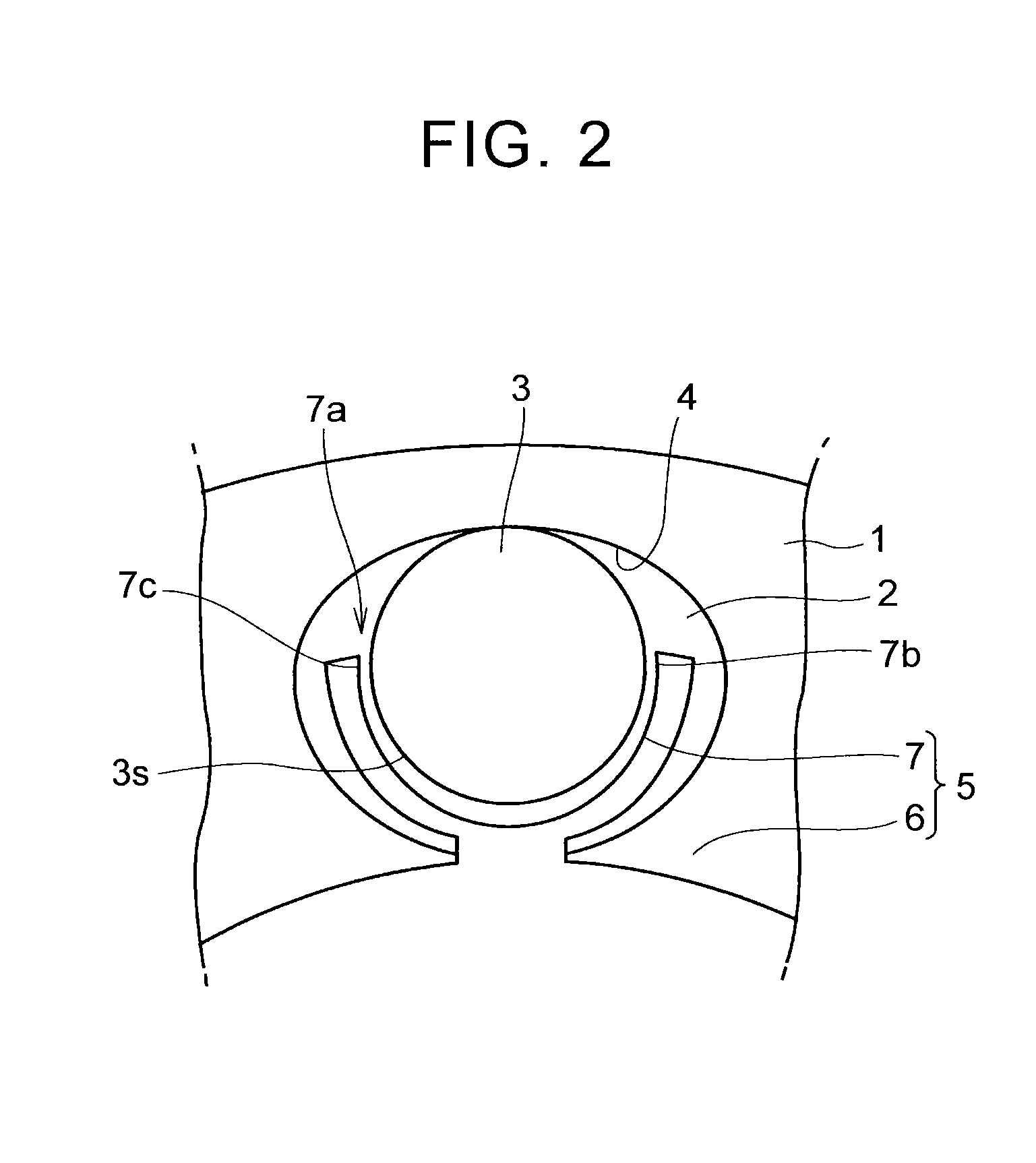

Torsional vibration reducing device

ActiveUS20160169318A1Reduce sliding frictionIncrease the lengthRotating vibration suppressionShock absorbersTorsional vibrationMechanical engineering

A torsional vibration reducing device is provided. The torsional vibration reducing device includes a rotating body, a plurality of rolling bodies, and a connection member. The connection member connects the plurality of rolling bodies, and at least two contact portions are positioned on an inner surface of each of the plurality of accommodating portions, a portion of an outer peripheral surface of each of the plurality of rolling bodies being positioned in each of the plurality of accommodating portions, and the outer peripheral surface of each of the plurality of rolling bodies being configured to come into point contact with the contact portions in the circumferential direction of the rotating body.

Owner:TOYOTA JIDOSHA KK

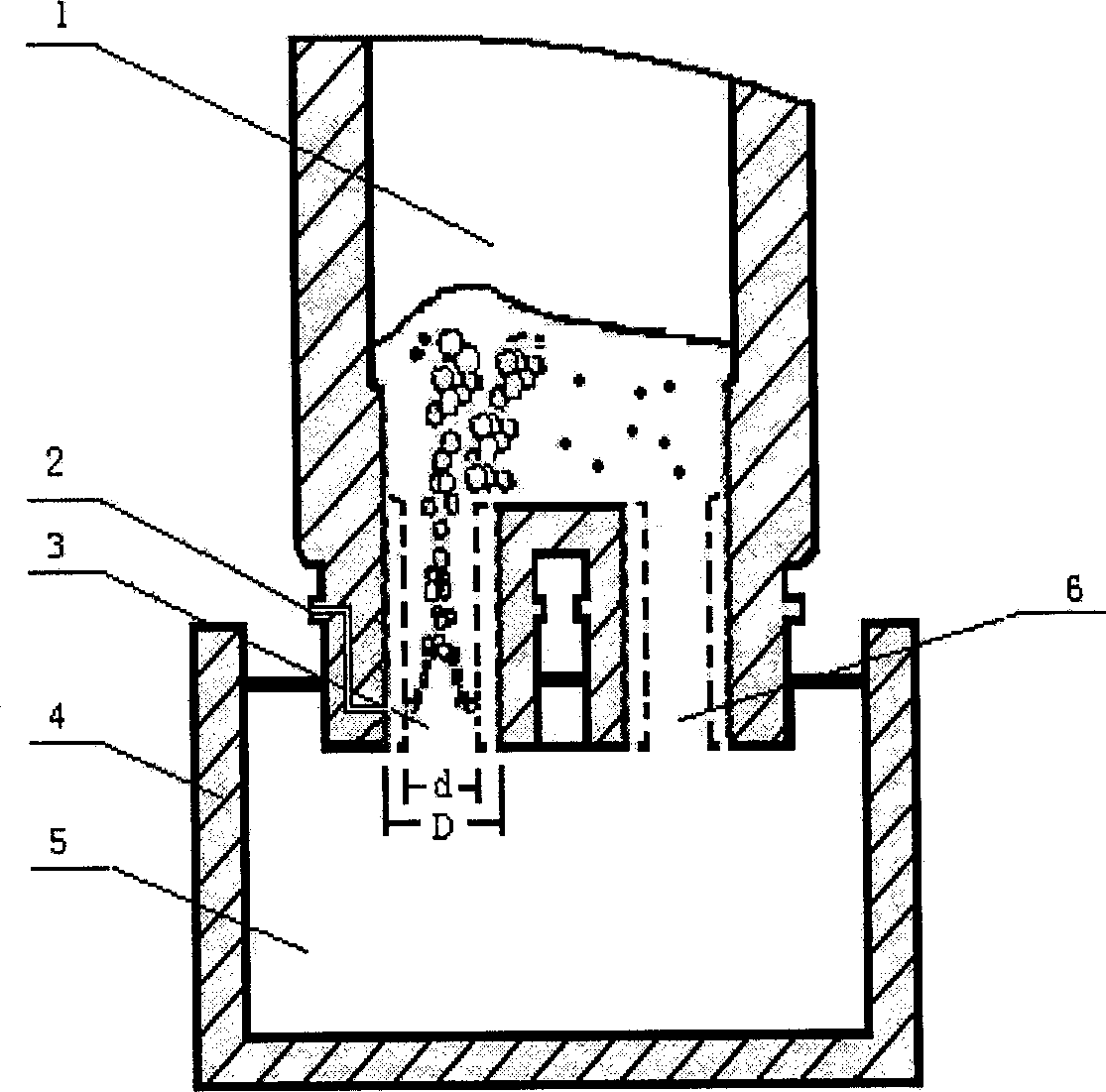

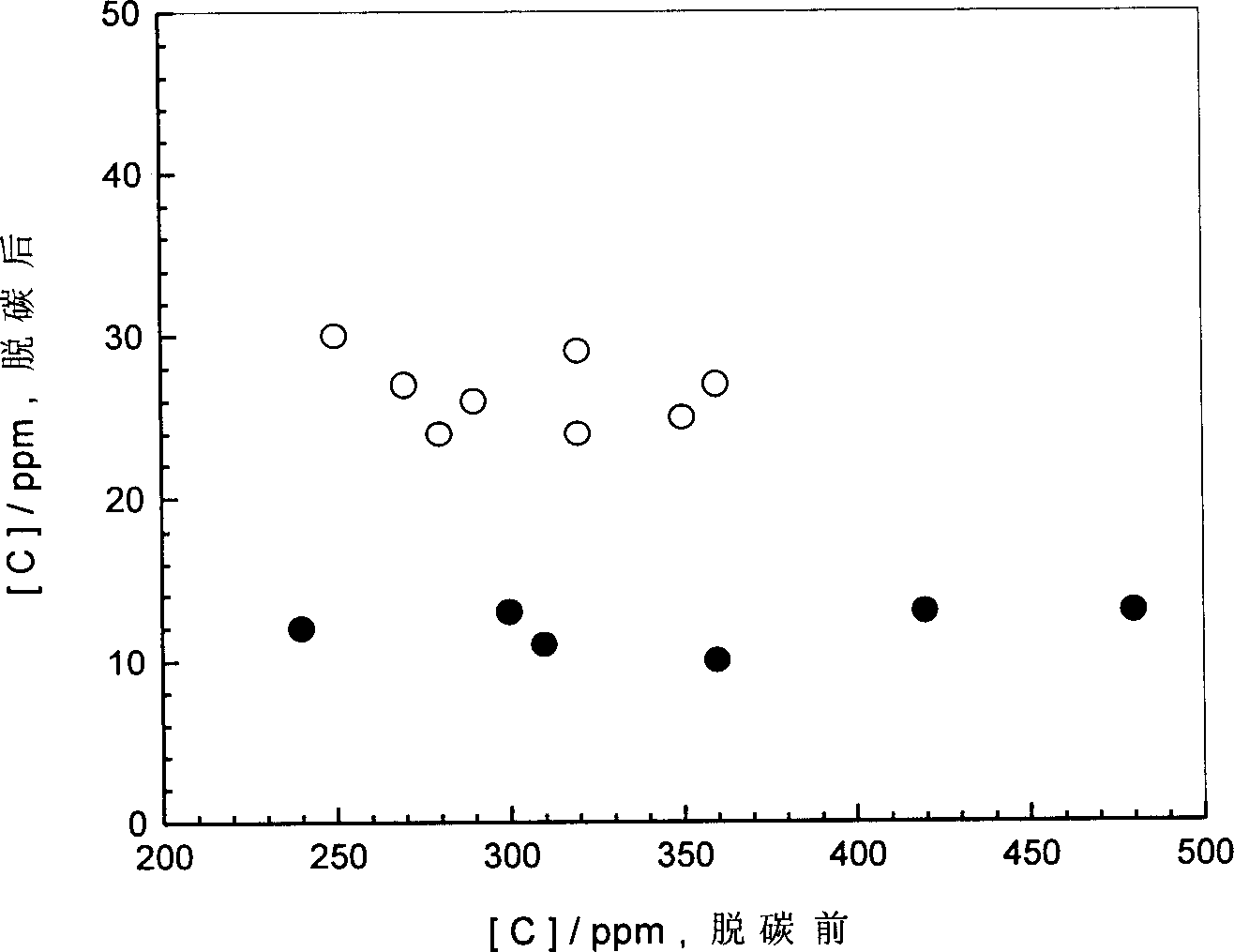

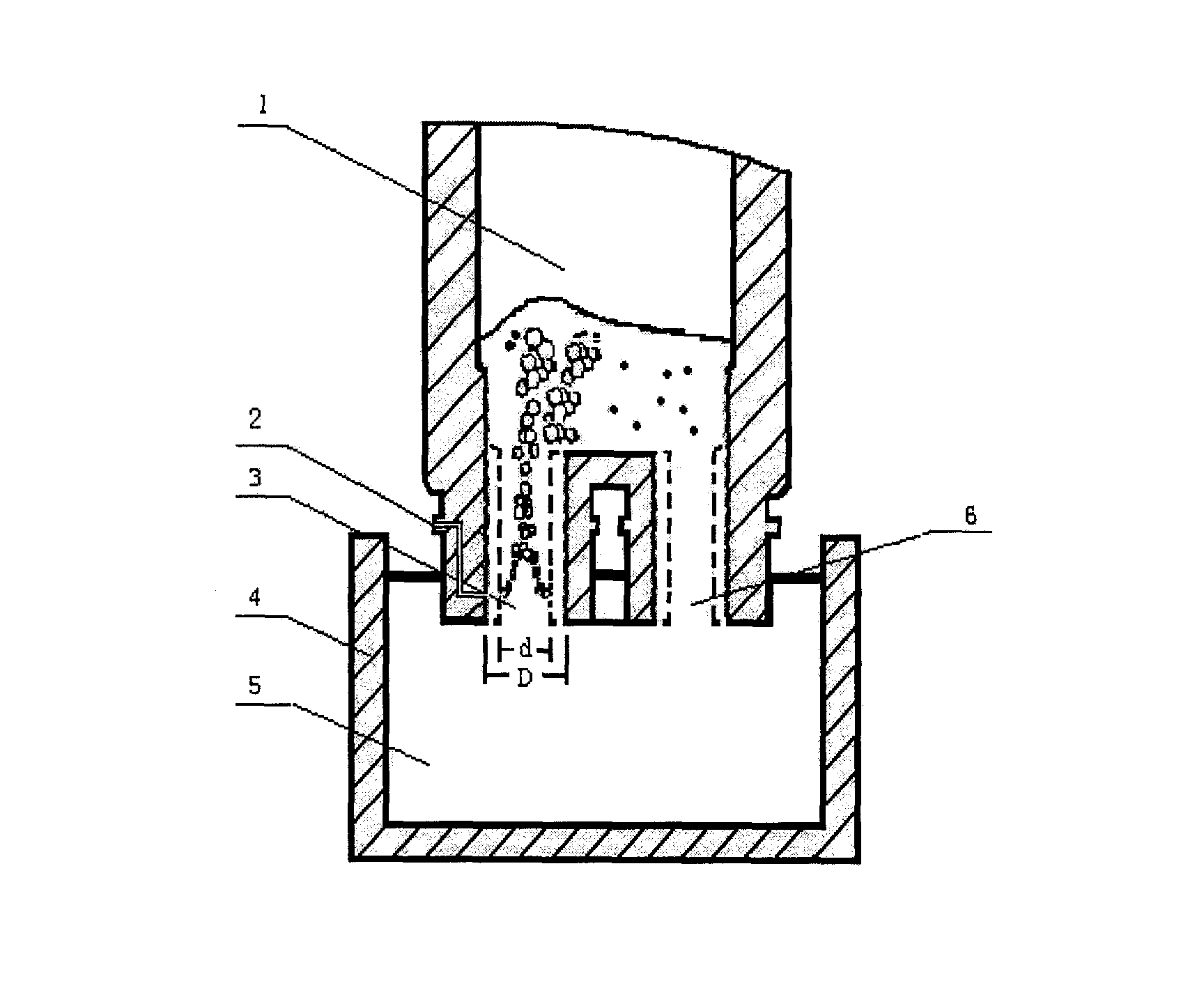

Method of producing super low carbon steel using vacuum degassing

InactiveCN1410559AAvoid damageSolve the problem that the decarburization ability increases with the erosion of the inner diameter of the insertion tubeMetallurgyVacuum level

A process for preparing ultralow-carbon steel by vacuum degassing features that the argon flow and the vacuum level are dependent on the service age of the furnace, that is, for the initial 20 batches, the argon flow is matched with inner diameter of insertion-in tube, and for the following batch whose decarbonizing time is longer than 5 min, the argon flow is increased by more than 20%. Before decarbonizing the molten steel, the vacuum chamber is depressurized in advance. Within 0-10 min after beginning decarbonization, the depressurizing speed is increased.

Owner:武钢集团有限公司

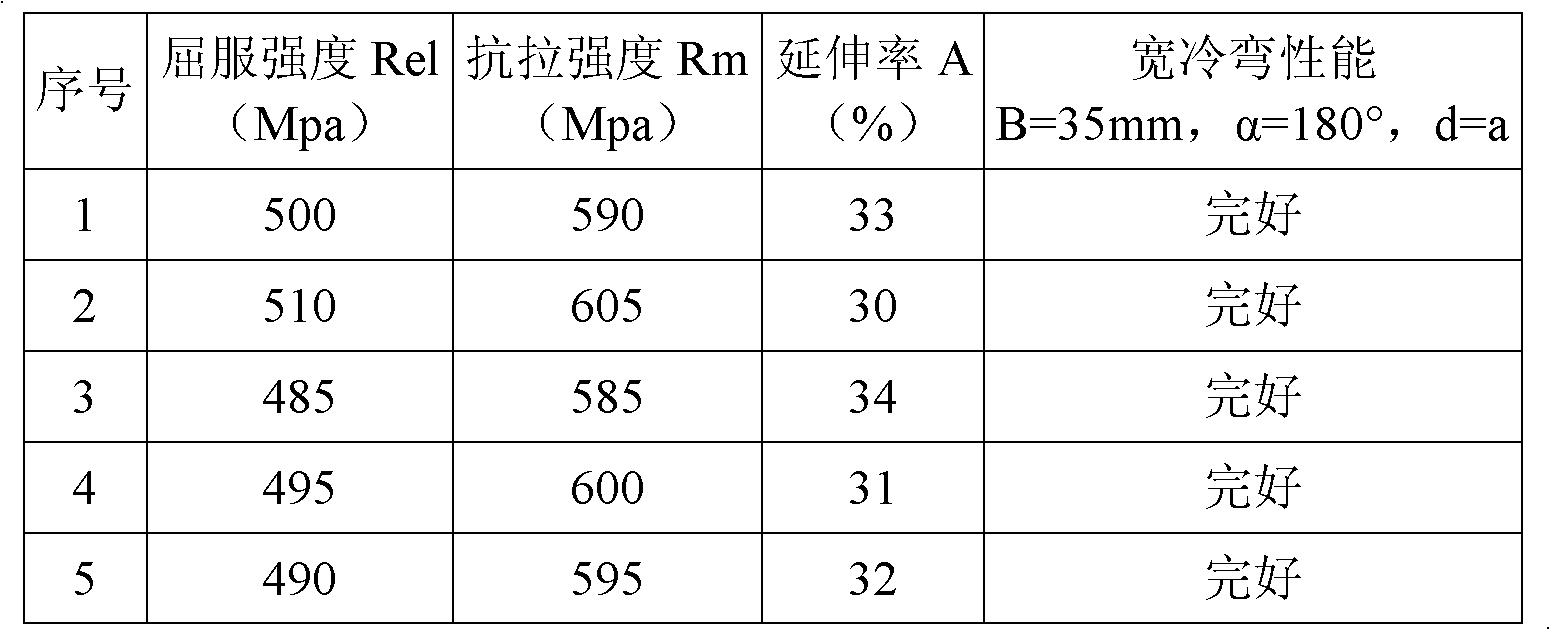

Composite micro-alloying hot rolled steel plate containing V and Nb and preparation method thereof

InactiveCN101899614ALower the furnace temperatureReduce the number of spawnsSheet steelChemical composition

The invention belongs to the technical field of hot continuous rolled plate strips, in particular relates to a composite micro-alloying hot rolled steel plate containing V and Nb and a preparation method thereof, which can achieve the purpose of controlling the surface quality thereof. The composite micro-alloying hot rolled steel plate containing V and Nb, which is provided by the invention, not only can reduce the generation of red scales but also can not increase the production cost. The composite micro-alloying hot rolled steel plate comprises the following chemical components in percentage by weight: C which is greater than or equal to 0.06% and is less than or equal to 0.08%, Si which is greater than 0.20% and is less than or equal to 0.30%, Mn which is greater than or equal to 0.70% and is less than or equal to 0.90%, V which is greater than 0.04% and is less than or equal to 0.05%, Nb which is greater than or equal to 0.02% and is less than or equal to 0.03%, P which is less than or equal to 0.025%, S which is less than or equal to 0.015%, and the balance iron and inevitable impurities. The preparation method provided by the invention has no need of reconstructing the existing equipment, has simple and controllable technological conditions, realizes the purpose of reducing the generation of scales by controlling the tapping temperature, the precision rolling temperature, the finishing temperature, the coiling temperature and the cooling mode of a plate blank, and has the advantages of low energy consumption and low cost.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

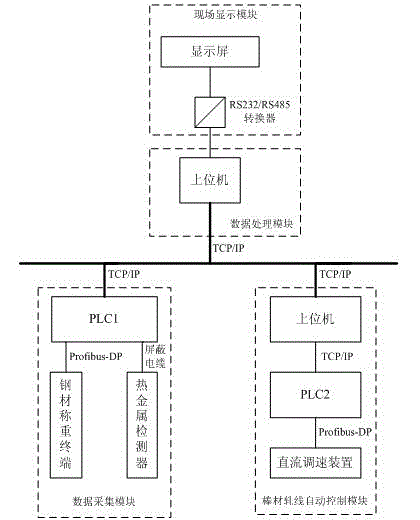

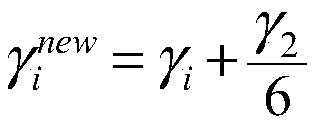

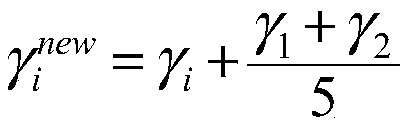

Negative deviation monitoring system and negative deviation detection calculation method for ribbed steel bars

ActiveCN104858242AReduce labor intensityReduce difficultyRoll mill control devicesMetal rolling arrangementsRebarProgrammable logic controller

The invention relates to a negative deviation monitoring system and a negative deviation detection calculation method for ribbed steel bars. The negative deviation monitoring system comprises a data acquisition system, a data processing system, a conventional automatic bar rolling line control system and a field display system; the data acquisition system and the conventional automatic bar rolling line control system communicate with the data processing system through industrial Ethernet; the data processing system and the field display system are connected through a serial bus; the data acquisition system comprises a steel material weighing terminal, a hot metal monitor and a programmable logic controller (PLC 1); the steel material weighing terminal is connected with the PLC 1 through a field bus; the hot metal monitor is connected with the PLC 1 through a screened cable; the conventional automatic bar rolling line control system comprises an upper computer, a DC speed regulation device and a programmable logic controller (PLC 2); the upper computer communicates with the PLC 2 through industrial Ethernet; the DC speed regulation device is connected with the PLC 2 through another field bus. The negative deviation monitoring system provided by the invention can effectively improve the steel billet yield and reduce the rolling cost.

Owner:JIANGSU YONGGANG GROUP CO LTD

Roller applicable to cross wedge rolling shaft type parts and production technology

The invention relates to a roller and a production technology, in particular to a roller applicable to cross wedge rolling shaft type parts and a production technology. The roller is prepared from chemical ingredients comprising 1.8-2.2% of C, 0.4-0.60% of Si, 0.8-1.2% of Mn, 0.03% or less of P, 0.025% or less of S, 1.2-1.6% of Cr, 1.6-2.0% of Ni, 0.6-0.8% of Mo, 0.2-0.4% of V, 0.2-0.4% of Nb andthe balance Fe and a small amount of residual elements, then, two-furnace smelting is carried out, yttrium-based rare earth alterant is added, and a special heat treatment technology is carried out, so that the roller is obtained. The phenomenon that carbide exists in a discontinuous (granular) state is changed by optimally allocating the chemical ingredients, particularly adding niobium and vanadium, and the microscopic structure of the roller is improved. Meanwhile, by adding the yttrium-based heavy rare earth alterant for purifying molten steel in the steel melting process, the purity is improved, the comprehensive mechanical property of the roller is improved, the yield and quality of rolled products are improved, the service life of the roller is prolonged, and the purposes of cost decreasing and benefit increasing for enterprises are achieved.

Owner:湖州中杭轧辊有限公司

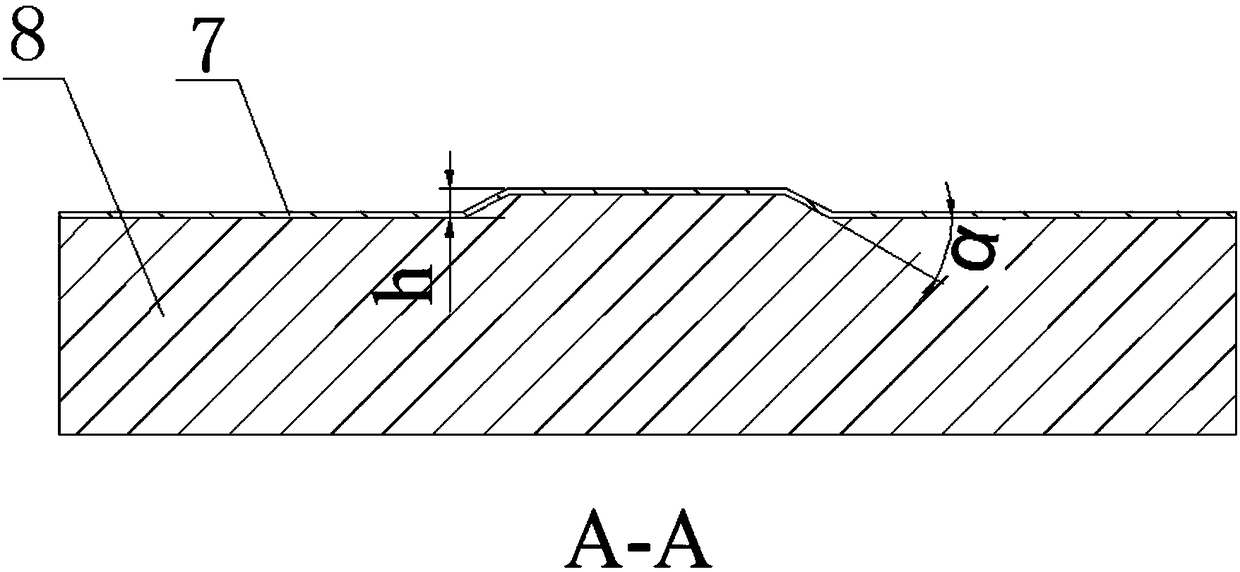

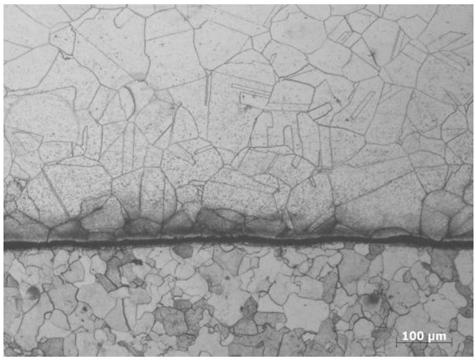

High-shear-strength super-thick composite steel plate for generation III nuclear power station and manufacturing method of composite steel plate

ActiveCN108995323AComposite effect is goodHigh mechanical properties and resistance to intergranular corrosionLaminationLamination apparatusAustenitic stainless steelReduction rate

The invention discloses a high-shear-strength super-thick composite steel plate for a generation III nuclear power station and a manufacturing method of the composite steel plate. The composite steelplate consists of steel-plate carbon steel and 304L austenitic stainless steel. The assembly sequence is as the follows from top to bottom: stainless steel, carbon steel, an isolating agent, carbon steel and stainless steel. Edge sealing is carried out on four edges of a combined billet by welding, vacuumizing treatment is carried out, and the vacuum degree is 100 Pa or lower. The heating temperature of the combined billet is 1200-1270 DEG C, the heating time is 10-15 hours, the single-stroke reduction rate is 5%-15%, the final rolling temperature is controlled to be 1050 DEG C or above, tempering heat treatment is carried out after rolling, the quenching temperature is 870-930 DEG C, the heat preservation time is 2-4 min / mm, and the heating rate is 1.0-1.5 min / mm. The tempering temperature is 620-660 DEG C, the heat preservation time is 3-6 min / mm, and the heating rate is 1.5-2.0 min / mm. The thickness of a finished composite steel plate is 29-110 mm, the shearing strength is good, andthe requirement of steel for composite boards of a nuclear power station is met.

Owner:ANGANG STEEL CO LTD

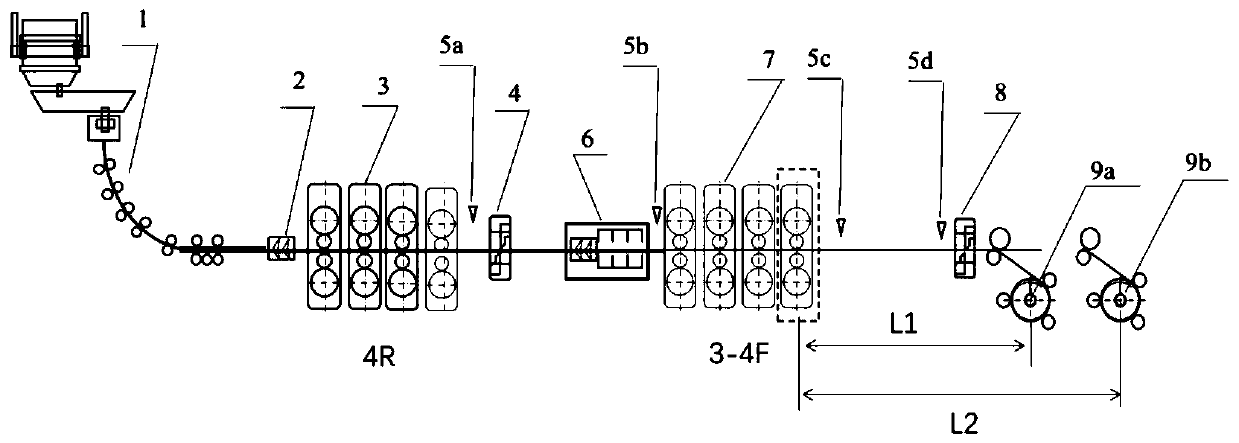

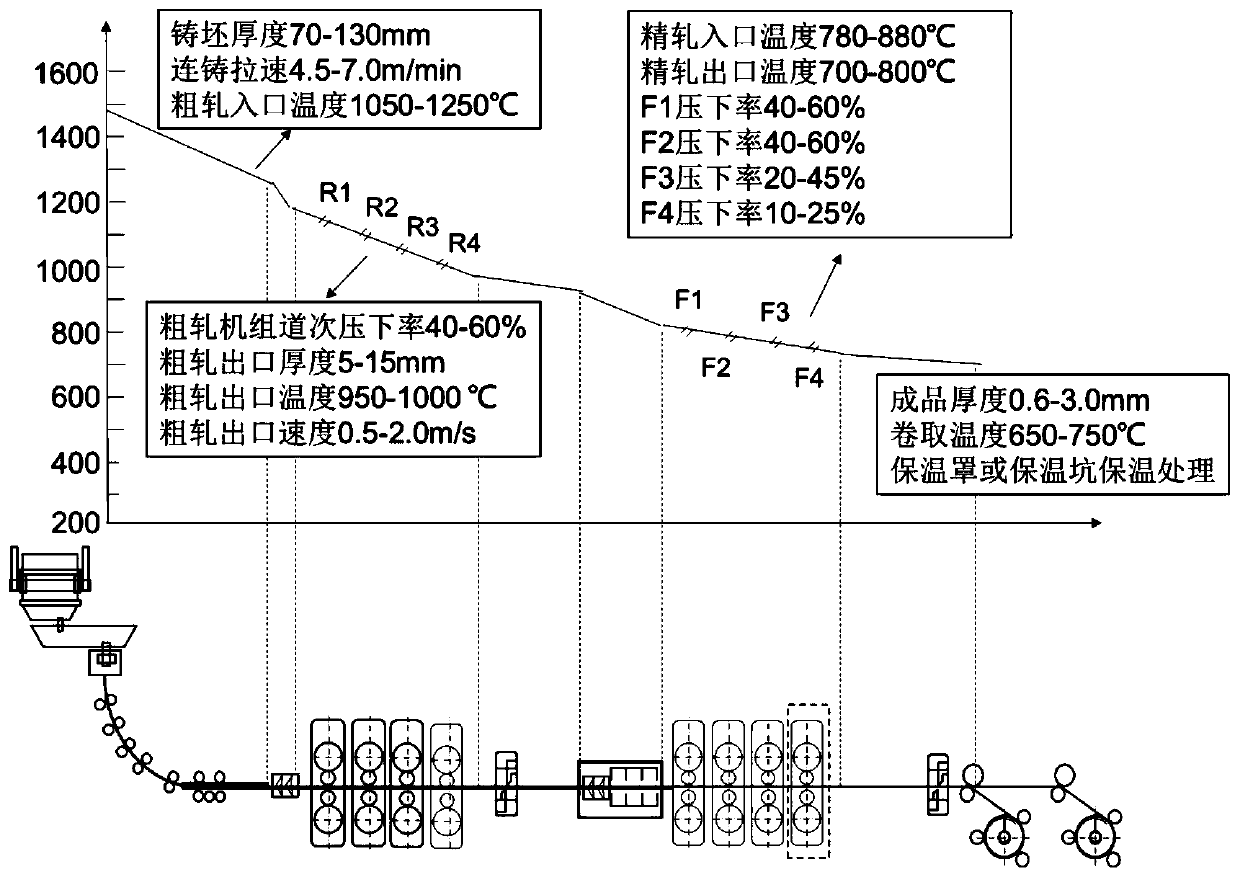

Hot-rolled strip steel full-continuous production device and method for ferrite rolling

ActiveCN110479762AReasonable configurationShort line lengthTemperature control deviceMeasuring devicesHigh pressure waterHigh pressure

The invention discloses a hot-rolled strip steel full-continuous production device and method for ferrite rolling. The hot-rolled strip steel full-continuous production device is characterized in thatthe production line of the device is short, and components are reasonably configured; a multifunctional cooling control device is adopted, and high-pressure water descaling and intermediate blank cooling functions are integrated so as to achieve simplicity and high efficiency; and 4R+(3-4) rolling mills, four temperature detectors and close-range underground coilers are arranged, so that the cooling load of an intermediate billet is reduced, accurate temperature control of the process is achieved, and the product quality is conveniently improved. The method comprises the steps of continuouslycasting to manufacture the billet; dephosphorizing by high-pressure water rotary; carrying out rough rolling by using a four-frame large screw-down rough rolling unit; shearing by using a rotary drum; carrying out cooling in a multifunctional cooling control device after dephosphorization through the high pressure water; performing fine rolling by using a three-frame or four-frame fine rolling unit; carrying out air cooling; shearing and dividing rollers by using a high-speed flying shear; and reeling by using a underground coiler, wherein the temperature monitoring is respectively carried out before roughing rolling, before and after fine rolling, and before reeling by the underground coiler. The method has the advantages of energy consumption and low cost, good product quality and thinthickness, and is capable of better meeting the performance requirement of replacing cold with heat.

Owner:武汉钢铁有限公司

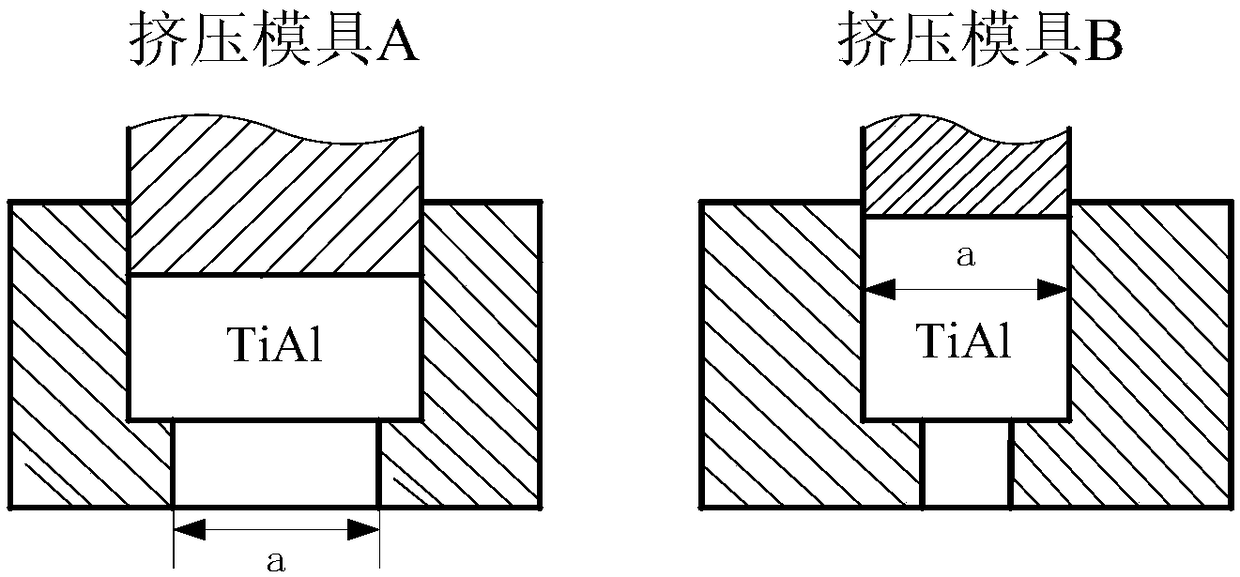

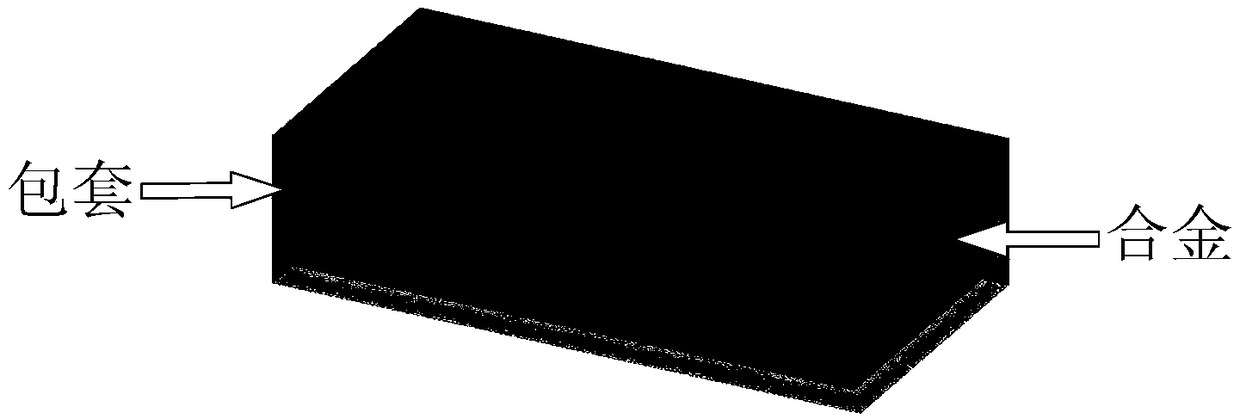

One-step large-deformation rolling method of beta solidification TiAl alloy plate

ActiveCN108787750AAvoid bulkyAvoid small amount of deformation in a single passForging/pressing devicesFurnace typesBeta phaseRoom temperature

The invention provides a one-step large-deformation rolling method of a beta solidification TiAl alloy plate. The method comprises the following steps that 1, raw materials are weighed; 2, a TiAl alloy casted ingot is manufactured by utilizing a vacuum induction melting technology, and heat treatment is carried out; 3, two-step hot extrusion deformation is carried out on the alloy; and 4, one-steplarge-deformation packing rolling is carried out on the alloy, and a pack is removed so as to obtain the TiAl alloy plate which is uniform and fine in structure. According to the one-step large-deformation rolling method of the beta solidification TiAl alloy plate, the beta solidification TiAl alloy with excellent high-temperature deformation capability is adopted, the beta phase content is controlled to be 15%-25%, and the excellent high-temperature deformation capability of the TiAl alloy is ensured; meanwhile, the alloy structure of a blank is refined violently through the two-step extrusion so as to remarkably improve the structure uniformity of the alloy, and therefore, one-step large-deformation rolling of the blank can be guaranteed, finally, the TiAl alloy plate with the uniform and fine structure and good room temperature plasticity is obtained, and the problems that in the prior art, a TiAl alloy rolled blank is coarse in structure, plate forming is difficult, and the platestructure uniformity is poor are solved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

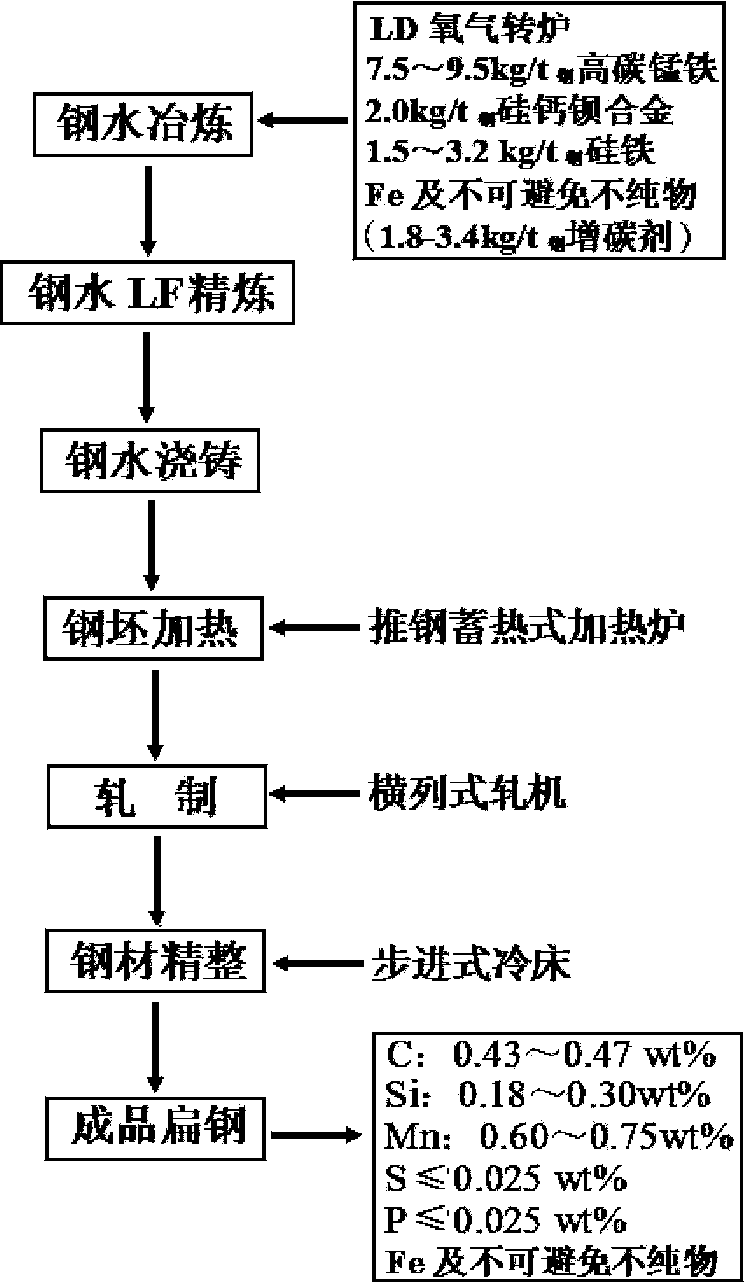

Steel flat for high-performance farm tools and working tools and processing method of steel flat

The invention discloses steel flat for high-performance farm tools and working tools and a processing method of the steel flat. The steel flat is composed of the following components in percentage by weight: 0.43-0.47 wt% of C, 0.18-0.30 wt% of Si, 0.60-0.75 wt% of Mn, not larger than 0.025 wt% of S, not larger than 0.025 wt% of P, and the balance of Fe and inevitable impurities. The steel flat is prepared by the procedures of molten steel smelting and deoxidation alloying, molten steel LF furnace refining, molten steel casting, billet heating, rolling and steel finishing. The 90mm*16mm steel flat for hoe and shovel tools is obtained by the processing method disclosed by the invention, the mechanical processing property of the steel flat is better than that of GB / T699 standard, and the section of the steel flat is rectangular. Compared with 45 steel for hoe and shovel tools produced by a complete continuous-rolled bar rolling mill process, the steel flat disclosed by the invention has the advantages that the rolling cost is reduced by more than 20 Yuan / ton, and the steel flat has the advantages of low production cost, strong process adaptability and controllability, excellent comprehensive product performance and the like, thereby being capable of well meeting the requirements of city greening and farm production development.

Owner:WUKUN STEEL

Torsional vibration reducing device

ActiveUS9803718B2Reduce sliding frictionIncrease the lengthRotating vibration suppressionTorsional vibrationMechanical engineering

A torsional vibration reducing device is provided. The torsional vibration reducing device includes a rotating body, a plurality of rolling bodies, and a connection member. The connection member connects the plurality of rolling bodies, and at least two contact portions are positioned on an inner surface of each of the plurality of accommodating portions, a portion of an outer peripheral surface of each of the plurality of rolling bodies being positioned in each of the plurality of accommodating portions, and the outer peripheral surface of each of the plurality of rolling bodies being configured to come into point contact with the contact portions in the circumferential direction of the rotating body.

Owner:TOYOTA JIDOSHA KK

Method for employing large cross-section continuous casting round billet to roll round steel bar

InactiveCN104190706AOvercoming the defects of easy-to-fall steelHigh strengthMetal rolling arrangementsReduction ratioContinuous casting

The invention belongs to the field of iron steel processing and particularly relates to a method for employing large cross-section continuous casting round billet to roll a round steel bar. The method for employing the large cross-section continuous casting round billet to roll the round steel bar comprises the following steps: 1) clamping plates arranged on pushing beds are adopted to align the large cross-section continuous casting round billet with a rolling trough; the large cross-section continuous casting round billet is sent to a rough mill for rolling, so as to produce intermediate billet; from the third rolling pass of the rough mill, steel turning is carried out once in each odd-numbered pass ; 2) the intermediate billet is sent to finishing mills for rolling with 4-6 pressing passes, so as to produce finished round steel bar; the diameter Phi of the finished round steel bar is in a scope that is larger than or equal to 120 mm and is less than or equal to 150 mm; the rolling pass of the rough mill is the eleventh pass; the rolling passes of the finishing mills are 4-6 passes; or the diameter Phi of the finished round steel bar is in a scope that is larger than or equal to 160 mm and is less than or equal to 280 mm; the rolling pass of the rough mill is the thirteenth pass; the rolling passes of the finishing mills are 4-6 passes. The method for employing the large cross-section continuous casting round billet to roll round steel bar has the advantages of shallow-slot large rolling reduction cogging, high rolling efficiency, low rolling cost and energy conservation. The method for employing the large cross-section continuous casting round billet to roll round steel bar has an outstanding advantage that under equal specification, the reduction ratio of the finished round steel bar is large and the quality is good.

Owner:SHANDONG IRON & STEEL CO LTD

Centrifugal casting mold composite end cover and method for carrying out composite roll centrifugal casting through same

The invention discloses a centrifugal casting mold composite end cover and a method for carrying out composite roll centrifugal casting through the same. The centrifugal casting mold composite end cover comprises a casting mold end cover and an additional end cover. The casting mold end cover and the additional end cover are movably connected through a rotary buckle device composed of screw holes, bolts and protruding clamping openings. The method for carrying out composite roll centrifugal casting through the centrifugal casting mold composite end cover comprises the steps that the centrifugal casting mold composite end cover is installed at the two ends of a metal cast mold, a thickened roll working layer is centrifugally cast, and the roll core portion and neck are statically cast in a mold assembling mode after the additional end cover is dismantled, wherein the specific steps comprise casting sand preparation, casting tool preparation and preheating, metal casting mold coating, liquid metal treatment, working layer centrifugal casting, static casting of the core potion and roll neck, and cooling machining. The centrifugal casting mold composite end cover and the method for carrying out composite roll centrifugal casting through the same have the advantages that installation is easy and convenient, the thickened working layer is formed during centrifugal casting, the roll service life is prolonged, the rejection rate and cost are reduced, and meanwhile casting and machining of the roll core portion and neck are not affected.

Owner:江苏环宇冶金科技有限公司

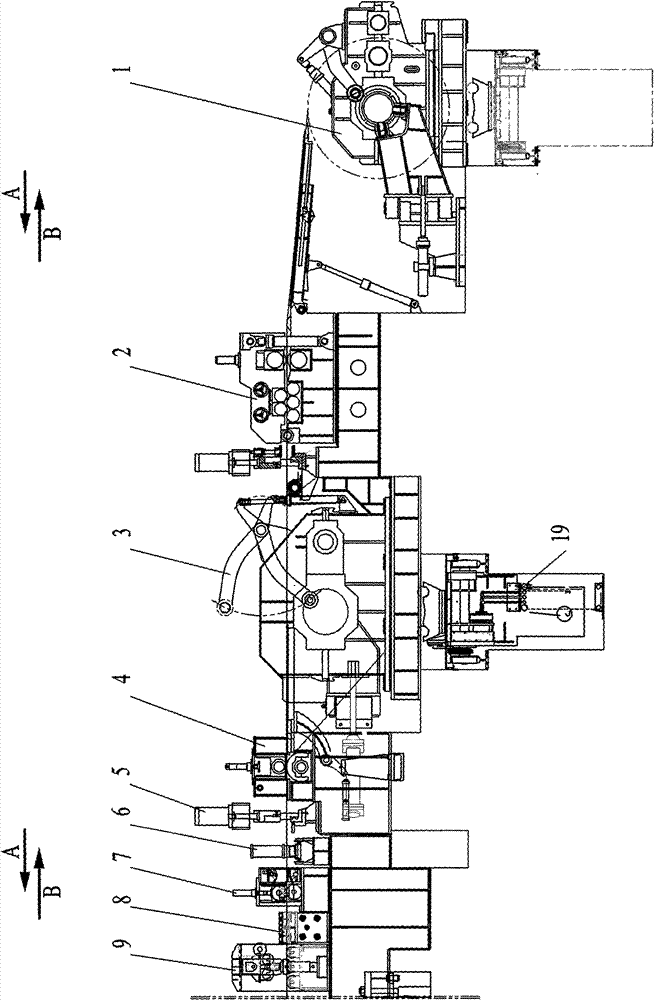

Vertical loop device for high-speed wire rod rolling mill

InactiveCN103182395AAvoid scratchesImprove work efficiencyFlexible work arrangmentsMetal rolling arrangementsWire rodEngineering

The invention discloses a vertical loop device for a high-speed wire rod rolling mill. The device is arranged between an upstream rolling mill and a downstream rolling mill, and comprises a loop rising roller, a guide roller, and loop side plates arranged on two sides of the guide roller, wherein a guide slot with a guide centering function is formed in the roller surface of the guide roller. A rolled piece can always operate at the middle position of a loop rolling channel by the guide slot, the rolled piece is prevented from being scratched by the loop side plates, and the product quality is improved; the wire scratching phenomenon is eliminated, the rolling fault time is greatly reduced, and the working efficiency of the rolling mill is improved; and the wear of the loop side plates and a downstream rolling mill inlet guide and protection part is reduced, the service life is prolonged, and the rolling cost is reduced.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

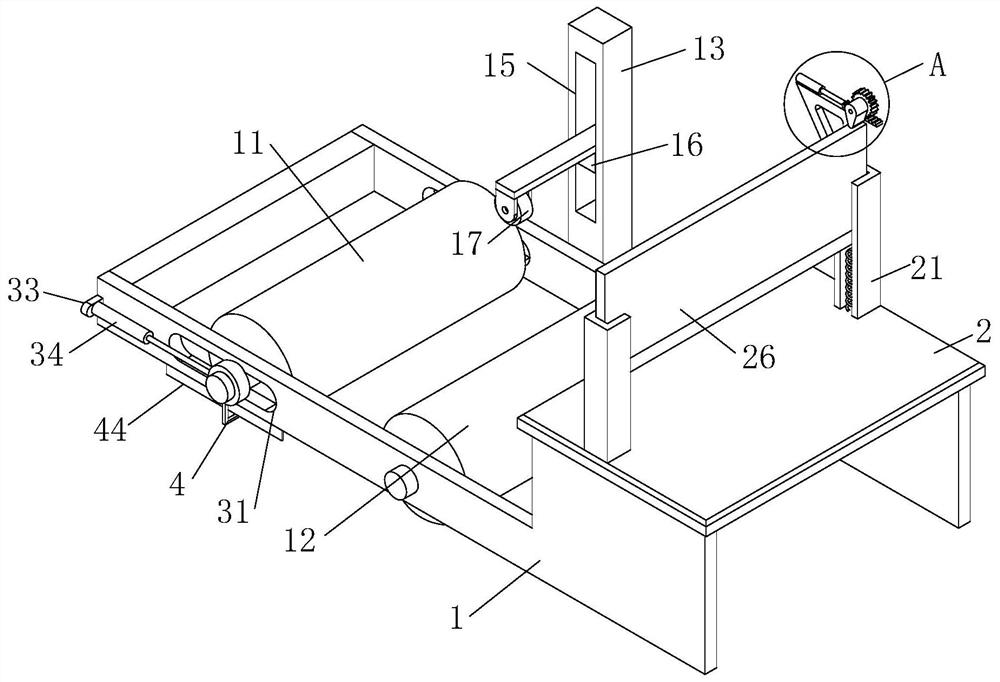

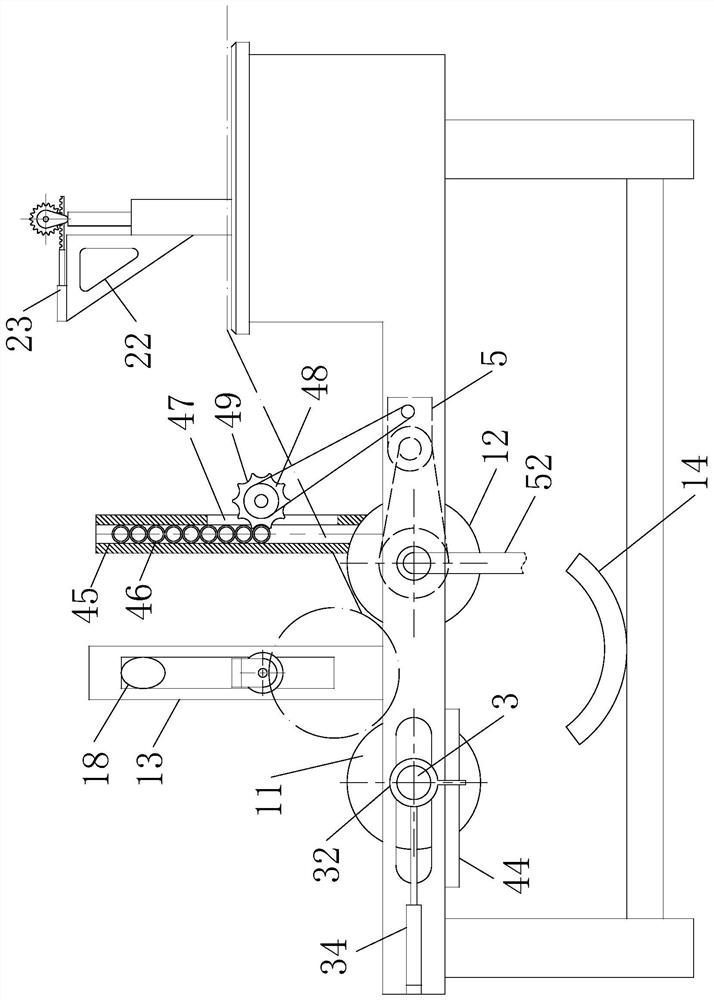

Efficient rolling machine for garment accessories

InactiveCN112249770AReduce rolling costsReduce human care costsSevering textilesWebs handlingGear wheelEngineering

The invention belongs to the technical field of garment rolling machines, and particularly relates to an efficient rolling machine for garment accessories. The efficient rolling machine comprises a rack, wherein a driving roller and a driven roller are rotationally connected to the rack; a sliding block is slidably connected in a first sliding groove formed in a vertical rod, and a guide wheel isrotationally connected to the side surface of the sliding block through a cross rod; an air bag is arranged at the top of the first sliding groove; a platform is fixedly connected to the rack, a pairof guide rails are fixedly connected to the two sides of the top of the platform, a cutter is slidably connected between the two guide rails, and springs are fixedly connected to the positions, corresponding to the guide rails, of the two sides of the bottom of the cutter; a first air cylinder is fixedly connected to the tops of the guide rails through a supporting plate, and a rack is fixedly connected to one end of a piston rod of the first air cylinder; a gear is rotationally connected to the position, corresponding to the rack, of the tops of the guide rails through a support; and a cam isfixedly connected to the side, close to the cutter, of the gear. According to the efficient rolling machine, after the diameter of a cloth roll formed by the garment accessories is increased, the guide wheel and the sliding block are driven to slide upwards, the cutter is driven to slide downwards and cut off cloth, then the garment accessories are quantitatively rolled, and the manual nursing cost is reduced.

Owner:温州培堡尼服装有限公司

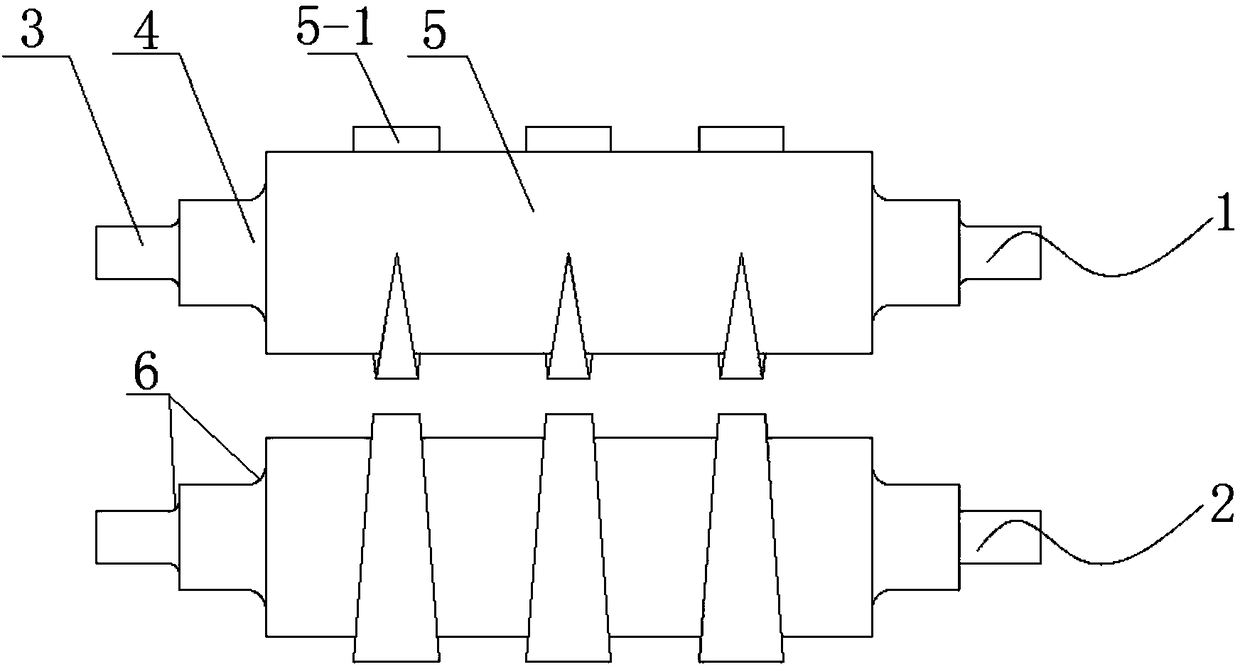

Novel graphite semi-steel bar and finished product roller and production method thereof

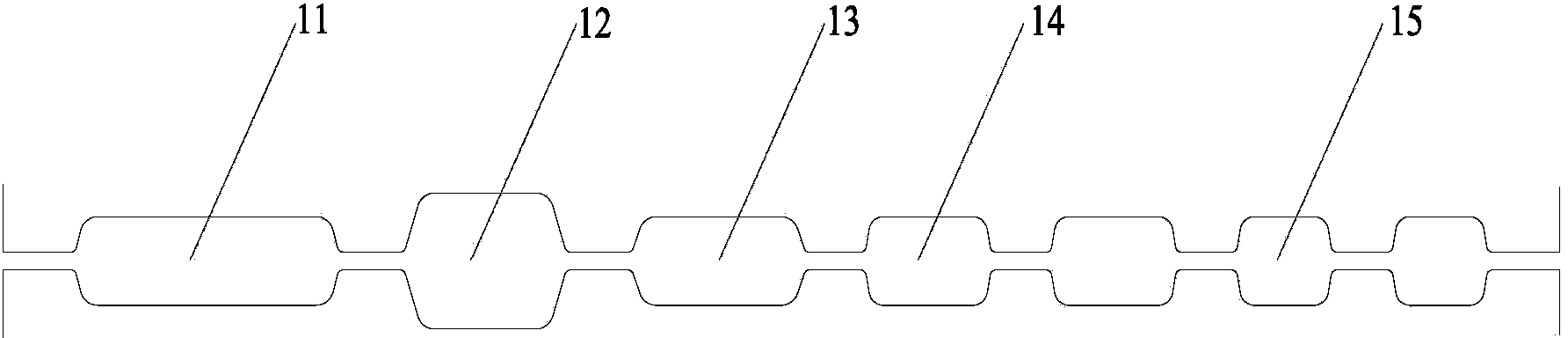

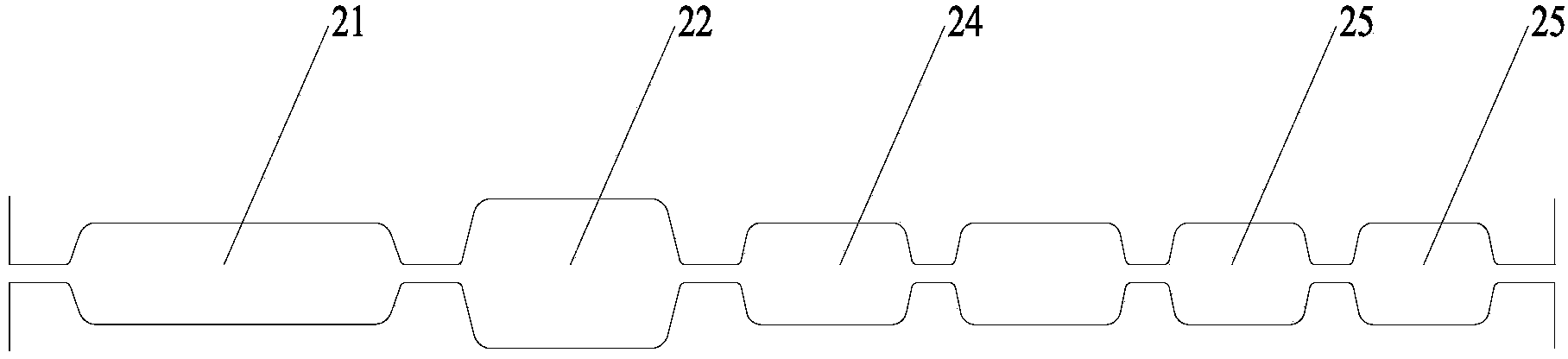

PendingCN108165894AImprove microstructureImprove plasticityFurnace typesRollsGraphitePulp and paper industry

The invention relates to a novel graphite semi-steel bar and finished product roller assembly, which comprises an upper roller and a lower roller. The upper roller comprises an upper roller body, andan upper roller neck and an upper bearing retainer roll neck located on two ends of the upper roller body; the lower roller comprises a lower roller body, and a lower roller neck and a lower bearing retainer roll neck arranged correspondingly; 2 to 5 'U'-shaped grooves surrounding the upper roller body are arranged on the upper roller body at intervals; 2 to 5 inverted 'U'-shaped bulges surrounding the lower roller body are arranged on the lower roller body at corresponding intervals; a smooth platform is arranged between each two adjacent grooves or bulges; and the upper roller body and the lower roller body are mutually meshed. According to the novel graphite semi-steel bar and finished product roller assembly provided by the invention, through the inverted 'U'-shaped bulges and the 'U'-shaped grooves of the roller bodies, bars and parts with required shapes are rolled, and meanwhile, through adjusting a distance between the two rollers, the thicknesses of the rolled bars and partsare adjusted, so that the production efficiency is improved.

Owner:常州市瑞宏轧辊有限公司

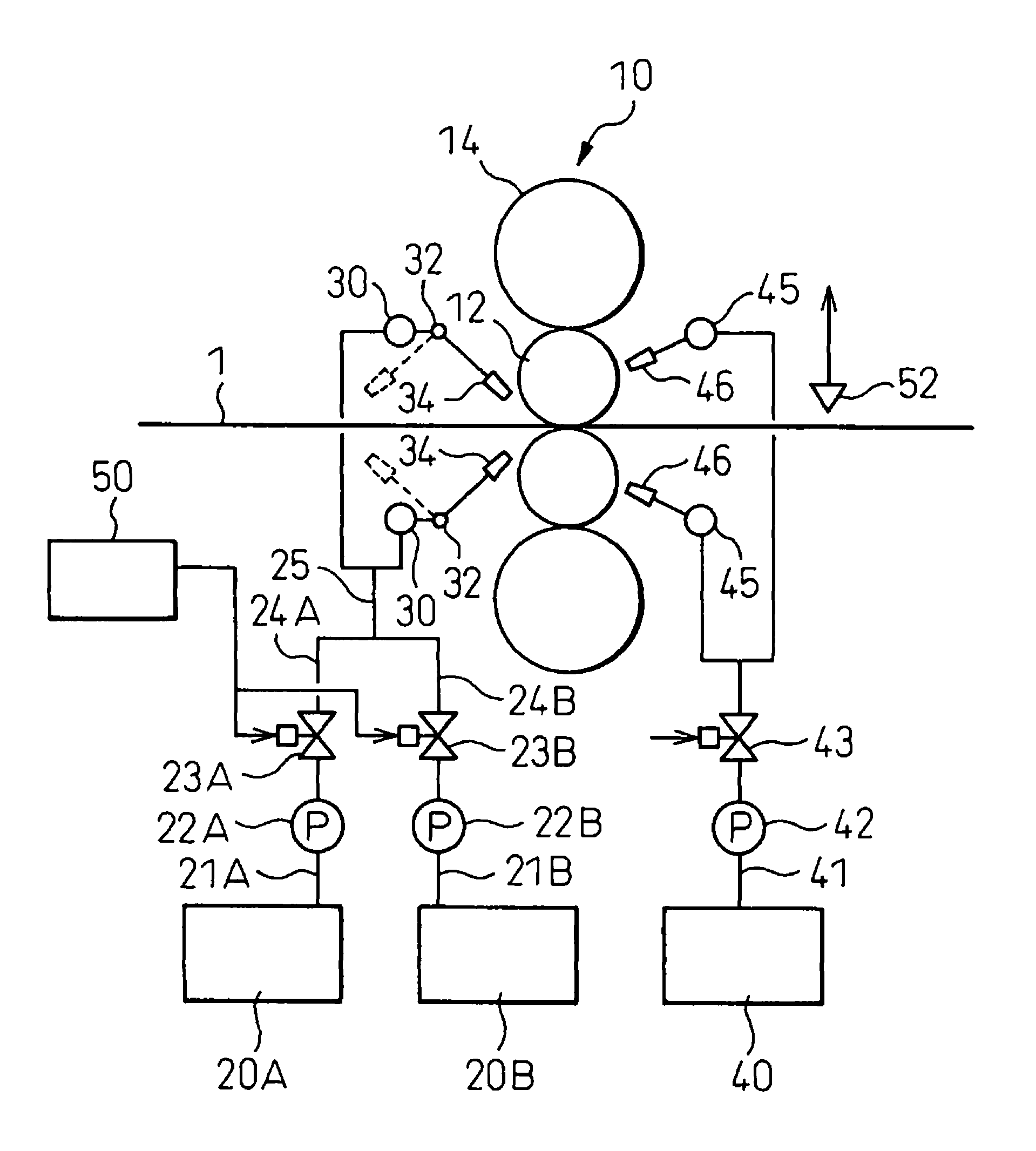

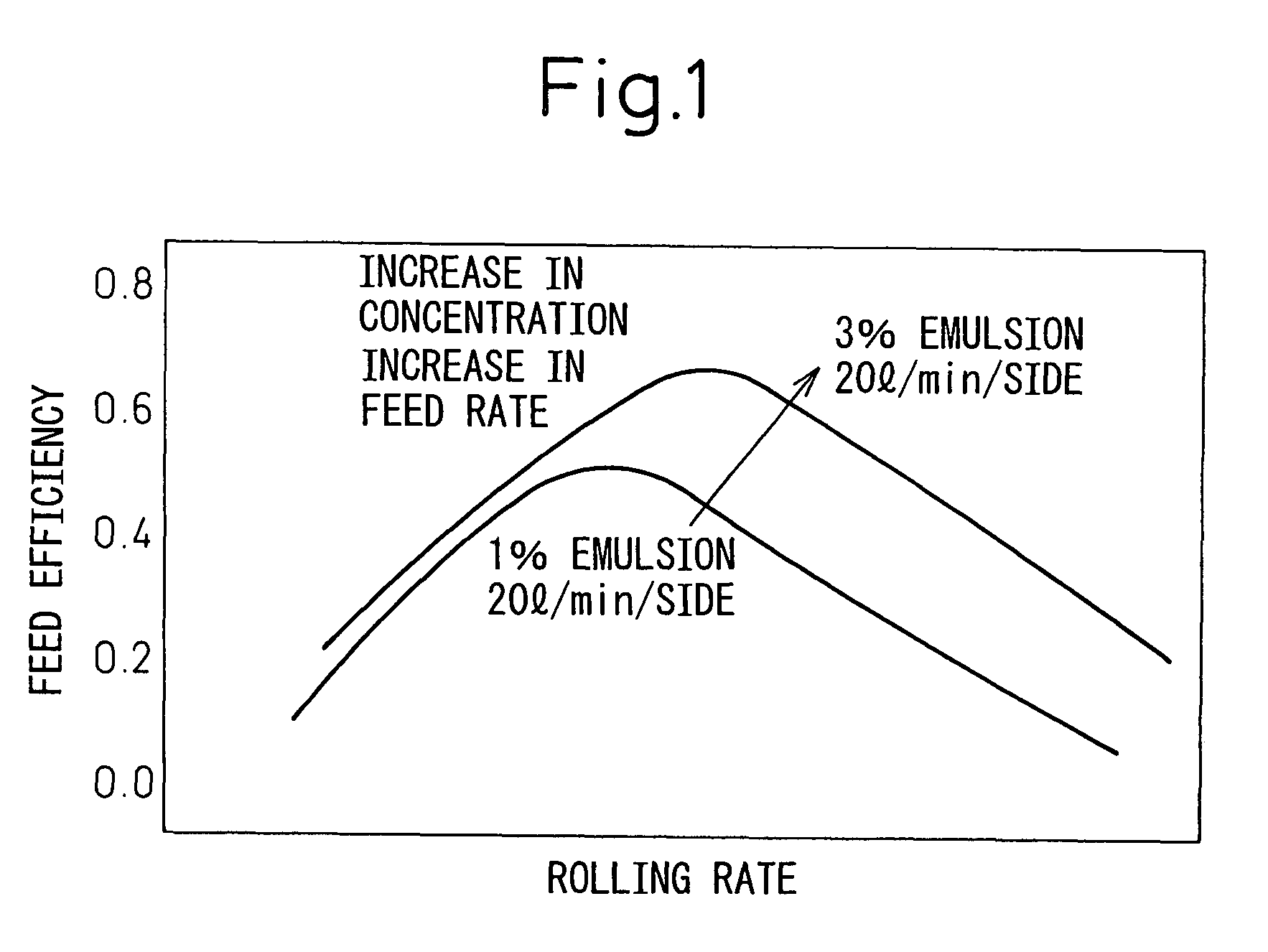

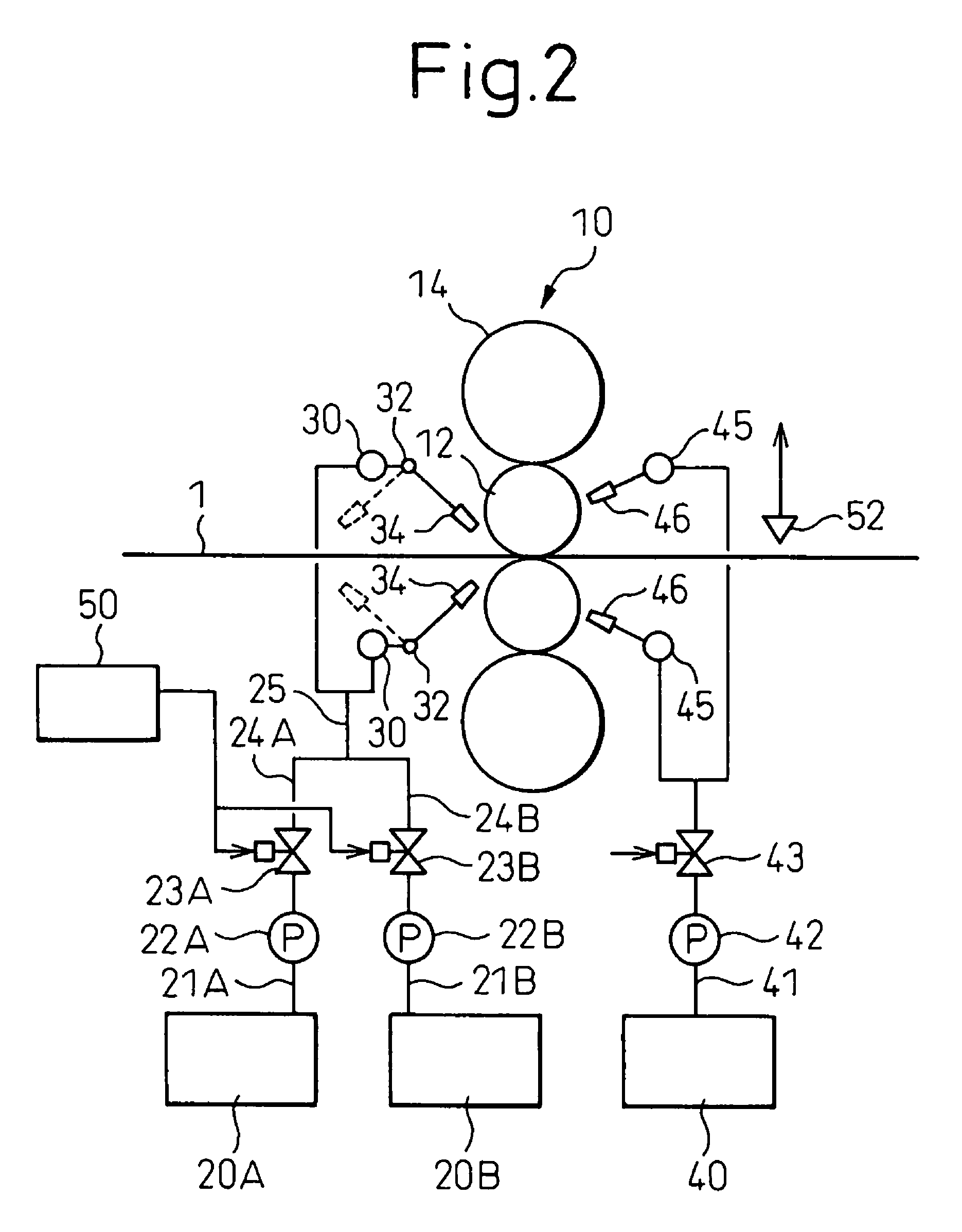

Method of supplying lubricating oil in cold-rolling

ActiveUS8047035B2Smooth rollingReduce rolling costsRolling equipment maintainenceRoll mill control devicesThermodynamicsEmulsion

A method of supplying lubricating oil in cold-rolling by emulsion lubrication, characterized by comprising:using a constant (supply efficiency) obtained under conditions of a specific rolling rate, emulsion supply, emulsion concentration, emulsion temperature, plateout length, rolled material width or roll barrel length, rolling load, grade of the rolled material, and type of lubricating oil and oil film thickness at the time of neat lubrication realized under the specific rolling lubrication conditions to estimate the oil film thickness realized by emulsion lubrication under the specific rolling lubrication conditions andcontrolling at least one of the emulsion supply, emulsion concentration, emulsion temperature, and plateout length so that the estimated oil film thickness matches with the target oil film thickness.

Owner:NIPPON STEEL CORP +1

Rolling method for controlling tissue homogeneity of high strength hot rolled steel plate

ActiveCN108941213AControl UniformityLow costTemperature control deviceMetal rolling arrangementsTemperature controlSheet steel

The invention discloses a rolling method, in particular a rolling method for controlling tissue homogeneity of a high strength hot rolled steel plate, and belongs to the technical field of steel platerolling processes. The invention provides the rolling method for controlling tissue homogeneity of the high strength hot rolled steel plate effectively by improving the rolling step and the parameters thereof. The rolling method comprises the following steps: uniform temperature heating and temperature different controlling discharging, intermediate speed rough rolling of a four reversible reversing roughing mill, surface temperature control finish rolling by a seven-rack continuous mill and cooling by a laminar cooling unit which controls inner and outer temperature conditions. In the intermediate speed rough rolling process of the four reversible reversing roughing mill, a high pressure water descaling nozzle at the inlet of the four reversible reversing roughing mill is opened to descale and cool the surface of strip steel, so that the surface temperature of the strip steel is reduced by 80-120 DEG C.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

Lubricating oil for cold rolling of tubular products and preparation method of lubricating oil

ActiveCN107446678AEasy to cleanImprove antioxidant capacityLubricant compositionVegetable oilHeating time

The invention relates to lubricating oil for cold rolling of tubular products and a preparation method of the lubricating oil. The preparation method comprises the steps of firstly weighing 5-60 parts of base oil and 2-35 parts of oxidized vegetable oil in parts by weight, adding the base oil and the oxidized vegetable oil into a container provided with a stirring device and a heating device, stirring at a heating state, adding 0.5-20 parts of vegetable oil, 1-10 parts of an oxidant, 0.1-20 parts of an oily lubricant, 0.2-15 parts of an extreme pressure anti-wear reagent and 0.1-15 parts of an anti-rusting agent, continuing to heat and stir, controlling the heating temperature, heating time and stirring speed during the heating and the stirring, adding 1-15 parts of a surfactant, heating, stirring, controlling the heating temperature, heating time and stirring speed during the heating and the stirring, cooling, and discharging, so as to obtain the lubricating oil for the cold rolling of the tubular products. The lubricating oil has the beneficial effects that the extreme pressure wear resistance is excellent; process links are few, and the comprehensive rolling cost is low; and the process flow is simple, and the process requirements are not strict.

Owner:SUZHOU MEIBEIER IND OIL

Supporting steel for containment vessel of nuclear power station and manufacturing method thereof

InactiveCN111363985AGuaranteed toughness indexGuaranteed performanceNuclear powerProcess engineering

The invention provides supporting steel for a containment vessel of a nuclear power station and a manufacturing method thereof. The steel comprises the following components in percentage by weight: 0.10%-0.16% of C, 0.25%-0.45% of Si, 1.40%-1.65% of Mn, 0.45%-0.65% of Ni, 0.20%-0.50% of Cr, 0.20%-0.55% of Mo, 0.02%-0.04% of Alt, 0.05%-0.10% of Cu, 0.03-0.05% of V, 0.005-0.020% of Ti, 0.008% or less of P, 0.005% of less of S, 0.010% or less of N, and the balance being Fe and unavoidable impurities. The manufacturing method comprises smelting, continuous casting, heating, rolling and heat treatment. The thickness of a steel plate produced from the steel is 30-80 mm, the steel plate in the quenched and tempered state, simulated post-weld heat treatment state and 200 DEG C high temperature state completely meets the requirements of technical indicators, and meanwhile -40 DEG C impact absorption energy is still remained at a high level.

Owner:ANGANG STEEL CO LTD +1

Method for preventing surface oxide film of nichrome roller from being peeling-off

InactiveCN100434200CLittle effect on cold workabilityGood effectTemperature control deviceRolling equipment maintainenceChromium nickelSurface roughness

A method for preventing the surficial oxide film of Ni-Cr roller from being stripped includes such steps as blooming the conticast billet of ferritic stainless steel at 1150 + / - 50 deg.C to become intermediate billet at 1020-1050 deg.C and with a thickness less than 35 mm, arranging an insulating hood between blooming and finish rolling, and finishing rolling of stainless steel band at a temp higher than 950 deg.C by three passes with relative surface roughness of rollers (0.9 microns, 0.6 microns and 0.6 microns) and relative maximal deformation rate (42%, 38% and 36%).

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

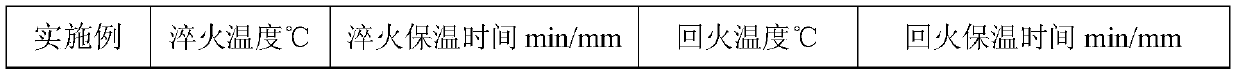

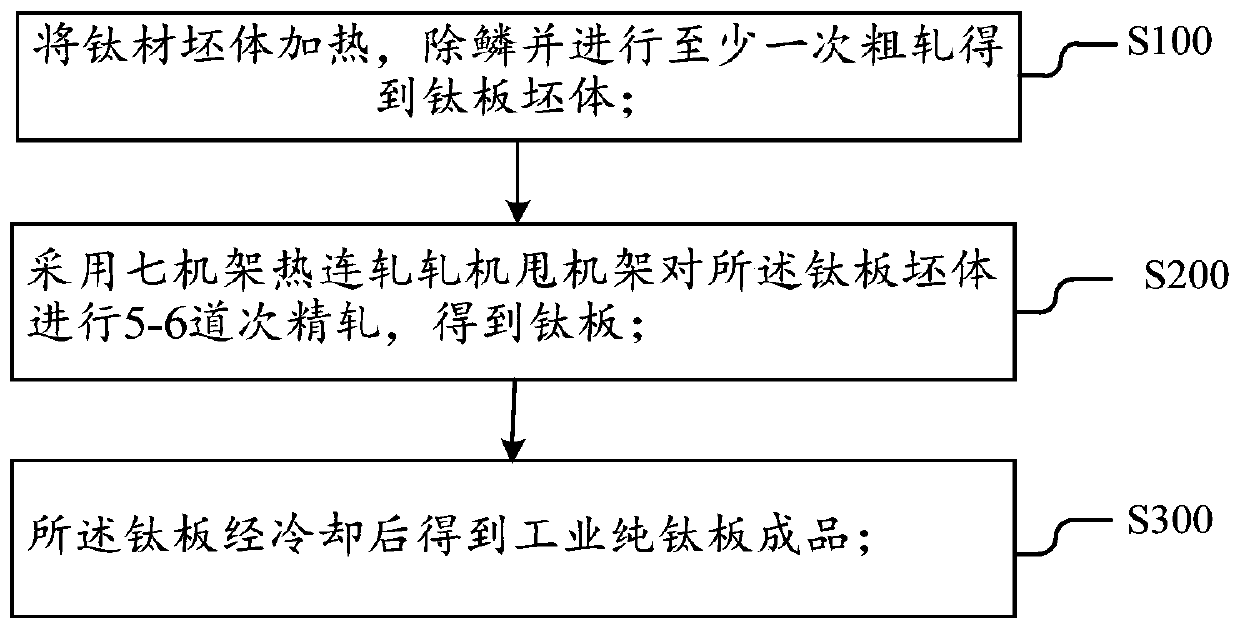

Production method for industrial pure titanium plate

ActiveCN110538872ALow costImprove performanceMetal rolling arrangementsReduction rateContinuous rolling

The invention discloses a production method for an industrial pure titanium plate. The production method for the industrial pure titanium plate comprises the steps that (1), a titanium material blankbody is heated, descaled and subjected to at least one time of rough rolling, and a titanium plate blank body is obtained; (2), 5-6 passes of finish rolling is conducted on the titanium plate blank body by adopting a seven-rack hot continuous rolling mill throwing rack, and a titanium plate is obtained; and (3), after the titanium plate is cooled, an industrial pure titanium plate finished productis obtained. By adopting the production method, the titanium plate rolling number can be decreased, the reduction rate of each pass is increased, grains are refined, and the properties of the titanium plate are improved; and meanwhile, rolling consumed oil and cooling water are reduced while the rolling number is decreased, and the rolling cost is reduced.

Owner:FOSHAN POLYTECHNIC

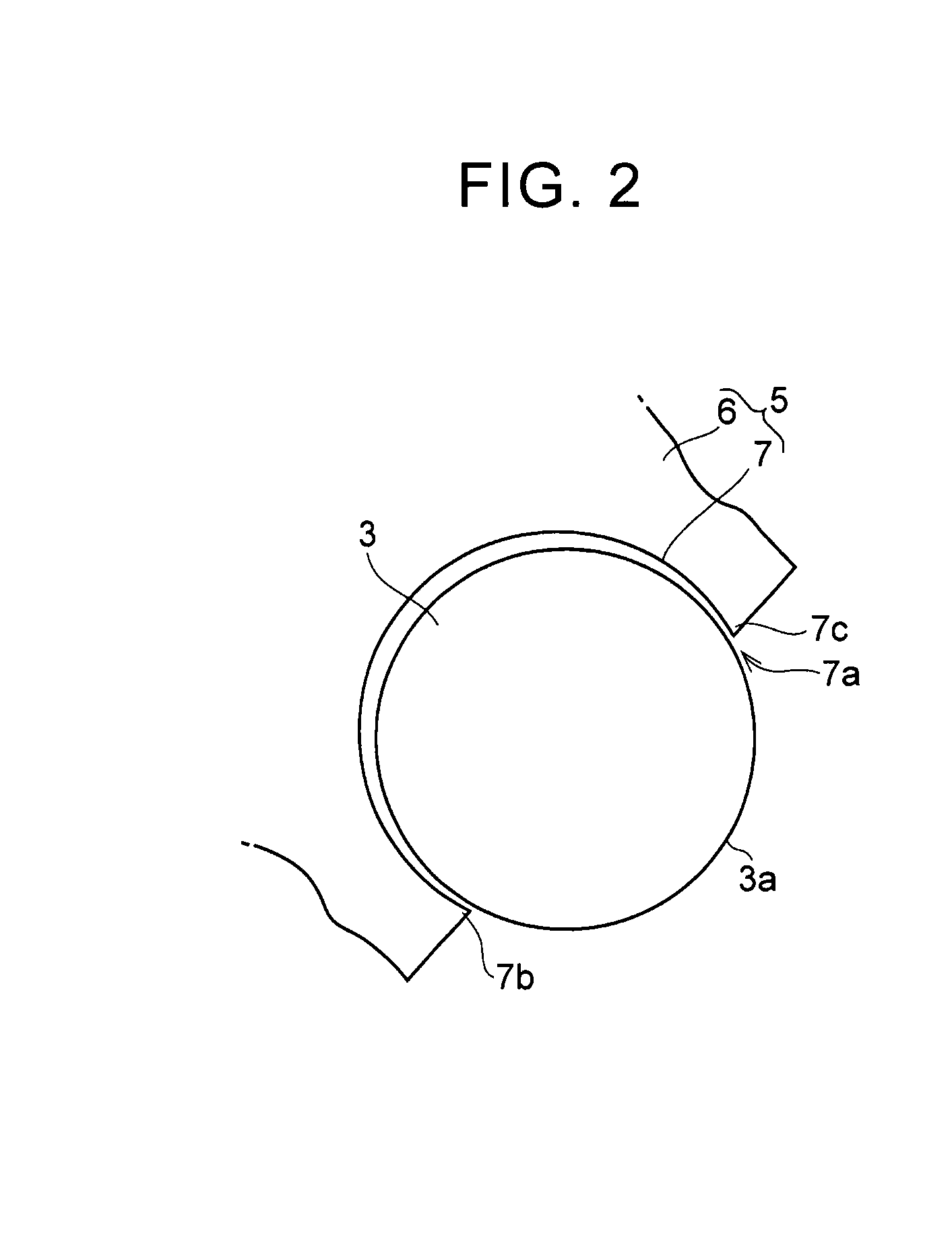

Torsional vibration reducing device

ActiveUS20160169319A1Reduce sliding frictionImprove damping performanceRotating vibration suppressionShock absorbersReciprocating motionTorsional vibration

A torsional vibration reducing device includes a rotating body, rolling bodies, and a connection member. The rotating body includes guide holes, and the connection member includes accommodating portions that has at least two contact portions. The accommodating portions are positioned in the guide holes, and the guide holes accommodate the rolling bodies. The accommodating portions are configured to hold the outer peripheral surface of each of the rolling bodies with the contact portions, in a direction in which the rolling body reciprocates.

Owner:TOYOTA JIDOSHA KK

Reversible cold-rolling equipment and production method thereof

InactiveCN101817016BSatisfy the bite conditionNo possibility of skewMetal rolling stand detailsRolling mill drivesWork rollStrip steel

The invention discloses reversible cold-rolling equipment, which comprises a main rolling mill, and a front tension device (9), a front alignment device (8), a rear tension device (11) and a rear alignment device (12) positioned on front and rear sides of the main rolling mill. The middle roll of the eight-roll rolling mill is a transmission roll, the transmission side of two lower supporting rolls (10-7) is provided with a lower rolling wire adjusting device connected with an eccentric shaft thereof, and the lower rolling wire adjusting device comprises a box body (20), a driving mechanism and two sets of worm gear transmission mechanisms placed in the box body. The invention also discloses a production method for the reversible cold-rolling equipment, which comprises working roll opening adjustment before rolling, low-speed direct bite of a to-be-rolled strip steel head, high-speed rolling operation and tensioned low-speed rolling operation of a to-be-rolled strip steel tail. The method can meet the bite condition of the rolling mill, realizes a reversible cold-rolling process without leading strip, has high rolling stability and high production efficiency, and is particularly suitable for reversibly cold-rolling thin specification strip steels.

Owner:唐山一重机械制造有限公司 +2

Nuclear container steel with tensile strength of more than 690MPa level and production method

The invention discloses a nuclear container steel with tensile strength of more than 690MPa level and a production method. The steel comprises the following chemical components in percentage by weight: less than or equal to 0.08 percent of C, 0.15 to 0.50 percent of Si, 1.30 to 1.60 percent of Mn, 0.01 to 0.05 percent of Alt, 0.42 to 0.70 percent of Ni, 0.32 to 0.60 percent of Mo, 0.10 to 0.30 percent of Cr, 0.01 to 0.04 percent of Ti, less than or equal to 0.008 percent of P, less than or equal to 0.005 percent of S, less than or equal to 0.005 percent of N, less than or equal to 0.03 percent of Cu, less than or equal to 0.007 percent of V, less than or equal to 0.005 percent of Sn, less than or equal to 0.005 percent of Sb, less than or equal to 0.010 percent of As, less than or equal to 0.005 percent of Pb, and the balance of Fe and inevitable impurities, wherein P, S, N, Cu, V, Sn, Sb, As and Pb are used as controlled elements. The production method comprises the following steps of: smelting clean steel, performing continuous casting, cooling casting blank to room temperature, heating the casting blank, performing heat preservation, rough rolling and finish rolling, quenching,tempering, and naturally cooling to room temperature. The steel can improve the safety and the reliability in the operation of a nuclear power plant, and has the advantages of high strength, low welding crack sensitivity, low radiation embrittlement effect and excellent tensile property and welding property at the temperature of 20 DEG C below zero.

Owner:武钢集团有限公司

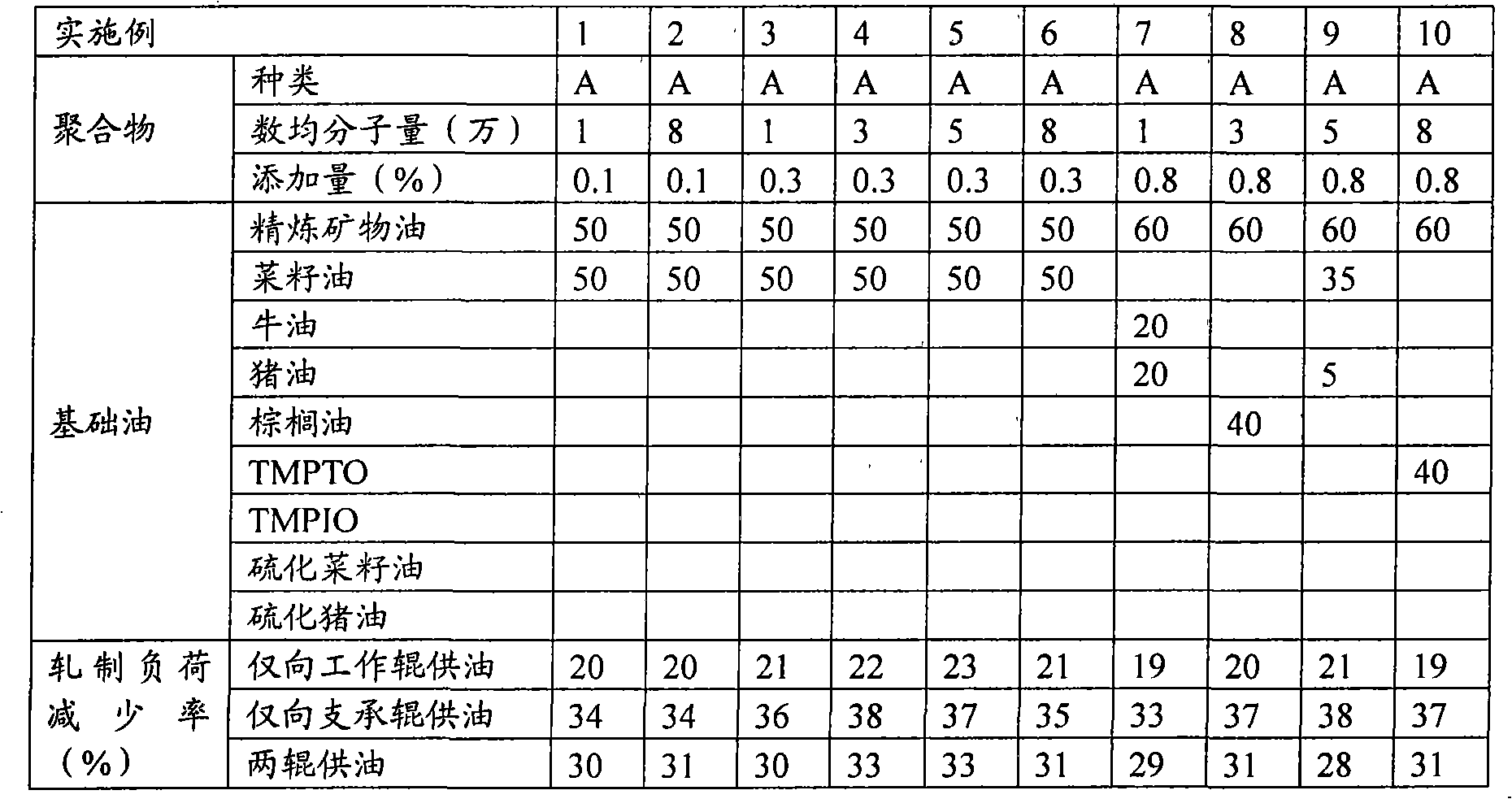

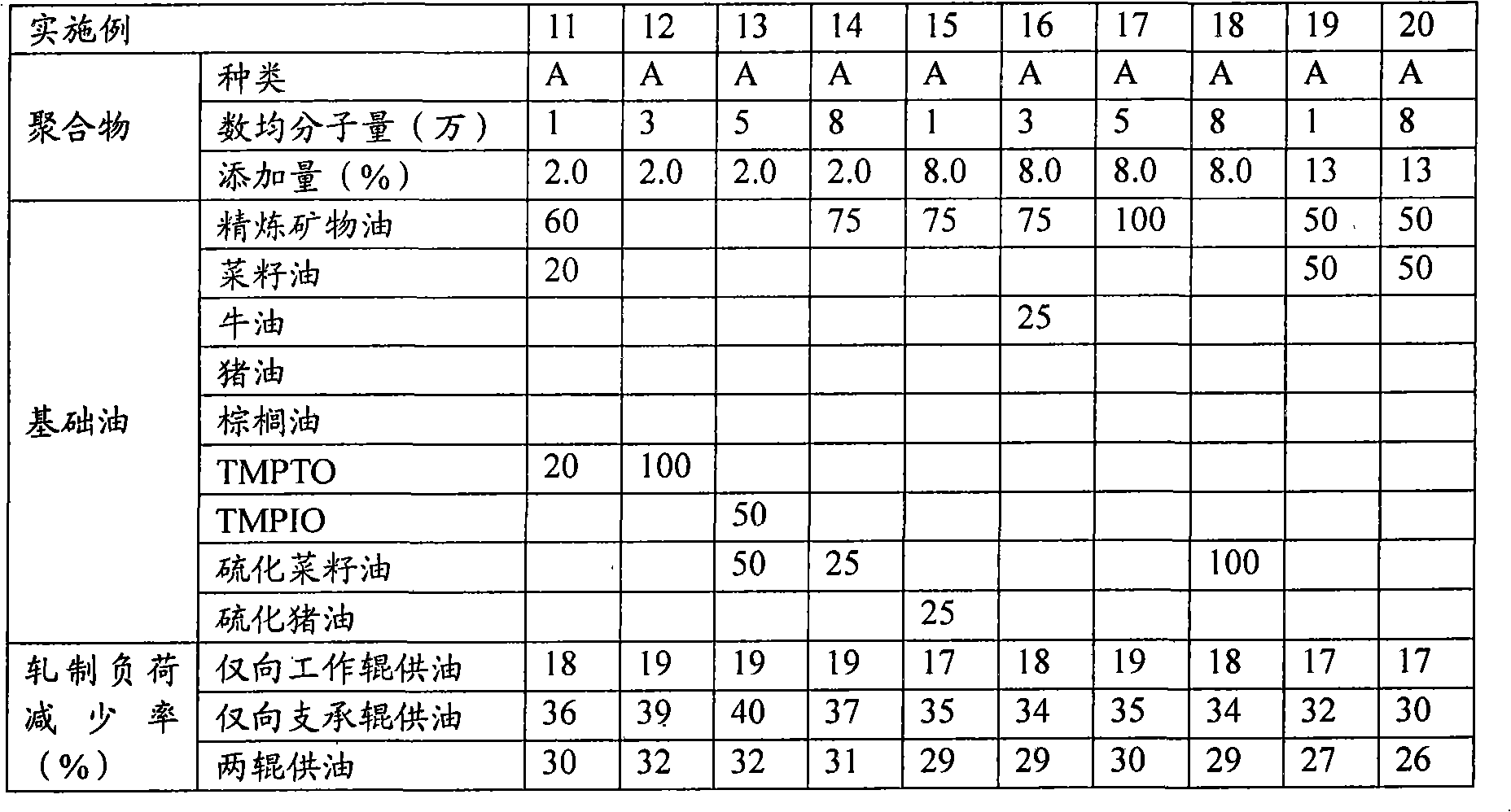

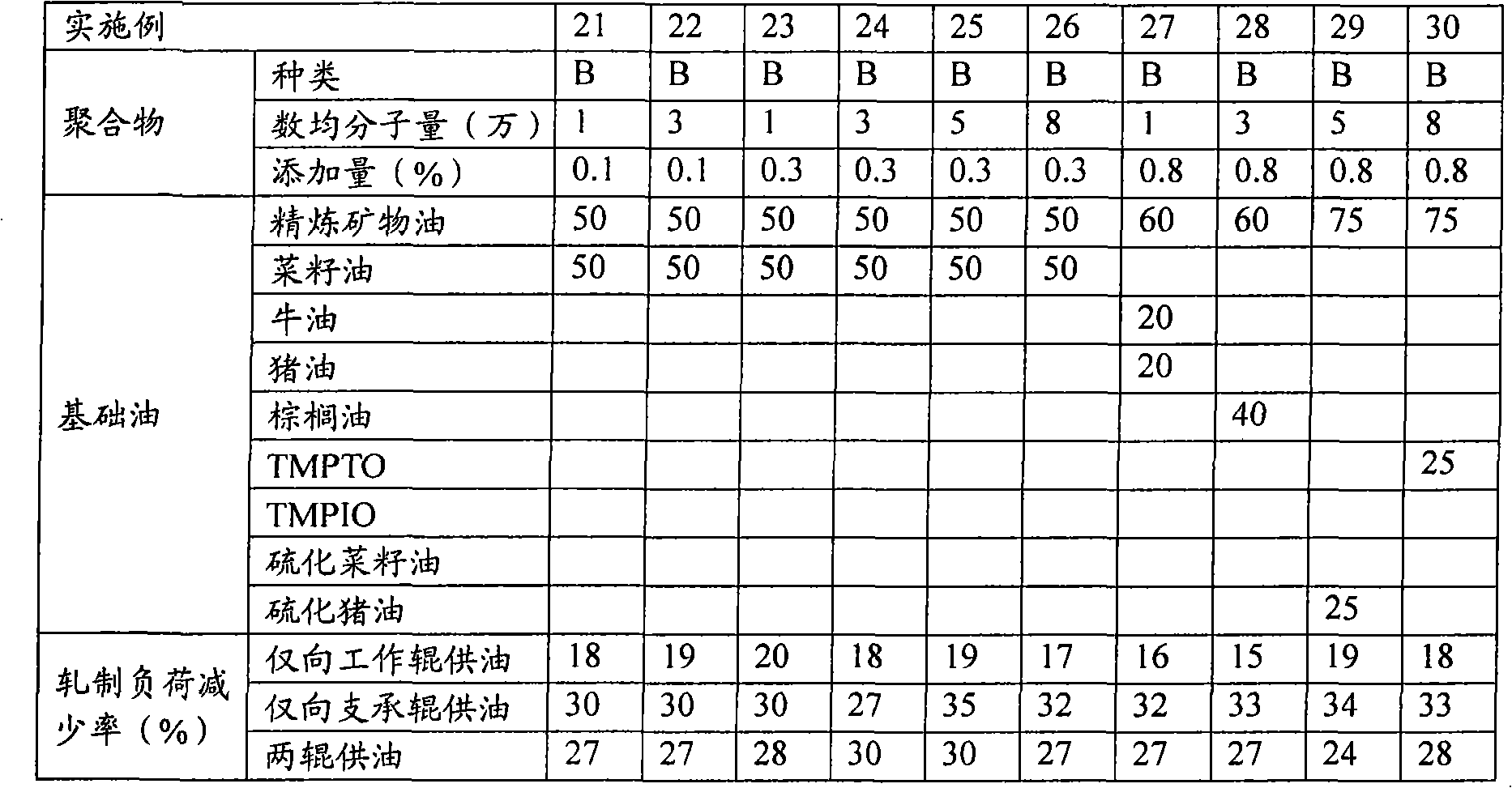

Hot rolling oil for steel member and method for hot rolling steel member

InactiveCN101605878AReduce rolling loadReduce rolling costsCounter-pressure devicesRollsMetallurgyEthylene Homopolymers

Disclosed is a hot rolling oil which enables to reduce a rolling cost by effectively decreasing a rolling load when a steel member is heated and rolled within a temperature range of 200-1200 DEG C. Also disclosed is a method for hot rolling a steel member by using such a hot rolling oil. Specifically disclosed is a hot rolling oil containing a base oil and at least one polymer selected from the group consisting of isobutylene homopolymers and isobutylene copolymers having a number average molecular weight of 8,000-100,000. Also specifically disclosed is a method for hot rolling a steel member, which is characterized in that the hot rolling oil is fed by a water injection system.

Owner:KYODO YUSHI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com