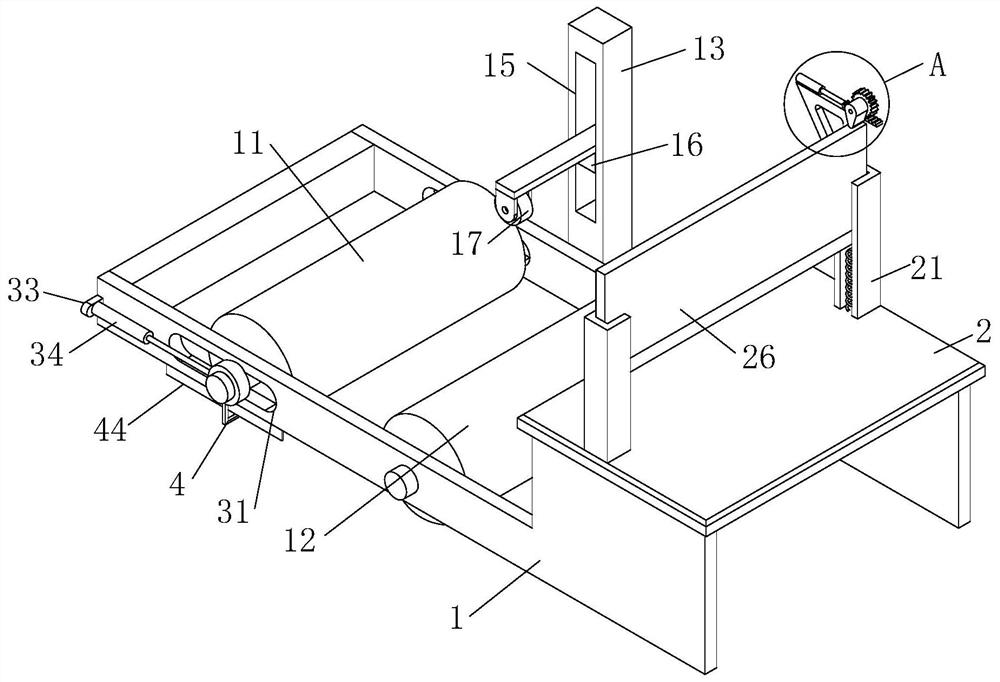

Efficient rolling machine for garment accessories

A technology of rolling machine and auxiliary materials, which is applied in the direction of winding strips, thin material processing, transportation and packaging, etc., can solve the problems of manual supervision, low quantitative accuracy, and increase the cost of manual care, so as to reduce the cost of rolling, reduce Effects of care costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

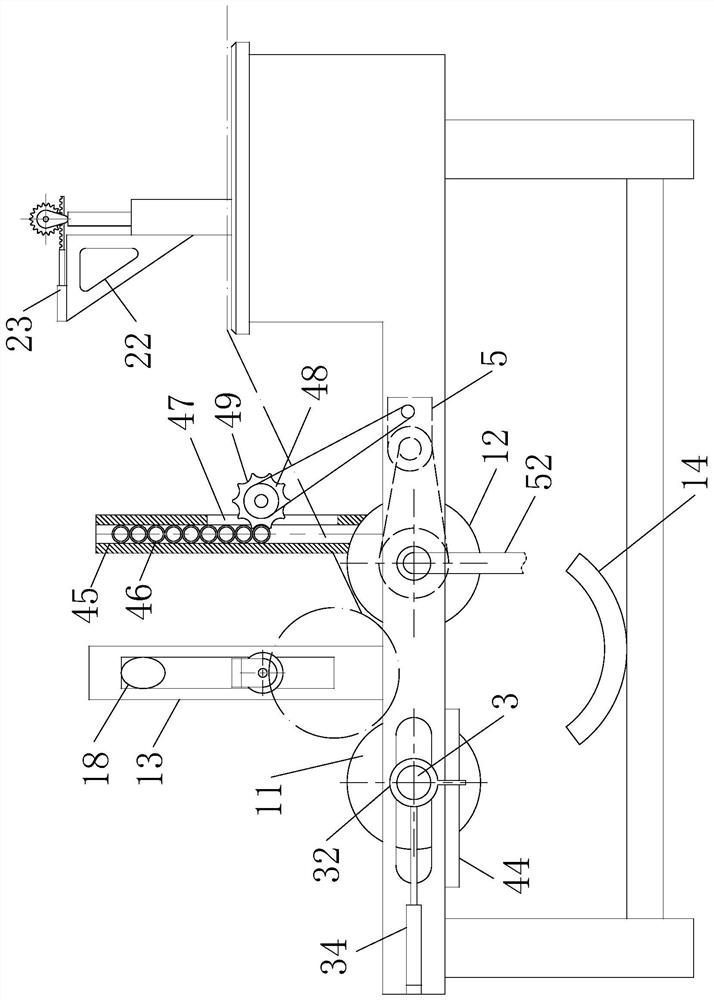

[0027] As an embodiment of the present invention, a No. 2 chute 31 is arranged horizontally on the frame 1 corresponding to the rotating shaft 3 of the driving roller 11; the rotating shaft 3 is slidably connected to the No. 2 chute 31; The sleeve is provided with a shaft sleeve 32, and the shaft sleeve 32 is rotationally connected with the rotating shaft 3; a support 33 is fixedly connected to the frame 1 on one side of the shaft sleeve 32, and a No. 2 cylinder is fixedly connected between the support 33 and the shaft sleeve 32 34; the No. 2 cylinder 34 is connected with an air intake pipe 35, and the air intake pipe 35 communicates with the air bag 18 through the pipe. After the air intake pipe 35 is inflated, it drives the shaft sleeve 32 and the driving roller 11 to slide away from the driven roller 12; when the air bag 18 When under pressure, a part of the compressed air generated in the air bag 18 is filled into the intake pipe 35 through the pipeline, and then drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com