Reversible cold-rolling equipment and production method thereof

A technology for equipment and strips, applied in the field of reversible cold rolling equipment, can solve the problems of bearing consumption and bearing damage, and achieve the effects of improving the yield, ensuring quality and reducing rolling costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

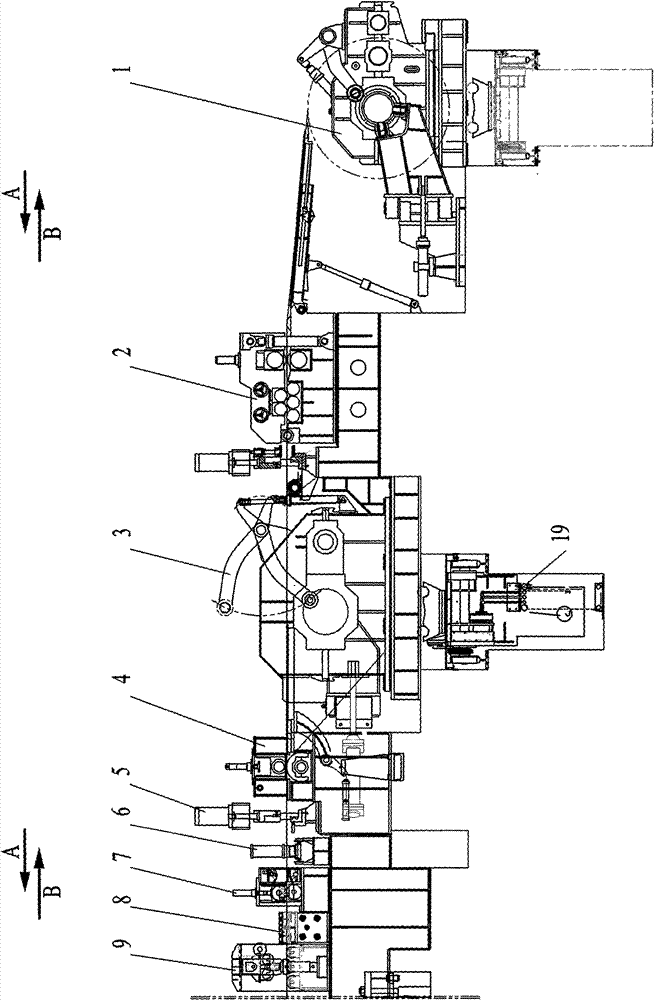

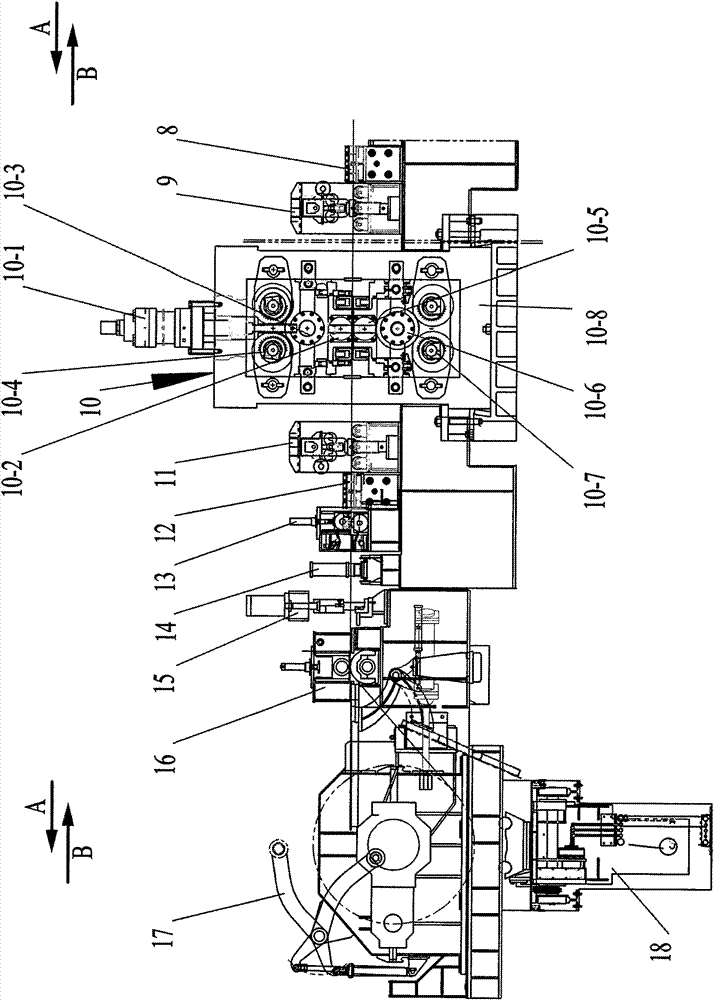

[0032] As shown in FIG. 1, the reversible cold rolling equipment of the present invention includes a main rolling mill, a front tension device 9 located on the front side of the main rolling mill, and a front centering device 8. In order to realize the "no-leader" reversible cold rolling process, an organic post-tension device 11 and a post-mill centering device 12 are also provided on the rear side of the main rolling mill.

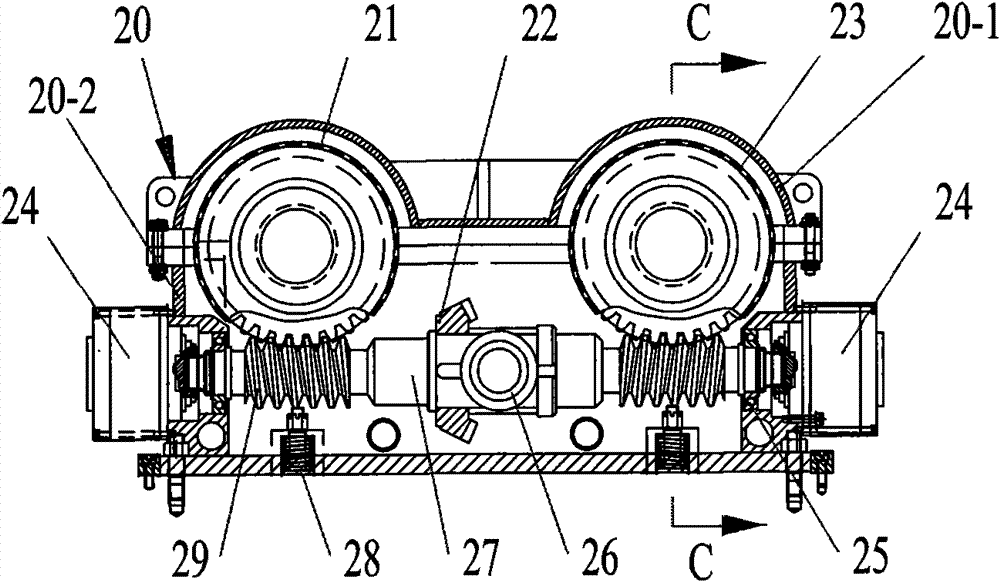

[0033] The main rolling mill is an eight-high rolling mill 10, that is, the eight-high rolling mill has two pairs of upper and lower support rolls 10-4 and 10-7 arranged in parallel in the horizontal direction in the rolling mill stand. Work rolls 10-2, 10-5, and an intermediate roll 10-3, 10-6 are installed between the upper and lower pairs of support rolls 10-4, 10-7 and work rolls 10-2, 10-5. The driving rollers of the eight-high rolling mill 10 are the upper middle roll 10-3 and the lower middle roll 10-6. The upper and lower pairs of support rolls 10-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com