Hot rolling oil for steel member and method for hot rolling steel member

A hot-rolled oil and steel technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of poor load reduction effect, poor heat-proof adhesion or lubricity, unclear influence of cooling water, etc., to reduce rolling The effect of reducing the rolling load and reducing the rolling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

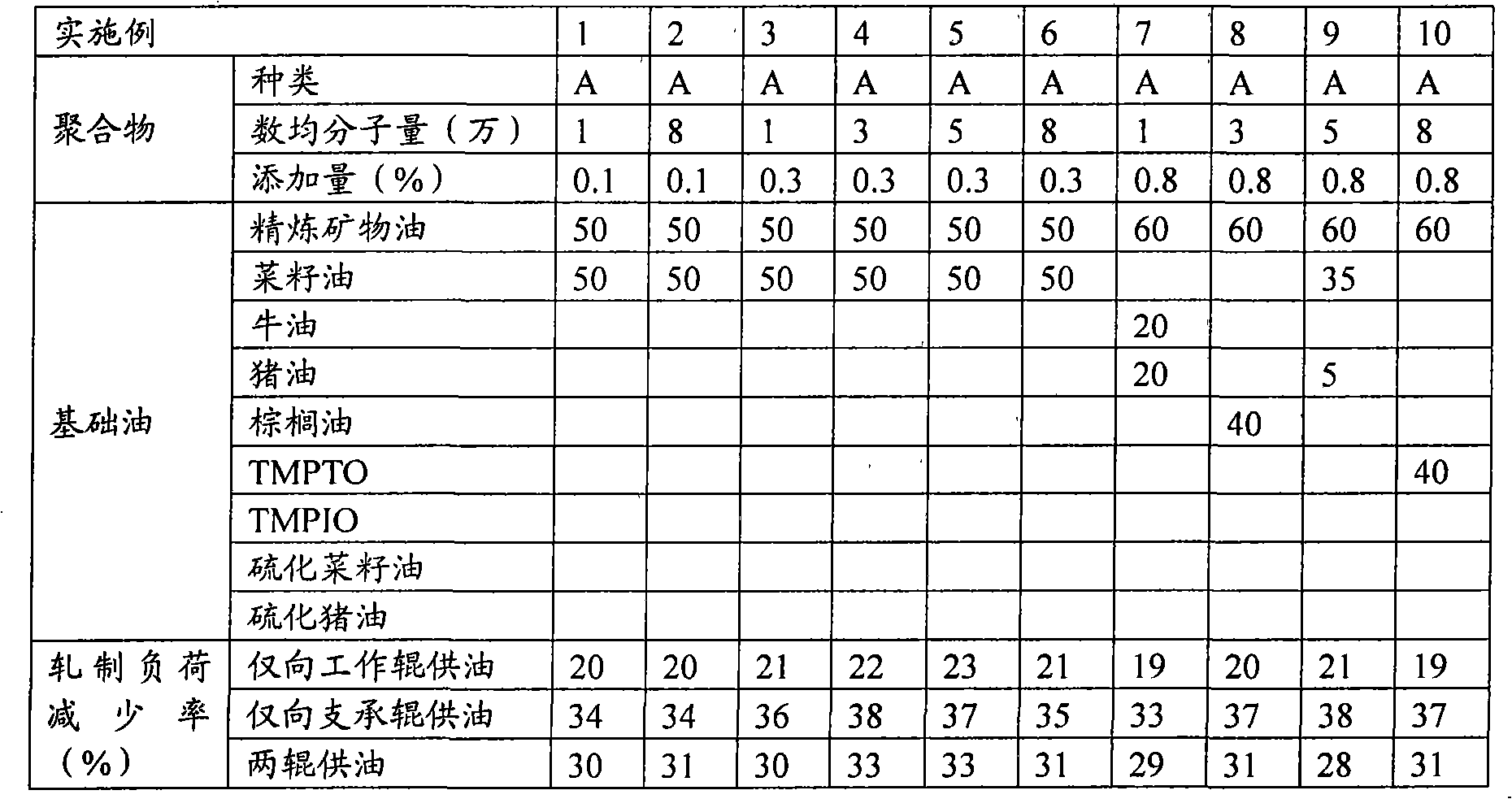

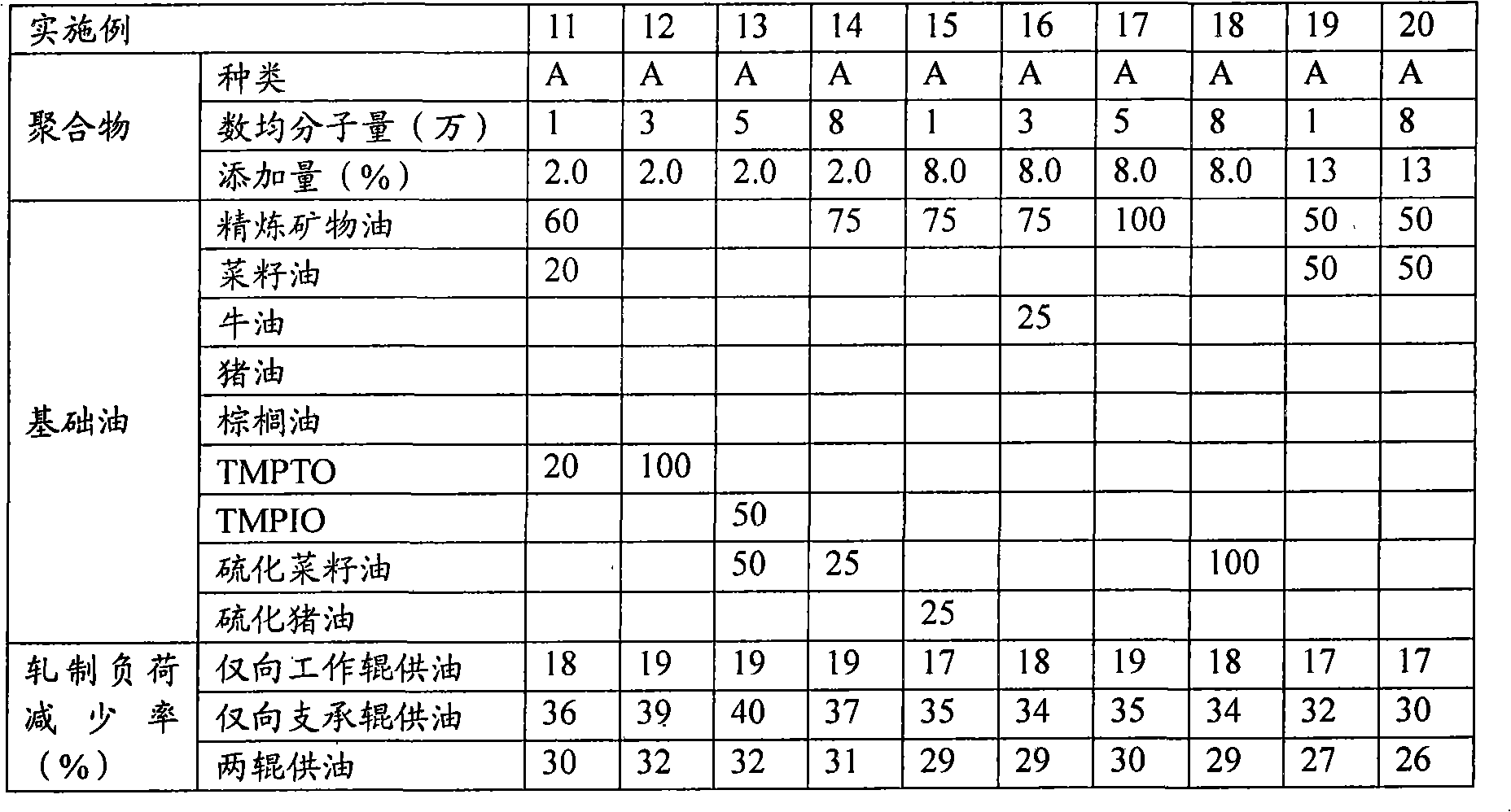

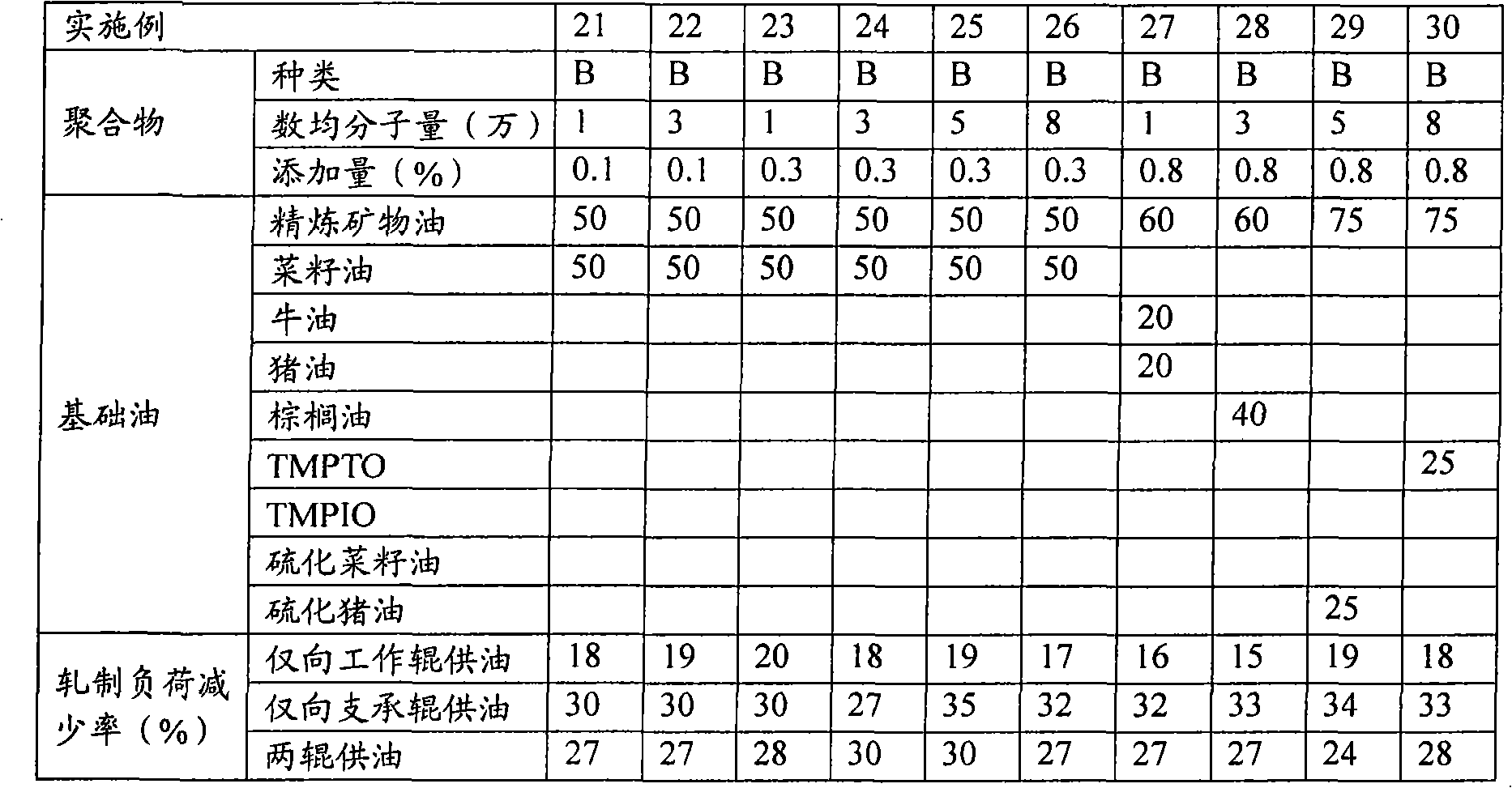

[0043] Hereinafter, the present invention will be specifically described based on examples.

[0044] Example

[0045] Using a four-stage hot rolling mill equipped with upper and lower backup rolls and upper and lower work rolls, according to the rolling conditions shown in Table 1, the rolling oil shown in Table 2 to Table 7 is supplied to the upper and lower backup rolls and / or the upper and lower rolls by water injection. work roll. The rolling load was measured with a rolling load meter installed in the rolling mill. Assuming that the rolling load when rolling oil is not supplied is X, and the rolling load when rolling oil is supplied is Y, the rolling load reduction rate (%) is obtained by the following formula.

[0046] Rolling load reduction rate (%)=100×(X-Y) / X

[0047] Table 1

[0048] work roll

High speed steel roller (diameter 80cm length 175cm)

Forged roll (diameter 125cm length 175cm)

Fuel supply method

water injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com