A kind of manufacture method of titanium alloy tie hoop material

A titanium alloy and hoop technology, which is applied in the manufacture of titanium alloy hoop materials and the field of titanium alloy hoop materials, can solve the problems of difficult development and processing technology of titanium alloy hoop materials, difficult processing and forming, and high strength. , to achieve the effect of good appearance quality, reduced heat preservation time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

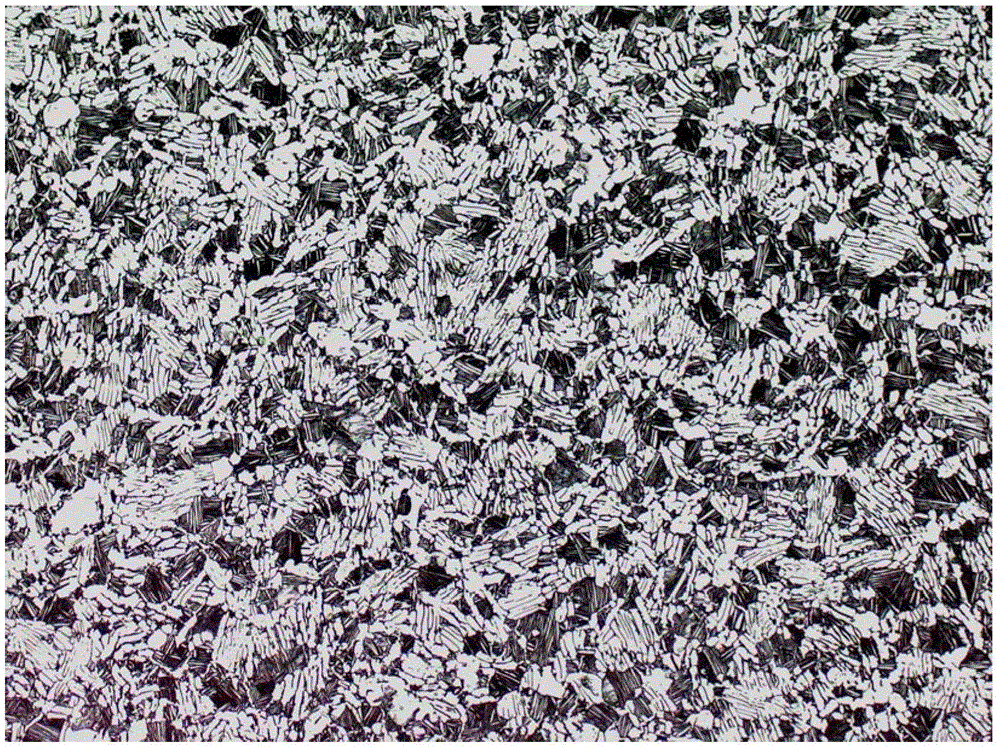

Image

Examples

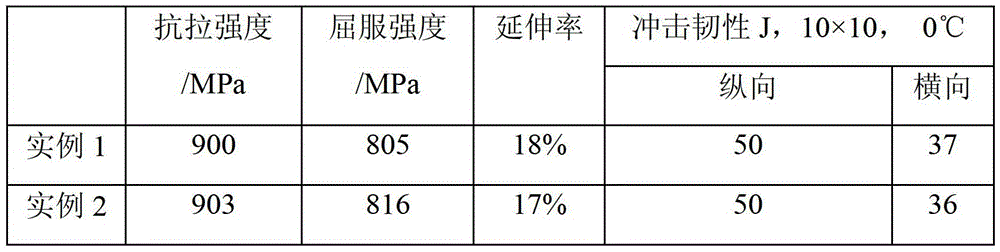

Embodiment 1

[0028] (1) Smelting: Prepare raw materials according to the following ingredients. The Ti is made of sponge titanium, smelted three times in a vacuum consumable electric arc furnace, and forged to obtain a Ф150mm billet tube;

[0029] The chemical composition is as follows: Ti balance, Al: 6%, Nb: 2.6%, Zr: 2.1%, Mo: 0.9%, Fe: 0.04%, Si: 0.02%.

[0030] (2) Heating: The blank tube enters the ring furnace for heating. The heating system of the ring furnace is 800°C in zone 1, 850°C in zone 2 for 2 hours, 970°C in zone 3, and 970°C in zone 4 for 1.5 hours; the reducing atmosphere is controlled in the furnace , maintain a slight positive pressure.

[0031] (3) Piercing and rolling: control the time for the round billet to reach the piercing machine from the heating furnace to 15-25s to ensure the rolling temperature of the piercing machine, and use a two-roll cross-rolling piercing machine to roll into a capillary tube of Ф163×20.5mm;

[0032] (4) Diameter reduction: Heat the ab...

Embodiment 2

[0035] (1) Smelting: Prepare raw materials according to the following ingredients. The Ti is made of sponge titanium, smelted three times in a vacuum consumable electric arc furnace, and forged to obtain a Ф150mm billet tube;

[0036] The chemical composition is as follows: Ti balance, Al: 7%, Nb: 2%, Zr: 0.7%, Mo: 0.9%, Fe: 0.04%, Si: 0.02%.

[0037] (2) Heating: The billet tube enters the annular furnace for heating. The heating system of the annular heating furnace is 800°C in zone 1, 850°C in zone 2 for 2 hours, 970°C in zone 3, and 970°C in zone 4 for 1.5 hours. Control the reducing atmosphere in the furnace and maintain a slight positive pressure;

[0038] (3) Piercing and rolling: the intermediate time of the round billet leaving the heating furnace and entering the piercing machine is controlled at 15-25s to ensure the rolling temperature of the piercing machine, and a two-roll cross-rolling piercing machine is used to roll into a capillary tube of Ф166×20.5mm;

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com