Negative deviation monitoring system and negative deviation detection calculation method for ribbed steel bars

A ribbed steel bar and monitoring system technology, which is applied in the direction of rolling mill control devices, metal processing equipment, metal rolling, etc., can solve the problems of affecting the production efficiency of rebar, the inability to realize dynamic real-time monitoring, and the low pass rate of finished steel products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

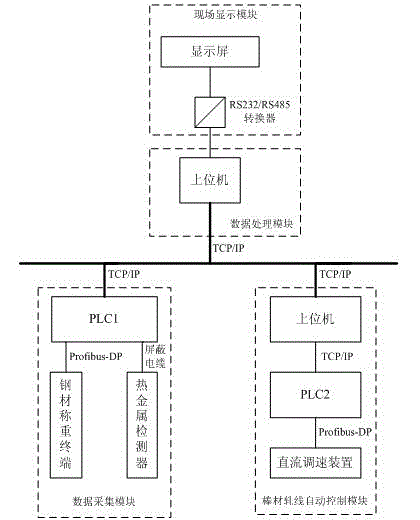

[0025] Such as figure 1 As shown, a ribbed steel bar negative deviation monitoring system includes a data acquisition system, a data processing system, an existing bar rolling line automatic control system and a field display system, and the data acquisition system and the existing bar rolling line automatic control system The system and the data processing system use Ethernet based on the TCP / IP network protocol to communicate, and the data processing system and the on-site display system are connected by an RS232 / RS485 converter; the data acquisition system includes a steel weighing terminal, a hot metal monitor and programmable controller PLC1, the steel weighing terminal communicates with the programmable controller PLC1 through the PROFIBUS-DP interface, and the hot meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com