Composite micro-alloying hot rolled steel plate containing V and Nb and preparation method thereof

A hot-rolled steel plate and micro-alloying technology, which is applied in the field of hot-rolled strips, can solve the problems of increased production costs of hot-rolled steel plates, achieve the effects of reducing cooling intensity, reducing the number of production, and improving toughness and stamping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

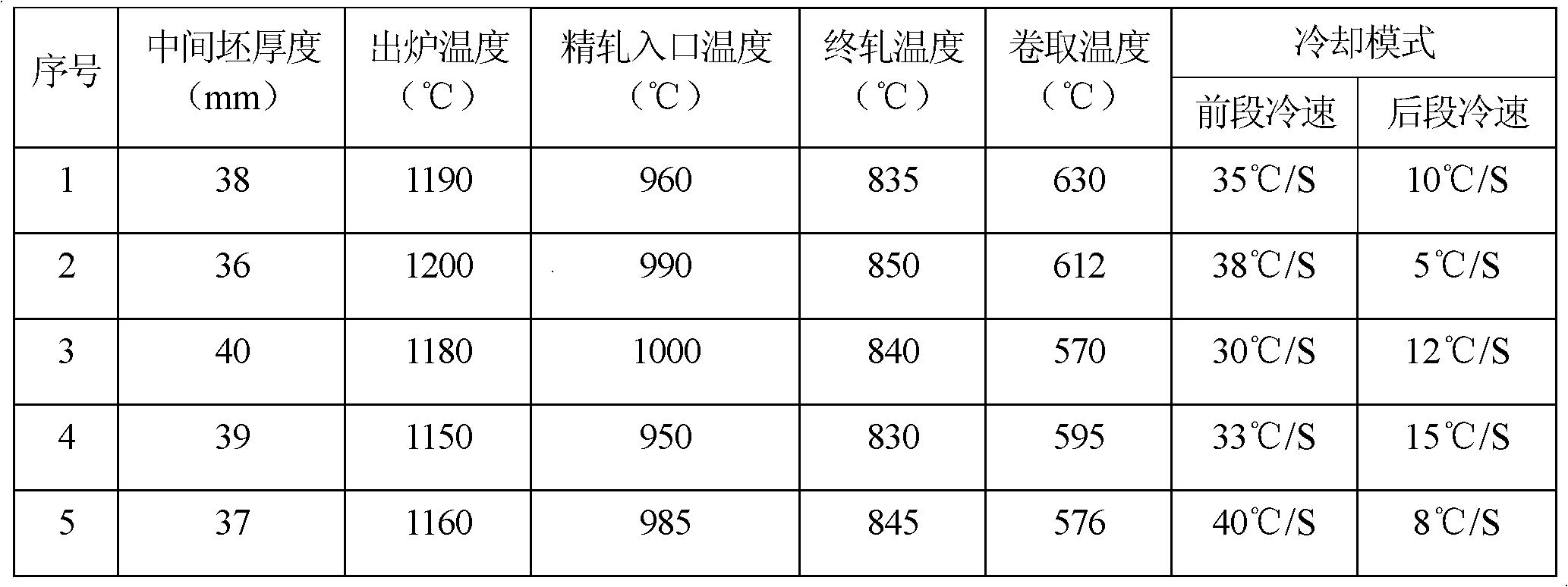

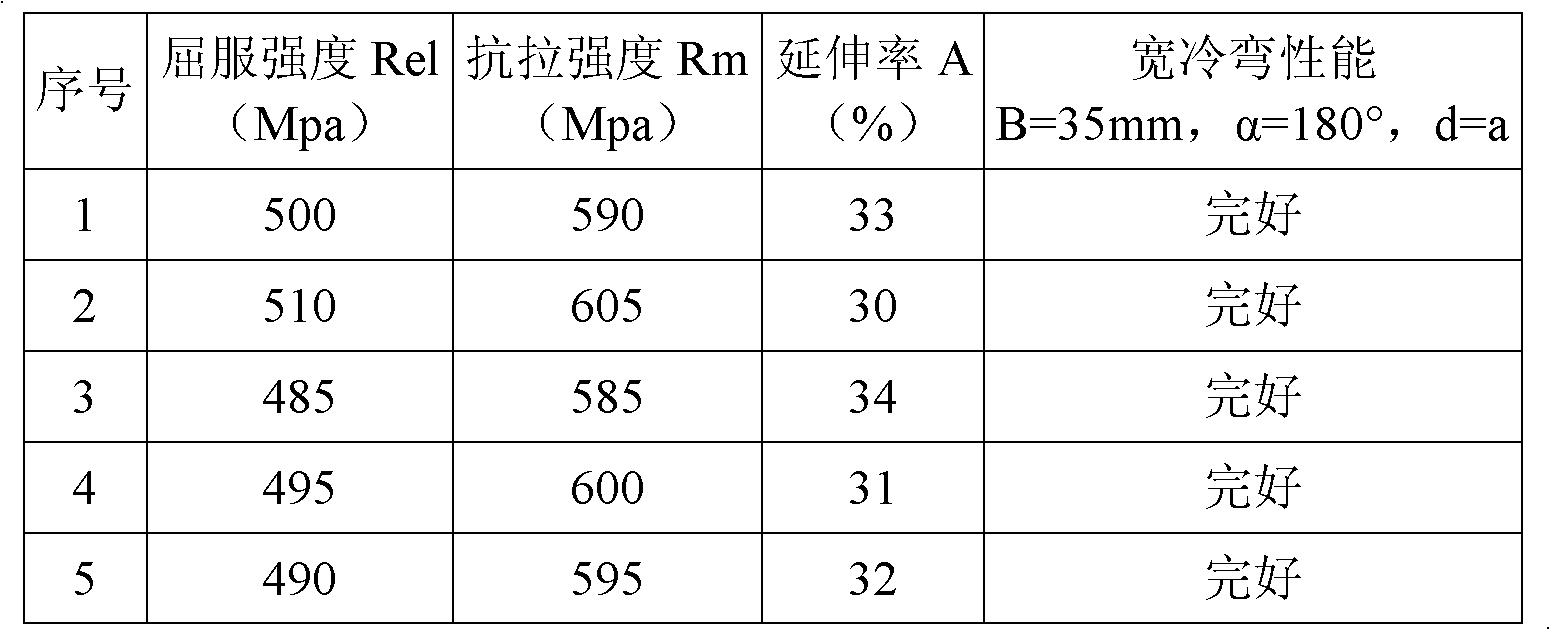

[0027] The chemical composition weight percentage of the hot-rolled steel sheet of the present invention is: 0.06%≤C≤0.08%, 0.20<Si≤0.30%, 0.70≤Mn≤0.90%, 0.04<V≤0.05%, 0.02≤Nb≤0.03%, P≤ 0.025%, S≤0.015%, and the balance is iron and unavoidable impurities. The preparation method comprises the following steps: casting slab → heating → descaling with high-pressure water → rough rolling → hot coil box coiling → finishing rolling → cooling → coiling.

[0028] The improvement points of the process part are:

[0029] 1. Heating: Control the furnace temperature to 1150°C-1200°C.

[0030] 2. Finish rolling: the starting rolling temperature is controlled at 950-1000°C, and the finishing rolling temperature is controlled at 830°C-850°C.

[0031] 3. Cooling: the cooling method of fast cooling in the front section + sparse cooling in the back section. Specifically, the front stage: cooling to 730-750°C at a cooling rate of 30-40°C / s; the latter stage: cooling to 580-620°C at a cooling r...

Embodiment

[0033] The chemical composition weight percentage of the hot-rolled steel sheet of the present invention is C: 0.06%≤C≤0.08%, 0.20<Si≤0.30%, 0.70≤Mn≤0.90%, 0.04<V≤0.05%, 0.02≤Nb≤0.03%, P ≤0.025%, S≤0.015%, the balance is iron and unavoidable impurities. Melt steel was smelted according to Table 1.

[0034] The chemical composition (weight percent %) of hot-rolled steel plate of the present invention of table 1

[0035] serial number

C

Si

mn

P

S

V

Nb

1

0.07

0.25

0.80

0.019

0.009

0.045

0.025

2

0.08

0.28

0.90

0.012

0.012

0.050

0.030

3

0.06

0.30

0.70

0.016

0.007

0.041

0.022

4

0.07

0.21

0.85

0.017

0.015

0.048

0.020

5

0.06

0.24

0.75

0.012

0.008

0.046

0.026

[0036] The above-mentioned five groups of molten steels were cast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com