Centrifugal casting mold composite end cover and method for carrying out composite roll centrifugal casting through same

A centrifugal casting and composite technology, which is applied in the field of composite roll centrifugal casting and centrifugal casting composite end caps, can solve the problems of great influence on rolling cost, increase rolling cost, and single function, so as to increase market competition Force, reduce rolling cost, increase the effect of filling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be further clarified with reference to the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. After reading the present invention, those skilled in the art will understand various aspects of the present invention. Modifications in equivalent forms fall within the scope defined by the appended claims of this application.

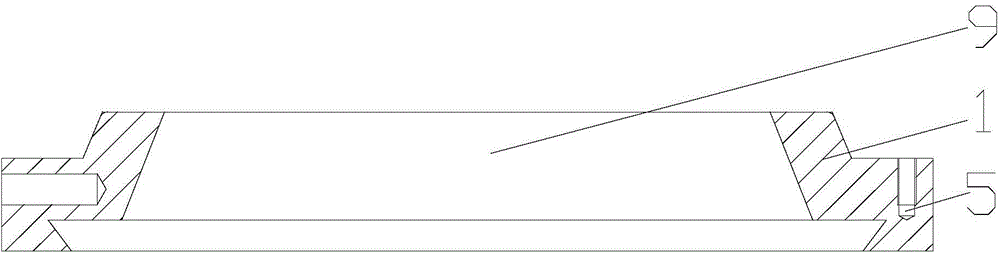

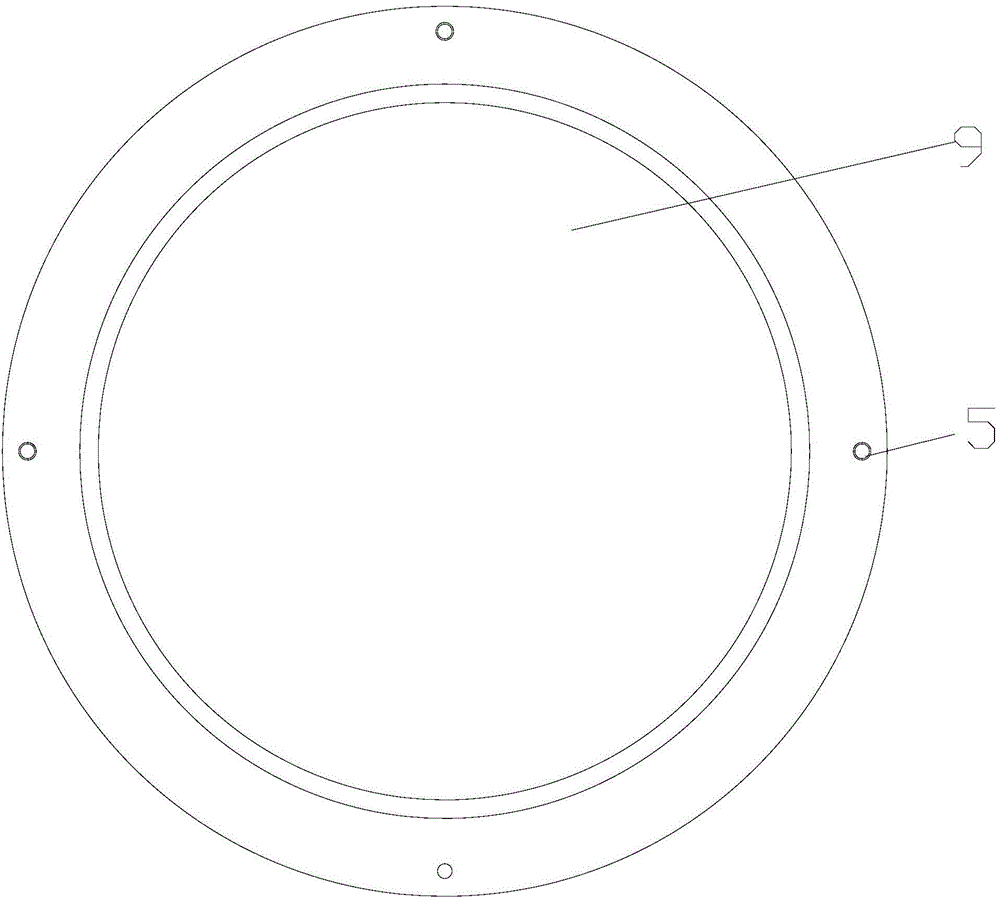

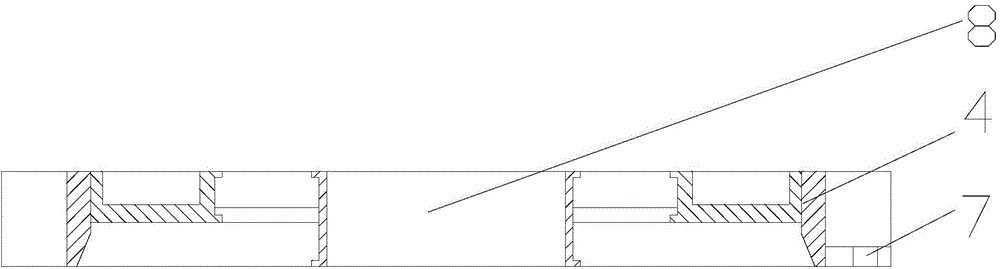

[0033] As attached Figure 1-8 As shown, a centrifugal casting composite end cover includes a casting end cover 1 and an additional end cover 4. The additional end cover 4 is placed above the casting end cover 1, and the two are movably connected by a rotary buckle device . The rotary buckle device includes screw holes 5, bolts 6 and protruding bayonet openings 7 corresponding to each other in number. The screw holes 5 are symmetrically arranged on the two sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com