Method for employing large cross-section continuous casting round billet to roll round steel bar

A continuous casting round billet and large cross-section technology, which is applied in metal rolling and other directions, can solve the problems of uneven heating temperature of the billet, failure to meet the large compression ratio, and affect the quality of finished steel, so as to overcome edge crack defects and low cost , the effect of rolling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

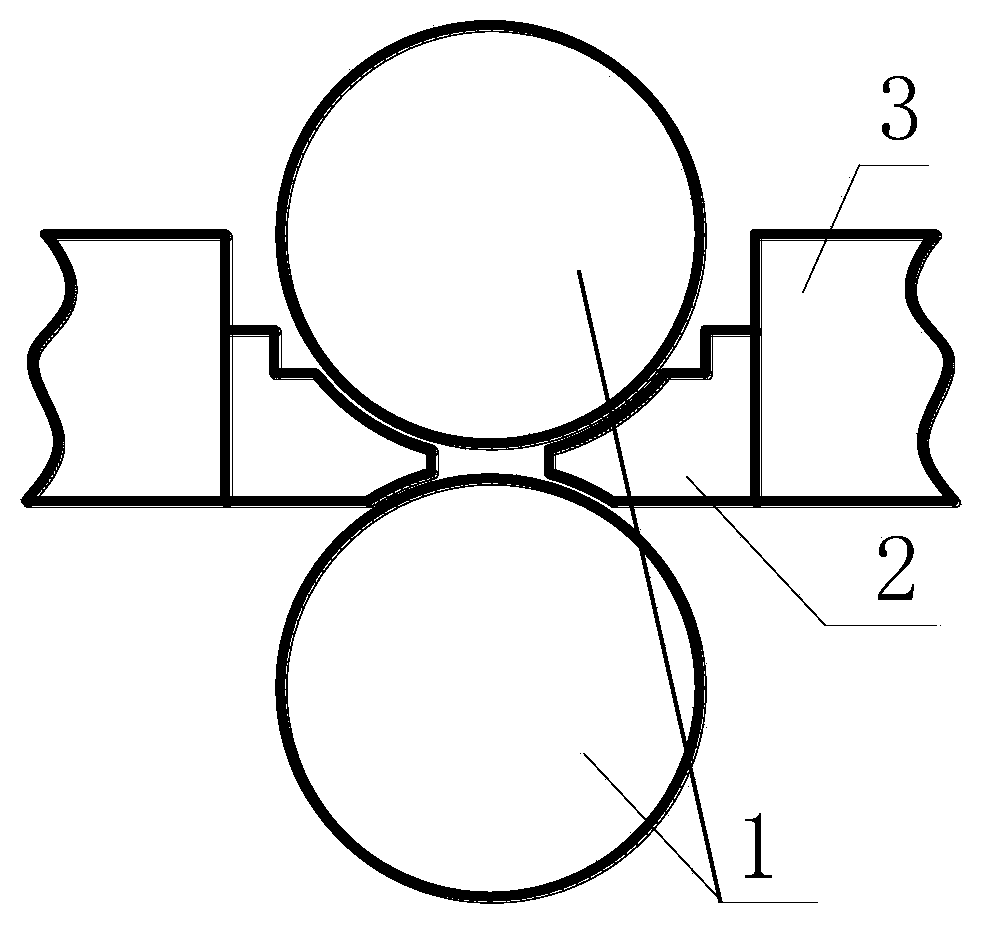

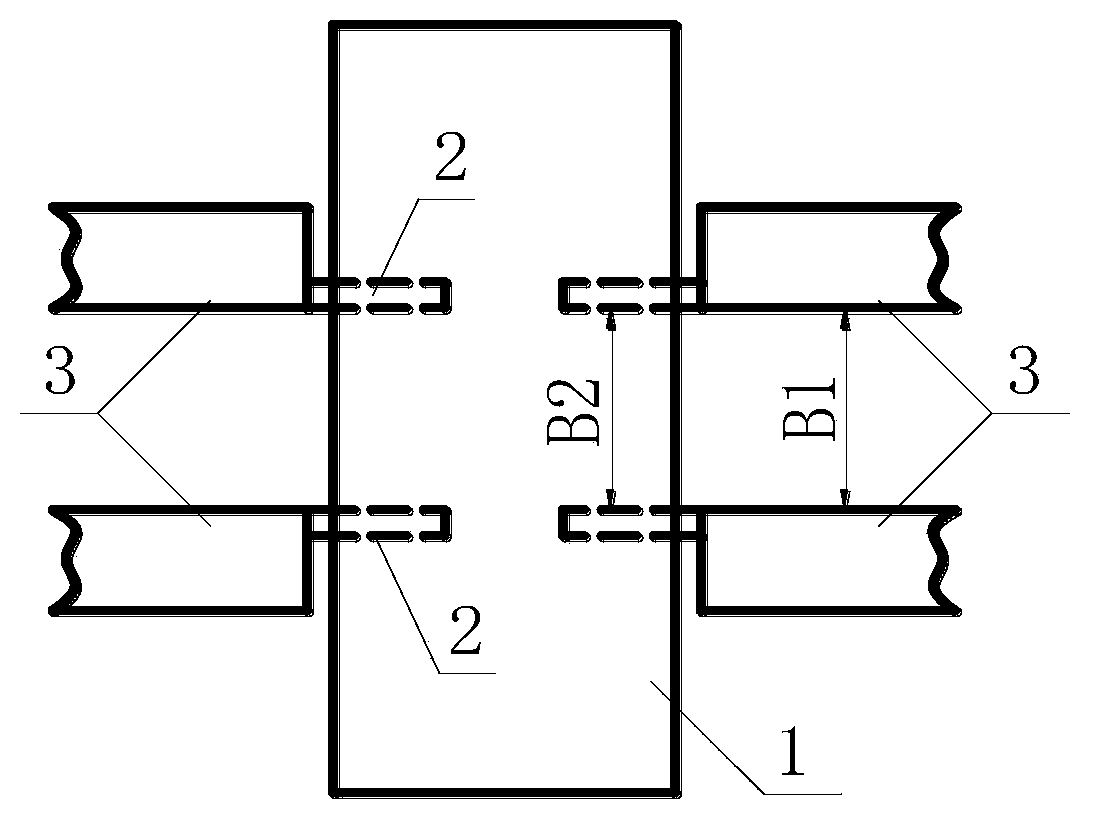

[0031] Below in conjunction with accompanying drawing, take rolling φ 280mm round steel as example, the present invention is described in detail.

[0032] Roll the φ280mm round steel with a φ650mm continuous casting round billet, send the continuous casting round billet into the heating furnace and heat it to about 1250°C according to the conventional method. The steel billet that deviates during transportation is pushed straight, centered on the rolling line, and sent to the roughing mill for multi-pass rolling. Starting from the third pass, each odd-numbered pass is rolled once, and a total of 13 passes are rolled. The final billet is 330mm high and 320mm wide. Then, the intermediate billet is sent to the finishing mill for rolling.

[0033] The layout of the finishing mill is: vertical-horizontal alternate arrangement, and the number of pressing passes is 4, that is, the finished round steel of φ280mm is obtained.

[0034] The pass system of the rough rolling mill is a bo...

Embodiment 2

[0039]Roll φ160mm round steel with φ550mm continuous casting round billet.

[0040] Send the continuous casting round billet into the heating furnace and heat it to about 1250°C according to the conventional method. After removing phosphorus from the furnace, use the pusher 3 and the clamping plate 2 to push and center the billet that deviates during the roller table transportation. and sent to the roughing mill for multi-pass rolling. Starting from the third pass, each odd-numbered pass turns over once, and a total of 13 passes are rolled. The height of the rolled billet is 260mm and the width is 260mm. Then, the intermediate billet is sent to the finishing mill for rolling.

[0041] The layout of the finishing mill is: vertical-horizontal alternate arrangement, and the number of pressing passes is 6, that is, the finished round steel of φ160mm is obtained.

[0042] The pass system of the rough rolling mill is a box-box pass, the slope of the side wall of the pass is 30°, th...

Embodiment 3

[0046] Roll φ120mm round steel with φ500mm continuous casting round billet.

[0047] Send the continuous casting round billet into the heating furnace and heat it to about 1250°C according to the conventional method. After removing phosphorus from the furnace, use the pusher 3 and the clamping plate 2 to push and center the billet that deviates during the roller table transportation. and sent to the roughing mill for multi-pass rolling. Starting from the third pass, each odd-numbered pass turns over once, and a total of 11 passes are rolled. The height of the rolled billet is 200mm and the width is 200mm. Then, the intermediate billet is sent to the finishing mill for rolling.

[0048] The layout of the finishing mill is: vertical-horizontal alternate arrangement, and the number of pressing passes is 6, that is, the finished round steel of φ120mm is obtained.

[0049] The pass system of the rough rolling mill is a box-box pass, the slope of the side wall of the pass is 30°, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com