Vertical loop device for high-speed wire rod rolling mill

A looper device and high-speed wire rod technology, applied in metal rolling, metal rolling, bending workpieces, etc., can solve the problems of unqualified cold heading performance, batch quality accidents, affecting product quality, etc., and eliminate the phenomenon of wire scraping , prolong the service life, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

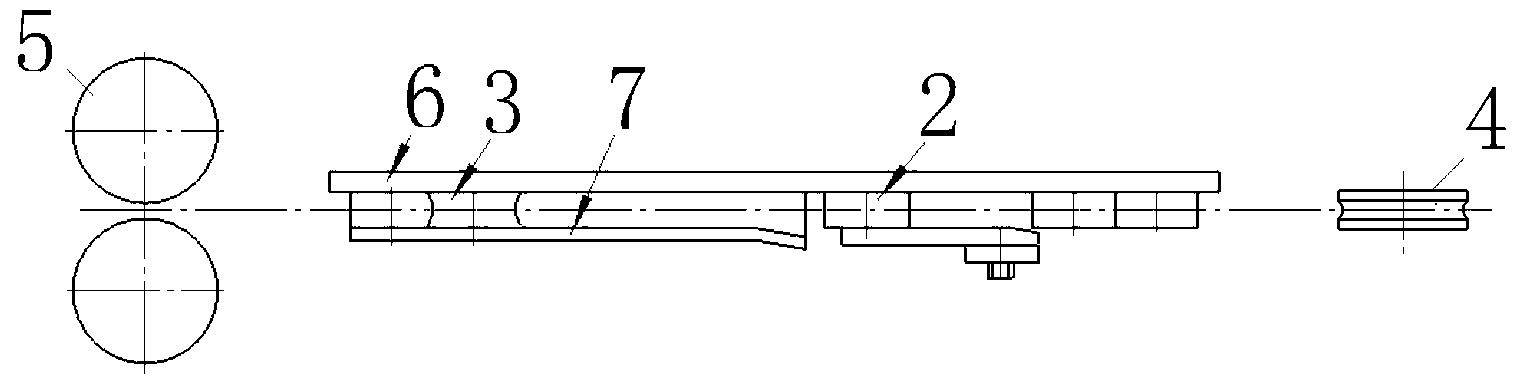

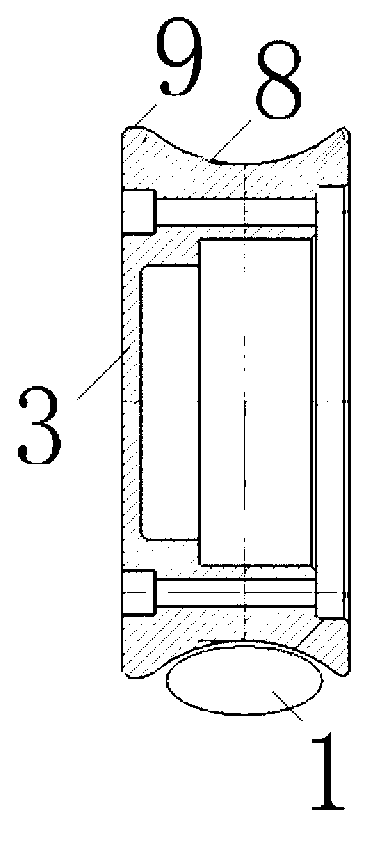

[0017] Such as Figure 1 to Figure 4 As shown, a high-speed wire rod rolling mill vertical loop device, the vertical loop device is located between the upstream rolling mill 4 and the downstream rolling mill 5, and it includes a sheathing roll 2 and a guide roll 3 and loopers located on both sides of the guide roll The side plates, that is, the looper side plate I6 and the looper side plate II7, are provided with a guide groove 8 with a guide centering function on the roller surface of the guide roller 3 . When the rolling piece 1 enters the vertical looper device, the rolling piece moves along the arc track after the sheathing roll 2 sets the rolling piece, and the rolling piece can always run in the looper rolling position through the guide groove 8 to limit the rolling piece. In the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com