Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Reduce residual content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-odor low-VOC (volatile organic compound)-content styrene polymer composition and preparation method thereof

ActiveCN103044793AOvercome the shortcomings of not being able to directly add to raw materialsWon't overflowPolymer scienceAntioxidant

The invention discloses a low-odor low-VOC (volatile organic compound)-content styrene polymer composition and a preparation method thereof. The composition is prepared from the following components in percentage by weight: 70-99% of styrene polymer, 0.5-29% of strippant master batch and 0.01-1% of antioxidant. The preparation method comprises the following steps: preparing a strippant master batch, mixing the components in a high-speed mixer, adding the mixture into a screw extruder, carrying out melt extrusion, and granulating. The invention has the advantages of simple production technique and lower production cost, and effectively lowers the order and VOC content of the styrene polymer; and the prepared styrene polymer composition can be used in the field of materials with strict environmental requirements in packaging materials, daily necessities, home appliances, OA, toys, sports equipment, shoe materials, cables, instruments and meters, electronic components and equipment, construction materials and automobile materials.

Owner:CHENGDU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD +2

Method of producing a carboxylic alkyl ester

ActiveUS20090137825A1Increase productionHigh purityOrganic compound preparationChemical industryCarboxylic saltReactive distillation

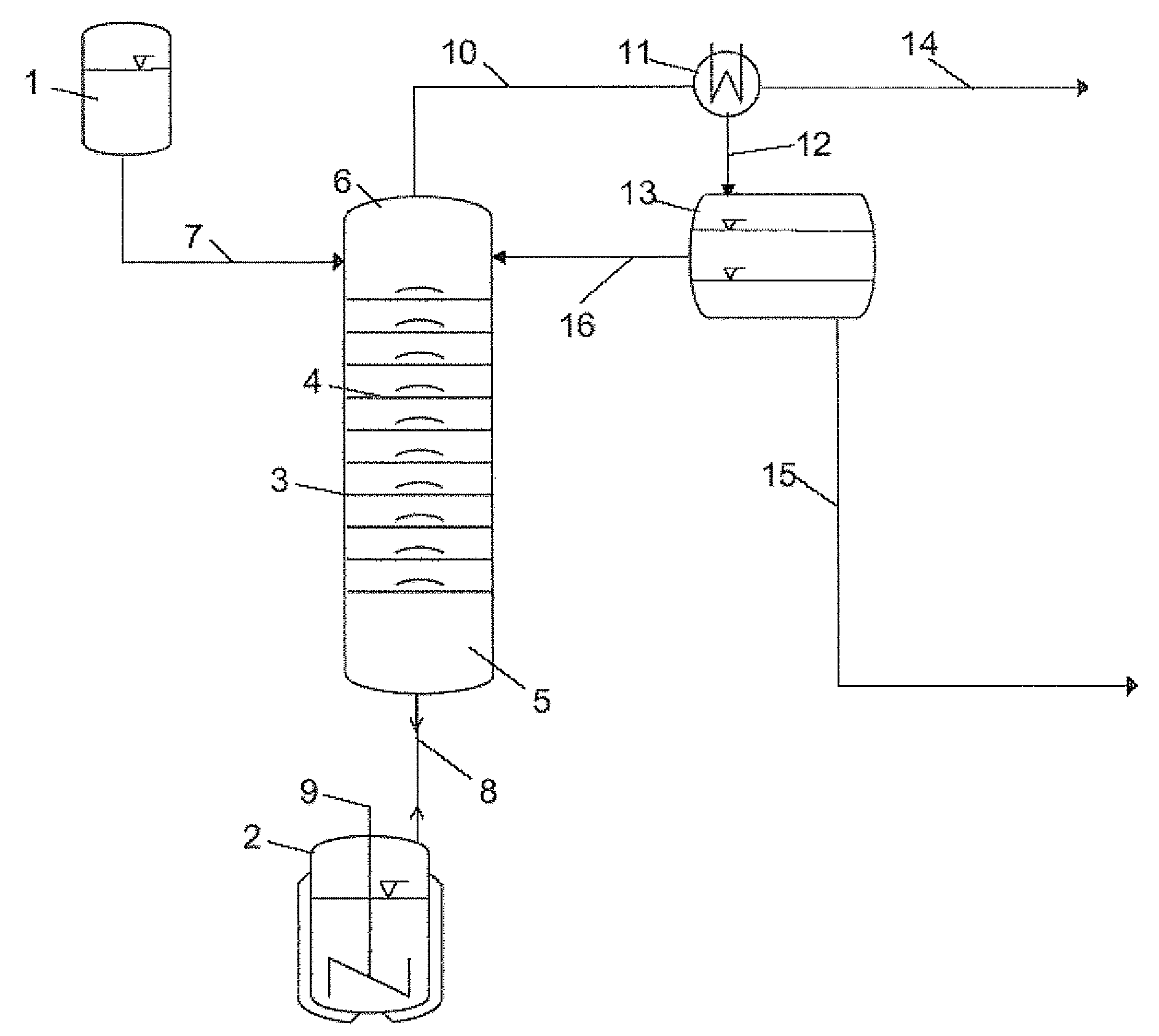

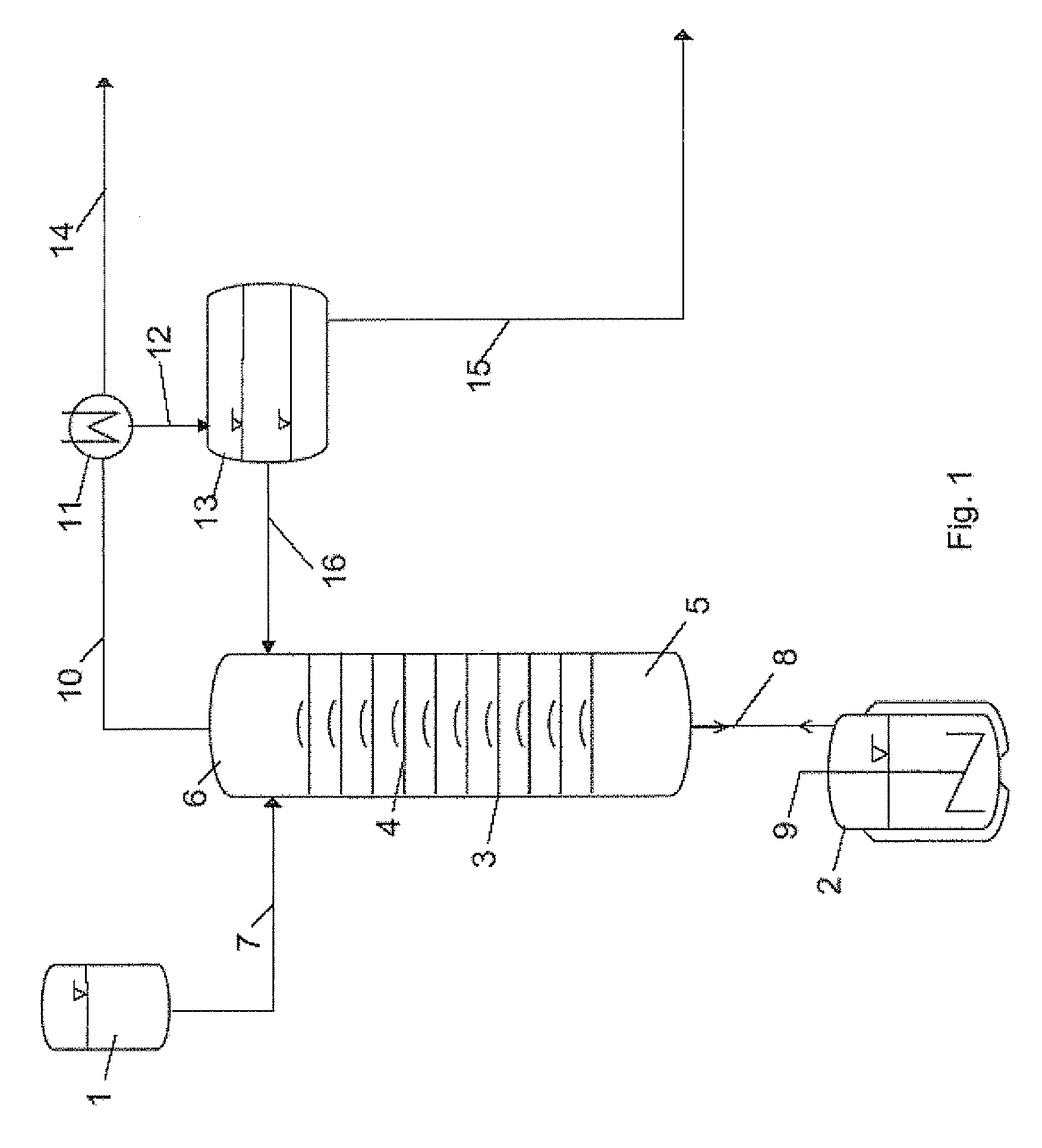

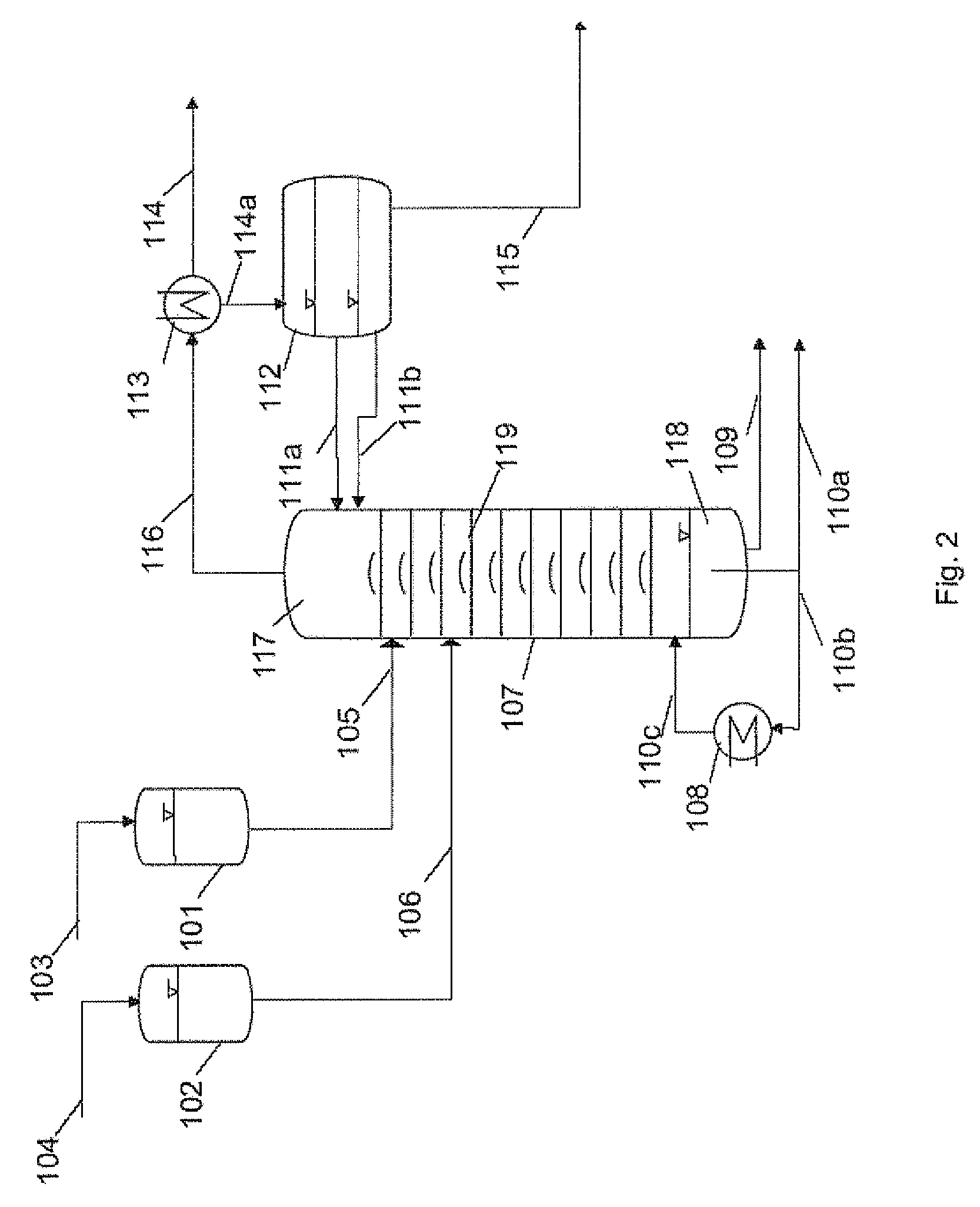

The present invention relates to a novel process for preparing alkyl polycarboxylates from an aqueous solution of an ammonium salt of the polycarboxylic acid by reactive distillation, and to a process for hydrogenating the alkyl carboxylates prepared in this way.

Owner:BASF AG

High-heat-resistance high-rigidity environmentally-friendly polystyrene resin composition and preparation method thereof

The invention discloses a high-heat-resistance high-rigidity environmentally-friendly polystyrene resin composition and a preparation method thereof. The polystyrene resin composition contains the following components in percentage by weight: 59-99 percent of polystyrene resin, 0.5-30 percent of SMA (Styrene-Maleic Anhydride) resin, 0-10 percent of stripping agent master batch and 0.01-1 percent of antioxidant, wherein the stripping agent master batch consists of a matrix and a stripping agent. The preparation method has the advantages of simple production process, reduced production cost and capabilities of effectively improving heat resistance and rigidity of polystyrene resin without reducing mechanical property thereof and meanwhile reducing smell and VOC (Volatile Organic Compound) content of the polystyrene resin; and the prepared polystyrene resin composition can be used in the fields of materials with strict requirements on heat resistance and environmental friendliness in packaging materials, daily articles, household appliances, OA (Office Automation), toys, electronic parts and components and equipment, building materials and automobile materials.

Owner:WUHAN JINFA TECH CO LTD

Zero-VOC (volatile organic compound) cement-based water-proof material copolymer emulsion and preparation method thereof

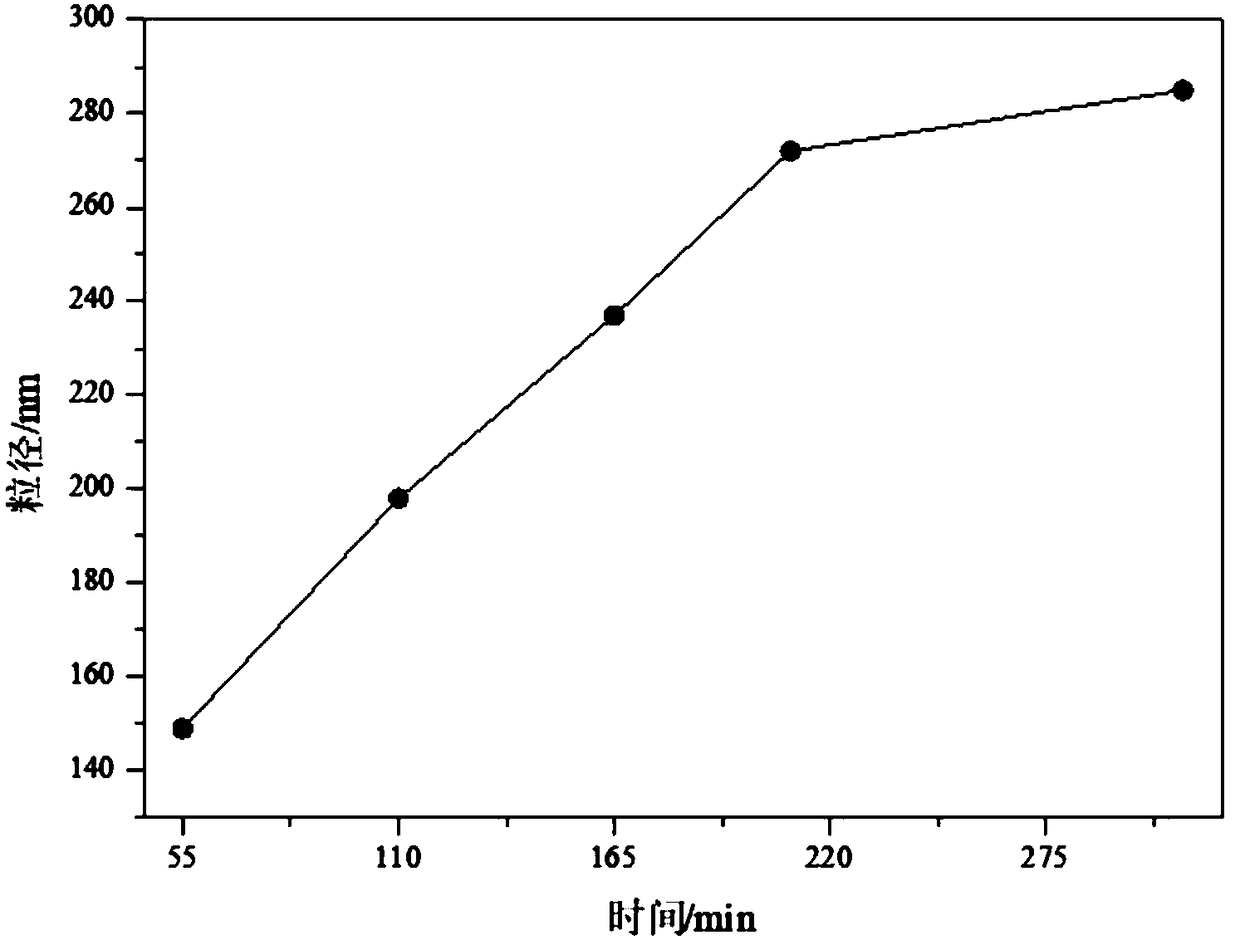

The invention discloses zero-VOC (volatile organic compound) cement-based water-proof material copolymer emulsion and a preparation method thereof. The preparation method adopts a zero-VOC copolymer emulsion component A and an inorganic powder component B, the zero-VOC copolymer emulsion component A is prepared from deionized water, alkyl acrylate, styrene, acrylic acid functional monomers, emulsifying agents, initiators, a buffer agents, polymerization inhibitors, oxidizing agents, reducing agents, sterilizing agents and defoaming agents through polymerization of pre-emulsification semi-continuous seed emulsion, and the inorganic powder component B comprises ordinary portland cement, quartz sand and water reducers. The prepared emulsion is high in solid content, low in viscosity, uniformin particle size and good in stability and has excellent rheological property and coating water absorption, the content of a residual monomer in an emulsion product is lower than 300ppm and meets national zero-VOC emulsion standards, the emulsion is environmentally friendly and free from toxicity and pollution, the compatibility of the emulsion and cement is good, and a prepared polymer cement waterproof coating is excellent in water resistance, good in low-temperature flexibility and low in water absorption.

Owner:SOUTH CHINA UNIV OF TECH

A kind of preparation method of amoxicillin sodium

The present invention relates to the field of drug synthesis, in particular to a method for preparing amoxicillin sodium. The method of the present invention comprises the following steps: (1) preparation of acid anhydride; (2) preparation of 6-APA solution; (3) condensation: Move the 6-APA salt solution into the mixed acid anhydride reaction bottle, and time it for 3 hours; (4) Hydrolysis: add the condensation solution of step (3) to the hydrolyzed solution; (5) Crystallization: Leave the crystal to grow for 1 hour and then stir to grow the crystal for 1 hour (6) Suction drying: wash with water first, then wash with acetone, and dry in vacuum at 40° C. for 3 hours to obtain amoxicillin.

Owner:HARBIN PHARMA GRP CO LTD GENERAL PHARMA FACTORY

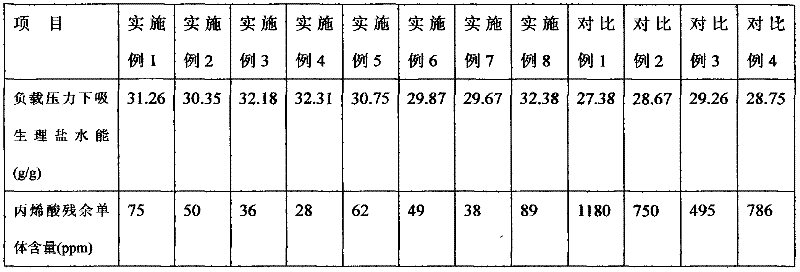

Method for preparing super absorbent resin with low residual acrylic monomer content

ActiveCN102127244AReduce residual contentHigh capacity to absorb salt waterPolymer scienceSuper absorbent

The invention discloses a method for preparing super absorbent resin with low residual acrylic monomer content. In the method, initiator solution and crosslinking agent solution are added in the process of making gel particles of the super absorbent resin, the gel particles added with the initiator solution and the crosslinking agent solution are subjected to microwave radiation, and the hydrogel particles are completely dried. The super absorbent resin product prepared by the process has low acrylic monomer content, and the liquid absorbing capacity of the product under load pressure is improved.

Owner:SHANGHAI HUAYI NEW MATERIAL

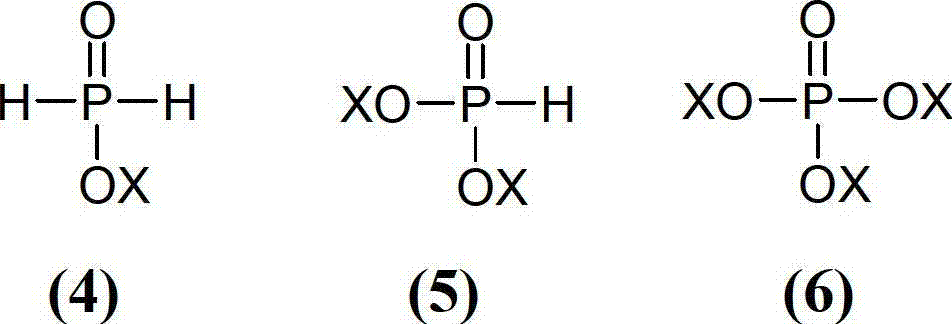

Method For Producing (Meth)Acrylate Derivative Having Isocyanate Group

ActiveUS20070197762A1High yieldResidue reductionOrganic compound preparationCarboxylic acid esters preparationMethacrylateMeth-

The invention aims to provide a method whereby (meth)acrylate derivatives having an isocyanate group can be obtained in high yield by dehydrochlorination of 3-chloropropionate derivatives having an isocyanate group under industrially advantageous and mild conditions, and the content of residual hydrolyzable chlorine can be reduced. A method for producing a (meth)acrylate derivative having an isocyanate group comprises performing dehydrochlorination of a 3-chloropropionate derivative having an isocyanate group in the presence of a basic nitrogen compound having a tertiary nitrogen, the tertiary nitrogen of the basic nitrogen compound having at least one group other than an aromatic ring group.

Owner:RESONAC CORP

Process for the preparation of polypropylene with low ash content

Process for the preparation of a polypropylene in a sequential polymerization process comprising at least three reactors connected in series, wherein the polymerization takes place in the presence of a Ziegler-Natta catalyst, said Ziegler-Natta catalyst comprises * a pro-catalyst comprising a compound of a transition metal (TM), a compound of a metal which metal is selected from one of the groups 1 to 3 of the periodic table (IUPAC), and an internal electron donor, * a co-catalyst (Co), and * an external donor (ED), wherein further the mol-ratio of co-catalyst (Co) to external donor (ED) [Co / ED] is in the range of above 12 to below 25, and the mol-ratio of co-catalyst (Co) to transition metal (TM) [Co / TM] is in the range of above 100 to below 200.

Owner:BOREALIS AG

Method for producing (meth)acrylate derivative having isocyanate group

ActiveUS7632965B2High yieldReduce residual contentOrganic compound preparationCarboxylic acid esters preparationMethacrylatePolymer science

The invention aims to provide a method whereby (meth)acrylate derivatives having an isocyanate group can be obtained in high yield by dehydrochlorination of 3-chloropropionate derivatives having an isocyanate group under industrially advantageous and mild conditions, and the content of residual hydrolyzable chlorine can be reduced. A method for producing a (meth)acrylate derivative having an isocyanate group comprises performing dehydrochlorination of a 3-chloropropionate derivative having an isocyanate group in the presence of a basic nitrogen compound having a tertiary nitrogen, the tertiary nitrogen of the basic nitrogen compound having at least one group other than an aromatic ring group.

Owner:RESONAC CORPORATION

Refined processing method of green tea

InactiveCN107125347AOutstanding aromaThe taste is mellow and sweetPre-extraction tea treatmentEngineeringWinnowing

The invention discloses a refined processing method of green tea. The method comprises the following steps: picking fresh leaves, withering, carrying out roller fixation, rolling, spreading for cooling, carrying out secondary fixation by means of microwaves, shaping by means of secondary rolling, drying step by step, screening, winnowing, blending, enhancing aroma and drying by means of microwaves, and packaging finish products. The method provided by the invention is simple in technology and easy to operate; the refined tea prepared by the method has the advantages of being prominent in aroma and having caramel aroma, being mellow, sweet and refreshing in taste, thick in soup color, brewing-resistant, low in microorganism content, less in pesticides residue, and the like.

Owner:贵州安顺春来茶业有限公司

Processing method for producing high-end green tea from Shiqian moss tea variety

The invention discloses a processing method for producing high-end green tea from a Shiqian moss tea variety. The processing method comprises the following steps: withering, fixation, fresh leaf tedding, tea strip tidying and trimming, step-by-step drying, screening, air classification, blending, microwave drying aroma enhancement and finished product packaging. By controlling the temperature andtime in the process steps and the parameters of moisture and the like in processed tea leaves, most organic matters in the tea leaves are preserved, so that the quality of the tea leaves is remarkablyimproved.

Owner:石阡裕和原生态农牧发展有限公司

Cleaner capable of reducing pesticide residues on fruits and vegetables

InactiveCN105950313AResidue reductionReduce residual contentInorganic/elemental detergent compounding agentsSurface-active detergent compositionsPesticide residueCombined use

The invention provides a cleaner capable of reducing pesticide residues on fruits and vegetables. The cleaner is prepared from, in parts by weight, 2 parts of attapulgite and 1 part of montmorillonite, the cleaner can be used after water is added, the ratio of the water to the cleaner is (50-300):1, and after the cleaner and the water are uniformly mixed, the mixture is used for washing the fruits and the vegetables. The residual quantity of fat-soluble pesticides and water-soluble pesticides can be effectively reduced through combined use of the water and the cleaner. The content of non-systemic pesticide residues of the fruits and the vegetables and the content of the systemic pesticide residues of the fruits and the vegetables can be effectively reduced.

Owner:JINAN KANGZHONG PHARMA TECH DEV

Method for purification of 4-hydroxyacetophenone

ActiveUS20200039911A1Easy to carryReduce residual contentCarbonyl compound separation/purificationAcetophenoneSolvent

Methods of purifying crude 4-hydroxyacetophenone using one or more solvents as well as products comprising or consisting of crystallized 4-hydroxyacetophenone and one, two or more solvent(s). The products may be obtained or obtainable from the methods for purifying crude 4-hydroxyacetophenone.

Owner:SYMRISE GMBH & CO KG +1

Method for processing preboiled rice through composite bio-enzyme fermentation

InactiveCN104273433AReduce viscosityIncrease nutritional value and absorption utilizationFood preparationPectinCellulase

The invention discloses a method for processing preboiled rice through composite bio-enzyme fermentation. The method comprises the steps of fermenting rice by adopting composite bio-enzyme nutritional liquid before steaming in a soaking stage, wherein the composite bio-enzyme nutritional liquid comprises cellulase, hemicellulase, pectinase, protease and amylase and also contains glucose and water; the using amount of single bio-enzyme is 0.05-0.8 percent of the dry weight of rice, the using amount of glucose is 1-10 percent of the dry weight of rice, and the using amount of water is 10-100 percent of the dry weight of rice; uniformly mixing rice with the composite bio-enzyme, the glucose and water, and performing fermentation under a condition that the temperature is 15-60 DEG C for 4-100 hours. The rice is fermented by composite bio-enzyme nutritional liquid and then is dried to prepare the preboiled rice, so that the content of coarse fibers, pectin substance and pesticide residue can be obviously reduced, and nutritional components are easy to absorb and use; furthermore, the content of protein peptides, vitamins and monosaccharide is increased.

Owner:罗福仲

Novel application of montmorillonite

InactiveCN105950314AReduce residual contentSurface-active non-soap compounds and soap mixture detergentsInorganic non-surface-active detergent compositionsFood safetyPesticide residue

The invention provides a novel application of montmorillonite. A cleaning agent for reducing pesticide residue content of fruits and vegetables is prepared from the montmorillonite, the montmorillonite accounts for 2%-15% of the prepared cleaning agent in percentage by weight, a ratio of water to the cleaning agent is (10-300): 1 according to the usage amount of the cleaning agent, the water and the cleaning agent are uniformly mixed to wash fruits or vegetables, the residue content of systemic and contact pesticides on fruits and vegetables can be greatly reduced, and the food safety is improved. Besides, the usage amount of the montmorillonite is small, and the cost is low.

Owner:JINAN KANGZHONG PHARMA TECH DEV

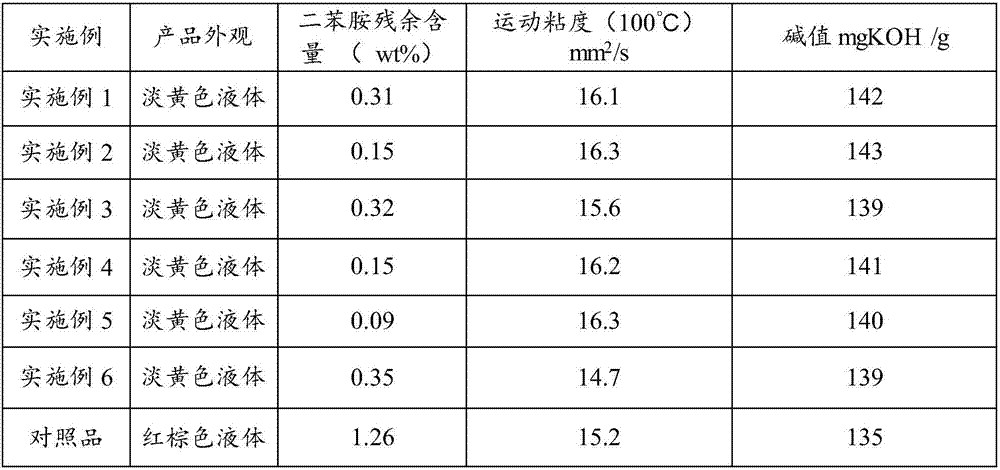

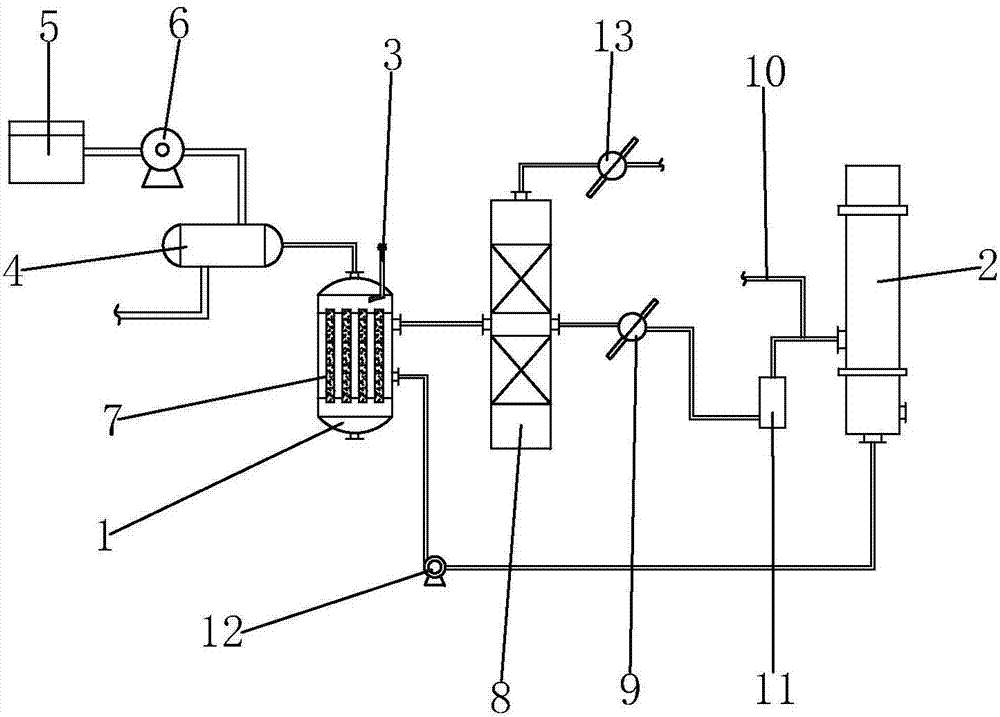

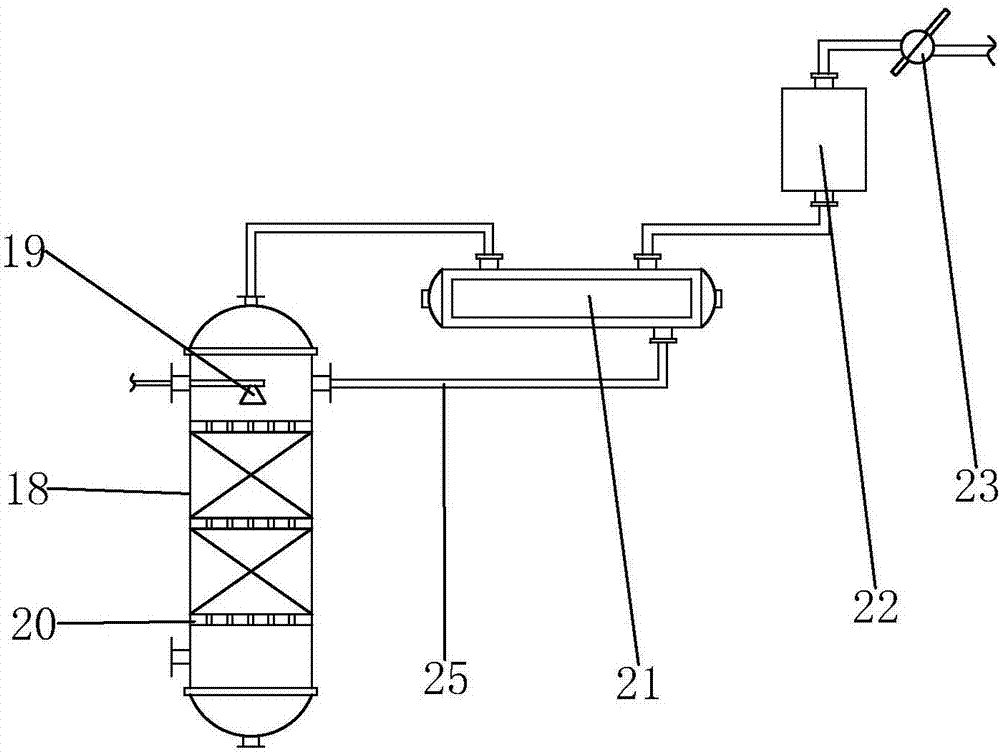

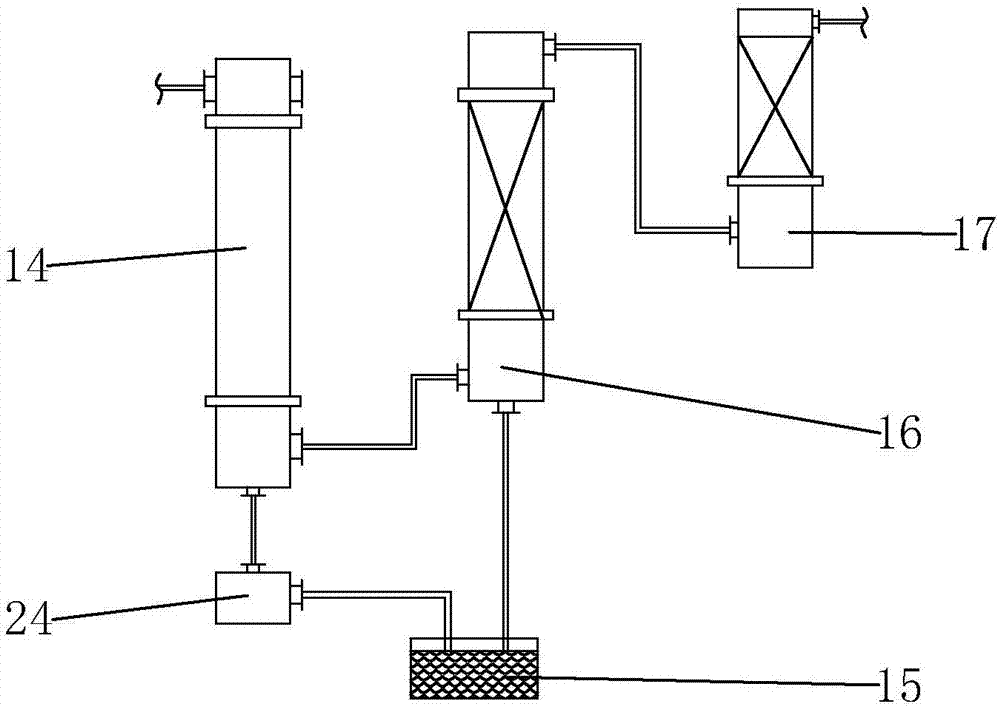

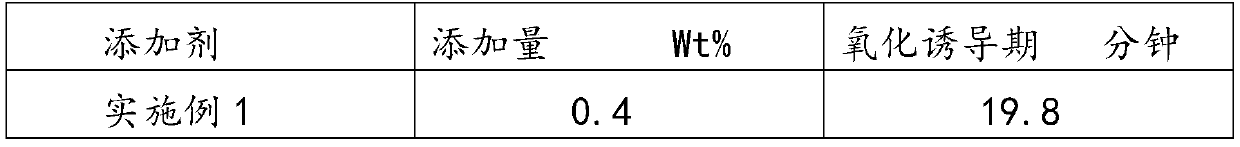

Composite catalyst, and preparation method of nonyldiphenylamine

ActiveCN106944142AHigh viscosityHigh base numberAmino preparation from aminesOrganic-compounds/hydrides/coordination-complexes catalystsOxideZinc

The invention provides a composite catalyst and a preparation method of nonyldiphenylamine. The composite catalyst comprises active clay, p-toluenesulfonic acid and active zinc oxide according to a mass ratio of 100:(0.1-5):(0.1-5). The composite catalyst can catalyze the alkylation reaction of diphenylamine and nonene, so the obtained nonyldiphenylamine product has light color, high viscosity and high base value, the residual content of diphenylamine in the product is low, and the performances of the product are greatly improved.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

Preparation method of foamed polypropylene beads

The invention belongs to the technical field of foamed polypropylene, and relates to a preparation method of foamed polypropylene beads, which comprises the following steps: (1) adding polypropylene particles, a dispersion medium, a dispersing agent and a dispersing aid into a closed high-pressure-resistant kettle, and conducting stirring to form a dispersion system; (2) conducting heating to a certain temperature, and conducting filling with a certain amount of CO2; and (3) releasing the dispersion to normal pressure to obtain foamed polypropylene beads, conducting washing with cleaning water, conducting dehydrating, and conducting drying to obtain a foamed polypropylene bead finished product. The polypropylene particles comprise the following components in percentage by weight: 94 to 99.94 percent of polypropylene, 0.01 to 2 percent of a crystallization nucleating agent, 0.02 to 4 percent of an organophosphate compound and 0.03 to 0.3 percent of a cell nucleating agent. The polypropylene particles used in the invention contain organophosphate compounds, and have the effect of inhibiting the particles from caking in a kettle or the beads from caking outside the kettle in the high-temperature and high-pressure kettle type foaming process, so that the use amount of a dispersing agent can be reduced, the content of attachments on the surface of the foamed polypropylene bead finished product is lower than 200ppm, and a water vapor molded part is lower in sintering pressure and excellent in apparent quality.

Owner:WUXI HI TEC ENVIRONMENTAL MATERIAL CO LTD

Method for preparing tetrafluoroethane by virtue of trichloroethylene

ActiveCN107266285AExtend your lifeImprove conversion ratePreparation by halogen replacementChemical industryExtractive distillationTrichloroethylene

The invention discloses a method for preparing tetrafluoroethane by virtue of trichloroethylene. The method comprises the following steps: (a) mixing, and carrying out preheating; (b) carrying out circular reaction; (c) absorbing tail gas; (d) carrying out extractive distillation; and (e) purifying a product. The reaction process is simple and easy to control, and the method has the characteristics of few synthesis steps and byproducts, high selectivity, cheap catalysts and the like and is applicable to industrial continuous production.

Owner:ZHEJIANG SANMEI CHEM IND

Method for preparing porous hydroxyapatite scaffold via two-step process

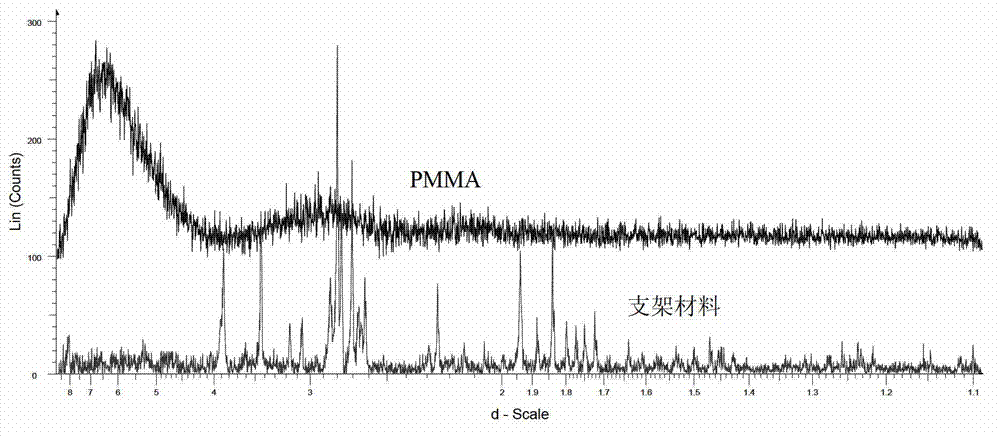

The invention relates to a method for preparing a porous hydroxyapatite scaffold via a two-step process, and belongs to the technical field of biomedical materials. The method comprises the following steps: evenly mixing fluoride hydroxyapatite, PMMA (polymethyl methacrylate) and SDS (sodium dodecyl sulfate); dripping an ammonium bicarbonate solution into the mixture and evenly stirring; drying and heating to reach the temperature of 400 to 600 DEG C; carrying out a heat preservation treatment; continuously heating to reach the temperature of 1000 to 1300 DEG C and carrying out the secondary heat preservation; and finally cooling along with a cooling furnace, thereby obtaining the porous hydroxyapatite scaffold. Based on the secondary high-temperature sintering process, the strength and the toughness of the scaffold material are improved. The residual quantity of the PMMA as a foaming agent in the scaffold is very low, so that the usage of a template is avoided; and the existing technological process is simplified greatly. In addition, the method is simple to operate.

Owner:SHANGHAI JIAO TONG UNIV

Foamed light diffusion material and preparation method thereof

ActiveCN113352536AReduce residual contentReduce the possibility of precipitation sticking moldBulk chemical productionPolymer scienceInjection molding process

The invention relates to the field of light diffusion materials, and particularly discloses a foamed light diffusion material and a preparation method thereof. The foamed light diffusion material is prepared from the components in parts by weight: 93-105 parts of PC, 0.1-0.5 part of antioxidant and 0.3-0.8 part of a release agent. The preparation method comprises the following steps that granules are prepared, and 93-105 parts by weight of PC, 0.1-0.5 part by weight of antioxidant and 0.3-0.8 part by weight of the release agent are uniformly mixed and extruded to obtain the granules; and injection molding foaming and monomer removal are carried out, supercritical carbon dioxide is injected in the injection molding process to carry out foaming and steam stripping monomer removal to obtain the foamed light diffusion material. The temperatures of different areas of a screw rod are 280 to 300 DEG C, 280 to 300 DEG C, 280 to 300 DEG C, 280 to 300 DEG C, 280 to 300 DEG C, 230 to 380 DEG C and 60 to 80 DEG C in sequence; and the pressure maintaining pressure is 60 to 100 MPa. The foamed light diffusion material can be used for processing an LED lamp housing, and has the advantages of high haze and low residual monomer content; and in addition, the preparation method has the advantage of reducing the possibility of mold sticking of a product in the processing process.

Owner:NINGBO ZHETIE DAPHOON CHEM

Tree leaf cultivation method

InactiveCN110050625AReduce labor intensityReduce residual contentFertilising methodsCultivating equipmentsInsect pestPlant disease

The invention discloses a tree leaf cultivation method. The tree leaf cultivation method comprises the following steps: (1) carrying out heavy pruning on tea trees at an adult production period at thelast ten-day period of May; (2) carrying out tree maintenance and tree crown growth from the first ten-day period of June to the last ten-day period of October; (3) applying biogenic pesticide; (4) applying base fertilizer; (5) carrying out top application in spring of the next year; (6) picking spring tea; (7) not picking summer tea and autumn tea, and carrying out the tree maintenance and treecrown growth in summer and autumn. According to the tree leaf cultivation method disclosed by the invention, plant diseases and insect pests are effectively prevented and controlled; only the spring tea is picked, and the summer tea and the autumn tea are not picked; the tree maintenance and tree crown growth are carried out in summer and autumn; the quality of picked spring fresh tea leaves is good and the yield and output value are high; the manual labor intensity for tea picking is reduced and the cultivation cost is reduced.

Owner:四川绿源春茶业有限公司

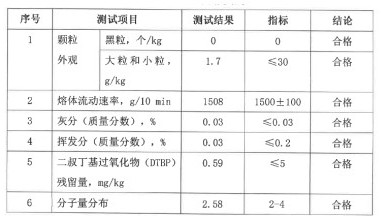

Production formula and process of modified polypropylene special for melt-blown cloth

InactiveCN112080065ASmall melt index fluctuation rangeReduce residual contentNon-woven fabricsMonocomponent polyolefin artificial filamentPeristaltic pumpPolymer science

The invention relates to the technical field of new materials, in particular to a production formula and process of modified polypropylene special for melt-blown cloth. According to the technical scheme, the modified polypropylene is composed of 99.4% of PP, 0.4% of di-tert-butyl peroxide (DTBP) and 0.2% of an antioxidant mixture; the 0.2% of antioxidant is formed by mixing an antioxidant 168 andan antioxidant 1010 according to the proportion of 2: 1; processing is completed in a closed space through seven steps; a peristaltic pump is adopted for injection from a first-area feeding port of anextruder; And the processing temperatures of different sections of the extruder are controlled. The production formula and process have the advantages that the ash content of the product is smaller,the residual content of di-tert-butyl peroxide (DTBP) is lower; meanwhile, uncontrollable potential safety hazards possibly occurring in the mixing process of a traditional process can be avoided, andthe melt index fluctuation range of the finished product is smaller.

Owner:江苏秀乐新材料科技有限公司

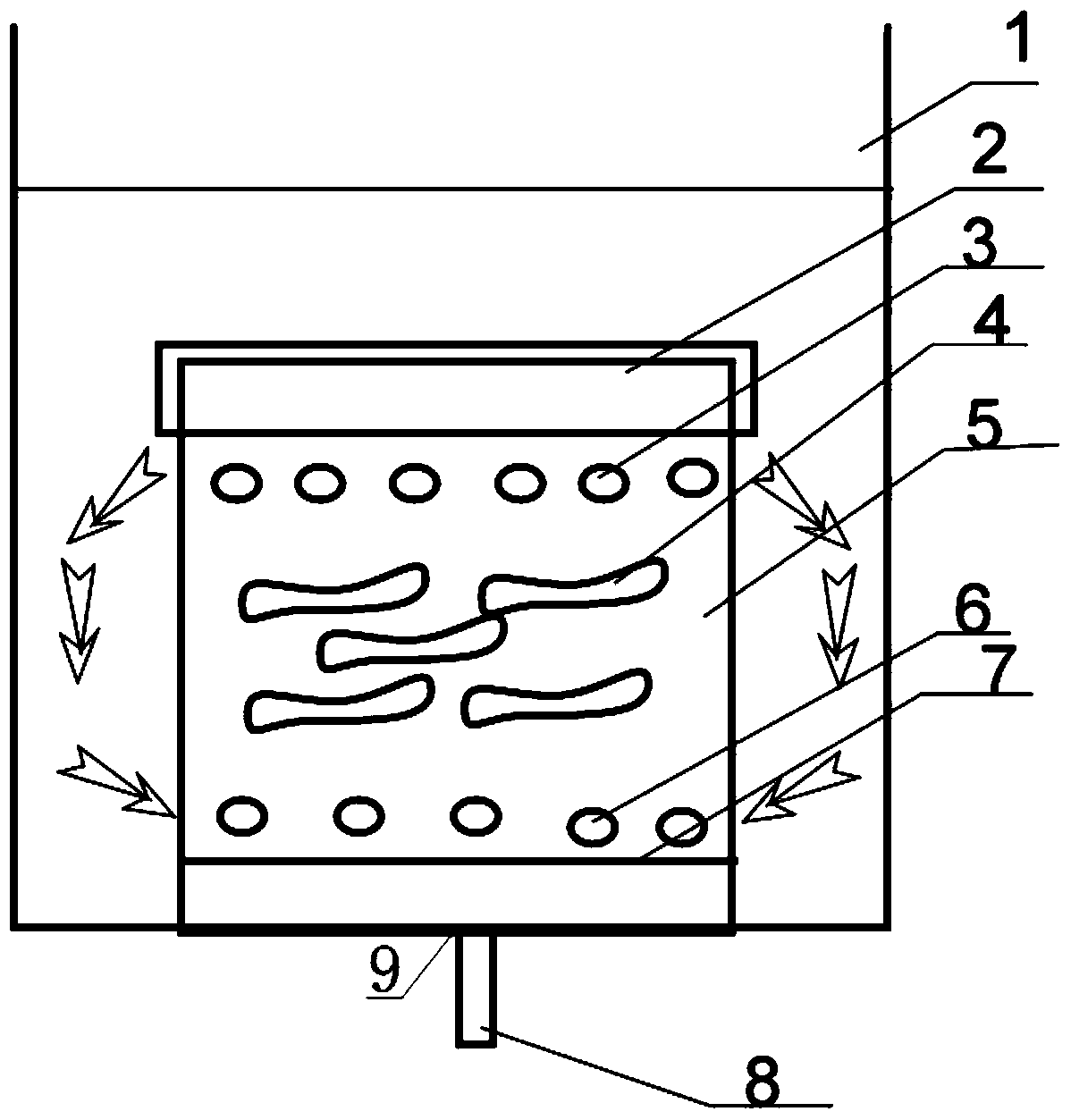

Method and device for stewing traditional Chinese medicine

ActiveCN103519996AOvercome the disadvantages of muddy bottomSolving Quantitative PuzzlesPharmaceutical product form changeEngineeringChinese drug

The invention discloses a method and a device for stewing traditional Chinese medicine. The device comprises an inner container, an inner container cover, an outer container, lower convection holes, upper convection holes and a heating portion. The inner container cover is arranged at the top of the inner container. The upper convection holes are formed in the side wall of the inner container or the inner container cover. The lower convection holes are formed in the side wall of the inner container and positioned below the upper convection holes. The heating portion is connected with the bottom of the inner container. An opening matched with the heating portion to allow the same to pass is further formed in the bottom of the outer container. By the method and the device, the problem about quantification of traditional Chinese medicine soup is solved, volatile elements in the traditional Chinese medicine are less prone to volatilizing into the air, and quantity of residual effective elements in dregs is reduced.

Owner:SHENZHEN ZOFU TECH

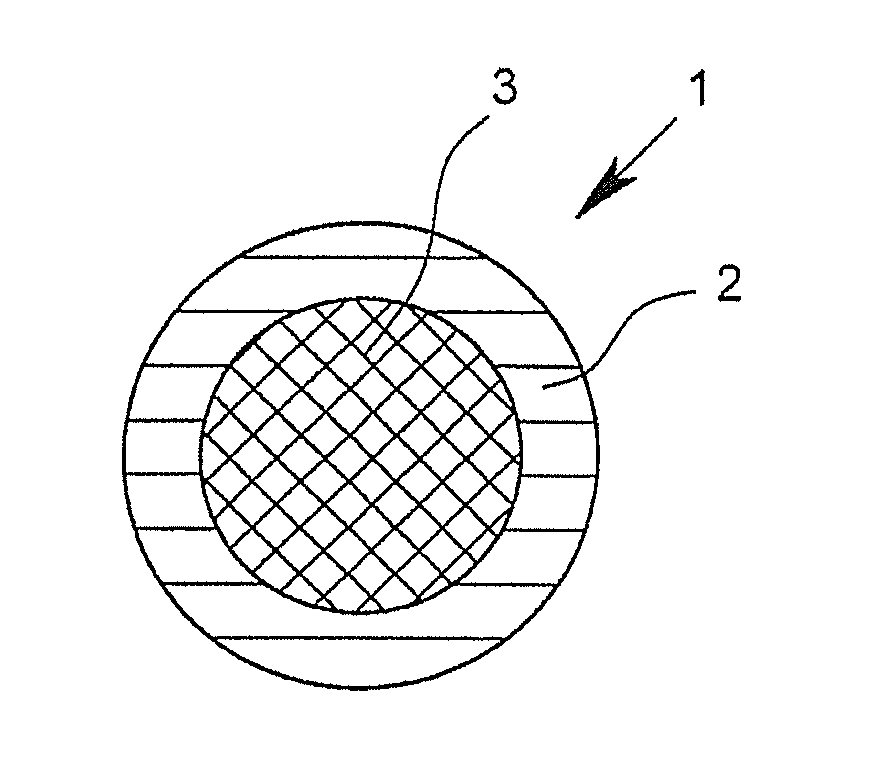

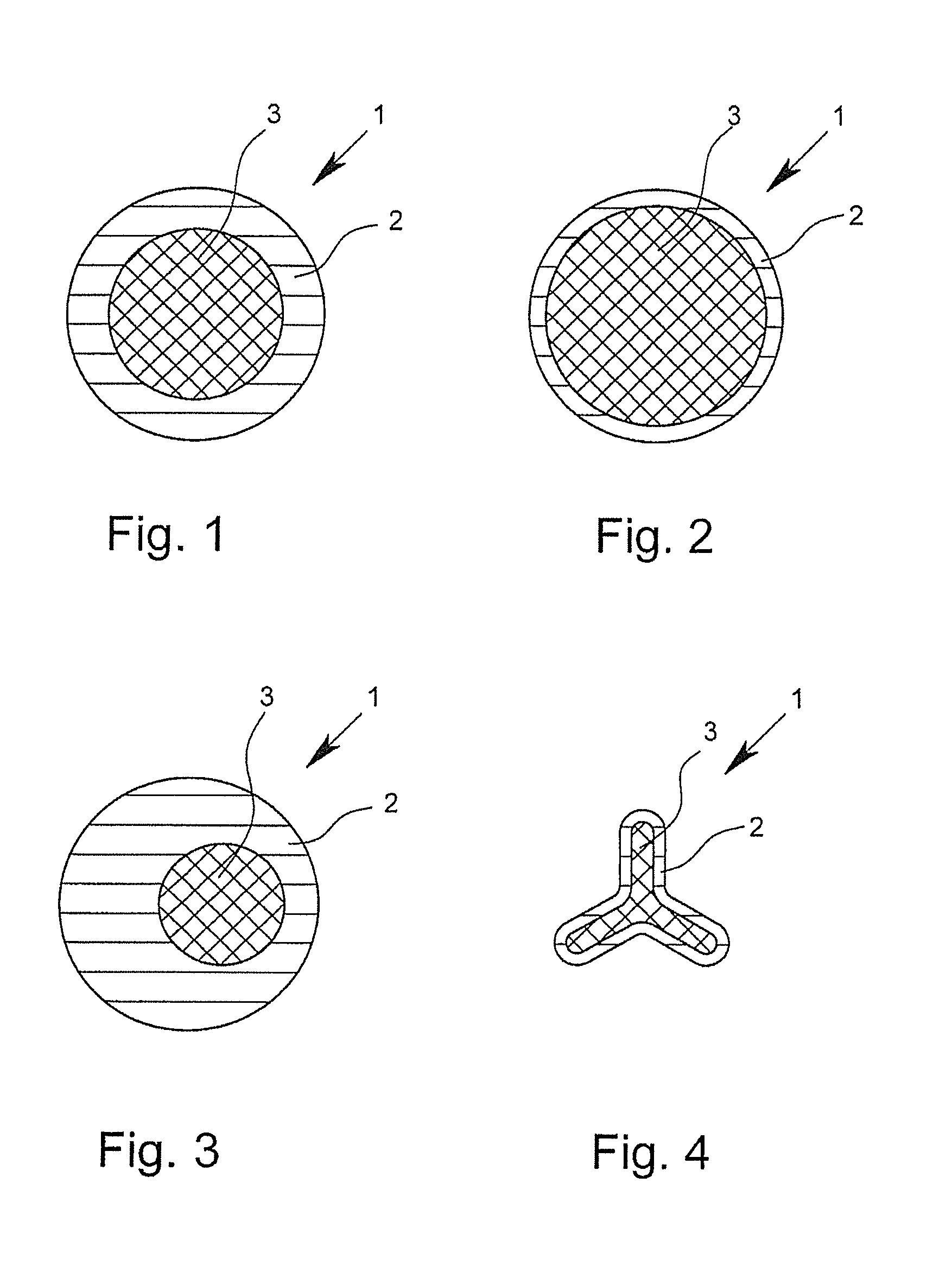

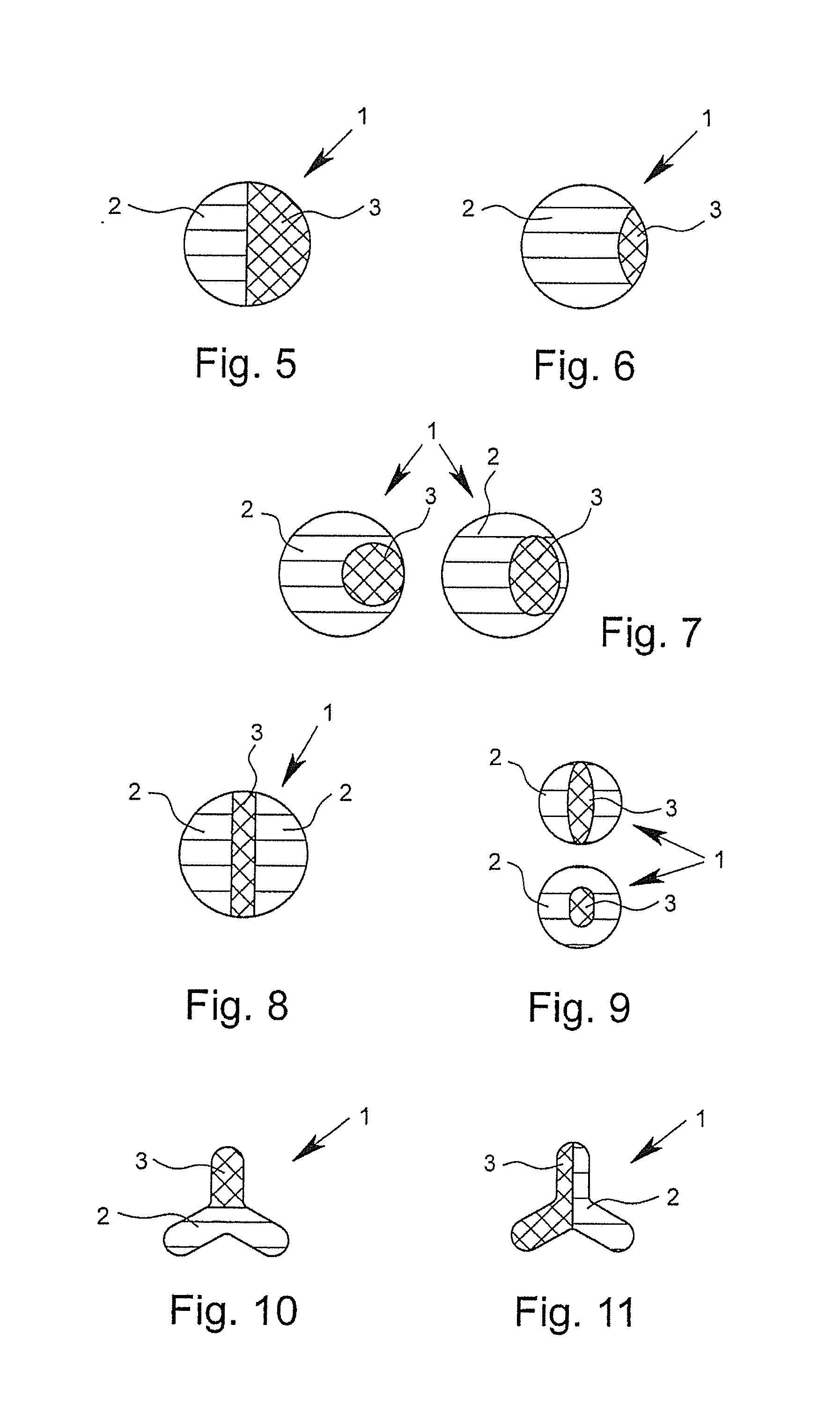

Bi-component fiber for the production of spunbonded fabric

InactiveUS20150017867A1Improve securityHigh elongationAntifouling/underwater paintsPaints with biocidesFiberZiegler–Natta catalyst

A bi-component fiber (1), in particular for the production of spunbond fabrics (4), with a first component (2) and a second component (3), whereby the first component (2) has a first polymer as an integral part and the second component has a second polymer as an integral part. The polymer of one of the two components (2, 3) has been polymerized with a metallocene catalyst and the polymer of the other component (2, 3) has been polymerized with a Ziegler-Natta catalyst and subjected to a subsequent visbreaking treatment.

Owner:EWALD DORKEN

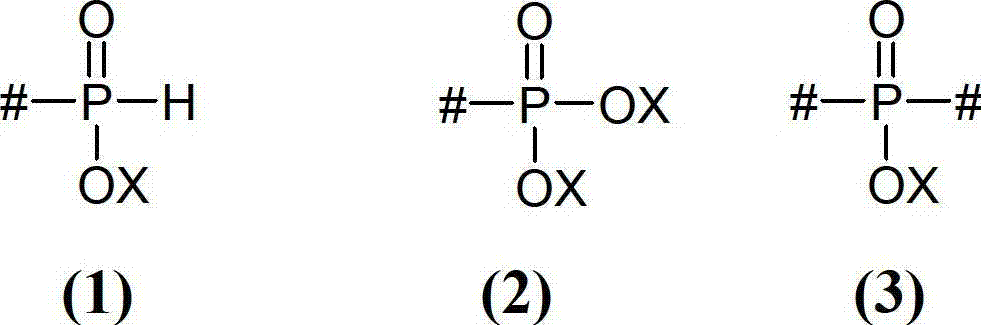

Copolymers of monocarboxylic acids and dicarboxylic acids, their preparation and use

InactiveCN102971344ASmall molecular weightHigh solid contentAnionic surface-active compoundsDetergent compounding agentsPhosphoric acidPhosphinic Acids

The invention relates to a process for preparing a polymer by free-radical polymerization of at least one ethylenically unsaturated monocarboxylic acid and / or a salt thereof, at least one ethylenically unsaturated dicarboxylic acid and / or an anhydride and / or a salt thereof, in the presence of hypophosphorous acid and / or a salt thereof. The invention also relates to a polymer composition obtainable by this process. The invention also relates to the use of such a polymer composition as detergent additive, e.g. as dispersant, scale inhibitor or sequestrant for laundry detergents.

Owner:BASF AG

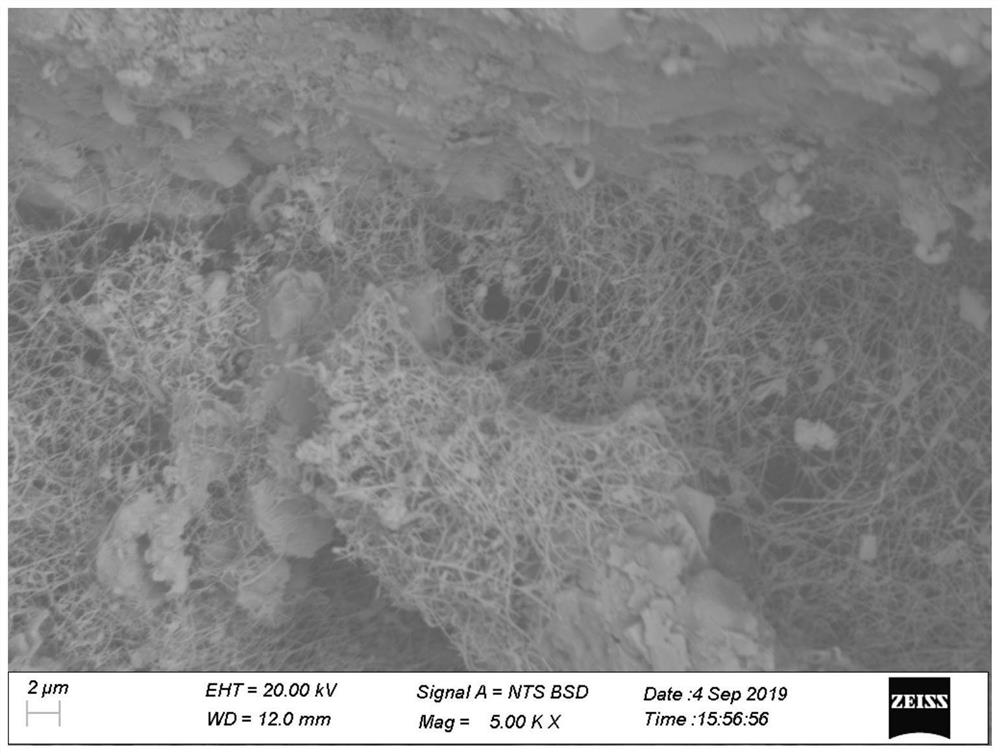

Preparation method of liquid amine type antioxidant

InactiveCN109734603AReduce residual contentSimple processAmino preparation from aminesAdditivesMother liquorDistillation

The invention discloses a preparation method of a liquid amine type antioxidant. The preparation method includes following steps: proportionally adding diphenylamine, activated clay composite catalystand polymerization inhibitor into a reaction kettle; proportionally adding diisobutylene into the reaction kettle, and rising temperature for alkylation reaction; cooling and filtering a reaction product after reaction in the step (2), and performing reduced pressure distillation on filtered-out mother liquid to remove unreacted olefin to obtain the liquid amine type antioxidant. The activated clay composite catalyst is adopted for alkylation reaction, so that reaction temperature is lowered, reaction time is shortened, generated alkyl diphenylamine RF5057 is little in diphenylamine residue,the antioxidant is shallow in appearance color and free of three wastes after aftertreatment, and the preparation method is an environment-friendly synthesis process.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

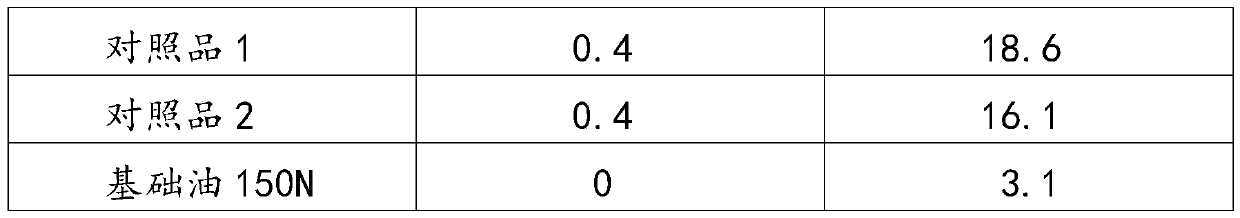

Extraction process for ultrahigh molecular weight polyethylene fibre

InactiveCN101525774AReduce residual contentHigh strengthArtificial filament physical treatmentWet spinning methodsFiberState of art

The invention relates to an extraction process for an ultrahigh molecular weight polyethylene fibre. The extraction process adopts multilevel continuous extraction technology and three-dimensional ultrasonic vibration extraction accelerating technology; and an extracting agent is a compounded alkane extracting agent. Compared with the prior art, the extraction process adopts the novel compounded alkane extracting agent and the three-dimensional ultrasonic vibration extraction accelerating technology, adopts multilevel continuous extraction, utilizes the gradient distribution of the solvent content in the extracting agent to form a set of the high-efficiency extraction process, improves the extracting speed, effectively reduces the residual content of the solvent in fibre yarn, establishes a good foundation for improving the drawing speed in the drawing procedure and the product quality, and can obtain the high-strength (more than 35 g / d) ultrahigh molecular weight polyethylene fibre.

Owner:SURREY HI TECH INC

Nano Al2O3-SiC composite powder, low-carbon pouring steel ladle sliding plate brick and preparation methods of nano Al2O3-SiC composite powder and low-carbon pouring steel ladle sliding plate brick

The invention discloses nano Al2O3-SiC composite powder, a low-carbon pouring steel ladle sliding plate brick and preparation methods of the nano Al2O3-SiC composite powder and the low-carbon pouring steel ladle sliding plate brick, and belongs to the technical field of refractory materials for steel ladles. The nano Al2O3-SiC composite powder is prepared by adopting a gas phase method, Al2O3 is uniformly dispersed on the surface of SiC fine powder, and D50 of Al2O3 is equal to 13nm; the low-carbon pouring steel ladle sliding plate brick is prepared by adding the prepared nano Al2O3-SiC composite powder and adopting a multi-time dispersing, pouring, multi-stage curing, asphalt dipping and dry distillation carbonization process, and the prepared sliding plate brick is high in volume density and strength, good in high-temperature sinterability, thermal shock stability and molten steel and steel slag corrosion resistance, good in thermal shock resistance, good in thermal shock resistance and long in service life. And the service life of the sliding plate brick is prolonged.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

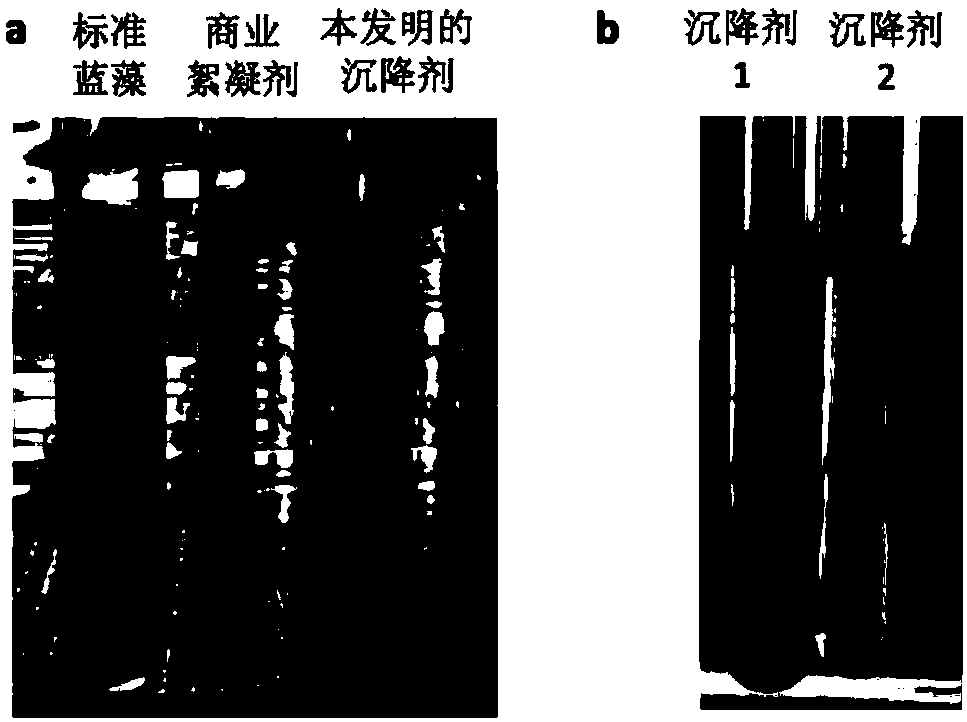

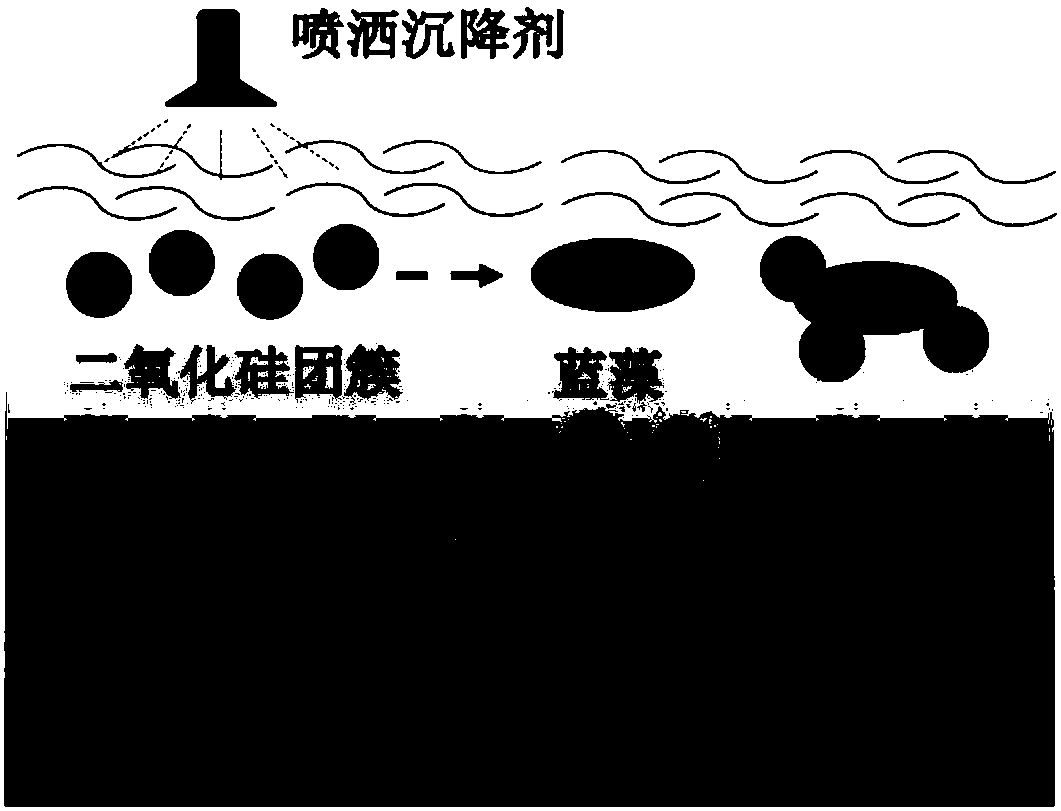

Preparation method and application method of silicon dioxide cluster-based novel settling agent

PendingCN108249532AReduce residueAdjustable densitySilicaAlkali metal silicatesChemistryCluster based

The invention discloses a preparation method and an application method of a silicon dioxide cluster-based novel settling agent. Silicon dioxide clusters serve as settling agent main bodies, and metalions and the silicon dioxide clusters are combined by utilizing the strong interaction between the silicon dioxide clusters and the metal ions, so that a metal ion modified settling agent is obtained,and the content of metal ion residues such as aluminum ions in the treated water body can be reduced; the settling agent provided by the invention can be selectively combined with blue-green algae, so the influence on other aquatic organisms is greatly reduced; the density of the final settling material can be adjusted by adjusting the polymerization degree or grain size of the silicon dioxide clusters in the settling agent and the metal content, the prepared settling material can float on the water surface and also can sink into the water bottom, and different salvage treatment requirementscan be met; and the settling agent provided by the invention is faintly acidic, so the living environment of the blue-green algae can be broken by a mode of reducing the pH value of the water body while the blue-green algae are settled, and the growth of the blue-green algae can be inhibited.

Owner:合肥星巢环保科技有限公司

Process for preparing polypropylene with lower ash content

Owner:BOREALIS AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com