Method for preparing super absorbent resin with low residual acrylic monomer content

A technology of superabsorbent resin and acrylic acid monomer, which is applied in the field of preparing superabsorbent resin with low residual acrylic acid monomer content, which can solve the problems of reduced drying efficiency, clogged nozzle production, high solution viscosity, etc., and achieve the effect of long drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Gel preparation:

[0024] at 1m 3 Add 293 kilograms of sodium hydroxide aqueous solution (32wt%) and 272 kilograms of deionized water into the reaction kettle, start the stirring of the reaction kettle, slowly add 225 kilograms of acrylic acid dropwise, keep the temperature of the reaction kettle at 20-30 ° C, and the addition of acrylic acid is completed , add 0.5 kilogram of crosslinking agent N, N-methylenebisacrylamide and 0.25 kilogram of crosslinking agent ethoxytrimethylolpropane triacrylate, then add 0.9 kilogram of initiator potassium persulfate, continue to stir, to reaction The kettle was filled with nitrogen, and the temperature of the reactor was kept at 20-30°C. The above-mentioned mixed material was continuously fed into a continuous conveyor belt with a length of 600cm and a width of 40cm at a flow rate of 48kg / hr for polymerization. The temperature of the conveyor belt was controlled at 85± 5°C, the reaction residence time is 1.5 hours, and the superab...

Embodiment 2

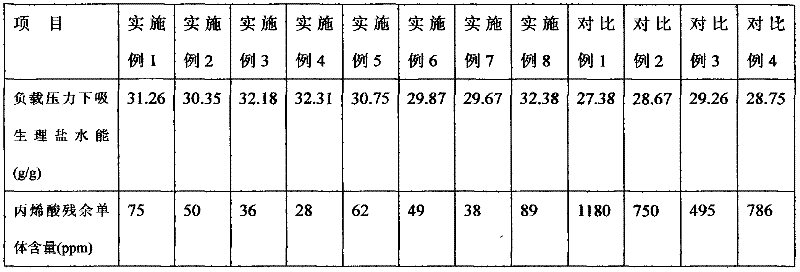

[0028] The preparation of gel is the same as in Example 1, and the disintegrating process of gel is the same as in Example 1. The difference is that the concentration of the initiator potassium persulfate aqueous solution sprayed into the disintegrating process is 1% by weight, and the amount added is 1% by weight. The weight is 3% by weight, and the crosslinking agent is a tripropylene glycol dimethacrylate crosslinking agent solution with a concentration of 0.5% by weight, and the added amount is 5% by weight of the weight of the gel. After 2 minutes of microwave radiation on the disintegrated material, the product obtained by drying, crushing and post-surface cross-linking treatment has been tested. The residual content of acrylic acid monomer is 50ppm, and the absorption rate of normal saline under load pressure is 30.35g / g.

Embodiment 3

[0030] The preparation of the gel is the same as in Example 1, and the disintegrating process of the gel is the same as in Example 1. The difference is that the aqueous solution of initiator potassium persulfate and ascorbic acid is sprayed into the disintegrating process, and the concentration of the aqueous solution is 0.5% by weight. The amount is 5% by weight of gel weight, and the addition type and consumption of crosslinking agent are the same as embodiment 1. After the disintegrated material was irradiated by microwave for 2 minutes, the product obtained by drying, crushing and post-surface crosslinking treatment was tested by performance. The residual content of acrylic acid monomer was 36ppm, and the absorption rate of normal saline under load pressure was 32.08g / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com