Nano Al2O3-SiC composite powder, low-carbon pouring steel ladle sliding plate brick and preparation methods of nano Al2O3-SiC composite powder and low-carbon pouring steel ladle sliding plate brick

A technology of composite powder and sliding brick, which is applied in the field of refractory materials for ladles, can solve the problem of SiC being difficult to mix evenly, and achieve the effects of improving thermal shock stability, improving oxidation resistance, and increasing bulk density and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

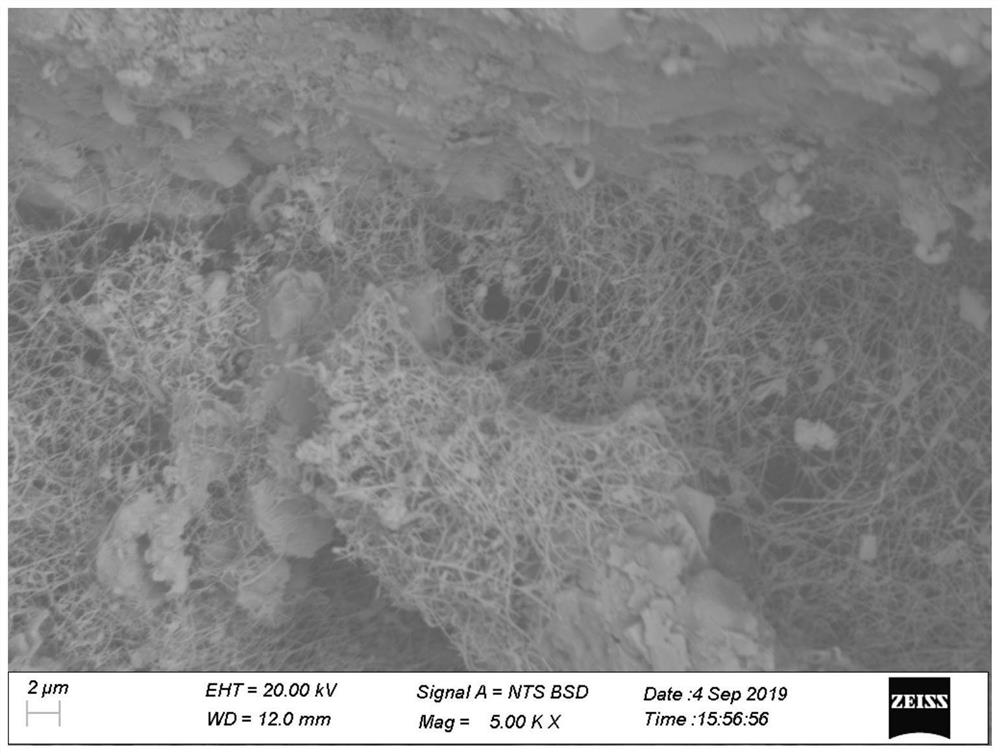

Image

Examples

Embodiment 1

[0069] The composition and weight percentage of the low-carbon poured ladle sliding brick of this embodiment are as follows: the granular material includes 5% of platy corundum particles with a particle diameter of 5-3mm, and 35% of platy corundum particles with a particle diameter of 3-1mm , 23% of fused white corundum particles with a particle size of 1-0mm, the fine powder material includes 10% of fused white corundum fine powder with a particle size of 0-0.045mm, fused magnesia fine powder with a particle size of 0-0.074mm Powder 8%, Nano Al 2 o 3 -SiC composite powder 3%, active α-Al 2 o 3 10% of fine powder, 5% of composite binder, 0.5% of water reducer and 0.5% of explosion-proof agent, the total weight percentage is 100%; plus liquid water accounting for 4% of the total weight. Among them, nano-Al 2 o 3 -Nano Al in SiC composite powder 2 o 3 The mass percentage of SiC fine powder is 4:6; the mass ratio of calcium aluminate cement, silica powder, and hydraulic al...

Embodiment 2

[0082] The composition and weight percentage of the low-carbon poured ladle sliding brick of this embodiment are as follows: the granular material includes 8% of platy corundum particles with a particle diameter of 5-3mm, and 33% of platy corundum particles with a particle diameter of 3-1mm , 20% of fused white corundum particles with a particle size of 1-0mm, the fine powder material includes 14% of fused white corundum fine powder with a particle size of 0-0.045mm, fused magnesia fine powder with a particle size of 0-0.074mm Powder 6%, nano Al 2 o 3 -SiC composite powder 4%, active α-Al 2 o 3 6% of micropowder, 8% of composite binder, 0.5% of water reducer and 0.5% of explosion-proof agent, the total weight percentage is 100%; plus liquid water accounting for 5% of the total weight. Among them, nano-Al 2 o 3 -Nano Al in SiC composite powder 2 o 3 The mass percentage of SiC fine powder is 2:8; the mass ratio of calcium aluminate cement, silica micropowder, and hydrauli...

Embodiment 3

[0095] The composition and weight percentage of the low-carbon poured ladle sliding brick of this embodiment are as follows: the granular material includes 10% of tabular corundum particles with a particle diameter of 5-3mm, and 28% of tabular corundum particles with a particle diameter of 3-1mm , 25% of fused white corundum particles with a particle size of 1-0 mm, the fine powder material includes 12% of fused white corundum fine powder with a particle size of 0-0.045 mm, fused magnesia fine powder with a particle size of 0-0.074 mm Powder 5%, nano Al 2 o 3 -SiC composite powder 5%, active α-Al 2 o 3 8% of fine powder, 6% of composite binder, 0.5% of water reducing agent and 0.5% of explosion-proof agent, the total weight percentage is 100%; plus liquid water accounting for 4.5% of the total weight. Among them, nano-Al 2 o 3 -Nano Al in SiC composite powder 2 o 3 The mass percentage of SiC fine powder is 2:8; the mass ratio of calcium aluminate cement, silica micropow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com