Copolymers of monocarboxylic acids and dicarboxylic acids, their preparation and use

A technology of monocarboxylic acid and dicarboxylic acid, used in detergent compositions, chemical instruments and methods, anionic surface active compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

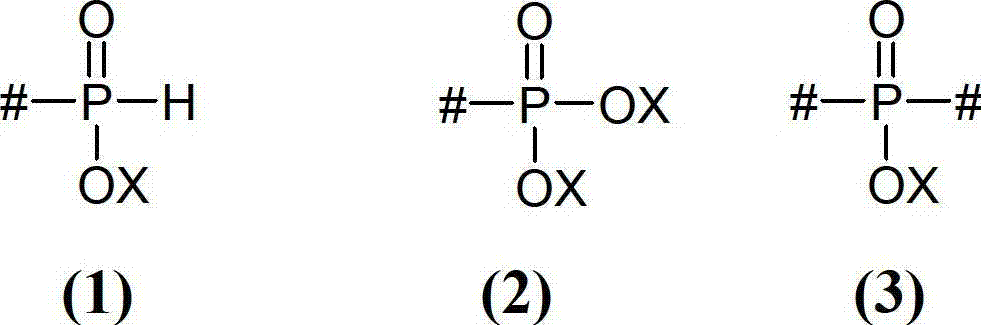

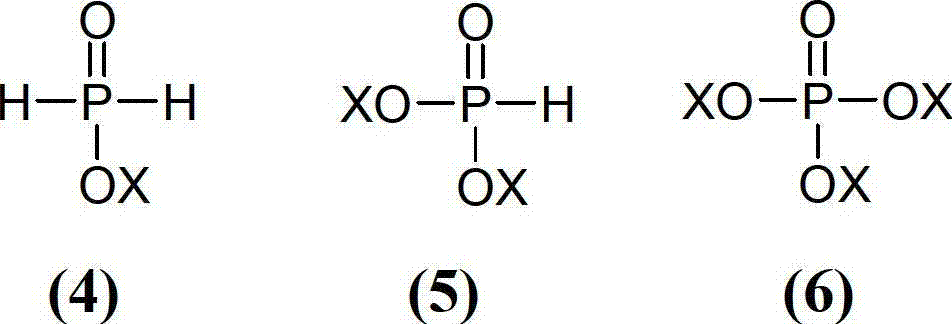

Image

Examples

preparation example Construction

[0037] According to another preferred type of preparation, the polymers are obtained by polymerizing monomer mixtures in the presence of redox initiator systems. The redox initiator system comprises at least one oxidizing agent component and at least one reducing agent component, wherein heavy metal ions, for example iron(II) salts, cerium salts or manganese salts, are preferably additionally present as catalysts in the reaction medium.

[0038] Suitable oxidizing agents are, for example, peroxides and / or hydroperoxides, such as hydrogen peroxide, tert-butyl hydroperoxide, cumene hydroperoxide, pinane hydroperoxide, diisopropylbenzene hydroperoxide dicyclohexyl percarbonate, dibenzoyl peroxide, dilauroyl peroxide and diacetyl peroxide. Hydrogen peroxide is preferred as oxidizing agent.

[0039] Suitable as reducing agent components or catalysts are iron(II) salts such as iron(II) sulfate, tin(II) salts such as tin(II) chloride, titanium(III) salts such as titanium(III) sulfat...

Embodiment 1

[0135] The weight ratio of acrylic acid to maleic anhydride is 70:30. To a 2L reactor was charged 214.00 g deionized water and 117.60 g maleic anhydride under nitrogen, heating to an internal temperature of 60°C while stirring. When an internal temperature of 60°C was reached, 172.80 g of a 50% caustic soda solution was added over 2 hours to raise the internal temperature of the vessel to 100°C. After the addition of caustic soda was complete, 325.00 g of acrylic acid and 261.60 g of aqueous sodium hypophosphite (59%) were added linearly at a rate such that the addition was complete within 4 hours. Simultaneously 398.34 g of aqueous hydrogen peroxide (4.4%) initiator was added linearly to the vessel such that the addition was complete within 5 hours. Postpolymerization was started at 100°C for 1 hour. The vessel was then cooled to 80°C, and then 300.00 g of 50% sodium hydroxide was added to the vessel with continuous stirring for 1 hour. The internal temperature was not all...

Embodiment 2

[0141] Repeat the program of Example 1, but there are following differences:

[0142] The weight ratio of acrylic acid to maleic anhydride is 90:10. The precharged amounts of water and maleic anhydride were 214.4 g and 39.2 g, respectively. The amount of sodium hydroxide was 57.6 g (50%). The amount of acrylic acid was 417.8 g. The amounts of initiator and chain transfer agent were changed to 338.20 g and 386.40 g of aqueous sodium hypophosphite (59%) and hydrogen peroxide (4.4%), respectively. Finally the solution polymer was neutralized with an additional 463.00 g of sodium hydroxide (50%). The resulting solutions were also evaluated for appearance, pH, K value, Mn, Mw, % solids content.

[0143]

[0144] a) ISO 3251 (0.25g, 150°C, 2h)

[0145] b) Determination in 1% deionized water by the Fikentscher method

[0146] c) Determination by Gel Permeation Chromatography

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com