Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduce chipping rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

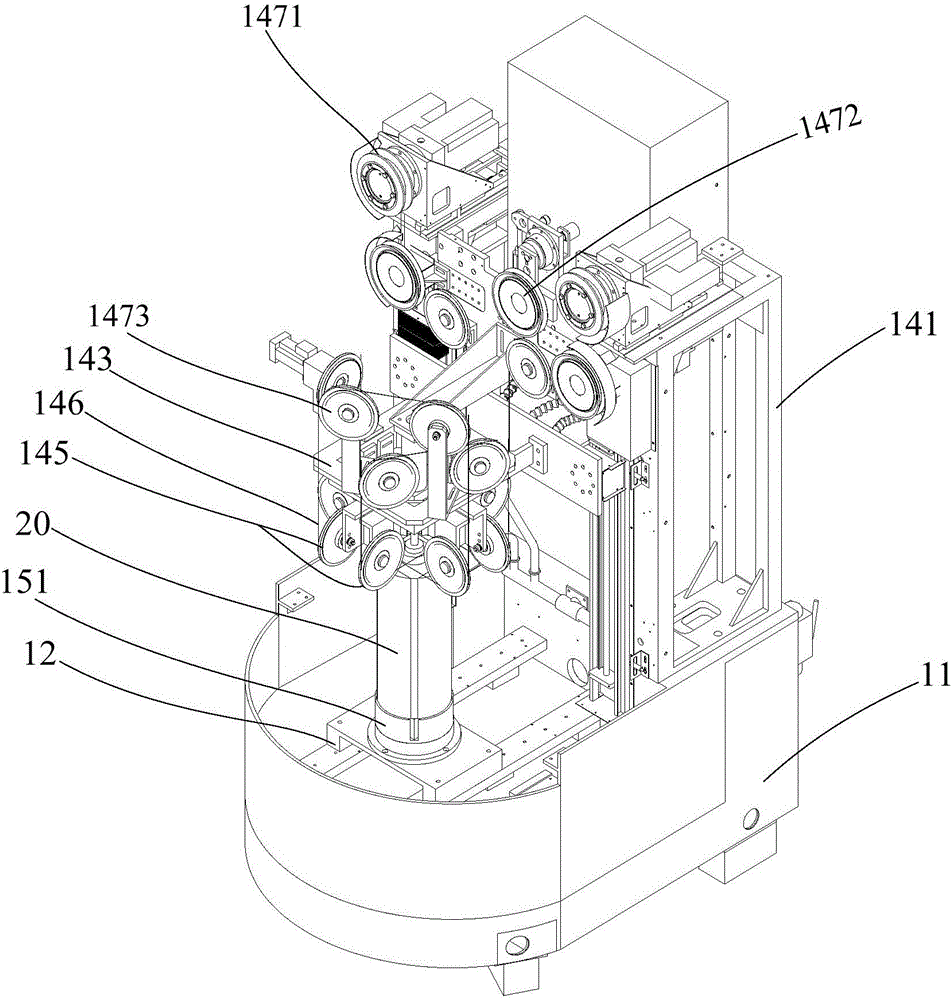

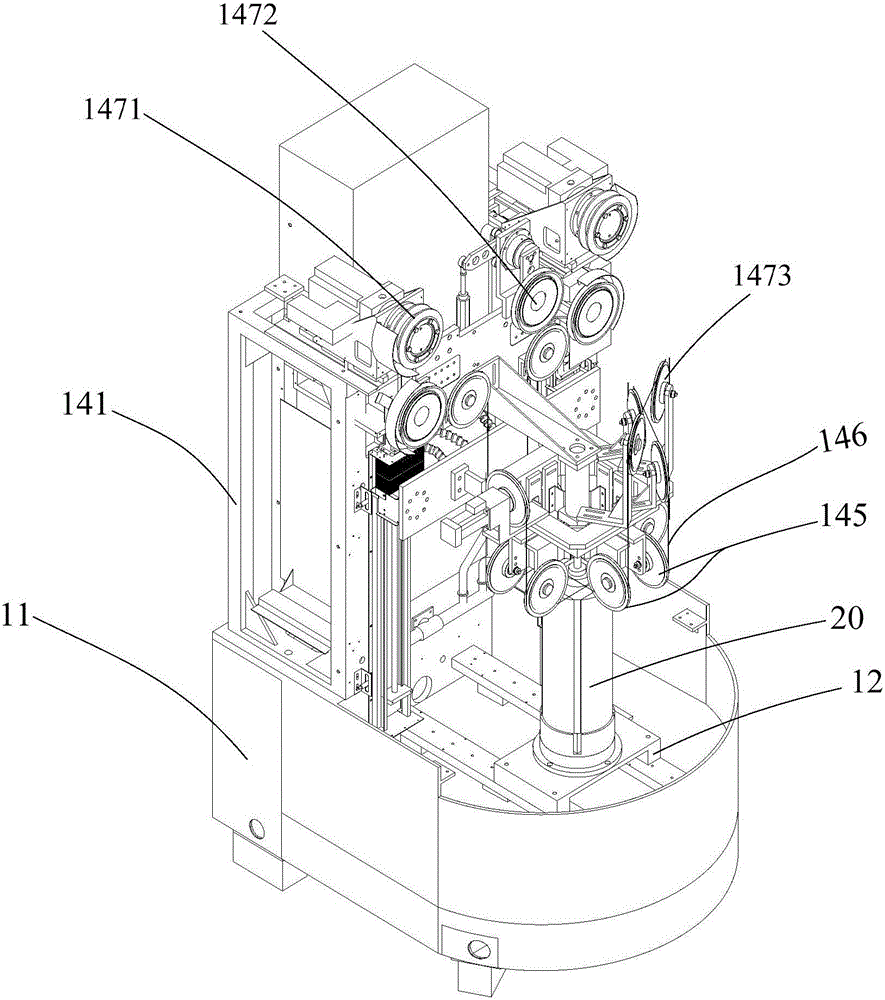

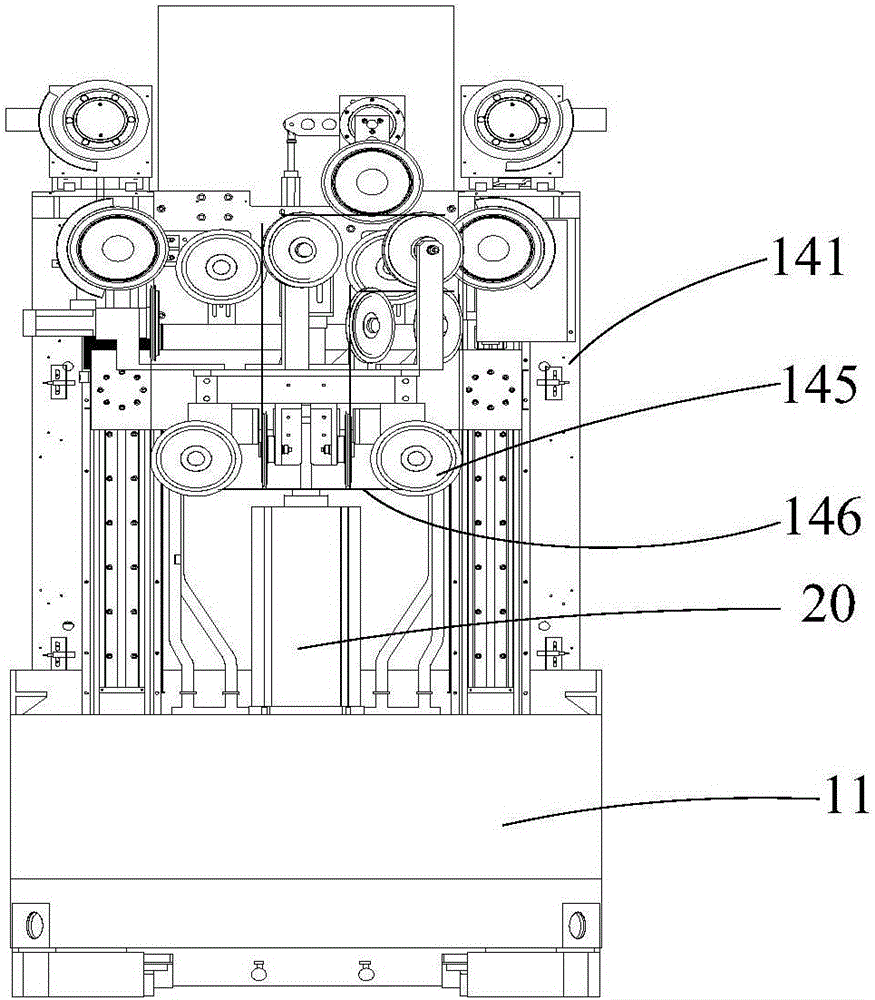

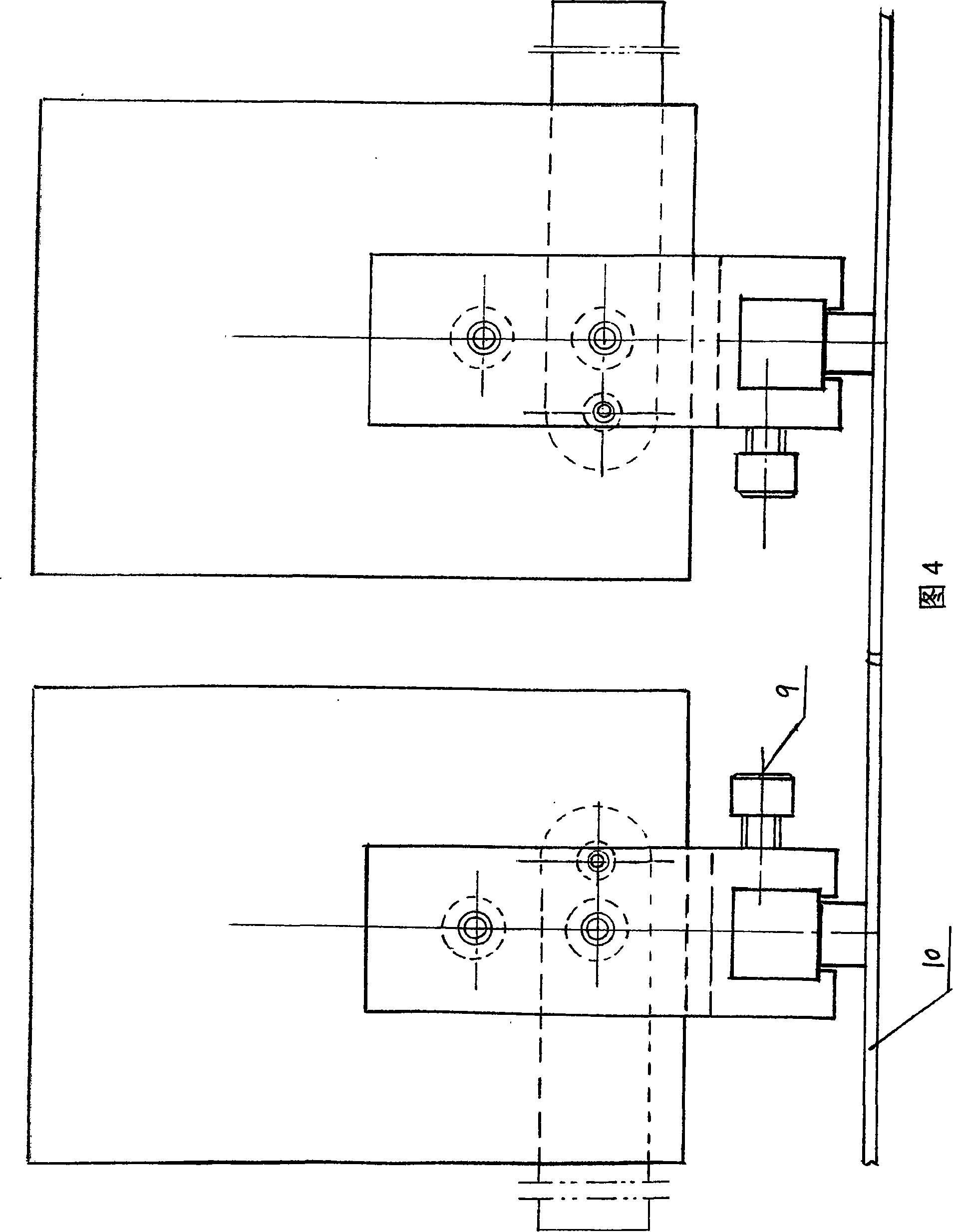

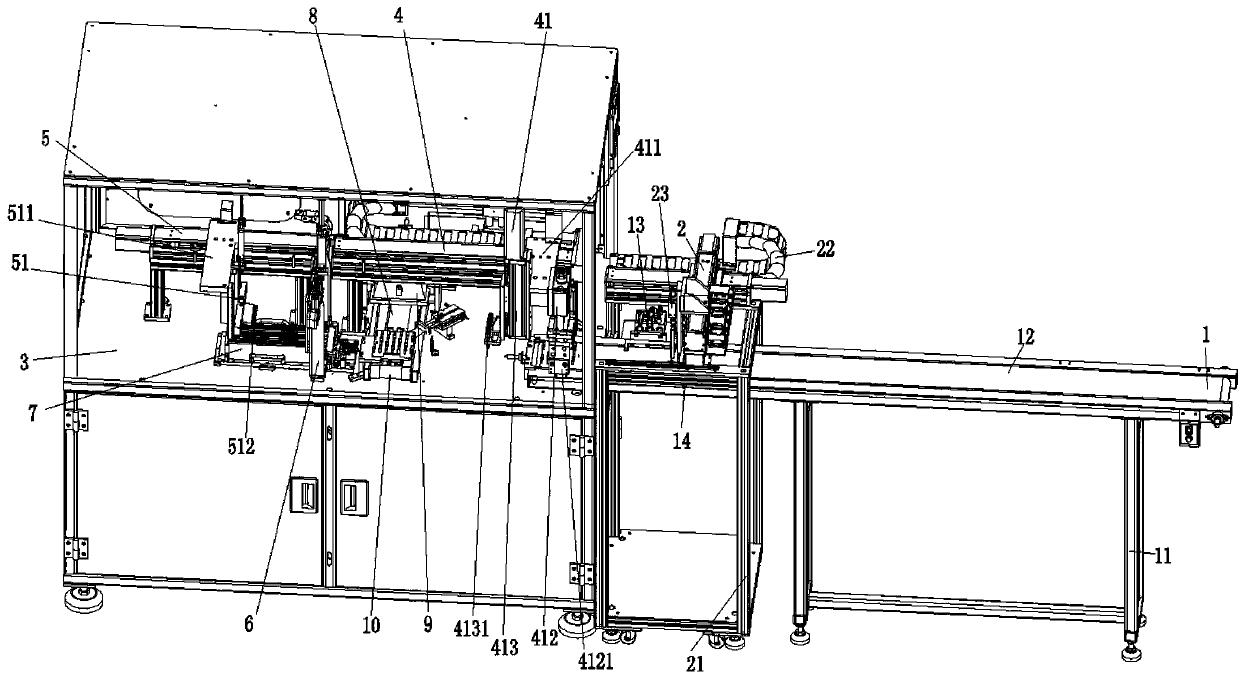

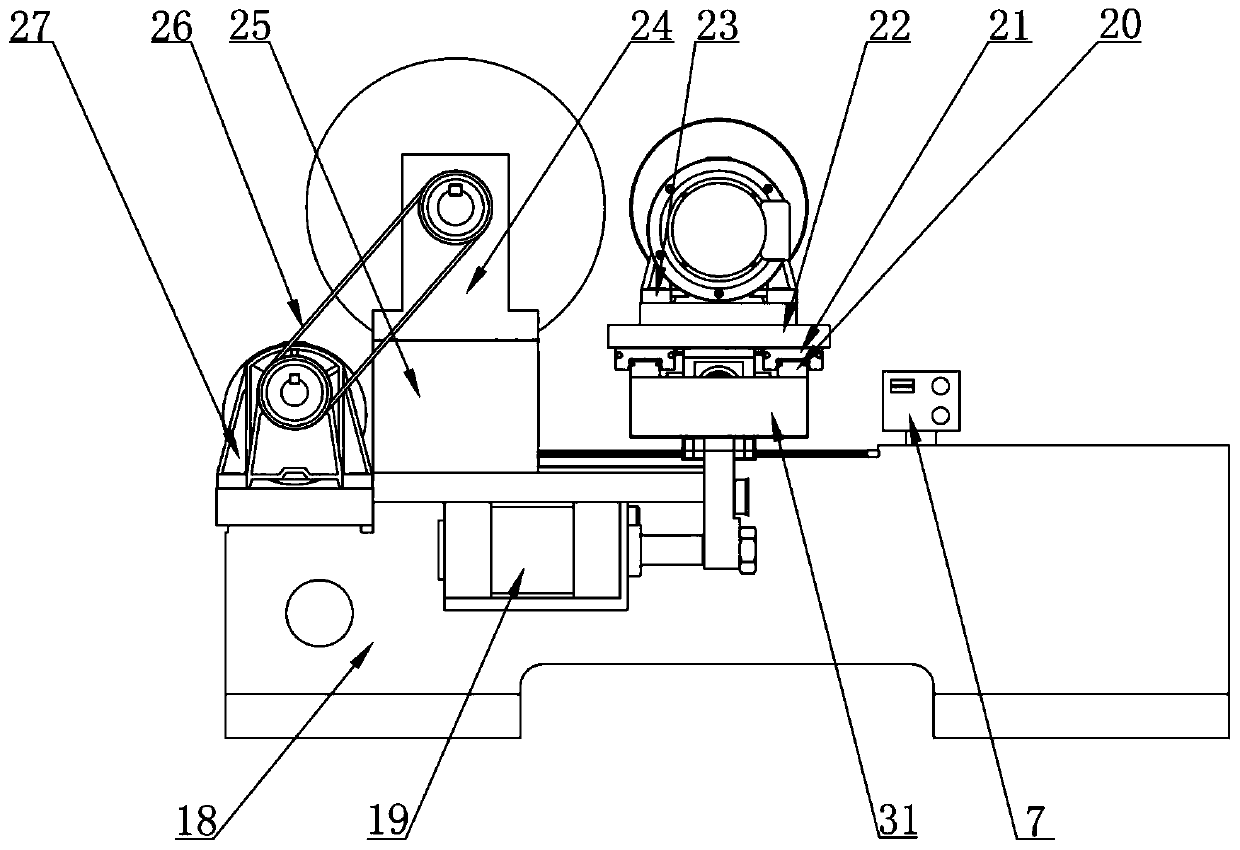

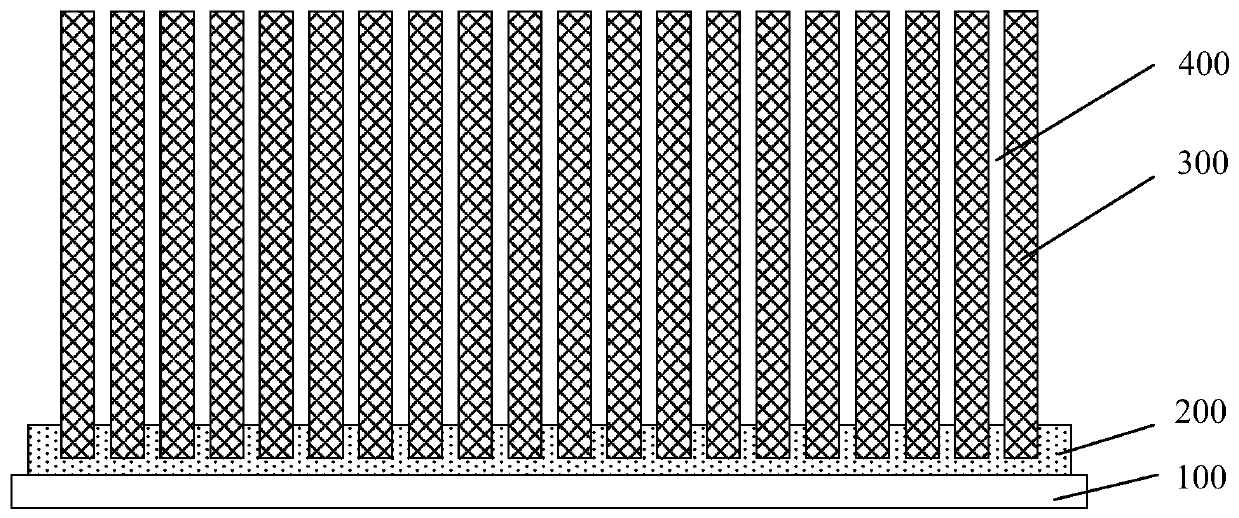

Silicon rod squarer

InactiveCN105818285AReduce labor costsIncrease productivityWorking accessoriesFine working devicesWire cuttingIngot

The invention provides a silicon rod squaring machine, comprising: a machine base with a square cutting area; a bearing platform arranged on the machine base and located in the square cutting area for carrying vertically placed silicon rods; The wire cutting equipment on the machine base includes: a cutting frame, which is arranged on the machine base and adjacent to the bearing table; The cut lines that form the cut line mesh. Compared with the prior art, the silicon ingot squaring machine of the present invention uses the supporting platform to carry the vertically placed silicon ingots, and cuts the silicon ingots below in a straight line through the wire cutting equipment, which can realize automatic cutting and complete the silicon ingot squaring operation. Save labor cost and improve production efficiency.

Owner:TDG NISSIN PRECISION MACHINERY CO LTD

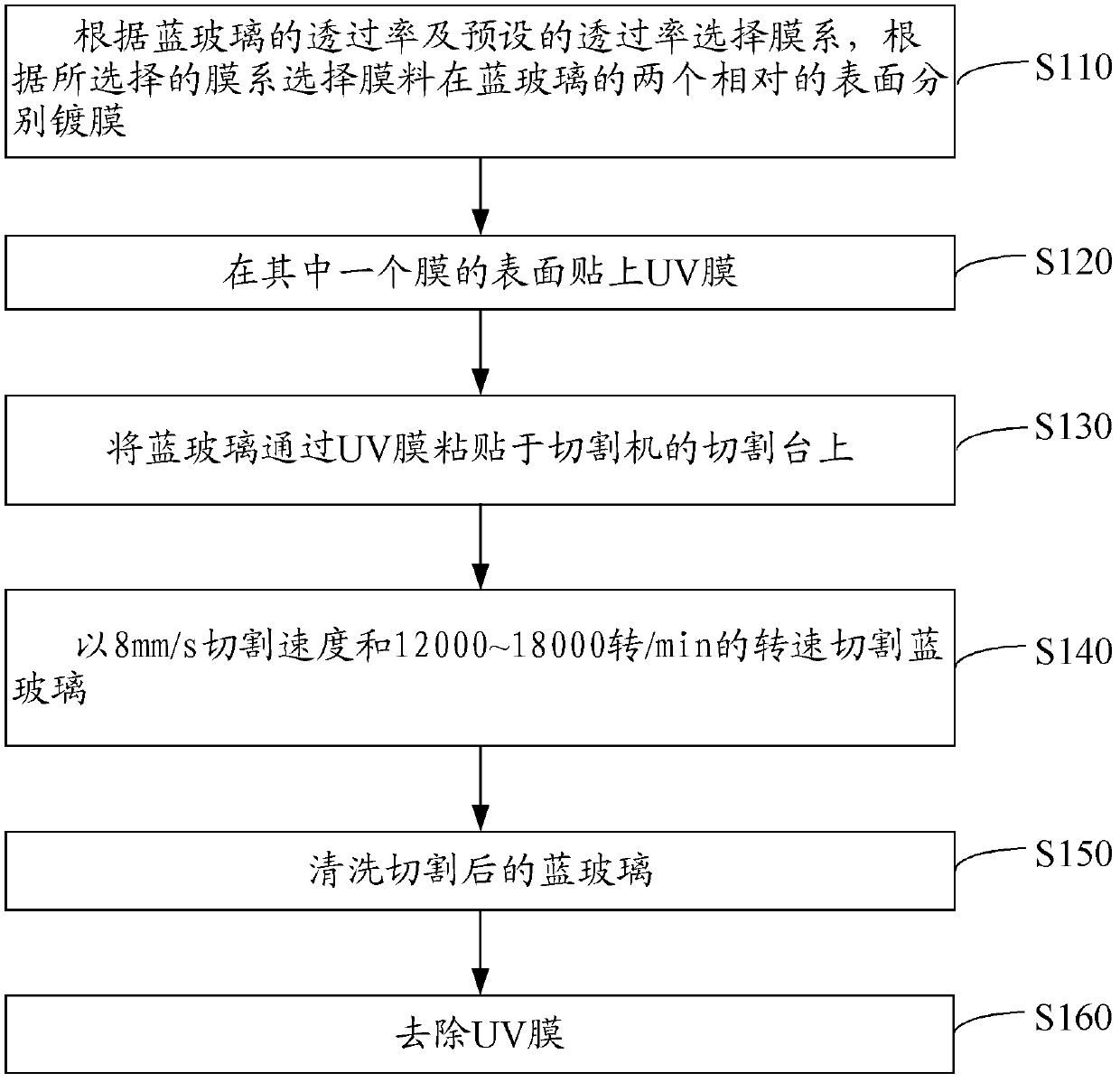

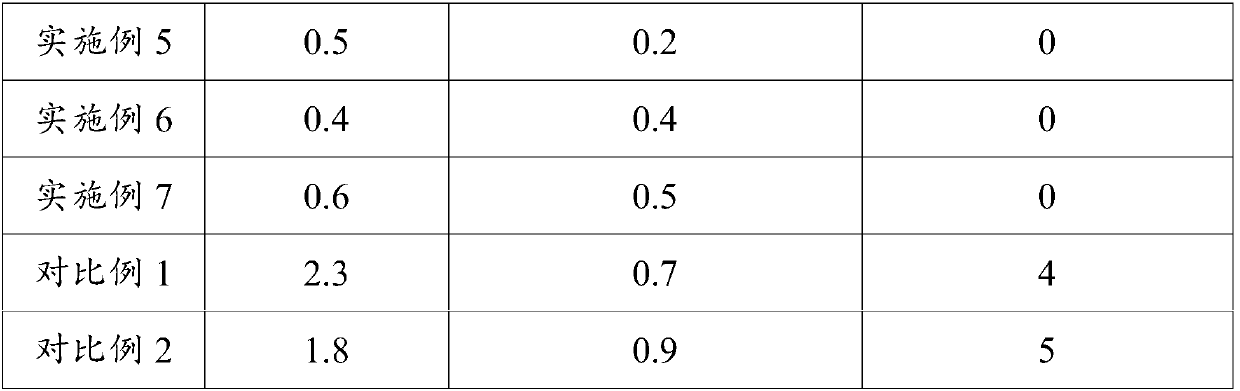

Preparation method for blue glass infrared cut-off filter

InactiveCN103376489AMeet spectroscopic requirementsReduce chipping rateOptical filtersTransmittanceBreakage rate

The invention provides a preparation method for a blue glass infrared cut-off filter. The method includes the steps that film system is selected according to transmittance and a preset transmittance of blue glass, and film coating is respectively carried out on two opposite surfaces of the blue glass by means of film materials according to the selected film system; a UV film is attached to the surface of one film; the blue glass is pasted to a cutting table of an ADT cutting machine through the UV film; the blue glass is cut at the cutting speed of 8 millimeters per second and at the revolving speed of 12000-18000 revolutions per minute. The method is achieved based on a blue glass film coating method, light splitting requirements of infrared cut-off filter can be met, the edge breakage rate of blue glass cutting can be effectively reduced through reasonable selection of blue glass cutting parameters, and thus the production yield of the blue glass infrared cut-off filter can be improved.

Owner:SHENZHEN O FILM TECH

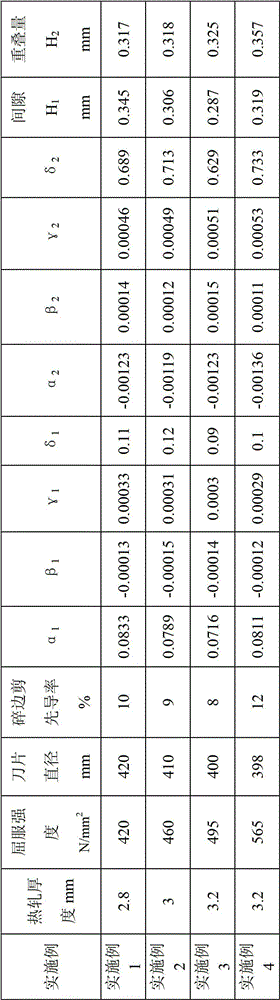

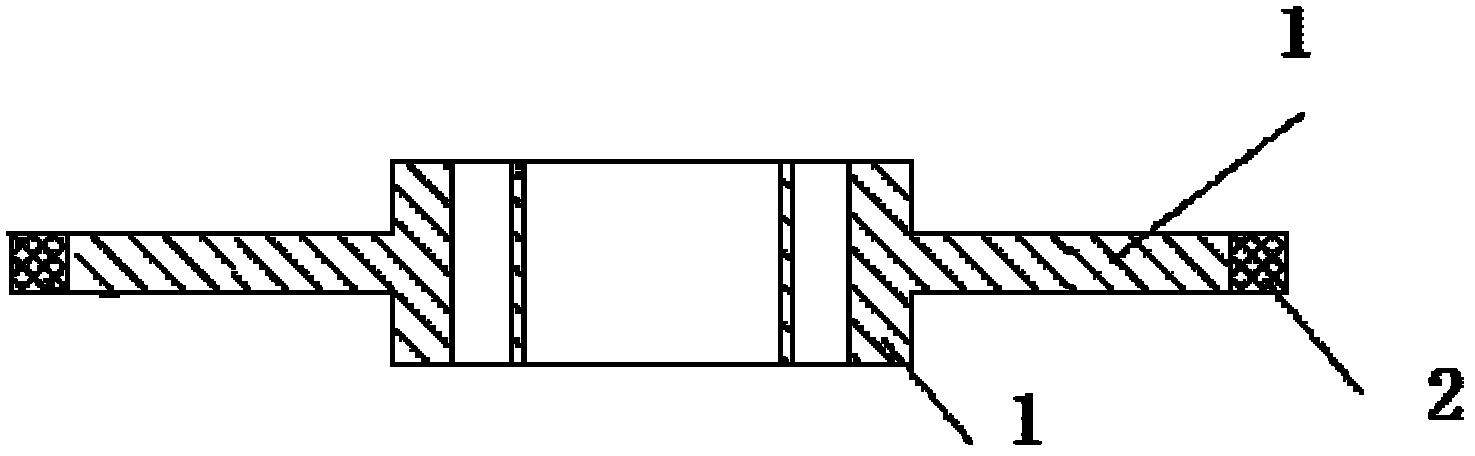

Method for controlling acid-washing and edge-shearing quality of high-strength steel

ActiveCN102722104AHigh precisionReduce the number of broken beltsAdaptive controlEngineeringAcid washing

The invention relates to a method for controlling the acid-washing and edge-shearing quality of high-strength steel. The method comprises the following steps of: respectively calculating setting values of a disc shear gap H1 and an overlapping amount H2 by adopting a process computer system, sending obtained setting values to an operation computer system, regulating a disc shear driving device by the operation computer system according to the obtained setting values, and controlling a disc shear to carry out the edge shearing on the high-strength steel. According to the method disclosed by the invention, the edge shearing quality of a high-strength steel product with the shear strength being in a range of 380 N / mm<2> to 600 N / mm<2> can be increased, abnormal situations of shear breaking and the like can be reduced, and the actual production demands of the high-strength steel product in a cold continuous rolling unit can be met.

Owner:BAOSHAN IRON & STEEL CO LTD

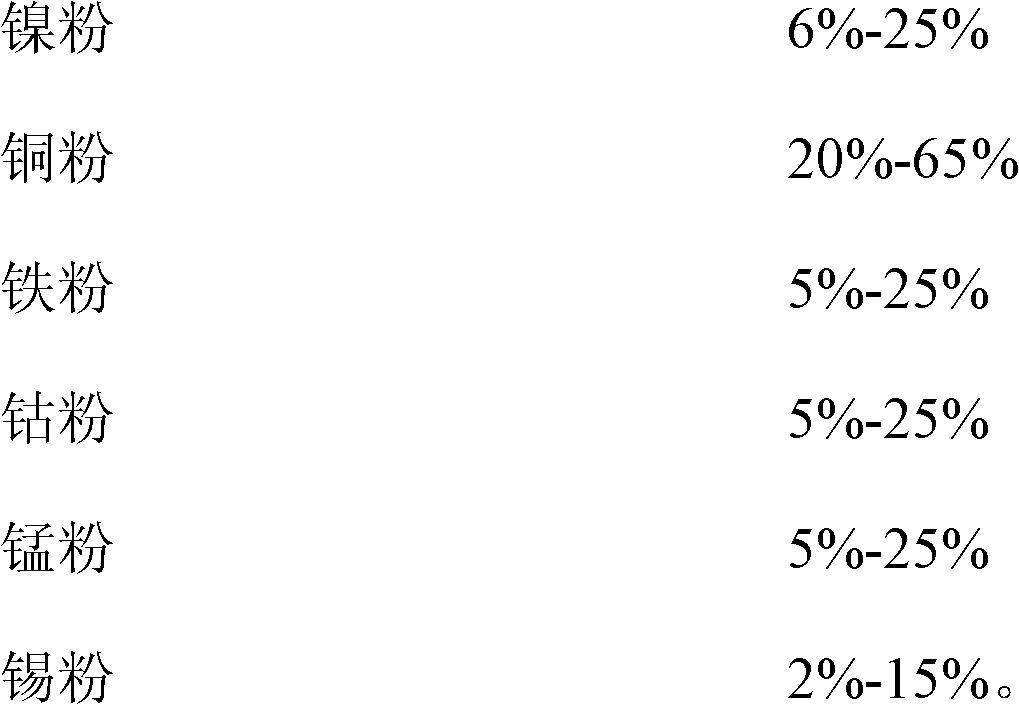

A special grinding wheel for photovoltaic glass and its processing method

InactiveCN102275139AAvoid chippingImprove stiffnessAbrasion apparatusGrinding devicesGrinding wheelMetal

The invention discloses a special grinding wheel for photovoltaic glass and a processing method thereof. The grinding wheel comprises a grinding wheel base body, a grinding layer is arranged on the edge of the grinding wheel base body, and the grinding layer is composed of diamond abrasive and a mixture, and the diamond abrasive: mixture =1:10 (weight ratio); the present invention mixes the mixture of metal components with diamond, and forms a grinding layer through sintering, which not only has good stiffness, but also greatly improves the adhesion of the grinding layer, avoids falling off, and prolongs The overall service life of the special grinding wheel for photovoltaic glass is improved, and the invention has the advantages of good adhesion, high cutting rate and can greatly reduce the chipping rate of photovoltaic glass.

Owner:江苏神龙光电设备科技有限公司

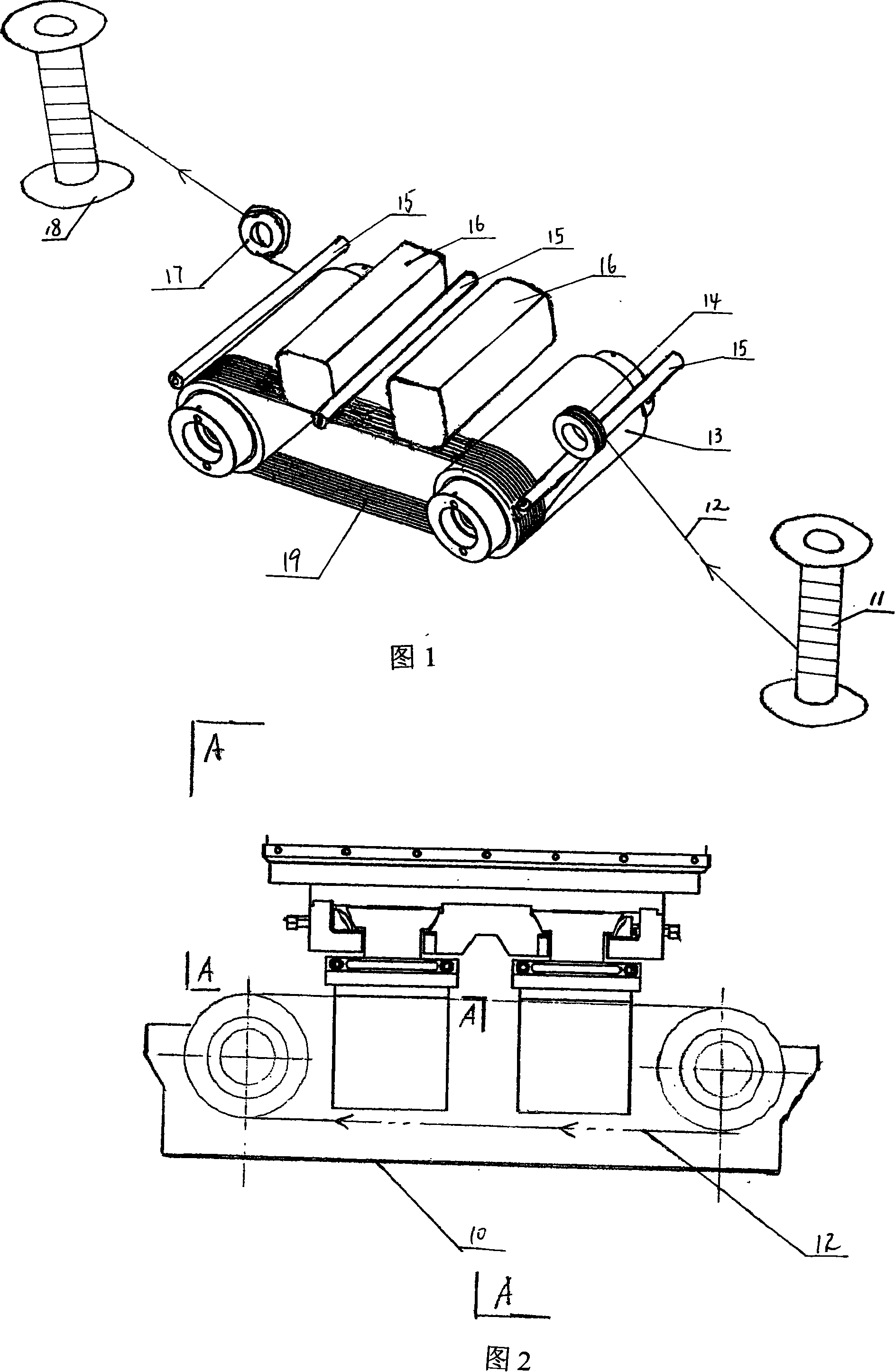

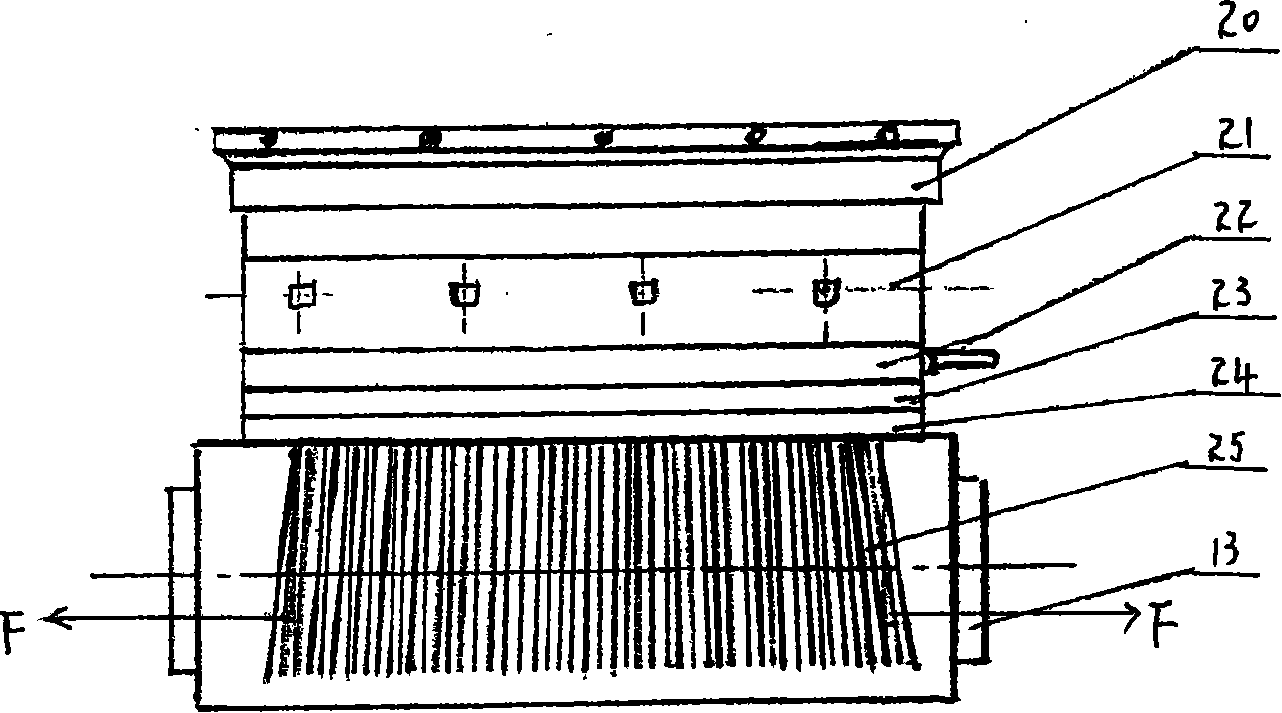

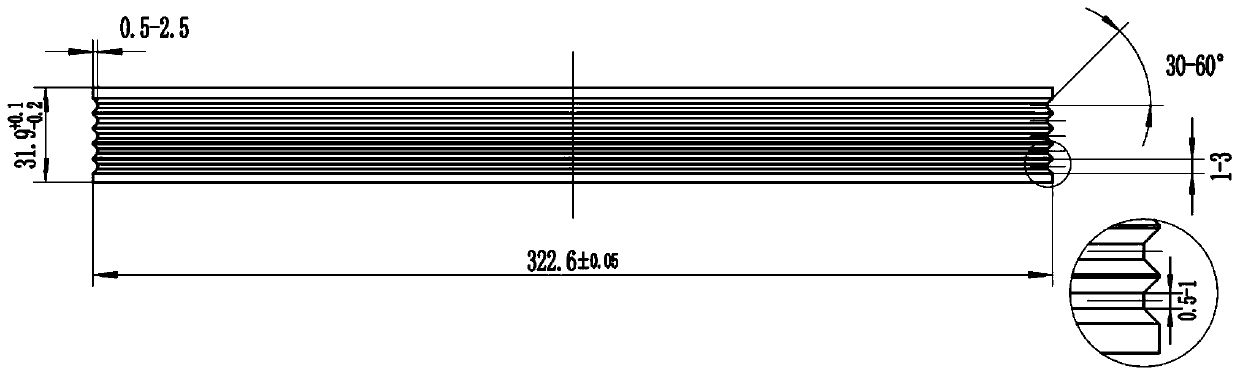

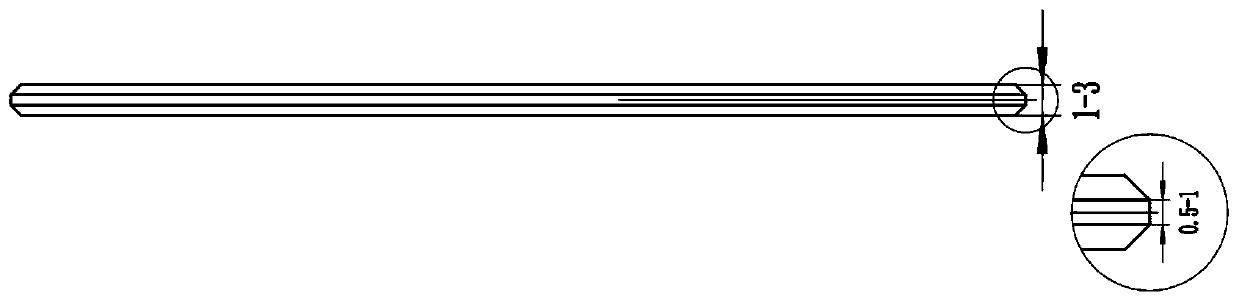

Novel edge-collapse proof unfilled corner proof gripper for silicon crystal-bar slicer

InactiveCN101249697AAvoid chippingReduce chipping rateStone-like material working toolsFour-slideSilicon

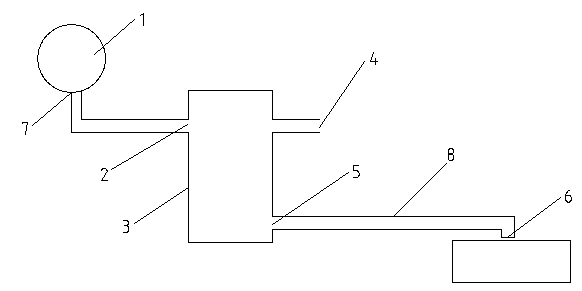

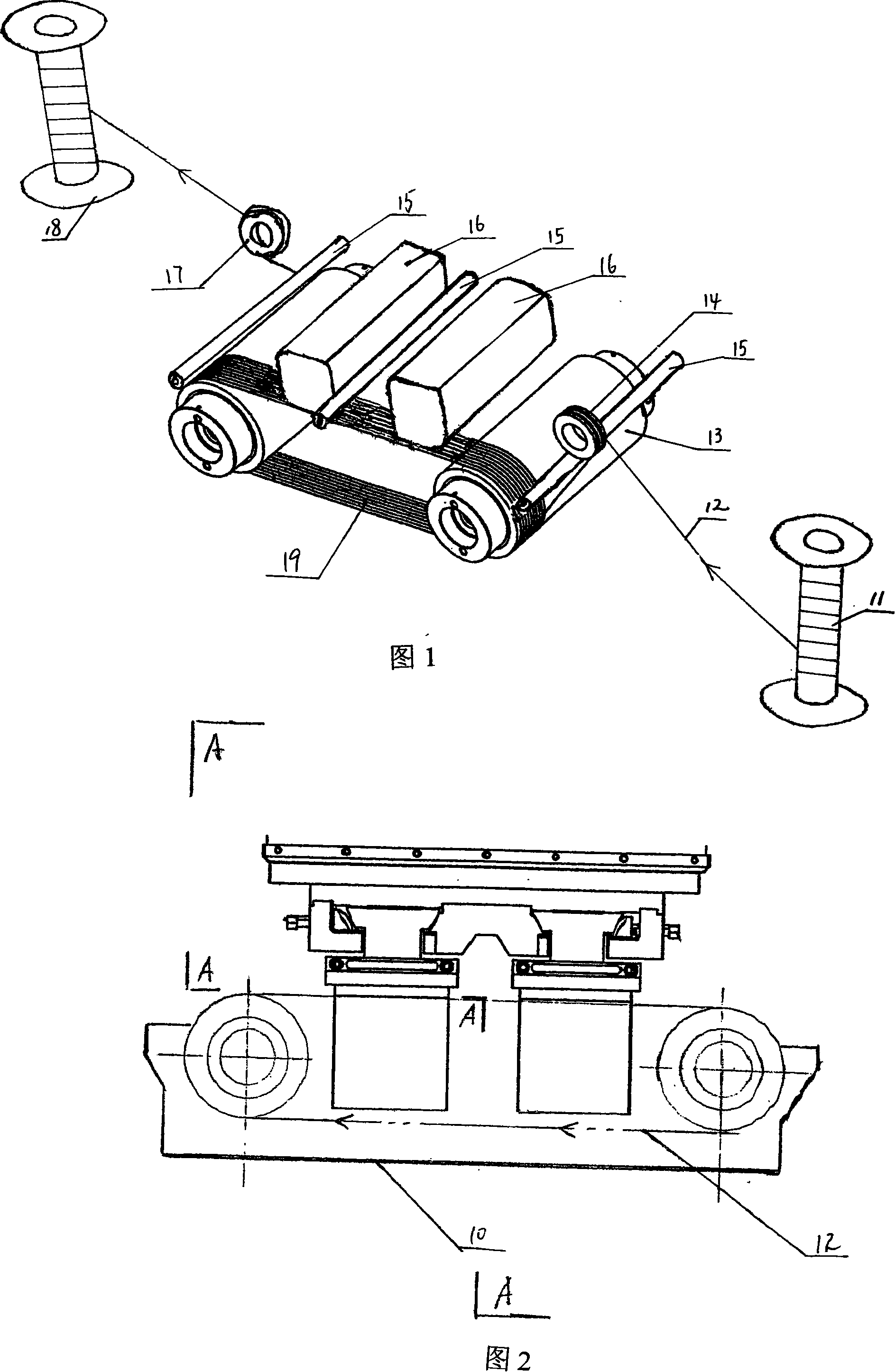

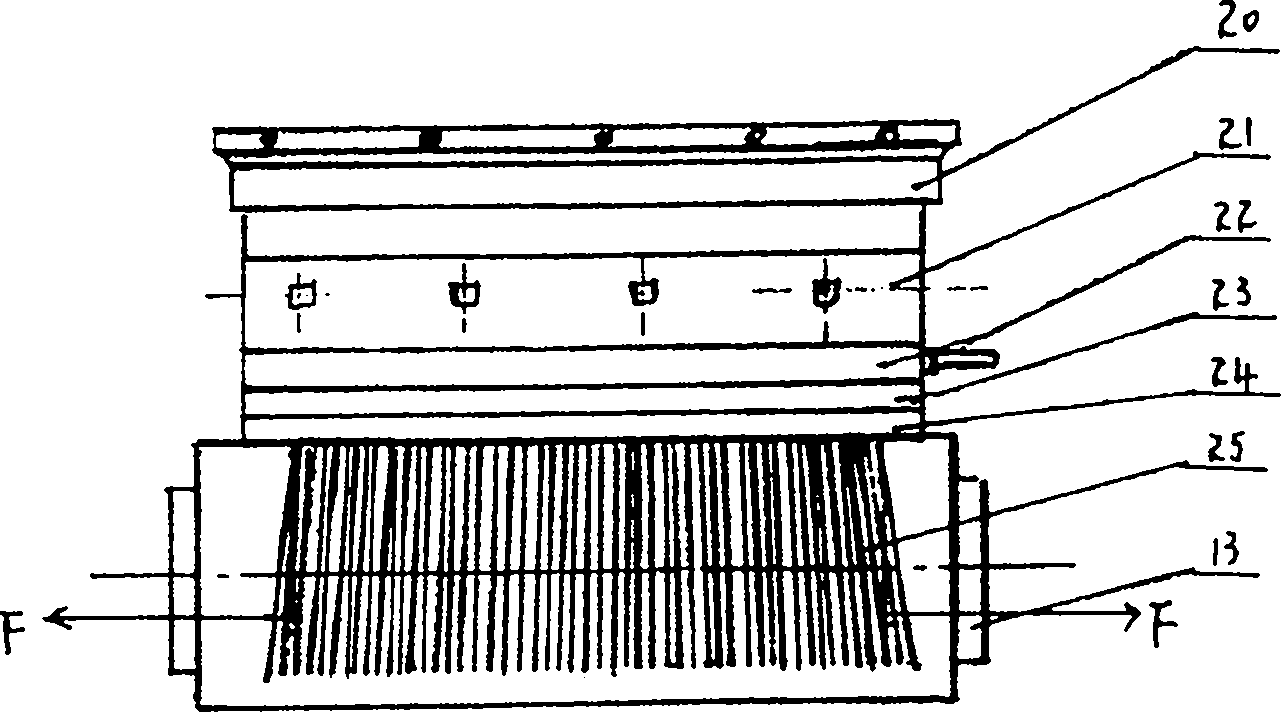

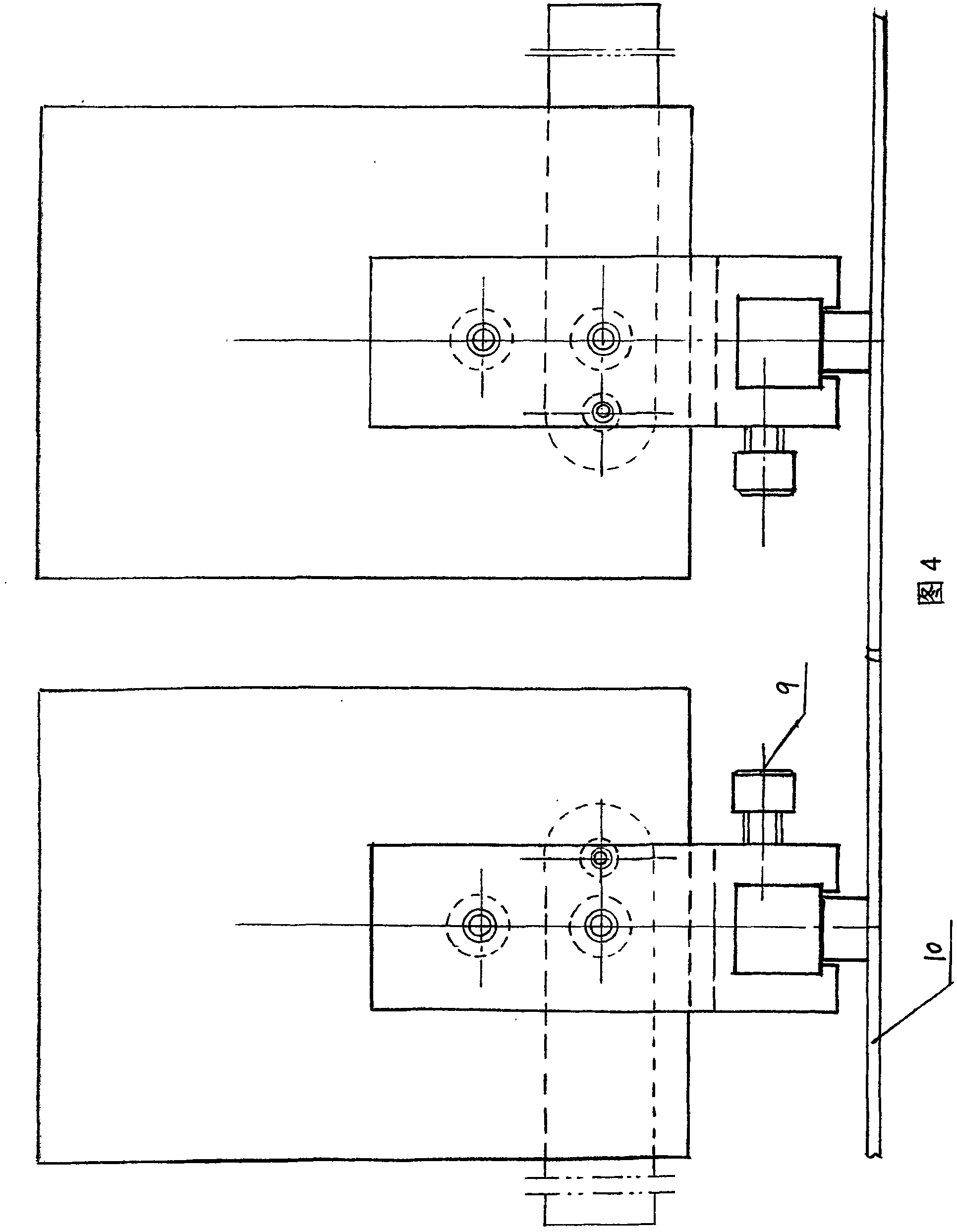

The invention relates to a novel clamp for preventing broken edge and broken corner used in a silicon stick section cutter. The clamp comprises two guide rails (6), four slide blocks (2), four baffle plates (1) and four staff gauges (4), wherein the two guide rails are arranged on the left and on the right respectively; the two ends of each guide rail (6) are fixedly mounted on the fragment box (10) of the section cutter. Every two of the four slide blocks (2) are sleeved on the two sides of every two guide rails (6); each slide block has an L-shaped section and consists of a transverse block and a vertical block, wherein the transverse block is sleeved on and fixedly connected with the guide rail (6); the four baffle plates (1) are fixedly connected on the inner sides of the vertical blocks of corresponding slide blocks (2) respectively; the four staff gauges (4) are fixedly connected at the lower section of the inner side of corresponding baffle plates (1) respectively. When in cutting operation, the section cutter adopts a mechanical method to block the two end faces of the silicon stick so that the silicon stick can not extend sideways before being cut off, thereby ensuring that the silicon stick is cut off instead of breaking off, thus preventing broken edge.

Owner:HAREON SOLAR TECHNOLOGY CO LTD

Acid-pickling edge-shearing control method of non-oriented silicon steel

The invention discloses an acid-pickling edge-shearing control method of non-oriented silicon steel. The controlling method includes that a gap set value and an overlap quantity set value of a circle shear are calculated according to a supplied material thickness, a product silicon content level, a circle shear blade diameter and a scrap shear guiding rate. Then, the circle shear shears the non-oriented silicon steel according to the gap set value and the overlap quantity set value. The acid-pickling edge-shearing controlling method of the non-oriented silicon steel obviously improves the precision of shearing parameter setting and improves shearing quality of the non-oriented silicon steels. Therefore, occurrence rates of belt-breaking and blade-fracturing are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

Wafer taking method for semiconductor silicon wafer polishing

The invention relates to a wafer taking method for semiconductor silicon wafer polishing. According to the method, a latex sucker with a hole in the center and an airbag at the rear end is used for taking a silicon wafer; during wafer taking, a user can exhaust part of air inside the airbag, then align the central hole of the latex sucker to the half-radius part of the silicon wafer and then release the airbag, accordingly, the silicon wafer is sucked onto the latex sucker; after the silicon wafer is taken out, the user can exhaust air inside the airbag by hand, and then the silicon wafer can automatically drop down from the latex sucker. By means of the wafer taking method for the semiconductor silicon wafer polishing, scratches on the surface of the silicon wafer and the edge breakage rate of a non-chamfering silicon wafer can be reduced, and the reject ratio of the silicon wafer is reduced from original 2% to 0.5%.

Owner:浙江普通电子股份公司

Method for preparing nano-oxide enhanced dental titanium-porcelain bonding porcelain

The invention relates to a method for preparing a nano-oxide enhanced dental titanium-porcelain bonding porcelain, and specifically to a preparation method for a dental titanium porcelain. Bisque powder of the bonding porcelain prepared by the method of the present invention is borosilicate glass, and a nano-oxide material addition method is adopted to carry out enhancing. The bisque powder of the bonding porcelain comprises, by mass, 50-60% of SiO2, 0-5% of Al2O3, 10-15% of B2O3, 5-10% of Na2O, 5-10% of K2O, 0-3% of Li2O, 0-3% of CaO, 0-5% of BaO, and 0-1% of F. A modified additive comprises a composition comprising one or a plurality materials selected from ZrO2, TiO2, SiO2, Al2O3 and SnO2. The preparation method of the present invention comprises: firstly preparing bisque powder of a bonding porcelain; and then adopting an intermediate material technology, and adding a nano-oxide having a certain ingredient to the bisque powder of the bonding porcelain to carry out secondary synthesis. According to the present invention, with addition of the nano-oxide material, a thermal expansion coefficient of the bisque powder is adjusted, strength and toughness of the bonding porcelain are increased, and titanium / porcelain bonding strength is improved; and the prepared bonding porcelain has good chemical stability, and can be adopted as a porcelain restoration in clinic.

Owner:CHINA UNIV OF MINING & TECH

Glass arranging and dispensing UV machine

PendingCN111359842AHigh breaking process efficiencyReduce chipping ratePretreated surfacesGlass severing apparatusUV curingMotor drive

The invention discloses a glass arranging and dispensing UV machine. The glass arranging and dispensing UV machine is characterized in that jig plate dispensing, glass plate breaking, feeding and UV curing are all completed through a mechanical arm, a breaking mechanism passes through two sets of breaking plates, one sets of breaking plates are used for fixing and limiting glass plates, the othersets of breaking plates are used for vertically breaking the glass plates, and in this way, the broken glass plates are smooth in edges and low in edge breakage rate; multiple sets of side-by-side design is adopted for a stock bin, glass is manually loaded into the stock bin to be positioned, a motor drives a lead screw nut mechanism to upwards stretch in an ejecting mode according to the thickness of the glass, and then a push plate of a pushing manipulator pushes the glass plates to the glass breaking mechanism to be broken; the other operations are completed by automatic equipment except the operations of supplementing the glass plates and taking the processed finished product from the stock bin. According to the scheme, and compared with a traditional semi-automatic dispensing piece arranging breaking process, the mechanism of the glass arranging and dispensing UV machine is higher in efficiency and saves the labor cost.

Owner:SHENZHEN RUI EURO OPTICAL ELECTRONICS CO LTD

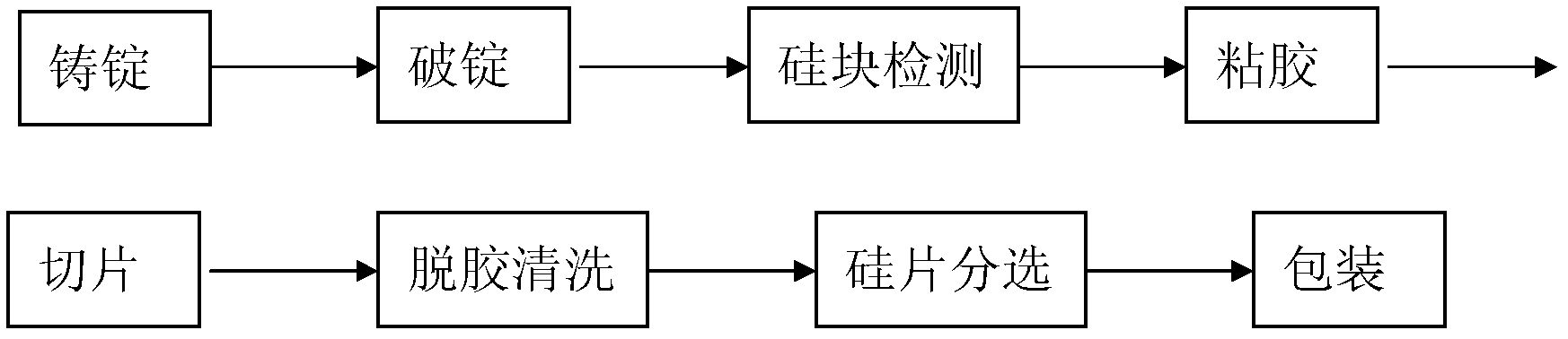

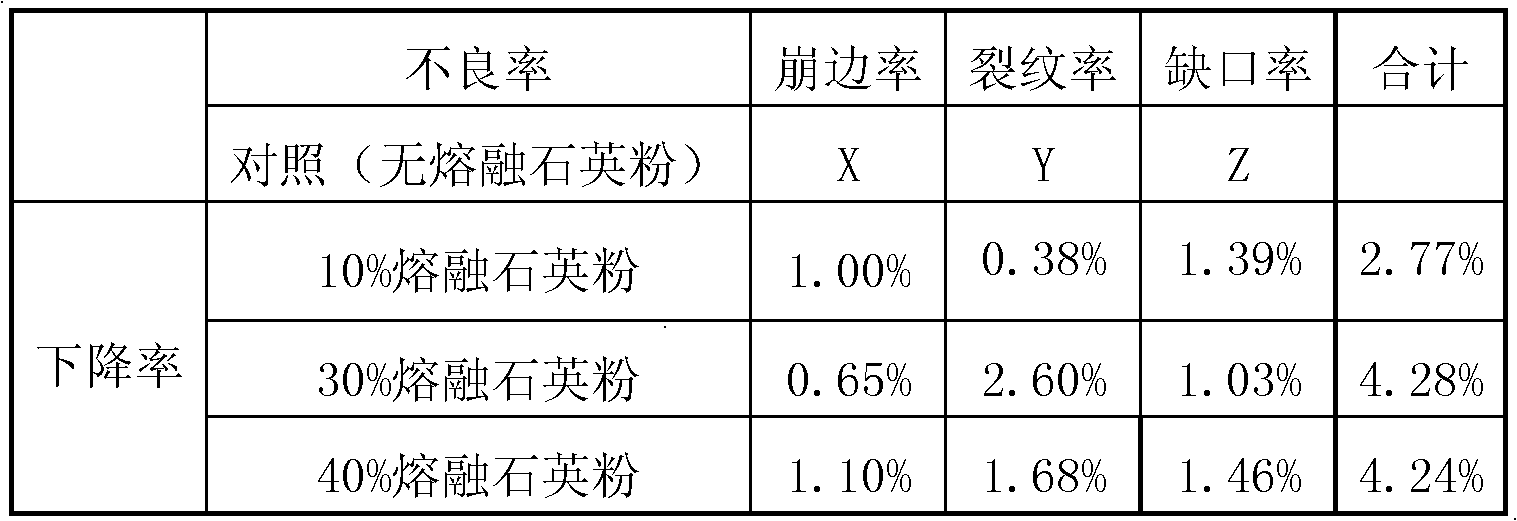

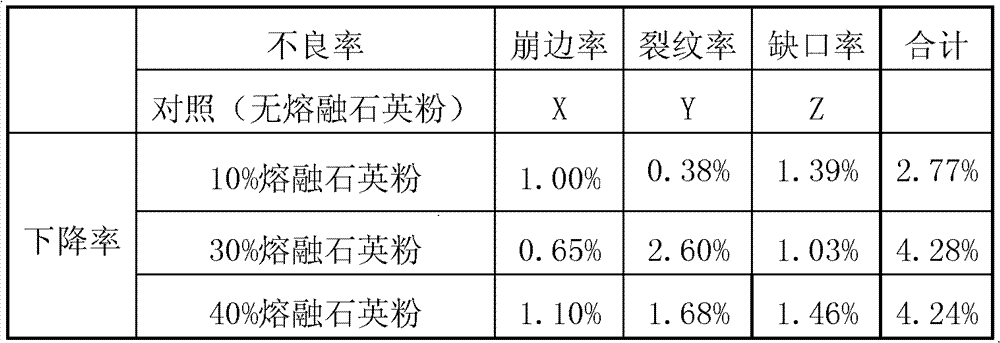

Epoxy resin composite material

The invention provides an epoxy resin composite material, comprising epoxy resin and powder material, wherein the mass proportion of the epoxy resin to the powder material is 9: 1-6: 4; the coefficient of thermal expansion of the powder material is 0.1-3.5 PPM, and mean particle size D50 thereof is 0.1-10 microns. The epoxy resin composite material provided by the invention can obviously lower edge breakage rate, crack rate and gap rate during the production process of the silicon wafer, and obviously raise the yield of production of silicon wafer, and has excellent economic benefit and market prospect.

Owner:TIANWEI NEW ENERGY HLDG +1

Chip to be coated and processing process thereof

ActiveCN109686700AThe treatment process is easy to operateReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingFailure rateManufacturing technology

The present invention provides a chip to be coated and a processing process thereof, and relates to the technical field of chip manufacturing. The process for processing the chip to be coated includesthe following steps: a chip is provided, the chip includes an upper surface and a lower surface disposed opposite to each other, the lower surface of the chip is provided with a silicon oxide layer,the lower surface of the chip is divided into a plurality of first sub-regions, and each of the first sub-regions includes a first intermediate region and a first edge region, a silicon oxide layer ofthe first intermediate region is removed, the first intermediate region is subjected to boron doping, aluminum doping, and aluminum layer removal, to form a first sub-region with a recessed first intermediate region, the first intermediate region is corroded, the corrosion depth is 3-8Mum, and the chip to be coated is obtained. The technical problems that a conventional process has high chippingrate after dicing, siliconized powder is scratched and the application failure rate after packaging is high are solved. The process for processing the chip to be coated is simple and convenient to operate, a device is simple, and an application prospect is wide.

Owner:JILIN SINO MICROELECTRONICS CO LTD

Preparation method of blue glass infrared cut filter

InactiveCN103376489BMeet spectroscopic requirementsReduce chipping rateOptical filtersCoatingsTransmittanceBreakage rate

The invention provides a preparation method for a blue glass infrared cut-off filter. The method includes the steps that film system is selected according to transmittance and a preset transmittance of blue glass, and film coating is respectively carried out on two opposite surfaces of the blue glass by means of film materials according to the selected film system; a UV film is attached to the surface of one film; the blue glass is pasted to a cutting table of an ADT cutting machine through the UV film; the blue glass is cut at the cutting speed of 8 millimeters per second and at the revolving speed of 12000-18000 revolutions per minute. The method is achieved based on a blue glass film coating method, light splitting requirements of infrared cut-off filter can be met, the edge breakage rate of blue glass cutting can be effectively reduced through reasonable selection of blue glass cutting parameters, and thus the production yield of the blue glass infrared cut-off filter can be improved.

Owner:SHENZHEN O FILM TECH

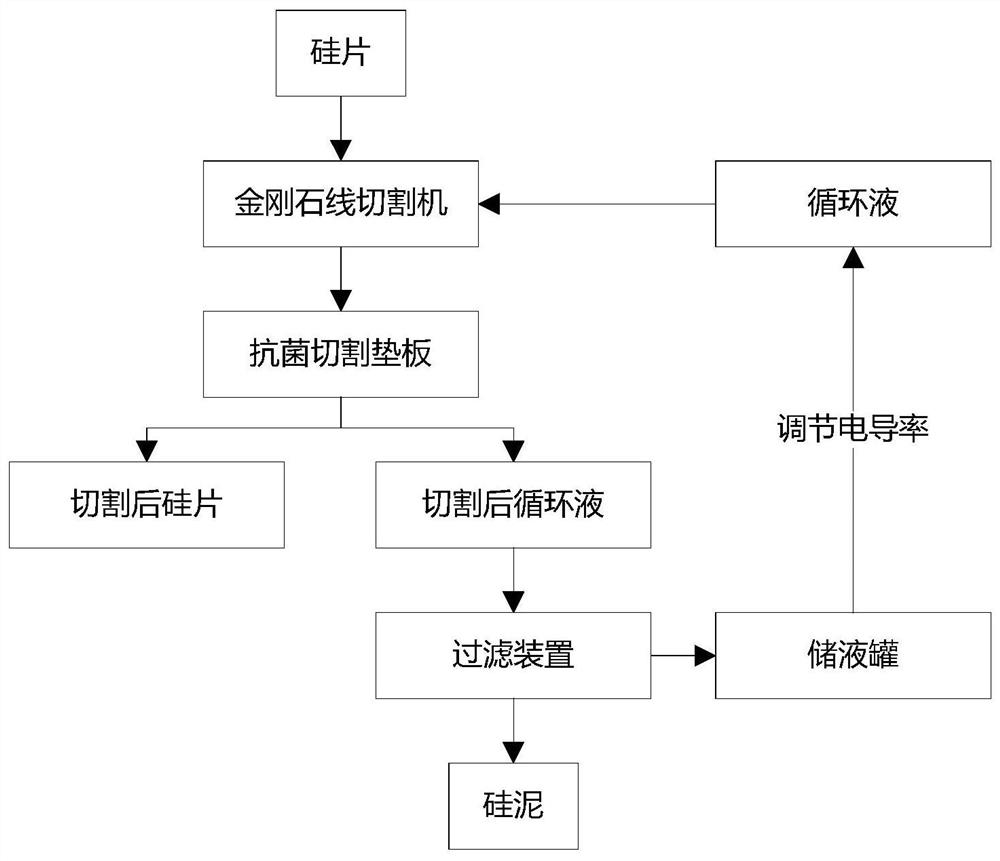

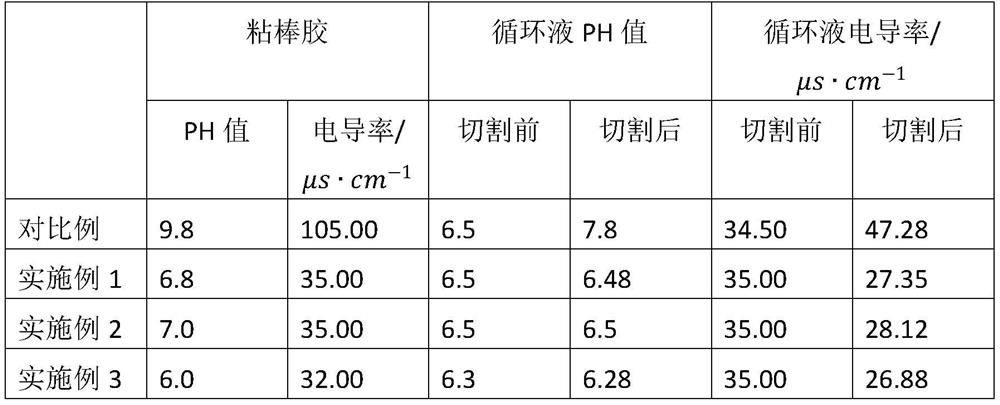

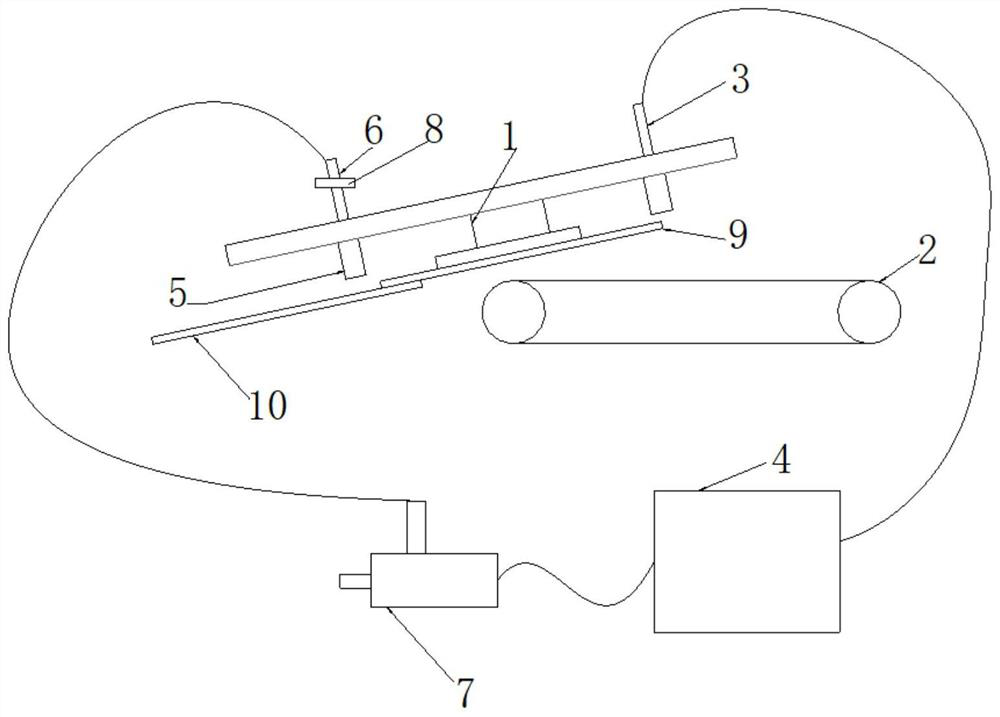

Diamond wire cutting circulation system

ActiveCN112720888BLittle change in conductivityLow costWorking accessoriesGrinding machinesDiamond cuttingLiquid storage tank

Owner:句容协鑫光伏科技有限公司

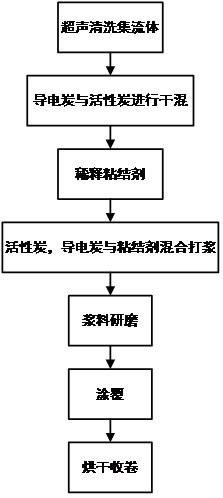

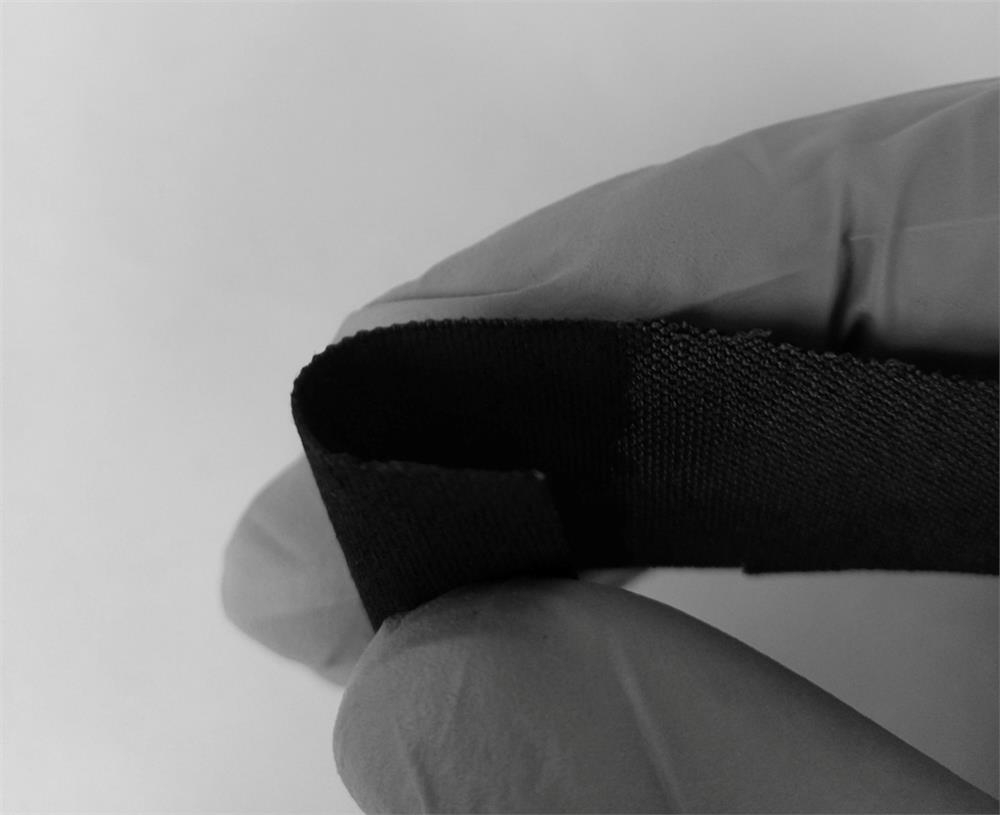

Preparation method of flexible electrode of supercapacitor, flexible electrode and application thereof

PendingCN114446675AFlexibleExtended service lifeHybrid capacitor electrodesHybrid/EDL manufactureActivated carbonFiber

The invention relates to the field of super capacitor electrodes, in particular to a preparation method of a flexible electrode of a super capacitor, the flexible electrode and application of the flexible electrode. According to the technical scheme, the preparation method comprises the following steps: cleaning and drying a flexible carbon-based carrier; diluting a binder into a binder solution; stirring and mixing the activated carbon and the conductive carbon; mixing the mixed material with a binder solution; uniformly dispersing the mixture of the activated carbon and the conductive carbon in the binder solution; grinding the dispersed slurry to obtain electrode slurry; coating a flexible carbon-based carrier with the electrode slurry to form an electrode plate; baking the electrode plate; and finally, obtaining a baked finished product electrode plate. According to the technical scheme, the carbon fiber cloth serves as the current collector, the carbon fiber cloth has flexibility, the electrode piece made of the carbon fiber cloth can be bent, the material falling and edge breakage probability is low during bending, the service life of the super capacitor can be effectively prolonged, and capacitor internal short circuit caused by material falling and edge breakage is avoided.

Owner:山东精工能源科技有限公司

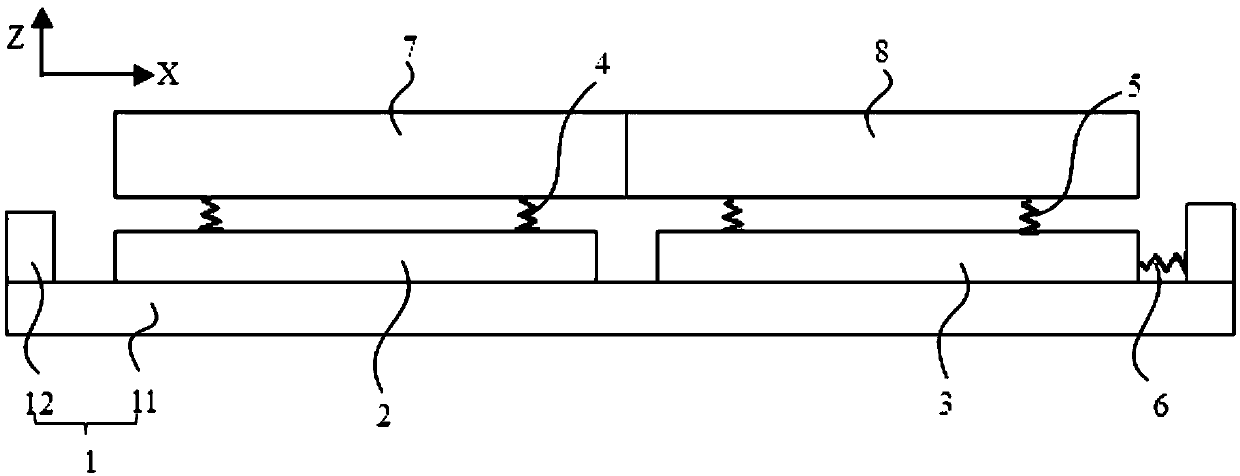

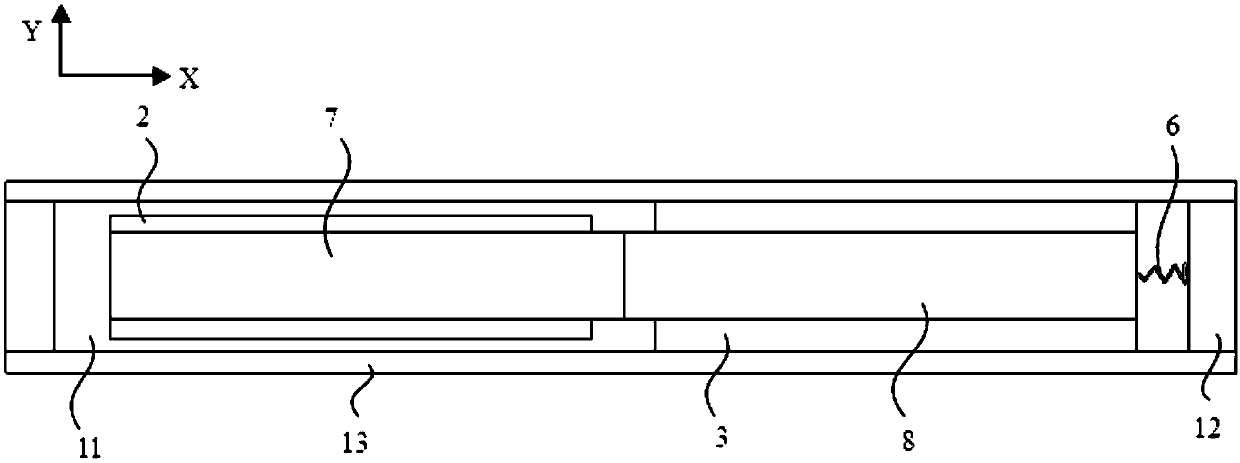

Quartz rod butt joint table

ActiveCN110941147AReduce chipping rateGuarantee docking qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusButt jointPhysics

The invention relates to a quartz rod butt joint table which comprises a base.. The table comprises a first mounting table, wherein the lower surface of the first mounting table is connected with thebase and first mounting table can slide in the first horizontal direction relative to the base, the upper surface of the first mounting table is connected with the lower end of a first elastic element, and the upper end of the first elastic element is used for being connected with a first quartz rod; a second mounting table, wherein the lower surface of the table is connected with the base; the upper surface of the second mounting table is connected with the lower end of a second elastic element, the upper end of the second elastic element is used for being connected with a second quartz rod,the second mounting table and the first mounting table are adjacently arranged in the first horizontal direction, and one end of the first quartz rod faces the second quartz rod. Edge breakage probability in the quartz rod butt joint process can be reduced, and the butt joint quality of the quartz rods and the light homogenizing effect of the quartz rods are guaranteed.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

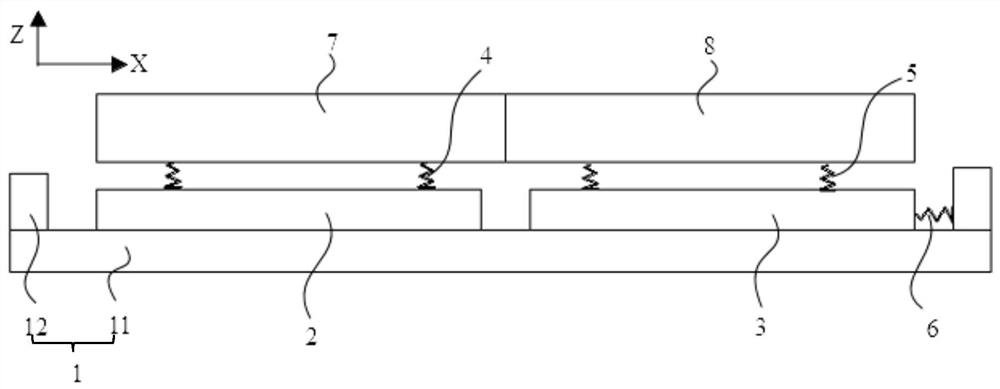

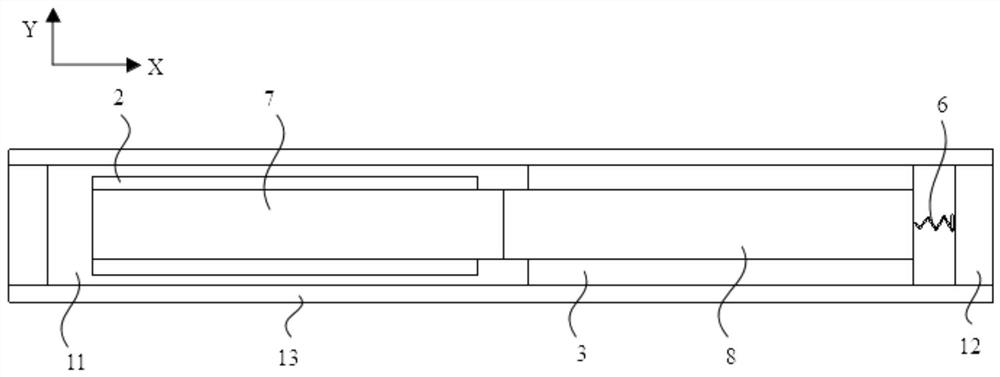

A docking station for quartz rods

ActiveCN110941147BReduce chipping rateGuarantee docking qualityPhotomechanical exposure apparatusMicrolithography exposure apparatusDocking stationClassical mechanics

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Epoxy resin composite material

The invention provides an epoxy resin composite material, comprising epoxy resin and powder material, wherein the mass proportion of the epoxy resin to the powder material is 9: 1-6: 4; the coefficient of thermal expansion of the powder material is 0.1-3.5 PPM, and mean particle size D50 thereof is 0.1-10 microns. The epoxy resin composite material provided by the invention can obviously lower edge breakage rate, crack rate and gap rate during the production process of the silicon wafer, and obviously raise the yield of production of silicon wafer, and has excellent economic benefit and market prospect.

Owner:TIANWEI NEW ENERGY HLDG +1

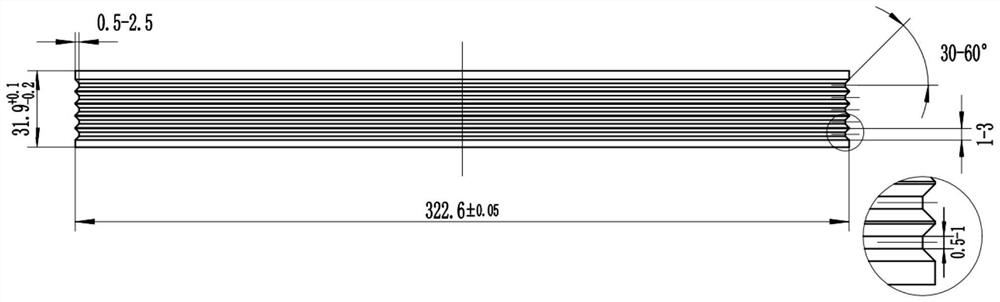

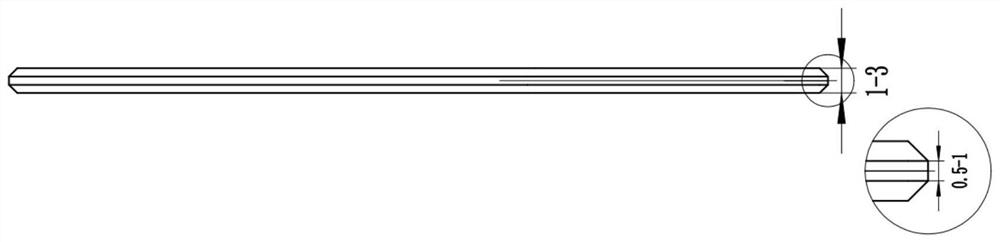

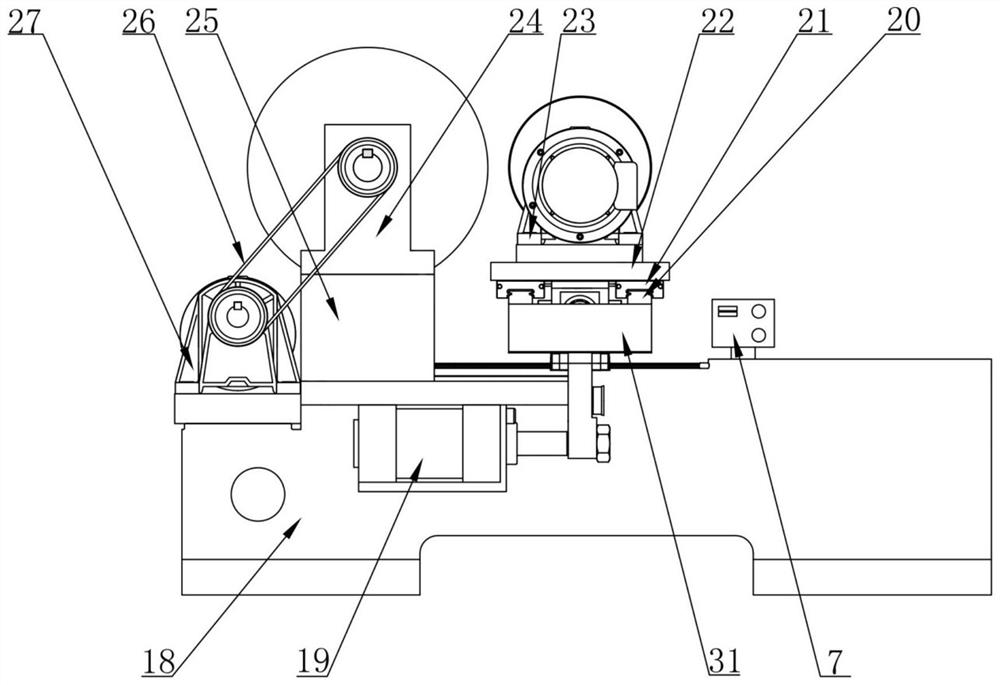

Grinding wheel manufacture method used for silicon wafer chamfering, and manufacture device

The invention relates to a grinding wheel manufacture method used for silicon wafer chamfering, and a manufacture device. The manufacture method comprises the following steps of: 1) adopting a hot pressed sintering method to sinter and form a round-disk-shaped metal binding agent diamond grinding wheel; 2) adopting an electrosparking method to trim the outer cylindrical surface shape of the metalbinding agent diamond grinding wheel obtained by sintering; 3) adopting a rigid alloy rolling wheel with a specific shape to carry out rolling on the outer cylindrical surface of the diamond grindingwheel to obtain a trapezoid groove; and 4) adopting a working electrode which has the same shape with the rigid alloy rolling wheel to carry out electrosparking trimming on the trapezoid groove of thediamond grinding wheel. The device is provided with a rough machining rigid alloy rolling wheel, a finish machining rigid alloy rolling wheel, a diamond grinding wheel trimming working electrode anda grinding wheel groove trimming working electrode to independently manufacture and process the diamond grinding wheel. According to the grinding wheel manufacture method disclosed by the invention, the problems in a traditional grinding wheel manufacture method used for silicon wafer chamfering that diamond abrasive particles are likely to fall, the section shape of the grinding wheel groove is low in accuracy, the shape and the interval of the groove are inconsistent and a groove bottom circular arc is difficult to form can be solved.

Owner:SHENYANG POLYTECHNIC UNIV

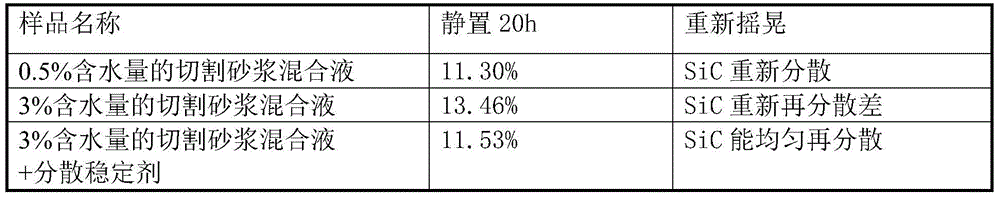

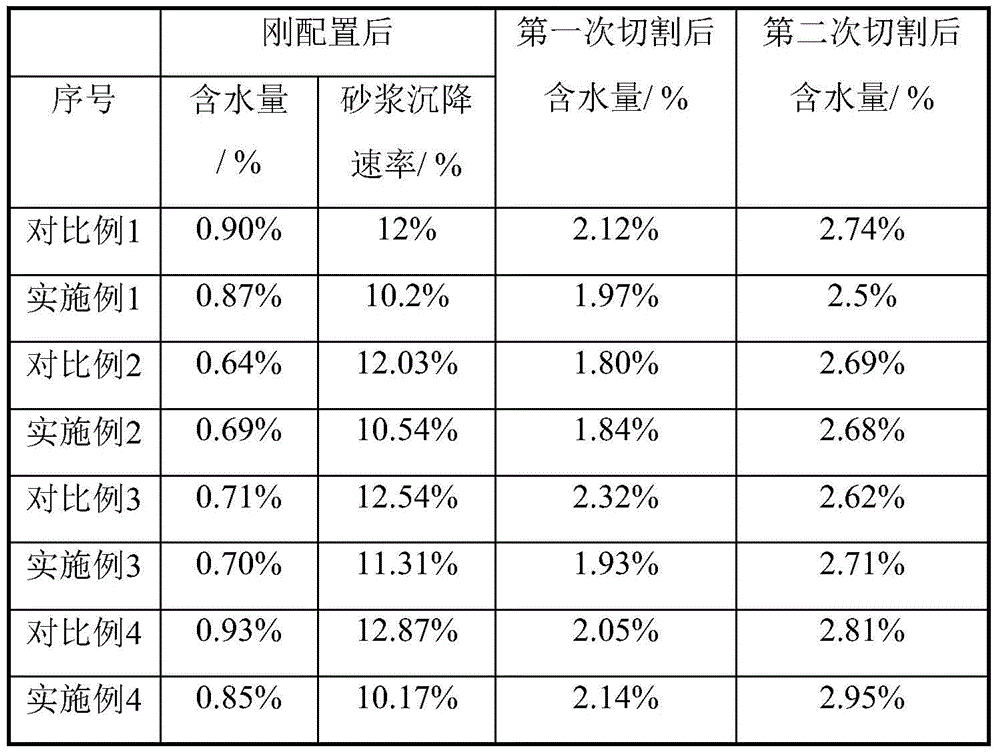

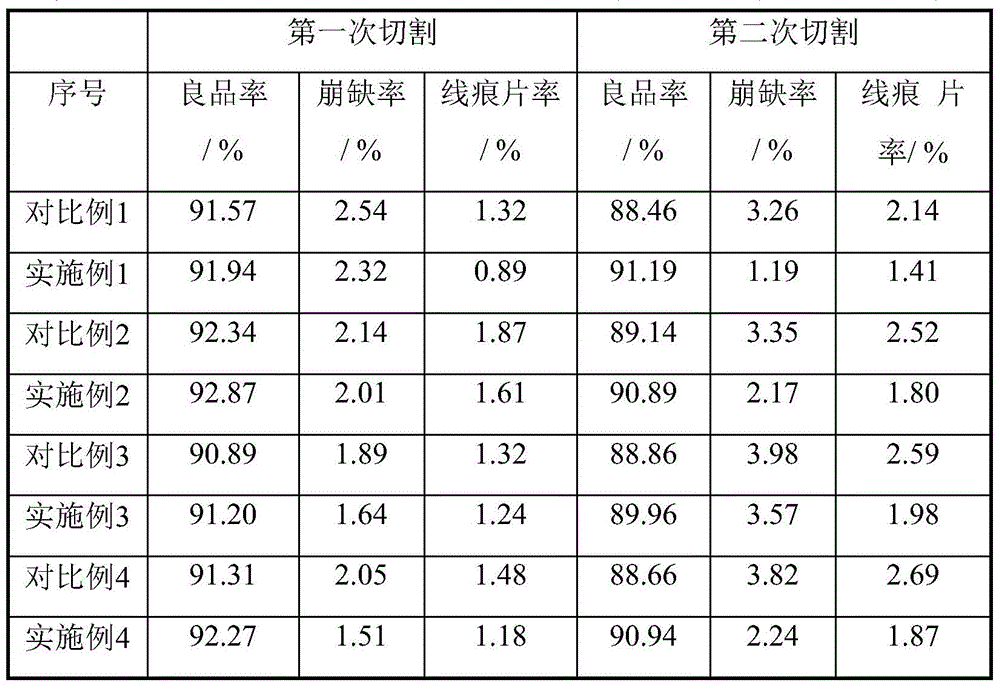

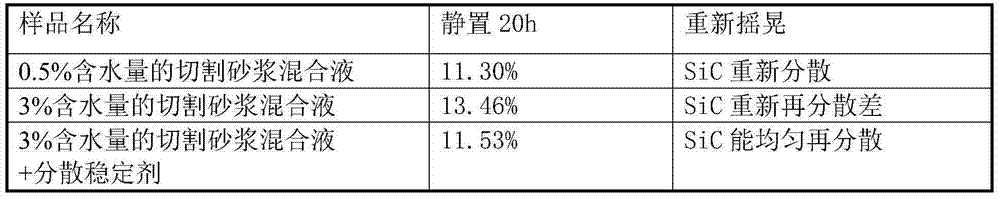

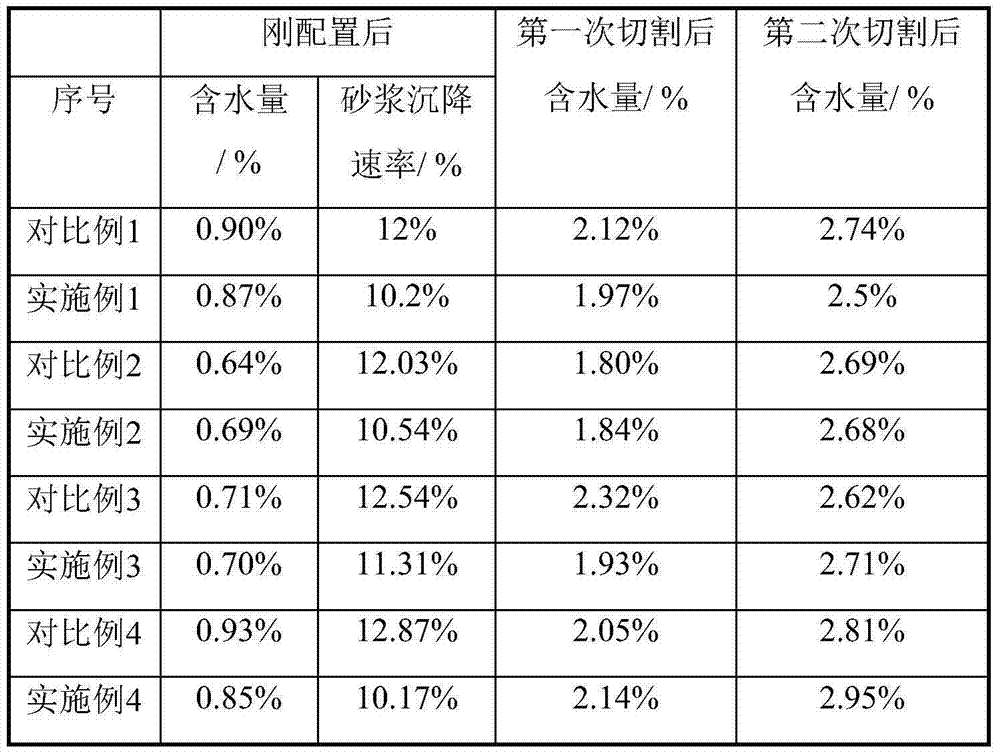

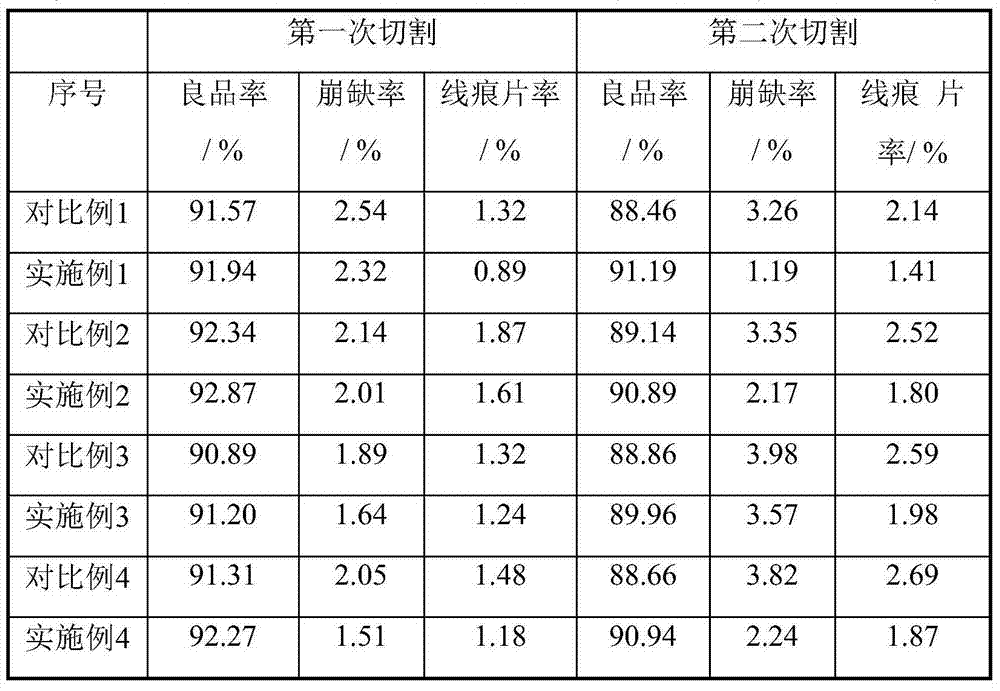

A kind of solar silicon chip cutting mortar and preparation method thereof

The invention provides solar silicon wafer cutting mortar which comprises a polyethylene glycol cutting liquid, silicon carbide micropowder and a dispersing stabilizer, wherein the dispersing stabilizer comprises a modified carbamido polymer, and the ratio of the mass sum of the polyethylene glycol cutting liquid, the silicon carbide micropowder to the mass of the modified carbamido polymer is 1: (0.02-4%). The solar silicon wafer cutting mortar provided by the invention is low in sedimentation rate and high in stability. Under the premise of not reducing the water content of the mortar, the solar silicon wafer cutting mortar is used for continuously cutting a silicon wafer twice, so that the yield of the silicon wafer is improved. The invention further provides a preparation method of the solar silicon wafer cutting mortar.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

Acid-pickling edge-shearing control method of non-oriented silicon steel

The invention discloses an acid-pickling edge-shearing control method of non-oriented silicon steel. The controlling method includes that a gap set value and an overlap quantity set value of a circle shear are calculated according to a supplied material thickness, a product silicon content level, a circle shear blade diameter and a scrap shear guiding rate. Then, the circle shear shears the non-oriented silicon steel according to the gap set value and the overlap quantity set value. The acid-pickling edge-shearing controlling method of the non-oriented silicon steel obviously improves the precision of shearing parameter setting and improves shearing quality of the non-oriented silicon steels. Therefore, occurrence rates of belt-breaking and blade-fracturing are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

A grinding wheel manufacturing method and manufacturing device for silicon wafer chamfering

ActiveCN111230761BHigh precisionGood molding effectGrinding devicesCircular discManufactured apparatus

The invention relates to a method and device for manufacturing a grinding wheel for chamfering silicon wafers: 1) A metal bond diamond grinding wheel in the shape of a disc is sintered by hot pressing and sintering; The surface shape of the outer cylinder of the metal bond diamond grinding wheel; 3) Use a specific shape of the carbide rolling wheel to roll out a trapezoidal groove on the outer cylindrical surface of the diamond grinding wheel; 4) Use the same shape as the carbide rolling wheel Electrode EDM for dressing trapezoidal grooves of diamond grinding wheels. The device is equipped with a rough machining carbide rolling wheel, a finishing carbide rolling wheel, a diamond grinding wheel dressing working electrode and a grinding wheel groove dressing working electrode to respectively manufacture and process the diamond grinding wheel. The invention effectively solves the problems that diamond abrasive grains are easy to fall off in the traditional preparation method of silicon wafer chamfering grinding wheel, the shape accuracy of the groove section of the grinding wheel is not high, the groove shape and spacing are inconsistent, and the arc at the bottom of the groove is difficult to form.

Owner:SHENYANG POLYTECHNIC UNIV

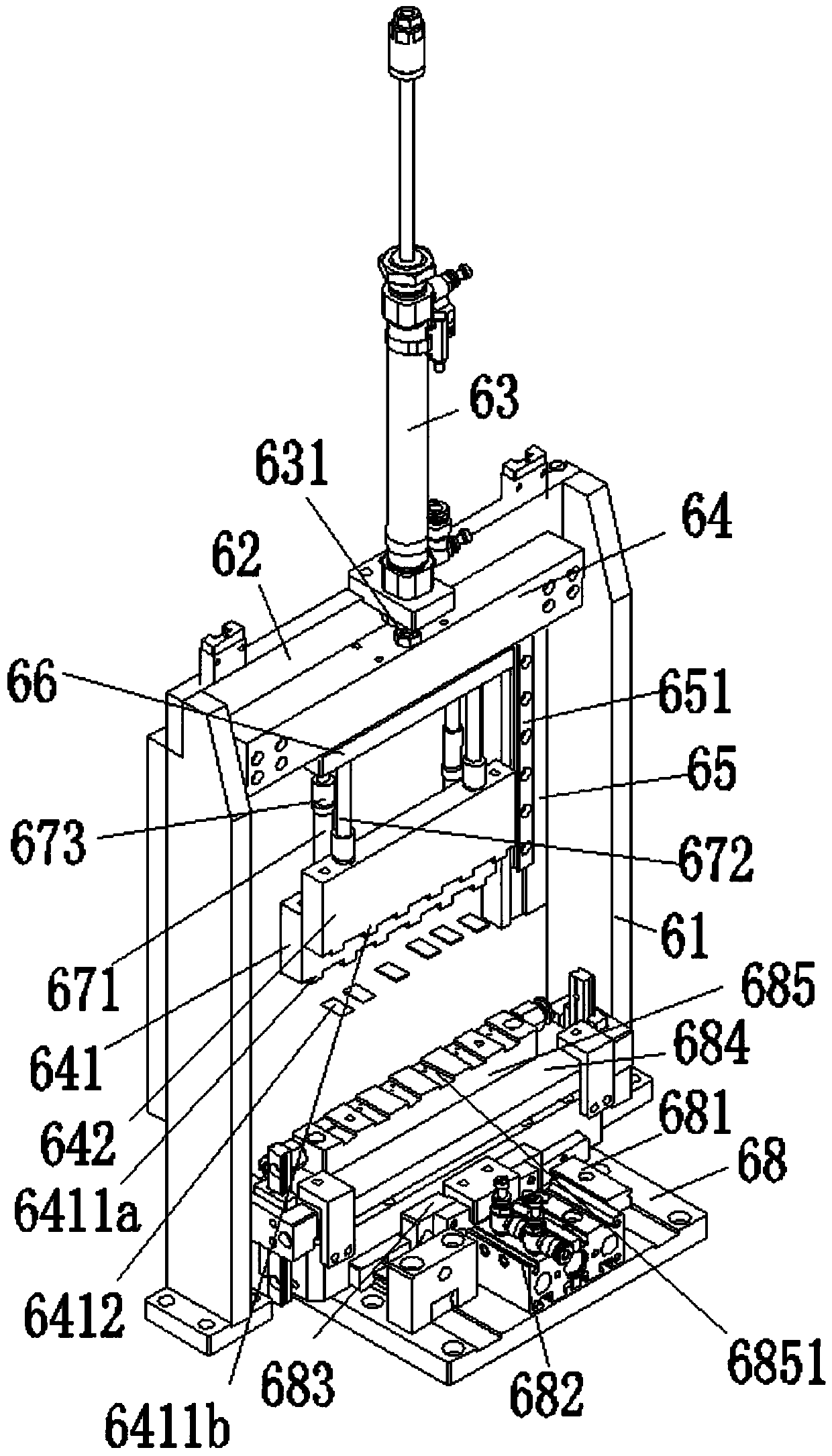

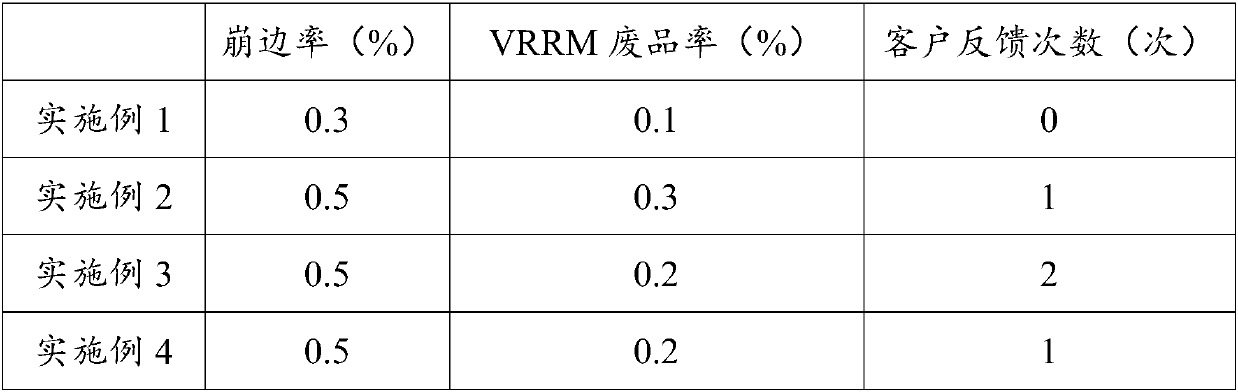

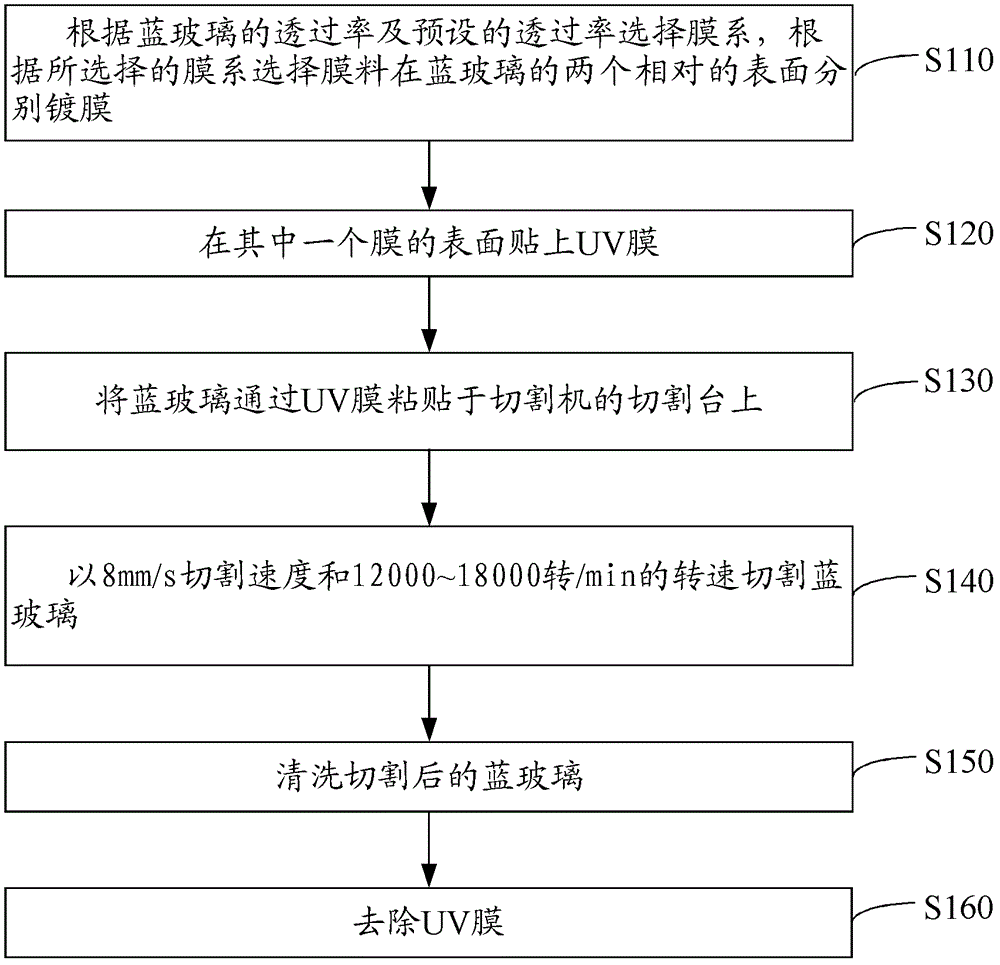

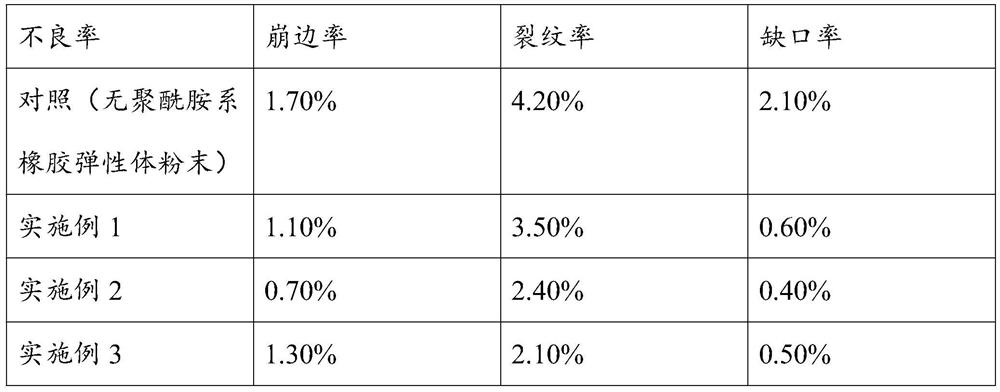

Epoxy resin composite material and preparation method thereof

InactiveCN113072798AReduce chipping rateImprove yieldSemiconductor/solid-state device manufacturingMacromolecular adhesive additivesEpoxy resin compositePolyamide

The invention provides an epoxy resin composite material which comprises epoxy resin and a powder material, the mass ratio of the epoxy resin to the powder material is 10: 1-2: 1, and the average particle size of the powder material is 1-15 microns; the epoxy resin is one or more of bisphenol A type epoxy resin, hydrogenated bisphenol A type epoxy resin or bisphenol F type epoxy resin; the powder material is polyamide rubber elastomer powder; the epoxy resin composite material further comprises a curing agent, and the curing agent is polymercaptan. According to the epoxy resin composite material, the edge breakage rate, the crack rate and the notch rate of the silicon wafer in the silicon wafer production process can be remarkably reduced, the yield of silicon wafer production can be remarkably improved, and good economic benefits and market prospects are achieved.

Owner:无锡协芯半导体科技有限公司

Solar silicon wafer cutting mortar and preparation method thereof

The invention provides solar silicon wafer cutting mortar which comprises a polyethylene glycol cutting liquid, silicon carbide micropowder and a dispersing stabilizer, wherein the dispersing stabilizer comprises a modified carbamido polymer, and the ratio of the mass sum of the polyethylene glycol cutting liquid, the silicon carbide micropowder to the mass of the modified carbamido polymer is 1: (0.02-4%). The solar silicon wafer cutting mortar provided by the invention is low in sedimentation rate and high in stability. Under the premise of not reducing the water content of the mortar, the solar silicon wafer cutting mortar is used for continuously cutting a silicon wafer twice, so that the yield of the silicon wafer is improved. The invention further provides a preparation method of the solar silicon wafer cutting mortar.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

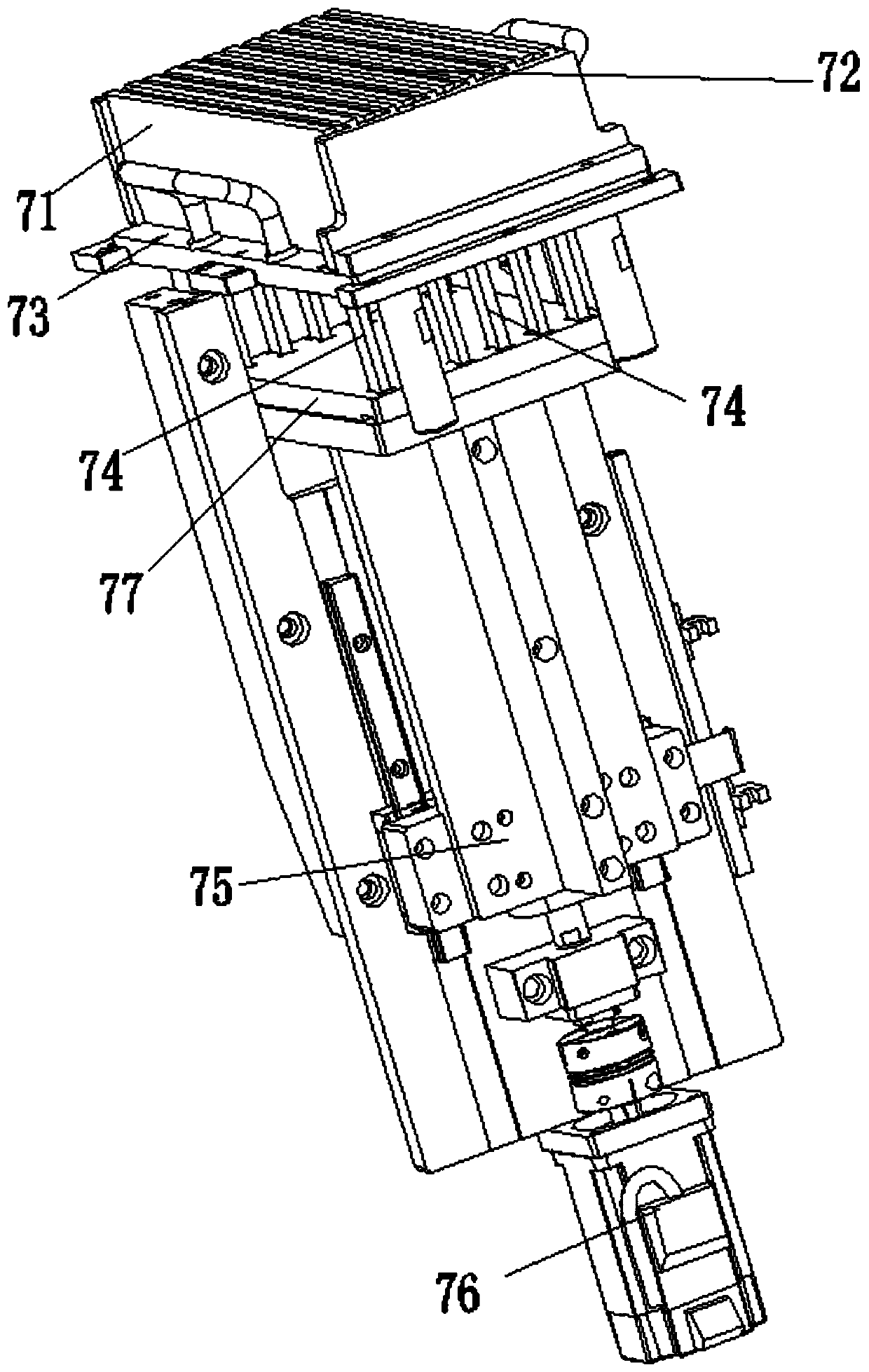

Mechanism for preventing edge breakage during solar silicon wafer fragmentation

PendingCN112038278AReduce chipping rateImprove yieldFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSilicon chip

The invention belongs to the technical field of solar silicon wafer fragmentation, and particularly relates to a mechanism for preventing edge breakage during solar silicon wafer fragmentation, whichcomprises a transplanting manipulator, a conveying belt, a downward pressing in-place sensor, an upper computer, a downward pressing spray head, a downward pressing spray head water inlet pipe and a water pump, wherein the conveying belt is placed right below the transplanting manipulator; the downward pressing in-place sensor is installed on the right side of the transplanting manipulator and electrically connected with an upper computer; the downward pressing spray head is installed on the left side of the transplanting manipulator and connected with a water outlet of a water pump through adownward pressing spray head water inlet pipe, and the water pump is electrically connected with the upper computer. The invention provides a mechanism for preventing edge breakage during solar silicon wafer fragmentation, which can reduce the edge breakage rate in the wafer fragmentation process and can also improve the yield of the silicon wafers and the separation effect of the silicon wafers.

Owner:天津源启晟科技发展有限公司

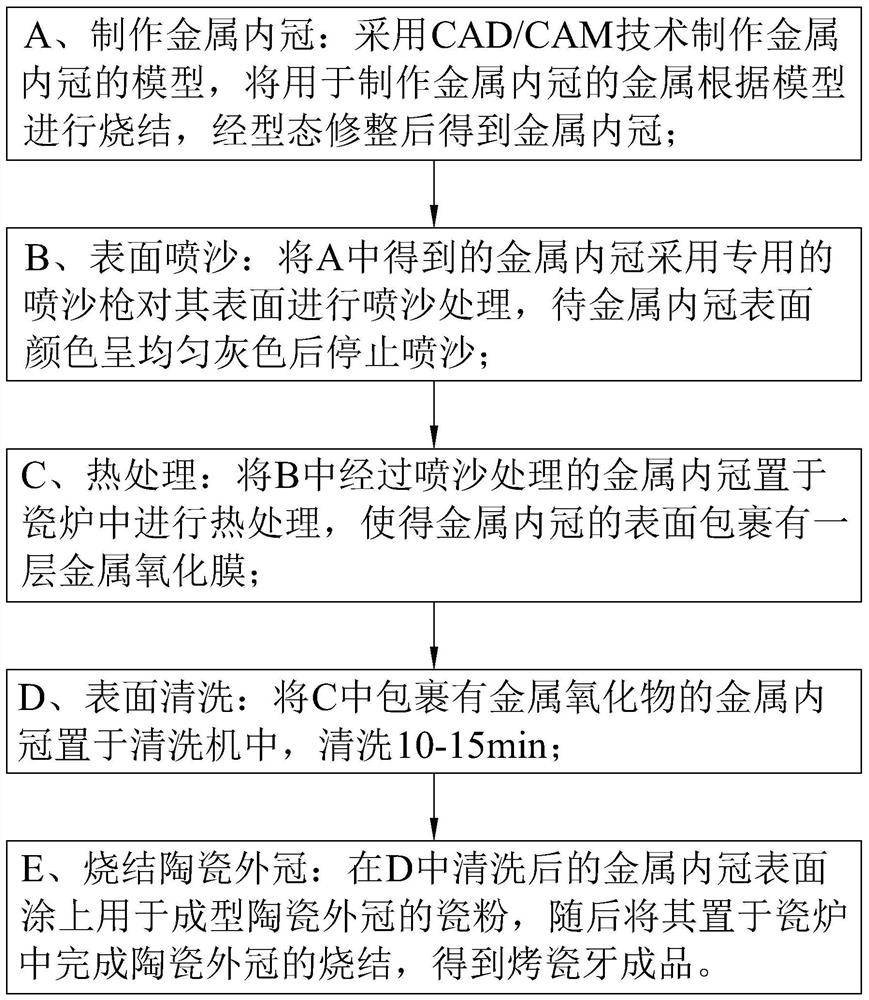

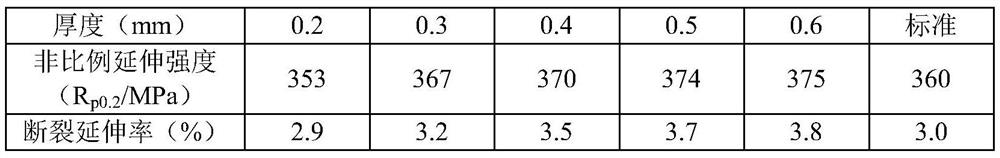

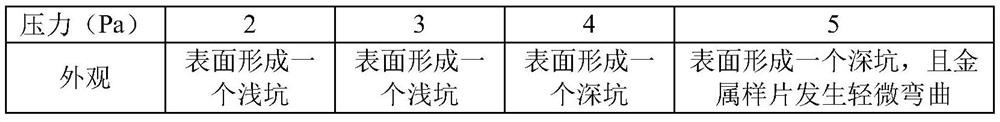

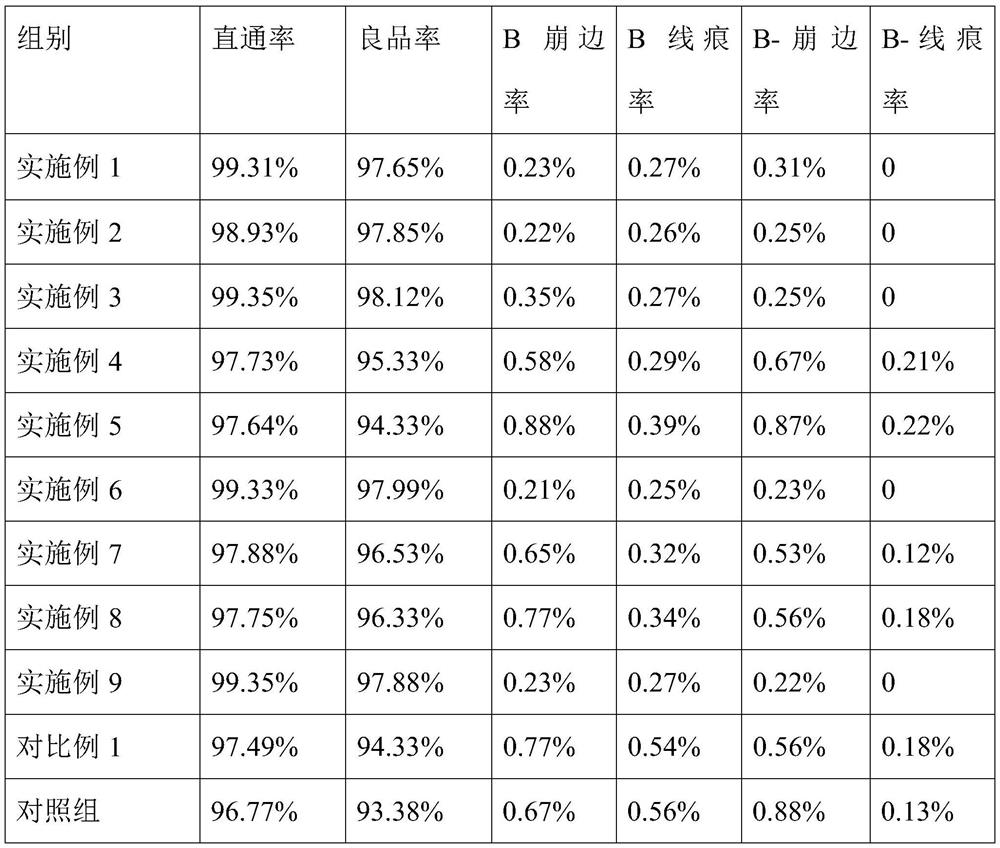

A kind of preparation technology of porcelain tooth

ActiveCN108685618BHigh bonding strengthReduce chipping rateArtificial teethSand blastingSurface cleaning

The invention discloses a preparation technology for porcelain teeth, and relates to the technical field of dental restoration. The preparation technology is technically characterized by comprising the steps of manufacturing a metal inner crown, carrying out sand blasting on the surface, carrying out heat treatment, carrying out surface cleaning, and sintering a ceramic outer crown so as to obtaina finished product of the porcelain tooth. According to the preparation technology, through a mode that the metal inner crown is subjected to sand blasting treatment and then is subjected to heat treatment, a metal oxide film is formed on the surface of the metal inner crown, so that the bonding strength between the ceramic outer crown and the metal oxide film is improved, and therefore the probability that the porcelain teeth are fractured is lowered.

Owner:厦门市仿真美义齿科技有限公司

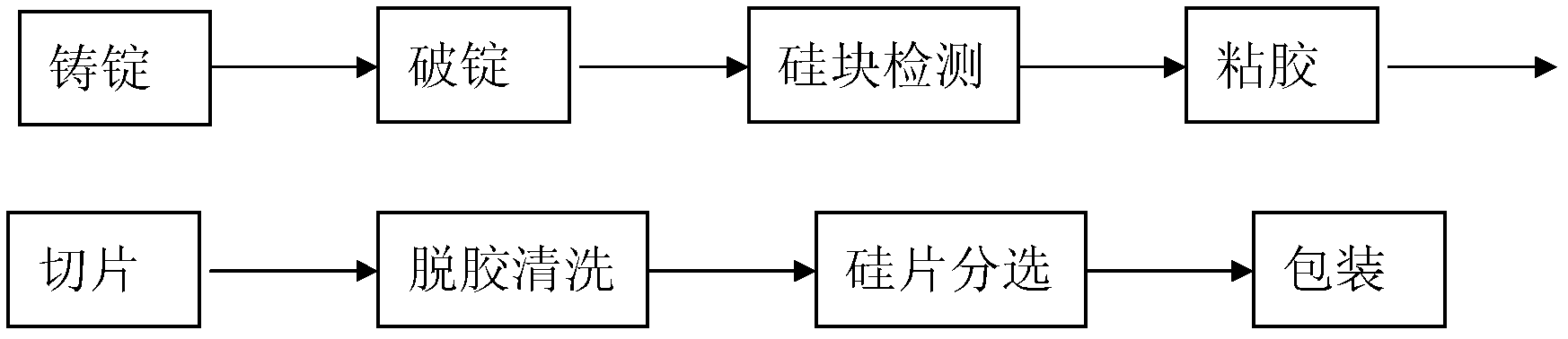

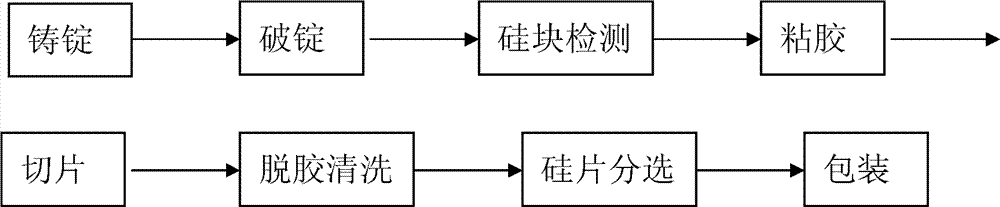

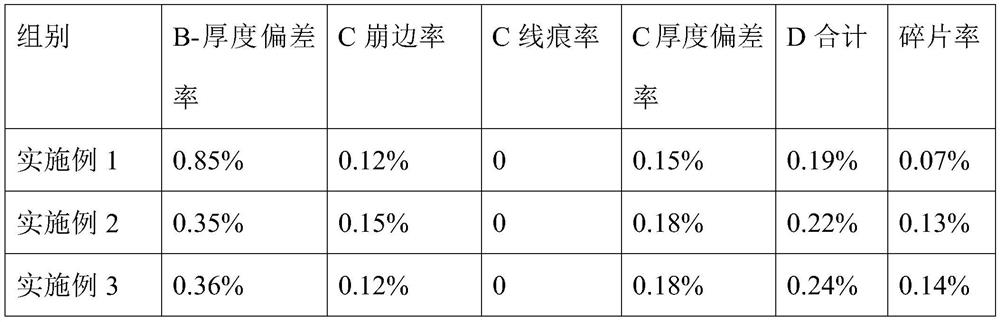

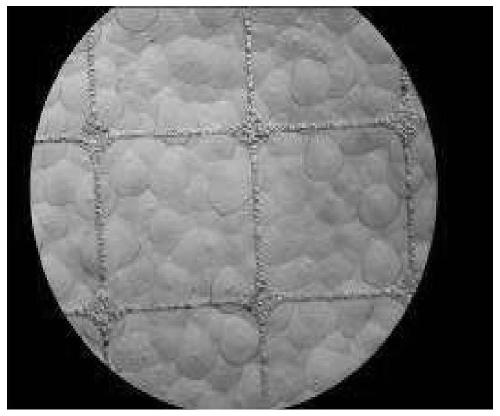

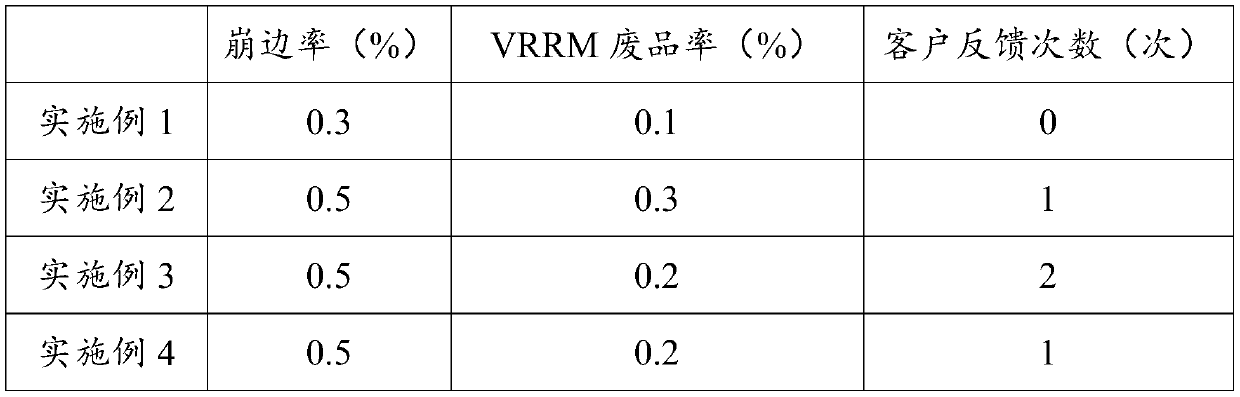

Processing method of crystalline silicon rod and product thereof

ActiveCN112342616AImprove pass rateReduce hardnessPolycrystalline material growthSingle crystal growth detailsCrystallographyFirst pass yield

The invention relates to a processing method of a crystalline silicon rod and a product thereof. According to the machining method, the crystalline silicon rod is subjected to staged heat treatment, so that the hardness of the crystalline silicon rod is reduced, the internal stress of the crystalline silicon rod is reduced, the first pass yield of the crystalline silicon rod in the cutting processcan be increased finally, the yield is remarkably increased, and the line mark rate, the edge breakage rate and the fragment rate can be effectively reduced.

Owner:LUOYANG CSI PHOTOVOLTAIC TECH CO LTD +1

Chip to be filmed and its processing technology

ActiveCN109686700BThe treatment process is easy to operateReduce manufacturing costSolid-state devicesSemiconductor/solid-state device manufacturingPhysical chemistrySilicon oxide

Owner:JILIN SINO MICROELECTRONICS CO LTD

Silicone wafer degumming pre-washing device

InactiveCN103506333AAlleviate heat and cold shrinkage problemsReduce energy consumptionCleaning using toolsCleaning using liquidsPlate heat exchangerEngineering

The invention provides a silicone wafer degumming pre-washing device. The silicone wafer degumming pre-washing device comprises a plate heat exchanger (3), wherein a first inlet (2) and a second inlet (4) are formed in the two sides of the upper end of the plate heat exchanger (3) respectively, the first inlet (2) is connected with an outlet (7) of ingot furnace cooling water, the second inlet (4) is a cold water injection port, a plate heat exchanger outlet (5) is formed in the lower end of the plate heat exchanger (3) and connected with a silicone wafer pre-washing pipeline (8), and a pre-washing port (6) is formed in the other end of the silicone wafer pre-washing pipeline (8). By means of the silicone wafer degumming pre-washing device, the inlet water temperature for silicone wafer pre-washing can be kept at 20-25 DEG C to adapt to the temperature after a silicone wafer is cut, the problem that glue contracts due to the temperature is relieved, the qualification rate is improved, and edge breakage rate is lowered. Meanwhile, energy consumption of a cooling water machine is reduced, and therefore the energy consumed in cooling with cooling water of ingots and single crystal is lowered.

Owner:无锡荣能半导体材料有限公司

Novel edge-collapse proof unfilled corner proof gripper for silicon crystal-bar slicer

InactiveCN101249697BAvoid chippingReduce chipping rateStone-like material working toolsEngineeringFour-slide

The invention relates to a novel clamp for preventing broken edge and broken corner used in a silicon stick section cutter. The clamp comprises two guide rails (6), four slide blocks (2), four baffle plates (1) and four staff gauges (4), wherein the two guide rails are arranged on the left and on the right respectively; the two ends of each guide rail (6) are fixedly mounted on the fragment box (10) of the section cutter. Every two of the four slide blocks (2) are sleeved on the two sides of every two guide rails (6); each slide block has an L-shaped section and consists of a transverse blockand a vertical block, wherein the transverse block is sleeved on and fixedly connected with the guide rail (6); the four baffle plates (1) are fixedly connected on the inner sides of the vertical blocks of corresponding slide blocks (2) respectively; the four staff gauges (4) are fixedly connected at the lower section of the inner side of corresponding baffle plates (1) respectively. When in cutting operation, the section cutter adopts a mechanical method to block the two end faces of the silicon stick so that the silicon stick can not extend sideways before being cut off, thereby ensuring that the silicon stick is cut off instead of breaking off, thus preventing broken edge.

Owner:HAREON SOLAR TECHNOLOGY CO LTD

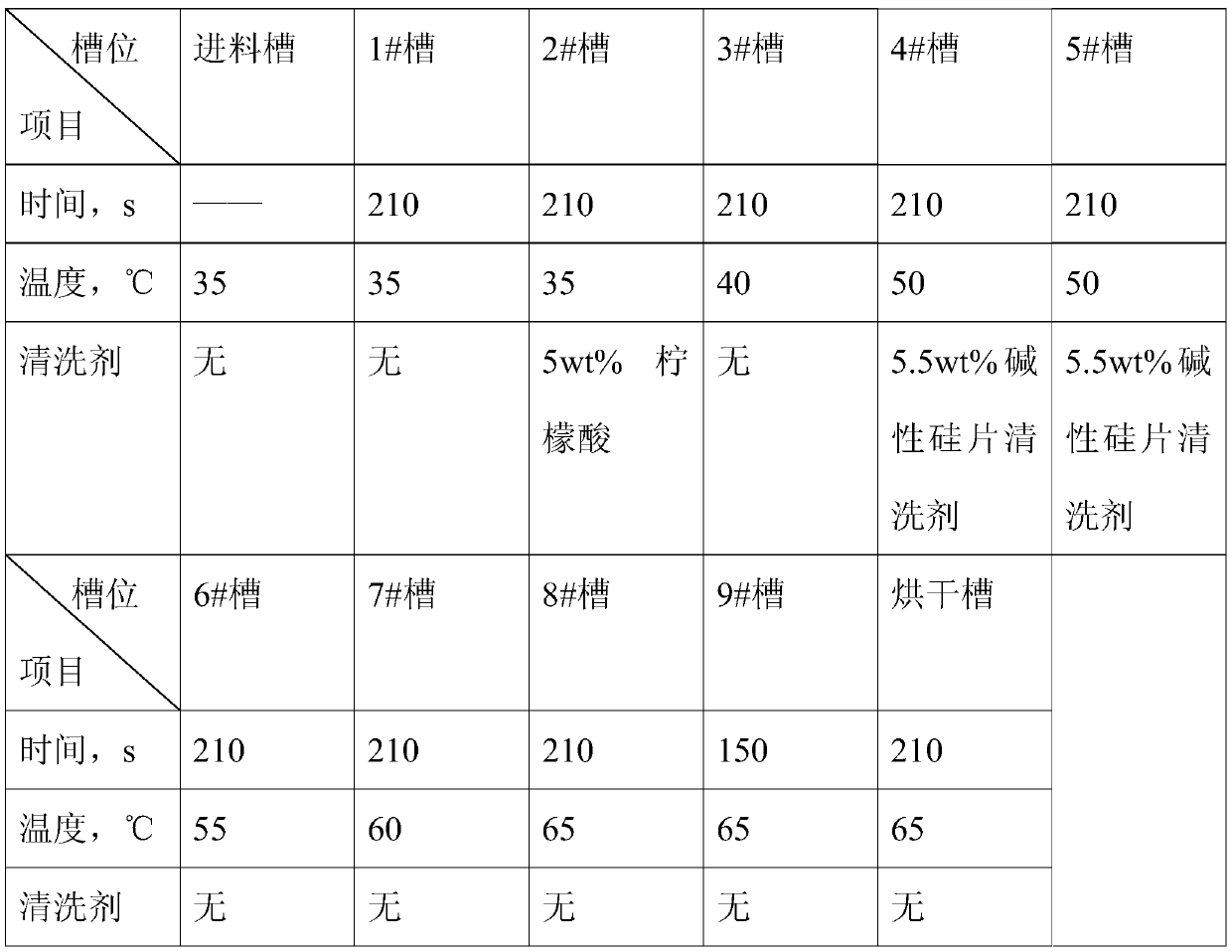

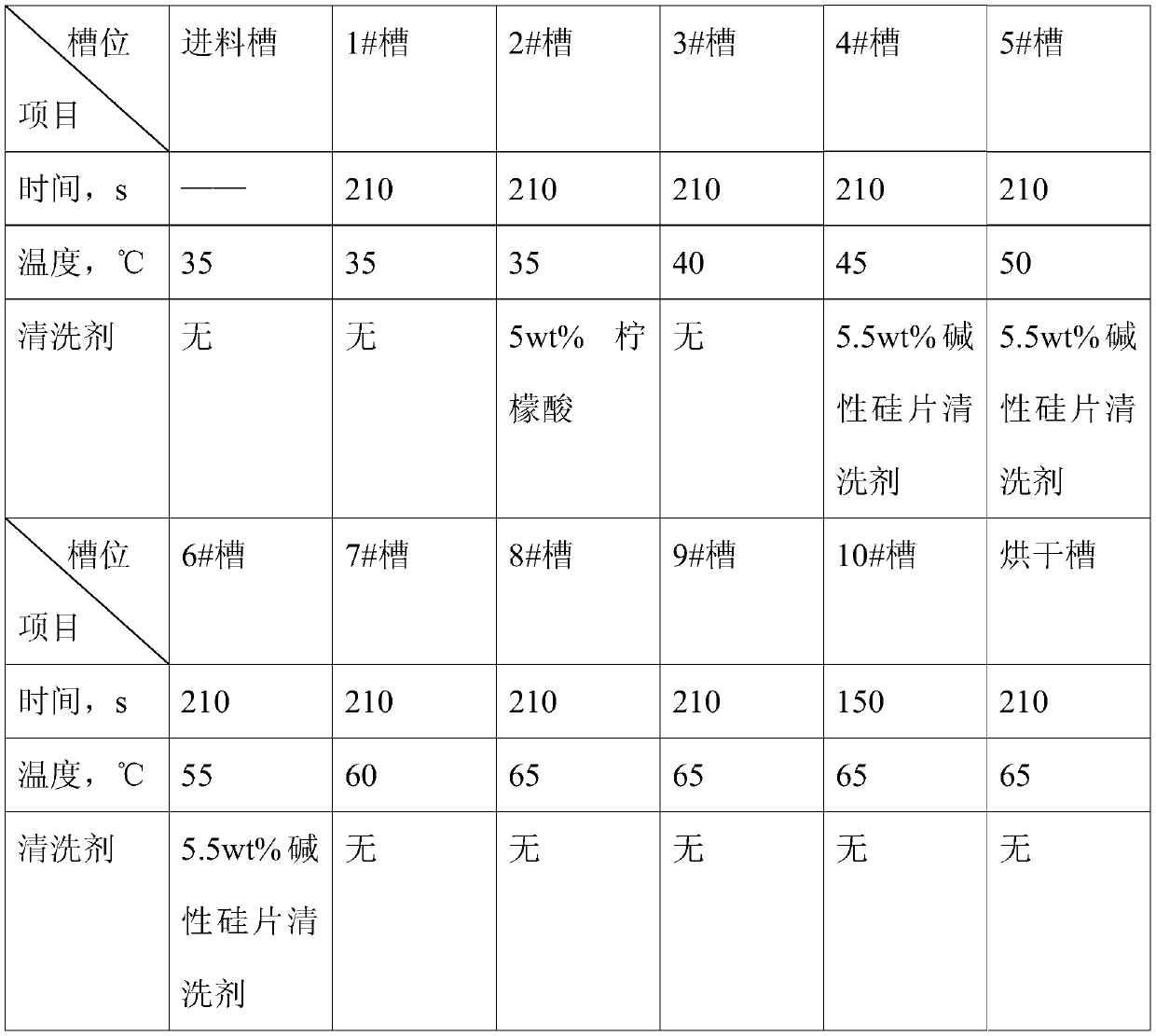

A kind of cleaning method of diamond wire cut crystalline silicon wafer

ActiveCN106733876BEasy to cleanReduce chipping rateCleaning using liquidsDiamond wire sawEngineering

The invention relates to a method of cleaning a crystal silicon wafer cut by a diamond wire saw. The method comprises the following steps: (1)precleaning: (2) cleaning with a reagent; (3) rinsing; and (4) drying; according to the sequence of the working procedure steps, the treatment temperature is gradually raised step by step; the drying temperature in the step (4) is equal to or higher than 65 DEG C; each technological unit comprises a cleaning tank; the temperature of the cleaning tank of a first precleaning technological unit in the step (1) is 30-35 DEG C lower than the drying temperature; the temperature D-value of two adjacent cleaning tanks is equal to or lower than 10 DEG C; and the soaking time of a crystal silicon wafer in each cleaning tank is equal to or shorter than 210 s. According to the invention, proper cleaning technology, cleaning tank temperature and soaking time are selected to obtain the cleaning method suitable for the crystal silicon wafer cut by the diamond wire saw; and with adoption of the method, the crystal silicon wafer can be effectively cleaned, the edge breakage rate, crystal silicon wafer breakage rate and manufacture procedure loss can be reduced, and the technological time also can be shortened.

Owner:CSI CELLS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com