Method for controlling acid-washing and edge-shearing quality of high-strength steel

A technology of high-strength steel and steel acid, which is applied in the general control system, adaptive control, control/regulation system, etc., can solve the problem of inability to accurately control the set value of disc shear gap and overlap, and is not suitable for edge trimming of high-strength steel products Control and other issues, to achieve the effect of reducing the chipping rate, reducing the number of broken belts, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

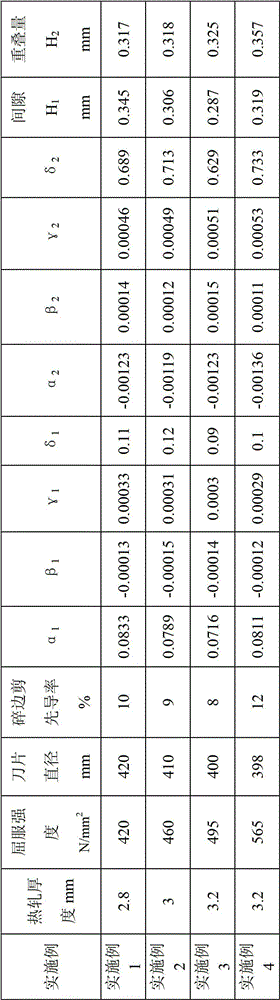

[0020] A specific embodiment of a method for controlling the quality of pickling trimming of high-strength steel provided by the present invention is given below.

[0021] The method comprises the steps of: adopting the process computer system to respectively cut the disc shear gap H 1 and the amount of overlap H 2 The set value is calculated, and then the obtained set value is transmitted to the operating computer system, and the operating computer system adjusts the disc shears transmission device according to the obtained set value, and controls the disc shears to operate on the high-strength steel Carry out trimming, it is characterized in that:

[0022] The disc shear gap H 1 and the amount of overlap H 2 The set value of is obtained by the following formula:

[0023] h 1 =α 1 X+β 1 Y+γ 1 Z+δ 1 Q

[0024] h 2 =α 2 X+β 2 Y+γ 2 Z+δ 2 Q

[0025] In the above formula, X is the thickness of the incoming material, Y is the yield strength of the high-strength ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com