Grinding wheel manufacture method used for silicon wafer chamfering, and manufacture device

A manufacturing method and a manufacturing device technology, which are applied in the field of the grinding wheel manufacturing method and manufacturing device for chamfering of silicon wafers, can solve the problems of low precision of the cross-sectional shape of the grinding wheel groove, easy falling off of diamond abrasive grains, inconsistent groove shape and spacing, etc. , to achieve the effect of solving the problem that diamond abrasive particles are easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

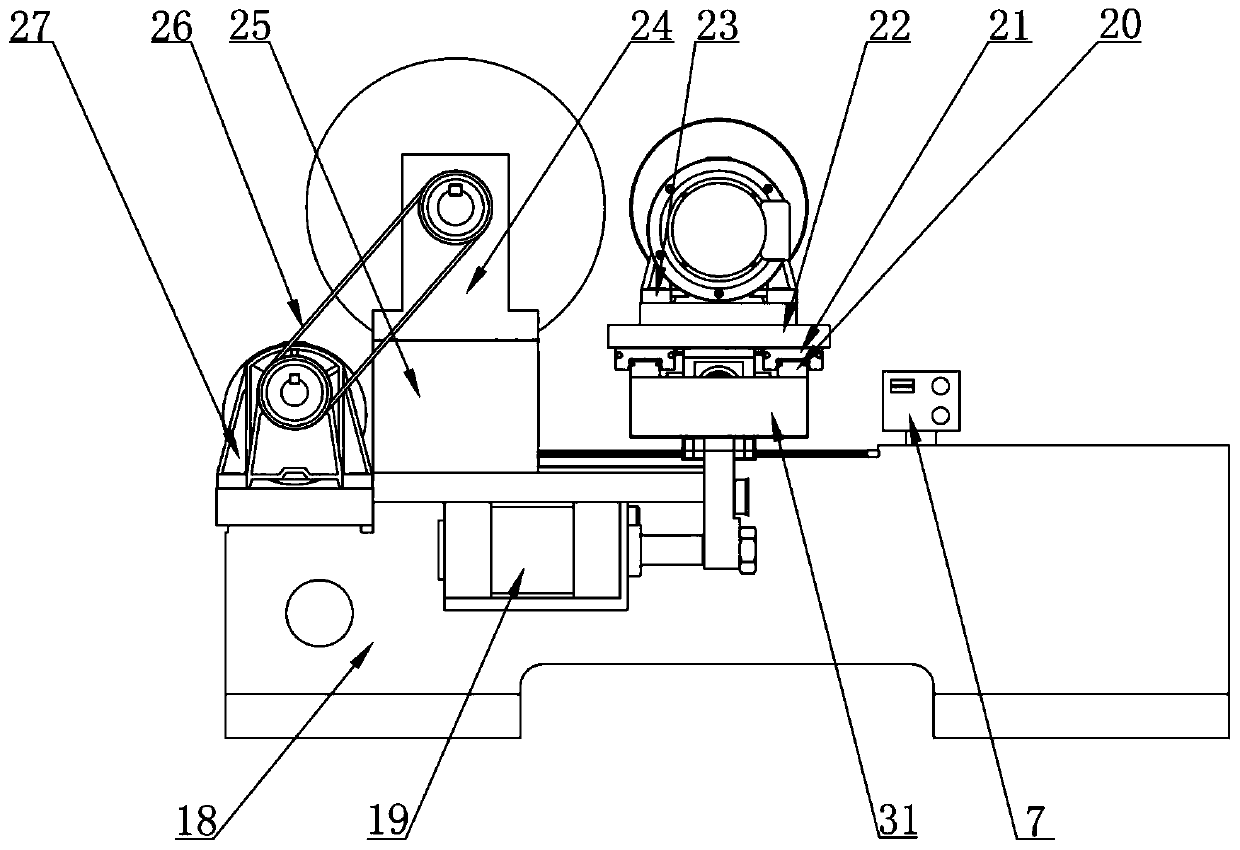

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0036] A method for manufacturing a grinding wheel for chamfering silicon wafers:

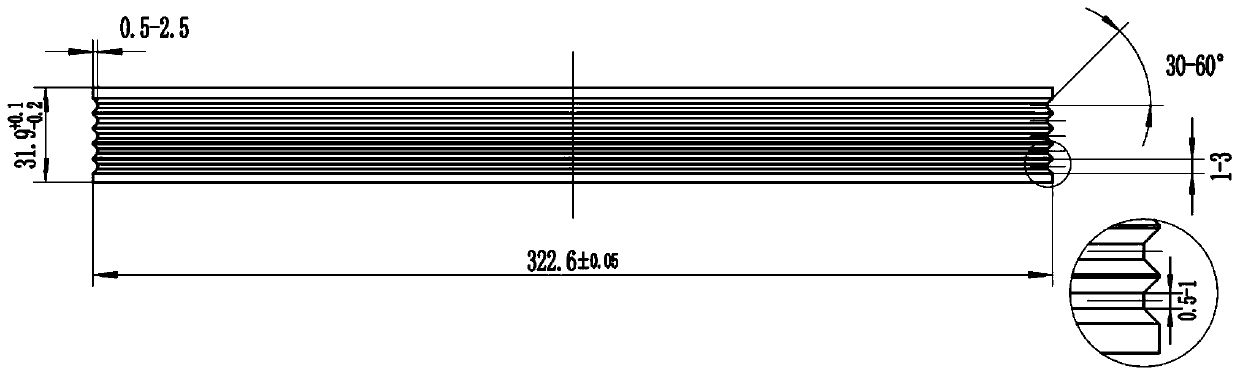

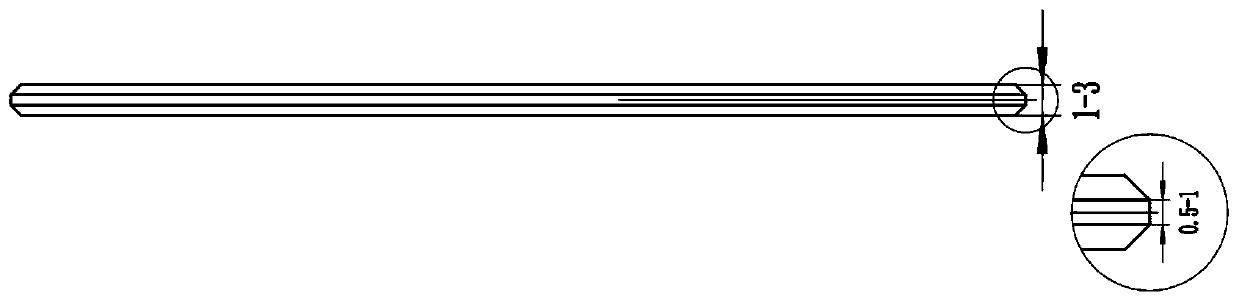

[0037] 1) Stir evenly the diamond powder with a particle size of 50-800 mesh and the Ti-Al-Cu-Sn metal powder at a volume concentration of 20%-95% to form the working layer powder of the grinding wheel; at the same time, the shape error is less than 10 Micron metal matrix, and put it into the metal mold; Next, inject the grinding wheel working layer powder into the annular cavity between the metal matrix and the metal mold, scrape it flat, and put it on the press for pressing, Form the compact on the surface of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com