Solar silicon wafer cutting mortar and preparation method thereof

A technology for solar silicon wafers and mortar, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of limited water absorption capacity, increased water content, easy sedimentation, etc., and achieves a simple preparation method, a reduced edge collapse rate, and a large improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

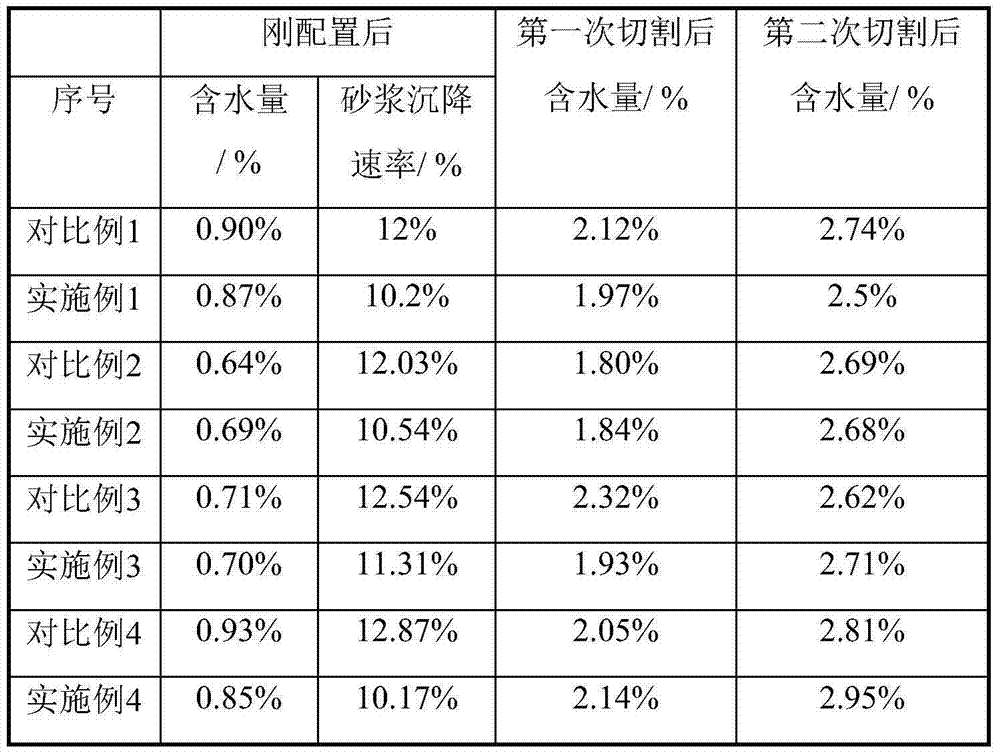

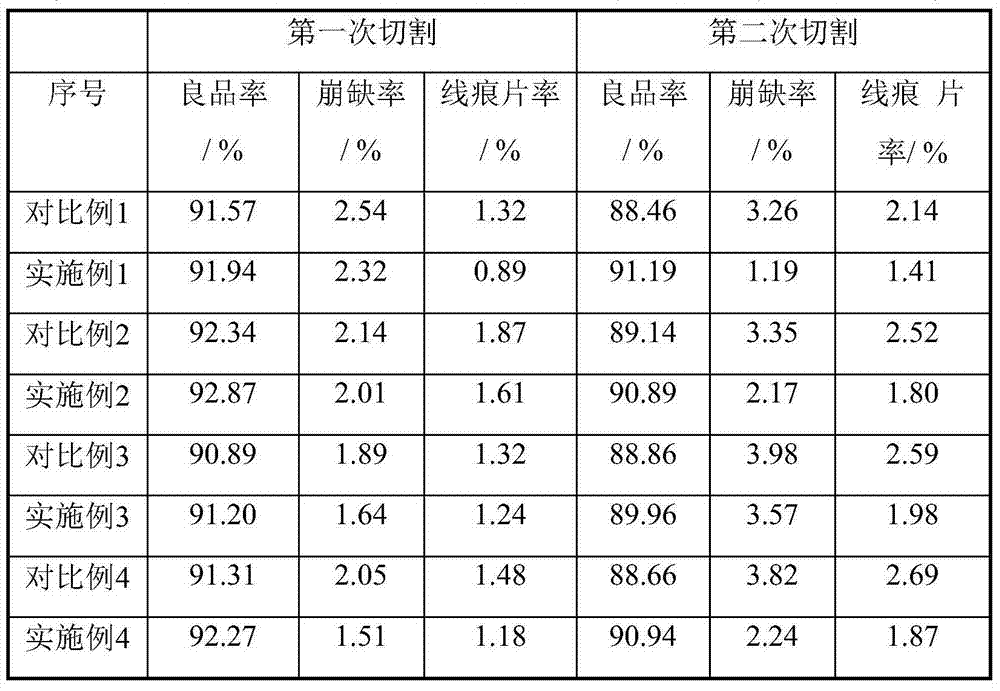

Embodiment 1

[0045] A preparation method of solar silicon chip cutting mortar, comprising the following steps:

[0046] (1) Take silicon carbide micropowder and PEG cutting liquid, mix to obtain cutting mortar mixed liquid, described cutting mortar mixed liquid is by the PEG cutting liquid of 710 L 205 models (concentration of PEG in PEG cutting liquid is 1.06kg / L, The density of the cutting fluid is 1.12Kg / m 3 ) is prepared by adding 750kg 1500# SiC;

[0047] (2) Dissolve the modified urea-based polymer in N-methylpyrrolidone to obtain a dispersion stabilizer, add 2.75L dispersion stabilizer to the cutting mortar mixture in step (1), and the density of the dispersion stabilizer is 1.12Kg / m 3 , the mass fraction of the modified urea-based polymer in the dispersion stabilizer is 52%, and the mass ratio of the mass ratio of the polyethylene glycol cutting fluid and silicon carbide micropowder to the modified urea-based polymer is 1 : 0.1%, fully stirred for 2h to prepare solar silicon ch...

Embodiment 2

[0052] A preparation method of solar silicon chip cutting mortar, comprising the following steps:

[0053] (1) Take silicon carbide micropowder and PEG cutting liquid, mix to obtain cutting mortar mixed liquid, described cutting mortar mixed liquid is by the PEG cutting liquid of 750 L 209 models (concentration of PEG in PEG cutting liquid is 1.02kg / L, The density of the cutting fluid is 1.12Kg / m 3 ) is prepared by adding 800kg 1200#SiC;

[0054] (2) Dissolve the modified urea-based polymer in N-ethylpyrrolidone to obtain a dispersion stabilizer, add 1.5L dispersion stabilizer to the cutting mortar mixture in step (1), and the density of the dispersion stabilizer is 1.12Kg / m 3 , the mass fraction of the modified urea-based polymer in the dispersion stabilizer is 52%, and the mass ratio of the mass ratio of the polyethylene glycol cutting fluid and silicon carbide micropowder to the modified urea-based polymer is 1 : 0.05%, fully stirred for 3 hours to prepare solar silicon...

Embodiment 3

[0058] A preparation method of solar silicon chip cutting mortar, comprising the following steps:

[0059] (1) Weigh silicon carbide micropowder and PEG cutting liquid, mix to obtain cutting mortar mixed liquid, described cutting mortar mixed liquid is made of PEG cutting liquid of 760L 209 model (concentration of PEG in PEG cutting liquid is 1.02kg / L, cutting The density of the liquid is 1.12Kg / m 3 ) is prepared by adding 825kg 1200#SiC;

[0060] (2) Dissolve the modified urea-based polymer in dimethyl sulfoxide to obtain a dispersion stabilizer, and add 0.65L of the dispersion stabilizer to the cutting mortar mixed solution in step (1), and in the dispersion stabilizer, modify The mass percentage of the permanent urea-based polymer is 45%, the mass ratio of the sum of the polyethylene glycol cutting fluid and the silicon carbide micropowder to the modified urea-based polymer is 1:0.023%, fully stirred for 5h, Prepare solar silicon chip cutting mortar, said solar silicon ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com