Mechanism for preventing edge breakage during solar silicon wafer fragmentation

A technology of solar silicon wafers and bit machines, which is applied in the direction of conveyor objects, final product manufacturing, photovoltaic power generation, etc., can solve the problem of chipping of solar silicon chips, achieve the effect of reducing chipping rate and improving the yield of silicon chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

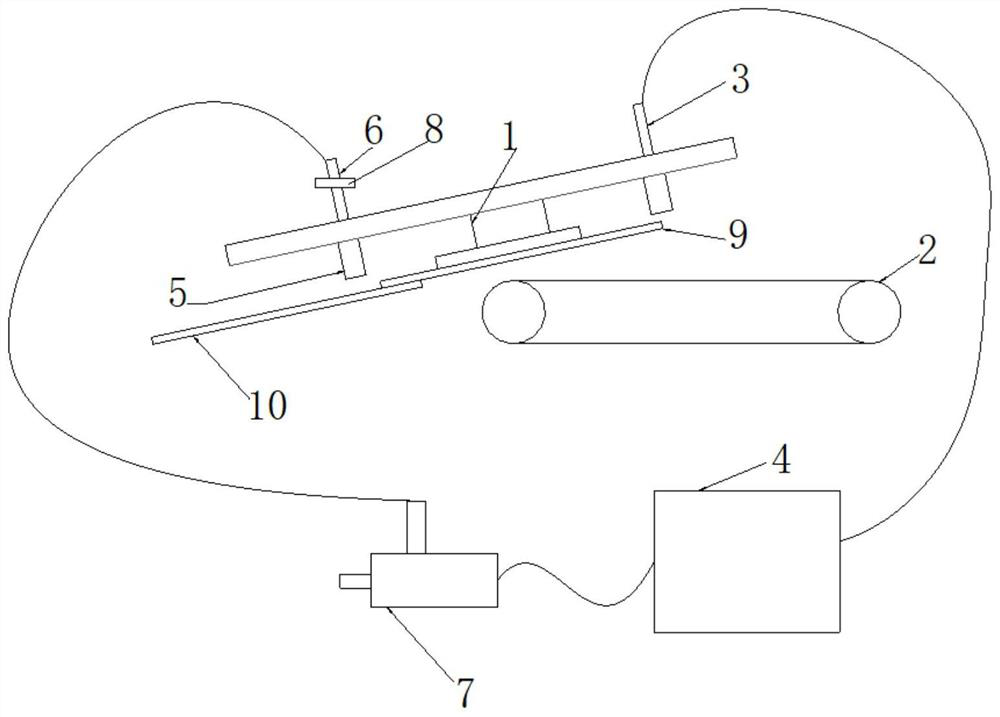

[0023] Such as figure 1 As shown, the conveyor belt 2 is arranged on the lower right side of the transplanting manipulator 1, and the down-pressing sensor 3 is installed on the right side of the transplanting manipulator 1, and the down-pressing in-position sensor 3 is electrically connected to the upper computer 4, and then the left side of the transplanting manipulator 1 Install the down-pressing nozzle 5 so that the down-pressing nozzle 5 is connected to the water outlet of the water pump 7 through the down-pressing nozzle water inlet pipe 6, and the water pump 7 is electrically connected to the upper computer 4. After the mechanism for preventing edge collapse is connected and installed, the specific motion operation is performed.

[0024] During specific motion operation, the front silicon wafer 9 overlaps the position directly above the rear silicon wafer 10, and the transplanting manipulator 1 moves to the front silicon wafer 9 directly above and drives the front silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com