Epoxy resin composite material

A technology of epoxy resin and composite material, applied in the field of chemistry, can solve the problems of adding silicon wafers, etc., and achieve the effect of improving yield, reducing edge collapse rate, good economic benefits and market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

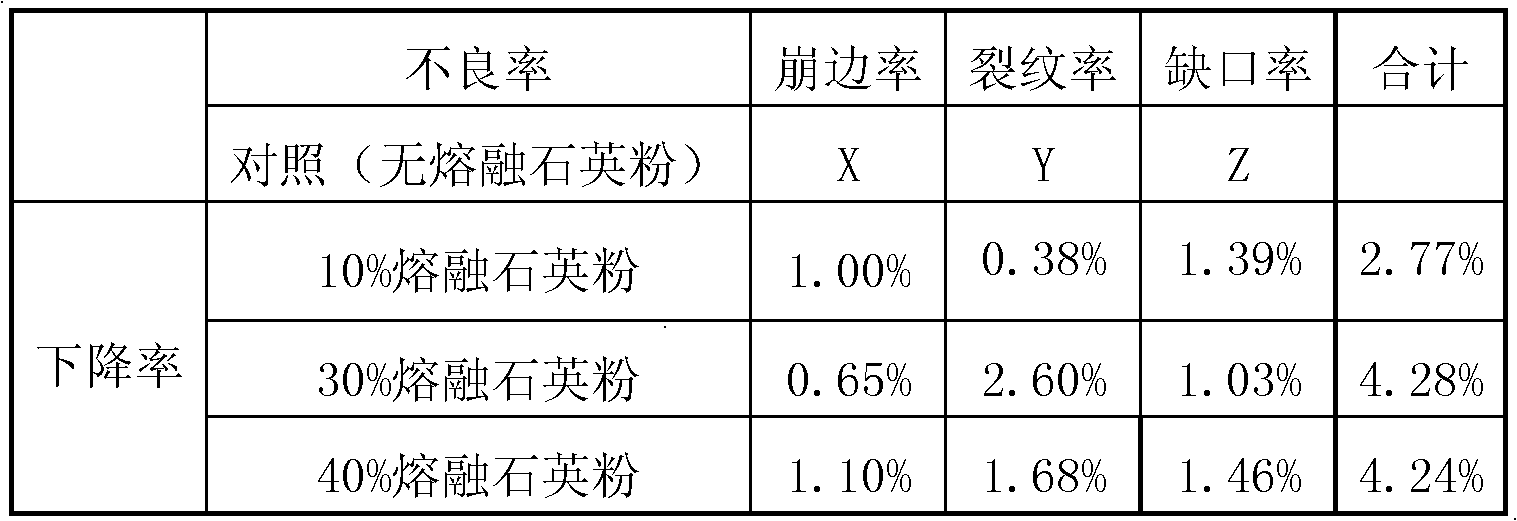

[0020] Example 1 Proportion screening experiment of epoxy resin glue and fused silica powder

[0021] 1. Experimental materials: Epoxy resin glue is AB two-component glue of Loctite 3382 from Henkel, Germany. Among them, A glue is glycidyl ether epoxy resin glue, B glue is polythiol curing agent, and the added powder The body material is fused silica powder, the expansion coefficient of the fused silica powder is 0.4PPM, and the average particle size D50 is 5 microns.

[0022] Their matching is as shown in Table 1:

[0023] Table 1 Proportion of epoxy resin glue and fused silica powder

[0024] Additive ratio

A glue weight (g)

Fused silica powder weight (g)

B glue weight (g)

10%

22.5

2.5

25

30%

17.5

7.5

25

40%

15

10

25

[0025] 2. Experimental method

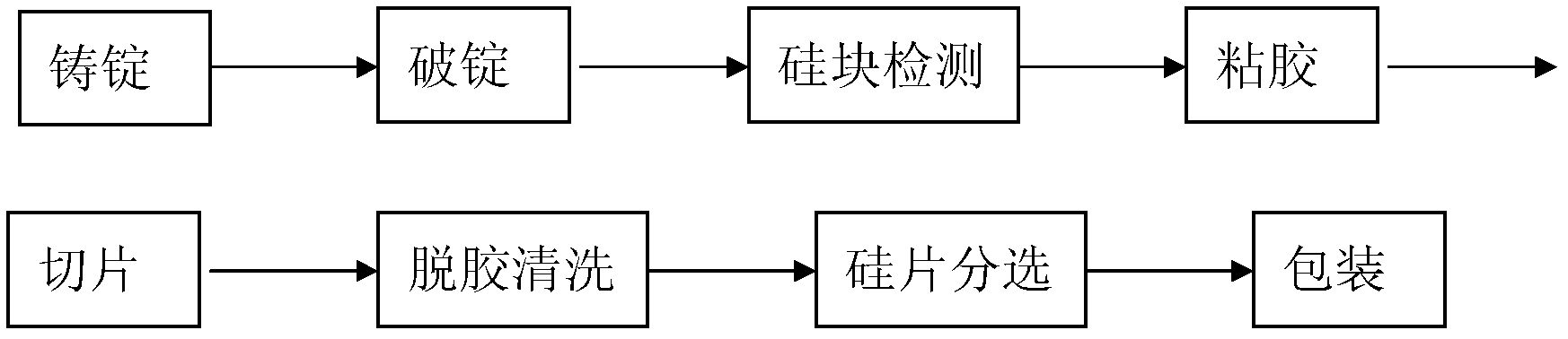

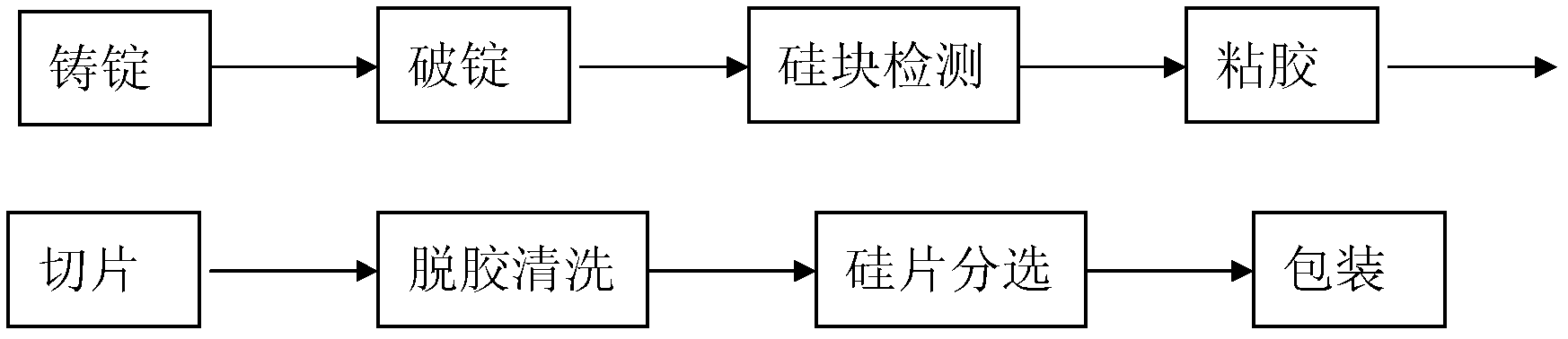

[0026] Silicon wafer manufacturing process such as figure 1 Shown, wherein, viscose process comprises the steps:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com