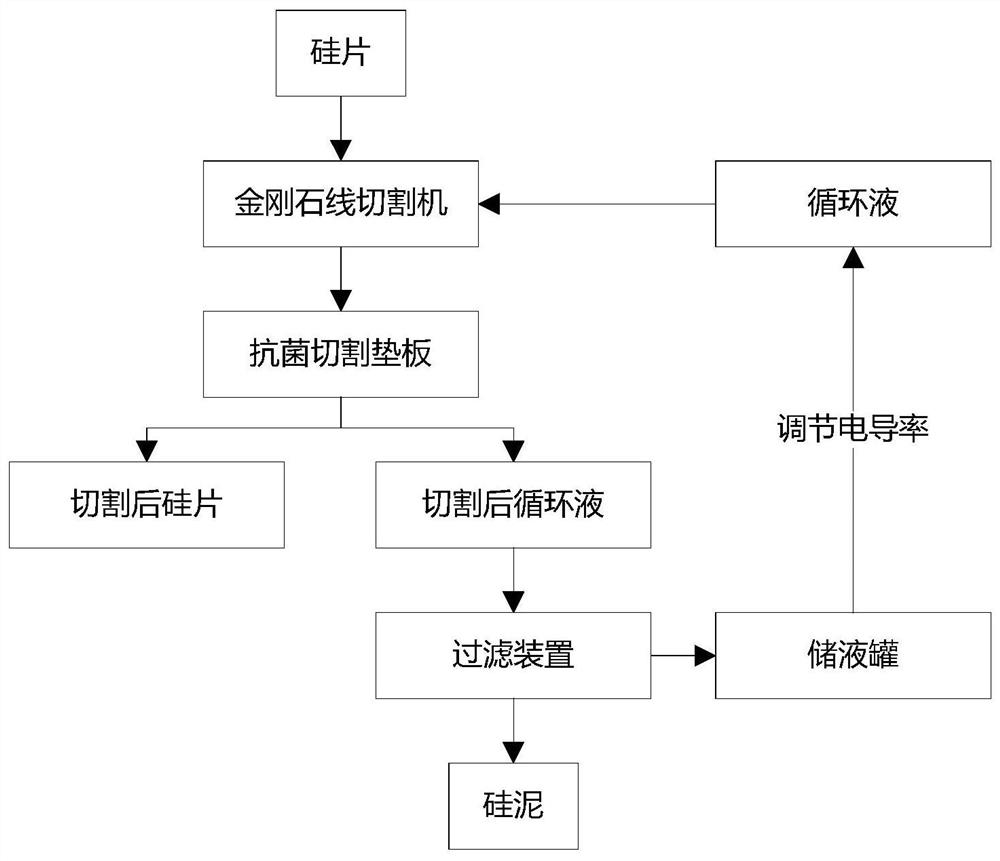

Diamond wire cutting circulation system

A diamond wire and circulation system technology, applied in metal processing equipment, stone processing equipment, lubricating composition, etc., can solve problems such as hidden dangers, diamond wire jamming, burning through filter cloth, etc. The effect of small rate change and increased stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

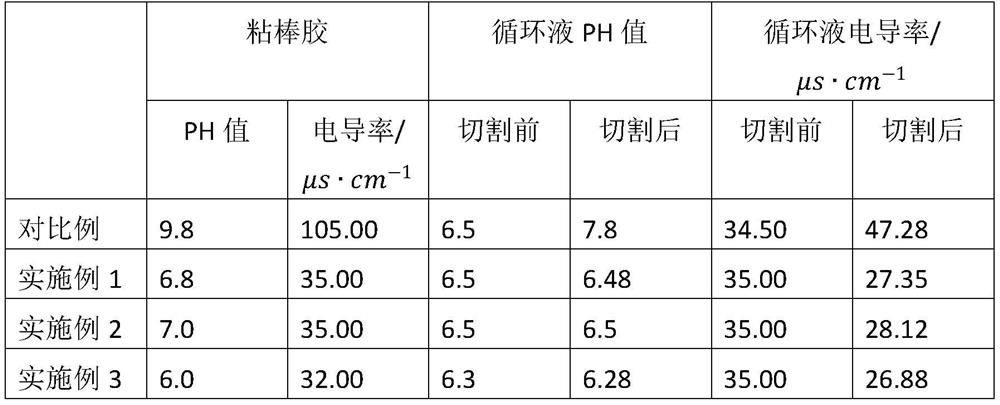

Embodiment 1

[0026] Stick glue PH value 6.8, conductivity 35.00μs cm -1 , configure the circulating fluid PH6.5 before cutting, conductivity 35.00, after cutting the circulating fluid PH6.48, conductivity 27.35μs·cm -1 .

Embodiment 2

[0028] Stick glue PH value 7.0, conductivity 35.00μs cm -1 , configure the circulating fluid PH6.5 before cutting, conductivity 35.00, after cutting the circulating fluid PH6.5, conductivity 28.12μs·cm -1 .

Embodiment 3

[0030] Stick glue PH value 6.0, conductivity 32.00μs cm -1 , configure the circulating fluid PH6.3 before cutting, conductivity 35.00, after cutting the circulating fluid PH6.28, conductivity 26.88μs·cm -1 .

[0031]

[0032] By comparison, it is found that the circulating liquid configured by the low pH value and low conductivity stick glue used in the present invention has little change in pH and conductivity before and after cutting, and maintains low pH and low conductivity. The operation of dripping citric acid and using an ion exchange column to reduce the conductivity of the circulating liquid during the cutting process can be cancelled, which ensures the processing effect and reduces the construction cost.

[0033] Among them, in the cutting operation test in Example 3, a total of 320 cuts were made, the comprehensive edge chipping rate was 1.61%, and the wire breakage rate was 0. It further proves the superiority of the diamond wire cutting cycle system of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com