Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

131results about How to "Reduce bulge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spine formation device, post-processing apparatus, spine formation system, and spine formation method

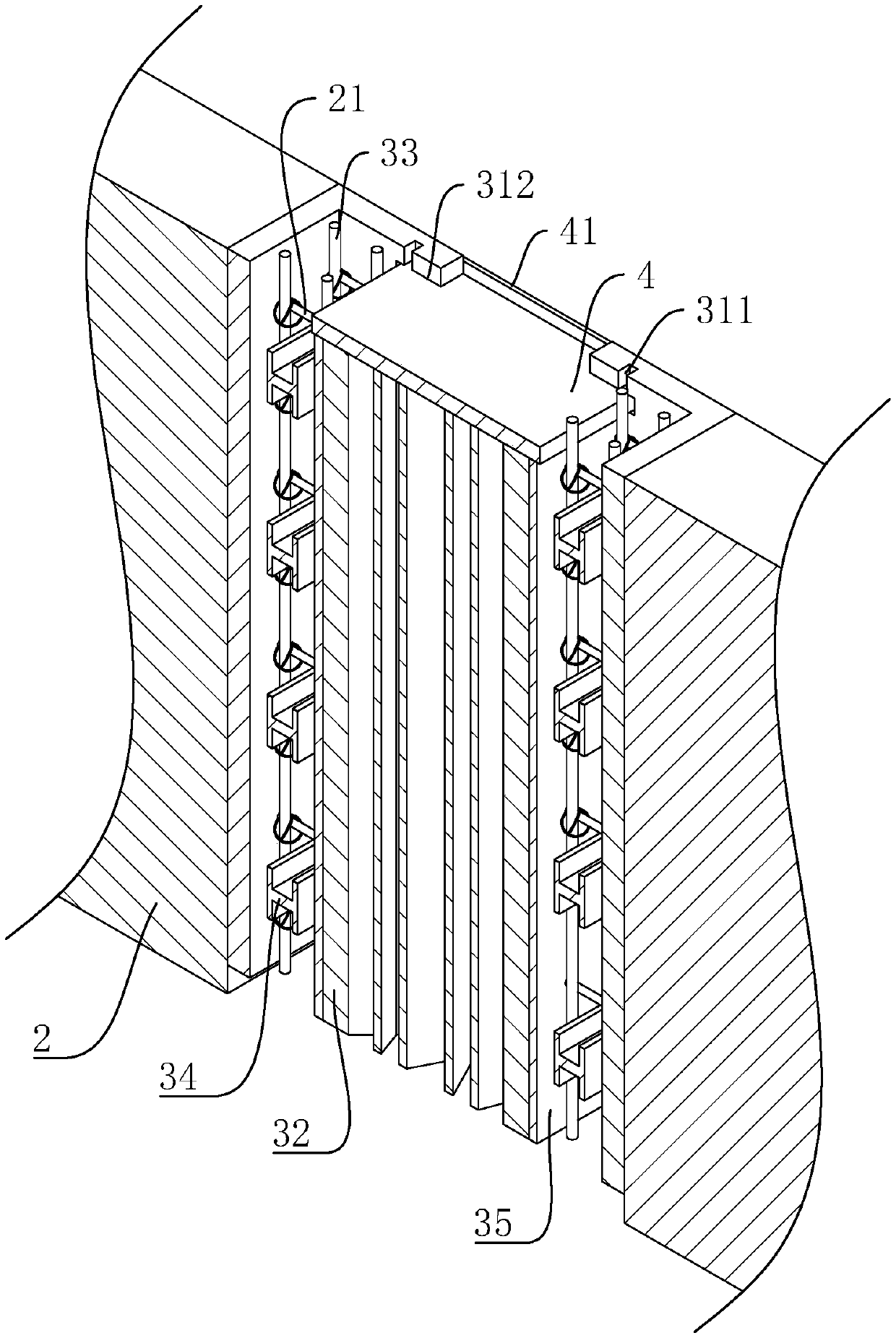

ActiveUS20100310340A1Short period of timeReduce bulgeFolding thin materialsOffice printingContact positionSheet material

An spine formation device includes a sheet conveyer that conveys the bundle of folded sheets in a sheet conveyance direction with a folded portion of the bundle forming front end portion thereof, first and second sandwiching units disposed downstream from the sheet conveyer, a contact member disposed downstream from the second sandwiching unit, against which the folded portion of a bundle of folded sheets is pressed, and a controller. The controller stops the sheet conveyer after the bundle is transported a predetermined distance from a contact position between the contact member and the folded portion of the bundle, causing the bundle to bulge, and causes the first and second sandwiching units to squeeze the bulging of the bundle of folded sheets in a thickness direction sequentially with the folded portion of the bundle pressed against the contact member to form a spine of the bundle.

Owner:RICOH KK

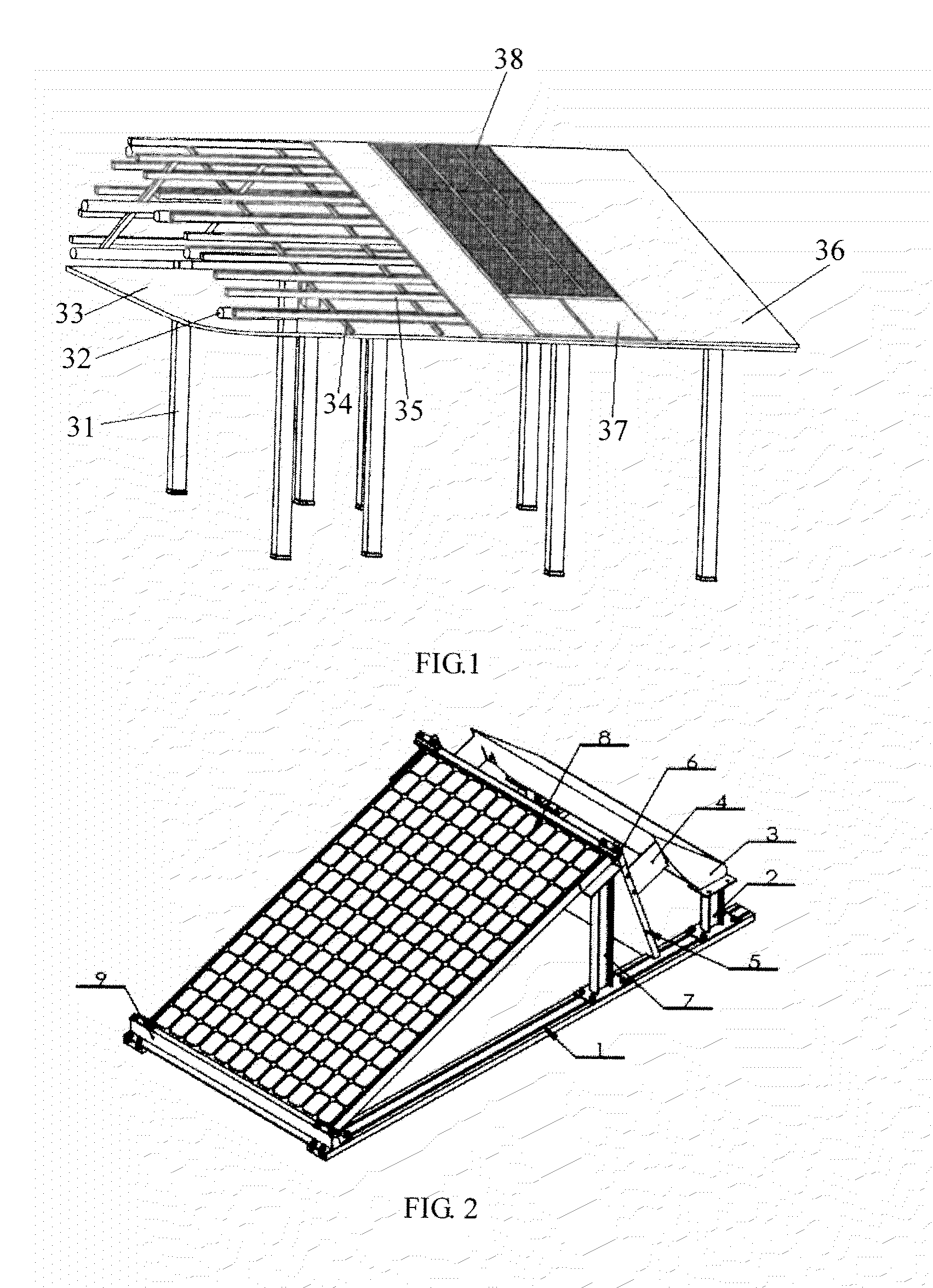

Photovoltaic Device

ActiveUS20140083488A1Reduction factorReduce bulgePhotovoltaic supportsSolar heating energyEngineeringPhotovoltaics

A photovoltaic device comprising: a base (1), a photovoltaic assembly (8) and a baffle plate (5), wherein the photovoltaic assembly is arranged in an inclined manner on the base from bottom up in a direction from front to rear, and behind the photovoltaic assembly, the baffle plate is arranged in an inclined manner on the base from bottom up in a direction from rear to front. The baffle plate reduces the profile coefficient and decreases the uplift by the action of wind load.

Owner:BOE TECH GRP CO LTD +1

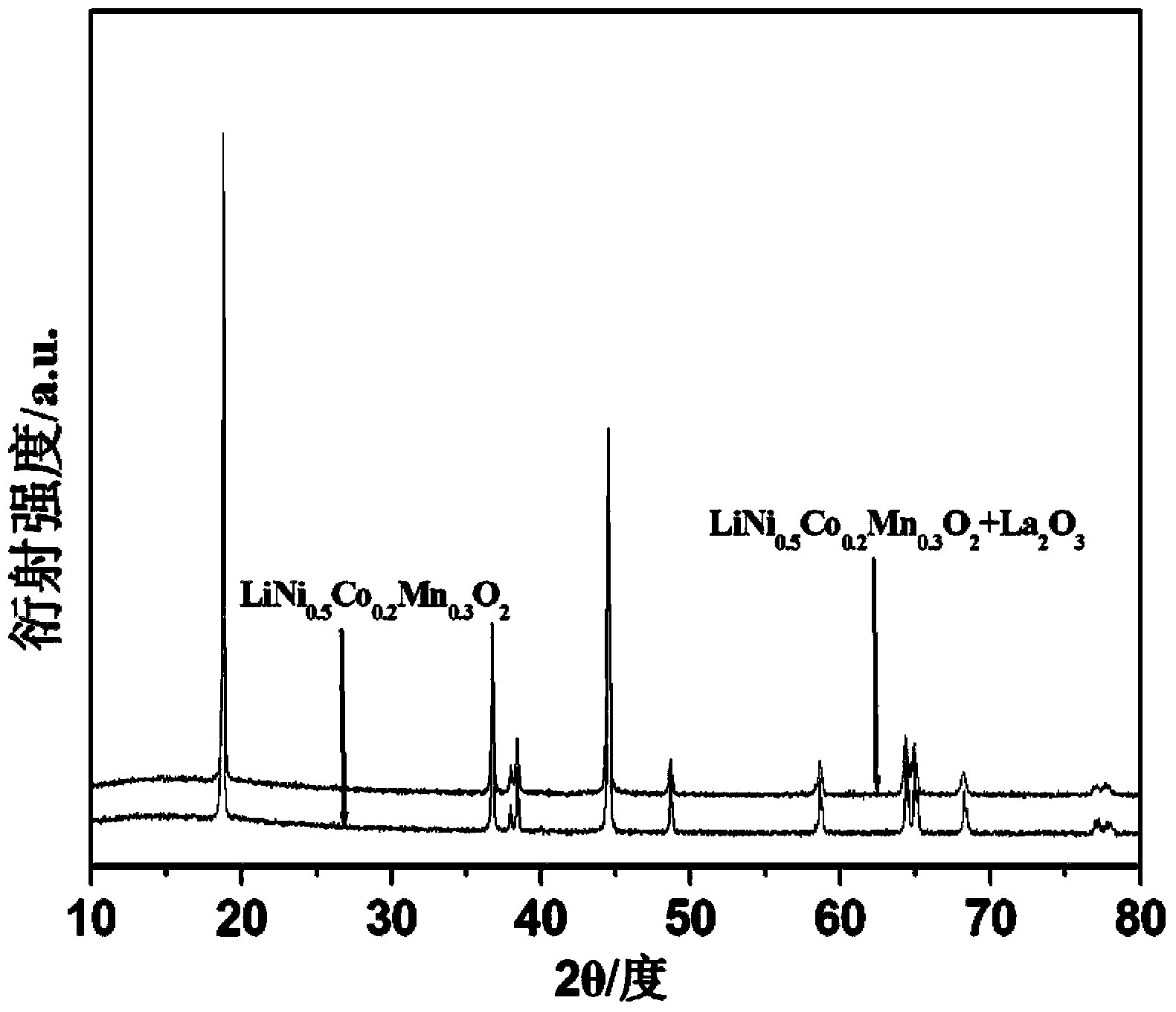

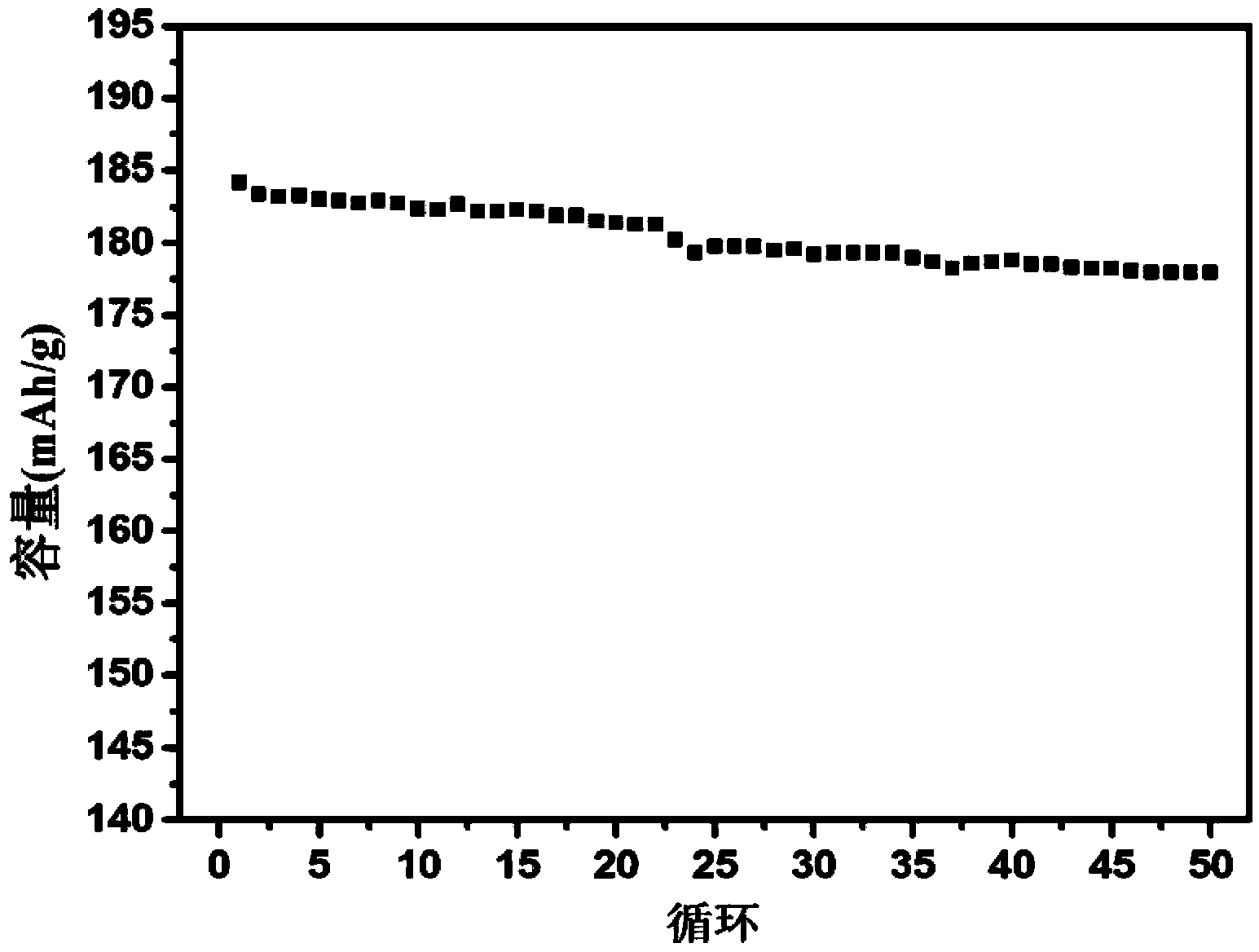

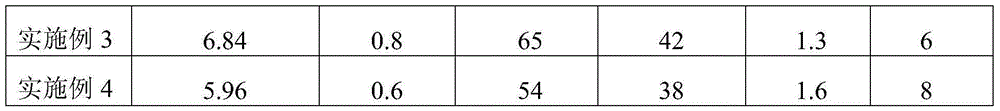

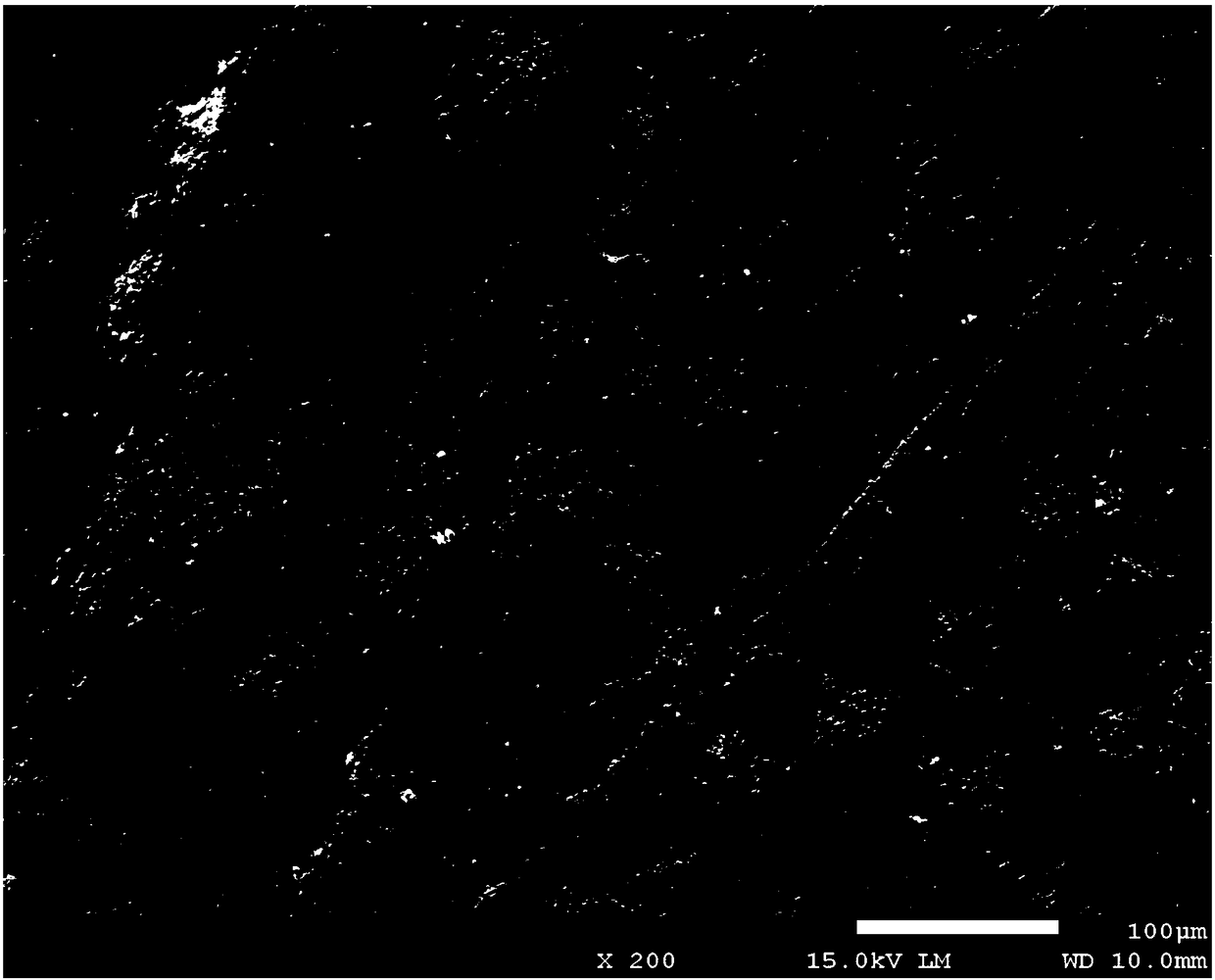

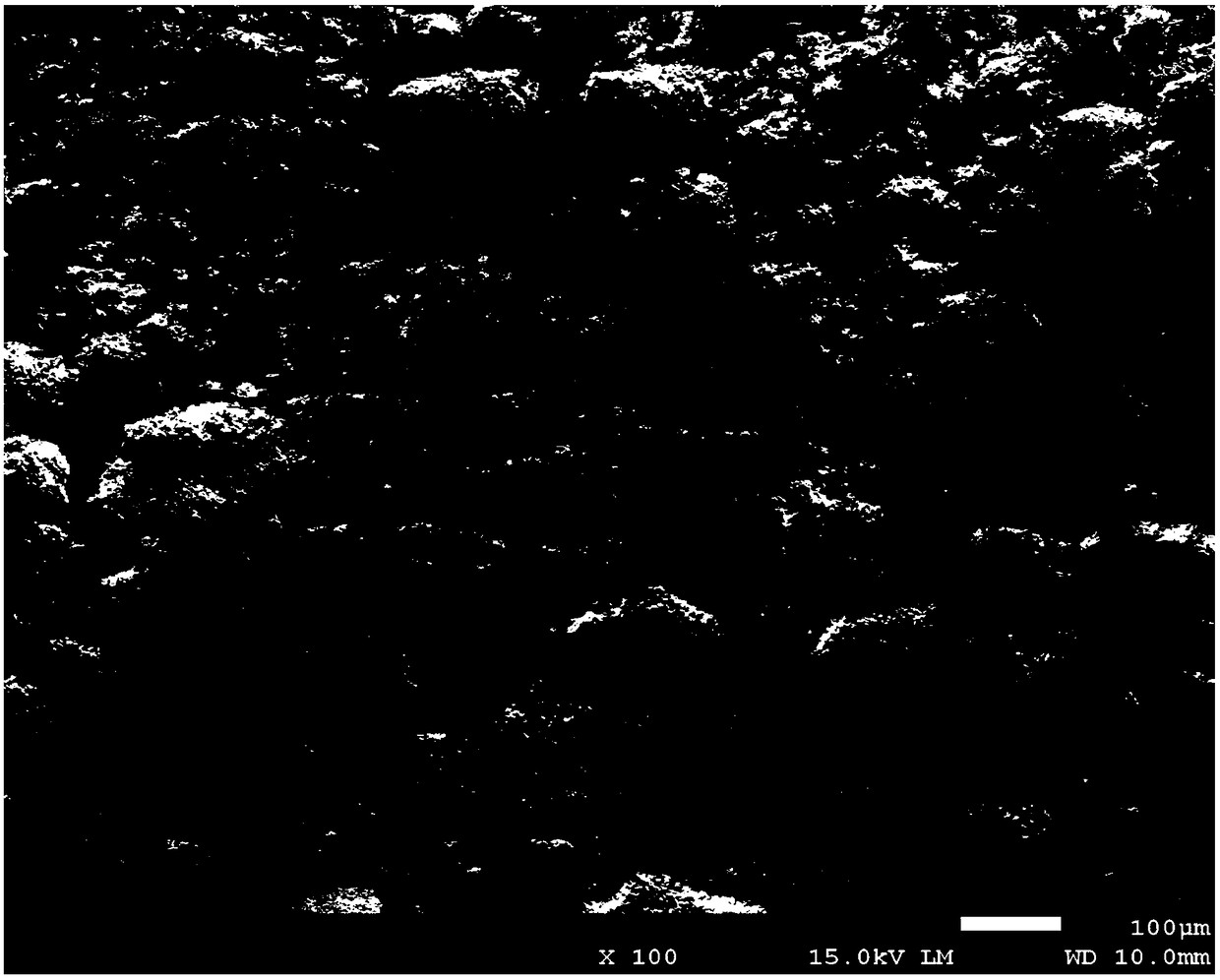

Modifying method of ternary anode material

The invention discloses a modifying method of a ternary anode material. The modifying method is characterized by comprising the following steps: (1), adding the ternary anode material LiNixCoyMnzO2 into an acetic acid solution, stirring for 20 min-40 min, and then washing and drying, wherein x is not less than 0.3 and not more than 1, y is not less than 0 and not more than 0.5, z is not less than 0 and not more than 0.5, and (x+y+z) is equal to 1; (2), adding a lanthanum element into the dried ternary anode material, wherein the lanthanum element is metal lanthanum or a compound of metal lanthanum of which the mass is 0.5%-2% of the mass of the ternary anode material; then adding distilled water, uniformly stirring to form slurry; and (3), directly heating the slurry material in an air atmosphere to 600-900 DEG C according to a heating rate step by step, sintering for 2-8 hours, cooling to the room temperature, grinding and sieving to obtain the lanthanum oxide-coated ternary anode material.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Mixed powder for electric tool and preparation method thereof

The invention belongs to the field of powder metallurgy, and particularly relates to mixed powder for an electric tool and a preparation method thereof. The mixed powder is characterized by being prepared by mixing and bonding water-atomized diffused alloy powder with water-atomized pure iron powder, graphite powder, copper powder and a lubricating agent in a segregation-free way, wherein the ratio of components by weight percentage as follows: 50-55 percent of water-atomized diffused alloy powder, 0.4-0.5 percent of graphite powder, 0.3-0.35 percent of copper powder, 0.7-0.8 percent of lubricating agent and the rest of water-atomized pure iron powder. The preferable ratio is as follows: 50 percent of water-atomized diffused alloy powder, 0.5 percent of graphite powder, 0.35 percent of copper powder, 0.7 percent of lubricating agent and the rest of water-atomized pure iron powder. Compared with the prior art, the mixed powder has the advantages that 1) the mix powder has over 7.05g / cm3 of compressed density; 2) alloy elements cannot be segregated in the transport and mixing treatment process; and 3) the mechanical performance of sintering parts is effectively improved.

Owner:ANGANG (ANSHAN) METALLURGY POWDER MATERIAL CO LTD

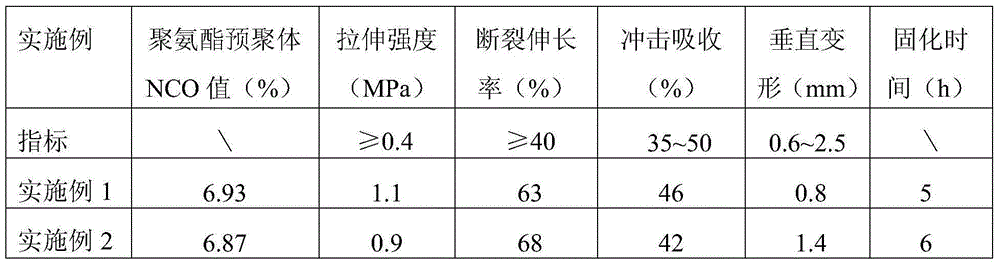

Method for preparing environment-friendly polyurethane adhesive for plastic track

InactiveCN105038684AWell formedImprove quality scoreNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesiveChlorinated paraffins

The invention discloses a method for preparing an environment-friendly polyurethane adhesive for a plastic track. According to the method, polyether polyol and aromatic diisocyanate serve as raw materials, chlorinated paraffins and dibutyl phthalate serve as auxiliaries, white carbon black serves as packing, organotin serves as a catalyst, and the environment-friendly high-performance polyurethane adhesive for the plastic track is prepared through a prepolymer method. The prepared adhesive is moderate in system viscosity in the preparation process, the temperature can be controlled easily, and the adhesive is good in product quality, stable in performance and high in yield and room temperature bonding strength. After the adhesive is evenly mixed with rubber particles according to a certain proportion and compressed, a sample is very excellent in mechanical property, and the surface drying time and curing time are short. The adhesive is low in volatility, non-toxic and free of pungent smell, does not cause damage to constructors and users, is good in breathability and conforms to the environmental protection and construction requirements.

Owner:YANCHENG INST OF TECH

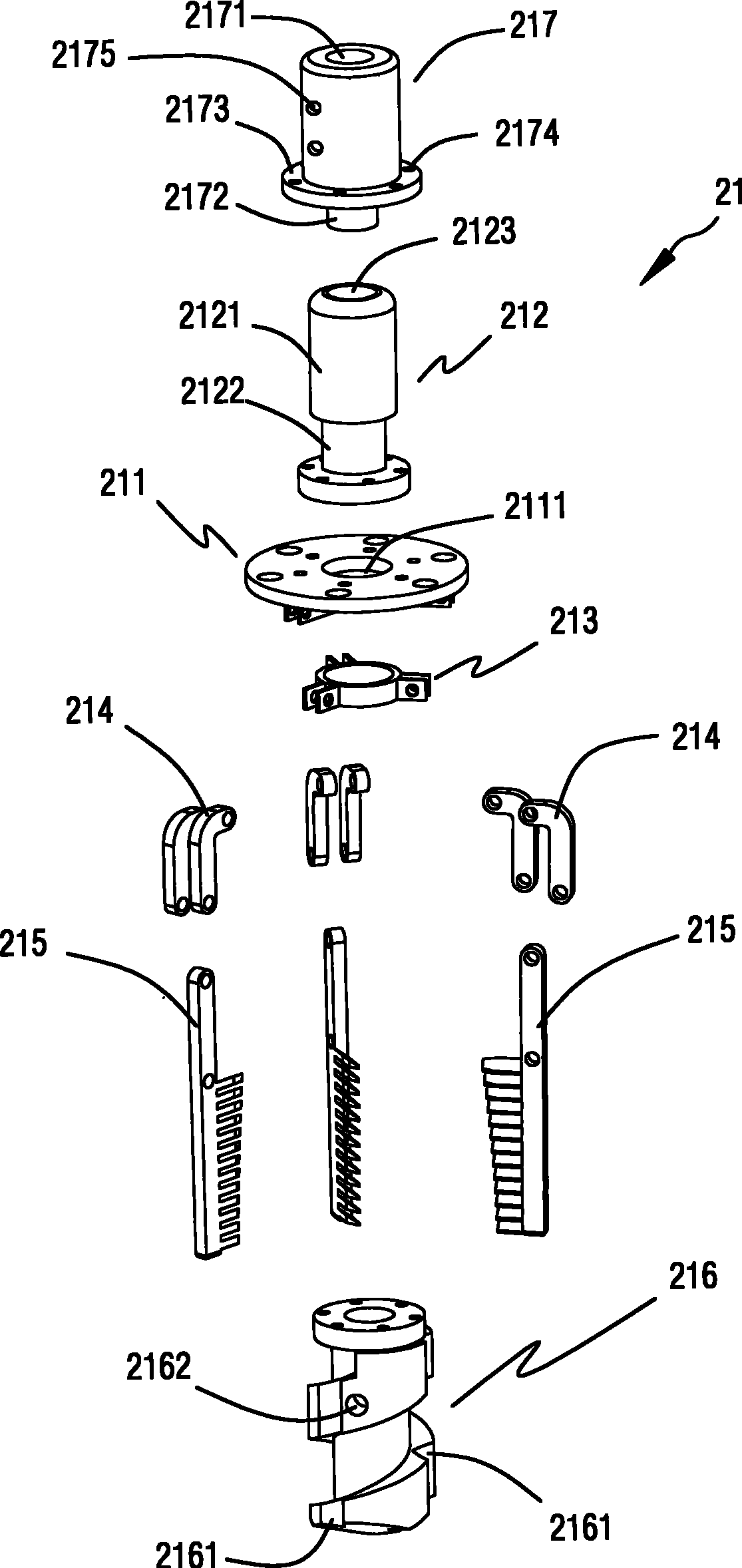

Cutter drive device of eccentric multi-axial type tunnelling machine

The invention is a kind of cutter plate driving device for eccentric multi spindle development machine, which belongs to building mechanical field. The sealing way of sand in the invention is: there sets a double sealing of maze sealing and the first teeth sealing between the bearing bracket base and the eccentric spindle, there sets a double sealing of maze sealing and the second teeth sealing between the bearing base and the eccentric spindle. The driving device hydraulic motor and the decelerator base are connected with one end of the bearing base through bolt. The decelerator output small gear spindle engages with the gear, the gear is covered in the eccentric spindle and connected with flat key, the second bearing and the third bearing in the bearing base are set on the neck part of the eccentric spindle, the first bearing in the bearing base is supported on another neck part of the eccentric spindle, the two ends of the eccentric spindle are fixed through a round bolt and stopping cushion to limit the axial movement of eccentric spindle. The invention reduces the project cost greatly and shortens the constructing period.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

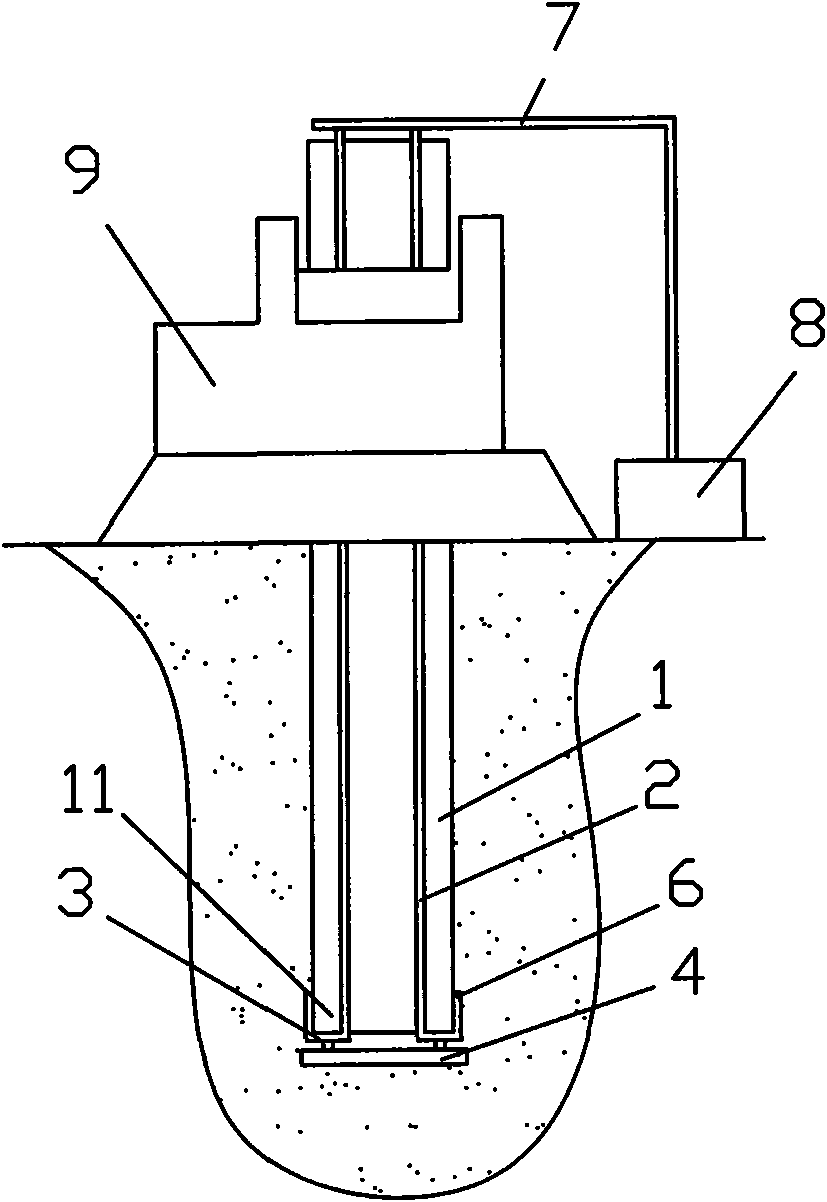

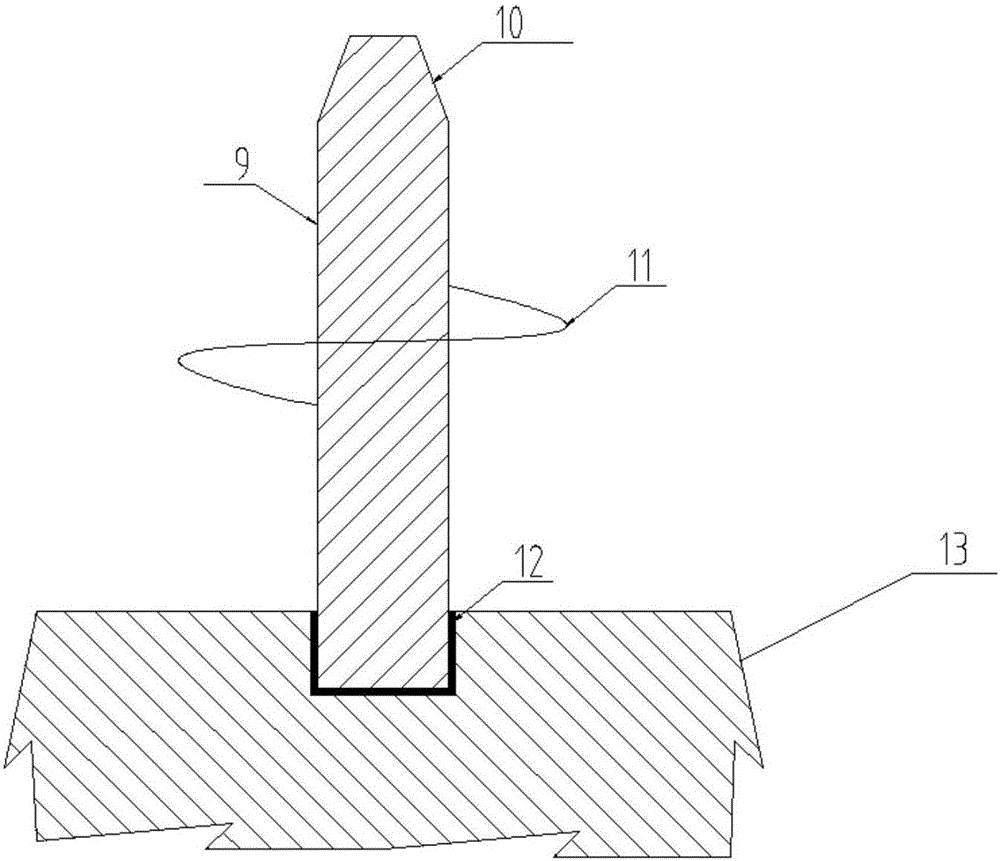

Pile-embedding method for hollow pile and auger drill for implementing same

InactiveCN101974905AQuality assuranceReduce adverse effectsDrill bitsCeramic shaping apparatusStructural engineeringEngineering

The invention relates to a pile-embedding method for a hollow pile. The pile-embedding method comprises the following steps of: hoisting the hollow pile to a pile-embedding position and hanging the hollow pile vertical to the ground; penetrating a central through hole of the hollow pile from top to bottom by using an auger drill with a reamer bit to reach the ground and starting to drill and carry soil; after the reamer bit is extended to the underground, carrying soil and expanding the reamer bit at the same time; along with the deep penetration of the drilling and soil-carrying operation, conveying the soil by using the auger drill; and embedding the hollow pile into the drill hole gradually until the hollow pile reaches to the set depth. The invention also provides the auger drill for implementing the pile-embedding method. Due to the construction by the auger drilling, soil-carrying and pile-embedding method, the problems of difficult soil extrusion in the pile-embedding process and difficult pile-embedding operation on hard-soil foundation can be solved; the project schedule is accelerated; the quality of the pile body is guaranteed; and adverse influence of construction on the ambient environment is reduced to a maximum degree.

Owner:SHANGHAI ZHONGJI PILE IND

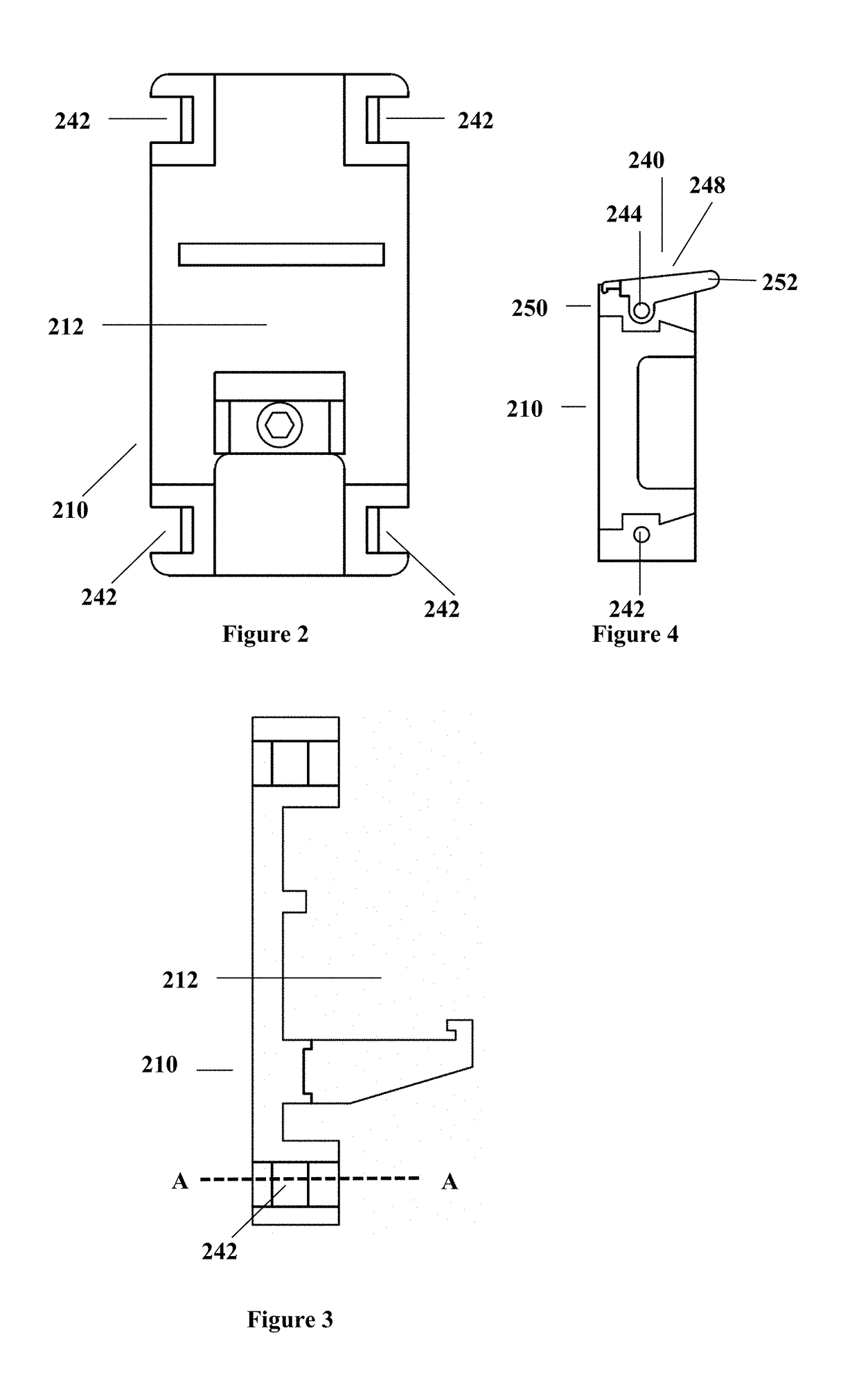

Alignment apparatus

InactiveUS20180078266A1Accurate measurementReduce bulgeDiagnosticsSurgical navigation systemsEngineeringPelvis

The present invention relates to an apparatus for aligning a sensor relative to at least two anatomical reference points of a patient's anatomy. In one embodiment, the apparatus includes: a body having a central axis; a sensor mount positioned relative to the body; at least two arms extending from the body, wherein two of said at least two arms are simultaneously and equidistantly moveable relative to the central axis; and at least two aligners connected to the at least two arms for aligning with said at least two anatomical reference points. The apparatus may also include an apparatus sensor. The present invention also relates to a surgical system for monitoring the orientation of a patient's anatomy, which includes the apparatus. Furthermore, the present invention also relates to a surgical system for guiding a surgical device to an optimal orientation relative to a patient's anatomy, wherein the surgical system includes the apparatus. The present invention also relates to: a method of aligning a sensor relative to at least two anatomical reference points of a patient's anatomy, and to a method of guiding a surgical device to an optimal orientation relative to a patient's anatomy. In one embodiment, the patient's anatomy is the pelvis.

Owner:INLINE ORTHOPAEDICS

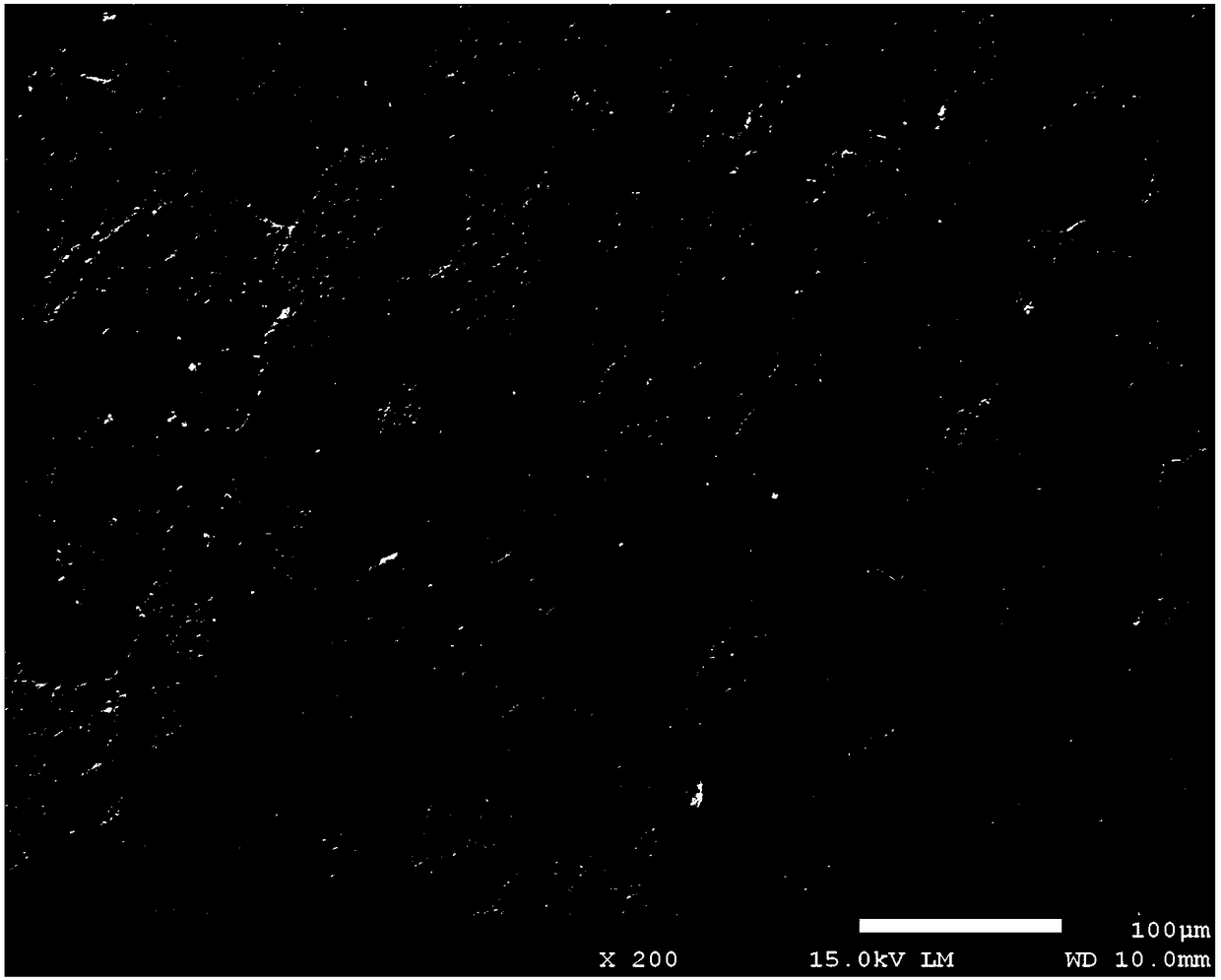

Copper clad ceramic and preparation method thereof

ActiveCN108147832AReduce small air bubbles and bulgesReduce air bubblesSurface modificationThermal treatment

In order to overcome the problems such as combination of a ceramic layer and a copper layer is not compact, small bubbles exist in an interface, bulge easily occurs, and bonding strength is relativelylow in the existing aluminium nitride ceramic copper cladding technology, the invention provides a copper clad ceramic and a method for preparing the copper clad ceramic. The method comprises following operation steps: forming an aluminium oxide film on an aluminium nitride ceramic surface; forming a modification layer on the aluminium oxide film surface. The modification layer includes modifiedparticles, and the modified particles include glass powder; a copper layer is formed on the modified layer surface; and the copper layer, the modification layer and the aluminium nitride ceramic are combined integrally through thermal treatment. The invention also provides the copper clad ceramic prepared by the method. The surface modification layer containing the glass powder is formed on the aluminium nitride ceramic surface, the phenomena such as the generation of small bubbles and bulges are inhibited in a DBS technical process, and interface bonding force between the copper layer and thealuminium nitride ceramic is added.

Owner:BYD CO LTD

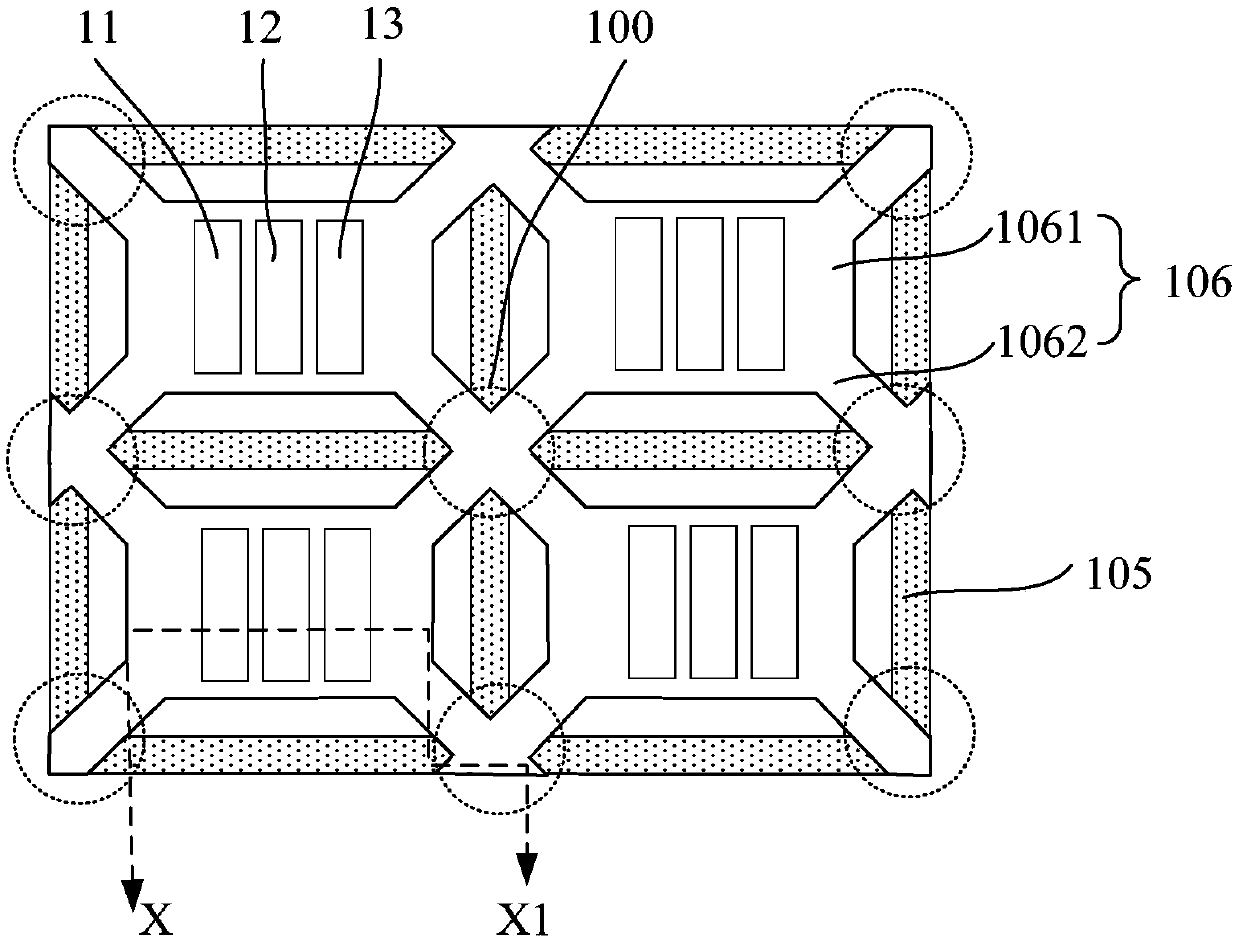

Color cathode ray tube for reducing landing drift of electron beams on phosphor layers

InactiveUS6384522B1Reducing landing driftNot perishableElectrode and associated part arrangementsPhosphorClassical mechanics

A main body 34 of a shadow mask is opposed to a phosphor screen and is formed in a substantially rectangular shape. The main body 34 has a main surface portion 31 where a number of electron beam apertures are formed, and a skirt portion 33 provided around the main surface portion with a non-aperture portion 32 interposed between the skirt portion and the main surface portion. A plurality of rectangular openings 38a extending in the long axis direction (or X-direction) of the mask body are formed at the skirt portion. Concave portions 47 extending in the long axis direction (X-direction) of the mask body are formed at the non-aperture portion. The openings and concave portions are provided within a range of about ¼ of the length W of the mask body in the long axis direction, with respect to a center of the range defined at a position distant from the short axis Y by about ⅓ of the length W of the long axis direction of the mask body.

Owner:KK TOSHIBA

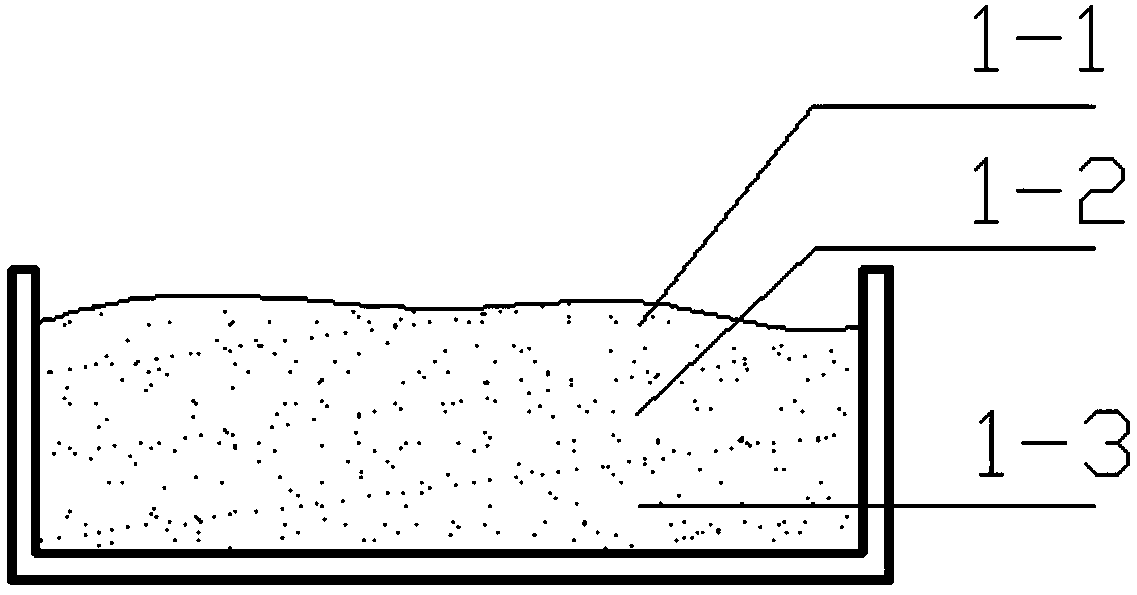

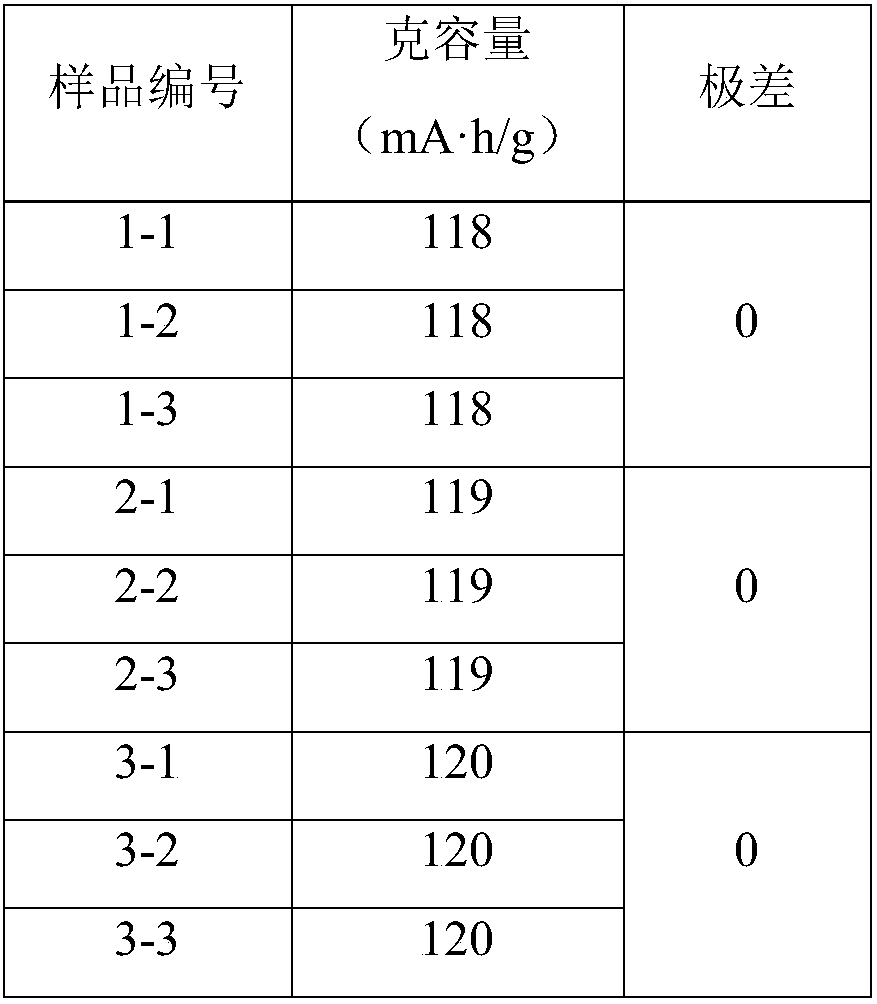

Lithium manganate composite manganous-manganic oxide and industrial preparation method thereof

ActiveCN108059190AAvoid Lattice Oxygen DefectsImprove performanceCell electrodesSecondary cellsLattice oxygenManganous-manganic oxide

The invention discloses lithium manganate composite manganous-manganic oxide and an industrial preparation method thereof. The method comprises the following steps: crushing high-purity manganese metal powder till the particle size of 10-300mu m by using a dry method, grading the manganese metal powder by using grading equipment, putting into a reactor with pure water and an ammonium salt, introducing air for oxidation, stirring at a speed of 100-500r / minute, introducing air at a flow of 100-300m<3> / hour, reacting for 20-25 hours, adding dissoluble manganese salt, sufficiently stirring, further adding bicarbonate, continuously reacting for 3-5 hours till the reaction is completed, further washing, drying, and roasting, thereby obtaining a composite manganous-manganic oxide product. The composite manganous-manganic oxide prepared by using the method is prevented from lithium manganate lattice oxygen defects, product properties and consistence are improved, meanwhile the amount of blownair is reduced, and the energy consumption of a kiln is reduced.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

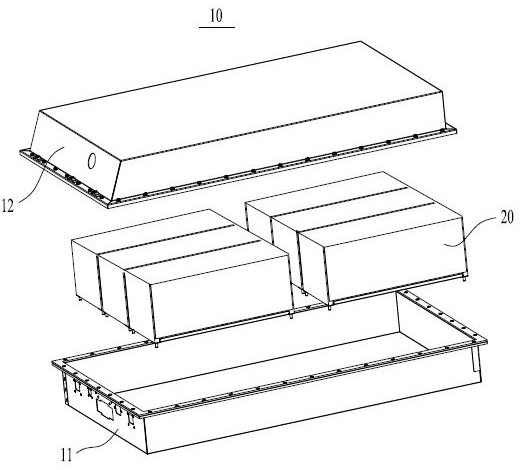

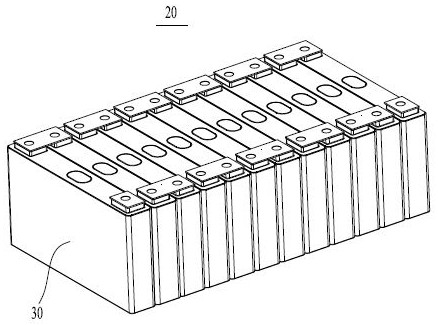

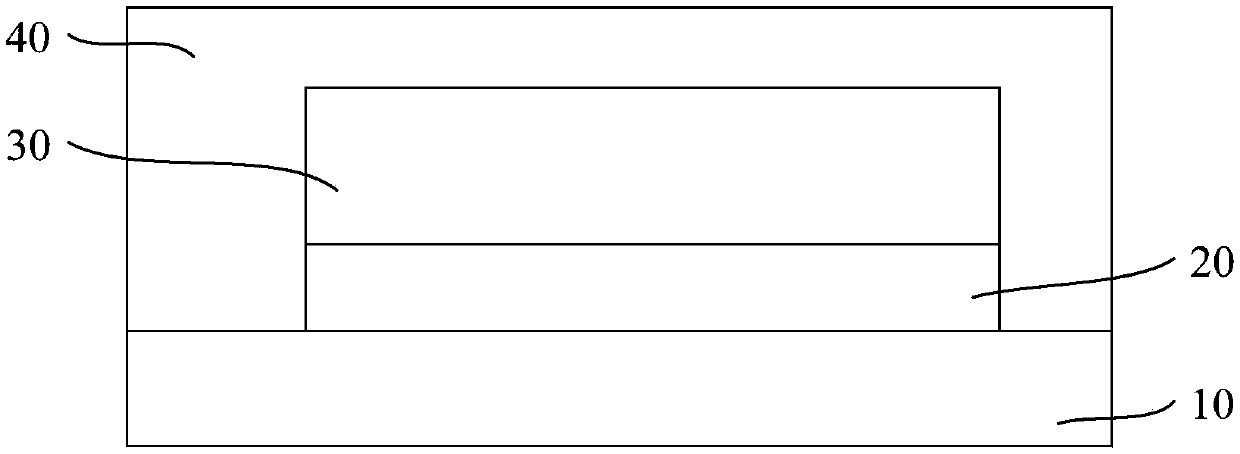

Battery monomer, battery, electric device, manufacturing method and manufacturing equipment

ActiveCN112713345AImprove the safety of useImprove the stability of useCell component detailsElectrical batteryMechanical engineering

The invention relates to a battery monomer, a battery, an electric device, a manufacturing method and manufacturing equipment. The battery monomer includes: a shell having a wall portion; and a pressure relief mechanism which is arranged on the wall part and comprises a main body part and a weak part connected to the main body part, wherein the main body part is used for being connected with the wall part, and the pressure relief mechanism is used for damaging the weak part to relieve pressure when the internal pressure or temperature of the battery monomer single battery reaches a threshold value, the pressure relief mechanism further comprises a reinforcing part arranged on the main body part in the thickness direction of the main body part, the reinforcing part is used for reducing deformation of the main body part, and the reinforcing part protrudes out of the surface of the main body part in the thickness direction. The battery monomer provided by the invention aims to solve the problem of explosion pressure relief when the single monomer is not subjected to thermal runaway.

Owner:JIANGSU CONTEMPORARY AMPEREX TECHNOLOGY LIMITED

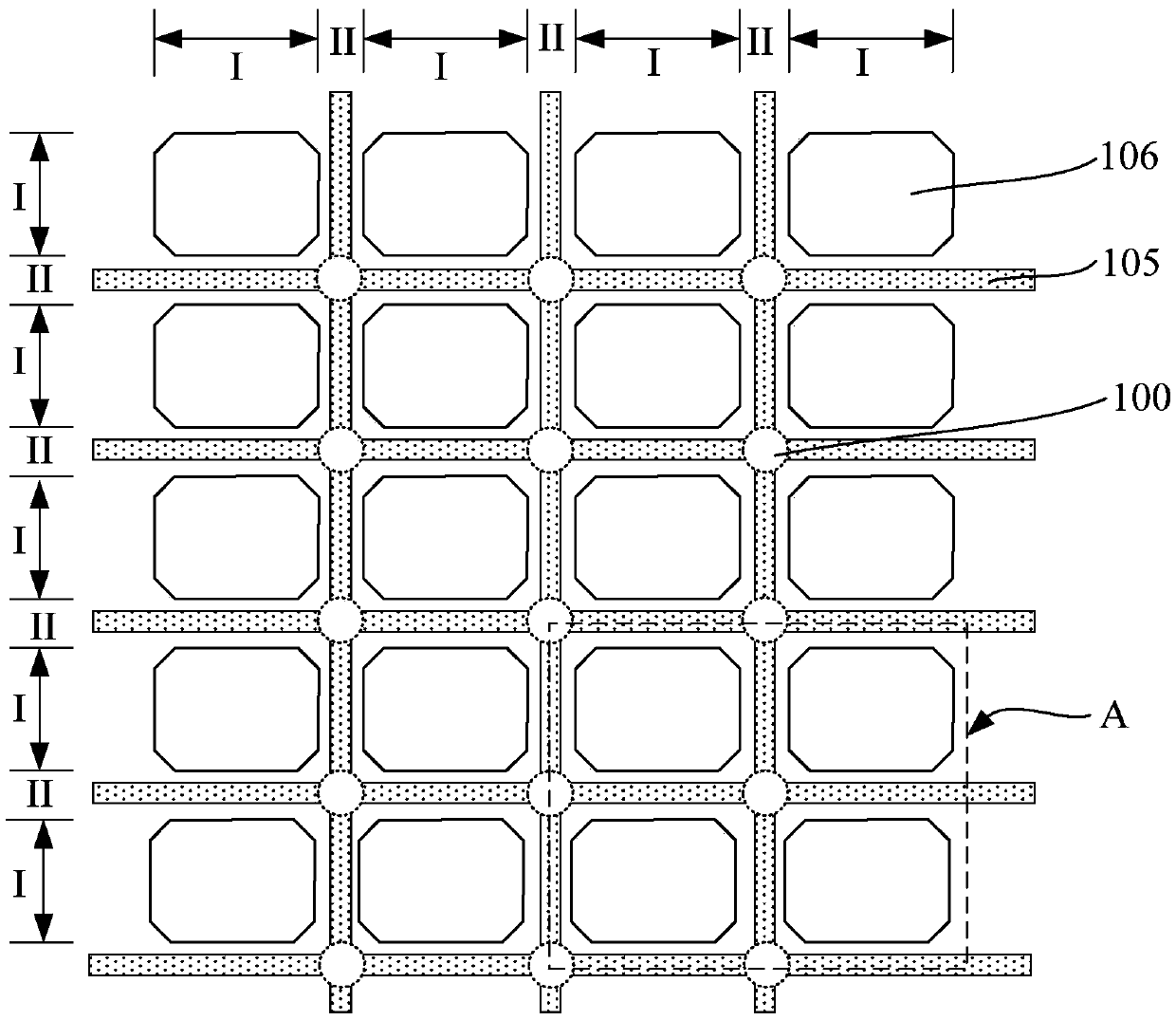

OLED structure, preparation method thereof, display panel and electronic device

ActiveCN109524437AImprove flexibilityImprove bending resistanceSolid-state devicesSemiconductor/solid-state device manufacturingFiberAuxiliary electrode

The present invention provides an OLED structure, a preparation method thereof, a display panel and an electronic device. The OLED structure includes an array substrate, a first electrode on one sideof the array substrate, a plurality of light emitting units, a pixel defining layer separating the light emitting units, and a second electrode arranged opposite to the first electrode. The pluralityof light emitting units are corresponding to light emitting regions of the OLED structure, and the pixel defining layer is corresponding to a non-light-emitting region of the OLED structure. The OLEDstructure further comprises an auxiliary electrode which is located in the non-light-emitting region and is electrically connected to the first electrode and / or the second electrode, and the materialof the auxiliary electrode is a conductive fiber material. The auxiliary electrode has good electrical conductivity and bending resistance, the circuit is damaged when the first electrode or the second electrode is broken is prevented, and the reliability of the electrodes of the OLED structure is improved.

Owner:YUNGU GUAN TECH CO LTD

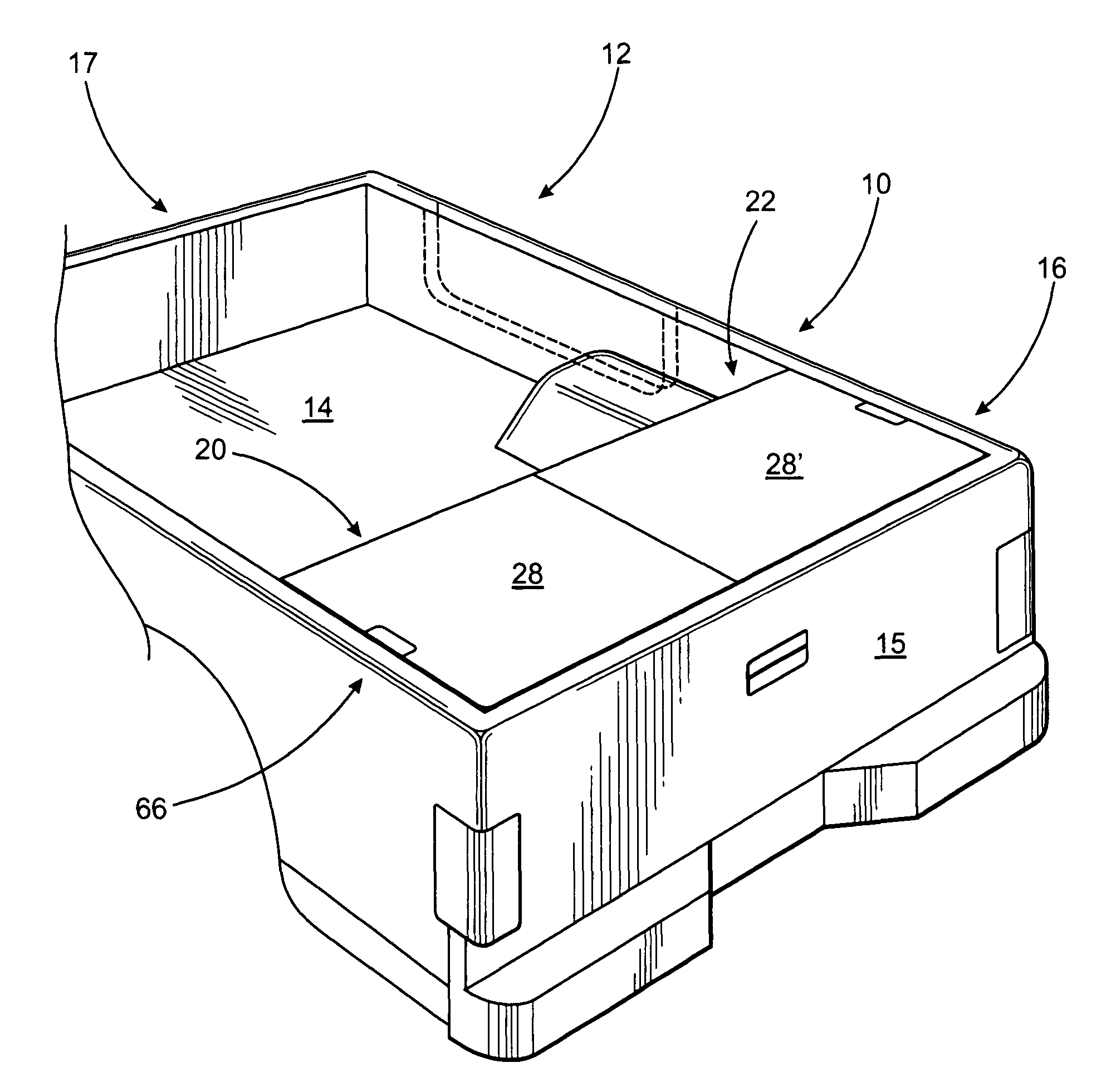

Airflow deflector assembly

InactiveUS7878576B1Great tractionImprove fuel efficiencyVehicle seatsWindowsInterconnectionEngineering

An airflow deflector assembly for an open bed truck or like vehicle including a plurality of preferably two cover sections each having a base and an attachment assembly cooperatively disposed and structured to adjustably interconnect the two cover sections facilitating their selective positioning into any one of a plurality of operative orientations. The selected operative orientation corresponds to the width of the trailing end of the open bed of the vehicle so as to so as to establish a substantially continuous air deflecting surface over the trailing end and thereby increasing the aerodynamics of the vehicle. The cooperative structuring of the attachment assemblies facilitate an adjustable sliding interconnection there between such that the bases of each cover section may be reciprocally positioned toward and away from one another to assume the preferred operative orientation corresponding to the width of the truck bed.

Owner:EMBLER SUSAN +2

Non soil taking hole guiding process for sinking prestressed pipe pile or prefabricated square pile

The invention relates to a non soil taking hole guiding process for sinking a prestressed pipe pile or a prefabricated square pile, which mainly comprises that: a liquid spray pipe is pre-buried or pre-placed in the prestressed pipe pile or the prefabricated square pile, liquid enters the outside wall of a pile end through the liquid spray pipe during pile sinking, a soil body on the outside wall of the pile end is sprayed at high pressure, and a water film is formed between the outside wall of the pile end and the soil body. The method for high-pressure jet grouting or water injection only destroys a structure of soil near the pile side in a small range by means of the cleavage function of injection water, quickly weakens the construction squeezing effect in a short time, can fully recover the frictional resistance of the soil body along with the drainage and consolidation of the soil body at the pile side, and does not influence the long-term bearing capacity of engineering piles.

Owner:徐汉东

Self-heat-setting type anti-freezing and anti-spalling valve

PendingCN112610750AExtended service lifeHigh strengthValve members for heating/coolingThermal insulationProcess engineeringHot Temperature

The invention discloses a self-heat-setting type anti-freezing and anti-spalling valve, and belongs to the field of valves. According to the self-heat-setting type anti-freezing and anti-spalling valve, a self-heat-setting sleeve is arranged, and after a self-breaking water bag is broken under the action of low temperature in winter, water in the self-breaking water bag is in contact with heat-setting particles through a water guide ball rod. On the one hand, firstly quick lime particles react with the water, so that heat is generated and uniformly gathered on the inner wall of the self-heat-setting sleeve through the action of a soaking net to heat the surface of the valve, then condensation of water passing through the interior of the valve due to low temperature is effectively avoided, meanwhile, the occurrence rate of spalling caused by cold and hot temperature difference is remarkably reduced, and the service life of the valve is effectively prolonged; and on the other hand, after the quick lime is reacted, cement powder in the quick lime leaks out and is hardened after being in contact with the water, so that the overall strength of the self-heat-setting sleeve is effectively improved, the protection effect of the self-heat-setting sleeve on the internal valve body is higher, the force generated on the valve during partial thermal expansion can be counteracted, and the probability that the self-heat-setting sleeve is cracked by expansion is further reduced.

Owner:高洋

Preparation method of composite sheathed iron-based superconducting wire strip

InactiveCN109903927AEliminate compound stressEfficient removalSuperconductors/hyperconductorsSuperconductor devicesAtmosphereMetal

The invention relates to the technical field of iron-based superconductors, in particular to a preparation method of a composite sheathed iron-based superconducting wire strip. The preparation methodof the composite sheathed iron-based superconducting wire strip provided by the invention comprises a step of carrying out first heat treatment on iron-based superconducting precursor powder in an inert atmosphere. According to the method, the iron-based superconducting precursor powder placed into an inner sheath metal tube is subjected to pre-heat treatment in the inert atmosphere, so that bumpscan be effectively eliminated, and the product yield is improved.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Large-grip-type deep sea anchor

The invention discloses a large-grip-type deep sea anchor which comprises an anchor chain, a rotating ring and an anchor handle. An anchor end chain is arranged at one end of the anchor chain. The anchor end chain is connected with the rotating ring through a bolt. The rotating ring is connected with the anchor handle through an anchor shackle. The tail end of the rotating ring is cylindrical. An external thread is arranged at the tail end of the rotating ring. A nut is installed on the anchor shackle. The rotating ring is screwed into the nut, the anchor handle is connected with an anchor head through a small shaft, and the anchor head is connected with anchor flukes through a transverse pin. According to the large-grip-type deep sea anchor, the center of gravity of the anchor is lowered, the anchor handle is of a slab structure, a double-screw bolt, an anchor blade and other structures are arranged on an anchor fluke arm, so that the engaging-in depth of the anchor is increased, the limit bearing capacity is improved, dynamic loads transmitted by mooring cables are balanced, the higher holding power to weight ratio of the deep sea anchor under various soil textures is ensured, and the effect of the large-grip-type deep sea anchor is brought into full play.

Owner:CHONGQING JIAOTONG UNIVERSITY

Device for improving degree of security of foundation ditch construction and method thereof

ActiveCN101545261AImprove securityReduce tensionProtective foundationExcavationsRock boltBuilding construction

The invention relates to a device for improving the degree of security of foundation ditch construction and a method thereof. The device comprises a lifting anchor rod, an inhaul cable and supporting equipment, wherein the lifting anchor rod is vertically plunged into a soil body at the periphery of a foundation ditch; the lower end of the inhaul cable is connected with the lifting anchor rod, and the upper end is fixed on the supporting equipment; and the supporting equipment exerts a vertically upward pull for the lifting anchor rod through the inhaul cable. For the device for improving the degree of security of foundation ditch construction, the lifting anchor rod is plunged into the soil body at the periphery of the foundation ditch, and the inhaul cable exerts the vertically upward pull for the lifting anchor rod so that the lifting anchor rod can exert the vertically upward pull for the soil body at the periphery of the foundation ditch, the soil body at the periphery of the foundation ditch can be prevented from sinking under the action of the gravity thereof, the probability of proruption of the soil body in the foundation ditch can be reduced, the horizontal thrust of the soil body outside the foundation ditch to the inside of the foundation ditch can be also reduced, and the degree of security of the foundation ditch can be generally improved.

Owner:张庆中

Orientation film forming device, orientation film forming method, drawing device, and drawing method

ActiveCN1707335AImprove uniformityReduce bulgeOptical filtersSolid-state devicesMechanical engineeringEngineering

The present invention can improve the uniformity of film thickness after drying. Its solution is, comprises: with respect to the drawing area (21) of the area smaller than desired drawing area on the glass substrate (30), the step of jetting alignment film ink from inkjet head; With respect to drawing area (21) ) around the surrounding drawing area (22), the step of ejecting the alignment film ink from the inkjet head; and relative to the surrounding drawing area (23) around the surrounding drawing area (22), ejecting the alignment film from the inkjet head The step of ink, thereby, can reduce the swelling of the alignment film ink after drying in the peripheral drawing area (23) of the peripheral portion.

Owner:SEIKO EPSON CORP

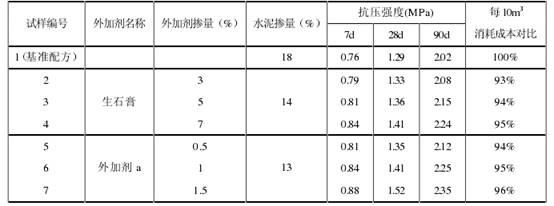

Supporting process of portal frame type anchor pipe soil nail spraying net and modified reinforcing cement mortar employed by same

ActiveCN101906779AImprove early strengthIncreased unconfined compressive strengthExcavationsBulkheads/pilesSocial benefitsExperimental research

The invention discloses a supporting process of portal frame type anchor pipe soil nail spraying net and a modified reinforcing cement mortar employed by the same, which can greatly change the compression resistance and the shearing resistance of soft cement soil. In the novel supporting process of the portal frame type anchor pipe soil nail spraying net, a vertical large-diameter anchor pipe soil nail is added on the basis of the existing supporting technique of the conventional soil nail spraying net, a new formula of a 'modified' curing admixture is adopted to perform cement mortar blowing, and when the cross section of a foundation pit has large changes, theoretical and experimental researches are performed on a failure mode and deformation characteristics of the cross section of the foundation pit. Simultaneously, the supporting process is combined with actual projects to prove that the new type foundation pit support form can be adopted to excavate a foundation pit with the depth of 4 to 6 meters in Wenzhou, so not only the technical problem that a conventional soil nail spraying net support cannot be adopted when the excavation depth of the foundation pit in an urban area of Wenzhou is more than 4 meters is solved, but also compared with other available supports, the supporting process is money-saving and time-saving, reduces risks, and has good economic and social benefits.

Owner:SANJIAN CONSTR ENG GROUP

Die casting surface treatment process

PendingCN108355931AReduce bulgeImprove yield ratePretreated surfacesCoatingsSurface finishingPowder Spray

The invention relates to a die casting surface treatment process. The die casting surface treatment process comprises the following steps: (S1) ash materials are filled in holes of die castings; (S2)the filled die castings are baked; (S3) after the ash materials of the die castings are dried and solidified, projections and recess positions formed by baking on the die castings are leveled until the surfaces of the projections or the recess positions are dry and smooth; and (S4) the die castings are sprayed to obtain finished products. The die casting surface treatment process effectively reduces the paint film bump phenomenon of the finished products by adopting a mode of spraying after baking, so that the yield of the products is improved; and in particular, the die castings are baked after paint or powder spraying to obtain finished die castings.

Owner:佛山市南海区合亿金属制品有限公司

Phosphorus-containing mixed iron powder for automobiles and preparation method thereof

ActiveCN108160987AReduce use costTypes used lessTransportation and packagingMetal-working apparatusIron powderMaterials science

The invention relates to phosphorus-containing mixed iron powder for automobiles. The phosphorus-containing mixed iron powder is prepared from the following chemical components in percentage by weight: 0.001 percent to 0.2 percent of C, 0 percent to 0.50 percent of Si, 0.1 percent to 1.0 percent of Mn, 0.1 percent to 1.0 percent of P, 0 percent to 0.050 percent of S and the balance of Fe and inevitable impurities, wherein the loose packed density is 3.10g / cm<3> to 3.20g / cm<3>, the compressibility under the pressure of 600MPa is more than 7.05g / cm<3>, and the flowability is 32.0s / 50g to 33.8s / 50g. The phosphorus-containing mixed iron powder is prepared by performing diffusion bonding on water atomized pure iron powder with high compressibility and ferrophosphorus powder; the water atomizedpure iron powder is used as basic powder, the ferrophosphorus powder is added into the water atomized pure iron powder according to requirements of the components, and then the ferrophosphorus powderand the water atomized pure iron powder are uniformly mixed and then are diffused through a reducing furnace so as to obtain powder containing ferrophosphorus powder; the powder containing ferrophosphorus powder is added into 0.1 percent by weight to 1.0 percent by weight of lubricant, and then mixing is carried out for 20 minutes to 40 minutes to obtain a finished product. The phosphorus-containing mixed iron powder disclosed by the invention has the advantages that the using of alloy auxiliary categories is less so that the using cost of alloys is reduced, segregation on alloy element components is not produced in transportation and mixing processes, the stability of dimensional tolerance can be maintained in a sintering process of the product, and an iron-based alloy product having a uniform microscopic structure is conveniently obtained.

Owner:ANGANG (ANSHAN) METALLURGY POWDER MATERIAL CO LTD

Plastering anti-crack waterproof mortar and preparation method thereof

The invention relates to the field of concrete, and particularly discloses plastering anti-crack waterproof mortar and a preparation method thereof. The mortar comprises 280-314 parts of cement; 1100-1320 parts of sand; 66-78 parts of stone powder; 6.5-8.1 parts of an admixture; 0.8-1.3 parts of polypropylene anti-cracking fibers; 8.9-11.7 parts of a waterproof agent; 36-48 parts of coumarone resin; 28-42 parts of aluminum dihydrogen phosphate; 185-215 parts of water; the preparation method comprises the following steps: sequentially mixing and stirring the raw materials of the mortar to obtain the mortar. The coumarone resin is cracked and shrunk under the high-temperature condition, so that the high-temperature expansion efficiency of the plastering mortar is relieved, the high-temperature bonding strength of the aluminum dihydrogen phosphate is improved, and the phenomena of bulging and cracking occurring after a mortar fire disaster are improved.

Owner:佛山市建通混凝土制品有限公司

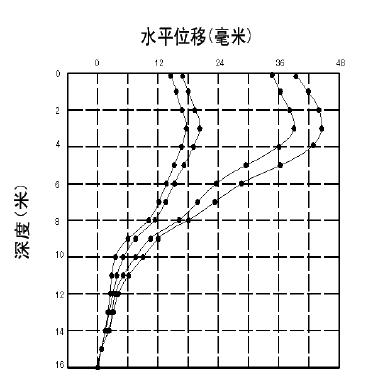

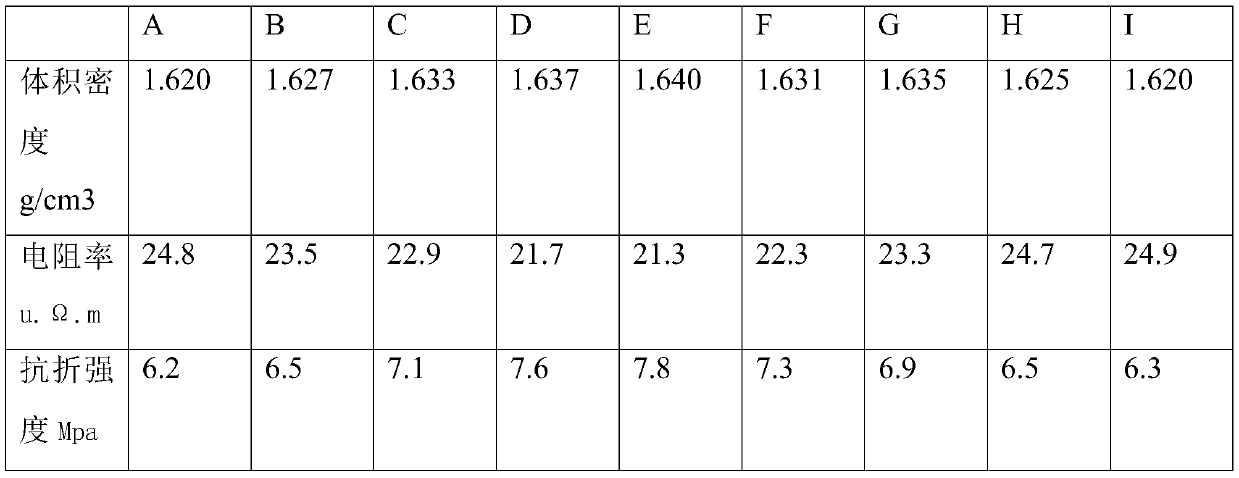

Graphite porous crucible and preparation method thereof

InactiveCN111087249AAvoid breakingLow resistivityCrucible furnacesThermal insulationUltimate tensile strength

The invention relates to a preparation method of a graphite porous crucible. The raw materials of the crucible comprise a solid raw material and modified asphalt, the solid raw material comprises, byweight, 52%-64% of graphitized calcined coke and 36%-48% of a graphitized thermal insulation material, and the modified asphalt accounts for 20%-24% of the solid raw material. The graphite porous crucible is not prone to breakage, low in resistivity and excellent in mechanical property, the prepared graphite crucible is high in compactness, the volume density ranges from 1.62 g / cm3 to 1.64 g / cm3,the resistivity ranges from 20 u.[Omega].M to 25 u.[Omega].M, and the breaking strength is not smaller than 5.7 Mpa; the compact green body is formed by gradually stacking and compacting under the action of self-weight and external force by adopting a horizontal vibration molding process, so that the compactness of the graphite crucible is greatly improved; and the warm roasting mode can greatly reduce the problems of bulging, cracking and the like of the crucible caused by over-high temperature rise or over-fast temperature reduction of the graphite crucible in the roasting process and the cooling process.

Owner:CHONGQING EASTSTAR HIGH TEMPERATURE MATERIAL

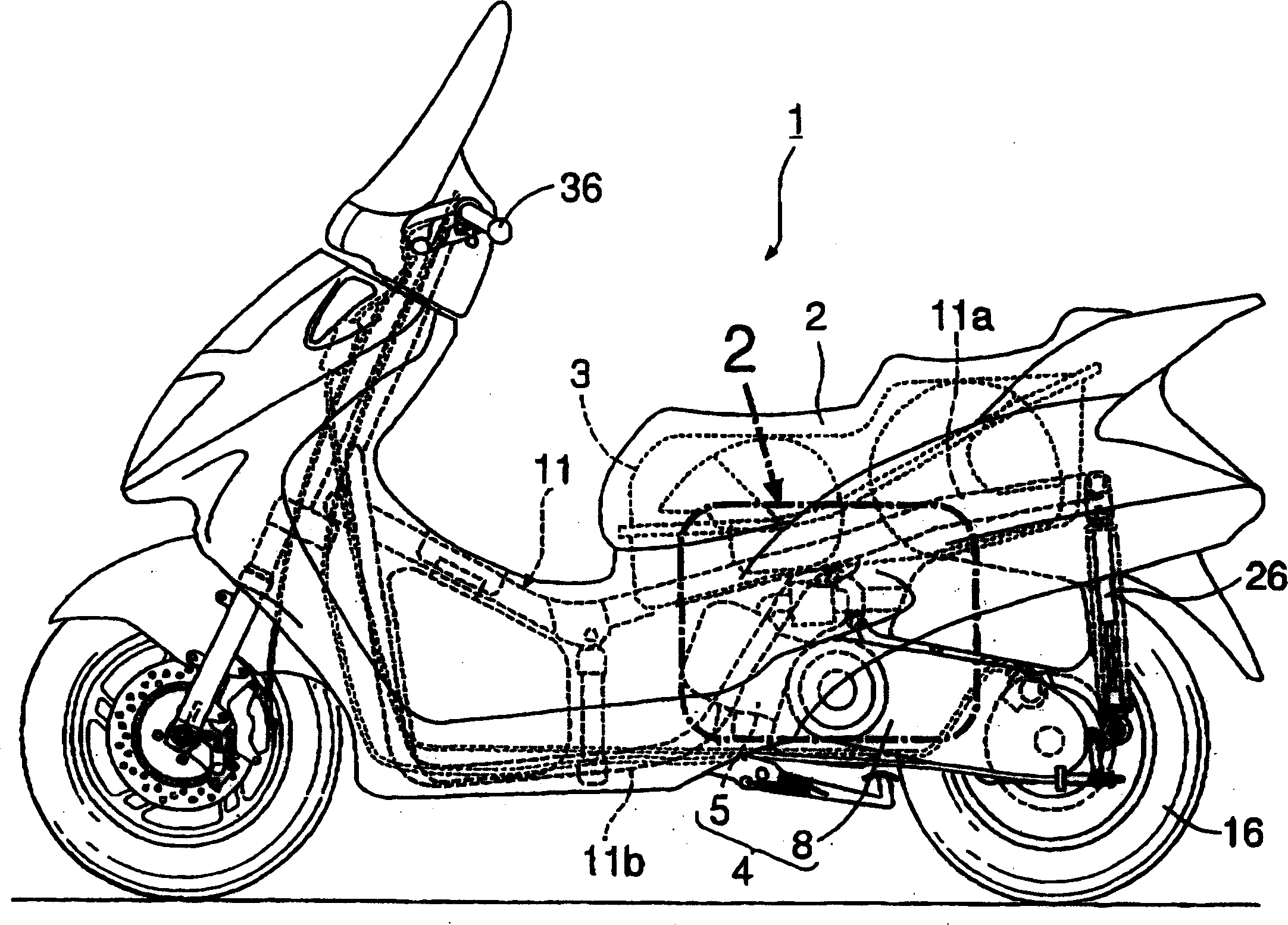

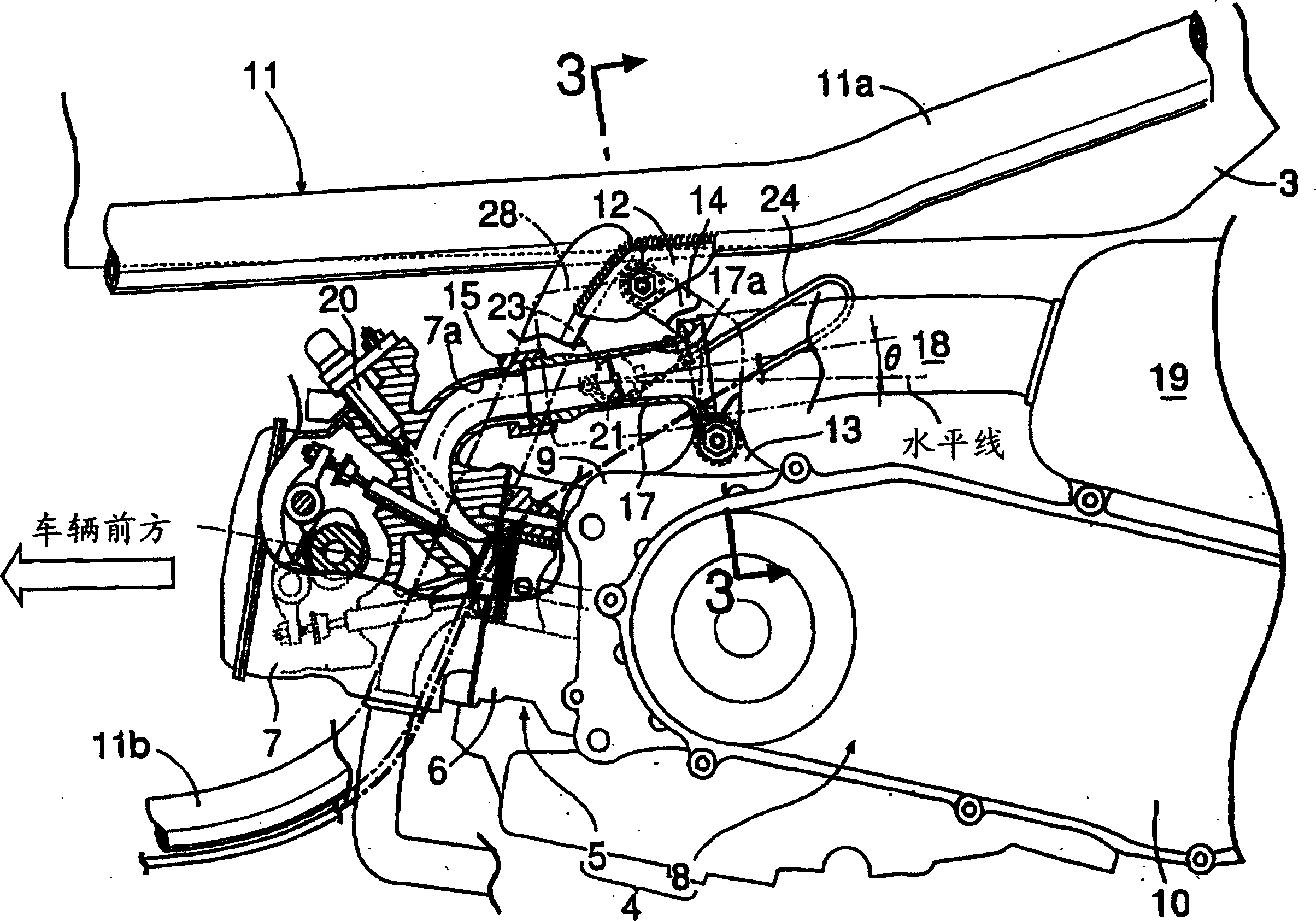

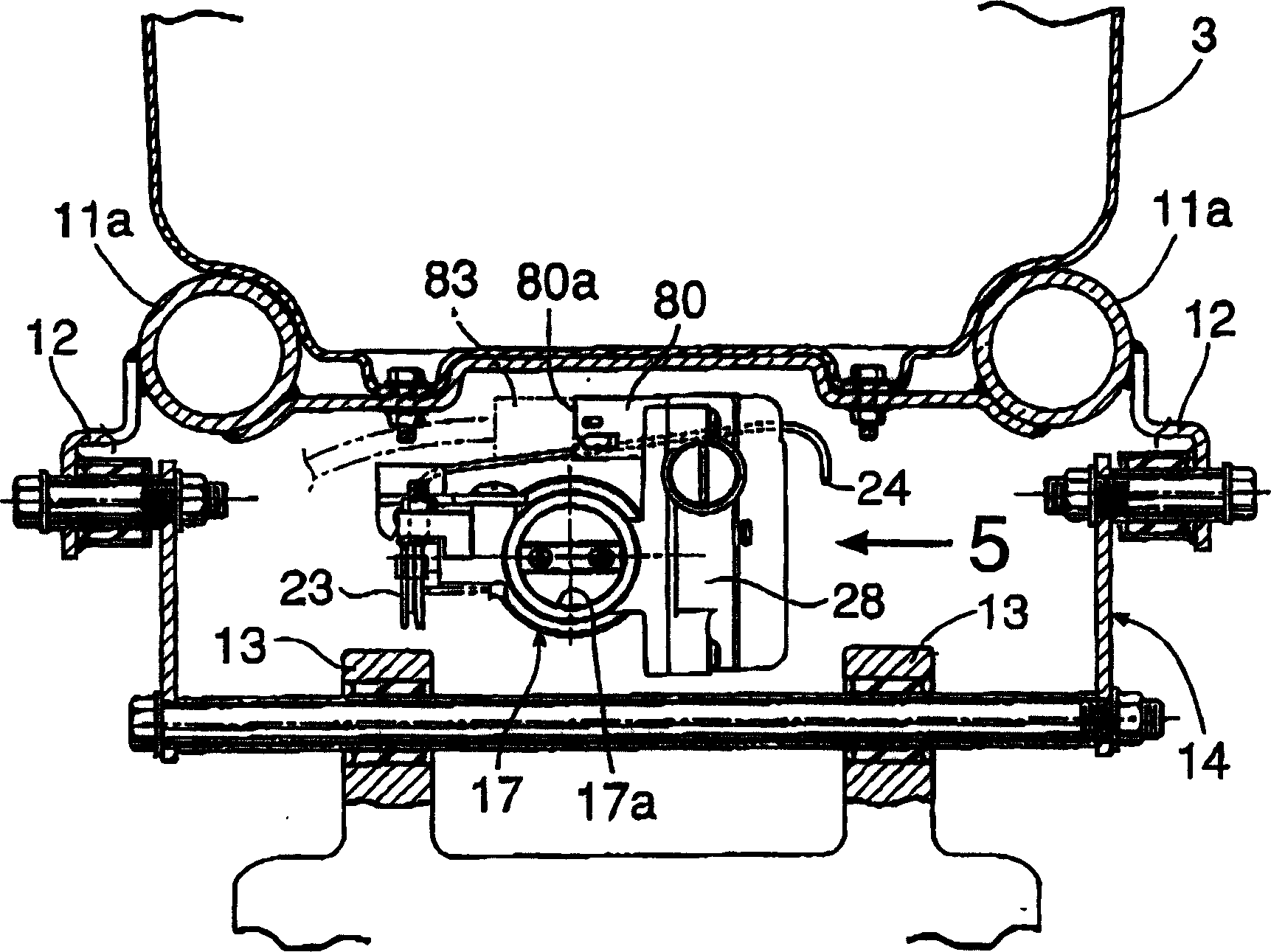

Engine intake control device

InactiveCN1505731AImprove productivityReduce bulgeMotorised scootersLow pressure fuel injectionControl systemEngineering

In an intake-air amount control system for an engine, a joint surface (28f) of a control block (28) is coupled to a mounting surface (27f) formed on a throttle body (17) in parallel to an intake passage (17a), and a bypass upstream groove (32i) communicating with an upstream portion of the intake passage (17a) and a bypass downstream groove (32o) communicating with a downstream portion of the intake passage (17a) are defined in at least one of the surfaces (27f, 28f). A valve bore (34) is provided in the control block (28) to permit the communication between the bypass upstream groove (32i) and the bypass downstream groove (32o), and a bypass valve (25) provided in the valve bore (34) and an actuator (28) for the bypass valve (25) are disposed in a device block (11) in parallel to the intake passage (17a). Thus, the workability and the assemblability can be enhanced, while enabling the intake-air amount control system for the engine including the bypass valve and the actuator to be constructed compactly.

Owner:KEIHIN CORP +1

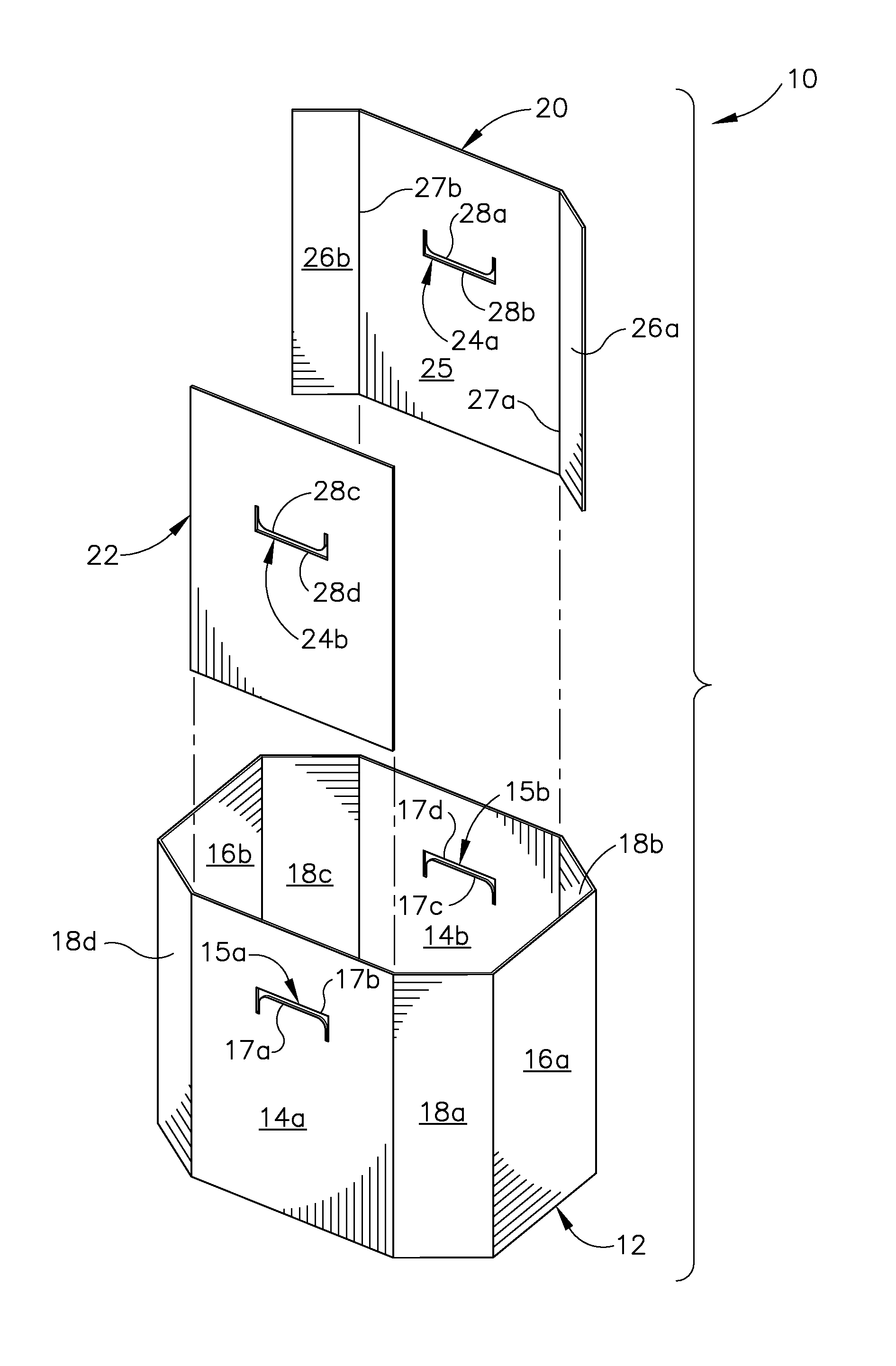

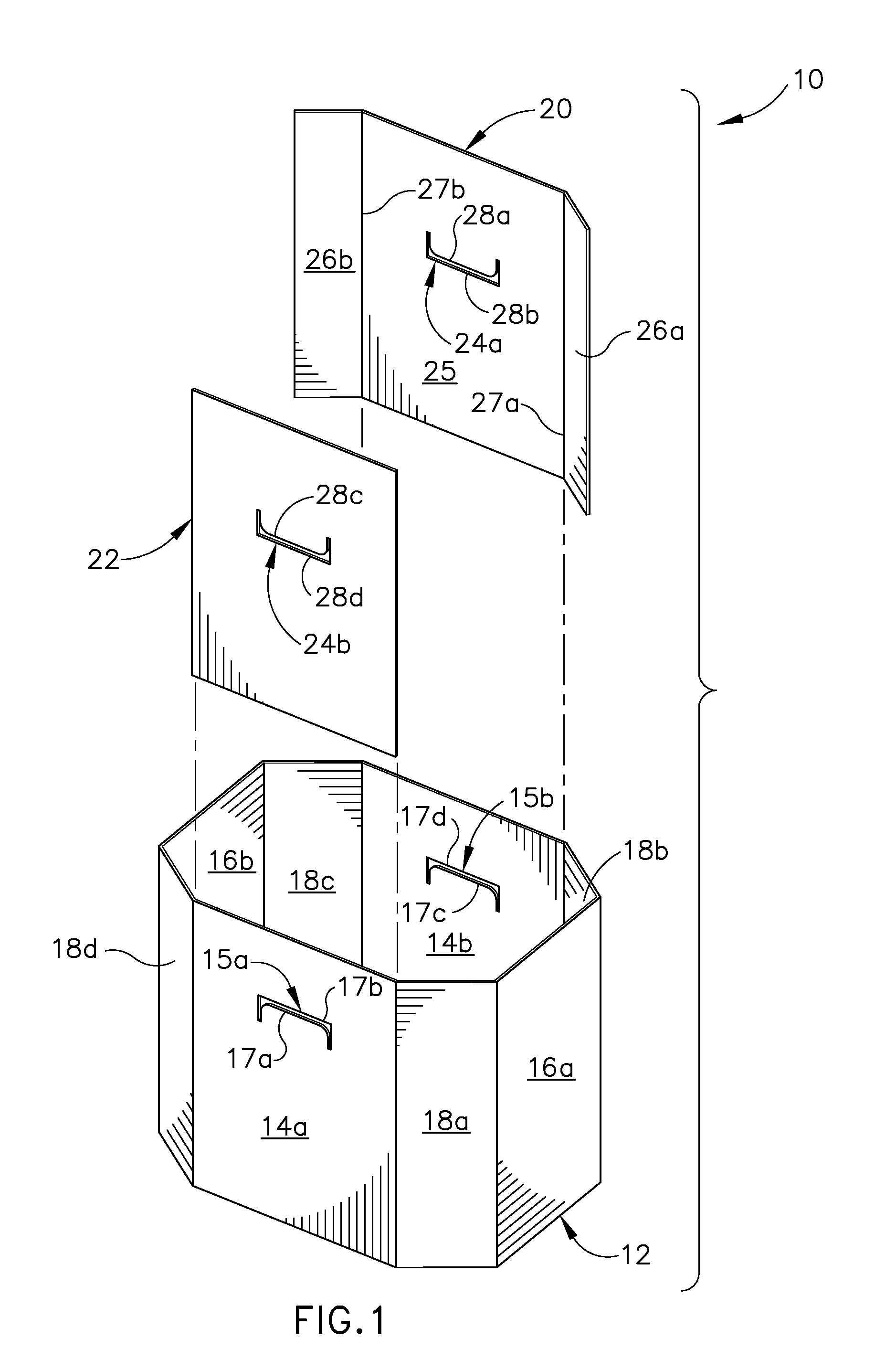

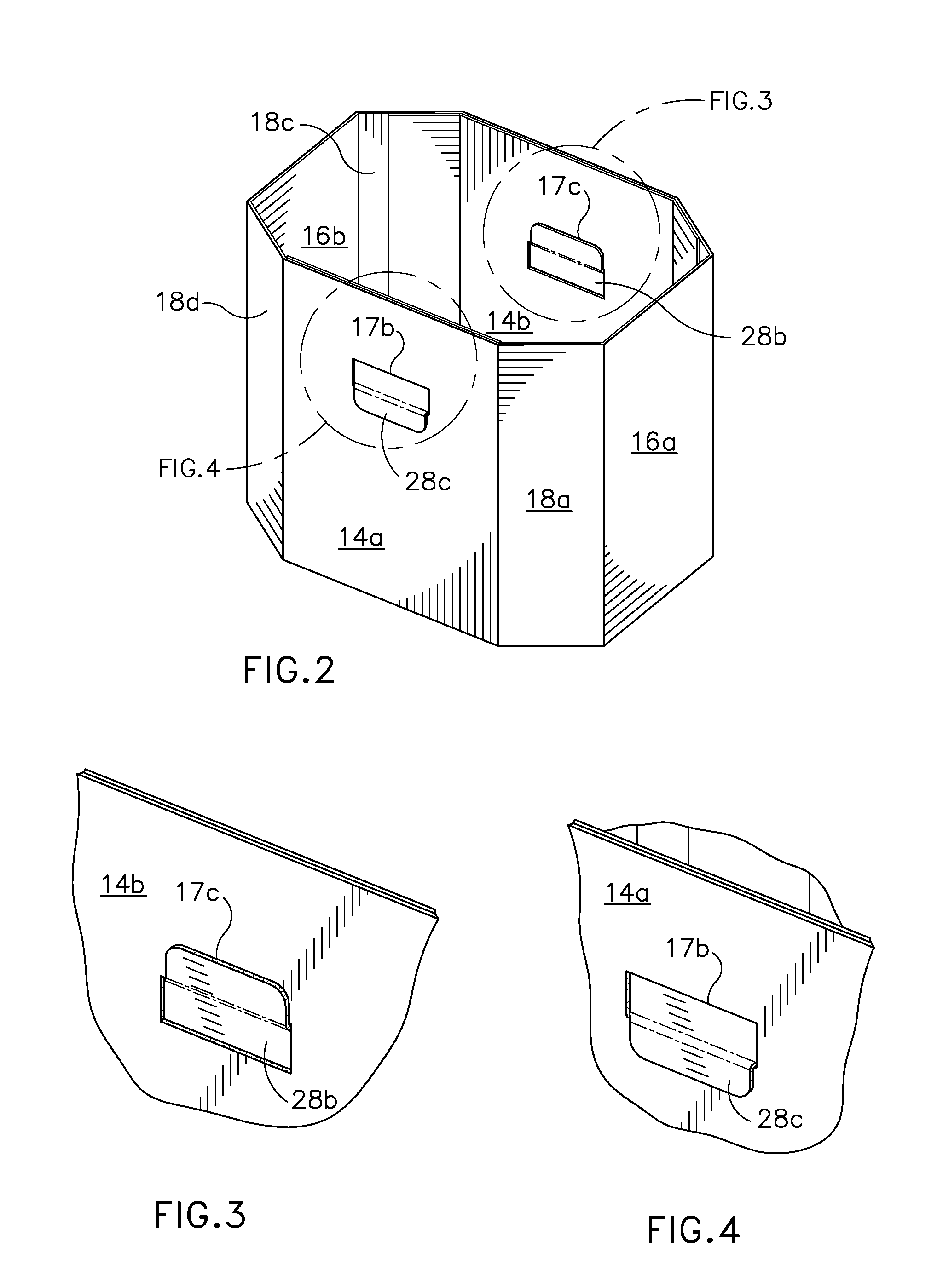

Self-Locking Support Panel For Corrugated Container

ActiveUS20130146651A1Increased flexural rigidityEnhance increased flexRigid containersSelf lockingEngineering

Owner:INT PAPER CO

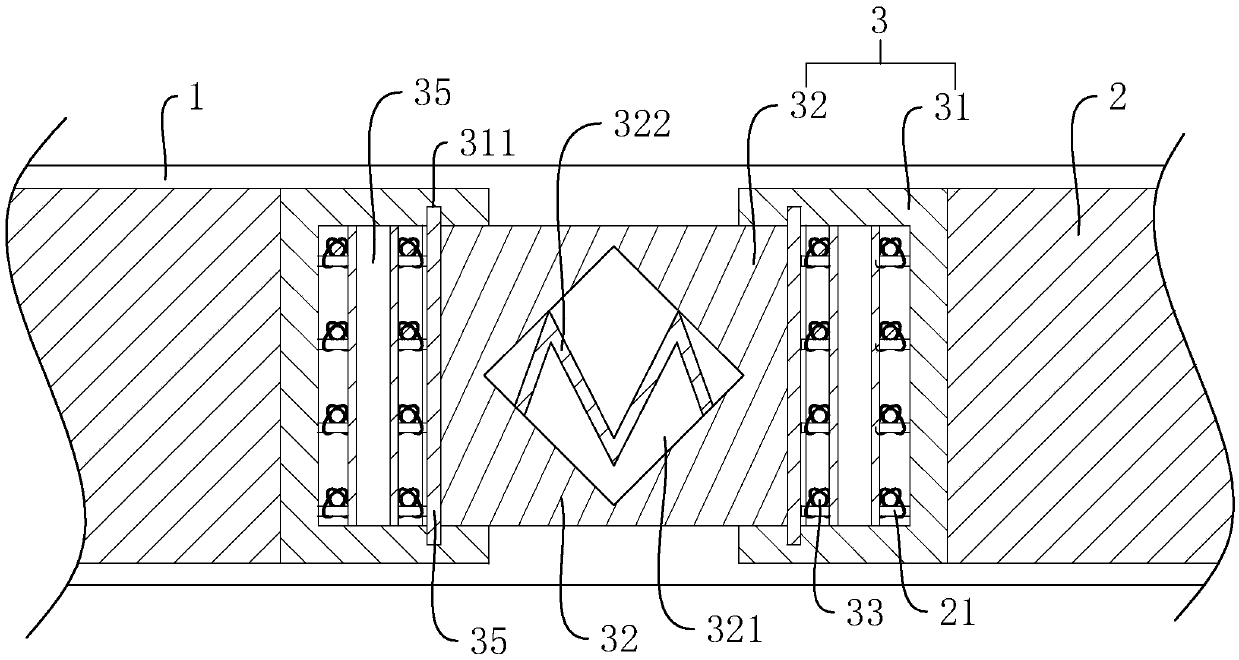

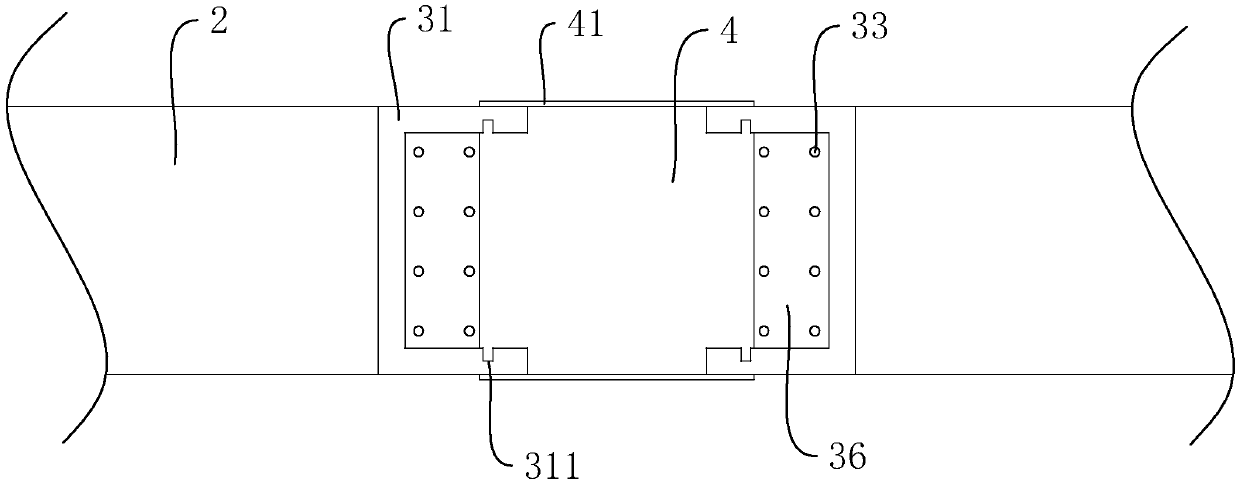

Fabricated underground continuous wall and construction method thereof

ActiveCN109653192AImprove progress and intensityImprove construction efficiencyBulkheads/pilesSlurry wallThermal expansion

The invention relates to the technical field of civil engineering and aims at providing a fabricated underground continuous wall and a construction method thereof. The technical scheme of the construction method of the fabricated underground continuous wall is characterized by comprising forming a mounting ditch in the ground, sequentially mounting a plurality of continuous wall units inside the mounting ditch, and clamping extension modules between every two neighboring continuous wall units, wherein every extension module comprises two mounting plates and an extension rubber strip, the extension rubber strip is clamped between the two mounting plates, and the two mounting plates are attached onto the opposite side walls of the corresponding two continuous wall units. According to the construction method of the fabricated underground continuous wall, the extension rubber strips can adapt to thermal expansion and contraction between the continuous wall units to reduce upheaval and depression between the continuous wall units.

Owner:江苏城归设计有限公司

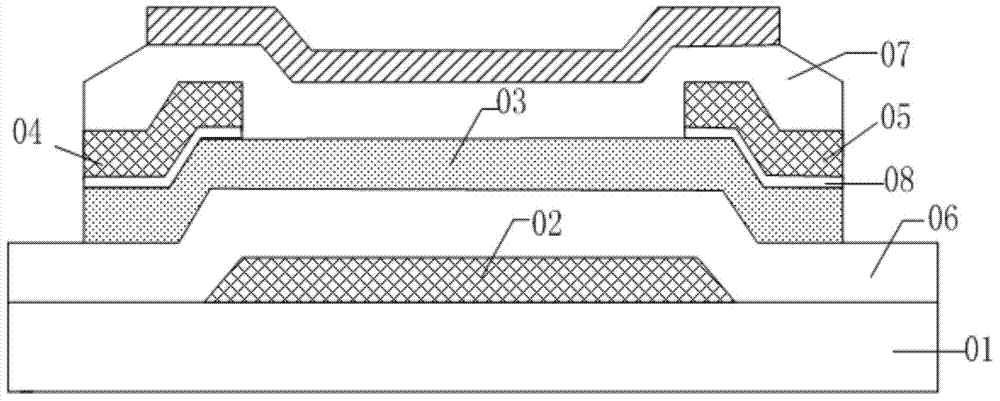

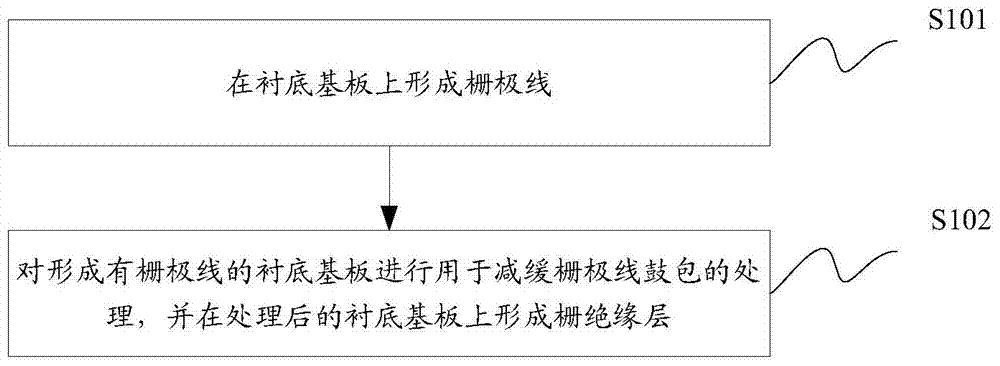

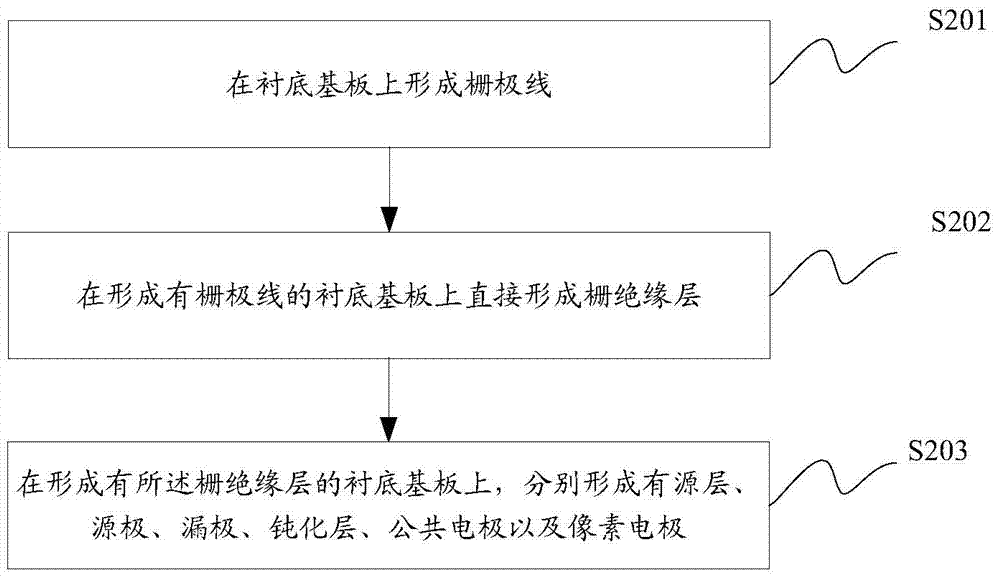

Thin film transistor and production method of thin film transistor, array substrate and display equipment

InactiveCN104716201AReduce bulgeSlow down or even avoid the problem of bulgingTransistorSolid-state devicesInsulation layerDisplay device

The invention discloses a thin film transistor and a production method of the thin film transistor, an array substrate and display equipment, aiming at slowing down and even avoiding the problem of gate line bulging in a production process for the thin film transistor, so that the resistance of a gate line is uniform, and then the display effect of a display is uniform, and the display quality of the display is improved. The method comprises the following steps: forming the gate line on a substrate; carrying out processing of slowing down the gate line bulging on the substrate on which the gate line is formed, and forming a gate insulation layer on the processed substrate.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

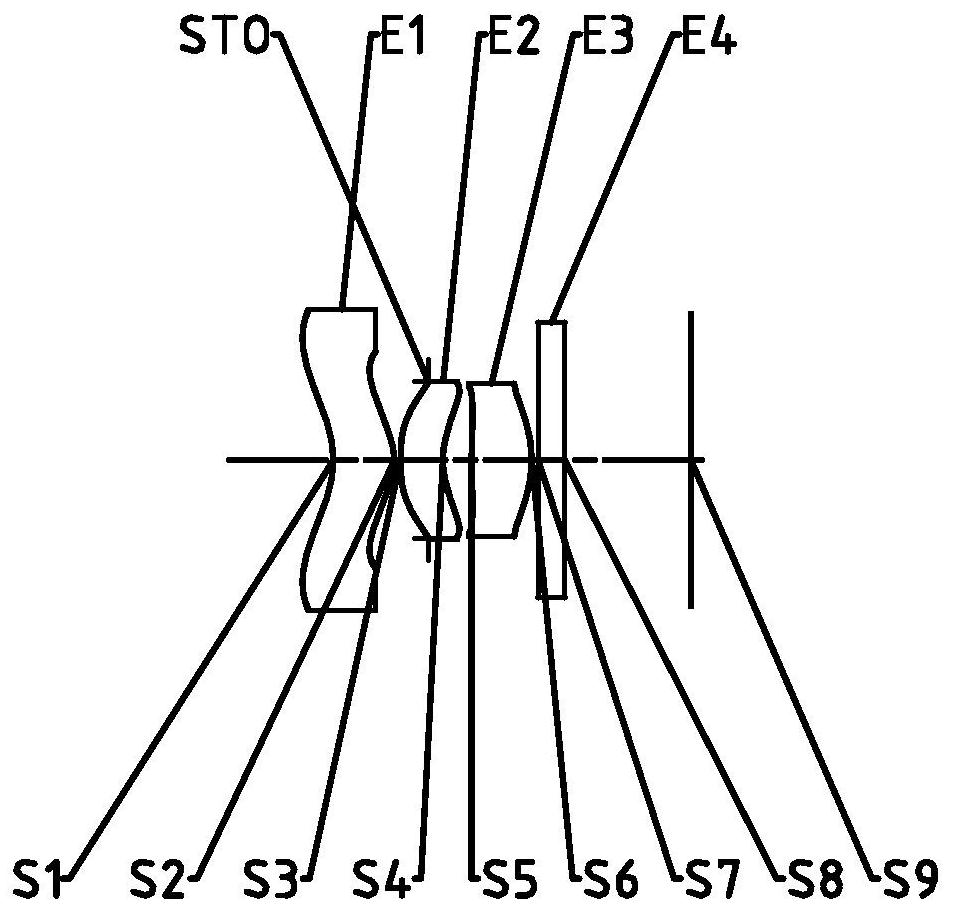

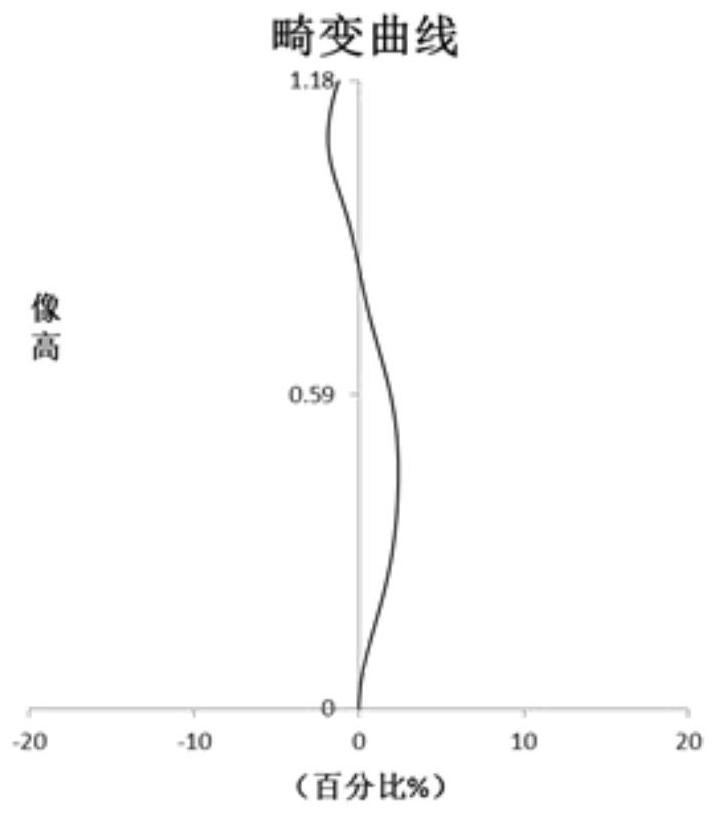

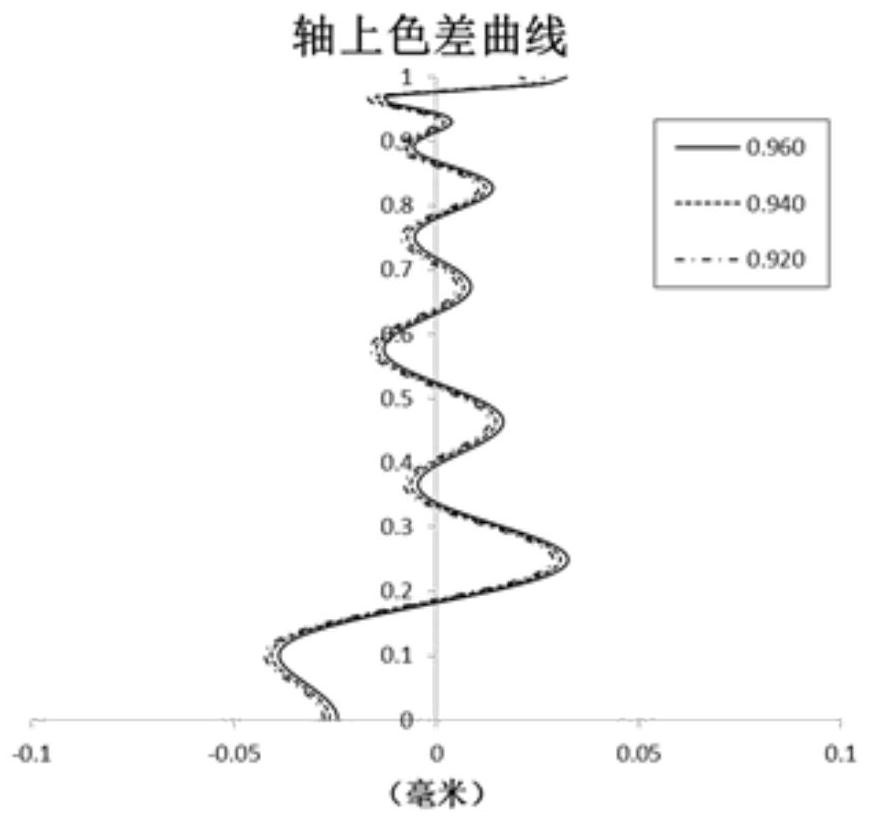

Image pickup system

PendingCN114047598AGuaranteed ultra-thin characteristicsGuaranteed aestheticsOptical elementsOphthalmologyOptical axis

The invention discloses an image pickup system. The system sequentially comprises a first lens, a second lens and a third lens from an object side to an image side along an optical axis, wherein the first lens has positive focal power and an image side surface is a convex surface; the second lens has negative focal power, and the the image side surface of the second lens is a concave surface; the third lens has positive focal power; and the distance TS3 from the diaphragm of the image pickup system to the image side surface of the third lens on the optical axis and the distance TTL from the object side surface of the first lens of the image pickup system to the imaging surface on the optical axis meet the following condition: 0.2 < TS3 / TTL < 0.3. By controlling the on-axis distance from the object side surface of the first lens to the imaging surface and the distance from the diaphragm of the image pickup system to the image side surface of the third lens on the optical axis, the ultra-thin characteristic of the lens is ensured, the lens miniaturization is realized, the space utilization rate of the whole machine is improved, the convex phenomenon of the lens is reduced, and the attractive appearance of the whole machine is ensured.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com