Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Realize synergy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

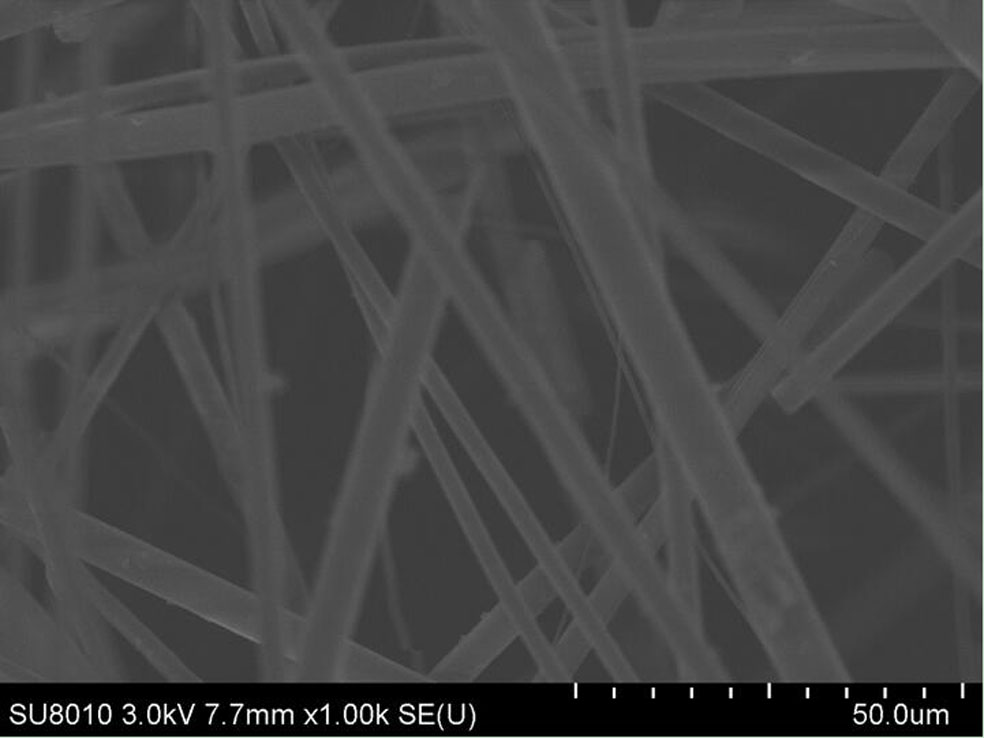

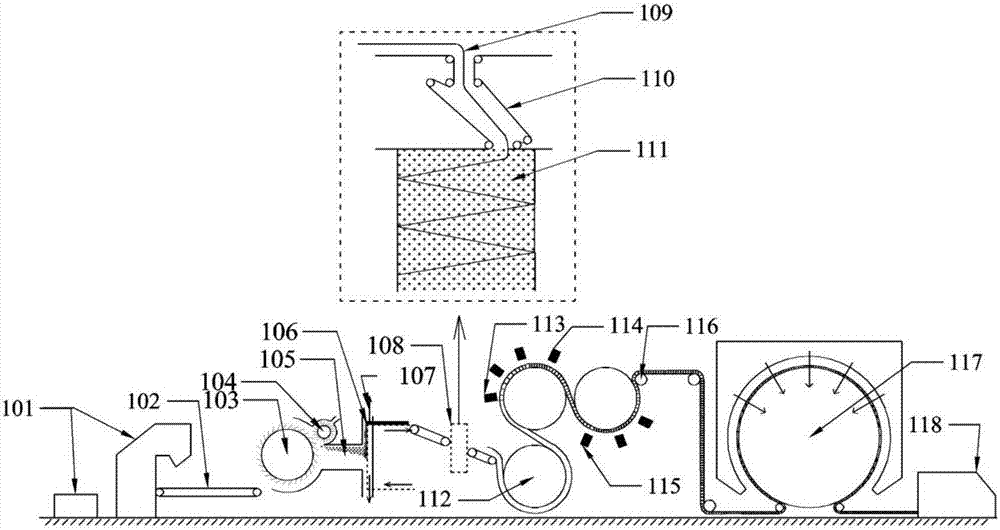

Preparation method of spun-laced regenerated leather for automotive interior surface

ActiveCN105970657AImprove product added valueMany categoriesNon-woven fabricsWettingCost performance

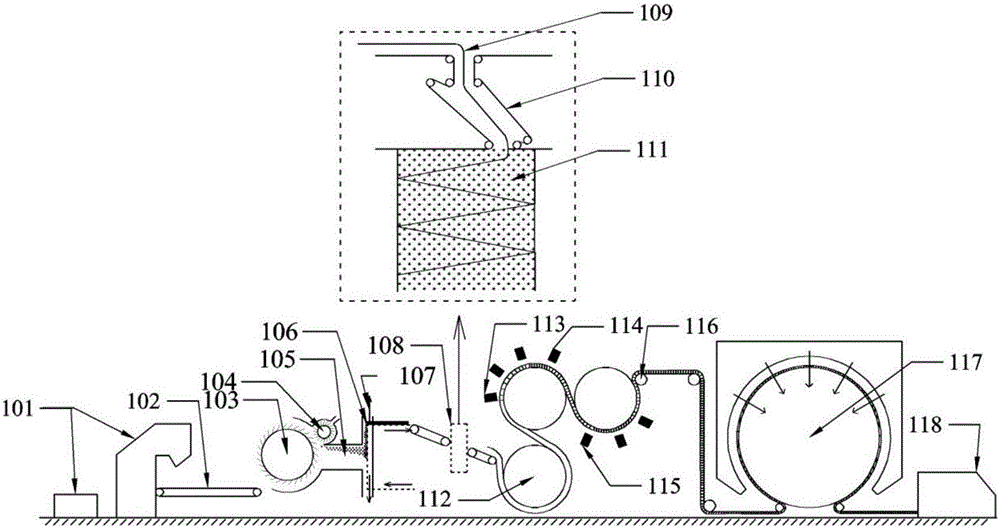

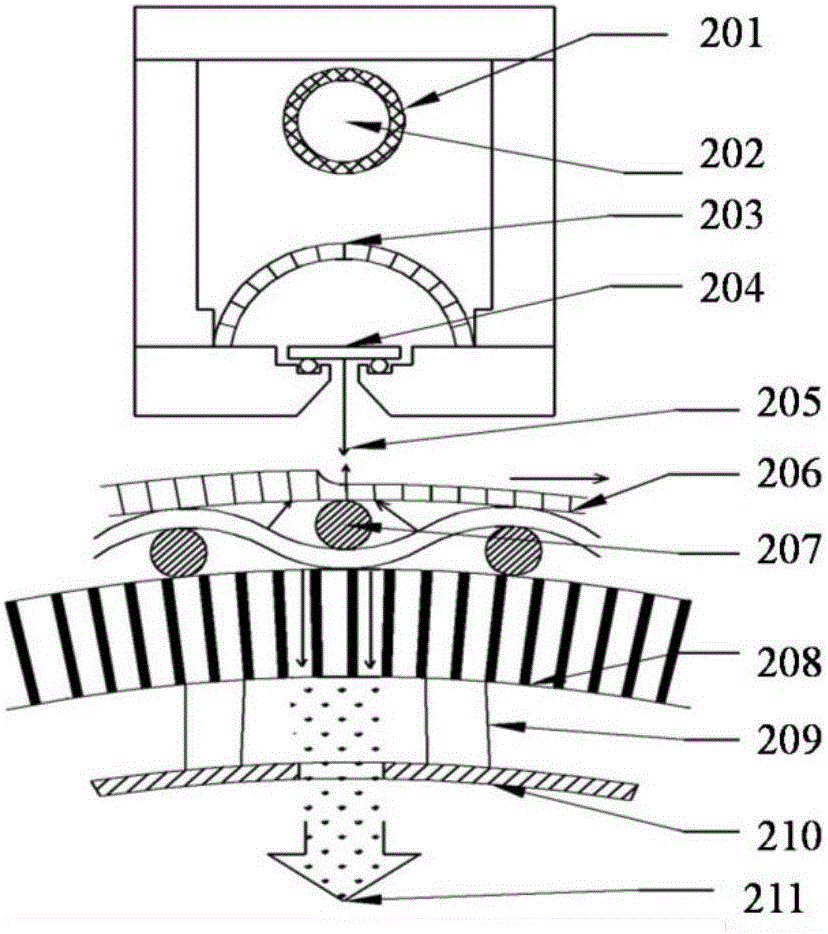

The invention provides a preparation method of spun-laced regenerated leather for an automotive interior surface. The preparation method comprises the following specific steps: (1) loosening and mixing fibers; (2) forming a net; (3) spreading the net; (4) pre-wetting; (5) spun-lacing; (6) drying; (7) carrying out vacuum plastic-absorption and molding. The requirements on material molding properties and mechanical properties by the automotive interior surface and industrial standards are sufficiently considered at the beginning of designing, and raw material ratios and a production process are reasonably optimized, so that collaboration of design, preparation and molding machining of a composite material is realized. Compared with traditional automotive interior surfaces including polyvinyl chloride, polyurethane and the like, the prepared automotive interior surface has the advantages of greenness and environmental friendliness, no odor, excellent elasticity, moderate strength, comfortable hand feeling, high cost performance and the like and is suitable for large-scale industrial production.

Owner:SHANDONG UNIV

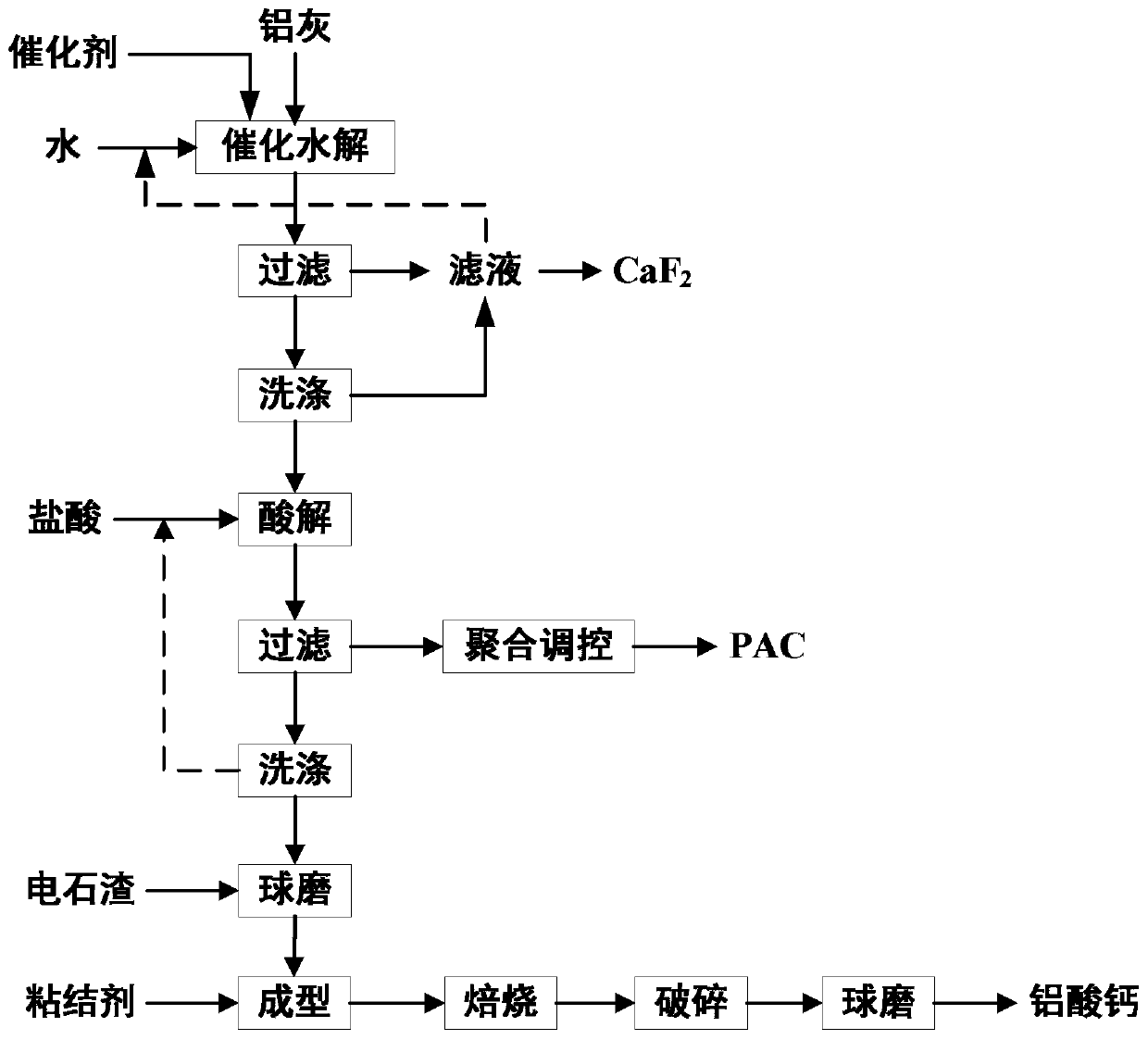

Method for preparing calcium aluminate by utilizing aluminum ash and acetylene sludge

ActiveCN110028092AFix security issuesSolve resource problemsCalcium aluminatesResource utilizationSlag

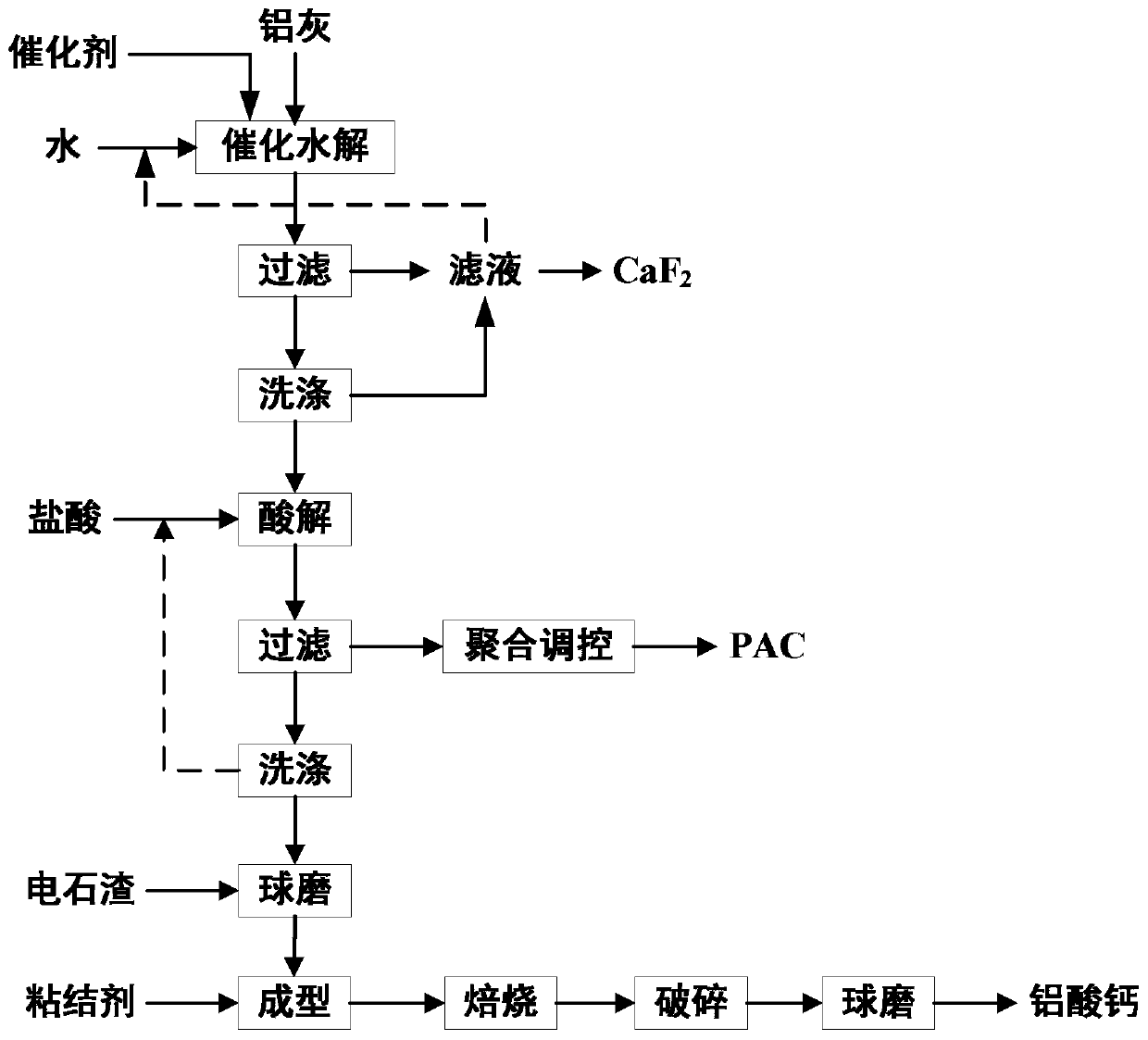

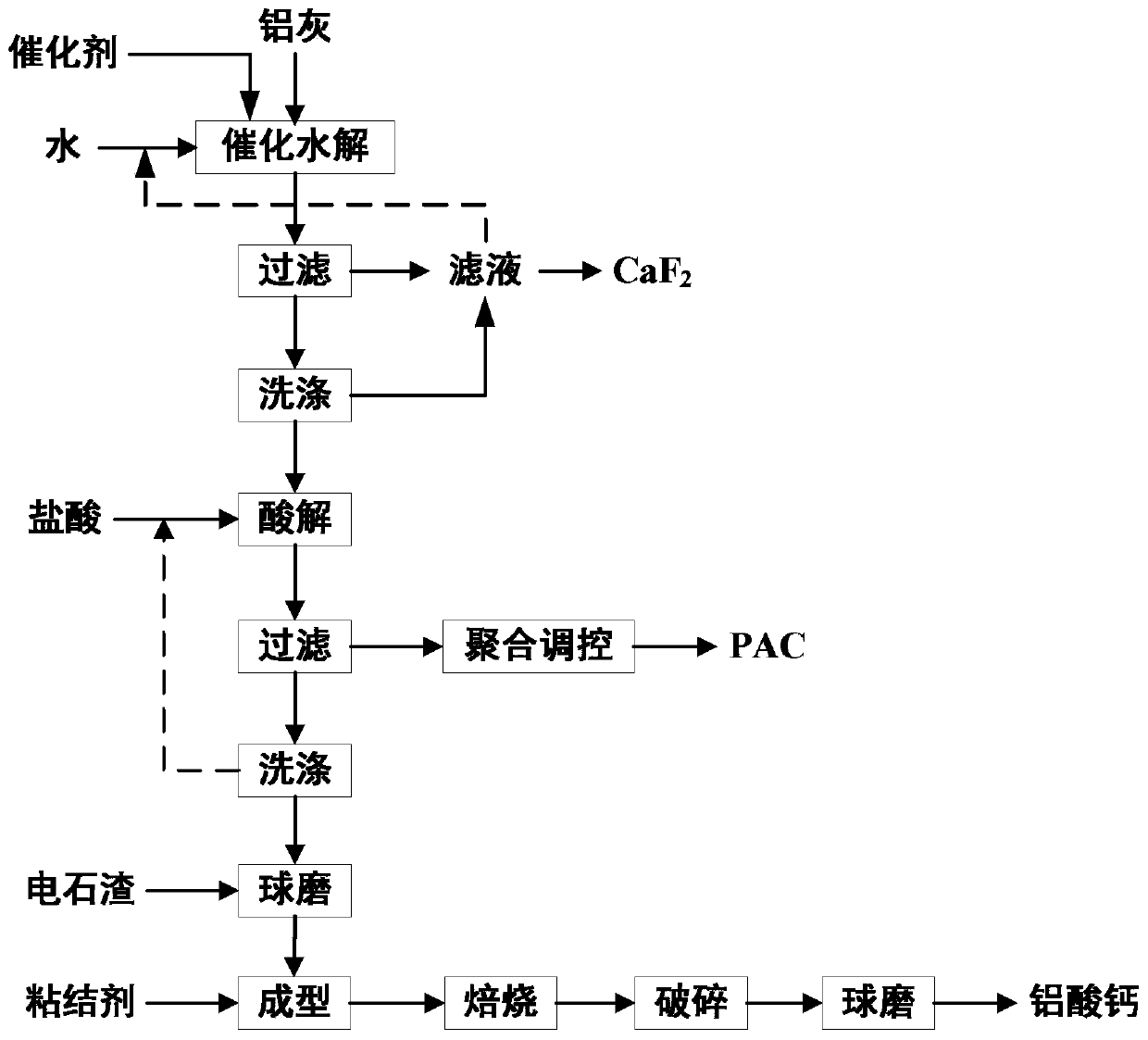

The invention discloses a method for preparing calcium aluminate by utilizing aluminum ash and acetylene sludge. The method comprises the following steps: performing catalytic hydrolysis, acidolysis and washing on aluminum ash so as to prepare high-purity aluminum ash powder; performing ball-mill mixing on the high-purity aluminum ash powder and acetylene sludge, performing compression molding onthe mixed powder, and sintering in a sintering furnace to prepare an active calcium aluminate bulk material; crushing and performing ball milling, thereby obtaining the high-activity calcium aluminaterefining agent. The calcium aluminate refining agent prepared by the method disclosed by the invention is excellent in property, and standard requirements of calcium aluminate YB / T4265-2011 for a steel-making slag remover are met. The method disclosed by the invention solves the pollution problems of the aluminum ash and acetylene sludge hazardous / solid wastes to the environment, realizes resource utilization, and has excellent environmental, economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

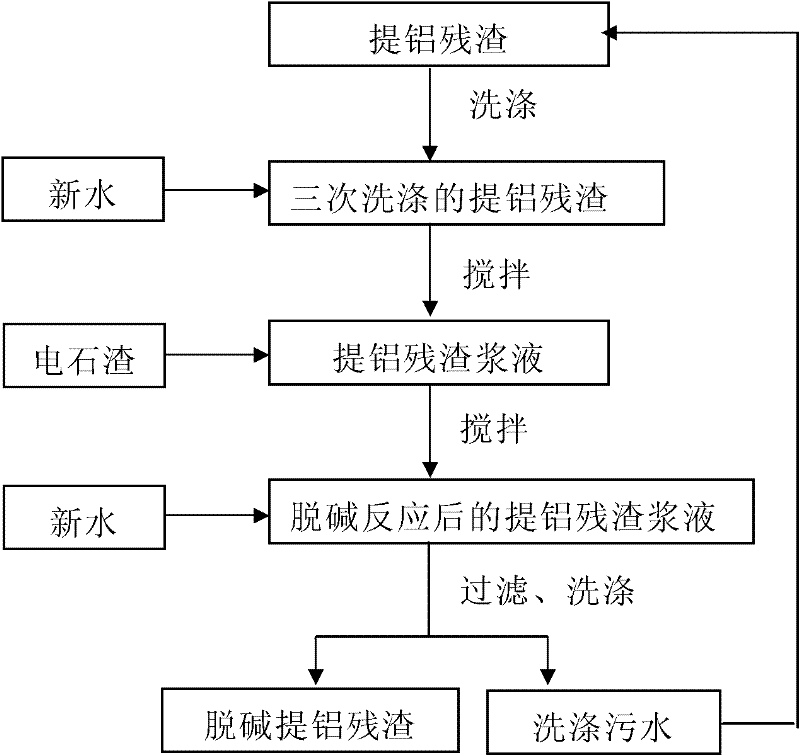

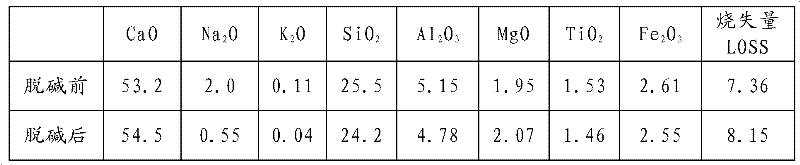

Dealkalization method of fly ash Al-extraction residues

InactiveCN102351451ARealize synergyReduce manufacturing costSolid waste managementCement productionSlagSlurry

The invention discloses a dealkalization method of fly ash Al-extraction residues, comprising the following steps of: (1) adding water into the Al-extraction residues with stirring to prepare an Al-extraction residue slurry; (2) slowly adding calcium carbide slag into the Al-extraction residue slurry with stirring for a dealkalization reaction; (3) filtering the Al-extraction residue slurry which has undergone the dealkalization reaction, followed by washing to obtain the dealkalized Al-extraction residues. The invention is suitable for dealkalization of the Al-extraction residues by the fly ash alkali lime sintering method. After the dealkalization processing, the content of sodium oxide in the Al-extraction residues by the fly ash alkali lime sintering method is reduced from 1.3-2.0% to 0.4-0.6%, which can satisfy the requirement of mixing material addition material and cement clinker raw materials on the alkali content in the building material industry. The method provided by the invention has advantages of simple process, low energy consumption, less material consumption amount and low treatment cost, and is suitable for industrial popularization.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Method for improving recovery rate of iron component in steel slag

ActiveCN106492981AIncrease sensible heatEfficient use ofRecycling and recovery technologiesMagnetic separationMolten stateAlkalinity

The invention discloses a method for improving the recovery rate of an iron component in steel slag. The method comprises the steps of: mixing modifiers in a predetermined proportion in the steel slag in a molten state, that is, in a process of discharging the molten steel slag, adding the modifiers into the steel slag, directly melting the modifiers by virtue of sensible heat of the steel slag, and changing the alkalinity of the steel slag by means of a molten state modifying method, wherein the adulterate amount of the modifiers is smaller than or equal to 25% by mass of the steel slag; and by adding the modifiers containing silicon oxide and / or iron oxide to recombine the component of the steel slag, increasing the contents of magnetite and hercynite so as to improve the recovery rate of the iron component. According to the method disclosed by the invention, sensible heat of the molten steel slag is effectively utilized, so that heat needs not to be compensated in the modifying process; the modifiers which are added into the steel slag are either cheap raw materials or solid wastes such as tailings and dust slime, so that optimization and synergic action of resources are realized. Meanwhile, by adding the modifiers containing silicon oxide and / or iron oxide and increasing the contents of magnetite and hercynite after component recombination, the recovery rate of the iron component in the steel slag is improved.

Owner:UNIV OF SCI & TECH BEIJING

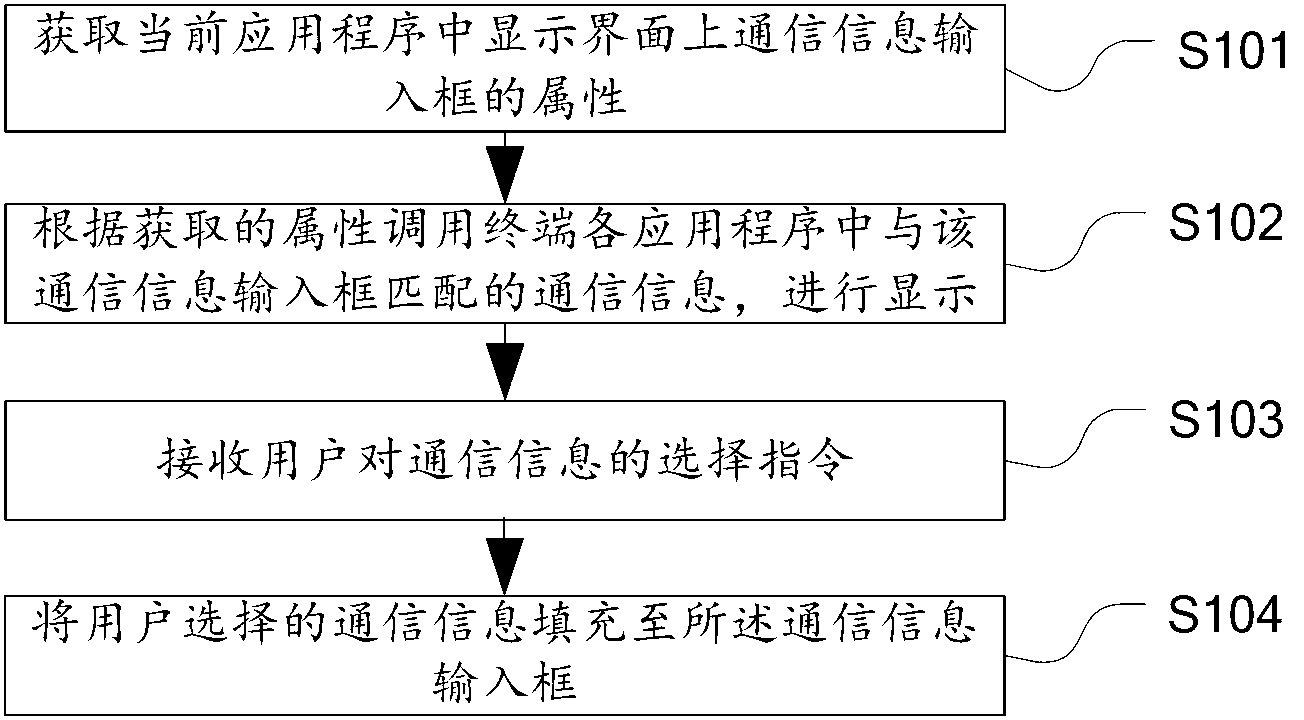

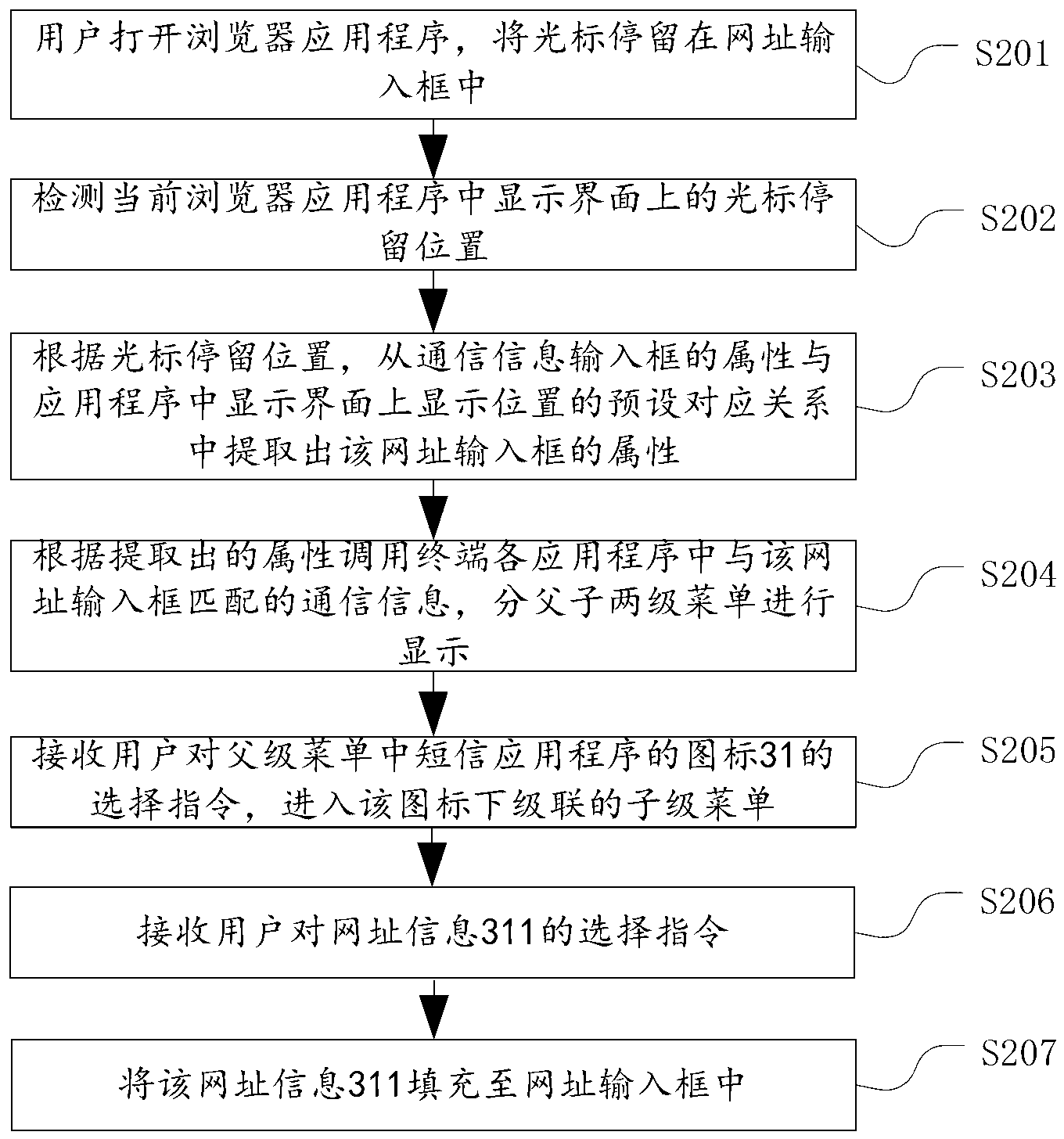

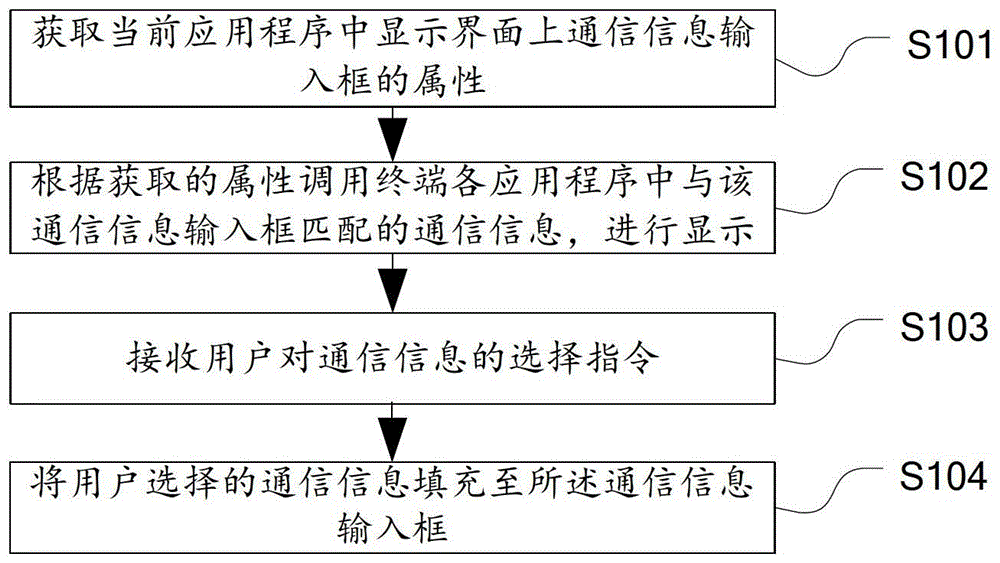

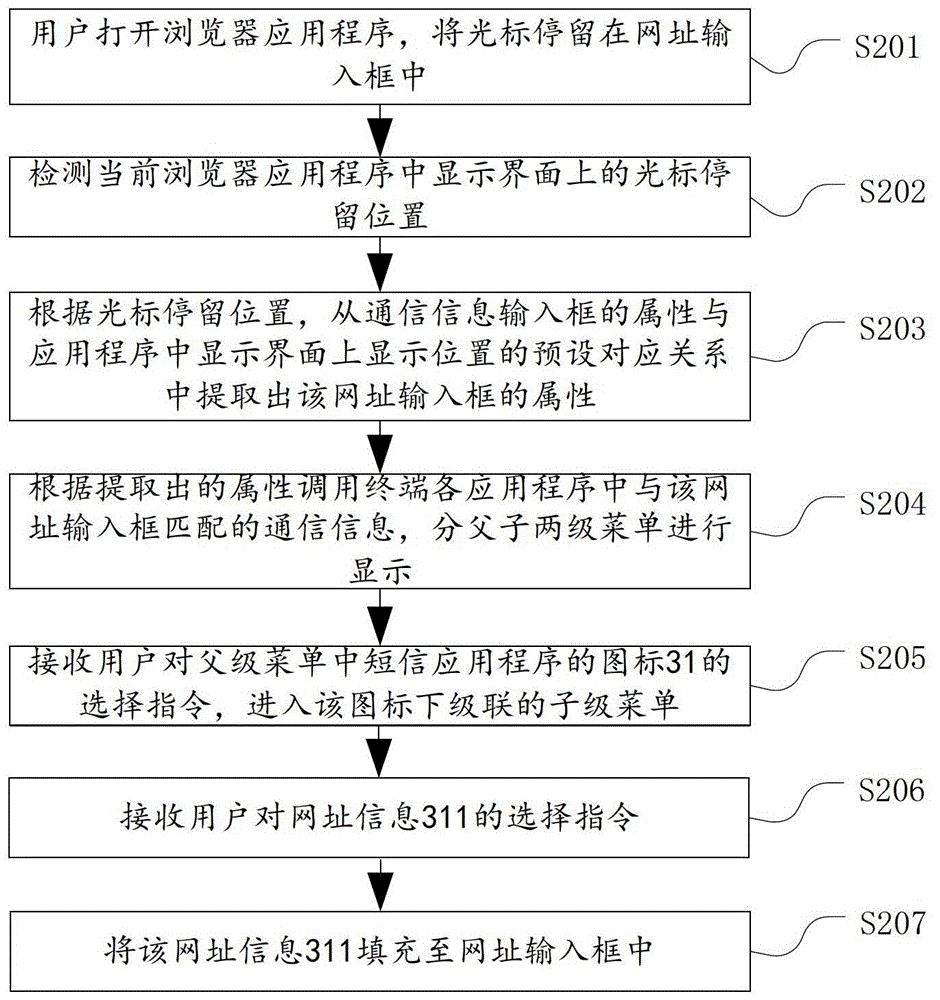

Method and device for quickly inputting communication information in terminal

ActiveCN103235677ARealize synergyImprove input efficiencySubstation equipmentInput/output processes for data processingComputer terminalComputer science

The invention discloses a method and a device for quickly inputting communication information in a terminal. The method comprises the steps as follows: obtaining attributes of a communication information input field on a display interface in current application program; calling communication information matched with the communication information input field in each application program of the terminal according to the obtained attributes; displaying; receiving a selection instruction of a user to the communication information; and filling the communication information input field with the communication information selected by the user. Through the technical scheme, the technical problem that the conventional scheme is not perfect is solved.

Owner:DONGGUAN YULONG COMM TECH +1

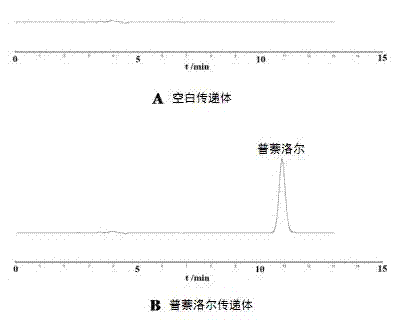

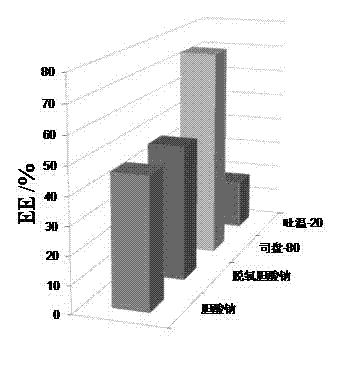

Percutaneous-absorption-promoting propranolol composite phospholipid transfersome, and prepartion method and application thereof

InactiveCN102846546APromote percutaneous absorptionImprove bioavailabilityOrganic active ingredientsPharmaceutical non-active ingredientsInfantile haemangiomaBlood plasma

The invention provides a composite phospholipid transfersome which promotes propranolol percutaneous absorption, and a preparation method thereof. According to the invention, two phospholipid materials with different phase-change temperatures, which are dipalmitoyl phosphatidyl choline and soybean lecithin, are adopted as a composite phospholipid material. Compared with a transfersome with a single phospholipid material in prior art, the propranolol composite phospholipid transfersome prepared with the phospholipid material provided by the invention has substantially improved encapsulation efficiency, reduced leakage, improved stability in rat plasma, and substantially improved bioavailability after percutaneous administration. The propranolol composite phospholipid transfersome provided by the invention is especially suitable to be used for treating infantile hemangioma. With the transfersome, propranolol percutaneous administration can be realized, and propranolol can directly act upon a hemangioma affected part. The treatment effect is improved, toxic and side effects are reduced, and children medication compliance can be improved. Also, the invention provides a preparation method of the propranolol composite phospholipid transfersome.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

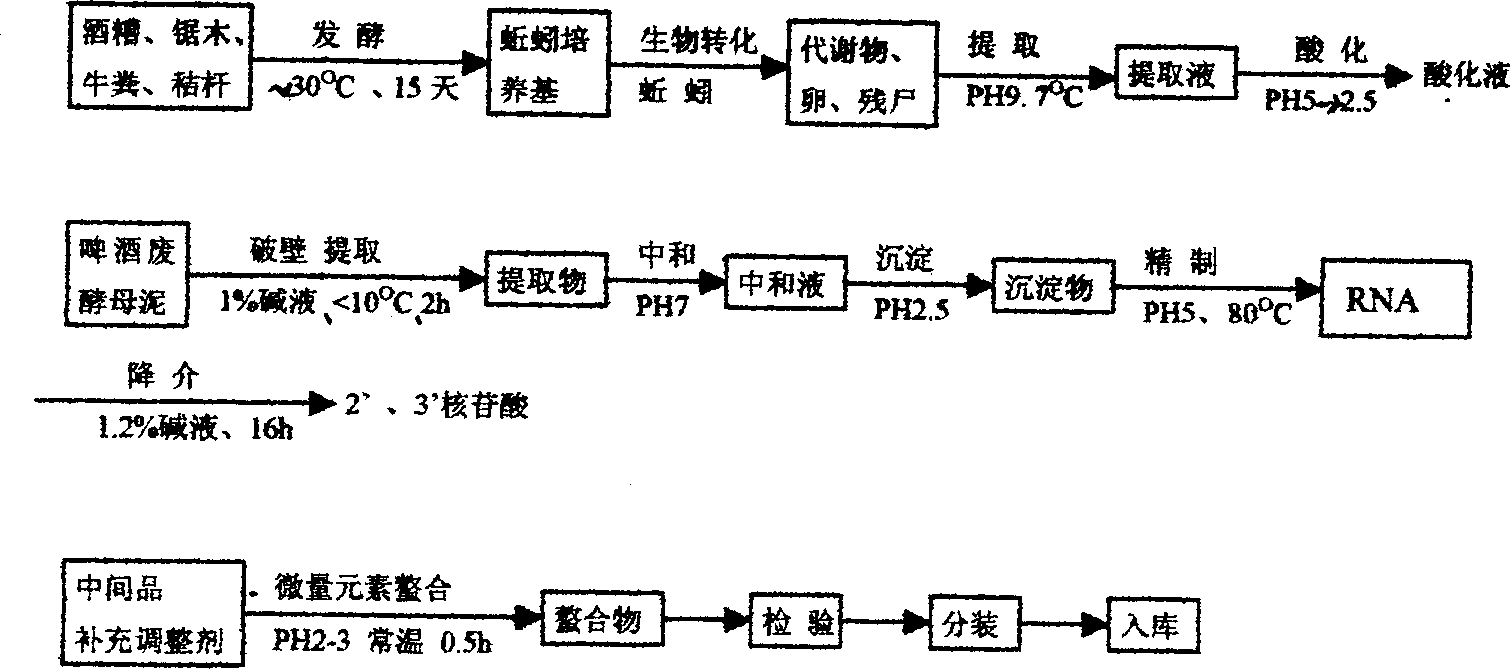

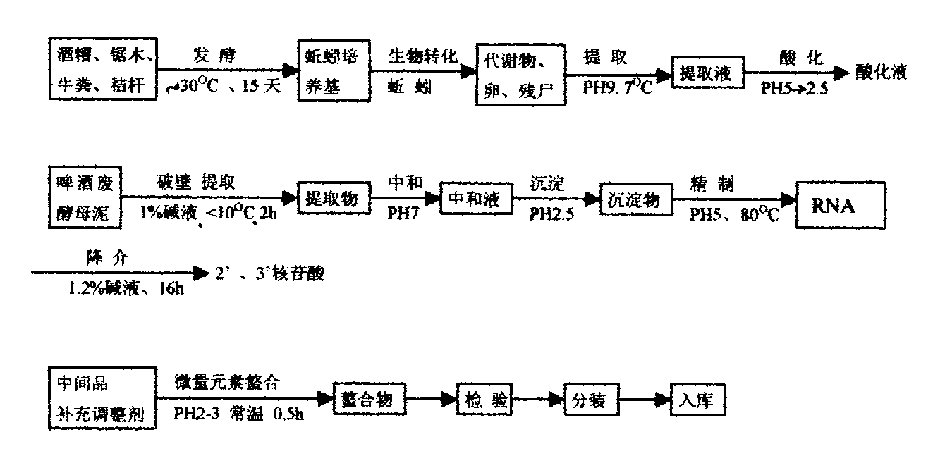

Plant regulation biocide (0.05% aqueous nucleotide) and preparation process thereof

The composition with the function of regulating plant growth and fungicidal action contains nucleotide, fulvic acid, amino acid, chelate of trace element and water, in which nucleotide content is greater than 0.01 wt% of total weight of said composition. The described fulvic acid, amino acid and partial nucleatide are extracted from metabolite of earthworm, and another part of nucleotide is extracted from waste yeast slurry produced by fermentation for making beer, and all the processes for extraction include cell wall-breaking process.

Owner:洛阳龙门生化制品厂

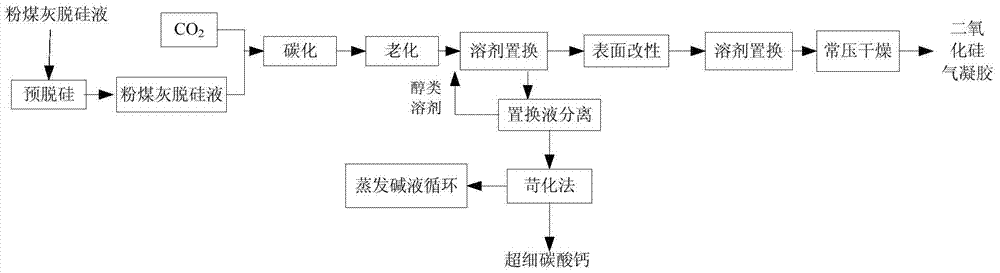

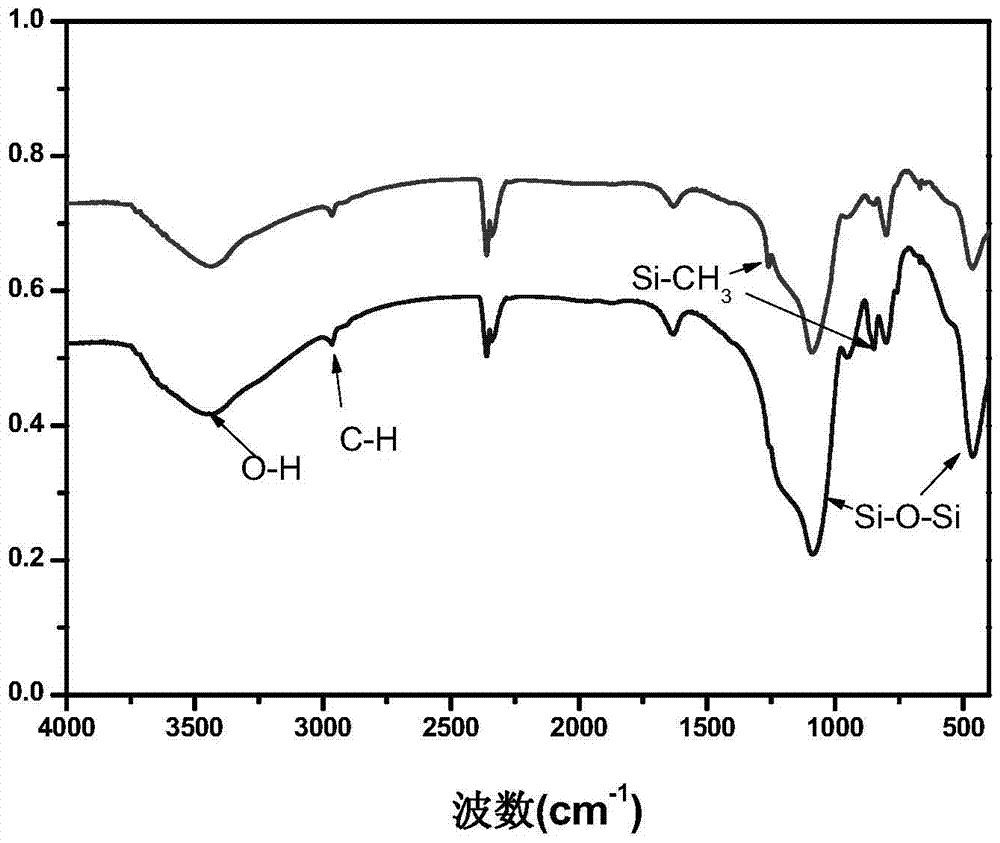

Method for preparing silica aerogel from desilicication liquid of fly ash

InactiveCN106986346AAvoid it happening againRealize synergyCalcium/strontium/barium carbonatesSilicon compoundsCarbonizationSilica gel

The invention provides a method for preparing a silica aerogel from desilicication liquid of fly ash. The method comprises the following steps: (1) subjecting the desilicication liquid of fly ash and carbon dioxide gas to a carbonization reaction at 0 to 90 DEG C so as to obtain a wet silica gel; (2) carrying out ageing on the wet silica gel and then subjecting the aged wet silica gel to displacement with a solvent so as to obtain displacement liquid and a displaced wet gel; and (3) carrying out aftertreatment on the displaced wet gel so as to obtain the silica aerogel. The method can prepare the silica aerogel with the cheap and easily available desilicication liquid of fly ash as a raw material under cooperation of recycled carbon dioxide, prevents production of a great amount of waste inorganic salt liquid, realizes cyclic utilization of an alkaline solution and combined production of an ultrafine calcium carbonate product, and has the advantages of low cost, no secondary pollution, mild conditions, suitability for industrial application, etc.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

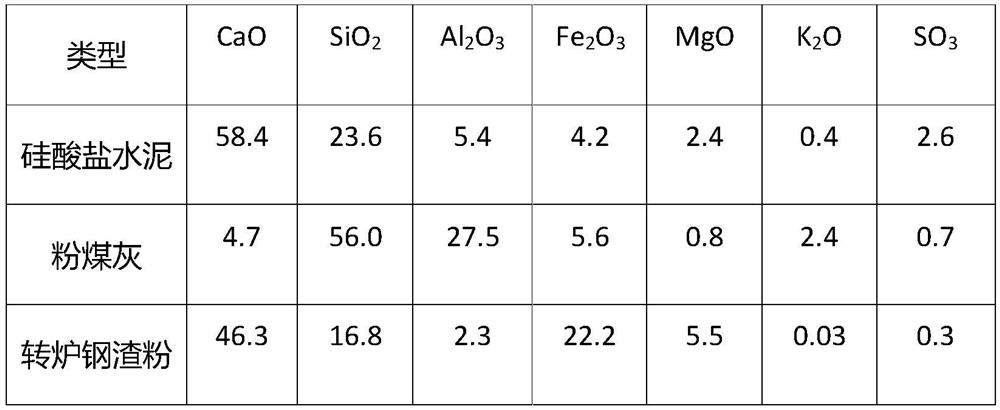

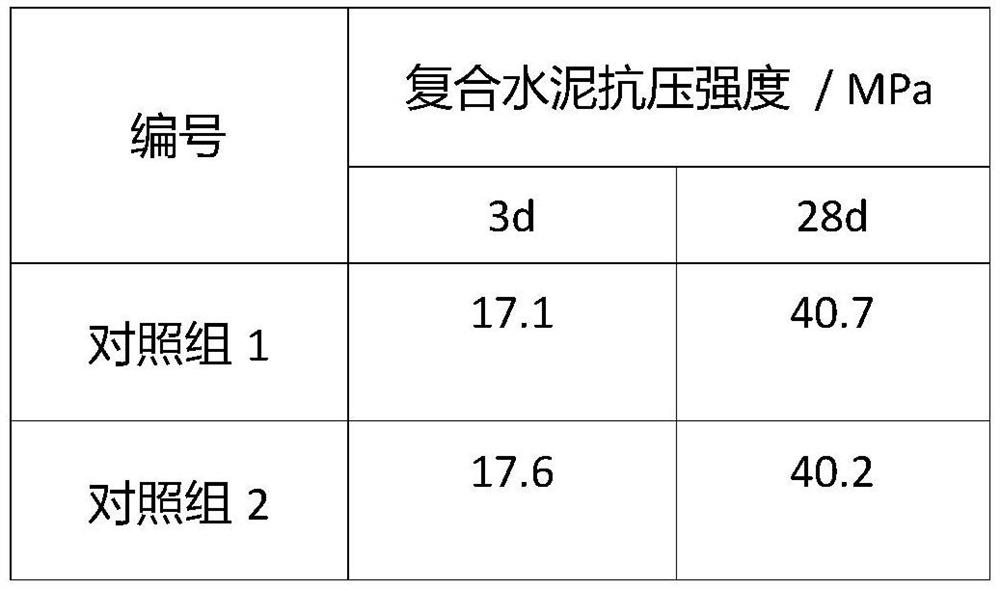

Electric furnace steel slag-based cement admixture or concrete admixture as well as preparation method and application thereof

ActiveCN111689701ASolve the accumulationMitigate insufficient resourcesCement productionSlagPhosphogypsum

The invention discloses an electric furnace steel slag-based cement admixture or concrete admixture comprising the following components in parts by mass: 80-93 parts of ladle furnace refined steel slag, 2-8 parts of phosphogypsum, 5-12 parts of lithium slag and 0-0.2 part of an additive. The invention further provides a preparation method of the electric furnace steel slag-based cement admixture or concrete admixture and an application of the electric furnace steel slag-based cement admixture or concrete admixture in production and preparation of cement and concrete. The electric furnace reduction steel slag is utilized to the maximum extent, byproducts such as phosphogypsum and lithium slag are combined to serve as auxiliary components, the characteristics of self-hydration hardening andhigh adaptability are achieved, the superposition effect and synergistic efficient utilization of multiple kinds of waste are achieved, waste utilization is achieved, environmental protection is achieved, the cost is low, the cost performance is high, and the application prospect is wide.

Owner:SUN YAT SEN UNIV

Preparation method of solid waste-based cementing material early strength auxiliary agent

The invention provides a method for preparing a cementing material early strength auxiliary agent by using industrial waste residues, the method specifically comprises the following steps: calcining desulfurized gypsum at 600-700 DEG C to obtain anhydrous desulfurized gypsum, and mixing the anhydrous desulfurized gypsum with dihydrate desulfurized gypsum to obtain mixed desulfurized gypsum; mixing materials such as slag, waste incineration fly ash, refining slag, mixed desulfurized gypsum, calcium aluminate cement and water, heating to react, drying, and grinding to obtain the early strength auxiliary agent. The early strength auxiliary agent can improve the early strength of the solid waste-based cementing material, has the characteristics of low cost, environmental protection and the like, and a new way is developed for synergistic utilization and synergism of industrial waste residues.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

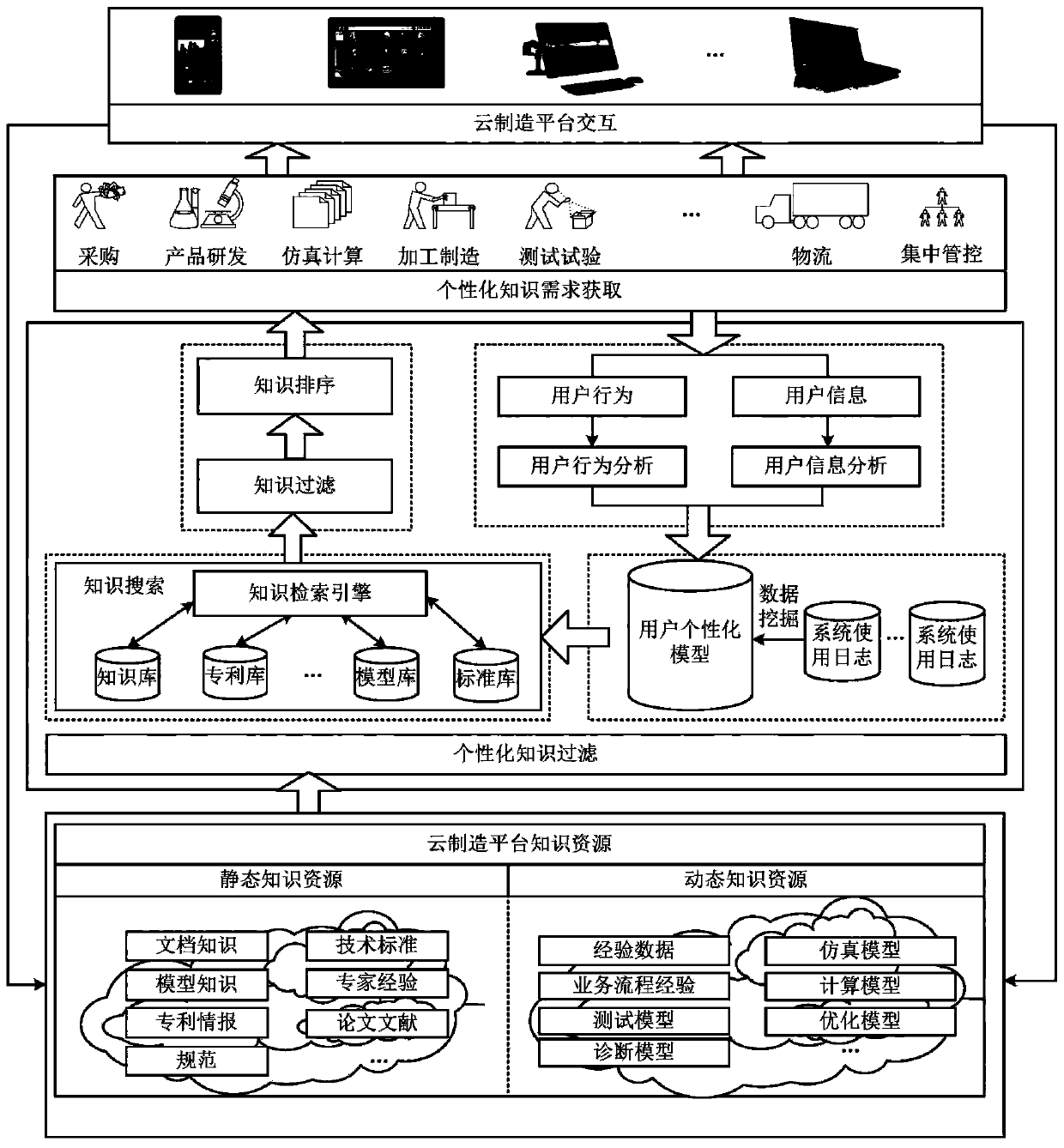

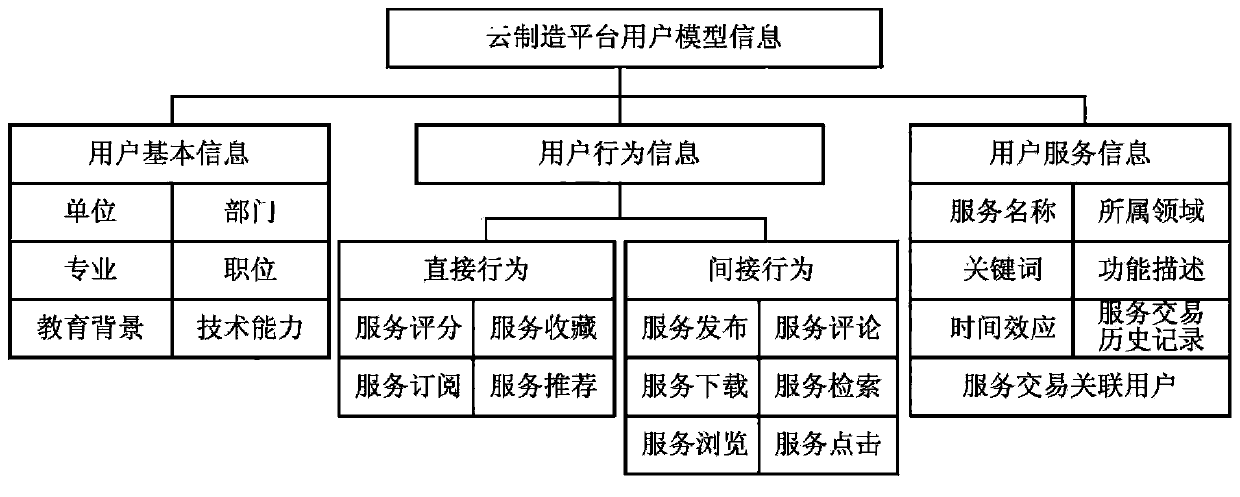

Knowledge service method and system based on industrial service cloud platform user behavior perception

ActiveCN109800249AIncrease profitHigh viscosityDigital data information retrievalSpecial data processing applicationsPersonalizationKnowledge services

The invention relates to a knowledge service method and system based on industrial service cloud platform user behavior perception. The method comprises the following steps: 1) uniformly describing knowledge resources in an industrial service cloud platform through an ontology, and eliminating the isomerism of different knowledge resources in structure and semantics; 2) obtaining personalized knowledge demands of the user according to business activities of the user in the industrial service cloud platform, and establishing a user personalized model according to the personalized knowledge demands of the user; and 3) on the basis of the established user personalized model, retrieving the knowledge resources of the industrial service cloud platform to obtain the knowledge resources meeting the personalized knowledge requirements of the user. According to the invention, personalized intelligent knowledge services of user behavior perception can be provided for various large, medium and small industrial manufacturing enterprises of the industrial internet, blindness of knowledge resource searching by a user can be greatly reduced, and required knowledge resources can be provided for the user quickly.

Owner:北京航天智造科技发展有限公司

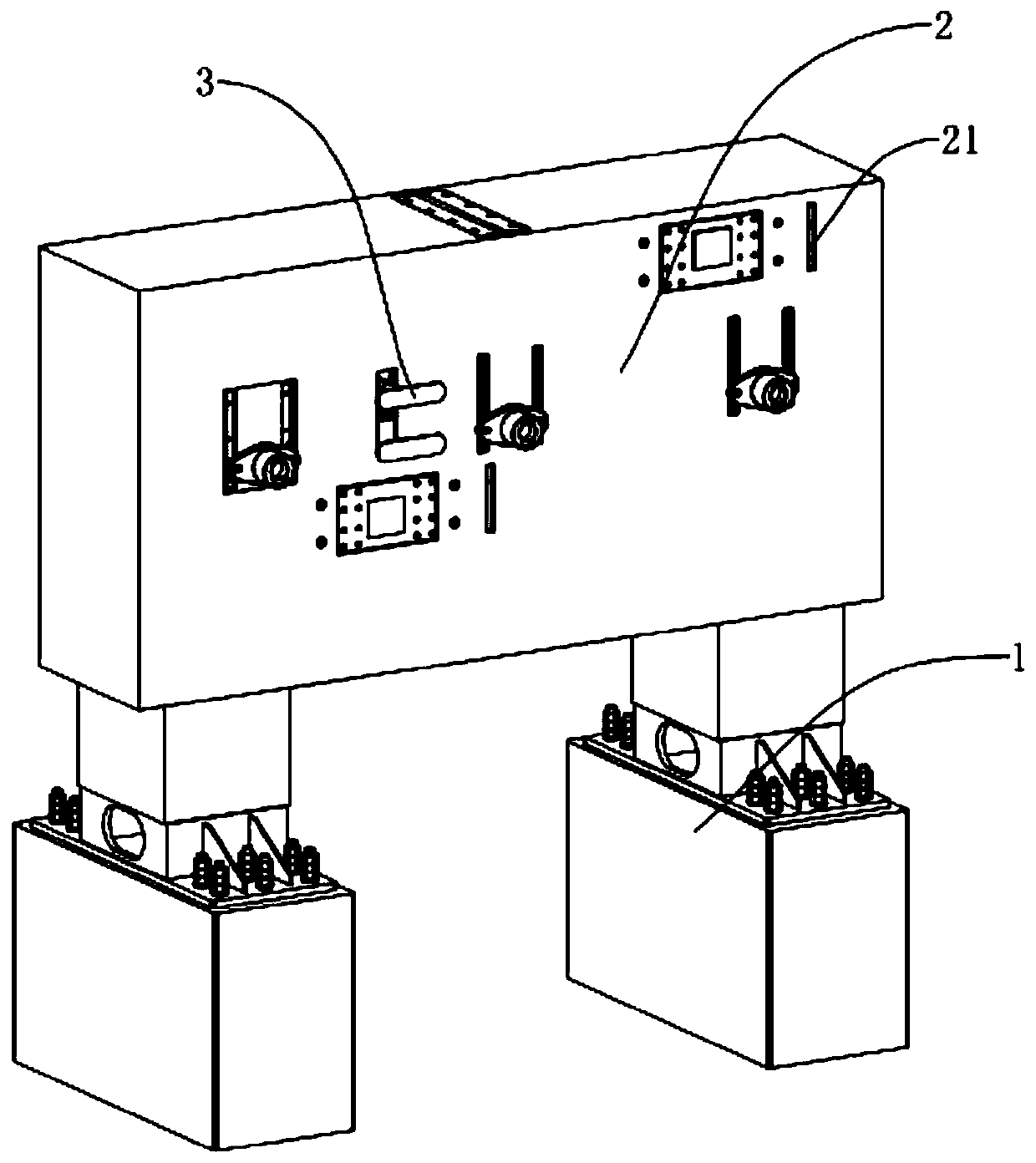

Monorail train contact and non-contact online detection steel beam

PendingCN111122603AHigh measurement accuracyProcessing speedOptically investigating flaws/contaminationEngineeringMonorail

The invention discloses a monorail train contact and non-contact online detection steel beam, and relates to the technical field of train detection, the steel beam comprises a base and a steel beam body fixed above the base, a plurality of horizontal wheel abrasion detection devices, horizontal wheel pressure detection devices, collector shoe pressure detection devices, collector shoe abrasion detection devices and at least one walking wheel abrasion detection device facing the upper side are arranged in the steel beam body, wherein the horizontal wheel abrasion detection devices, the horizontal wheel pressure detection devices and the collector shoe pressure detection devices face the front side and the rear side respectively. The horizontal wheel pressure detection device and the collector shoe pressure detection device penetrate out of the side faces of the corresponding sides of the front side and the rear side of the steel beam body. Square holes matched with the corresponding horizontal wheel abrasion detection devices, the corresponding collector shoe abrasion detection devices and the corresponding walking wheel abrasion detection devices in position are formed in the frontside face, the rear side face and the upper side face of the steel beam body. According to the steel beam, online real-time detection is realized, networked, visual, cooperative and integrated management is realized, the manual detection cost and error are reduced, and the detection efficiency is improved.

Owner:中数智科(杭州)科技有限公司 +1

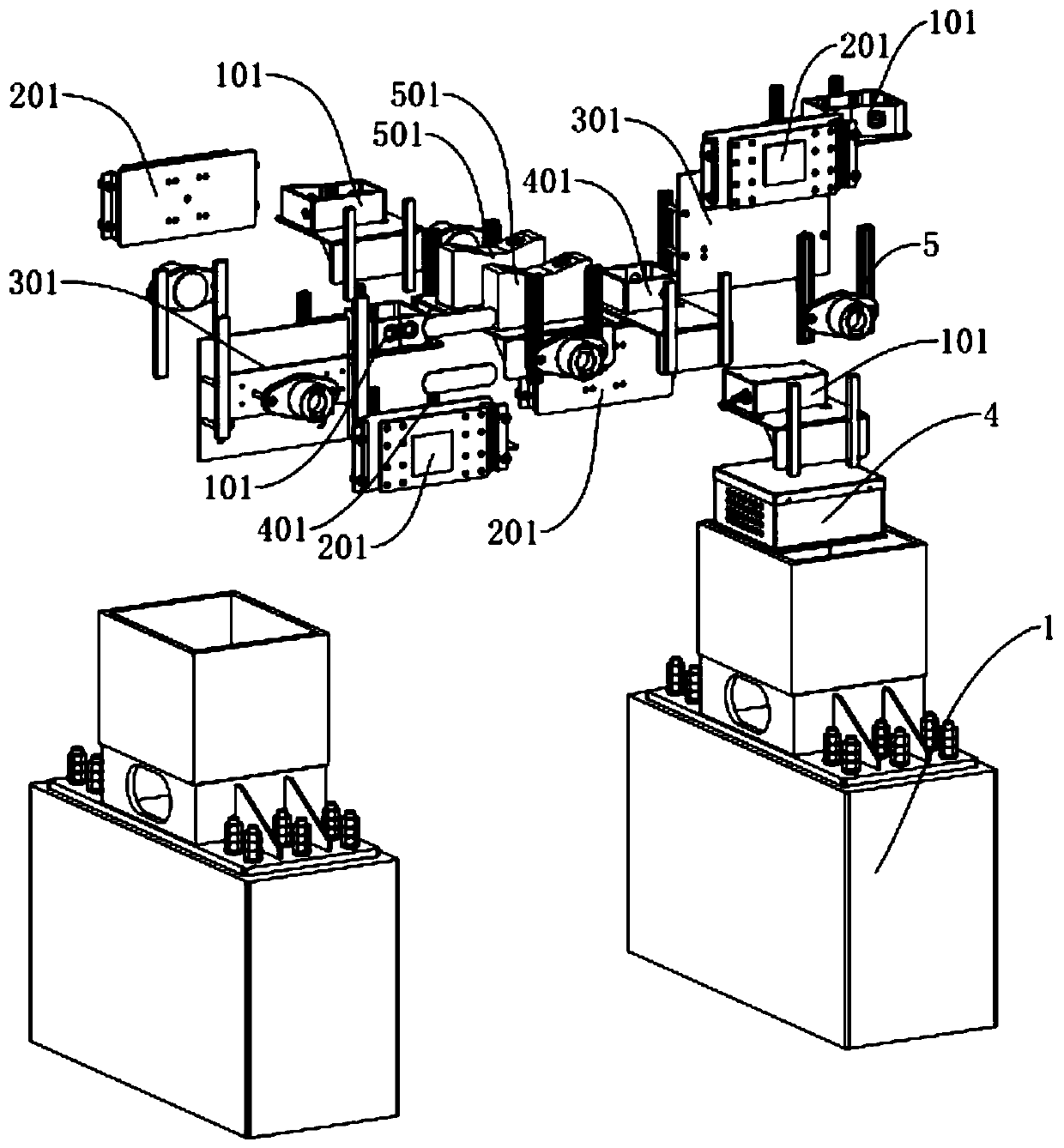

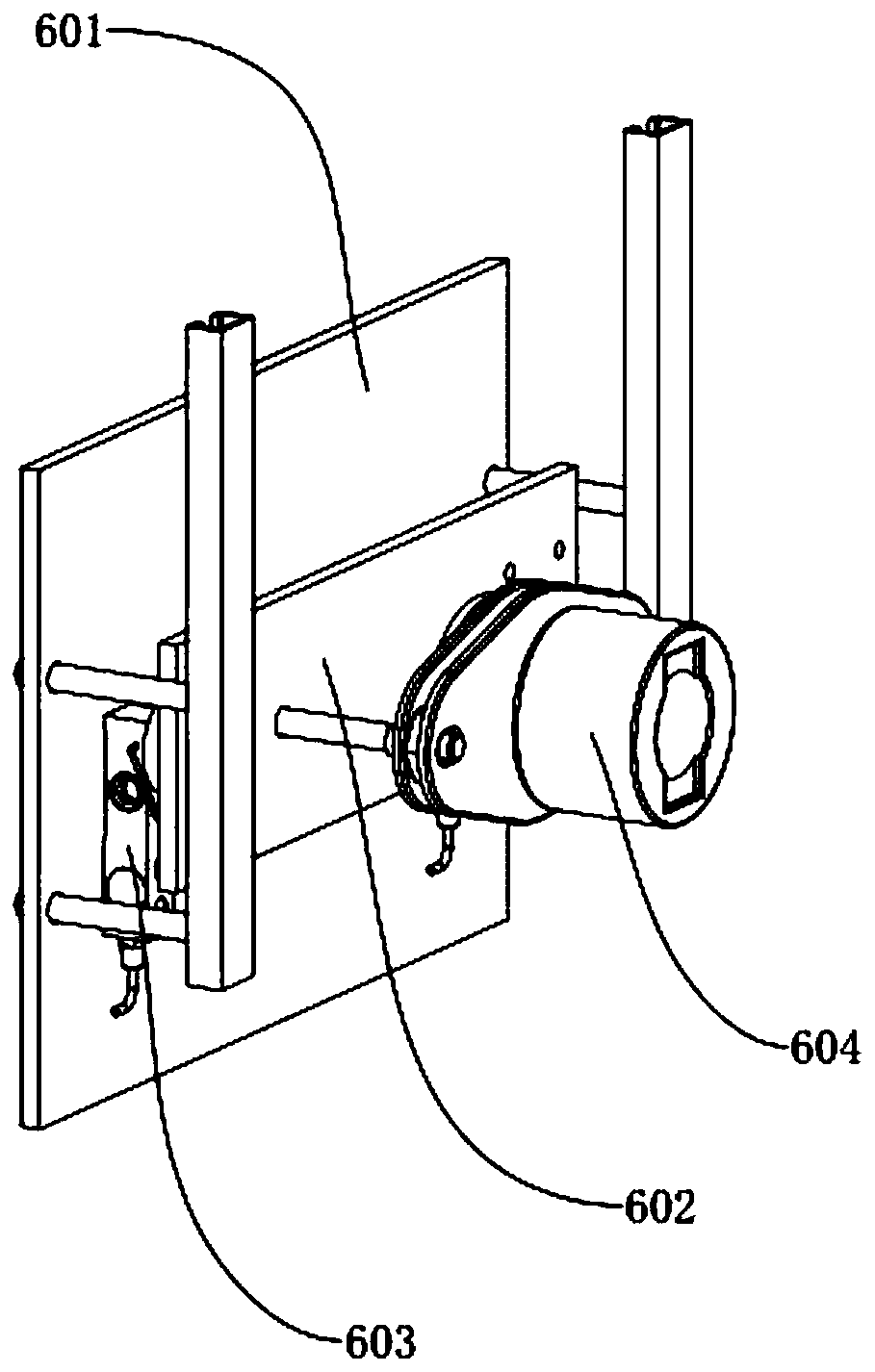

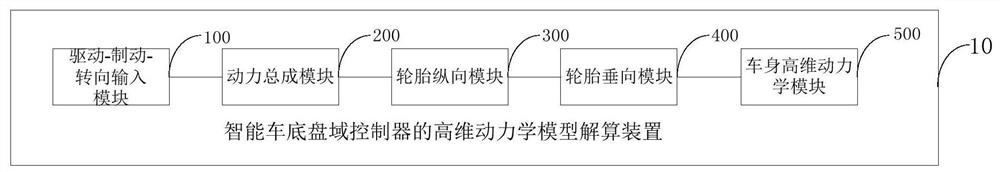

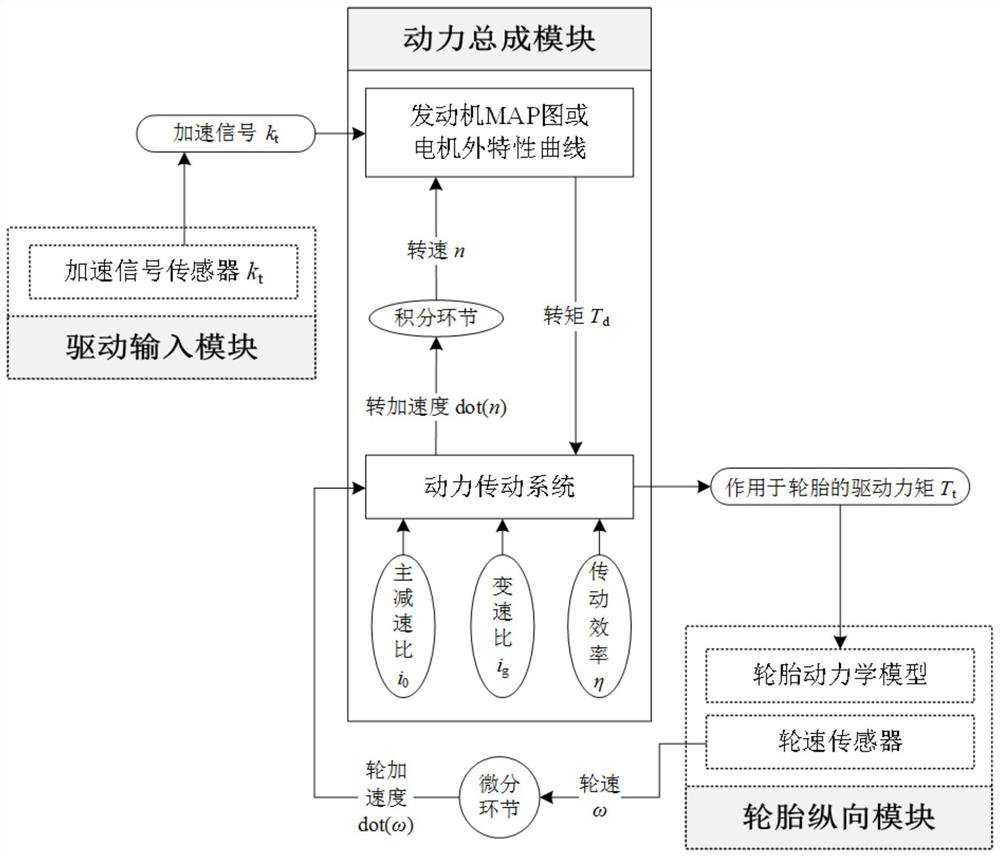

High-dimensional dynamic model resolving device and method of intelligent vehicle chassis domain controller

ActiveCN113359457AStrong real-time online solutionMovement state precisionAdaptive controlDrive wheelDynamic models

The invention discloses a high-dimensional dynamic model resolving device and method of an intelligent vehicle chassis domain controller. A driving-braking-steering input module obtains an acceleration signal instruction, a braking signal instruction and / or a steering signal instruction; a power assembly module determines an input parameter according to the obtained instruction, and obtains a driving torque acting on each driving wheel in combination with a wheel speed signal of the vehicle, a system parameter of a power transmission system, a wheel acceleration and a power output torque; a tire longitudinal and vertical module calculates tire longitudinal and vertical dynamic state parameters of each driving wheel according to the driving torque; and a vehicle body high-dimensional dynamics module obtains 15-degree-of-freedom vehicle real-time state parameters of the vehicle by using a high-dimensional model in the intelligent vehicle chassis domain controller and based on the longitudinal and vertical dynamics state parameters of tires of each driving wheel, and the 15-degree-of-freedom vehicle real-time state parameters are used for decision making and execution of a chassis domain controller coordination control module. The precision of the motion state of the whole intelligent vehicle, the digitalization of the drive-by-wire chassis and the collaboration of the intelligent driving domain and the chassis domain are realized.

Owner:TSINGHUA UNIV

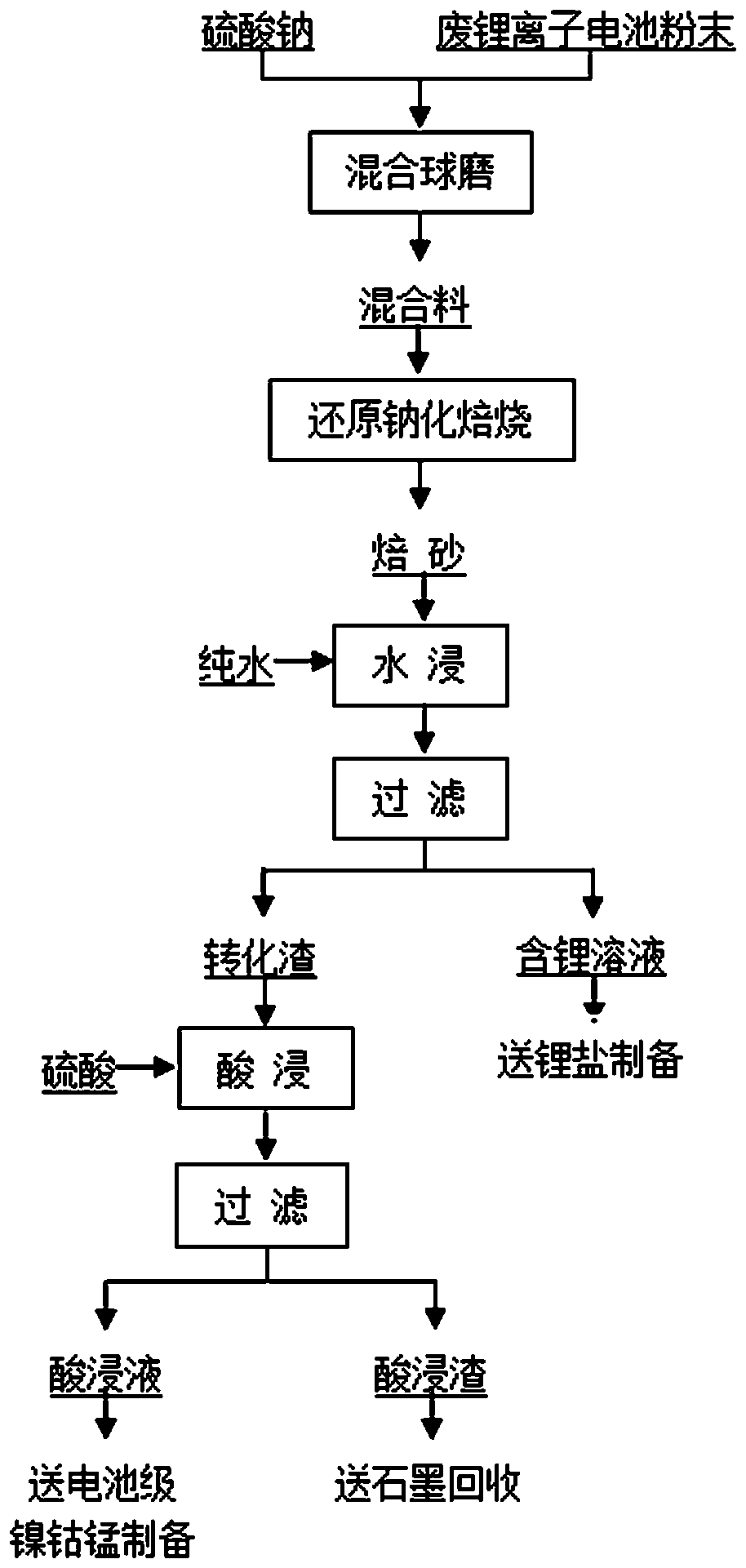

Method for selectively extracting valuable metals from waste lithium ion battery powder based on reduced sodium roasting phase conversion

InactiveCN111254276AEfficient and preferential extractionReduce the burden of cleaning and removing impuritiesWaste accumulators reclaimingProcess efficiency improvementElectrical batterySlag

The invention discloses a method for selectively extracting valuable metals from waste lithium ion battery powder based on reduced sodium roasting phase conversion. The method comprises the followingsteps: mixing waste lithium ion battery powder and sodium sulfate according to a preset molar ratio, and ball milling for a preset time to obtain a mixture; placing the mixture in an electric furnacefor reductive sodium roasting at a preset temperature, wherein an obtained reductive sodium roasting product is called calcine; leaching the calcine with pure water to obtain a lithium-containing leaching solution and conversion slag; and leaching the conversion slag by sulfuric acid to extract valuable metals such as nickel, cobalt, manganese and the like. The method is simple in flow, low in production cost and high in valuable metal recovery rate; according to the method, lithium is de-intercalated from the battery powder through reductive sodium roasting to form water-soluble lithium sulfate, and selective extraction of lithium can be realized by leaching with pure water; and meanwhile, valuable metal substances such as nickel, cobalt and manganese are converted into low-valence oxideswhich are likely to acid leaching, and favorable conditions are created for recovering nickel, cobalt and manganese through subsequent wet leaching.

Owner:CENT SOUTH UNIV

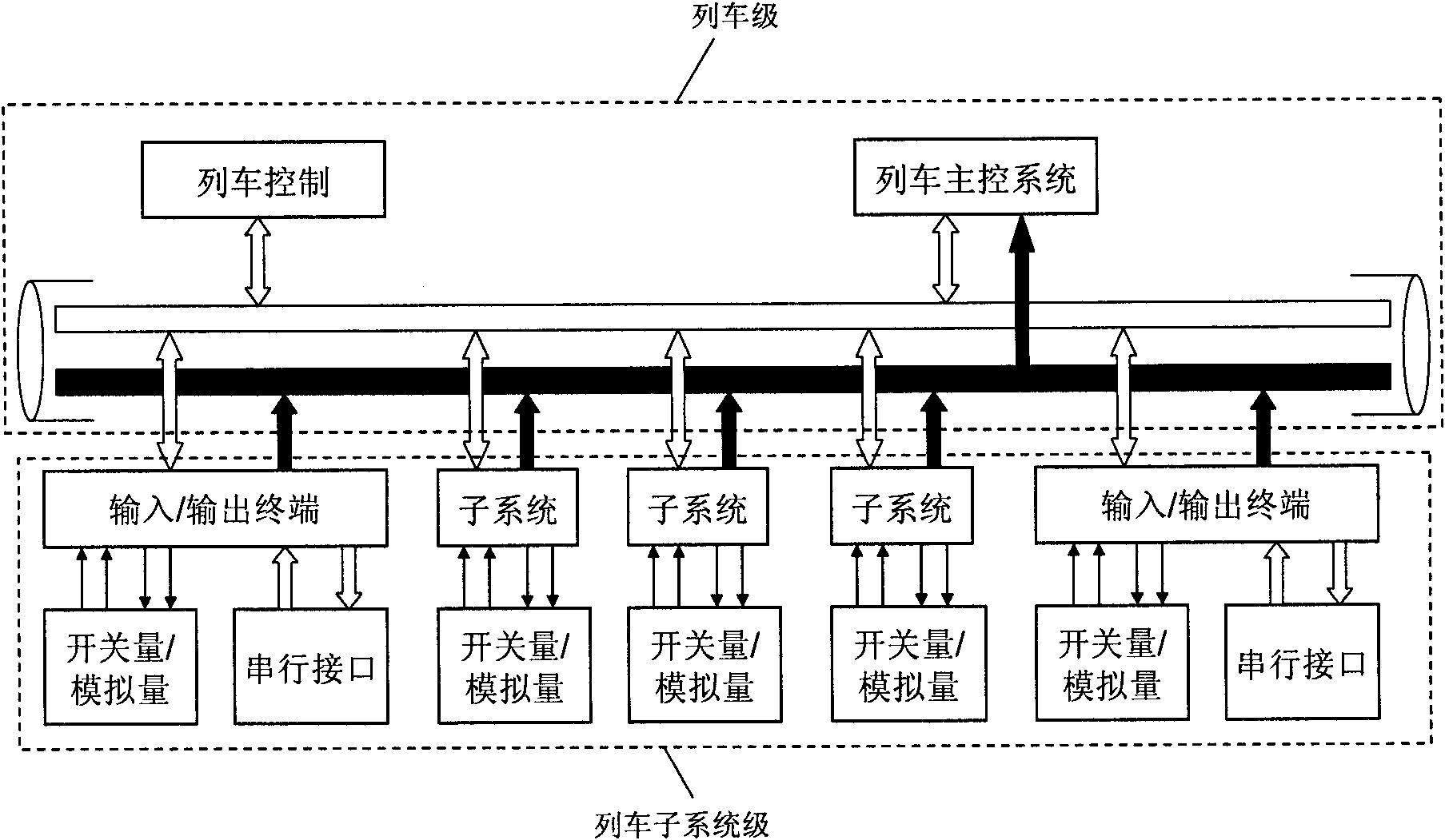

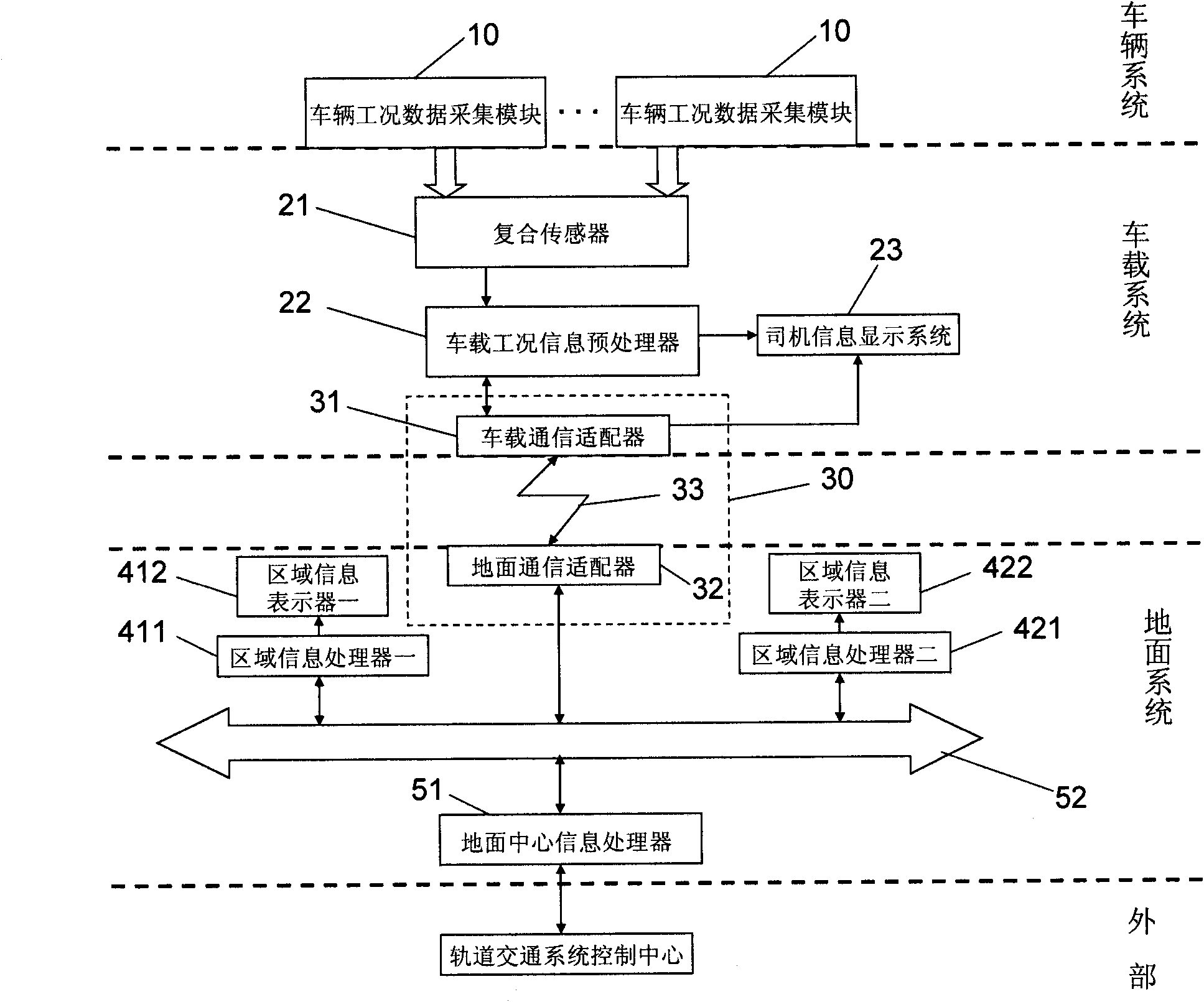

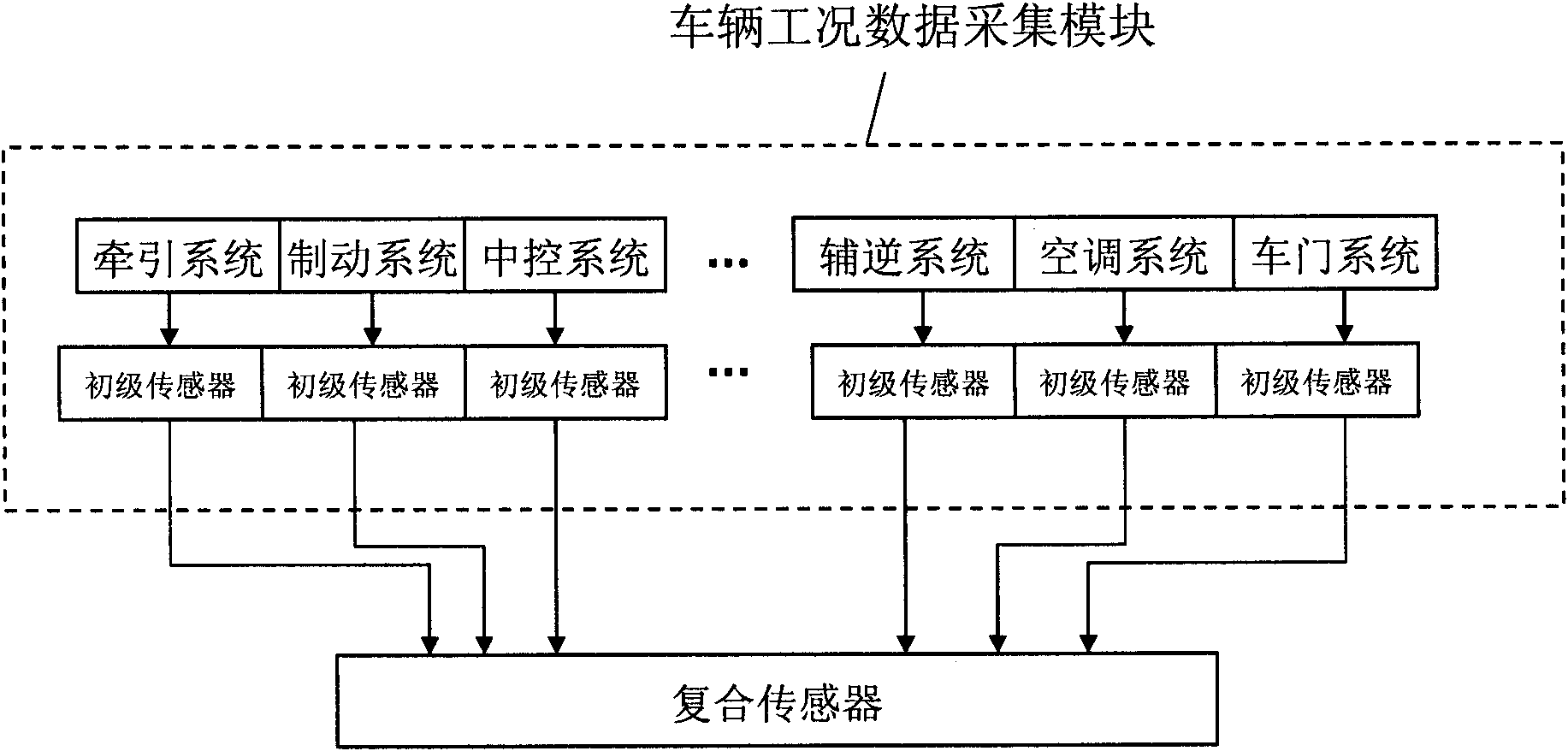

Vehicle working condition online monitoring system for rail transit

InactiveCN102139700BImprove reliabilityImprove securityRailway traffic control systemsLocomotivesInformation display systemsData acquisition

Owner:TONGJI UNIV

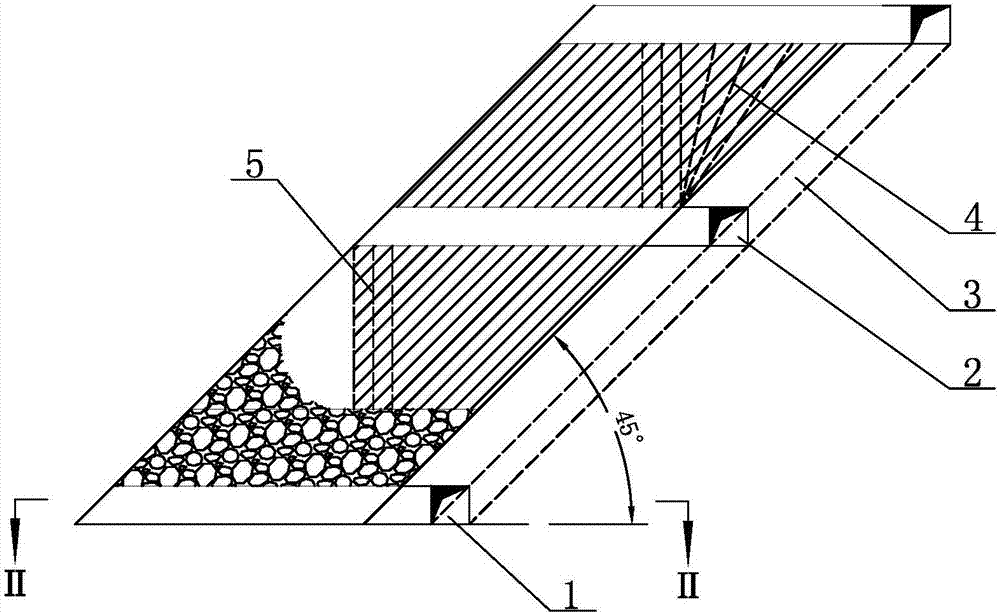

Collaborative mining method of rock-drilling stage and filling after inclined medium-thick ore body

ActiveCN106223958BReduce the amount of mining and cuttingLower filling costsUnderground miningSurface miningMineralogyCave

The invention belongs to the mining field and particularly relates to an ore-blast backfill synergetic mining method for a partitioned rock drilling stage of an inclined medium-thick ore body. According to the mining method, the partitioned rock drilling of fan-shaped blast holes of a trench ore section, annular blast holes of a non-triangular jamb and beam-shaped blast holes of triangular jamb in a rock drilling cave is realized based on different ore bodies and rock drilling conditions, the problem of blasting of a hanging side triangular jamb is solved, and the blasting effect of the annular blast holes in the rock drilling cave is improved; by comprehensively utilizing the dead load and the blasting-power handling of the ore body, the concentrated ore gathering of ores in ore gathering tunnels of trenches of different partitioned mining sections and the concentrated ore removal of ore removal lands and ore removal approach roads in the stage are realized, and the centralized working scale and efficiency of mining are improved; and by virtue of interval recovery, subsequent cementing and non-cementing synergetic backfilling on ore chambers and jambs, the continuity of the mining process among different mining sections is realized, and an efficient, safe and low-cost continuous mining method is provided for the inclined medium-thick ore bodies with medium stability and higher stability.

Owner:SHANDONG HUALIAN MINING +1

Percutaneous-absorption-promoting propranolol composite phospholipid transfersome, and prepartion method and application thereof

InactiveCN102846546BPromote percutaneous absorptionImprove stabilityOrganic active ingredientsPharmaceutical non-active ingredientsSide effectPhospholipid

The invention provides a composite phospholipid transfersome which promotes propranolol percutaneous absorption, and a preparation method thereof. According to the invention, two phospholipid materials with different phase-change temperatures, which are dipalmitoyl phosphatidyl choline and soybean lecithin, are adopted as a composite phospholipid material. Compared with a transfersome with a single phospholipid material in prior art, the propranolol composite phospholipid transfersome prepared with the phospholipid material provided by the invention has substantially improved encapsulation efficiency, reduced leakage, improved stability in rat plasma, and substantially improved bioavailability after percutaneous administration. The propranolol composite phospholipid transfersome provided by the invention is especially suitable to be used for treating infantile hemangioma. With the transfersome, propranolol percutaneous administration can be realized, and propranolol can directly act upon a hemangioma affected part. The treatment effect is improved, toxic and side effects are reduced, and children medication compliance can be improved. Also, the invention provides a preparation method of the propranolol composite phospholipid transfersome.

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

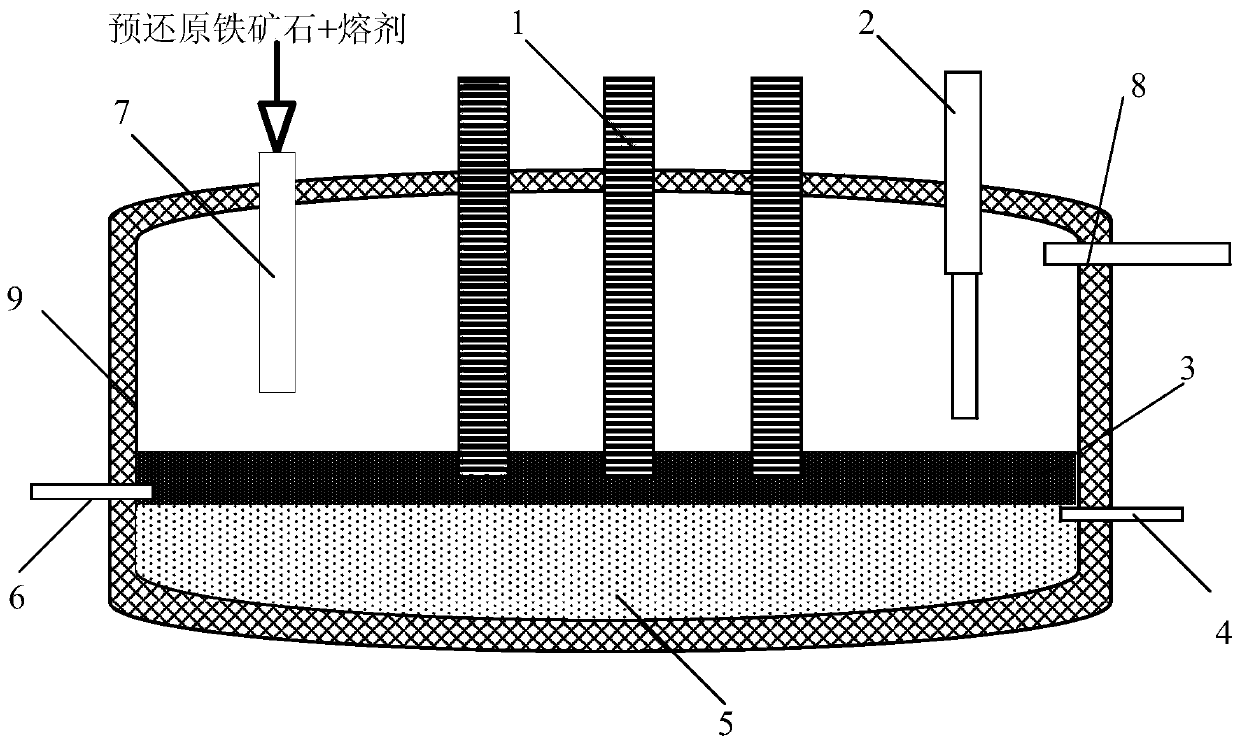

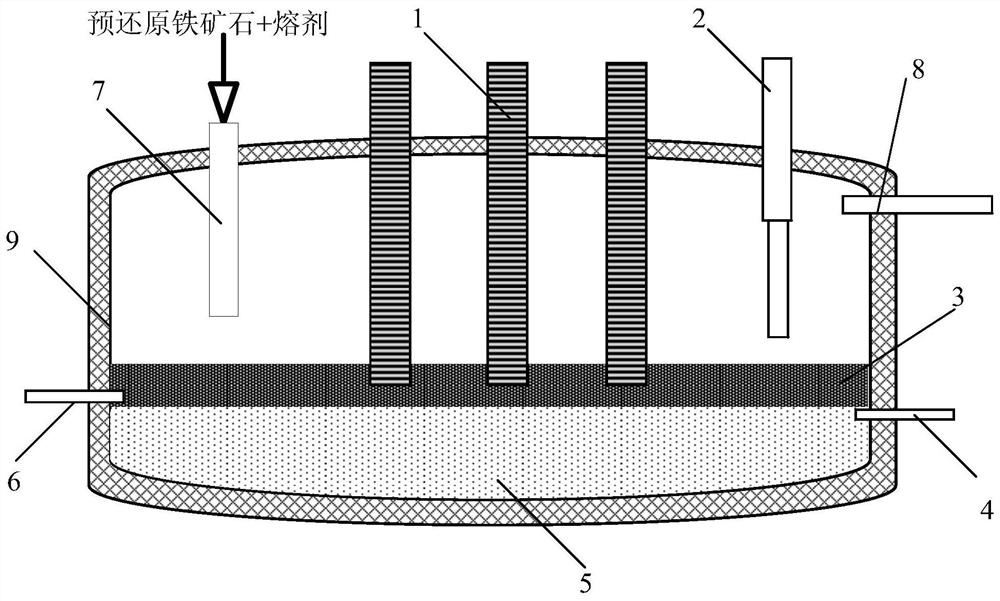

Device and method for producing molten iron by high-temperature smelting of pre-reduced iron ore

The device and method for producing a molten iron by high-temperature smelting of a pre-reduced iron ore. The device for producing the molten iron by high-temperature smelting of the pre-reduced ironore comprises a furnace body, an electrode and a coal-fired spray gun, and a raw material conveying pipeline is inserted into the furnace body; an upper-layer space is provided with a high-temperatureflue gas outlet, an electrode and a coal-fired spray gun, the bottom end of the electrode is located in a slag layer area, a slag discharging port is located in the slag layer space, and a molten iron outlet is in communication with a molten iron layer area; the method for producing the molten iron by high-temperature smelting of the pre-reduced iron ore comprises the following steps that (1) thepre-reduced iron ore and a fusing agent is mixed into a device, (2) a power supply is started, the coal powder is injected, the iron ore is pre-reduced and the fusing agent is molten to form a melt;(3) the iron oxide reacts with the coal powder to generate molten iron and furnace slag, and the electric arc generated through the molten iron to further heat the molten iron; and (4) the temperaturein the smelting process is 1350-1550 DEG C, the slag discharging opening is started to discharge the slag, and then the molten iron outlet is started to discharge the molten iron. According to the device and method for producing the molten iron by high-temperature smelting of the pre-reduced iron ore, the energy consumption is cooperatively utilized, the energy consumption loss is greatly reduced, and the energy utilization efficiency is improved.

Owner:NORTHEASTERN UNIV

Method and device for quickly inputting communication information in a terminal

ActiveCN103235677BRealize synergyImprove input efficiencySubstation equipmentInput/output processes for data processingComputer terminalComputer science

The invention discloses a method and a device for quickly inputting communication information in a terminal. The method comprises the steps as follows: obtaining attributes of a communication information input field on a display interface in current application program; calling communication information matched with the communication information input field in each application program of the terminal according to the obtained attributes; displaying; receiving a selection instruction of a user to the communication information; and filling the communication information input field with the communication information selected by the user. Through the technical scheme, the technical problem that the conventional scheme is not perfect is solved.

Owner:DONGGUAN YULONG COMM TECH +1

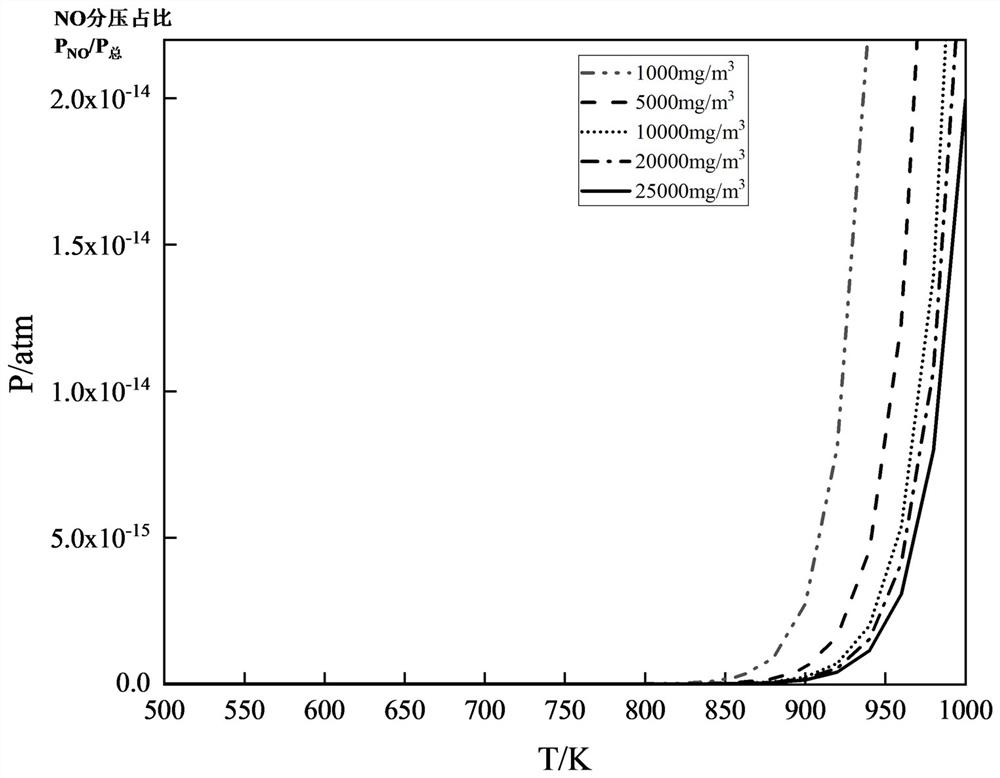

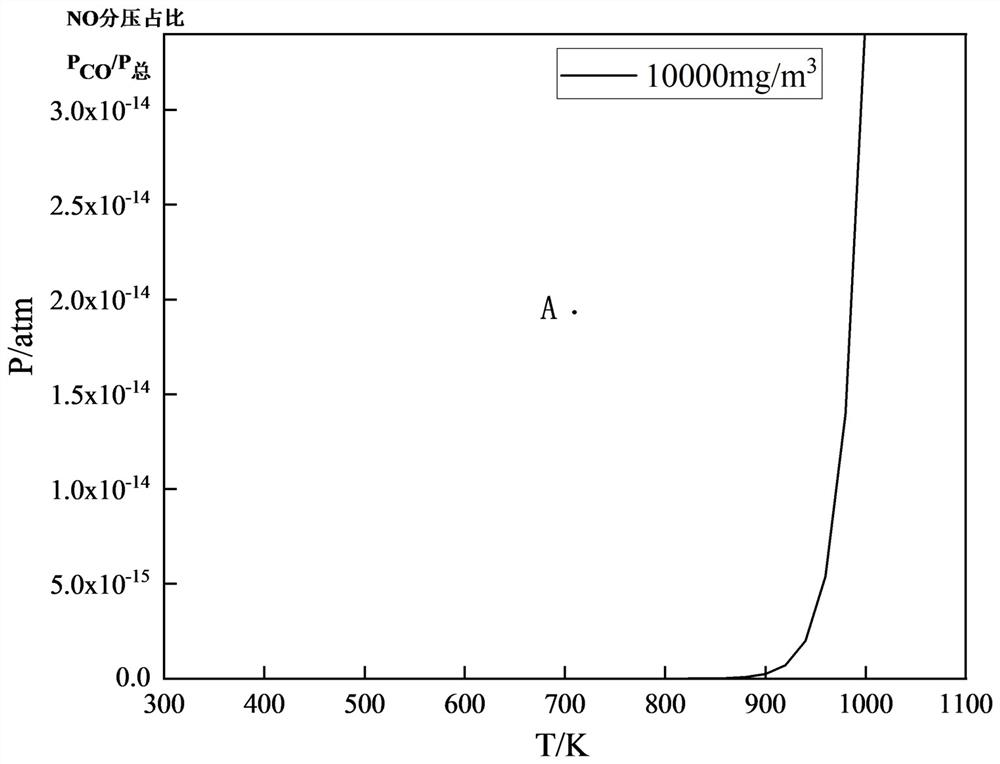

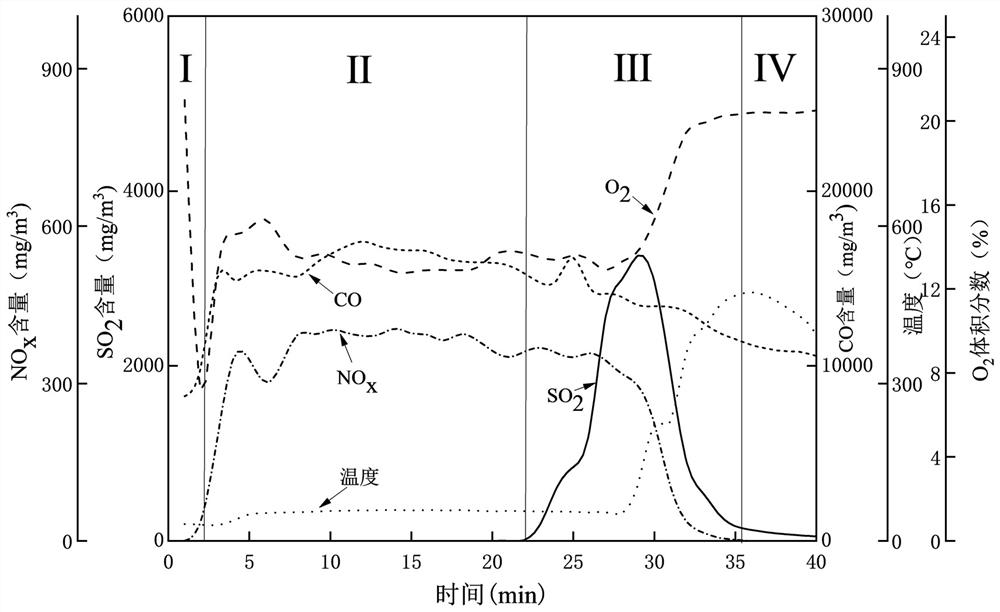

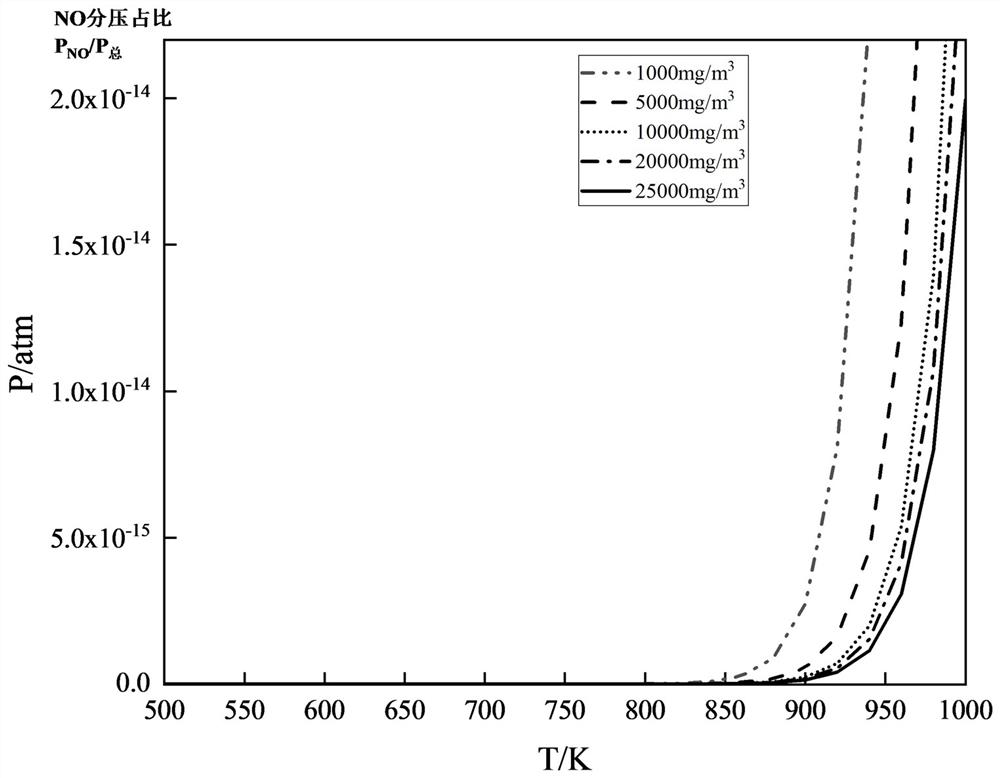

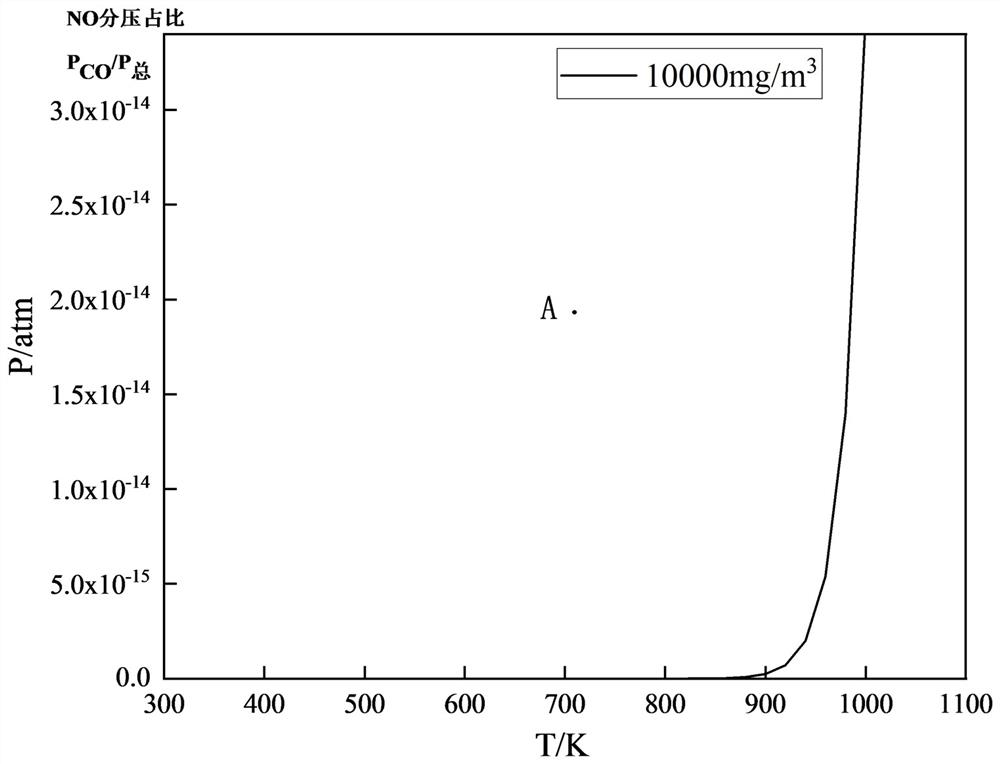

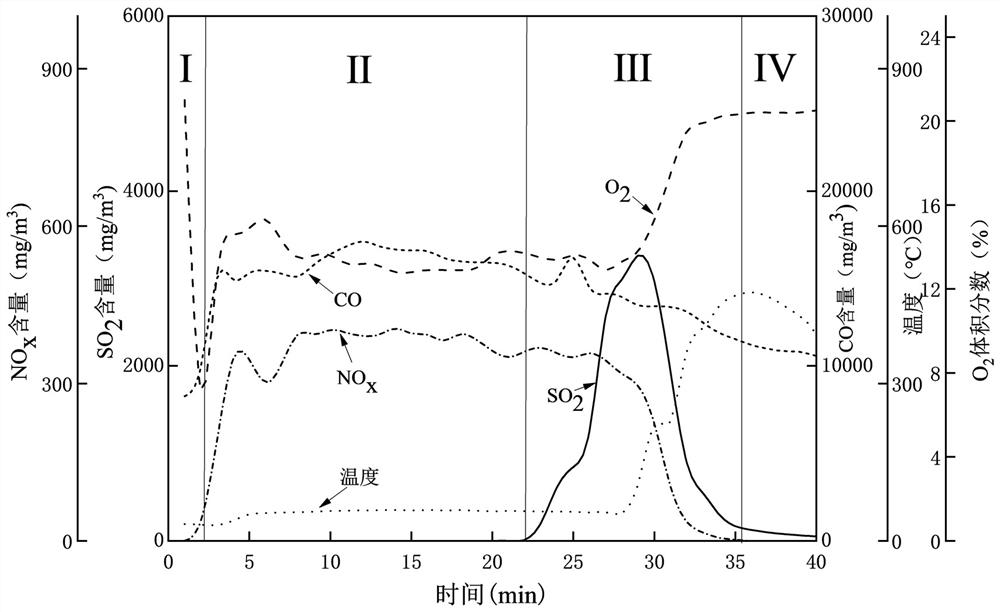

Method for denitration in sintering process by using multiple flue gases

ActiveCN114485196AImprove denitrification efficiencyEfficient emission reductionWaste heat treatmentThermodynamicsFlue gas

The invention discloses a method for denitration in a sintering process by using various flue gases. The method comprises the following steps: carrying out component analysis on flue gases of different furnaces and kilns; assembling and mixing the flue gas in a gas holder, monitoring the components and the temperature of the flue gas at an outlet of the gas holder in real time, adjusting a flue gas assembling scheme, determining that the components CO and the temperature of the assembled flue gas meet the requirements, and enabling the assembled flue gas to pass through a sintering pallet in production; after flue gas in the first middle stage of sintering production comes out of an ore deposit, the flue gas is led to a sinter circular cooler for NO removal, and the flue gas with NO removed is subjected to waste heat recovery to form external circulation; and flue gas in the later stage of sintering production is used as sintering circulating flue gas to return to the gas holder and is subjected to flue gas assembly together with industrial flue gas to form internal circulation. The effect of treating waste with waste is obvious, and a new thought is provided for efficient emission reduction of NOx in the sintering process.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A device and method for producing molten iron by high-temperature smelting of pre-reduced iron ore

A device and method for producing molten iron through high-temperature smelting of pre-reduced iron ore. The device includes a furnace body, an electrode and a coal-fired spray gun. A raw material transport pipe is inserted into the furnace body; the upper space is provided with a high-temperature flue gas outlet, an electrode and a coal-fired spray gun. The bottom end of the electrode is located in the slag layer area, the slag discharge port is located in the slag layer space, and the molten iron outlet is connected to the molten iron layer area; the method is: (1) Mix and transport the pre-reduced iron ore and flux to the device, (2) Turn on the power And spray pulverized coal, pre-reduced iron ore and flux are melted to form a melt; (3) Iron oxide reacts with pulverized coal to generate molten iron and slag, and an electric arc is generated through the molten iron to further heat the molten iron; (4) The temperature during smelting is 1350 ~1550℃, after the end, open the slag discharge port to discharge the slag, and then open the molten iron outlet to discharge the molten iron. The method of the present invention realizes the coordinated utilization of energy consumption, greatly reduces the loss of energy consumption, and improves the energy utilization efficiency.

Owner:NORTHEASTERN UNIV LIAONING

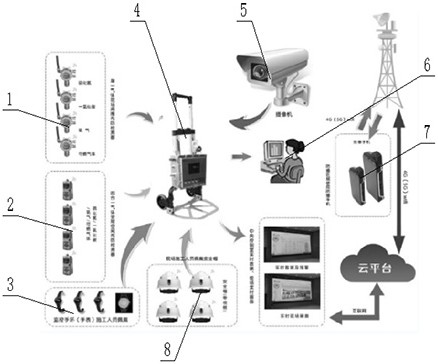

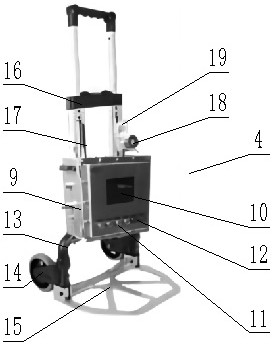

Intelligent special operation protection monitoring alarm system

PendingCN114821959AAchieve interactionRealize visualizationStands/trestlesAlarmsSite monitoringGas detector

The invention discloses an intelligent special operation protection monitoring alarm system, all devices are explosion-proof, wireless, mobile and self-powered, and the intelligent special operation protection monitoring alarm system comprises a management platform, a camera, a plurality of single gas detectors, a portable gas detector, an intelligent bracelet, a safety helmet, a mobile phone, a mobile monitoring terminal and a router. A plurality of single gas detectors, portable gas detectors and cameras are arranged in a field special operation or fire construction area (in a shielded and sealed space dangerous area), and a mobile monitoring terminal and a router are arranged in a monitoring area. Three-dimensional integration of an on-site monitoring area, a mobile phone APP and a central monitoring terminal and alarm, display and storage of intelligent videos and data are achieved, the data are transmitted to the central monitoring terminal and an intelligent mobile phone terminal through a mobile monitoring terminal, and therefore visualization, digitization and collaboration of special operation on-site operation management are achieved. Normative, efficient and safe operation and personnel life protection are ensured.

Owner:江苏红光仪表厂有限公司

A kind of method that utilizes aluminum ash and carbide slag to prepare calcium aluminate

ActiveCN110028092BSolve the problem of safe disposal and resource utilizationRealize synergyCalcium aluminatesSteelmakingCompression molding

The invention discloses a method for preparing calcium aluminate by utilizing aluminum ash and acetylene sludge. The method comprises the following steps: performing catalytic hydrolysis, acidolysis and washing on aluminum ash so as to prepare high-purity aluminum ash powder; performing ball-mill mixing on the high-purity aluminum ash powder and acetylene sludge, performing compression molding onthe mixed powder, and sintering in a sintering furnace to prepare an active calcium aluminate bulk material; crushing and performing ball milling, thereby obtaining the high-activity calcium aluminaterefining agent. The calcium aluminate refining agent prepared by the method disclosed by the invention is excellent in property, and standard requirements of calcium aluminate YB / T4265-2011 for a steel-making slag remover are met. The method disclosed by the invention solves the pollution problems of the aluminum ash and acetylene sludge hazardous / solid wastes to the environment, realizes resource utilization, and has excellent environmental, economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

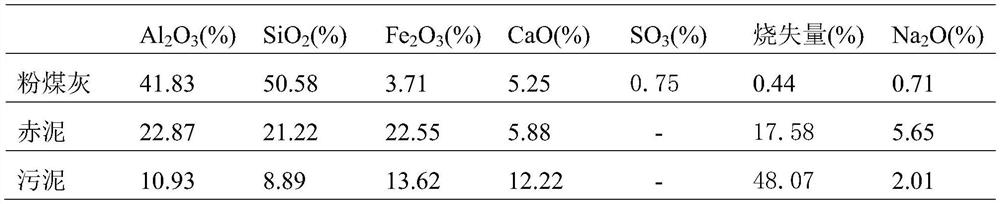

Method for preparing ceramsite filter material by synergistically utilizing solid waste

PendingCN114751722AImprove the utilization rate of solid waste resourcesHigh strengthFiltration separationClaywaresCorrosionWater treatment

The invention discloses a method for preparing a ceramsite filter material by synergistically utilizing solid wastes, and solves the technical problems that in the prior art, the doping amount of the solid wastes is small, and high-alumina fly ash is not adopted for preparing a high-performance ceramsite filter material. The method comprises the following treatment steps: S1, raw material pretreatment: taking high-alumina fly ash, red mud and sludge as raw materials for preparing the ceramsite filter material, airing the red mud and the sludge, and grinding to obtain red mud and sludge powder; s2, proportioning 65%-80% of high-alumina fly ash, 5%-25% of red mud and 5%-20% of sludge, and uniformly stirring the prepared mixture in a mixer; and S3, spraying water and granulating to prepare the ceramsite filter material raw material balls. The prepared filter material is high in strength, high in void ratio, large in specific surface area, high in acid and alkali corrosion resistance, basically insoluble in acid and alkali solutions and reusable, all indexes such as the mud content of the filter material meet the standard requirements of CJ / T299-2008 Artificial Ceramsite Filter Material for Water Treatment, and the filter material is a high-quality filter material product.

Owner:DATANG TONGZHOU TECH

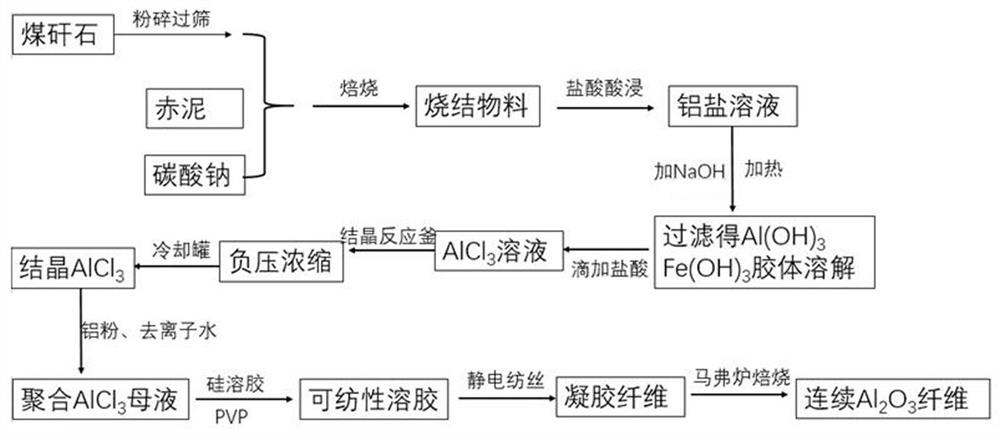

A method for preparing continuous alumina fiber from coal gangue

ActiveCN108866678BHigh extraction rateImprove heat stabilityInorganic material artificial filamentsChemical industryAluminium chlorideChemical industry

Owner:山西载驰科技有限公司

A method for denitrification in sintering process using various flue gases

ActiveCN114485196BImprove denitrification efficiencyEfficient emission reductionWaste heat treatmentFlue gasProcess engineering

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

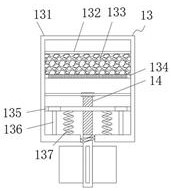

An alarm device for intelligent fire extinguishing equipment

ActiveCN113577619BEfficient storageLarge specific heat capacityFire rescueFire alarm smoke/gas actuationEnvironmental engineeringAlarm device

The invention discloses an alarm device for intelligent fire extinguishing equipment, which belongs to the technical field of alarm devices and comprises an alarm box and a box door. The interior of the alarm box is fixedly installed with a box control panel, and the side wall of the alarm box is fixedly equipped with a moisture collection mechanism; the present invention can realize automatic moisture collection by setting a moisture collection mechanism on the outside Function, the collected water will be effectively stored, through the design of the physical structure, through the use of physical phenomena during the operation and shutdown of the device, it can realize automatic water collection for secondary use, powerful functions, and a dredging and cleaning component for the water collection tank It can effectively cooperate with the moisture collection mechanism to realize the automatic cleaning process of the smoke sensor and temperature sensor on a regular basis, without manual management, and maintain the use effect of the smoke sensor and temperature sensor.

Owner:南通市大安消防技术服务有限公司

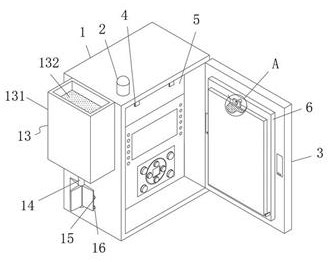

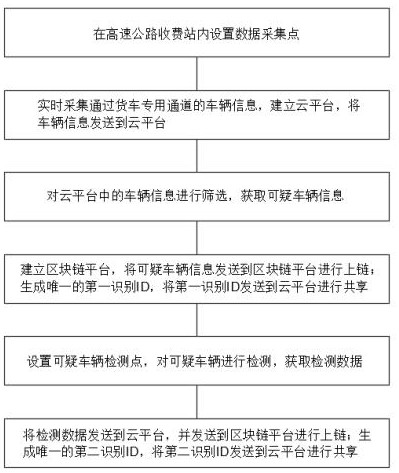

Application method of cloud technology in overload control system

ActiveCN114360258AAvoid cloggingAvoid synergiesRoad vehicles traffic controlCharacter and pattern recognitionOverload controlVehicle detection

The invention discloses an application method of a cloud technology in an overload control system, and belongs to the technical field of overload control, and the method specifically comprises the steps: 1, setting a data collection point in a highway toll station; 2, collecting information of vehicles passing through the special truck channel in real time, establishing a cloud platform, and sending the information of the vehicles to the cloud platform; 3, screening the vehicle information in the cloud platform to obtain suspicious vehicle information; 4, establishing a block chain platform, and sending the suspicious vehicle information to the block chain platform for uplink; generating a unique first identification ID, and sending the first identification ID to a cloud platform for sharing; 5, setting a suspicious vehicle detection point, detecting a suspicious vehicle, and obtaining detection data; 6, sending the detection data to a cloud platform, and sending the detection data to a block chain platform for uplink; and generating a unique second identification ID, and sending the second identification ID to the cloud platform for sharing.

Owner:GUANGDONG TELECOM ENG

A preparation method of needle-punched regenerated leather for automotive interior skin

ActiveCN107574677BEfficient use ofImprove product added valueFilament/thread formingTextile/flexible product manufactureFiberNeedle penetration

The invention provides a preparation method for needle-punched regenerated leather used as surface leather for automobile interior. The preparation method comprises the following concrete steps: (1) opening and mixing of fibers; (2) net formation; (3) net laying; (4) reinforcing through needle-punching; (5) drying and shaping; and (6) vacuum forming. In the beginning of the design of the needle-punched regenerated leather, requirements of the automobile interior surface leather on the molding performance and mechanical properties of materials and industrial standards are taken into consideration, and raw material proportioning and production process are reasonably optimized, so cooperation among the designing, preparation and molding of a composite material is realized. Compared with traditional polyvinyl chloride and polyurethane automobile interior surface leather, the automobile interior surface leather prepared in the invention has the advantages of environmental protection, no odor, excellent elasticity, moderate strength, comfortable handle, high cost performance, etc., and is suitable for large-scale industrial production.

Owner:SHANDONG UNIV

A kind of preparation method of spunlaced regenerated leather for automobile interior skin

ActiveCN105970657BImprove product added valueMany categoriesNon-woven fabricsFiberPolyvinyl chloride

The invention provides a preparation method of spun-laced regenerated leather for an automotive interior surface. The preparation method comprises the following specific steps: (1) loosening and mixing fibers; (2) forming a net; (3) spreading the net; (4) pre-wetting; (5) spun-lacing; (6) drying; (7) carrying out vacuum plastic-absorption and molding. The requirements on material molding properties and mechanical properties by the automotive interior surface and industrial standards are sufficiently considered at the beginning of designing, and raw material ratios and a production process are reasonably optimized, so that collaboration of design, preparation and molding machining of a composite material is realized. Compared with traditional automotive interior surfaces including polyvinyl chloride, polyurethane and the like, the prepared automotive interior surface has the advantages of greenness and environmental friendliness, no odor, excellent elasticity, moderate strength, comfortable hand feeling, high cost performance and the like and is suitable for large-scale industrial production.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com