Dealkalization method of fly ash Al-extraction residues

A technology for extracting aluminum from fly ash and extracting aluminum residues is applied in sustainable waste treatment, solid waste management, cement production, etc. The effect of synergistic utilization and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

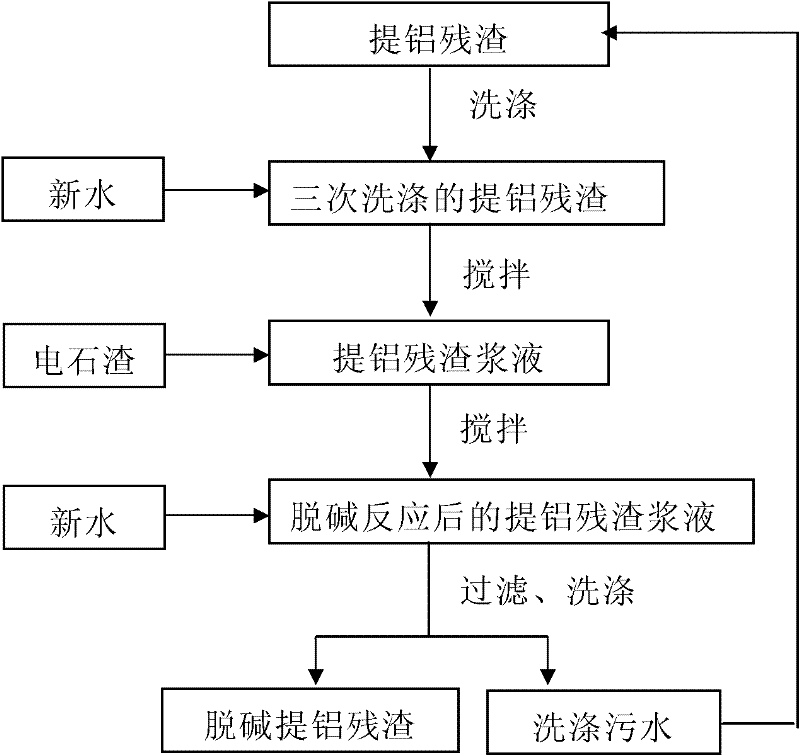

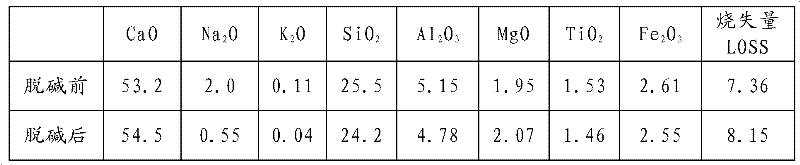

[0026] figure 1 It is a flow chart of the dealkalization method for the aluminum extraction residue from fly ash provided in Example 1 of the present invention. As shown in the figure, the step of the dealkalization method of the fly ash aluminum extraction residue is: first, the aluminum extraction residue (wherein the mass percentage content of sodium oxide is 2.0%, and the mass percentage content of water is 35%) through three times of washing is extracted. The main phase in the aluminum residue is C2S (dicalcium silicate), which accounts for 70-80% of the entire aluminum extraction residue. Scanning electron microscopy studies have shown that most of the non-free Na in the aluminum extraction residue 2 O to Na 2 O CaO SiO 3 (Basic calcium silicate) in the form of occurrence, which is the difference in the occurrence of alkali metal elements in aluminum extraction residues and red mud. In addition, it contains 5-10% 3CaO·Al 2 o 3 ·6H 2 O nSiO 2 (Garnet Hydrate), 1-2%...

Embodiment 2

[0031] The steps of the dealkalization method of the fly ash aluminum extraction residue provided by embodiment two are: first, the aluminum extraction residue (wherein the mass percentage content of sodium oxide is 1.4%, water The mass percentage content is 45%), and new water is added according to the mass ratio of water to aluminum extraction residue on a dry basis of 1.5, and the mixture is evenly stirred to obtain an aluminum extraction residue slurry. Then, under the condition of stirring, slowly add calcium carbide slag to the aluminum extraction residue slurry to carry out dealkalization reaction. Calculated on the dry basis of the aluminum extraction residue, the mass ratio of the dry basis of the aluminum extraction residue to the calcium carbide slag is 12:1, and the reaction temperature is 85°C. , The reaction time is 0.5h. Finally, filter the aluminum extraction residue slurry after the above dealkalization reaction, and wash once with new water to obtain the deal...

Embodiment 3

[0036] The steps of the dealkalization method of the fly ash aluminum extraction residue provided in Example 3 are as follows: first, the aluminum extraction residue of the fly ash soda-lime sintering method washed three times (wherein the mass percentage content of sodium oxide is 1.73%), according to The mass ratio of the water to the aluminum extraction residue on a dry basis is 2.0, adding fresh water and stirring evenly to prepare the aluminum extraction residue slurry. Then, under the condition of stirring, slowly add calcium carbide slag to the aluminum extraction residue slurry to carry out dealkalization reaction. Calculated on the dry basis of the aluminum extraction residue, the mass ratio of the dry basis of the aluminum extraction residue to the calcium carbide slag is 10:1, and the reaction temperature is 90°C. , The reaction time is 0.5h. Finally, filter the aluminum extraction residue slurry after the above dealkalization reaction, and wash once with new water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com