A device and method for producing molten iron by high-temperature smelting of pre-reduced iron ore

A high-temperature smelting and iron ore technology, applied in the field of metallurgy, can solve the problems of large coal consumption in smelting reduction furnaces, reduce pollutant emissions, reduce the use of coking coal, etc., and achieve the effects of reducing energy consumption loss and improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

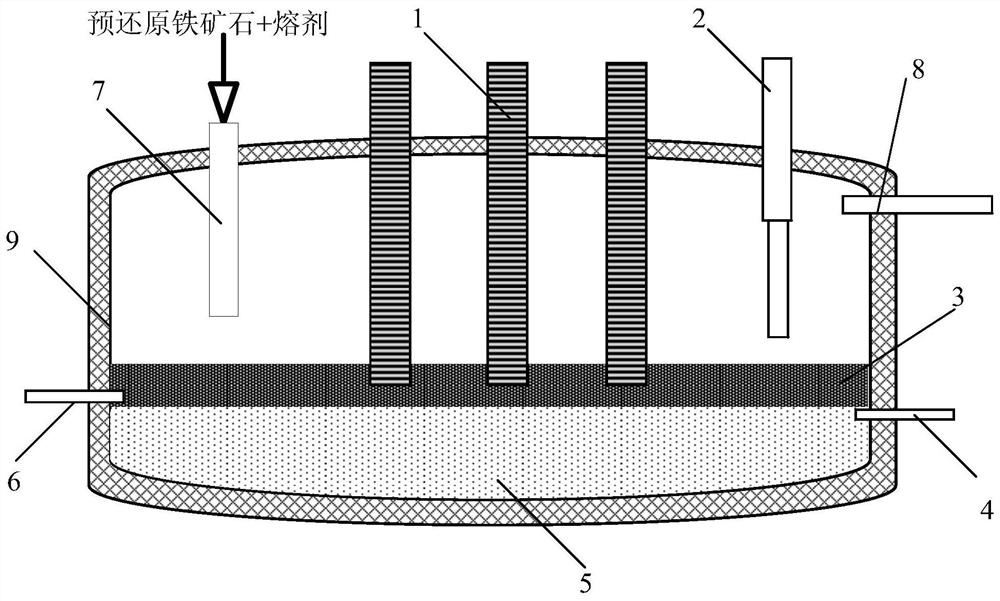

[0025] The structure of the device for producing molten iron by high-temperature smelting of pre-reduced iron ore is as follows: figure 1 As shown, it includes a furnace body 9, an electrode 1 and a coal-fired spray gun 2; the raw material delivery pipeline 7 is inserted into the furnace body; High-temperature flue gas outlet 8, electrode 1 and coal-fired spray gun 2, the bottom of electrode 1 is located in the slag layer area, the outlet of coal-fired spray gun 2 and the outlet of raw material delivery pipeline 7 are located in the upper space, and the slag discharge port 6 is located in the slag layer space Inside, the molten iron outlet 4 communicates with the molten iron layer area;

[0026] The pellets of a certain pre-reduced iron ore contain TFe 55.62%, MFe 38.93%, SiO by weight percentage 2 3.01%, Al 2 o 3 7.28%, CaO 0.10%, MgO 10.2%, P 0.08%, S 0.03%, particle size ≤12mm;

[0027] The reducing agent pulverized coal used contains 60% of fixed carbon by weight perc...

Embodiment 2

[0034] A pellet of pre-reduced powdered iron ore, containing TFe 57.73%, MFe 46.18%, SiO 2 7.55%, Al 2 o 3 3.42%, CaO 1.32%, MgO 2.36%, P 0.09%, S 0.04%, particle size ≤12mm;

[0035] The reducing agent pulverized coal contains 78% of fixed carbon by weight percentage, and the part with a particle size of -0.074mm accounts for 40% of the total weight;

[0036] Device structure is with embodiment 1; Method is with embodiment 1, and difference is:

[0037] (1) The add-on of flux is 1.80 by the alkalinity after pre-reduced iron ore and flux are mixed;

[0038] (2) The amount of pulverized coal injection is based on coal ratio = 200kg / t;

[0039] (3) The time for controlling the pre-reduced iron ore from entering the device to melting is 1.5h, and the temperature in the device is 1550°C;

[0040] The obtained molten iron contains Fe 93%, C 4.2%, P 0.03%, S 0.01%, Si 0.4%, Al 0.04% by mass percentage.

Embodiment 3

[0042] Pellets using a pre-reduced powdered iron ore, containing TFe 62.83%, MFe 50.55%, SiO 2 3.53%, Al 2 o 3 7.81%, CaO 0.10%, MgO 1.22%, P 0.09%, S 0.04%

[0043] The reducing agent coal powder used contains 63% of fixed carbon by weight percentage, and the particle size -0.074mm accounts for 60%;

[0044] Device structure is with embodiment 1; Method is with embodiment 1, and difference is:

[0045] (1) The add-on of flux is 2.30 by the alkalinity after pre-reduced iron ore and flux are mixed;

[0046] (2) The amount of pulverized coal injected is based on the coal ratio = 300kg / t;

[0047] (3) The time for controlling the pre-reduced iron ore from entering the device to melting is 2h, and the temperature in the device is 1400°C;

[0048] The obtained molten iron contains Fe 96%, C 3.5%, P 0.04%, S 0.01%, Si 0.3%, Al 0.03% by mass percentage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com