Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Realize energy cascade utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

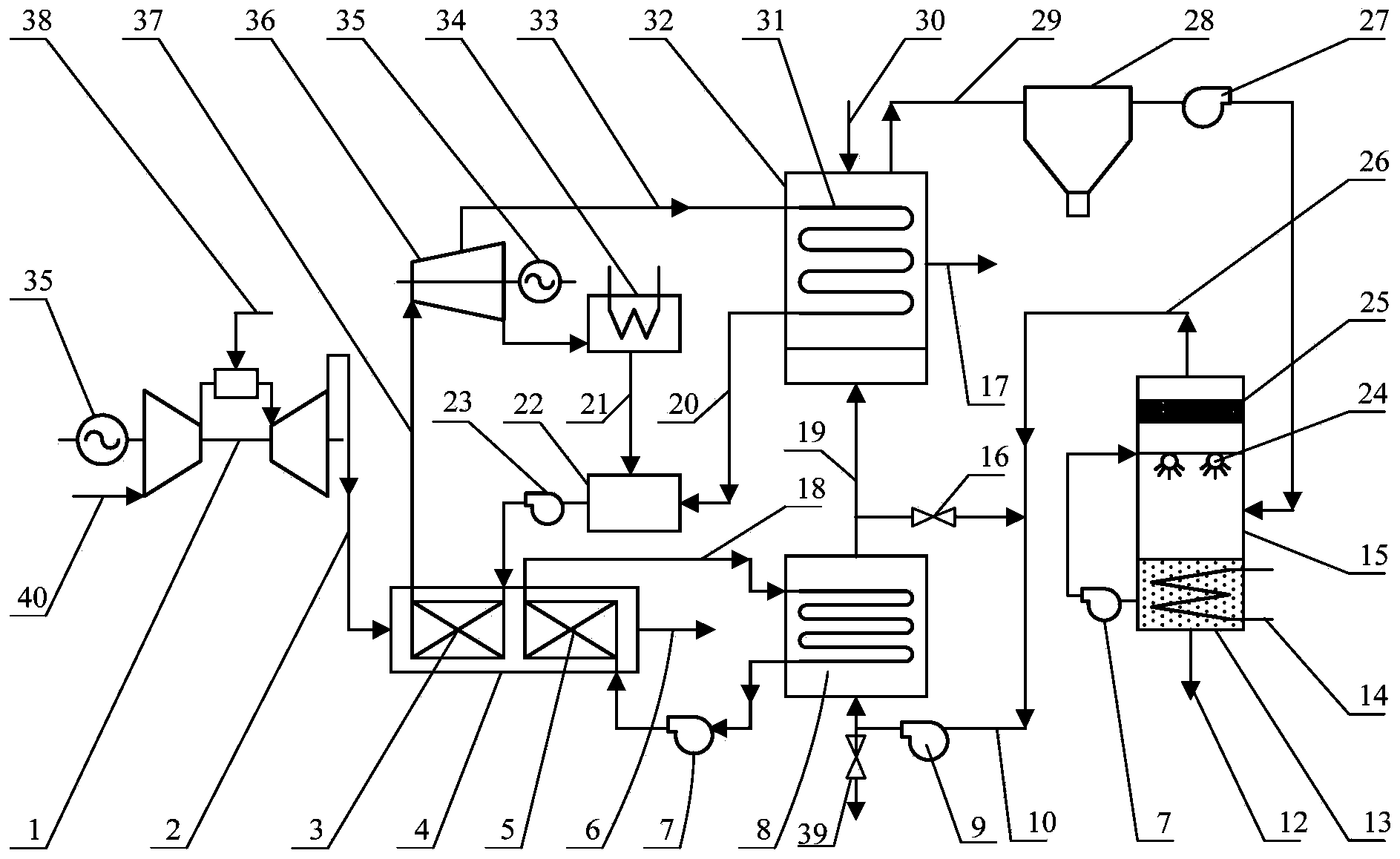

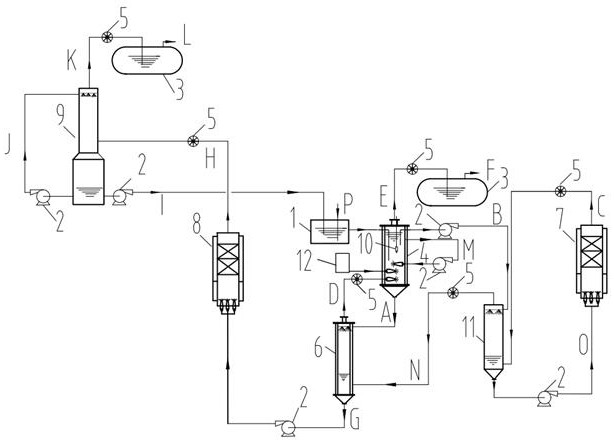

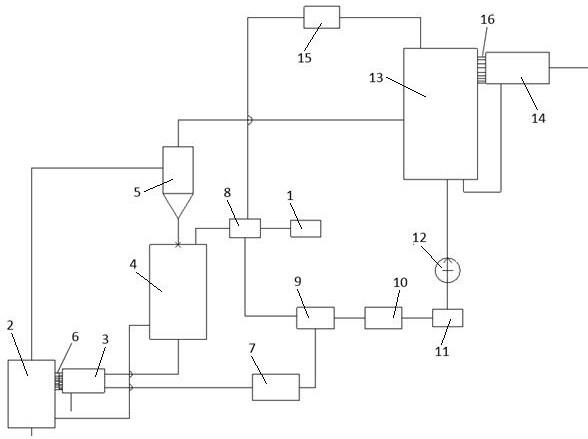

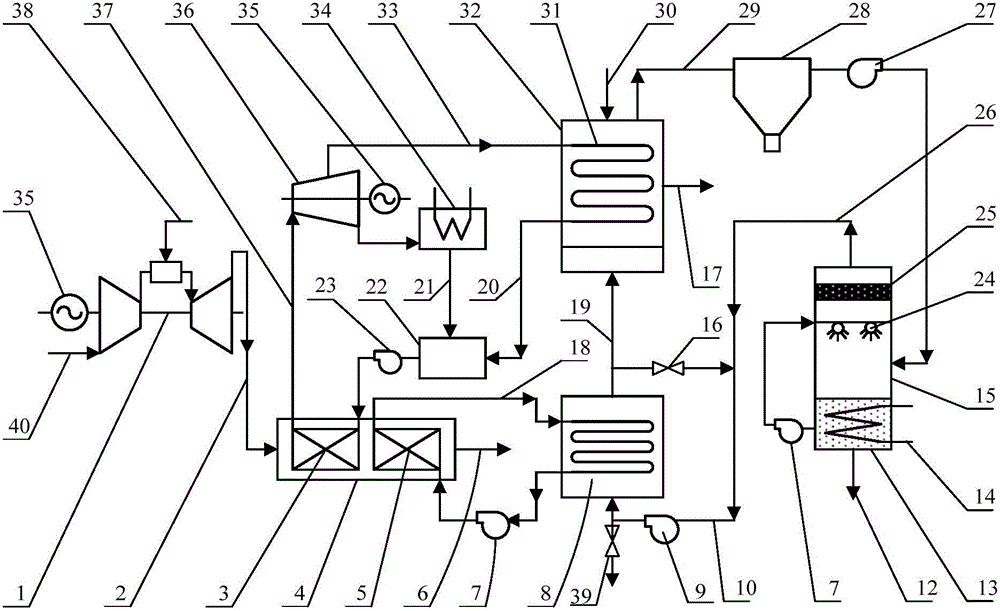

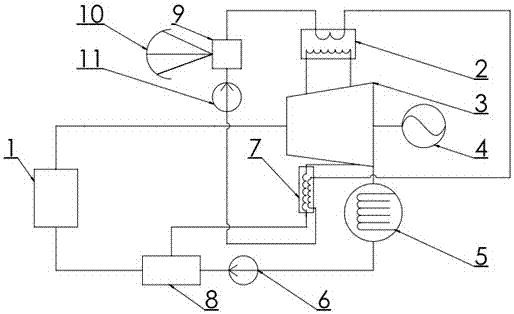

System and method for drying sludge through waste heat of gas turbine

ActiveCN103539333ALower fuel costsSolve the emission problemSludge treatment by de-watering/drying/thickeningSteam useFluidized bed dryingSludge

The invention provides a system and a method for drying sludge through the waste heat of a gas turbine. The gas turbine is connected with a generator; a flue gas outlet of the gas turbine is communicated with a waste heat boiler; a steam outlet of the waste heat boiler is communicated with a steam turbine; the steam turbine is connected with the generator; a steam extraction pipe of the steam turbine is communicated with an inlet of a heated surface pipe of an internal thermal type fluidized bed dryer; an air outlet of an air heater is communicated with an air inlet of the internal thermal type fluidized bed dryer; wet sludge enters the internal thermal type fluidized bed dryer through a wet sludge pipe, flows outside the heated surface pipe, is dried and then is discharged into a dry sludge pipe from a discharging hole. Steam is produced through the flue gas waste heat of the gas turbine to push a steam turbine generator set to generate power, and the waste heat of the steam turbine is taken as a heat source for drying the sludge, so that gradient energy utilization is realized, the heat efficiency is high, and a peculiar smell is not discharged; the fluidization air of the fluidized bed dryer is preheated by hot water, so that the energy utilization rate is further improved, and the environmental problems of groundwater pollution and the like caused by sludge burying and soil utilization are effectively solved.

Owner:凤阳县经济发展投资有限公司

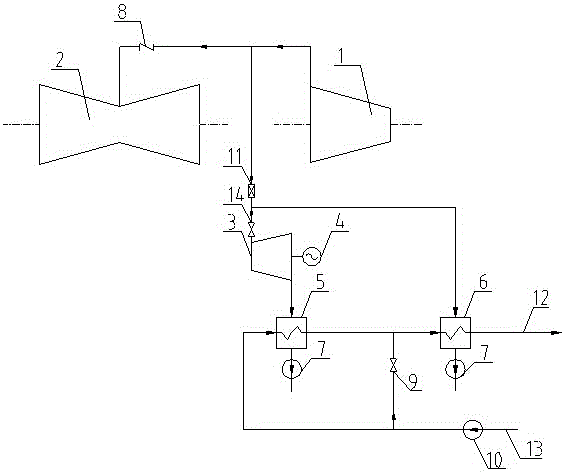

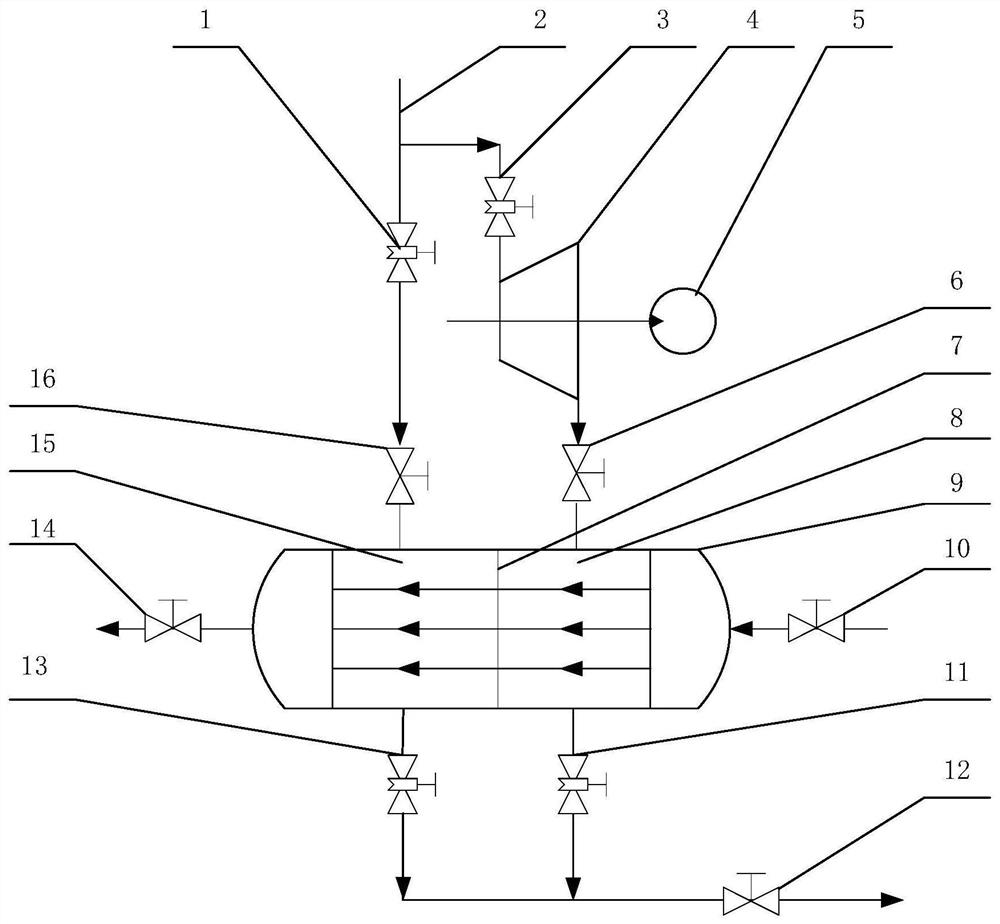

Heating steam-extraction and heating-supply system adopting high-back-pressure small steam turbine

InactiveCN105927298AIncrease power generation capacityMeet heat load requirementsSteam useEngine componentsEngineeringButterfly valve

A heating steam-extraction and heating-supply system adopting a high-back-pressure small steam turbine mainly comprises an intermediate-pressure cylinder, a low-pressure cylinder, the high-back-pressure small steam turbine, a peak-load calorifier, a front calorifier, an asynchronous generator, a drainage pump, an electric gate valve, an electric control valve, an electric butterfly valve, a circulating water pump, a heat supply network water supply pipe and a heat supply network return water pipe. The system is mainly used for turbine heating steam extraction heating supply reconstruction projects at the capacity level of subcritical 300 MW or above. High-quality steam pumped through a low-pressure communicating pipe passes through the high-back-pressure small steam turbine to do work; the steam enters the front calorifier to heat circulating water of a heat supply network after being depressurized. During the heating period, the high-back-pressure small steam turbine is made to operate at full load as far as possible, and the requirements for adjustment of changes of heating load are met by adjusting the peak-load calorifier. The circulating water of the heat supply network enters the front calorifier and the peak-load calorifier in sequence through the heat supply network return water pipe, is heated and then is supplied to heat consumers through the heat supply network water supply pipe. By means of the system, the power generation capacity of a unit is improved, gradient utilization of energy is realized, and the system has good economy and operating flexibility.

Owner:北京国能龙威发电技术有限公司

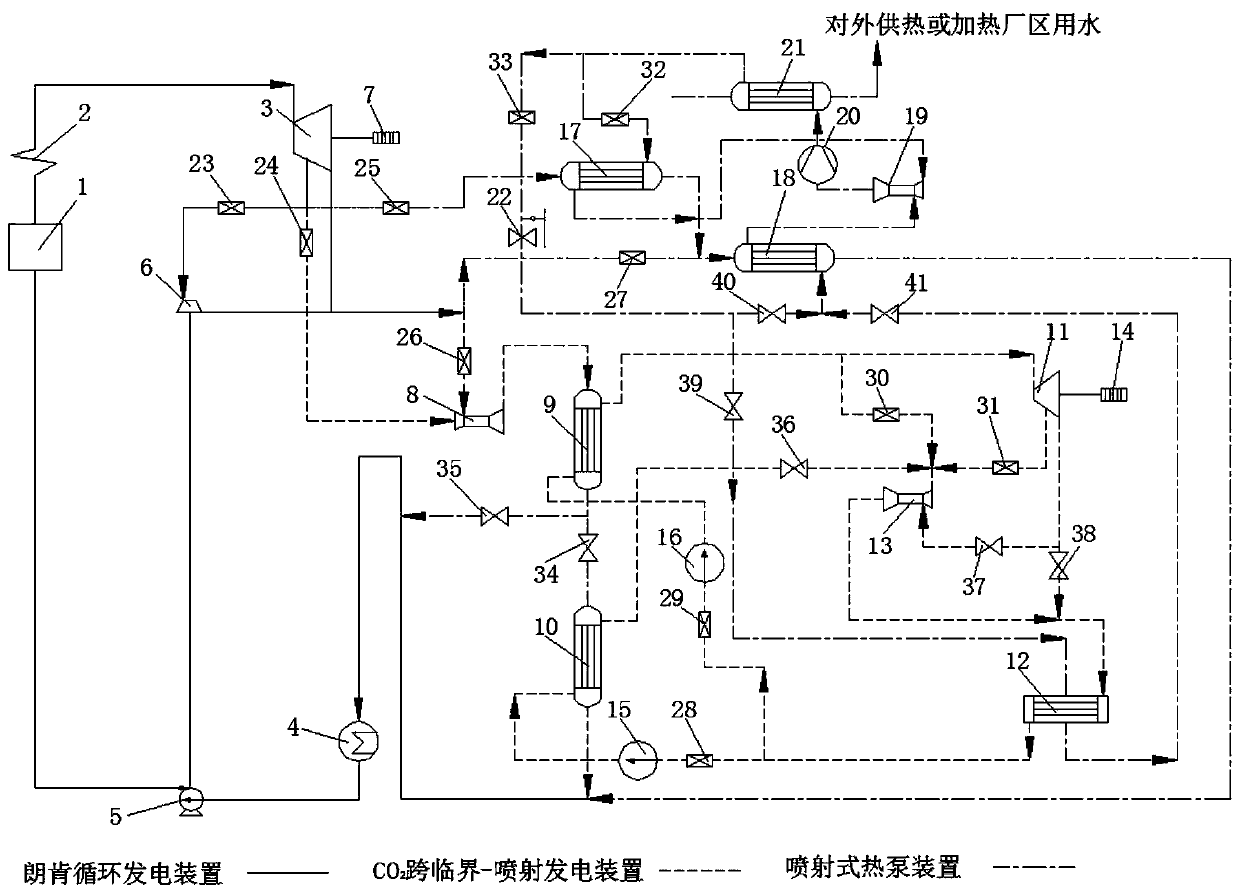

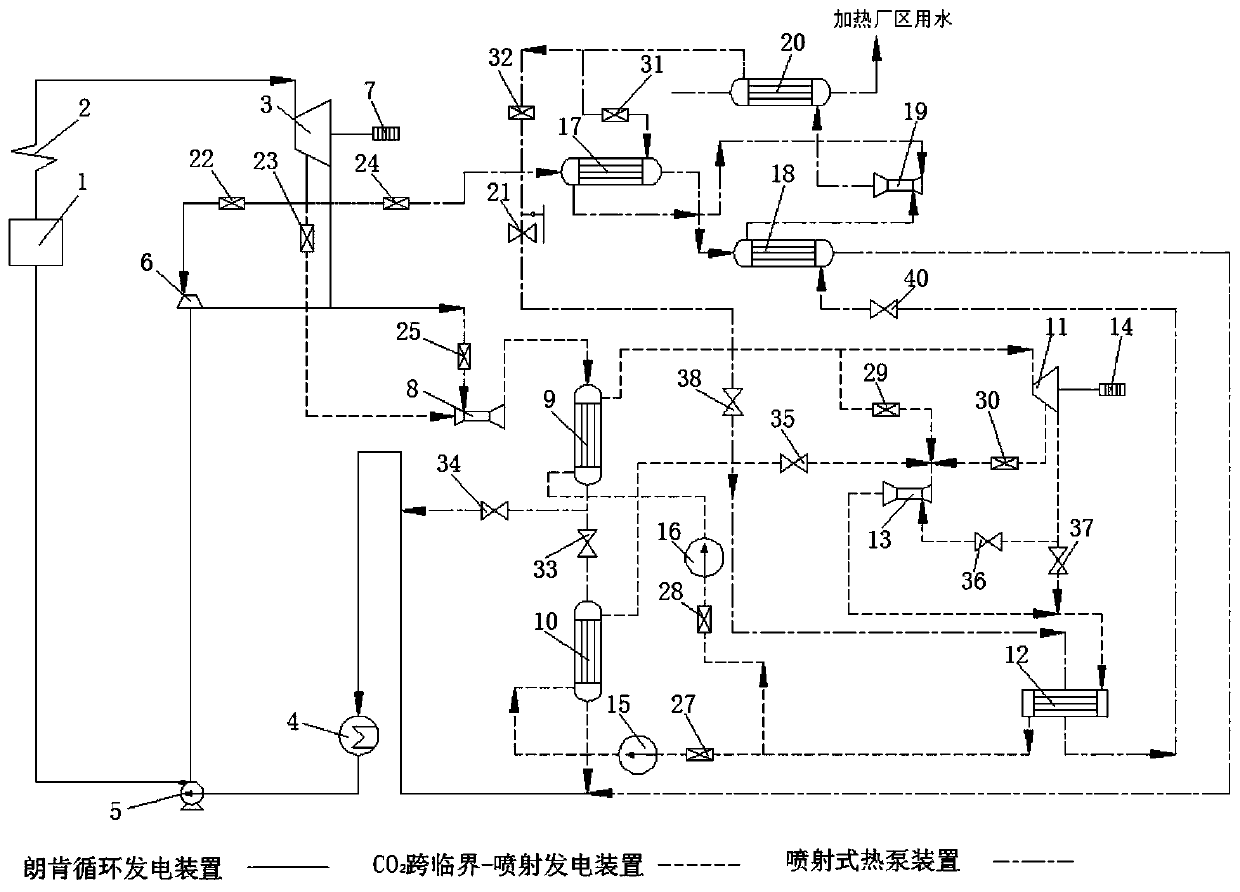

Power generation device and method for recovering heat of cold source of power plant

PendingCN109854314AFull recoveryIncrease temperatureSteam useMachines using refrigerant evaporationIsolation valveEngineering

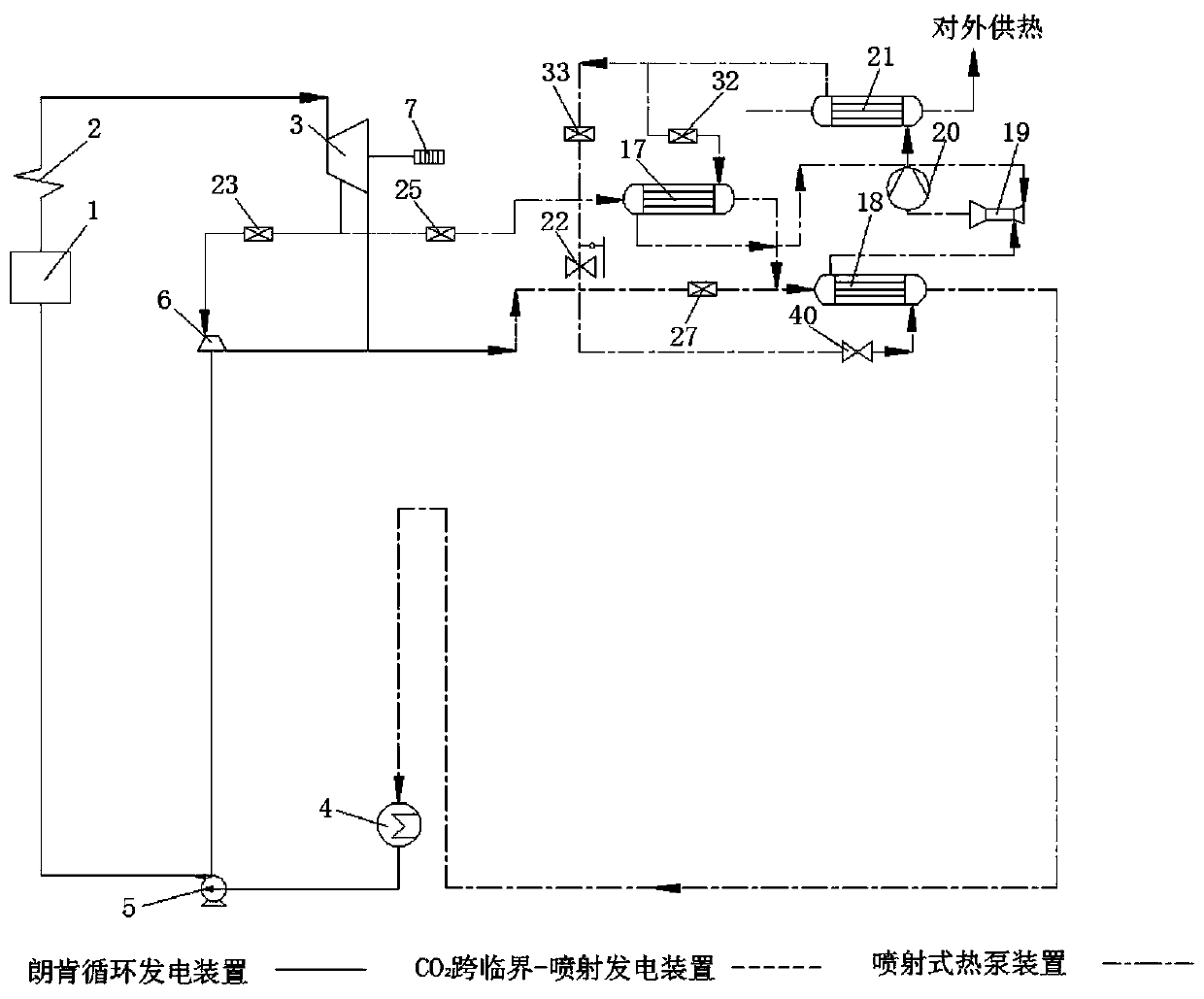

The invention discloses a power generation device and method for recovering the heat of a cold source of a power plant. The power generation device comprises a Rankine cycle power generation device, aCO2 trans-critical-jet power generation device and a jet heat pump unit, the Rankine cycle power generation device is connected with a first injector of the CO2 trans-critical-jet power generation device through a large steam turbine and a small steam turbine, the Rankine cycle power generation device is connected with the jet heat pump unit through a large steam turbine and a small steam turbine, and the jet heat pump unit is connected with the CO2 trans-critical-jet power generation device. A 11th flow adjusting valve and sixth, seventh and eighth isolation valves are arranged in the jet heat pump unit, the low-temperature and low-pressure CO2 flowing out of a throttle valve can be made to directly flow into an organic work medium condenser to carry out the heat exchange with CO2 gas exhaust, the temperature of CO2 entering into a secondary evaporator can be reduced, the heat source temperature of the outlet of the secondary evaporator is reduced accordingly, the temperature of thegas exhaust entering a steam condenser is reduced accordingly, and the great significance is achieved for the saving of the power consumption of a circulating pump in a traditional Rankine cycle, thereducing of the area of the steam condenser and the reducing of the circulating cooling water amount.

Owner:国能宿州热电有限公司

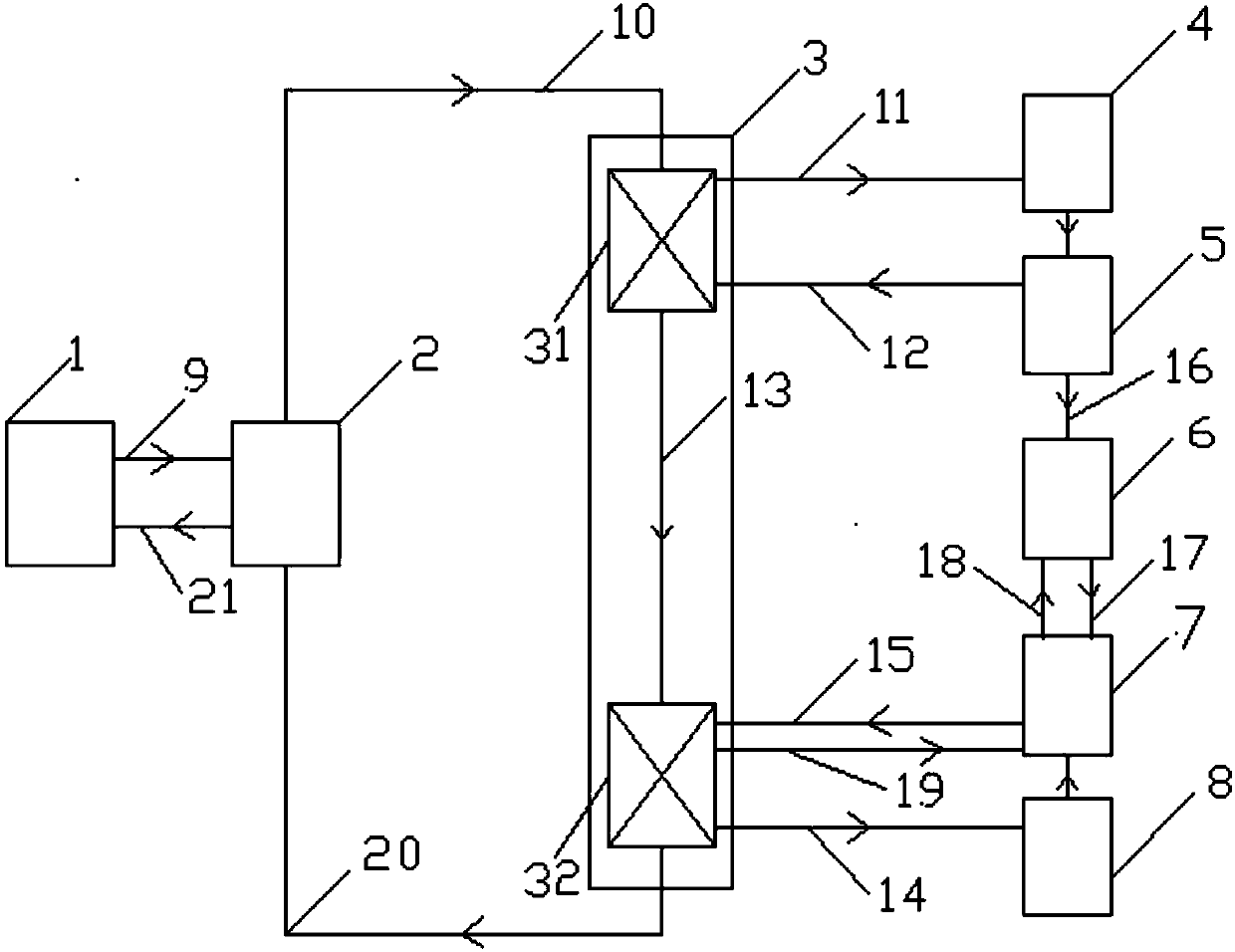

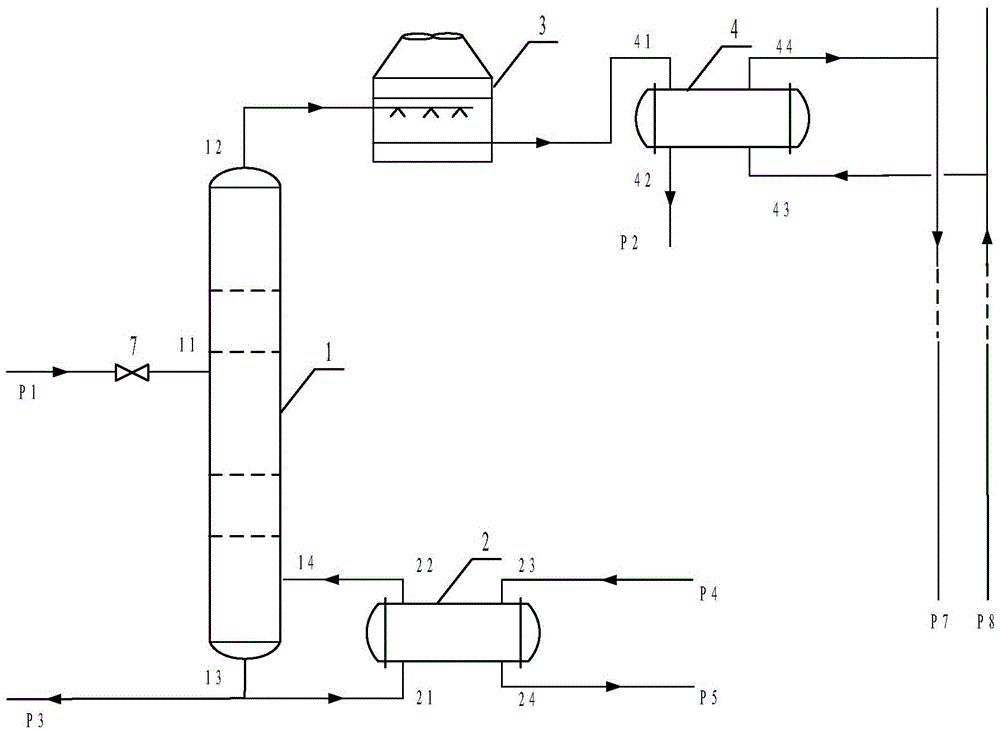

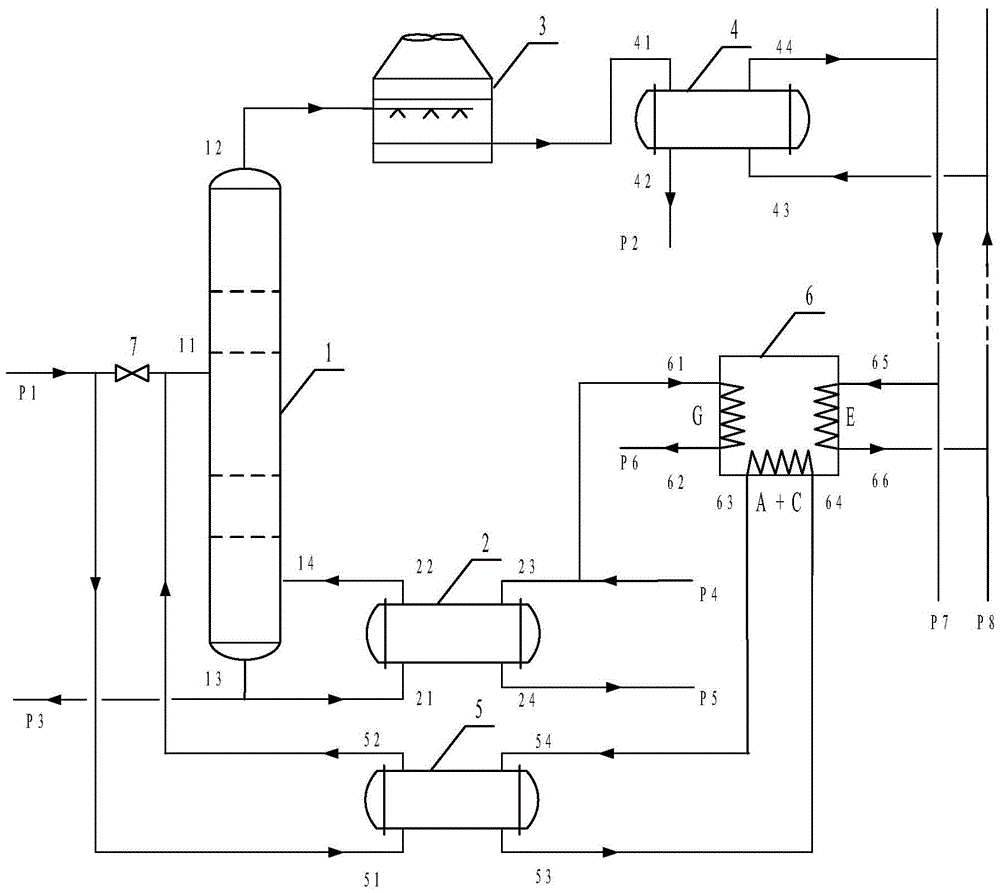

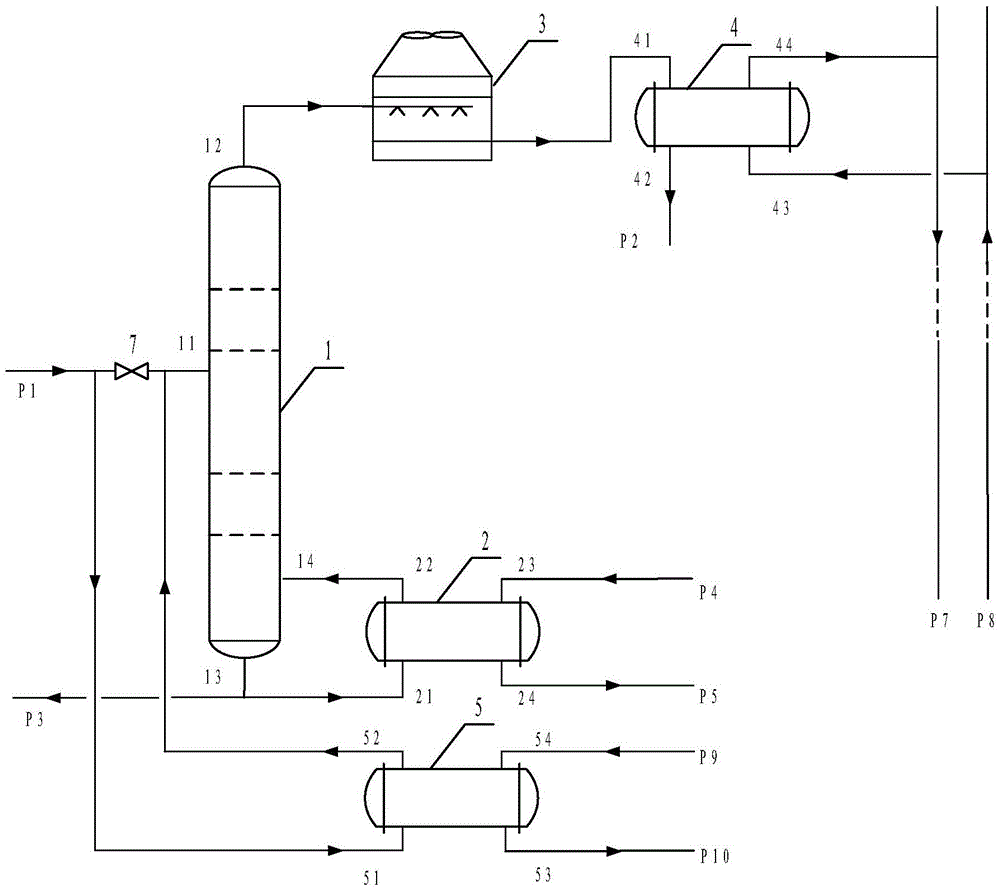

Step heating method and heating system for preheating of gas fractionating tower inlet material

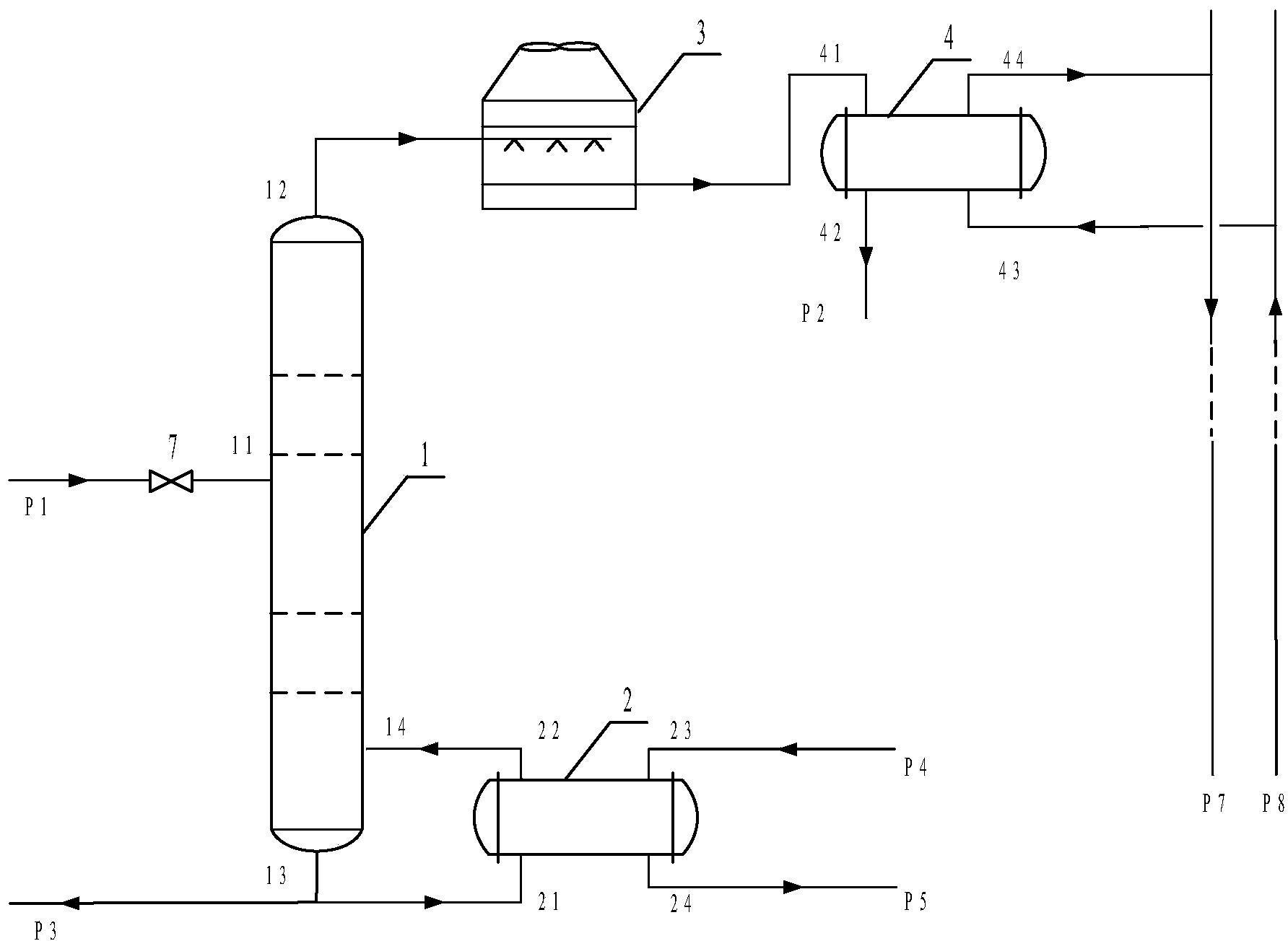

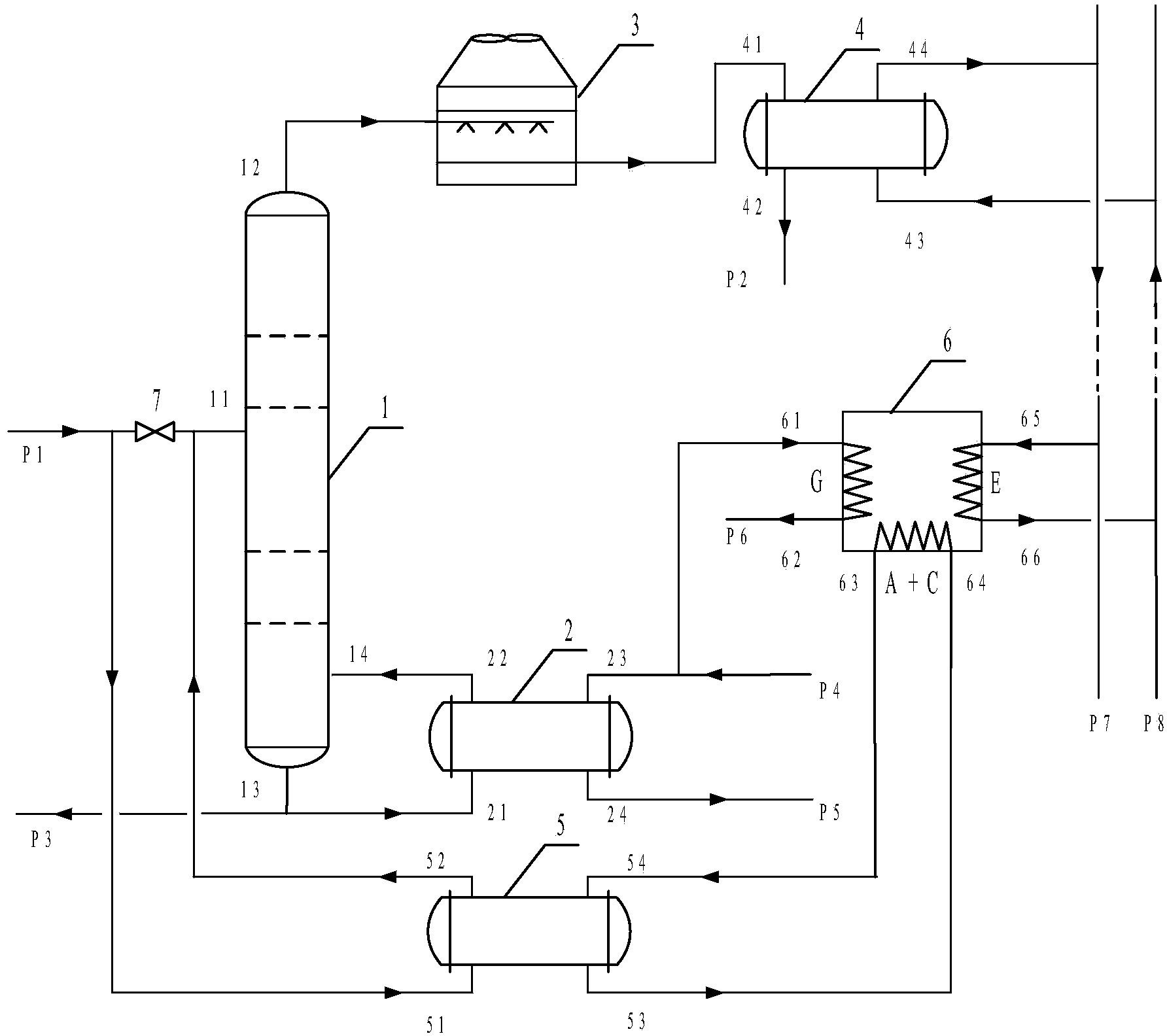

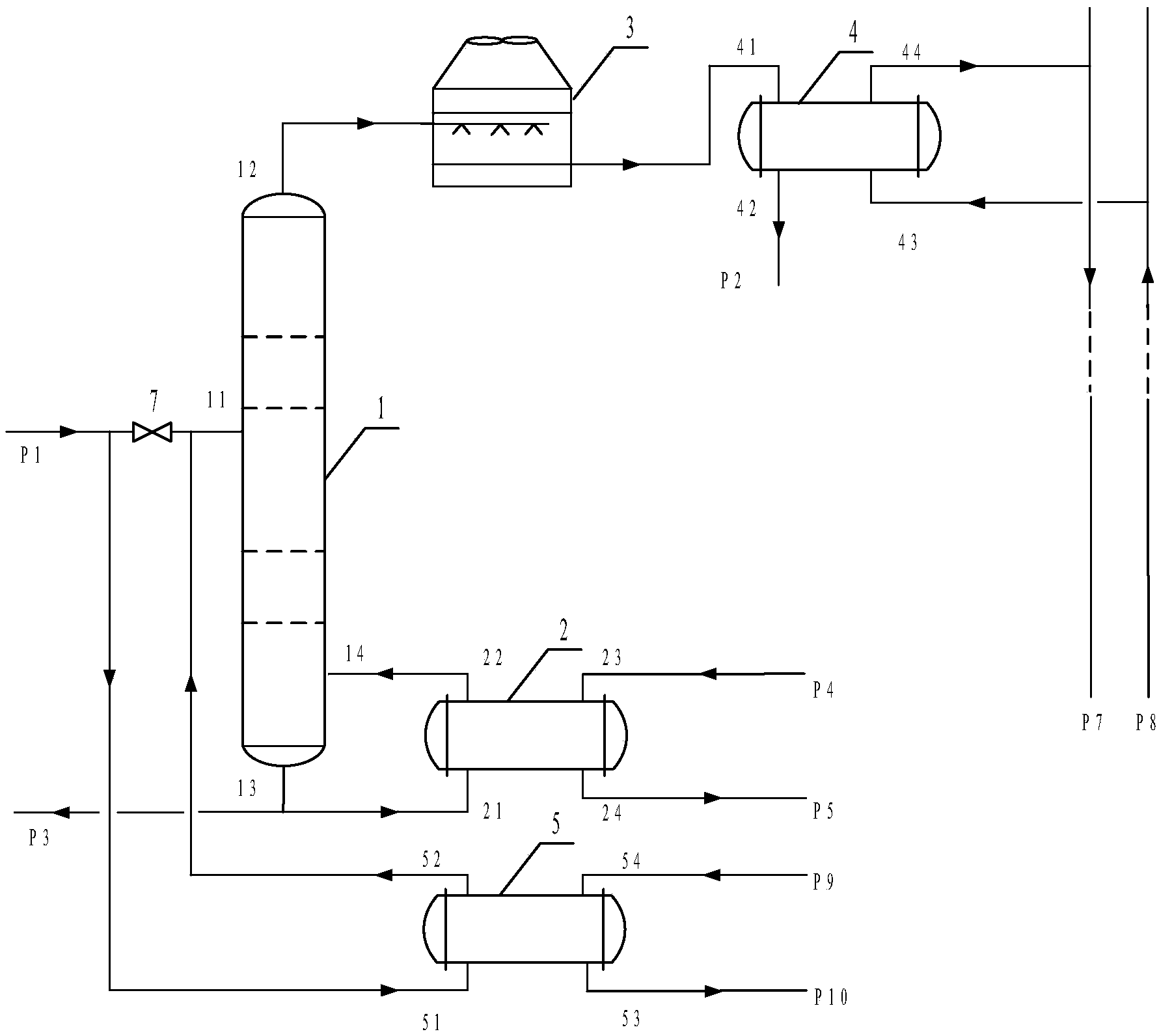

ActiveCN104383704ARealize energy cascade utilizationReduce consumptionDistillation regulation/controlHydrocarbon distillationReboilerFractionation

The invention relates to a step heating method and heating system for preheating of a gas fractionating tower inlet material. The heating method includes: preheating a material by a hot water / material heat exchanger outside a fractionating tower to 80+ / -10DEG C, letting the preheated material enter the fractionating tower, heating the material by a bottom reboiler in the tower and maintaining a working temperature required by material fractionation to realize step heating of the material. The heating system comprises a petroleum fractionating heating system component and a waste heat recovery inlet material heating system component. Specifically, the gas fractionating heating system component comprises: the fractionating tower, an air cooler, a water cooled heat exchanger and the reboiler; and the waste heat recovery inlet material heating system component includes: the hot water / material heat exchanger and a steam type lithium bromide absorption type heat pump. The method and the system provided by the invention utilize the recovered waste heat to preheat the inlet material, realize energy step utilization of the fractionating tower heating process, reduce the process steam consumption by over 20%, improve the energy utilization rate, and save the cost.

Owner:YANSHAN UNIV

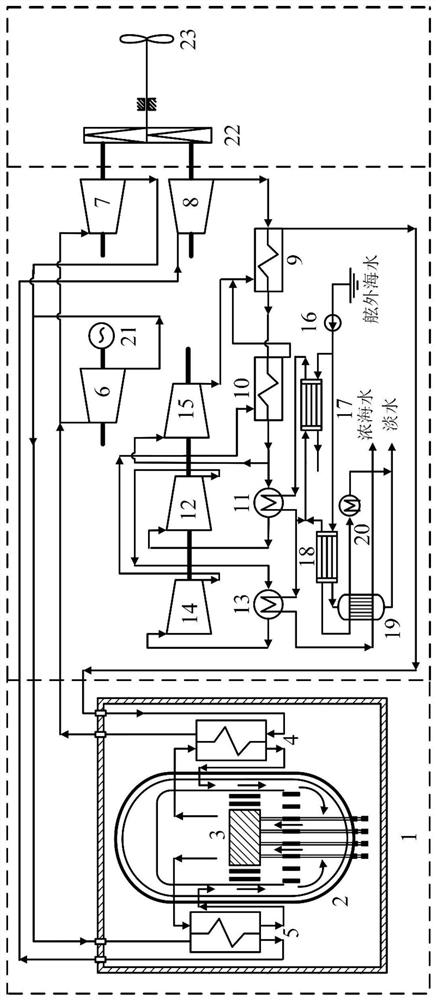

Supercritical carbon dioxide circulation and seawater desalination coupled vessel nuclear power system

InactiveCN112249293AImprove performanceGive full play to the advantages of high efficiencyPower plants using nuclear energyPropulsion based emission reductionIntercoolerSeawater

The invention discloses a supercritical carbon dioxide circulation and sea water desalination coupled vessel nuclear power system which comprises a reactor cabin, a ship cabin and a propelling device,the reactor cabin comprises a high-temperature gas cooled reactor system, and the ship cabin comprises a supercritical carbon dioxide power circulation system and a sea water desalination subsystem.A first-stage intermediate heat exchanger and a second-stage intermediate heat exchanger are arranged on the two sides of a high-temperature gas cooled reactor in the high-temperature gas cooled reactor system correspondingly. The supercritical carbon dioxide power circulation system is coupled with the high-temperature gas cooled reactor system through a first-stage intermediate heat exchanger and a second-stage intermediate heat exchanger. The seawater desalination subsystem is coupled with the supercritical carbon dioxide power circulation system through a precooler and an intercooler. Thepropelling device is connected with the supercritical carbon dioxide power circulation system. Vessel propulsion power and electric power are provided through the supercritical carbon dioxide circulation system, fresh water needed by the whole vessel is provided in cooperation with the sea water desalination system, the vessel is driven to sail in a direct propulsion mode, and the energy conversion rate and the device compactness are improved.

Owner:SOUTHEAST UNIV

Power and heat co-supply system based on Stirling engine and power and heat co-supply method of system

ActiveCN106351765AReduce manufacturing costReduce commercializationCombustion processStorage heatersEngineeringEconomizer

The invention discloses a power and heat co-supply system based on a Stirling engine and a power and heat co-supply method of the system. Grids cannot be laid in a great majority of families in mountainous areas and underdevelopment areas. Biomass combusts in a combustion furnace, molten salt in a heat storage pot is heated, and the high-temperature molten salt heats a hot end of the Stirling engine to drive the Stirling engine to generate power; a circulating water system for cooling a cold end of the Stirling engine flows through the cold end of the Stirling engine and an economizer, waste heat of the two parts is recovered, and hot water at 50-100 DEG C is finally obtained. With the adoption of the system and the method, the problems that the Stirling engine causes severe ash accumulation and coking at the hot end when applied to a biomass direct-combustion power generation boiler and the power generation efficiency is decreased are solved; gradient utilization of energy is realized and the thermal efficiency of the system is high; power and heat co-supply is realized and the energy saving effect is remarkable; the power output quality is stable, the system is very suitable for energy storage and release, and a way is provided for solving the problem about power in power islands in remote areas.

Owner:马加德

Sewage source heat pump and data center composited clean cold-supply and heat-supply system and method

InactiveCN107726424AReduce consumptionEmission reductionLighting and heating apparatusEnergy efficient heating/coolingEnergy gradientData center

The invention discloses a sewage source heat pump and data center composited clean cold-supply and heat-supply system and method and belongs to the technical field of recycling cold energy and heat ofsewage sources. The sewage source heat pump and data center composited clean cold-supply and heat-supply system comprises a sewage plant, a sewage source heat pump system, a heat exchange station, adata center refrigerating machine room, a data center, an air source heat pump and users requiring cold energy or heat; the cold energy recycled by the sewage source heat pump system from sewage is supplied to the data center and the nearby users; and the heat supplied by the sewage and the heat recycled from high-temperature air exhausted from the data center are supplied to the nearby users simultaneously. The cold energy and heat of the sewage in the sewage plant can be recycled through a sewage source heat pump, the heat generated by the data center can be also recycled, thus, the cold energy and the heat are supplied to the data center and the nearby users, energy consumption of the data center is reduced, the carbon emission amount of the sewage plant is reduced or offset, and the effects of energy gradient utilization and carbon neutrality are achieved.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

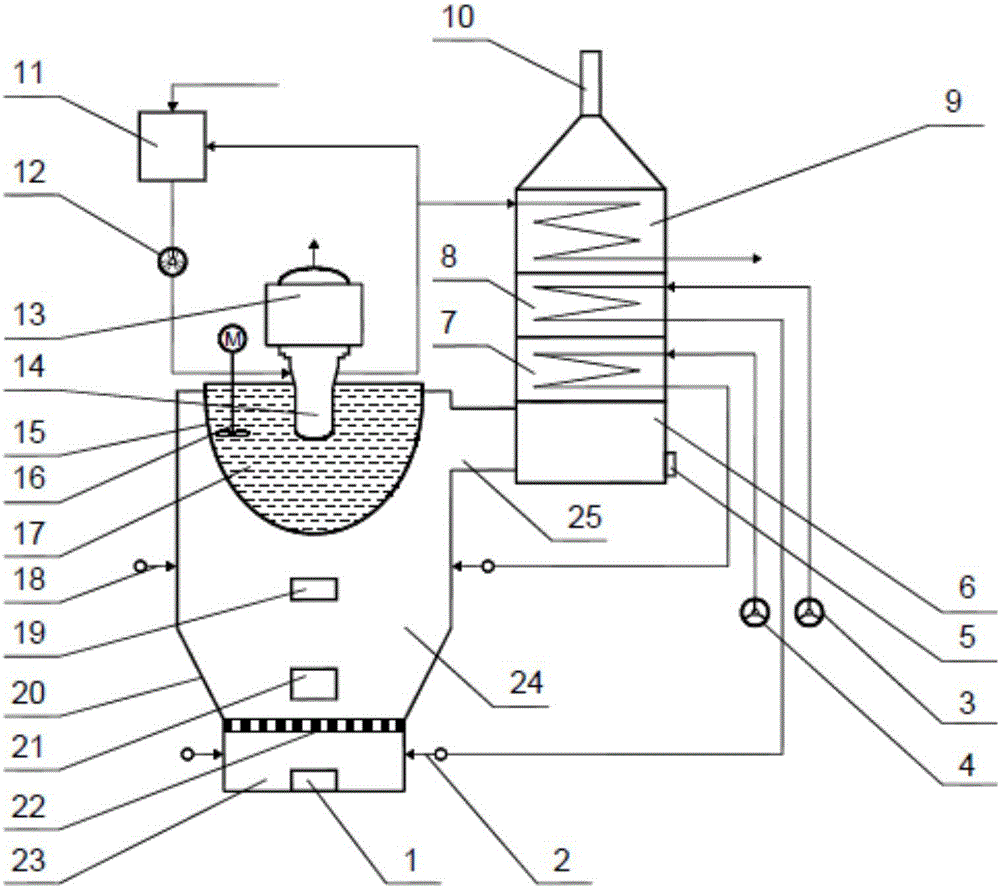

System and method for treating industrial waste liquid based on carrier gas extraction and low-temperature mass transfer

ActiveCN110498462AIncrease temperatureHigh trafficGas treatmentSpecific water treatment objectivesLiquid wasteDistributor

The invention provides a system and method for treating industrial waste liquid based on carrier gas extraction and low-temperature mass transfer. The system comprises an absorber, wherein the absorber is connected with a condenser, the condenser is connected with a waste liquid circulating pump, and the waste liquid circulating pump is connected with a liquid distributor of the absorber and a heater in the absorber; the system also comprises an analyzer, wherein the analyzer is connected with an evaporator, the evaporator is connected with a clean water pump, and the clean water pump is connected with a liquid distributor of the analyzer and a cooler in analyzer; an air outlet of the absorber is connected with an air inlet of the analyzer; an air outlet of the analyzer is connected with an air inlet of the absorber; and an air channel between the air outlet of the analyzer and the air inlet of the absorber is provided with a circulating fan and an adsorber. According to the invention,air can be utilized as a mass transfer medium to realize water migration in industrial waste liquid under the condition of a low temperature, and the system operates under normal pressure and is suitable for treatment of corrosive liquid which is crystallized easily and scaled easily, so that a series of pretreatment procedures such as precipitation, oil removal, pH value adjustment and the likerequired by conventional waste liquid treatment are greatly reduced.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

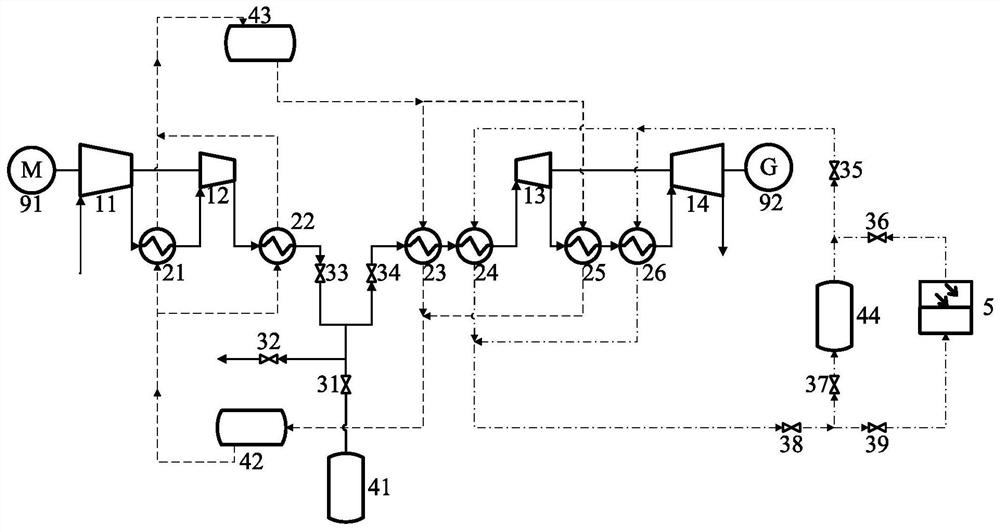

Solar energy auxiliary re-heat and back-heat thermal power generation system and emission reduction and dilatation method

ActiveCN104595136AReduce coal consumptionIncrease powerFrom solar energySteam engine plantsEngineeringHigh pressure

The invention discloses a solar energy auxiliary re-heat and back-heat thermal power generation system. A boiler is sequentially connected with a stream turbine, a condenser, a main circulation pump, a bleeder heater to form a main circulation circuit; a condenser mirror field focuses the sun light to a solar energy heat absorber; the solar energy heat absorber, a solar energy high temperature re-heater, a solar energy back-heat re-heater, a secondary circulation pump, the solar energy heat absorber are sequentially connected with to form a secondary circulation circuit; the inlet of a low pressure cylinder of the stream turbine is sequentially connected with the solar energy high temperature re-heater and the outlet of a high pressure cylinder of the stream turbine to form a re-heat circuit; a re-heat extraction opening of the low pressure cylinder of the stream turbine is sequentially connected with the solar energy back-heat re-heater, the bleeder heater; the stream turbine is connected with an electric generator. According to the solar energy auxiliary re-heat and back-heat thermal power generation system and an emission reduction and dilatation method, by the adoption of solar energy secondary circulation, the goal of reducing coal consumption and improving system total power is realized through increasing re-heat field and back-heat re-heat. On a basis of taking full advantage of the solar energy, the original system can automatically operate and the function of utilizing the solar energy thermal storage to meet the supply energy demand of adjusting peaks and valleys of the system is achieved.

Owner:ZHEJIANG UNIV

A whole-process method and device for thermochemical sulfur-iodine cycle hydrogen production

ActiveCN114195094BWell mixedPrevent precipitationHydrogen productionReactive separationPhysical chemistry

The invention discloses a method and a device for the whole process of thermochemical sulfur-iodine cycle hydrogen production. The present invention combines the Bunsen reaction section with HIx and H 2 SO 4 The two-phase separation section is coupled together, coupling the HIx purification section and the concentration section. h 2 SO 4 The high-temperature mixed gas of the decomposition tower is directly passed into the H 2 SO 4 In the concentration tower, under the condition of no external heat source, H 2 SO 4 A large amount of water in the solution vaporizes rapidly to achieve concentrated H 2 SO 4 The purpose of the solution: the high-temperature mixed gas continues to enter the downstream HIx purification and concentration tower, and a large amount of water in the HIx system is vaporized and taken away to achieve the purpose of concentrating the HI solution. H inclusion in HIx system 2 SO 4 Converted to SO in an oxygen-enriched environment 2 It is taken away to achieve the purpose of purifying the HI solution. After the hydrogen is separated in the condensation tower, the remaining iodine-containing liquid is reused and returned to the Bunsen reaction separation tower, which can reduce the investment and energy consumption of hydrogen production by more than 40% compared with the traditional sulfur-iodine preparation.

Owner:浙江百能科技有限公司

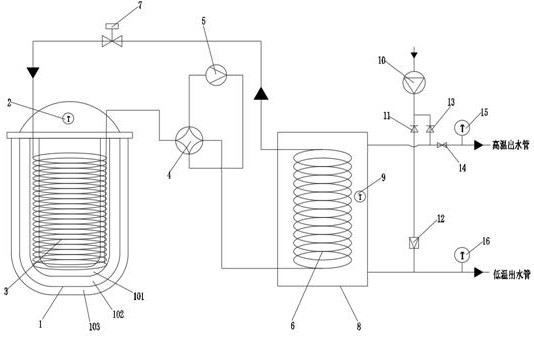

Flowing water source type temperature-controllable pharmaceutical reaction device

ActiveCN112427004AImprove energy efficiencyStable operating conditionsHeat storage plantsChemical/physical/physico-chemical stationary reactorsWater sourceElectronic expansion valve

The invention relates to a pharmaceutical reaction device, particularly to a flowing water source type temperature-controllable pharmaceutical reaction device, which comprises a medicine reaction kettle, a first phase-change heat exchanger, a second phase-change heat exchanger, an electronic expansion valve, a four-way reversing valve and an inverter compressor. According to the invention, under the working condition of refrigeration / heating, the second phase-change heat exchanger continuously releases / absorbs heat into the water tank, the position where flowing water with heat / cold is used isjudged according to the water temperature detected by the third temperature sensor and the fourth temperature sensor, and in the process, the efficiency that the first phase-change heat exchanger provides corresponding cold / heat for the medicine reaction kettle is improved, flowing water from the high-temperature / low-temperature water outlet pipe in the used water tank can be recycled in different process links such as a sterilization preheating link or a cooling precooling link and the like for medicine manufacturing according to actual requirements, gradient utilization of energy is achieved, energy is saved, and the environment is protected.

Owner:EAST CHINA JIAOTONG UNIVERSITY

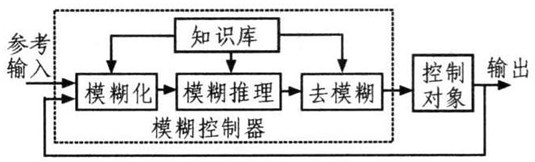

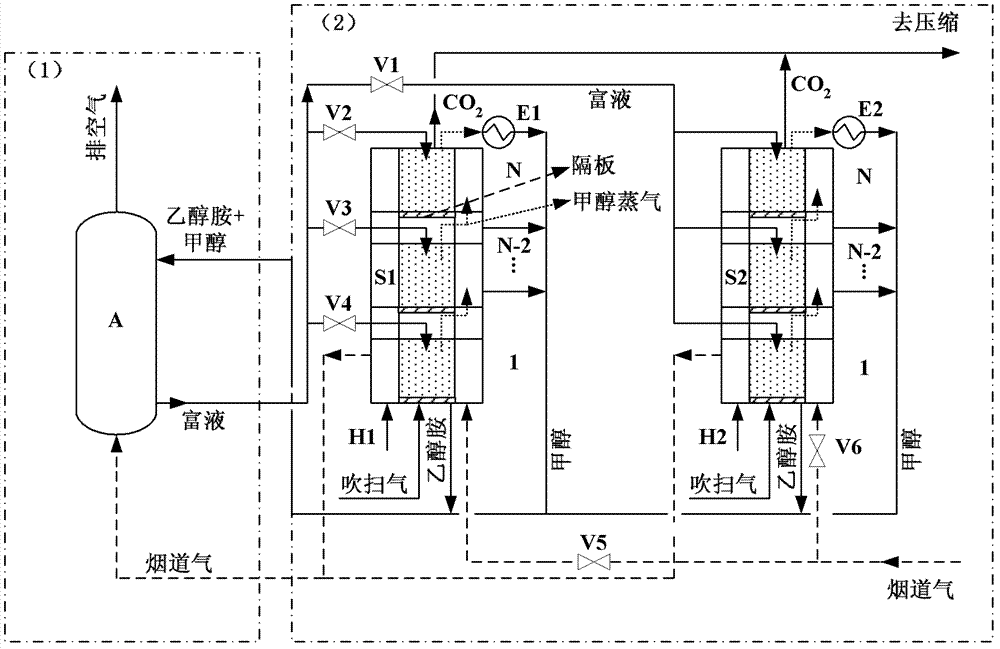

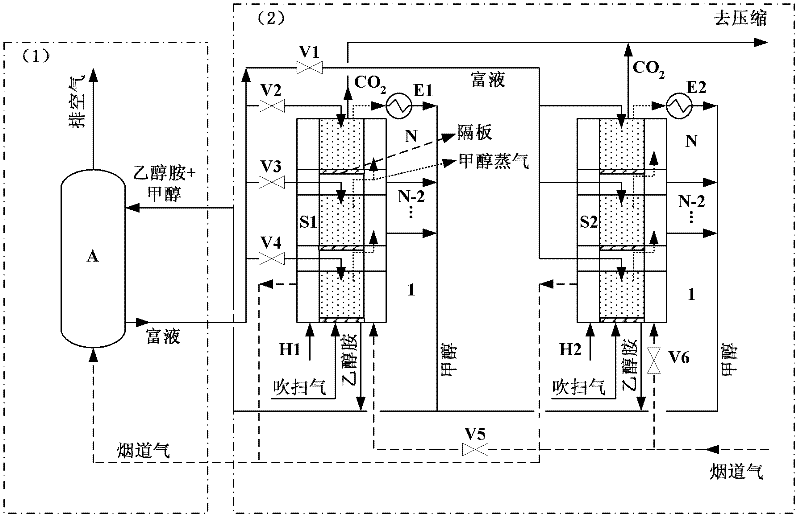

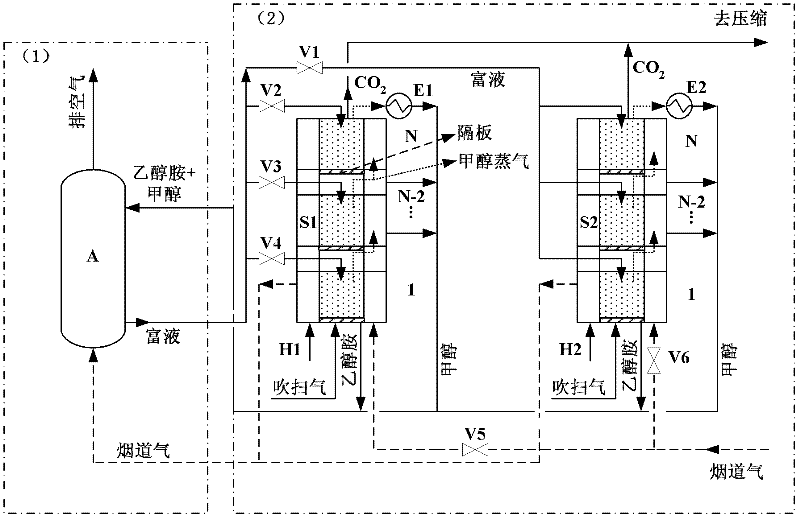

Flue gas decarbonization system and flue gas decarbonization method for two-step regeneration of carbon dioxide

The invention discloses a flue gas decarbonization system and a flue gas decarbonization method for two-step regeneration of carbon dioxide. The flue gas decarbonization system is formed by coupling an alkylol amine and methanol mixed solution adsorption system with a two-step carbon dioxide regeneration system, wherein when the two-step carbon dioxide regeneration system works, two steps of removing methanol before regeneration and regenerating alkylol amine carbonate are carried out. In the step of removing methanol before regeneration, flue gas waste heat is utilized to provide a heat source to remove the methanol in rich liquor after adsorption; the regeneration process only aims at the alkylol amine carbonate; the energy consumption of sensible heat and evaporation heat are avoided; and the steam consumption of the thermal regeneration process is reduced. Two regeneration towers alternately implement removal of the methanol and regeneration of the alkylol amine carbonate by two sets of valve equipment, so that the continuous operation of a trapping system is ensured. According to the invention, both the flue gas waste heat and the condensation heat of methanol steam are utilized, the temperature of the regenerated carbon dioxide is reduced, the flue gas decarbonization of a power plant is efficiently implemented, and the flue gas decarbonization system and the flue gas decarbonization method for two-step regeneration of carbon dioxide have the characteristics of cleanness, high efficiency, energy saving, high decarbonization rate and the like.

Owner:XI AN JIAOTONG UNIV

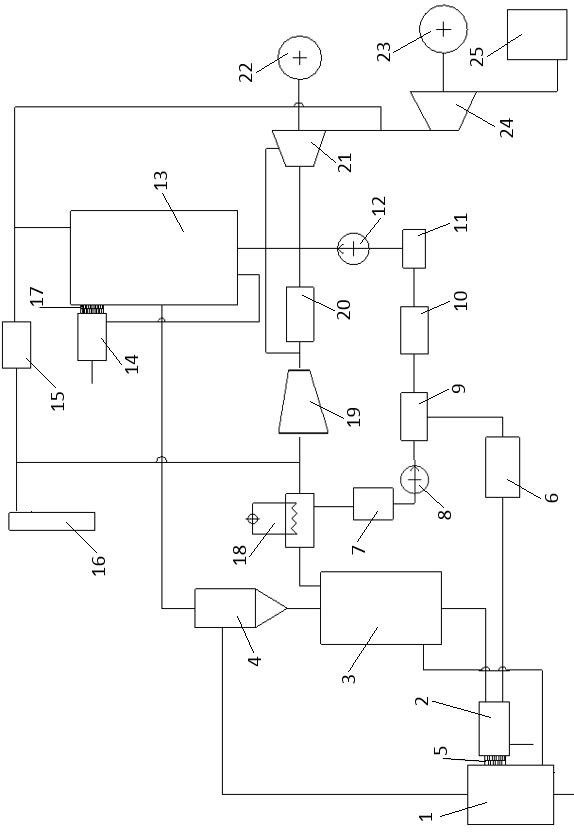

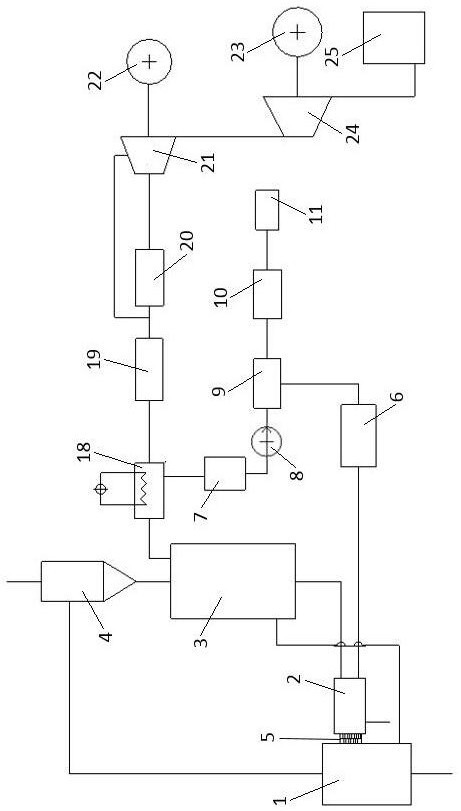

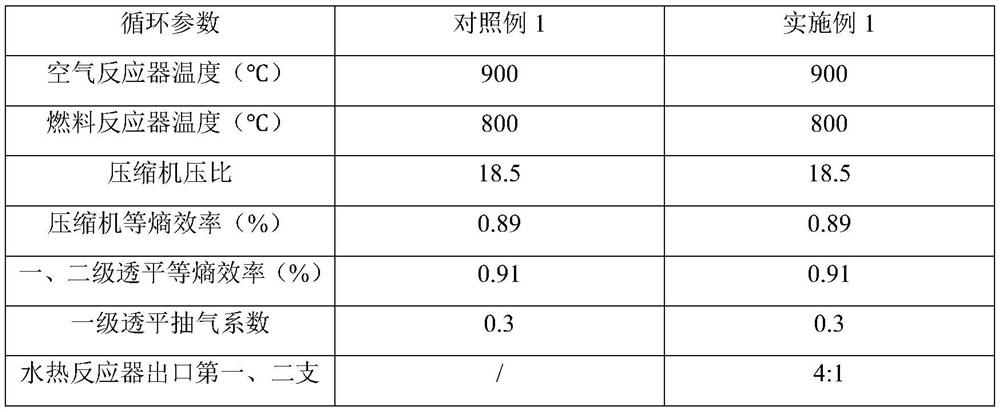

CO2 trapping system based on chemical-looping combustion coupled supercritical hydrothermal reaction, and working method

PendingCN111947139AAvoid Reactive Performance ImpactReduced Possibility of PoisoningGaseous fuelsLiquid carbonaceous fuelsReaction rateWater storage tank

The invention relates to a CO2 trapping system based on a chemical-looping combustion coupled supercritical hydrothermal reaction, and a working method. In an existing chemical-looping combustion cycle reaction, an oxygen carrier is sintered and melted, and consequently the cycle reaction rate is decreased. The CO2 trapping system comprises a chemical-looping combustion system which comprises an air reactor, a pyrolyzing furnace, a fuel reactor and a cyclone separator, and the pyrolyzing furnace is connected with the air reactor. The CO2 trapping system is characterized by further comprising aCO2 storage device, a coal water slurry system and a supercritical hydrothermal reaction system, wherein the coal water slurry system comprises coal grinding equipment, a water storage tank, a mixingtank, a colloid tank and a slurry storage tank, and the water storage tank, the mixing tank, the colloid tank and the slurry storage tank are sequentially connected through pipelines; and the supercritical hydrothermal reaction system comprises a high-pressure coal water slurry pump, a supercritical water oxidation reactor, a preheater and a CO2 separator, and the preheater is connected with thesupercritical water oxidation reactor. The chemical-looping combustion economy and the energy utilization efficiency are improved, and CO2 can be trapped with the low cost and low energy consumption.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Flue gas decarbonization system and flue gas decarbonization method for two-step regeneration of carbon dioxide

The invention discloses a flue gas decarbonization system and a flue gas decarbonization method for two-step regeneration of carbon dioxide. The flue gas decarbonization system is formed by coupling an alkylol amine and methanol mixed solution adsorption system with a two-step carbon dioxide regeneration system, wherein when the two-step carbon dioxide regeneration system works, two steps of removing methanol before regeneration and regenerating alkylol amine carbonate are carried out. In the step of removing methanol before regeneration, flue gas waste heat is utilized to provide a heat source to remove the methanol in rich liquor after adsorption; the regeneration process only aims at the alkylol amine carbonate; the energy consumption of sensible heat and evaporation heat are avoided; and the steam consumption of the thermal regeneration process is reduced. Two regeneration towers alternately implement removal of the methanol and regeneration of the alkylol amine carbonate by two sets of valve equipment, so that the continuous operation of a trapping system is ensured. According to the invention, both the flue gas waste heat and the condensation heat of methanol steam are utilized, the temperature of the regenerated carbon dioxide is reduced, the flue gas decarbonization of a power plant is efficiently implemented, and the flue gas decarbonization system and the flue gas decarbonization method for two-step regeneration of carbon dioxide have the characteristics of cleanness, high efficiency, energy saving, high decarbonization rate and the like.

Owner:XI AN JIAOTONG UNIV

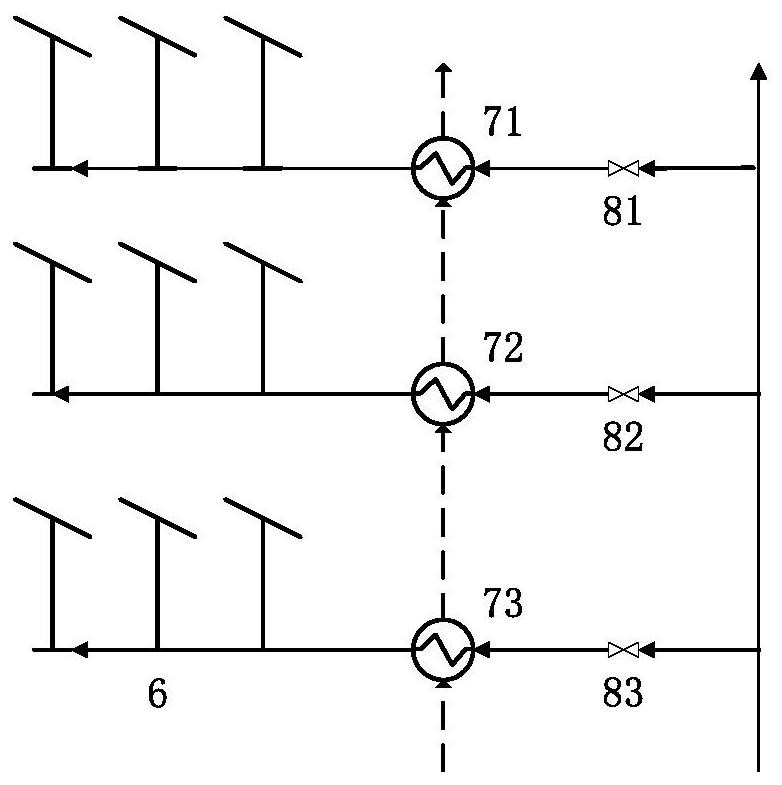

Multi-mode operation air pre-heater and waste heat recycling garbage power generation system with same

PendingCN113091063AOptimize the operation modeIncrease output powerSteam generation plantsIndirect carbon-dioxide mitigationAir preheaterProcess engineering

The invention relates to a multi-mode operation air pre-heater and a waste heat recycling garbage power generation system with the same. The system comprises a garbage incineration boiler, a steam turbine, a power generator, the steam air pre-heater and a heat exchanger. The garbage incineration boiler communicates with the steam turbine, and the steam turbine communicates with the power generator. The garbage incineration boiler communicates with a steam inlet of the steam air pre-heater to form a boiler steam passage, the steam turbine communicates with the steam inlet of the steam air pre-heater to form a steam turbine steam passage, an air outlet of the steam air pre-heater communicates with an inlet of the garbage incineration boiler, a drain port of the steam air pre-heater communicates with an inlet of the heat exchanger, and the heat exchanger is used for providing heat exchange for a user system. Steam with different parameters can be extracted to serve as a heating steam source according to the operating load of a unit, the operating mode of the air pre-heater is optimized, the output power of the steam turbine is increased, gradient utilization of energy is achieved, waste heat can be recycled and supplied to the user system, and the energy utilization efficiency of the system is effectively improved.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

An industrial waste liquid treatment system and method based on carrier gas extraction low-temperature mass transfer

ActiveCN110498462BNo secondary pollutionAchieve moisture purificationGas treatmentSpecific water treatment objectivesCirculator pumpProcess engineering

The invention proposes an industrial waste liquid treatment system and method based on carrier gas extraction low-temperature mass transfer. The system includes an absorber connected to a condenser connected to a waste liquid circulation pump connected to an absorber The liquid distributor of the resolver and the internal heater of the absorber; the resolver, which is connected to the evaporator, and the evaporator is connected to the clean water pump, and the clean water pump is connected to the liquid distributer of the resolver and the internal cooler of the resolver; the air outlet of the absorber is connected to the resolver The air inlet of the resolver, the air outlet of the resolver is connected to the air inlet of the absorber, and the air channel between the air outlet of the resolver and the air inlet of the absorber is provided with a circulating fan and an adsorber. The invention can use air as the mass transfer medium to realize the migration of water in the industrial waste liquid under the condition of relatively low temperature. A series of pretreatment processes such as precipitation, oil removal, and pH adjustment required for liquid disposal.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

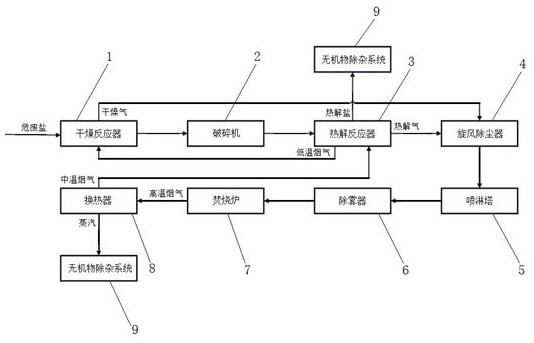

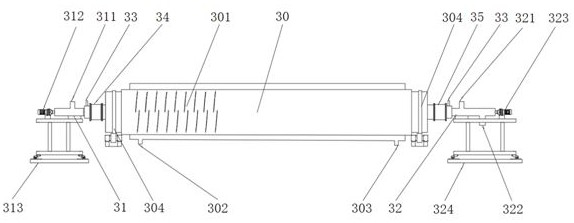

Hazardous waste salt pyrolysis system and pyrolysis process thereof

PendingCN114811591ARealize cascade utilizationAvoid corrosionIncinerator apparatusPhysical chemistrySpray tower

The invention relates to a hazardous waste salt pyrolysis system and a pyrolysis process thereof, the hazardous waste salt pyrolysis system is used for removing organic impurities in hazardous waste salt, the pyrolysis system comprises a drying reactor (1), a crusher (2), a pyrolysis reactor (3), a cyclone dust collector (4), a spray tower (5), a demister (6), an incinerator (7) and a heat exchanger (8); a solid outlet of the drying reactor is connected with a solid inlet of the pyrolysis reactor through the crusher, and a gas outlet of the drying reactor is connected with a first inlet of the cyclone dust collector; the pyrolysis salt outlet (322) is connected with an inorganic matter impurity removal system (9), the pyrolysis gas outlet (321) is connected with a second inlet of the cyclone dust collector, and the heating flue gas outlet (302) is connected with a gas inlet of the drying reactor; an outlet of the cyclone dust collector is connected with an inlet of the heat exchanger through the spray tower, the demister and the incinerator, a flue gas outlet of the heat exchanger is connected with a heated flue gas inlet (303) of the pyrolysis reactor, and a steam outlet of the heat exchanger is connected with the inorganic matter impurity removal system.

Owner:SHANGHAI ELECTROMECHANICAL DESIGN & RES INST CO LTD

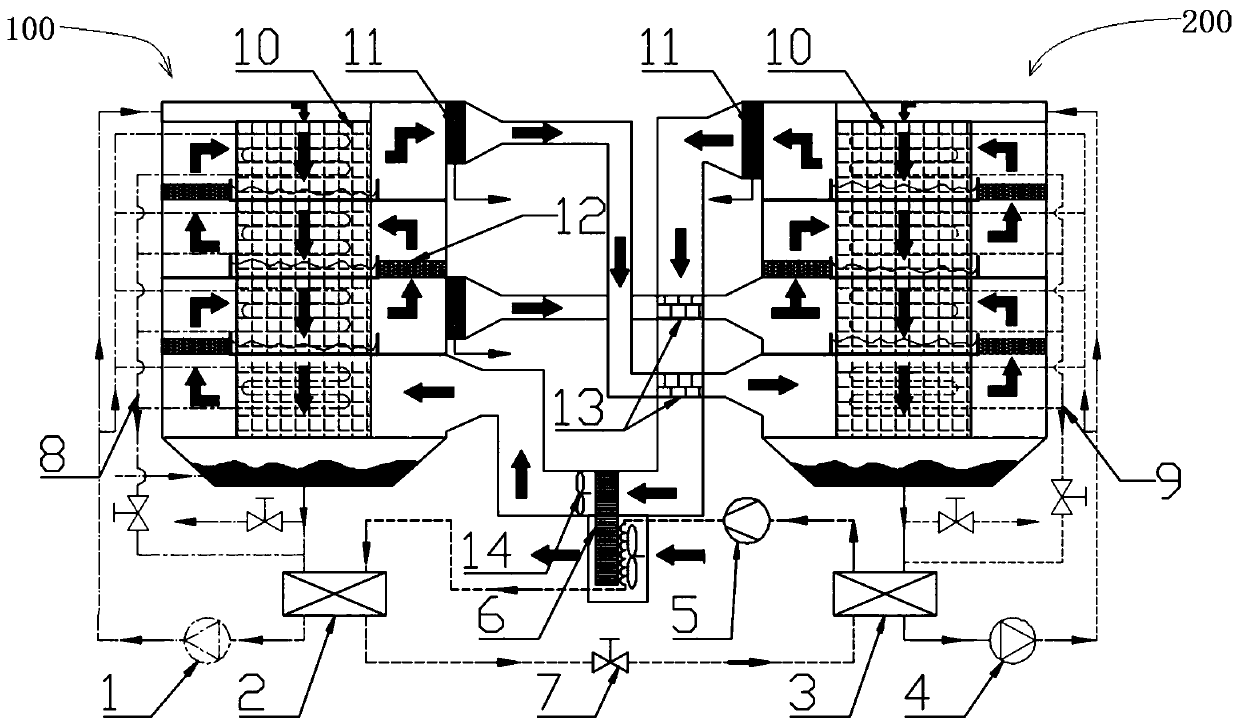

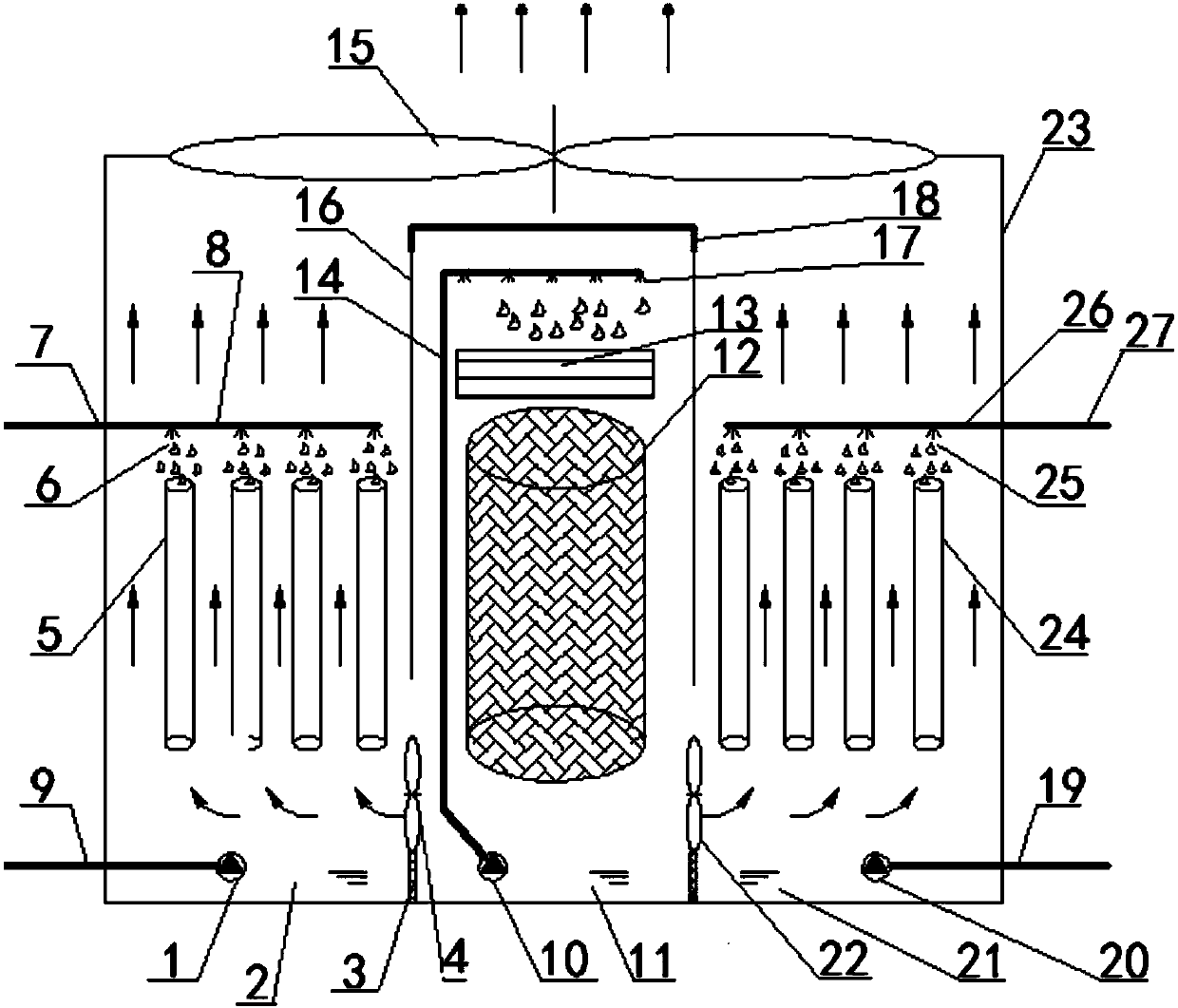

Cooling tower for cascaded cooling water preparation with composite structure

ActiveCN106091728BSmall footprintEasy to replaceHeat exchange apparatusTrickle coolersCooling temperatureComposite structure

The invention discloses a stepped temperature-decrease cooling water preparation cooling tower of a composite structure. The stepped temperature-decrease cooling water preparation cooling tower comprises a cooling tower shell. The top of the cooling tower shell is provided with an air outlet. A filler type direct evaporation cooling unit is arranged in the middle of the cooling tower shell. A first vertical tube type indirect evaporation cooling unit and a second vertical tube type indirect evaporation cooling unit are arranged on the left side and the right side of the filler type direct evaporation cooling unit respectively. The first vertical tube type indirect evaporation cooling unit and the second vertical tube type indirect evaporation cooling unit are both connected with a water chilling unit system arranged outside the cooling tower shell. According to the stepped temperature-decrease cooling water preparation cooling tower, water cooling temperature decrease and air cooling temperature decrease are combined in cooperation with a stepped temperature decrease mode, and thus the temperature decrease efficiency of the cooling tower can be improved, energy consumption can be reduced, and cooling temperature with lower temperature can be prepared; and the filler type direct evaporation cooling unit and the two vertical tube type indirect evaporation cooling units are arranged inside the cooling tower and can meet the requirements of different seasons, and the cooling tower has very important significance in application and popularization.

Owner:ZHEJIANG JINLING REFRIGERATION ENG

System and method for drying sludge through waste heat of gas turbine

ActiveCN103539333BLower fuel costsSolve the emission problemSludge treatment by de-watering/drying/thickeningSteam useFluidized bed dryingSludge

The invention provides a system and a method for drying sludge through the waste heat of a gas turbine. The gas turbine is connected with a generator; a flue gas outlet of the gas turbine is communicated with a waste heat boiler; a steam outlet of the waste heat boiler is communicated with a steam turbine; the steam turbine is connected with the generator; a steam extraction pipe of the steam turbine is communicated with an inlet of a heated surface pipe of an internal thermal type fluidized bed dryer; an air outlet of an air heater is communicated with an air inlet of the internal thermal type fluidized bed dryer; wet sludge enters the internal thermal type fluidized bed dryer through a wet sludge pipe, flows outside the heated surface pipe, is dried and then is discharged into a dry sludge pipe from a discharging hole. Steam is produced through the flue gas waste heat of the gas turbine to push a steam turbine generator set to generate power, and the waste heat of the steam turbine is taken as a heat source for drying the sludge, so that gradient energy utilization is realized, the heat efficiency is high, and a peculiar smell is not discharged; the fluidization air of the fluidized bed dryer is preheated by hot water, so that the energy utilization rate is further improved, and the environmental problems of groundwater pollution and the like caused by sludge burying and soil utilization are effectively solved.

Owner:凤阳县经济发展投资有限公司

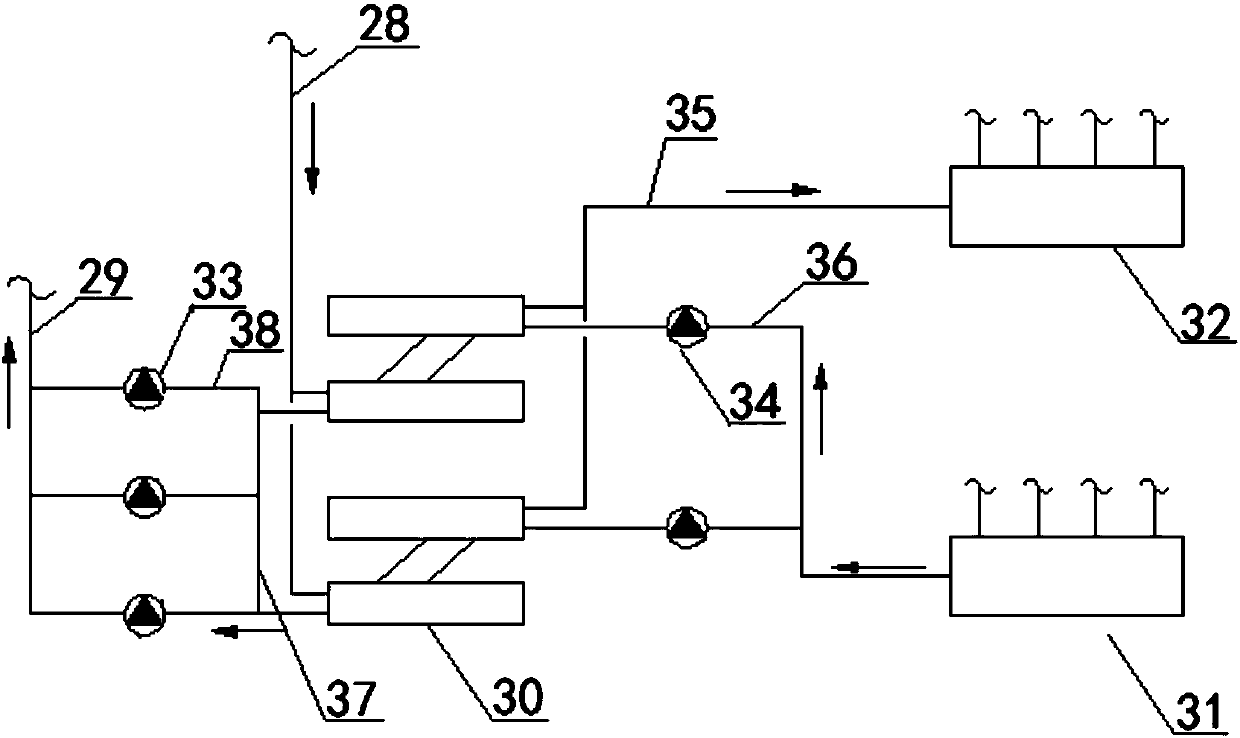

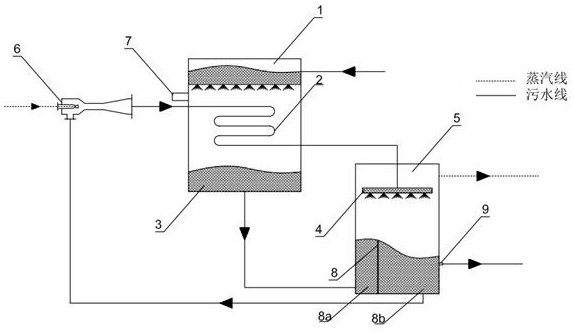

Spraying type heat exchange sewage circulation flash steam generation system

PendingCN114659081AGuaranteed uptimeRealize cascade utilization of waste heatSteam generationStationary conduit assembliesSprayerProcess engineering

The invention discloses a sprinkling type heat exchange sewage circulation flash steam generation system, and belongs to the technical field of waste heat utilization and sewage treatment. According to the steam generation system, a steam-liquid ejector adopts high-pressure steam to suck non-flash sewage gathered in a flash tank, and the non-flash sewage enters a spraying type heat exchanger to be heated after being pressurized and then is fed into a sprayer to be subjected to flash evaporation at the top of the flash tank; high-temperature sewage in the water distribution tank is heated by pressurized water in the sprinkling heat exchanger, is enriched in a water collecting tank, and is fed into the bottom of a flash tank to realize spewing depressurization flash evaporation; and saturated sewage which is not flashed in the flash tank is communicated with an injection inlet of the vapor-liquid injector through an outlet pipe at the bottom, so that circulating pressurized flash is realized. The steam generation system is driven by a small part of high-pressure steam, does not consume extra pump work, realizes gradient utilization of waste heat of medium-high-temperature sewage in a circulating pressurization mode, and generates continuous and stable medium-low-pressure saturated steam through up-and-down combined flash evaporation in a flash evaporation tank, so that a steam source is provided for seawater desalination, sewage treatment or other steam using processes, and the energy consumption is reduced. Waste heat utilization of sewage is achieved, and energy conservation and emission reduction are achieved.

Owner:DALIAN UNIV OF TECH

Photovoltaic power station energy storage matching system and operation method thereof

ActiveCN113541575AImprove operational efficiencyEmission reductionElectrical storage systemPV power plantsWater storage tankElectrical battery

The invention provides a photovoltaic power station energy storage matching system and an operation method thereof. The system comprises an energy storage section, an energy release section, a solar heat compensation module and a cooling nozzle arranged above a photovoltaic cell. A working medium outlet of the energy storage section is connected with an inlet of the high-pressure gas storage chamber; the working medium outlet of the energy storage section and an outlet of the high-pressure gas storage chamber are connected with a working medium inlet of the energy release section; the energy storage section is provided with two-stage compressors, coolers are arranged at outlets of the compressors, the energy release section is provided with two-stage expansion machines, and preheating heaters and heat supplementing heaters are arranged at inlets of the two-stage expansion machines. A hot medium outlet of the cooler is communicated with the high-temperature water storage tank, a cold medium outlet of the cooler is communicated with the low-temperature water storage tank, the high-temperature water storage tank is connected with the preheating heater, and a heating medium outlet of the preheating heater is communicated with the low-temperature water storage tank; a working medium inlet / outlet of the solar heat compensation module is communicated with a heating medium inlet / outlet of the heat compensation heater; the efficiency of the energy storage system can be obviously improved; solar heat compensation is cleaner, and carbon emission can be effectively reduced.

Owner:XI AN JIAOTONG UNIV

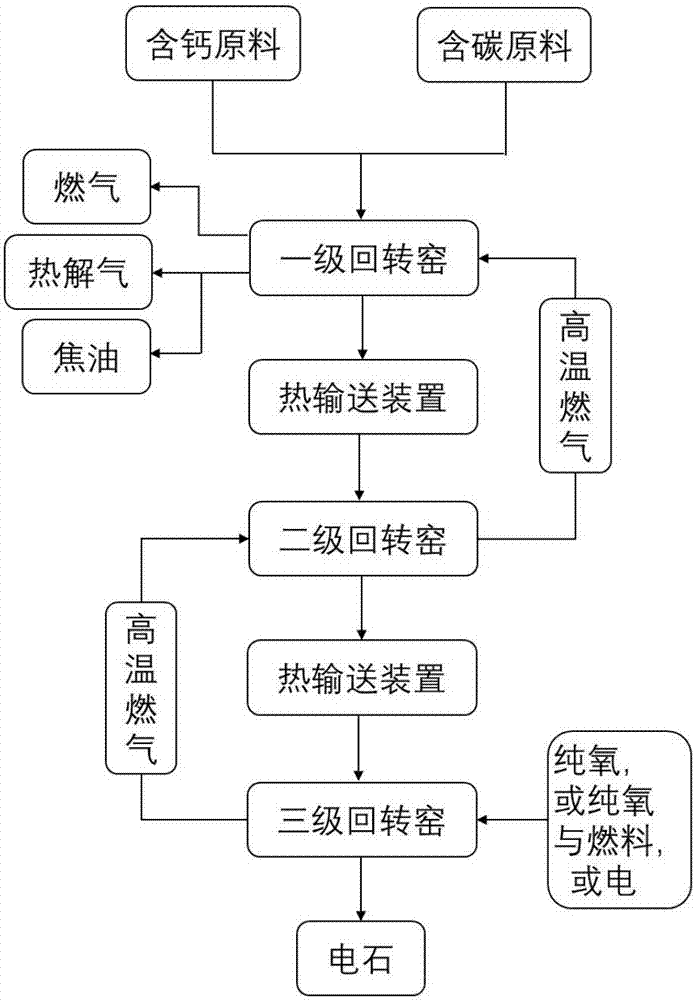

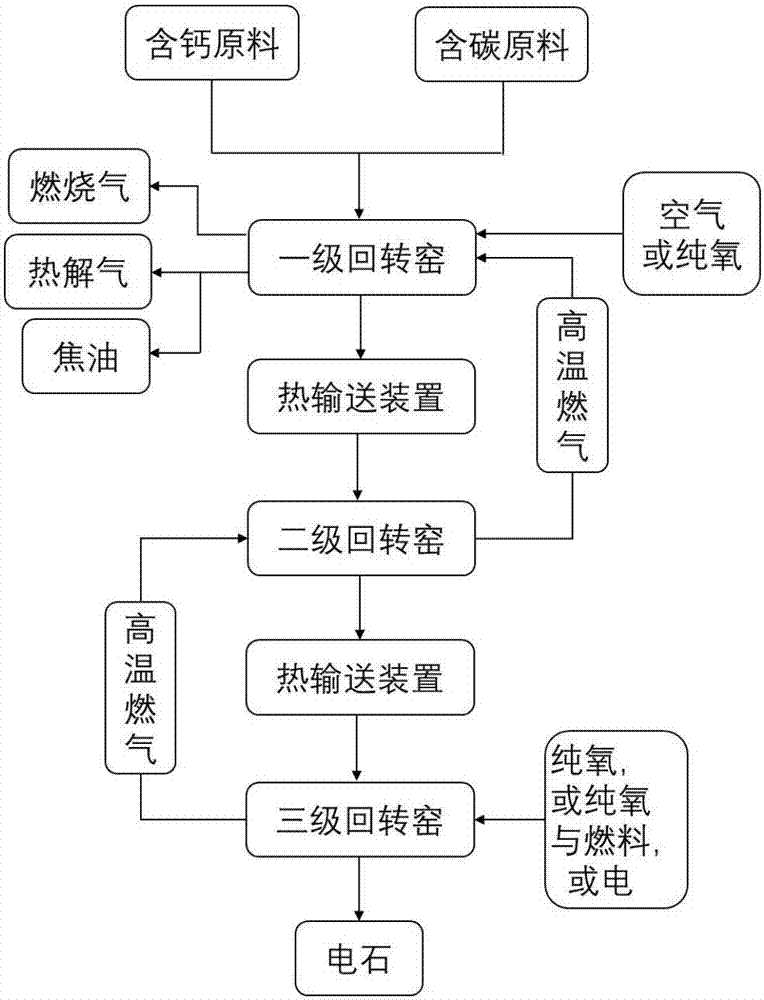

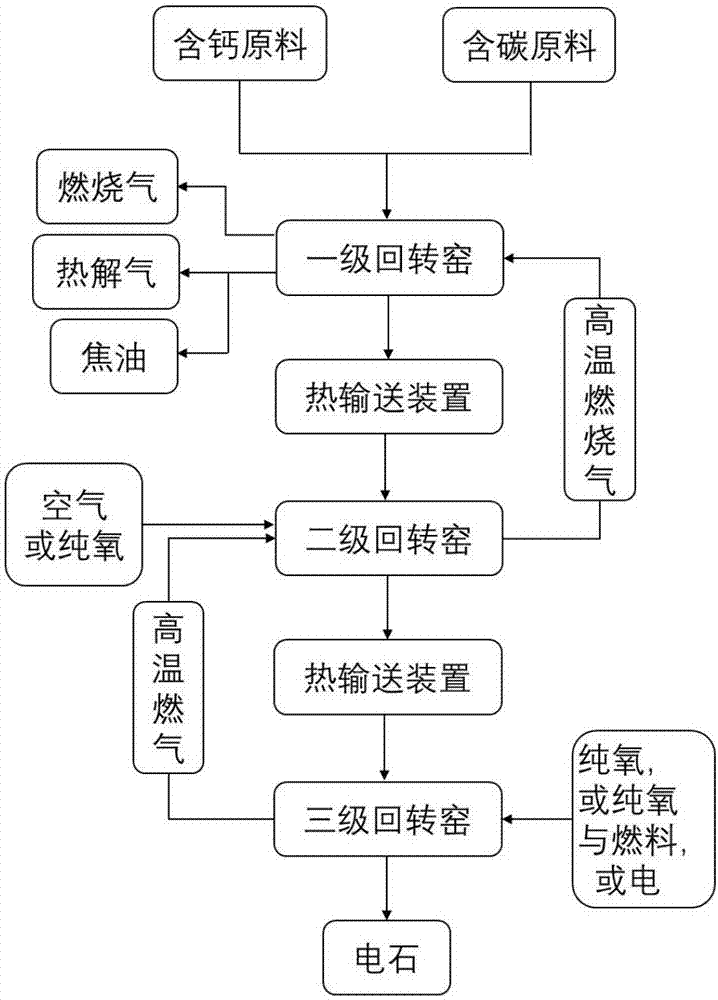

Calcium carbide preparation method

The invention provides a three-stage rotary kiln method for preparing calcium carbide. The method includes: heating a carbon-containing raw material and a calcium-containing raw material in a first-stage rotary kiln to 600-900 DEG C for pyrolysis; conveying into a second-stage kiln in a hot state, and preheating to 1000-1350 DEG C; conveying the preheated raw materials into a third-stage rotary kiln in a hot state; heating to 1500-1800 DEG C for reaction to produce solid-state calcium carbide. Compared with high-temperature arc processes, the method has the advantages that reaction temperatureand energy consumption for calcium carbide production are lowered, discharging is easy to perform, energy consumption for breaking calcium carbide in a molten state after solidification is omitted, equipment investment and running cost are lowered, and energy is saved by 30-46% in total. In addition, purity of calcium carbide prepared by the method is up to 93%, and conversion rate of CaO in thecalcium-containing raw material reaches 99%.

Owner:BEIJING UNIV OF CHEM TECH

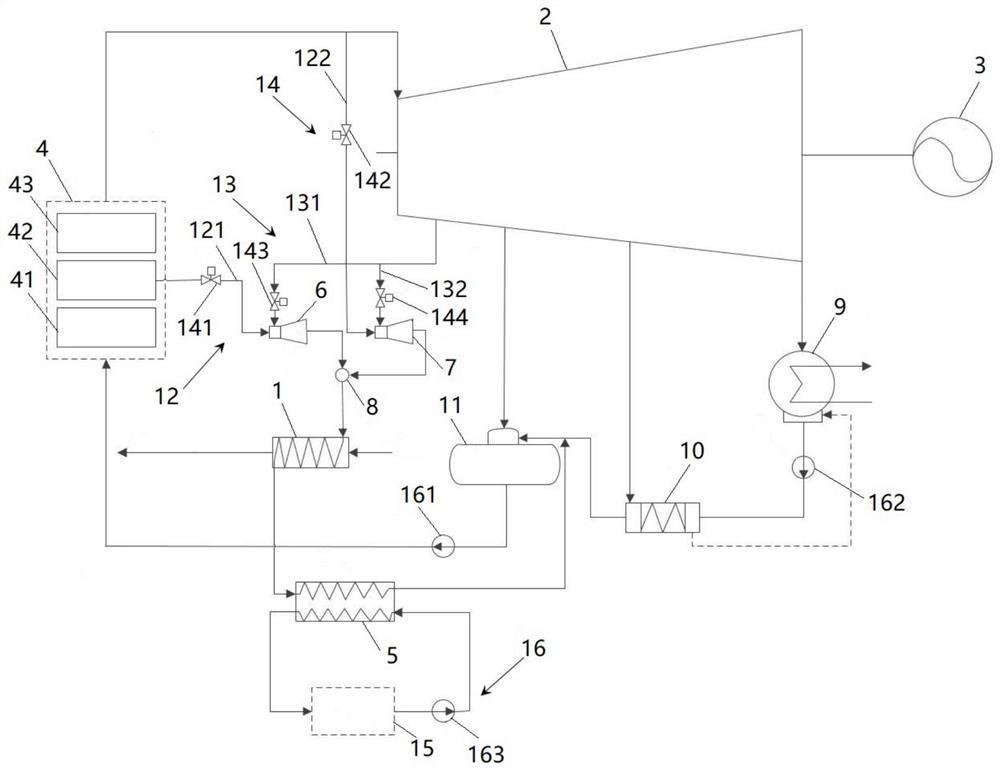

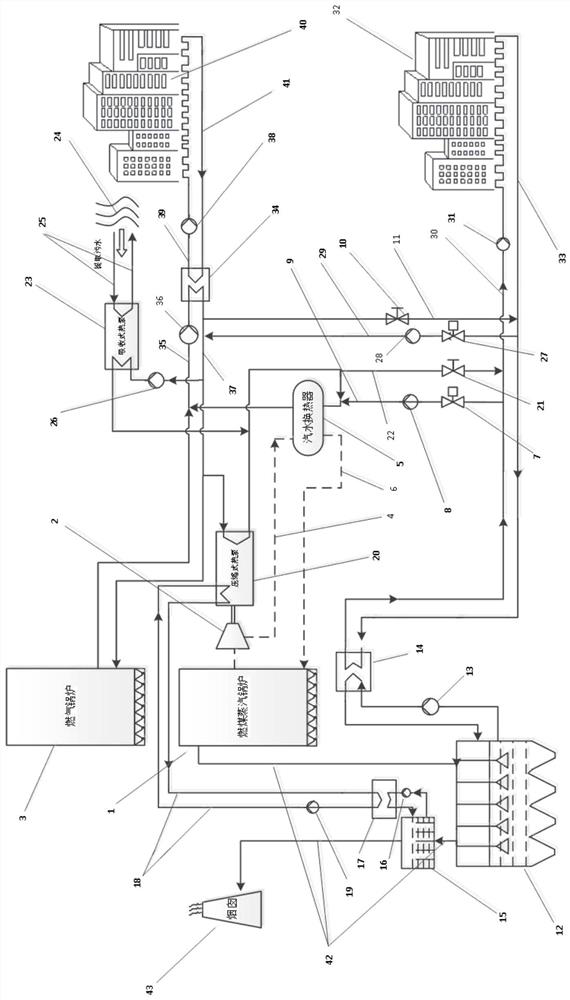

Multi-source complementary heat supply system and method for gradient utilization of energy

PendingCN112944426AIncrease heating capacityMeet heat demandLighting and heating apparatusEnergy efficient heating/coolingFlue gasProcess engineering

The invention discloses a multi-source complementary heat supply system for gradient utilization of energy. The multi-source complementary heat supply system comprises a coal-fired steam boiler, a steam turbine, a dead steam waste heat recovery mechanism, a first-stage flue gas waste heat recovery mechanism, a second-stage flue gas waste heat recovery mechanism, a sewage waste heat recovery mechanism, a near-end network circulation mechanism, a far-end first-stage network circulation mechanism, a far-end network second-stage circulation mechanism and a gas-fired boiler. The invention also discloses a multi-source complementary heat supply method for gradient utilization of energy. By the adoption of the multi-source complementary heat supply system for gradient utilization of energy, heat loss in the heat conveying process can be effectively reduced, equipment investment is reduced, and the ideal effect of excellent energy and excellent use is achieved; gradient utilization of energy is realized on the basis of ensuring that the indoor temperature of a heat consumer is appropriate, and pollution to the environment is reduced.

Owner:联美智慧能源科技(沈阳)有限公司 +1

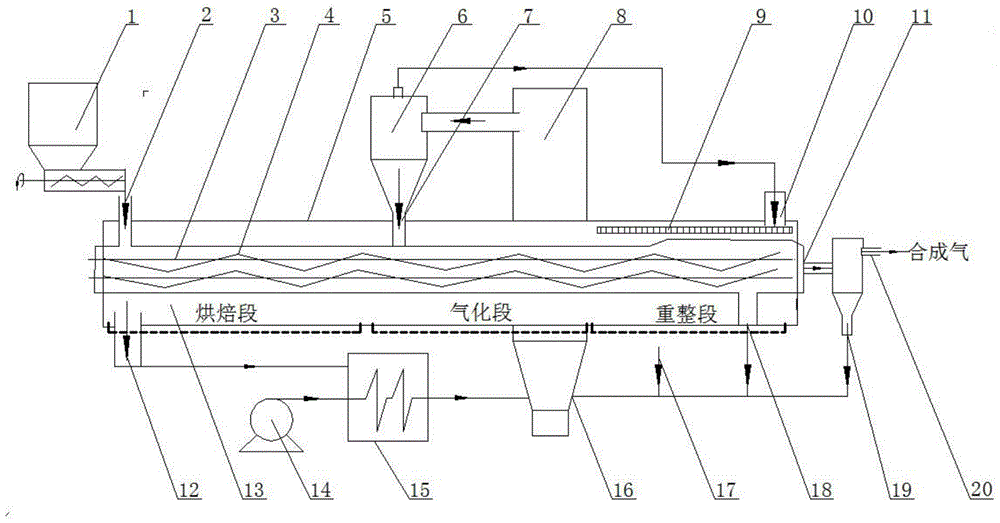

A method and device for preparing synthesis gas by pyrolysis and gasification of biomass

InactiveCN104593090BSimple crafting systemImprove gasification efficiencyHydrogenChemical recyclingProcess systemsRaw material

The invention provides a method and a device for preparing synthesis gas by biomass pyrolysis and gasification. The method comprises three stages of roasting at low temperature, catalytically gasifying at high temperature, and reforming through microwave; the three stages are respectively continuously performed in three relatively-independent spaces in a gasifying device, so as to obtain high-quality synthesis gas. The device comprises a double-shaft spiral pyrolysis reactor which is equipped with a roasting section at the front section, a gasifying section at the medium section, and a microwave assisting reforming section at the tail section; raw materials are fed into the double-shaft spiral pyrolysis reactor through a feeding device; the way of combining internal heat and external heat which are produced by smoke heat exchange, heat carried by a catalyst and microwave assisting heating is adopted to provide proper temperature of the three reaction stages to achieve staged pyrolysis and gasification; the produced gas is processed by a gas solid separator to obtain the synthesis gas; meanwhile, the deactivated catalyst and carbon coke and the like discharged by the reactor are fed into a combustion furnace to generate high-temperature smoke and regenerate the catalyst. With the adoption of the method and the device, the process system for preparing the synthesis gas can be simplified, the semi-coke and tar contents in pyrolysis and gasification can be decreased, and the gasifying efficiency of the system and the quality of the synthesis gas can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

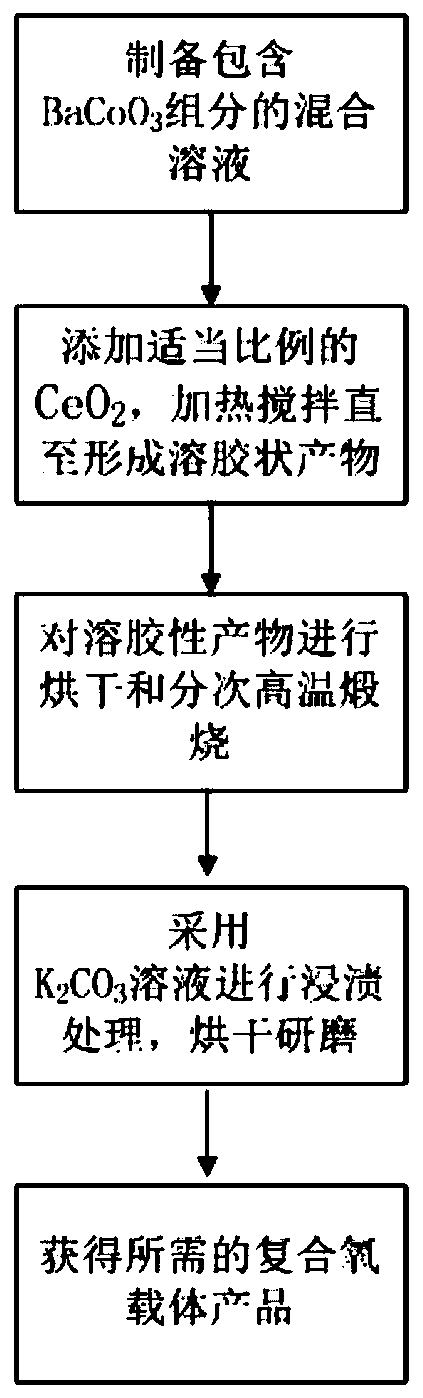

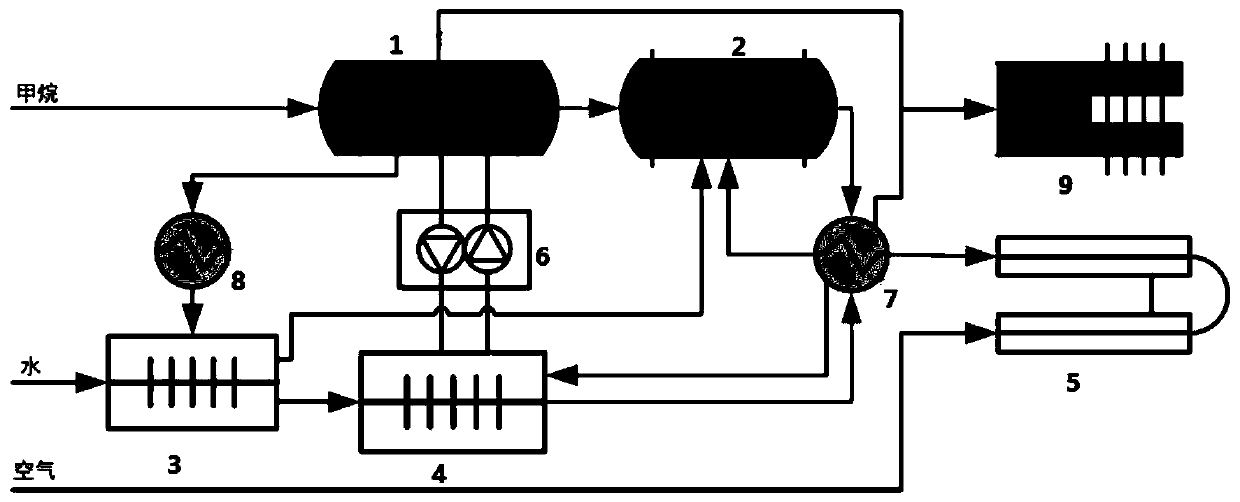

A combined heat and power system based on chemical chain methane reforming hydrogen production process

ActiveCN108328576BImprove energy utilizationCompact structureHydrogenChemical industrySteam reformingPartial oxidation

The invention discloses a cogeneration system based on a chemical-chain methane reforming process for hydrogen production, belonging to the related technical field of energy utilization equipment. Thecogeneration system comprises a reactor for partial oxidation of methane, a secondary steam reforming reactor, a steam generator, a steam reduction reactor, a fuel cell stack and an oxygen carrier cyclic feeder, wherein a process for preparing synthetic gas through partial oxidation of methane and a process for preparing hydrogen through steam reduction are coupled through a chemical-chain oxygencarrier; a secondary reforming device is adopted to realize low-energy-consumption hydrogen production; fuel cell fuel cells are utilized so as to realize the output of electric power; and heat produced in the reaction process is collected and distributed by a heat exchanger, so high-efficiency external heat supply is realized. Targeted design is carried out on the composite oxygen carrier used in the system. The cogeneration system provided by the invention can realize low-cost, high-energy-utilization-rate and environment-friendly gas power generation and heat supply under the conditions oflow energy consumption and miniaturization, and is compact in equipment layout and flexible and convenient to operate.

Owner:HUAZHONG UNIV OF SCI & TECH

Combined heat and power generation system based on supercritical CO2 coupling chemical looping combustion and supercritical hydrothermal reaction and working method

PendingCN111947140AImprove economyImprove energy efficiencyIndirect carbon-dioxide mitigationSteam engine plantsCogenerationHigh pressure water

The invention relates to a combined heat and power generation system based on supercritical CO2 coupling chemical looping combustion and supercritical hydrothermal reaction and a working method. At present, no combined heat and power generation system based on supercritical CO2 coupling chemical looping combustion and supercritical hydrothermal reaction with high energy utilization efficiency of achemical looping combustion system exists. The combined heat and power generation system comprises a chemical looping combustion system, a coal water slurry system and a heat and power generation system, and is characterized by further comprising a supercritical water oxidation system, wherein the supercritical water oxidation system comprises a high-pressure coal water slurry pump, a supercritical hydrothermal reactor, a preheater, a CO2 separator and an N2 tank; the high-pressure coal water slurry pump is connected with the coal water slurry system; the preheater is connected with the supercritical hydrothermal reactor; the supercritical hydrothermal reactor is connected with the high-pressure coal water slurry pump, the CO2 separator and a cyclone separator through pipelines respectively; and the N2 tank is connected with the CO2 separator and the heat and power generation system through pipelines respectively. The chemical looping combustion system is high in energy utilization rate, and oxygen-carrying particles in chemical looping combustion are not easy to sinter.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

A solar-assisted reheating heat recovery thermal power generation system and method for reducing emission and expanding capacity

ActiveCN104595136BReduce coal consumptionIncrease powerFrom solar energySteam engine plantsHigh pressureCoal

The invention discloses a solar energy assisted reheat heat recovery thermal power generation system. Boiler, steam turbine, condenser, main circulation pump, recuperation heater and boiler are connected in sequence to form the main circulation circuit; the concentrating mirror field focuses sunlight on the solar heat absorber; solar heat absorber, solar high temperature reheater, solar The heat recovery reheater, secondary circulation pump, and solar heat absorber are connected in sequence to form a secondary cycle solar heating circuit; the inlet of the low-pressure cylinder of the steam turbine is connected in sequence with the high-temperature solar reheater and the outlet of the high-pressure cylinder of the steam turbine to form a reheat circuit; the low-pressure cylinder of the steam turbine The regenerative steam extraction port is sequentially connected with the solar regenerative reheater and the regenerative heater; the steam turbine is connected with the generator. The present invention utilizes the secondary cycle of solar energy to realize the purpose of reducing coal consumption and increasing the total power of the system by increasing the reheating surface and regenerative reheating. Based on the full use of solar energy, the original system can operate independently, realizing the function of using solar heat storage to meet the peak and valley energy supply of the regulation system.

Owner:ZHEJIANG UNIV

Energy gradient utilization system

PendingCN113218217ASimple structureSimple systemBoiler cleaning apparatusSteam/vapor condensersThermodynamicsEngineering

An energy gradient utilization system comprises a heat supply steam pipeline and a two-stage heat supply network heater. A heater partition plate used for dividing the two-stage heat supply network heater into a heater low-pressure stage and a heater high-pressure stage is arranged in the two-stage heat supply network heater, a heater water inlet pipeline connected with the heater low-pressure stage is arranged at one end of the two-stage heat supply network heater, and a heater water outlet pipeline connected with the heater high-pressure stage is arranged at the other end of the two-stage heat supply network heater. An outlet of the heat supply steam pipeline is divided into two paths, one path communicates with the heater high-pressure stage, the other path is connected with an inlet of a small back pressure machine, and an outlet of the small back pressure machine communicates with the heater low-pressure stage. By arranging the small back pressure machine and the two-stage heat supply network heater, heat supply steam and steam exhausted by the small back pressure machine are exhausted to the high-pressure stage and the low-pressure stage of the two-stage heat supply network heater correspondingly, two strands of steam with different pressure grades are exhausted to one heat supply network heater, gradient utilization of energy is achieved through the small back pressure machine, and meanwhile gradient heating of heat supply network water through the heater low-pressure stage and the heater high-pressure stage is achieved.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

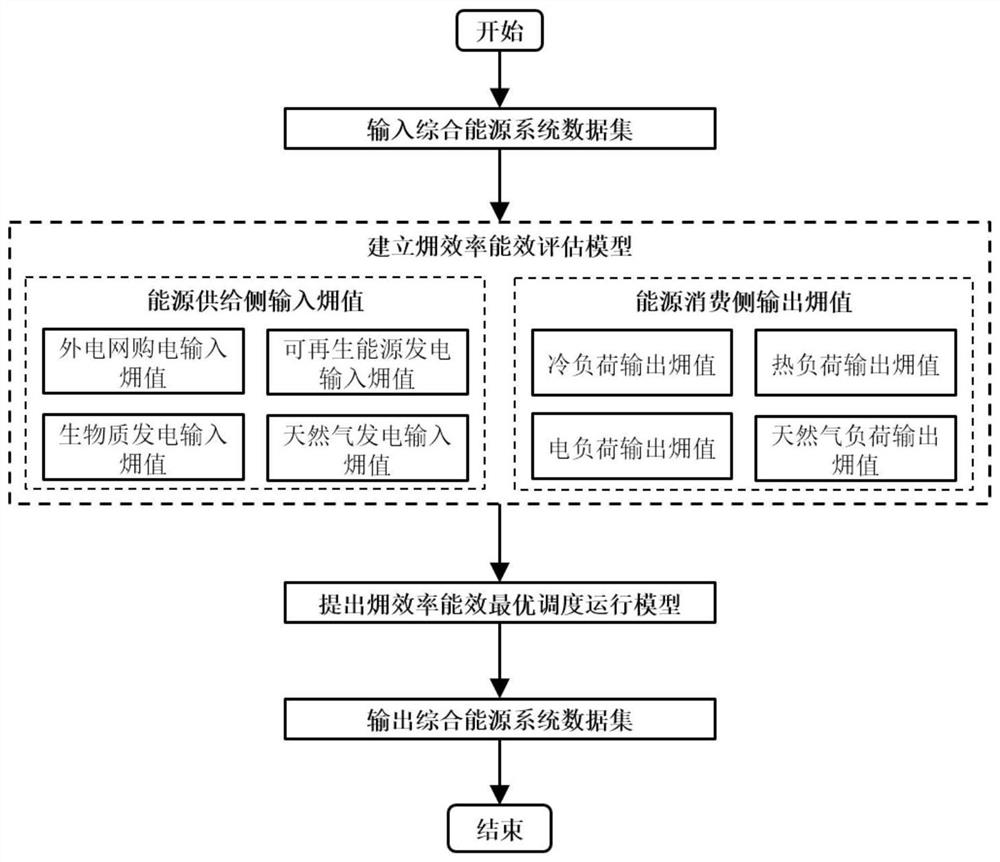

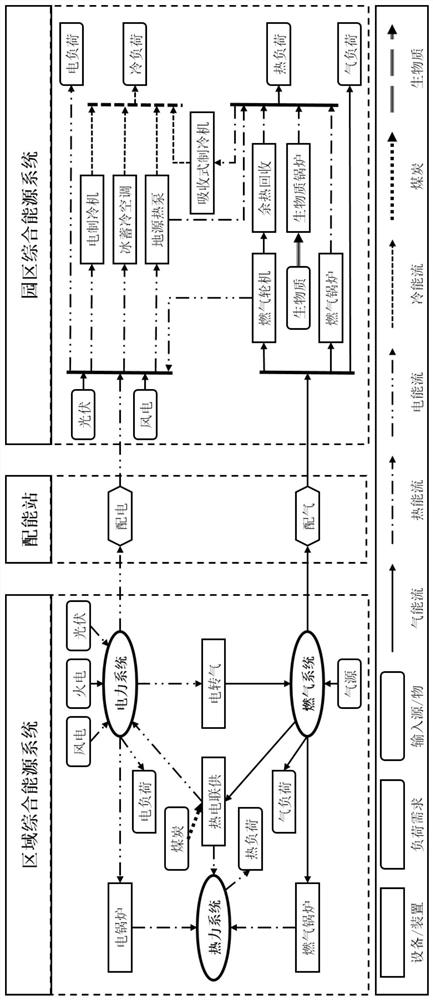

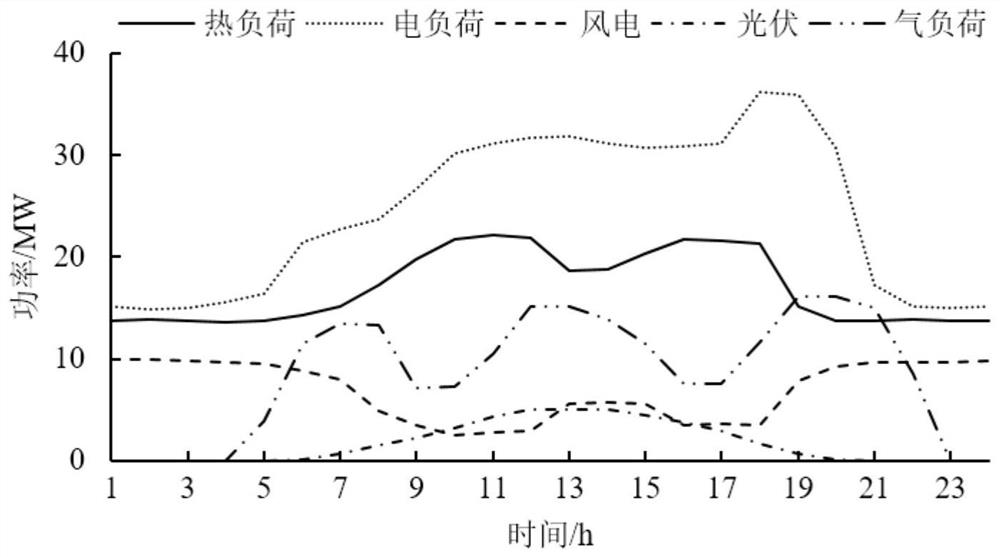

Comprehensive energy system Ex efficiency and energy efficiency evaluation method considering primary energy permeability

PendingCN113205208AEffective assessmentMeet diverse energy needsForecastingTechnology managementSupply energyProcess engineering

The invention discloses a comprehensive energy system Ex efficiency and energy efficiency evaluation method considering primary energy permeability, and the method comprises the steps: determining a total input value of each energy type at an energy supply side, including an external power network power purchase input value determined on the basis of considering the primary energy source permeability; determining the total output value of each energy type at the energy consumption side; and performing efficiency energy efficiency evaluation according to the ratio of the total output value of the energy consumption side to the total input value of the energy supply side. The method introduces efficiency to quantify the characteristics. According to the method, the external power grid power purchase input value is determined on the basis of considering the primary energy source permeability, the multi-type energy quality and the determined total input value of the integrated energy system are comprehensively considered, the two attributes of energy quantity and quality are comprehensively considered, and the energy efficiency of the integrated energy system can be evaluated more objectively and effectively.

Owner:NANJING GUODIAN NANZI POWER GRID AUTOMATION CO LTD

A cascaded heating system for preheating the inlet material of the gas fractionation tower

ActiveCN104383704BRealize energy cascade utilizationReduce consumptionDistillation regulation/controlHydrocarbon distillationReboilerWorking temperature

The invention relates to a step heating method and heating system for preheating of a gas fractionating tower inlet material. The heating method includes: preheating a material by a hot water / material heat exchanger outside a fractionating tower to 80+ / -10DEG C, letting the preheated material enter the fractionating tower, heating the material by a bottom reboiler in the tower and maintaining a working temperature required by material fractionation to realize step heating of the material. The heating system comprises a petroleum fractionating heating system component and a waste heat recovery inlet material heating system component. Specifically, the gas fractionating heating system component comprises: the fractionating tower, an air cooler, a water cooled heat exchanger and the reboiler; and the waste heat recovery inlet material heating system component includes: the hot water / material heat exchanger and a steam type lithium bromide absorption type heat pump. The method and the system provided by the invention utilize the recovered waste heat to preheat the inlet material, realize energy step utilization of the fractionating tower heating process, reduce the process steam consumption by over 20%, improve the energy utilization rate, and save the cost.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com