Multi-source complementary heat supply system and method for gradient utilization of energy

A heating system and cascade technology, applied in the field of multi-source complementary heating systems, can solve problems such as poor output safety and stability, low energy utilization, resource waste, etc., to improve linkage coupling, reduce heating network imbalance, The effect of increasing the heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

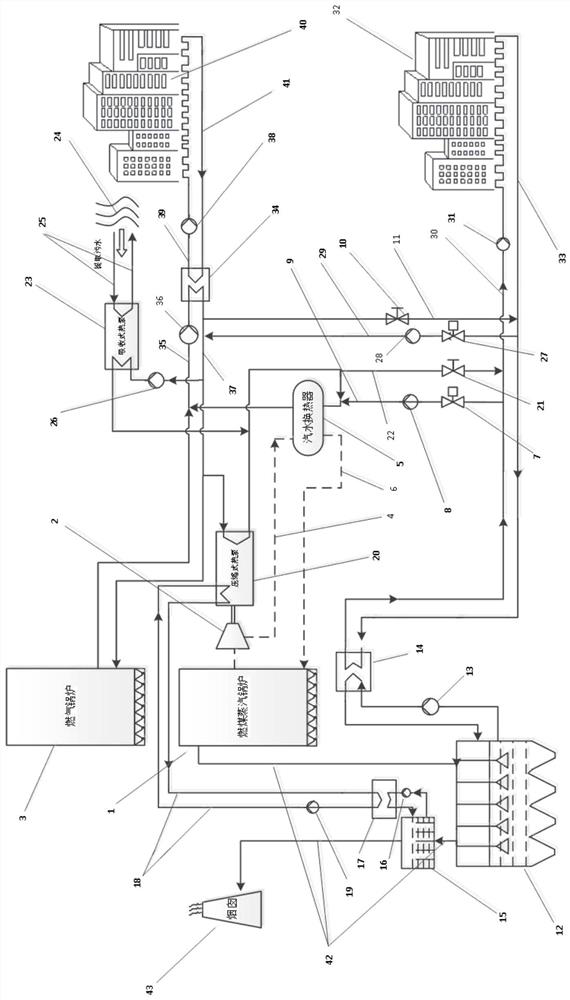

[0077] Embodiment 1 of the present invention discloses a multi-source complementary heat supply system for cascaded utilization of energy, including a coal-fired steam boiler, a steam turbine, a waste steam waste heat recovery mechanism, a primary flue gas waste heat recovery mechanism, a secondary flue gas waste heat recovery mechanism, Sewage waste heat recovery mechanism, near-end network circulation mechanism, remote primary network circulation mechanism, remote secondary network circulation mechanism and gas boiler;

[0078] The high-temperature steam outlet of the coal-fired steam boiler is connected to the steam turbine, and the flue gas outlet is connected to the first-level flue gas waste heat recovery mechanism and the second-level flue gas waste heat recovery mechanism through the flue;

[0079] Among them, the waste steam heat recovery mechanism includes a steam pipe, a steam-water heat exchanger and a condensate water pipe; the steam pipe is connected to the steam ...

Embodiment 2

[0101] Embodiment 2 of the present invention discloses a multi-source complementary heating method for cascaded energy utilization. Using the multi-source complementary heating system for cascaded energy utilization disclosed in Embodiment 1 includes the following steps:

[0102] (1) The high-pressure steam generated by the coal-fired steam boiler is input into the steam turbine to do work, and the low-temperature exhaust steam is discharged. The low-temperature exhaust steam is transported to the steam-water heat exchanger through the steam pipe for heat exchange, and the condensed water is returned to the coal-fired steam boiler through the condensate pipe for heating; Among them, the pressure of high-pressure steam is 3.11-3.96Mpa, the temperature is 430-480°C, the pressure of low-temperature exhaust steam is 0.12Mpa, and the temperature is 190°C

[0103] (2) The flue gas produced by the coal combustion process in the coal-fired steam boiler is transported to the first-level...

Embodiment 3

[0112] Embodiment 3 of the present invention takes the heating system of a heating company in Shenyang as an example. The company’s heat source is 60MW coal-fired steam boiler and 20MW gas boiler, the heating area is 1 million square meters, and the indoor standard temperature is 18°C. A heat supply method for cascade utilization of energy, comprising the steps of:

[0113] (1) The high-pressure steam generated by the coal-fired steam boiler is input into the steam turbine to do work, and the low-temperature exhaust steam is discharged. The low-temperature exhaust steam is transported to the steam-water heat exchanger through the steam pipe for heat exchange, and the condensed water is returned to the coal-fired steam boiler through the condensate pipe for heating; Among them, the pressure of high-pressure steam is 3.12Mpa and the temperature is 480°C, the pressure of low-temperature exhaust steam is 0.12Mpa and the temperature is 190°C;

[0114] (2) The flue gas produced duri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com