Heating steam-extraction and heating-supply system adopting high-back-pressure small steam turbine

A technology for heating extraction and heating systems, applied in steam engine installations, steam applications, mechanical equipment, etc., can solve problems such as waste of high-quality steam, achieve good economy, improve power generation capacity, and realize the effect of energy cascade utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

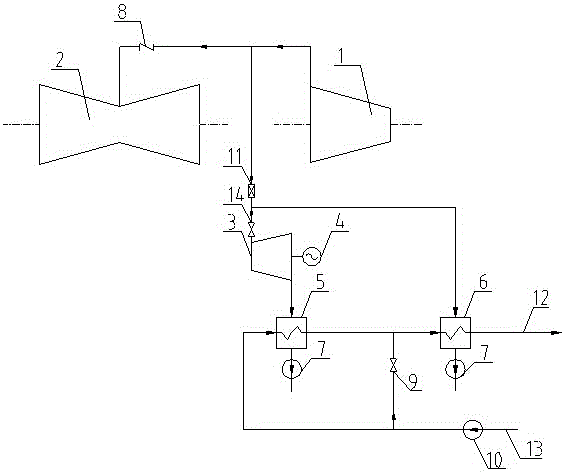

[0013] exist figure 1 In the shown embodiment, there are two branches at the exhaust port of the medium-pressure cylinder (1), one branch is connected with the inlet of the low-pressure cylinder (2), and an electric butterfly valve (8 ); the other branch is divided into two branches, one branch is connected with the high back pressure small turbine (3), and the high back pressure small turbine (3) is connected with the asynchronous generator (4); the other branch is connected with the peak heater ( 6) The steam side inlet is connected. The exhaust steam of the high back pressure small turbine (3) enters the steam side inlet of the front heater (5). The circulating water of the heating network enters the front heater (5) and the peak heater (6) sequentially through the return water pipeline (13) of the heating network, and the circulating water of the heating network coming out of the water side outlet of the peak heater (6) passes through the heating network The water supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com