Flue gas decarbonization system and flue gas decarbonization method for two-step regeneration of carbon dioxide

A carbon dioxide and flue gas technology, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems such as failure to effectively achieve energy saving, low cost, high cost of metal oxides, and complex adsorbent processes, etc. Process integration studies promote, improve energy efficiency, and save sensible and evaporative heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

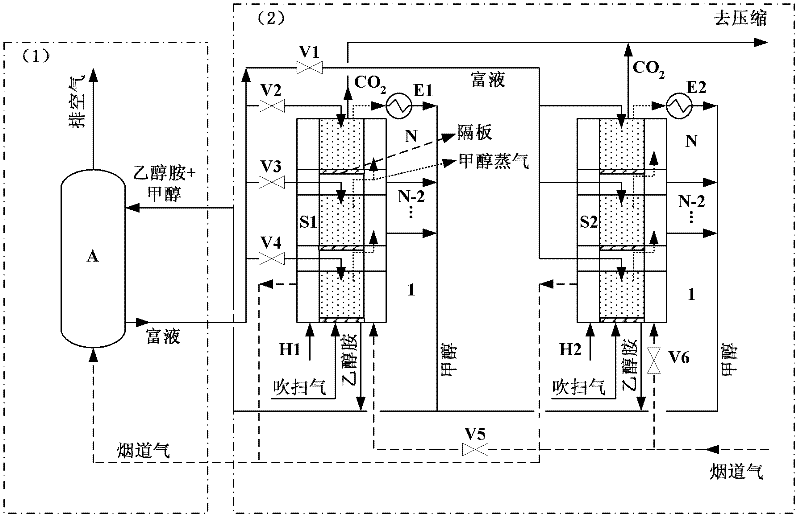

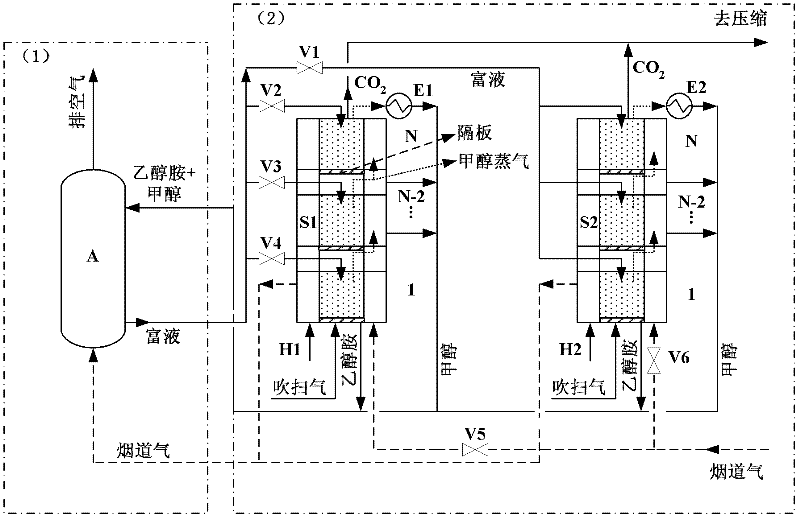

[0035] see figure 1 , a flue gas decarbonization system for carbon dioxide two-step regeneration, including an absorption tower with a flue gas inlet at the bottom and a regeneration tower with an N-level packed tower structure, and an alcohol amine-methanol mixture for absorbing carbon dioxide is installed in the absorption tower Solvent, the flue gas enters the absorption tower after the first heat transfer of the regeneration tower, absorbs carbon dioxide through the alcohol amine-methanol mixed solvent, and then discharges from the top outlet;

[0036] The alcohol amine-methanol mixed solvent absorbs carbon dioxide and then splits into the first to N stages of the regeneration tower. The first stage of the regeneration tower at the bottom is equipped with a heat exchange pipeline for flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com