Combined heat and power generation system based on supercritical CO2 coupling chemical looping combustion and supercritical hydrothermal reaction and working method

A technology of chemical chain combustion and supercritical water, which is applied in combustion methods, combustion equipment, fuel supply, etc., can solve the problems of easy sintering of oxygen carrier particles, achieve good CO2 emission reduction effects, improve energy utilization efficiency, and be economical Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

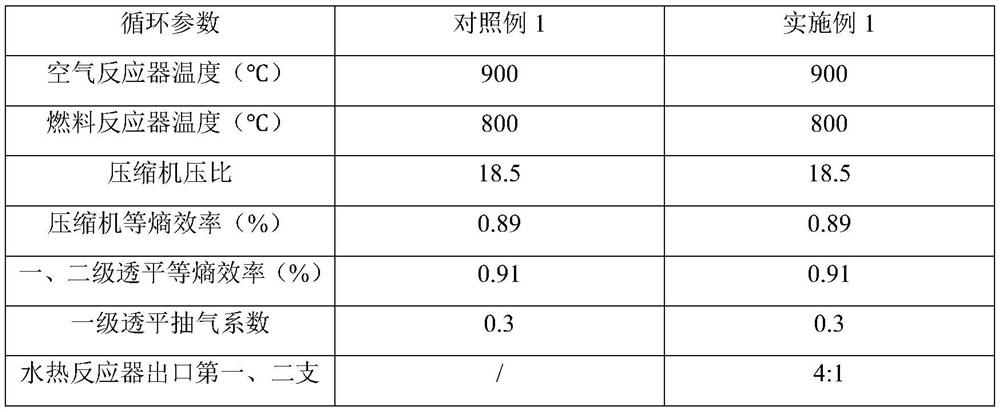

Embodiment 1

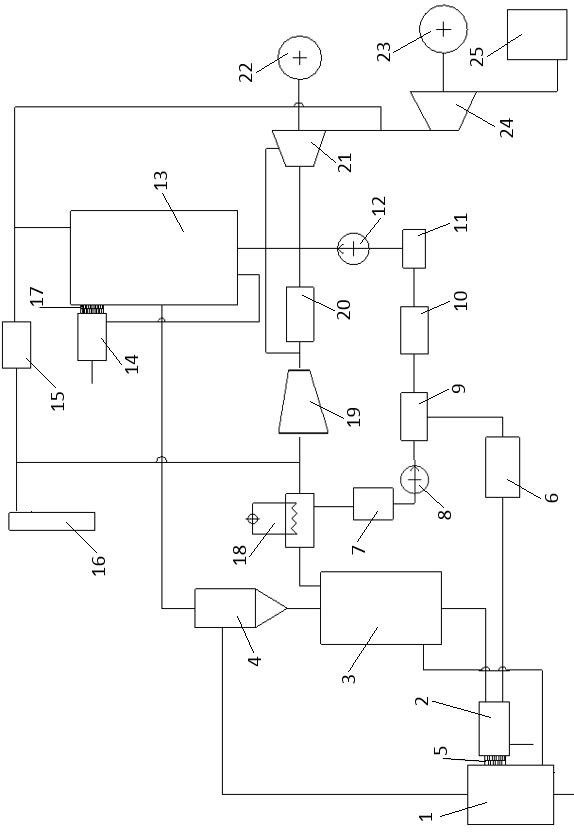

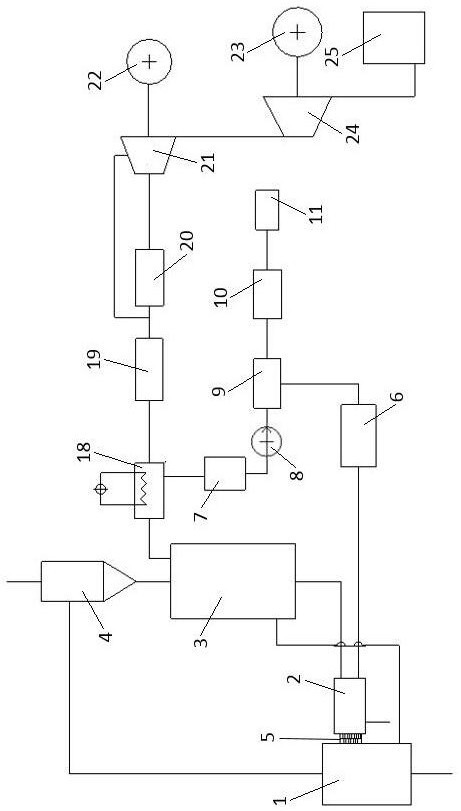

[0036] see figure 1 , the present invention is based on supercritical CO 2 The cogeneration system of cyclically coupled chemical chain combustion and supercritical hydrothermal reaction includes chemical chain combustion system, supercritical water oxidation system, coal-water slurry system and thermoelectric generation system.

[0037] The chemical chain combustion system includes an air reactor 1, a pyrolysis furnace 2, a fuel reactor 3 and a cyclone 4. The air reactor 1 includes 3 interfaces, which are the bottom air inlet, the bottom side oxygen carrier inlet and the top outlet. .

[0038] The pyrolysis furnace 2 has three interfaces, which are the bottom fuel inlet, the side gas product outlet and the side residual coke outlet. The pyrolysis furnace 2 and the upper part of the air reactor 1 are connected through the No. 1 prefabricated steel plate 5, and the No. 1 prefabricated steel plate 5 is connected by 3 It is made of high-chromium cast iron made of about % graphi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com