Power generation device and method for recovering heat of cold source of power plant

A power generation device and cold source technology, which can be applied to steam engine devices, machine operation modes, machines using refrigerant evaporation, etc., and can solve problems such as difficulty in recycling and utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

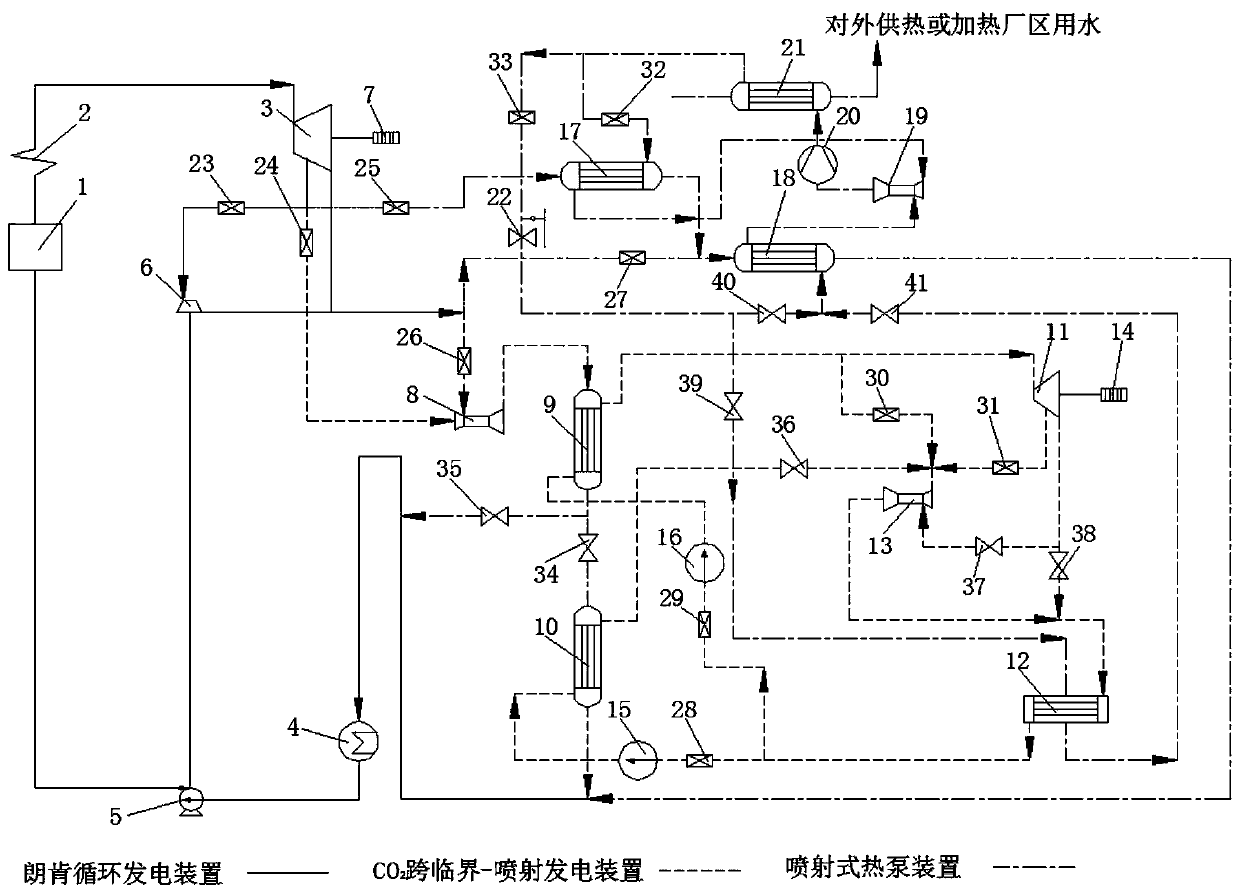

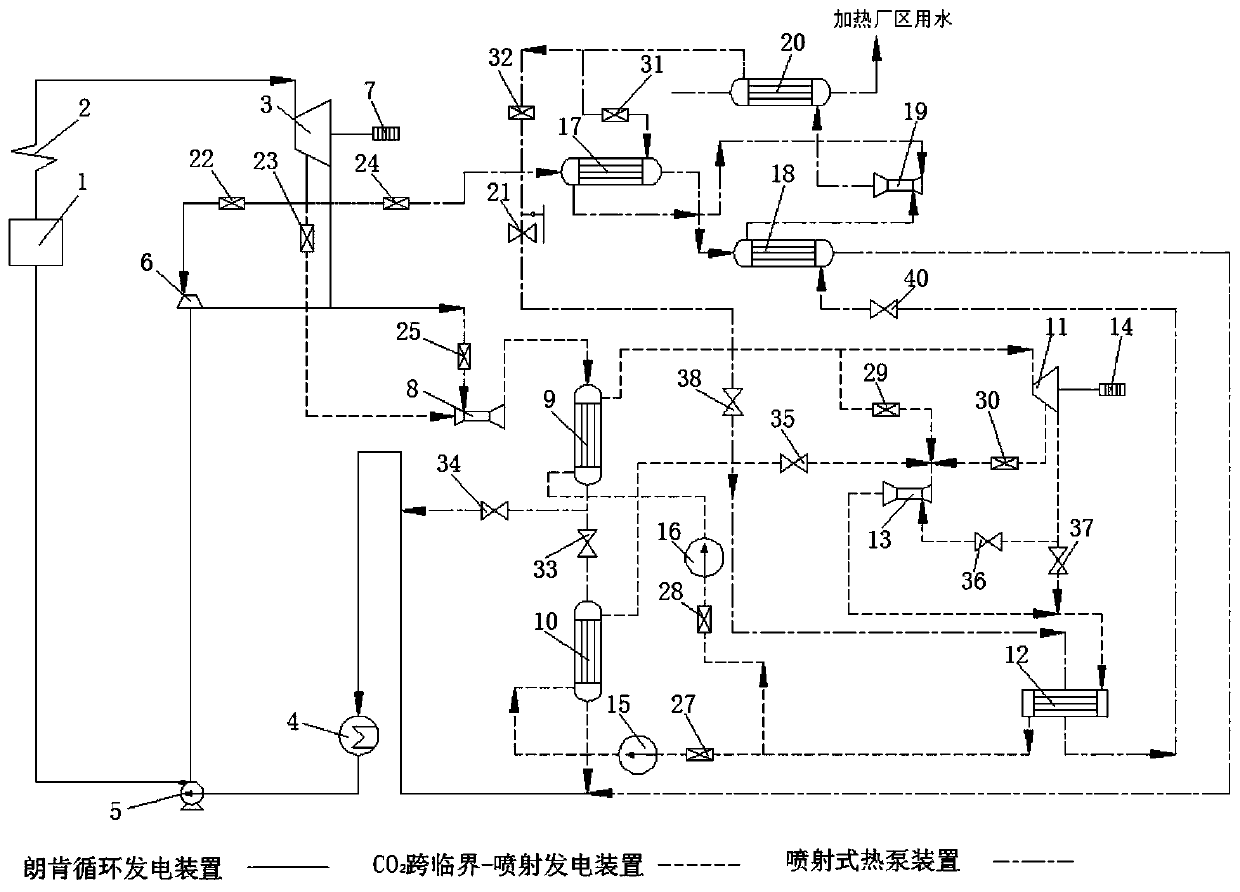

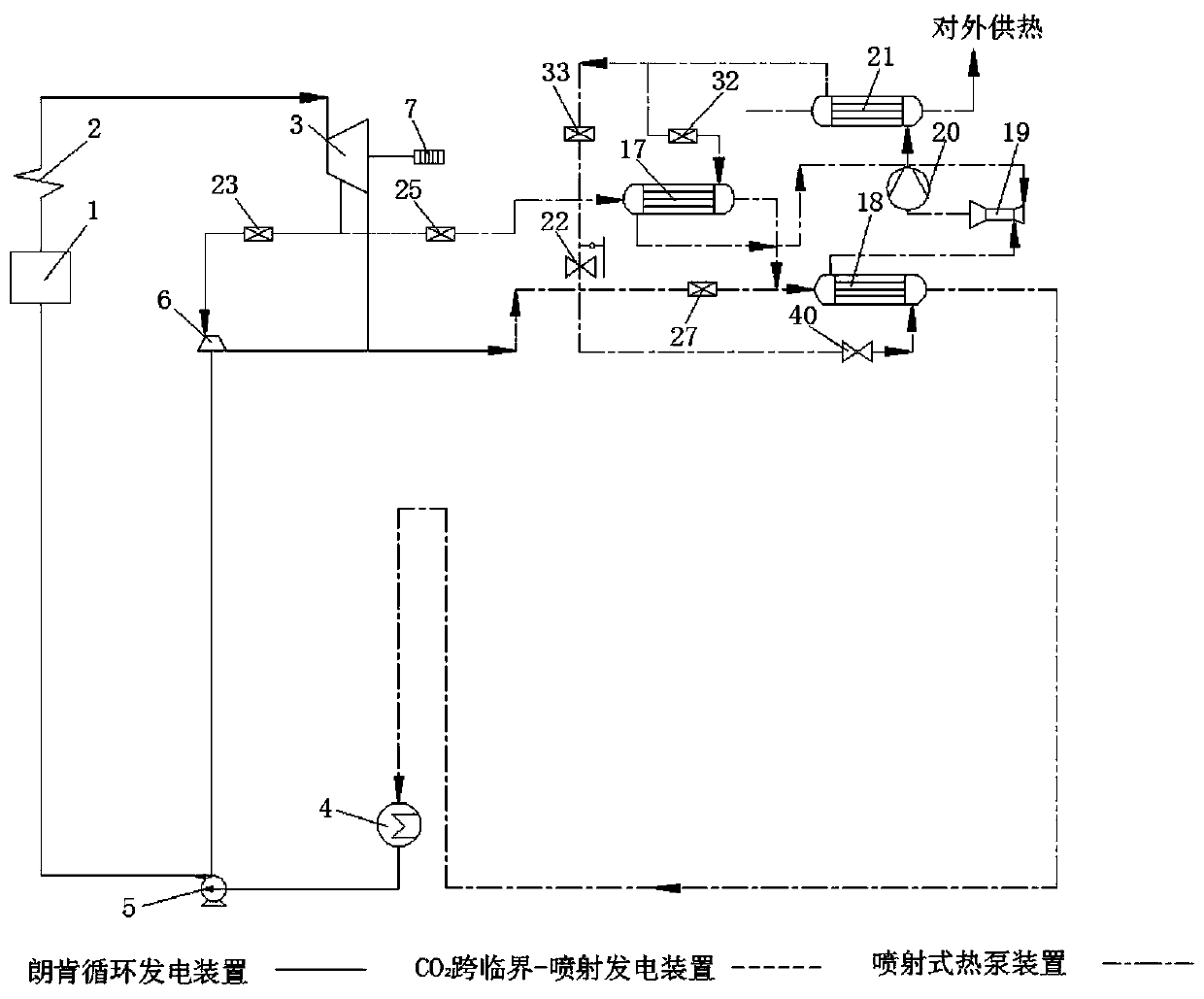

[0037] Such as figure 1 As shown, a power generation device for recovering heat from the cold source of a power plant, including a Rankine cycle power generation device, CO 2 Transcritical-jet power generation device and jet heat pump device;

[0038] The CO 2 The transcritical-jet power generation device includes a primary evaporator 9, a secondary evaporator 10, a low-pressure working medium pump 15, a high-pressure working medium pump 16, an organic working medium gas turbine 11, a first injector 8, and a second injector 13. Organic working medium condenser 12, organic working medium generator 14, second flow regulating valve 24, fourth flow regulating valve 26, sixth flow regulating valve 28, seventh flow regulating valve 29, eighth flow regulating valve 30 , the ninth flow regulating valve 31, the first isolation valve 34, the second i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com