Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

288results about How to "Quick grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

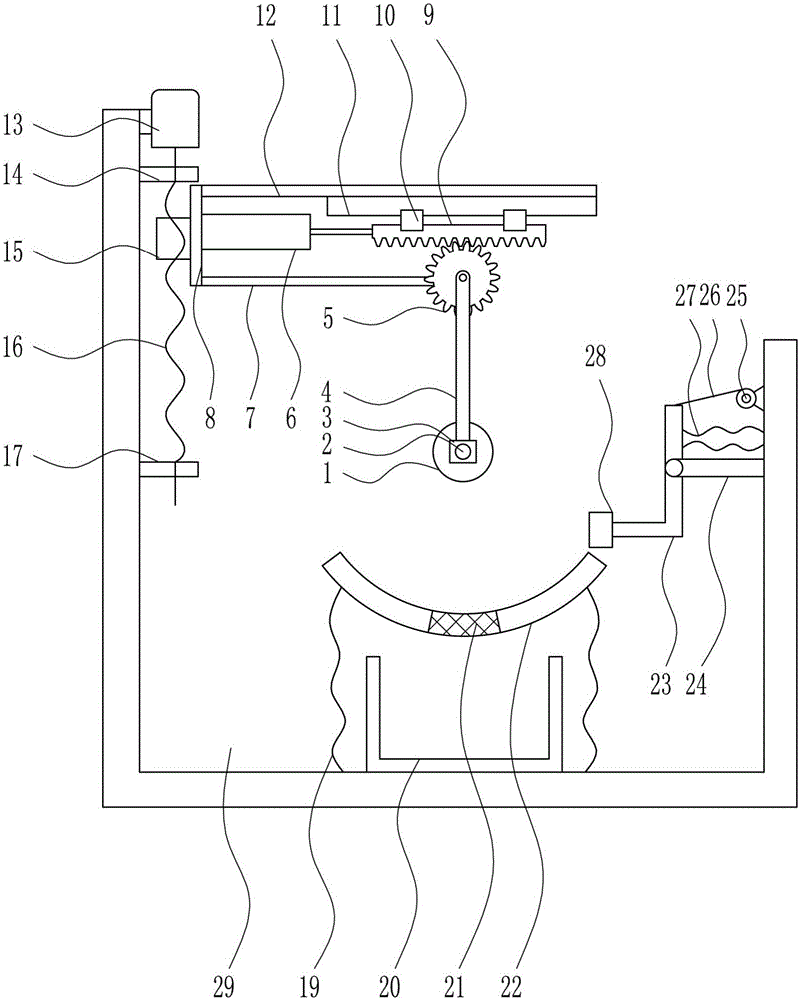

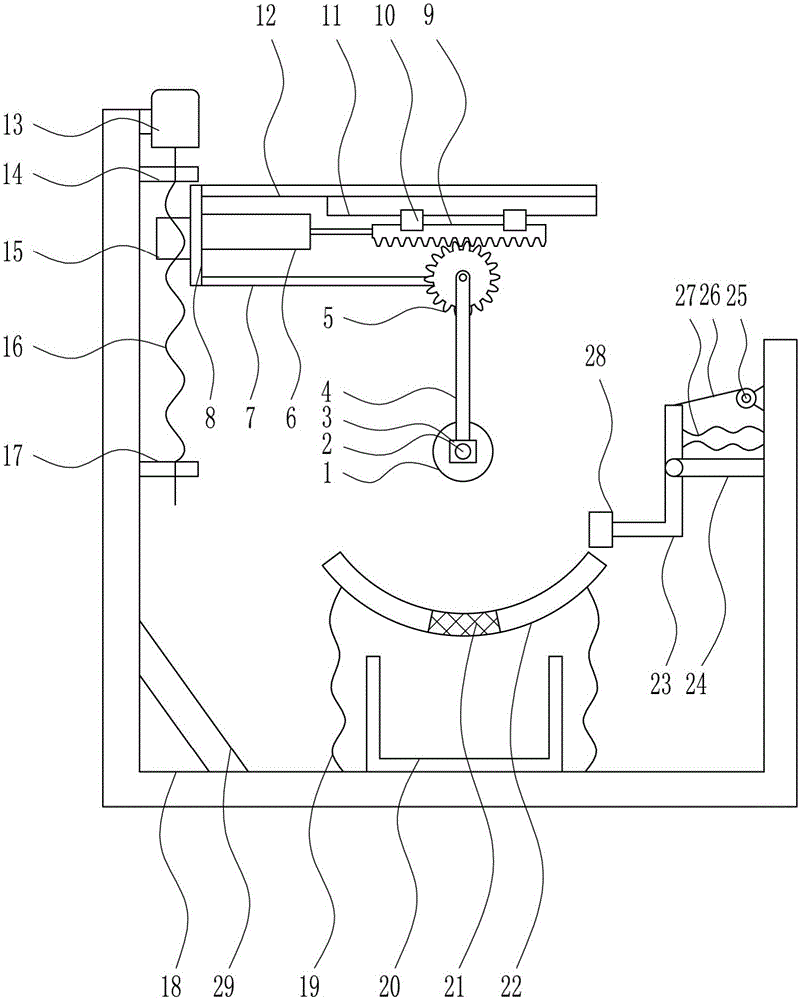

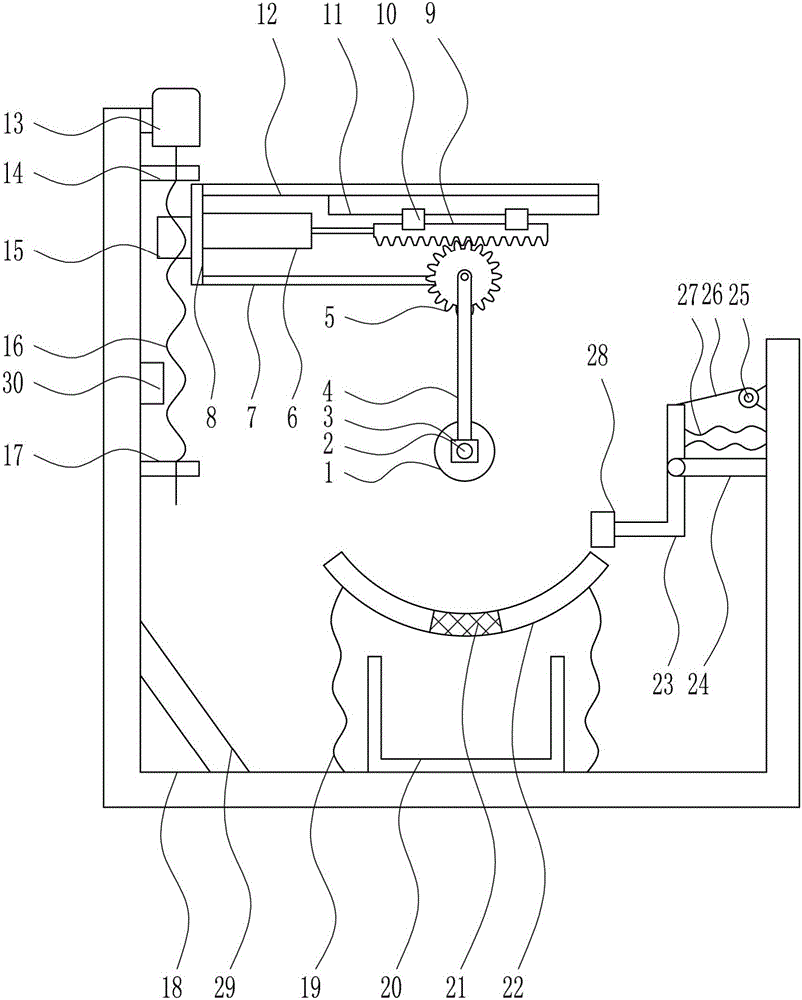

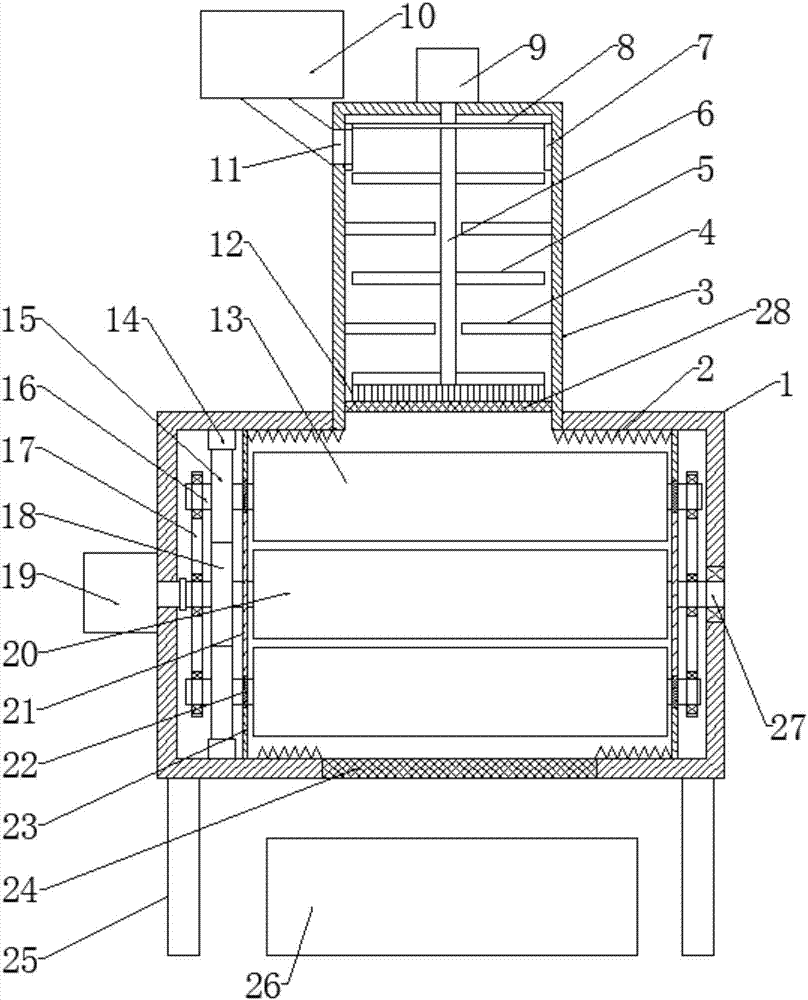

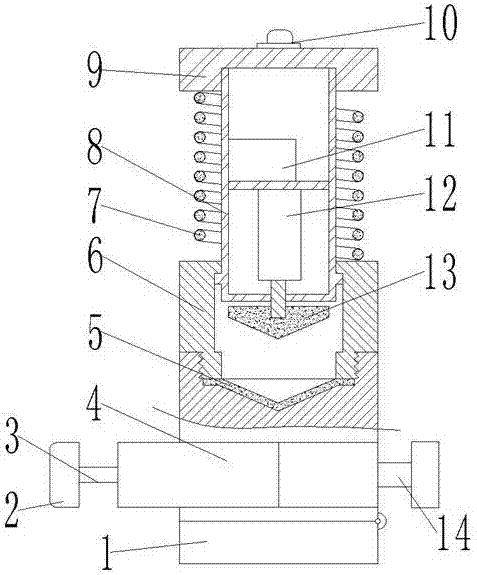

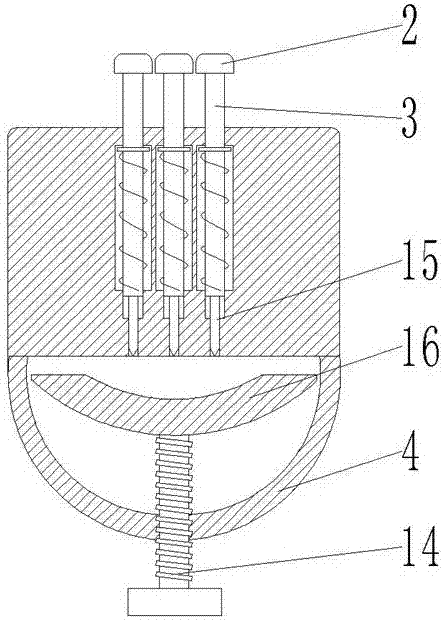

Rapid medicine grinding device for medical pediatrics

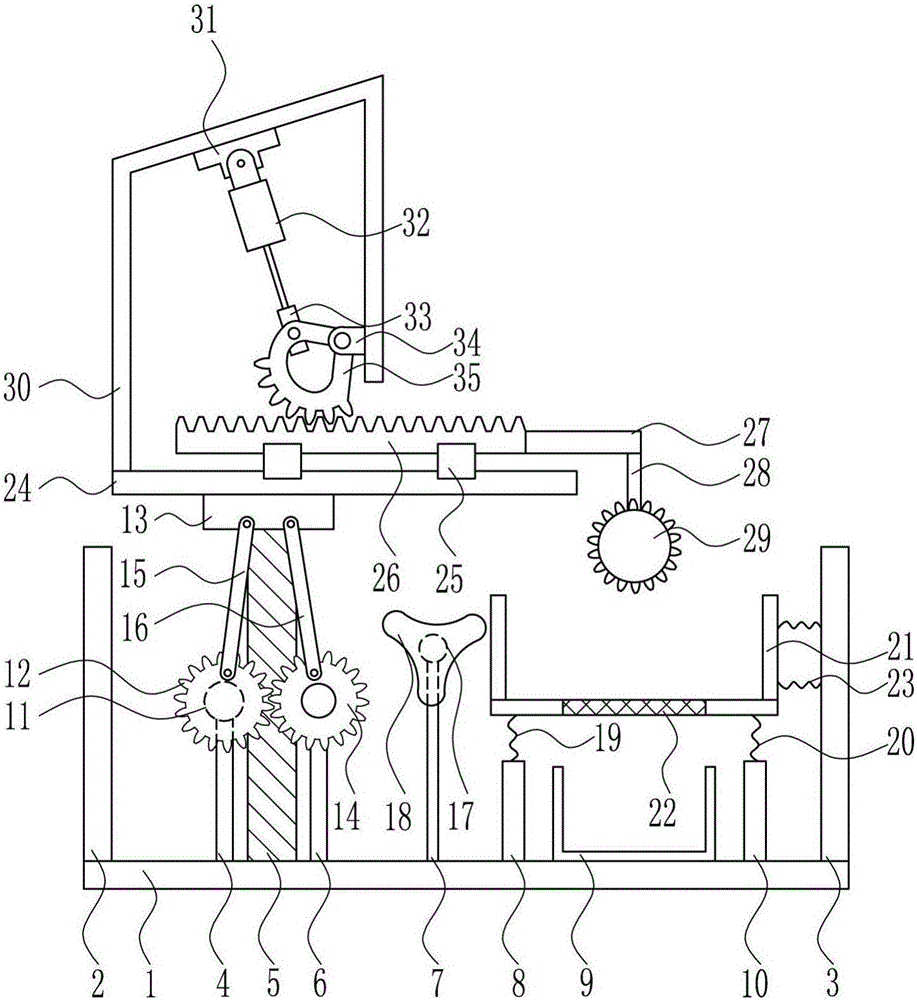

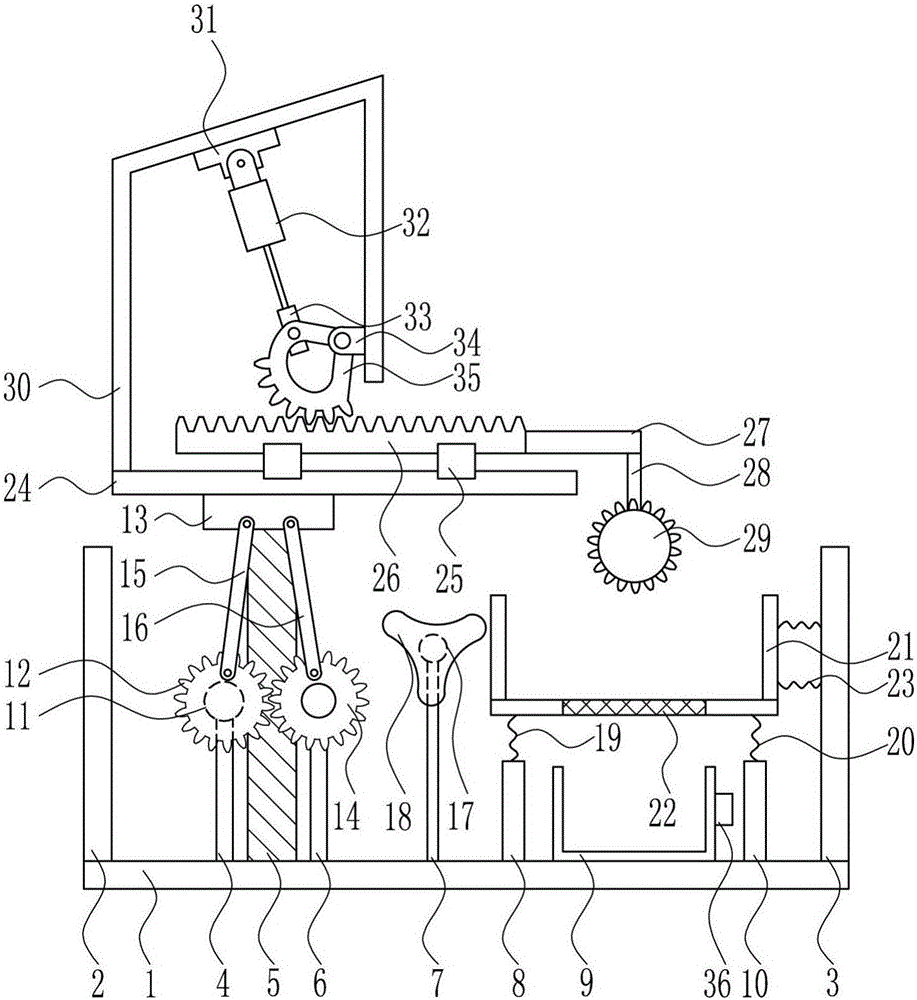

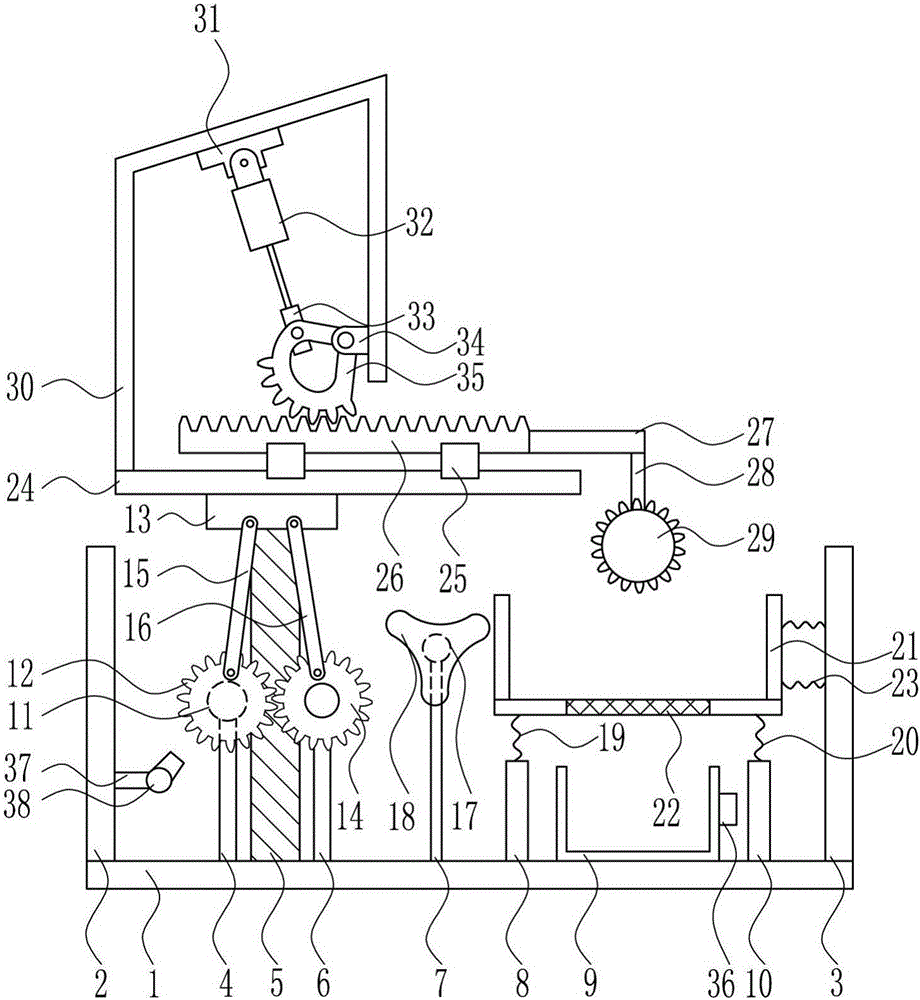

The invention relates to a medicine grinding device for medical pediatrics, in particular to a rapid medicine grinding device for medical pediatrics. The technical effect of providing the rapid medicine grinding device for medical pediatrics which is convenient to operate, rapid in grinding and capable of saving time and effort is achieved. In order to achieve the technical effect, the rapid medicine grinding device for medical pediatrics comprises a grinding disc, a rotary shaft, a first bearing seat, a swing rod, a gear, an air cylinder, a first connecting rod, a first fixing plate, a rack, a sliding block, a sliding rail, a second fixing plate and the like. A servo motor, an upper bearing seat and a lower bearing seat are sequentially arranged on the inner left wall of a mounting frame from top to bottom. A lead screw is mounted between the upper bearing seat and the lower bearing seat. The effects of convenient operation, rapid grinding and time and effort saving are achieved; and the rapid medicine grinding device is low in manufacturing cost, reasonable in structure, easy to maintain and repair and convenient to use, input of manpower and material resources is reduced, and the working efficiency is improved.

Owner:六安志成智能科技有限公司

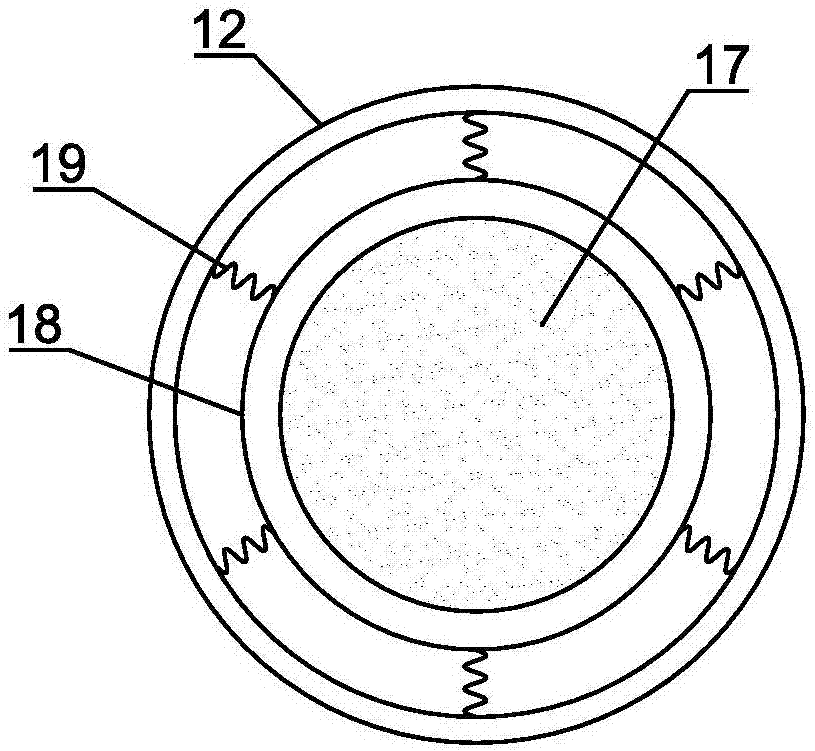

Efficient crushing and grinding equipment for traditional Chinese medicine

PendingCN107486321AAvoid cloggingAvoid insufficient crushingSievingScreeningGear wheelElectric machinery

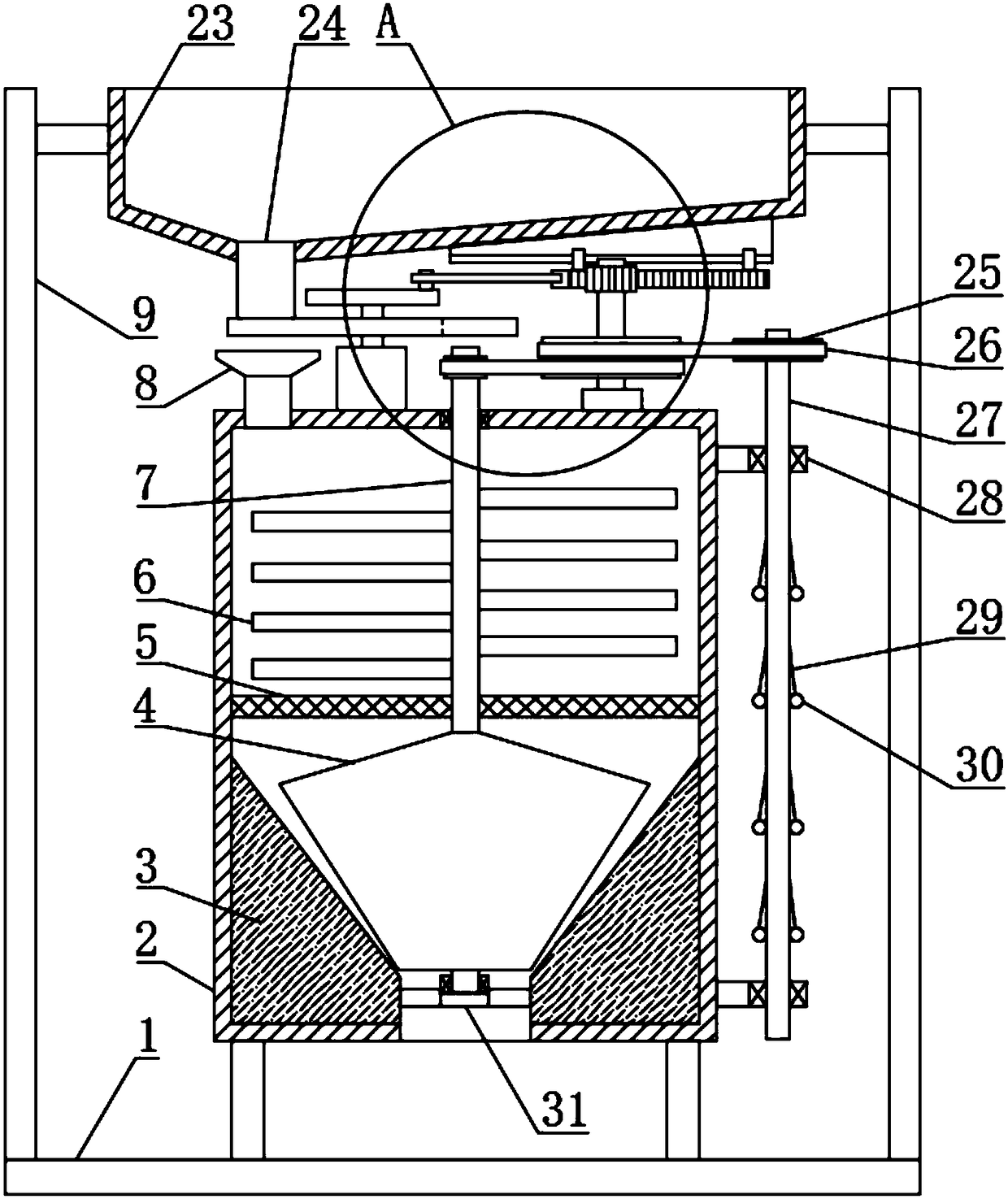

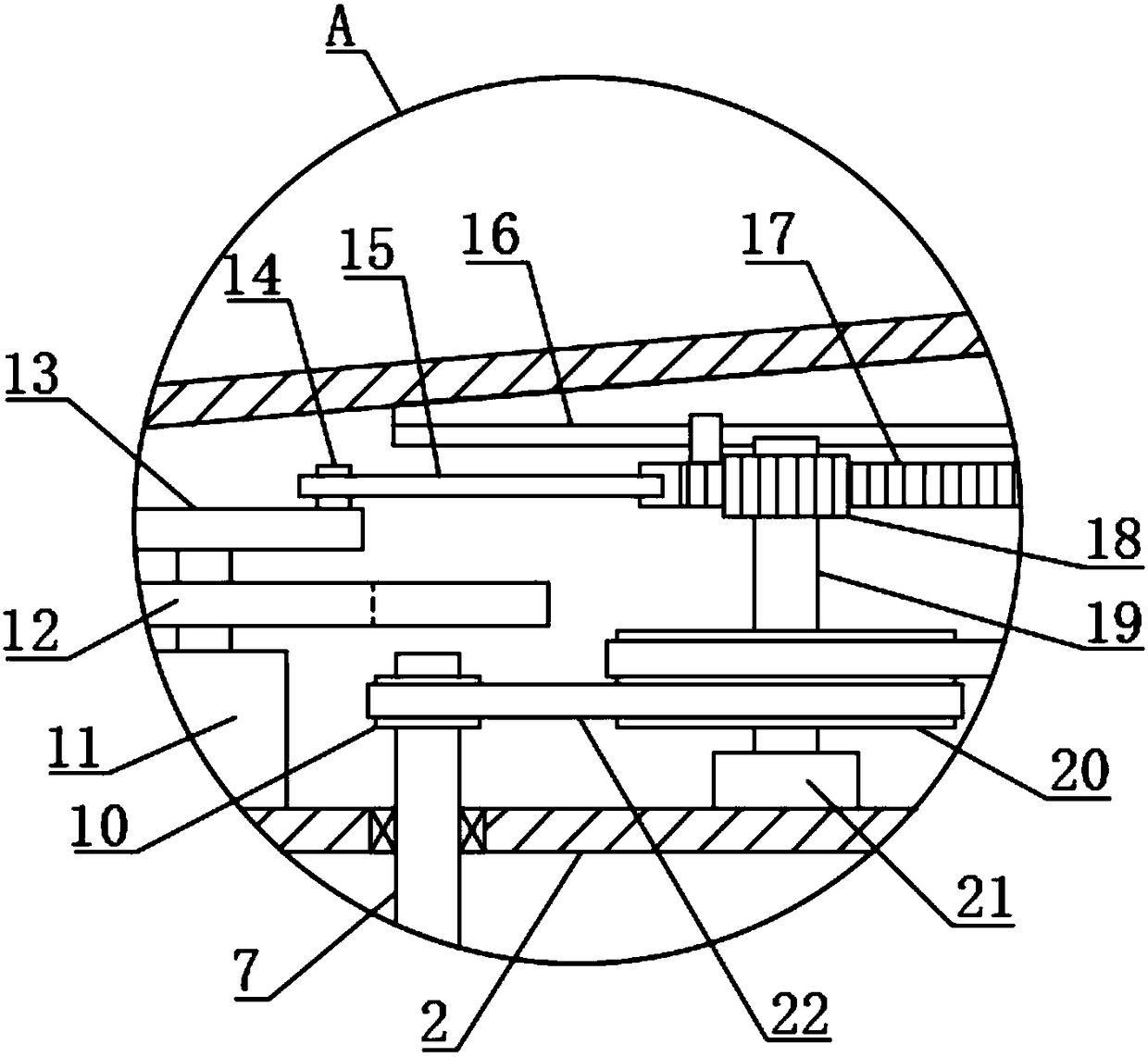

The invention discloses efficient crushing and grinding equipment for traditional Chinese medicine. The efficient crushing and grinding equipment for traditional Chinese medicine comprises a grinding barrel, a crushing barrel, a first screen mesh, an round feed inlet, a first motor, a rotary shaft, an annular baffle plate, a first crushing blade, a second crushing blade, a brush, a second motor, a first installing shaft, a first grinding roller, a second installing shaft, a second grinding roller, an active gear, a driven gear, an inner gear ring and a second screen mesh. The efficient crushing and grinding equipment for traditional Chinese medicine is provided with the first motor, the rotary shaft, the round feed inlet and the annular baffle plate, and through cooperation of the first motor, the rotary shaft, the round feed inlet and the annular baffle plate, intermittent feeding is achieved, insufficient crushing caused by excessive feeding at one time is avoided and the crushing efficiency is improved; the first crushing blade and the second crushing blade are further provided and set dislocated, so that the crushing speed is high and the crushing efficiency is high; and the second motor, the active gear, the driven gear, the inner gear ring, the first grinding roller and the second grinding roller are further provided, and through cooperation, continuous grinding of traditional Chinese medicine is conducted, the grinding is sufficient and fast, and the grinding efficiency is improved.

Owner:ZHENGZHOU UNIV

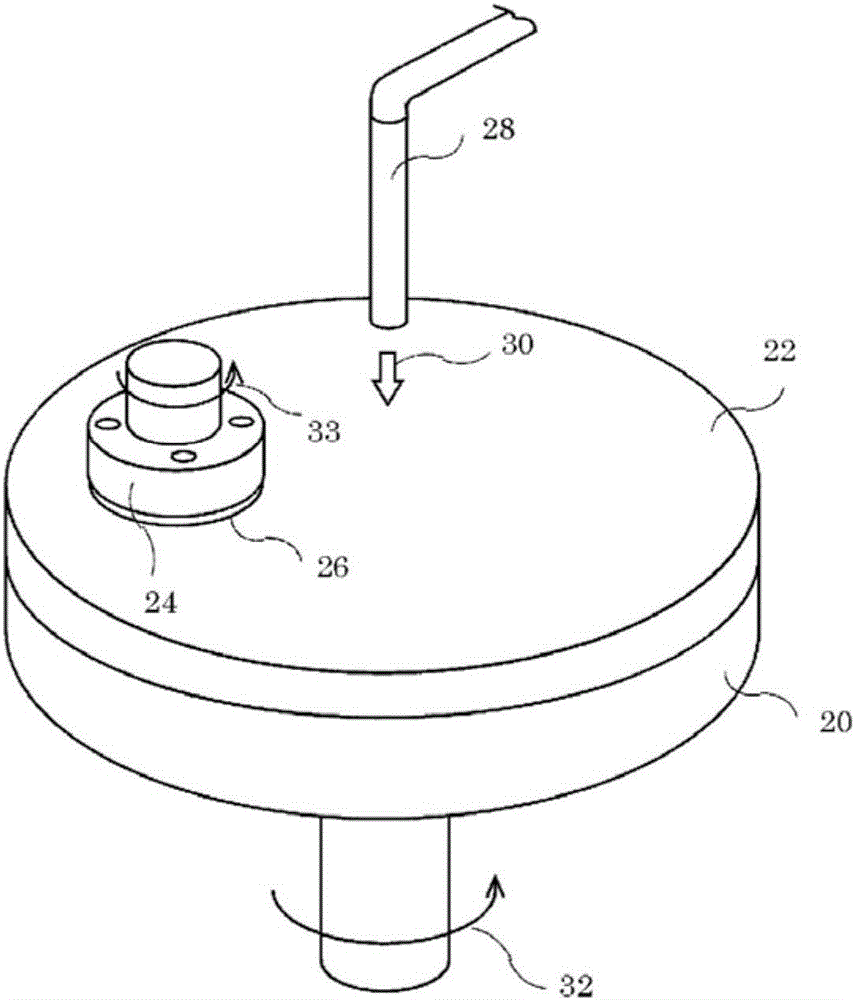

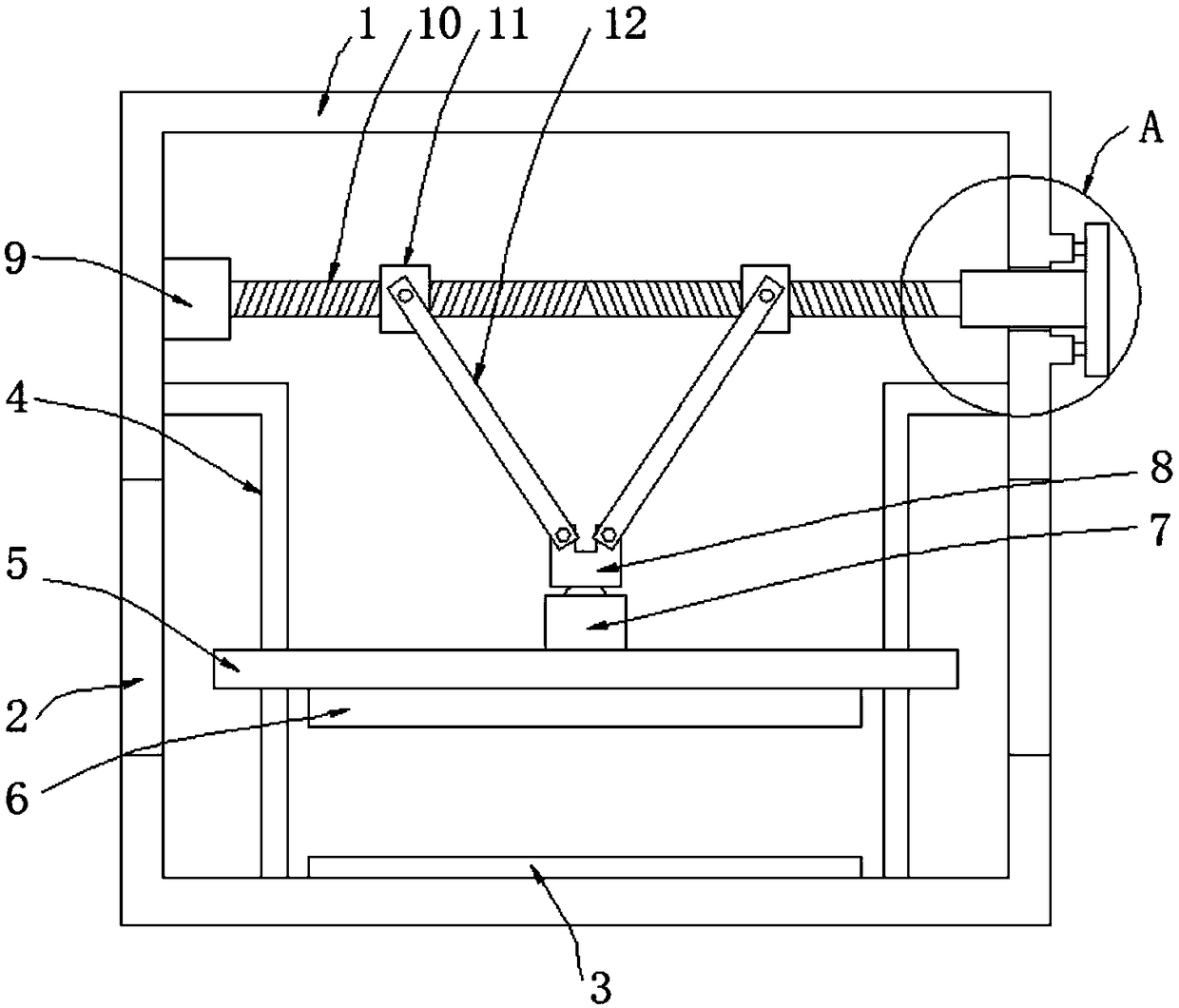

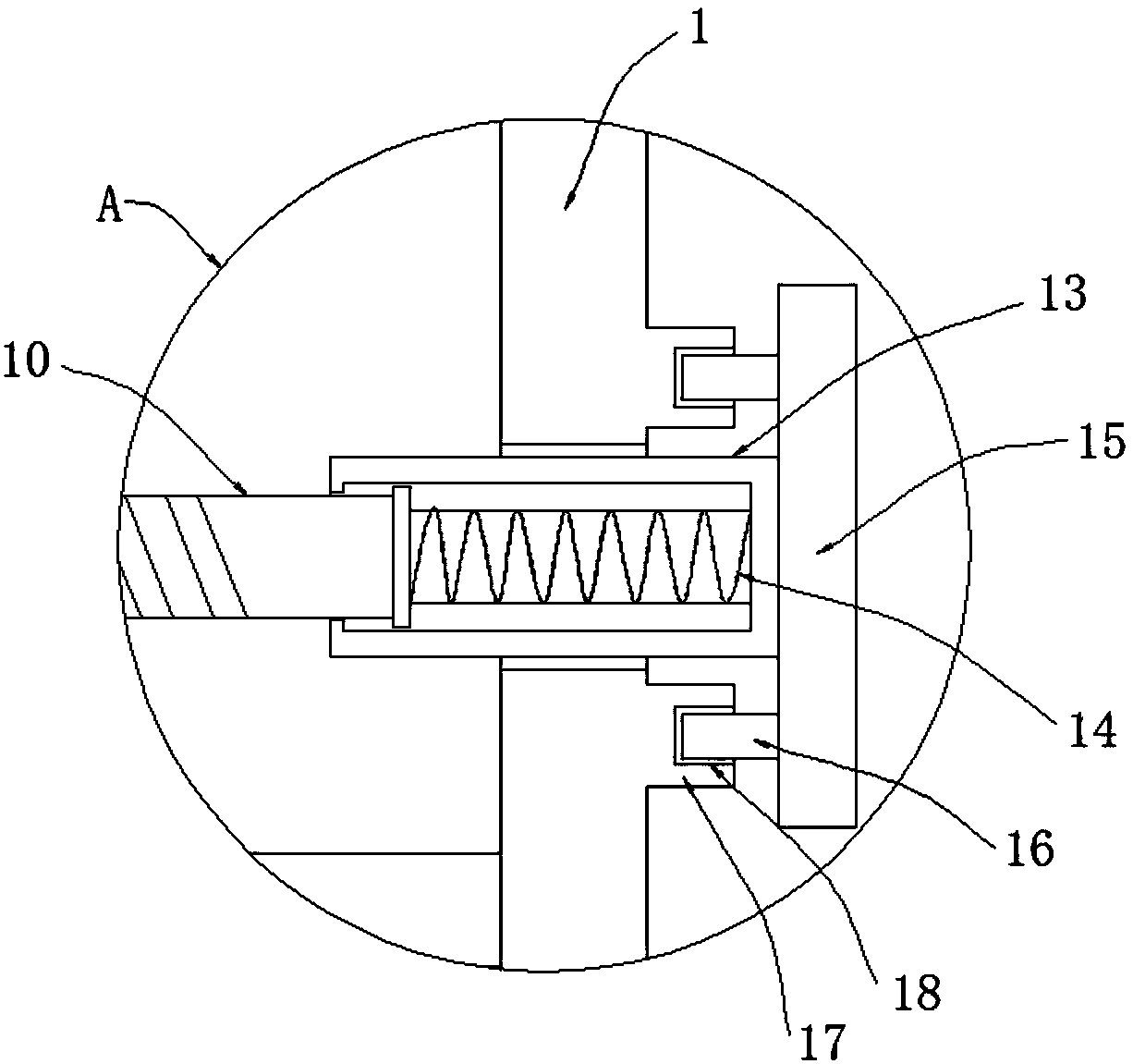

Rapid grinding device metal materials for 3D printing

ActiveCN106180736AControl rotationControl swingAdditive manufacturing apparatusMetallic materialsPolymer chemistry

The invention relates to a grinding device for metal materials for 3D printing, in particular to a rapid grinding device for metal materials for 3D printing. By the adoption of the rapid grinding device for the metal materials for 3D printing, the technical purposes of excellent grinding effect, high work efficiency and simple structure are achieved. For achieving the technical purposes, the rapid grinding device for the metal materials for 3D printing comprises a bottom plate, a left support, a right support, a top plate, first supporting rods, a collection frame, first springs, a grinding cylinder, a screen plate, a supporting base, a sliding rail, a sliding block, a rack, a second supporting rod and the like. The left support is arranged at the left end of the top of the bottom plate. The right support is arranged at the right end of the top of the bottom plate. The first supporting rods are symmetrically arranged on the left side of the top of the bottom plate. By the adoption of the rapid grinding device for the metal materials for 3D printing, the effects of excellent grinding effect, high work efficiency and simple structure are achieved, the metal materials can be ground rapidly, the work benefits are increased for enterprises, and the rapid grinding device is reasonably provided with a reinforcing rib.

Owner:NANTONG DONGFANG PLASTIC CO LTD

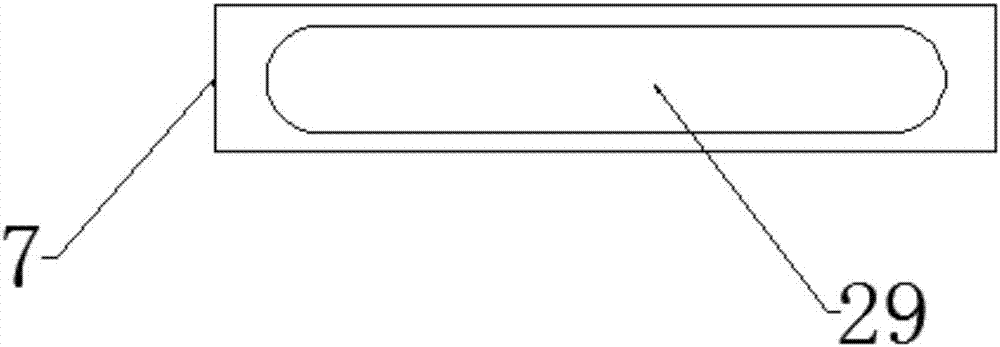

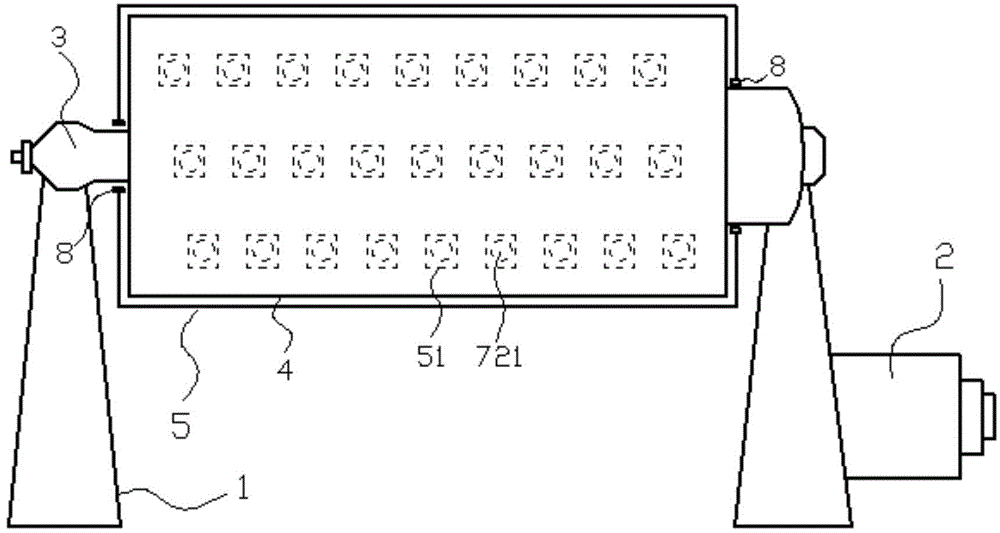

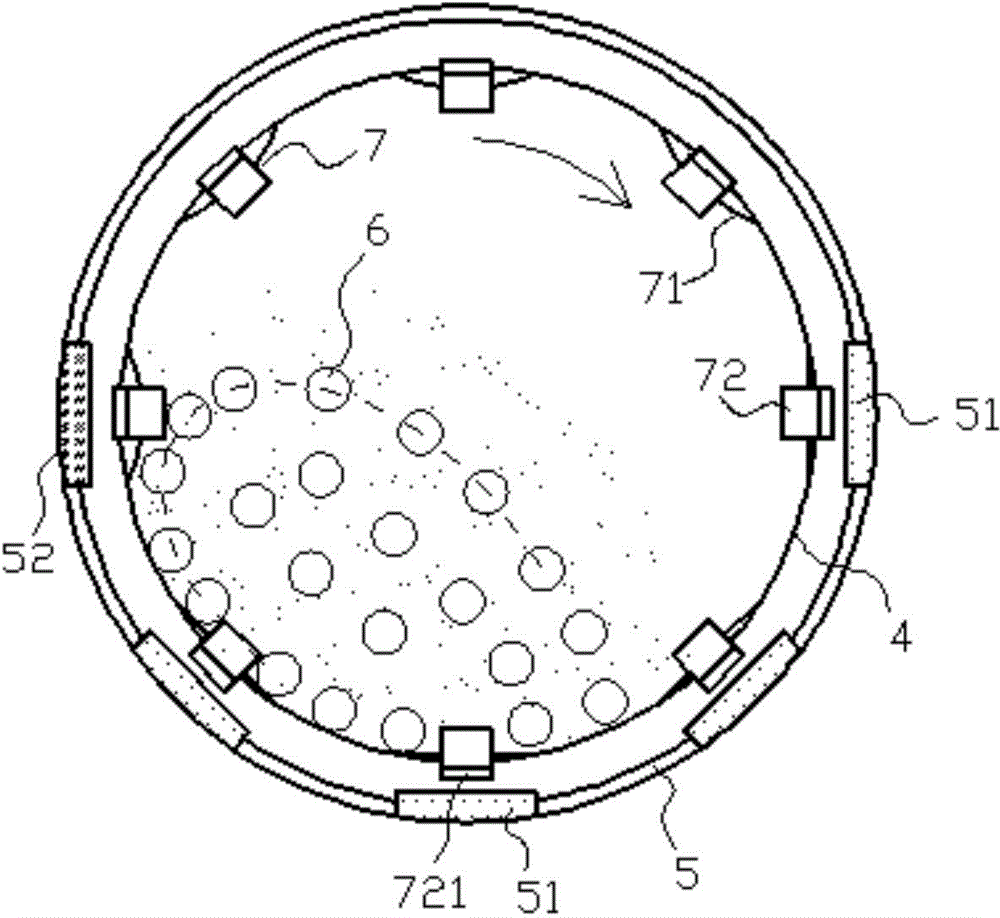

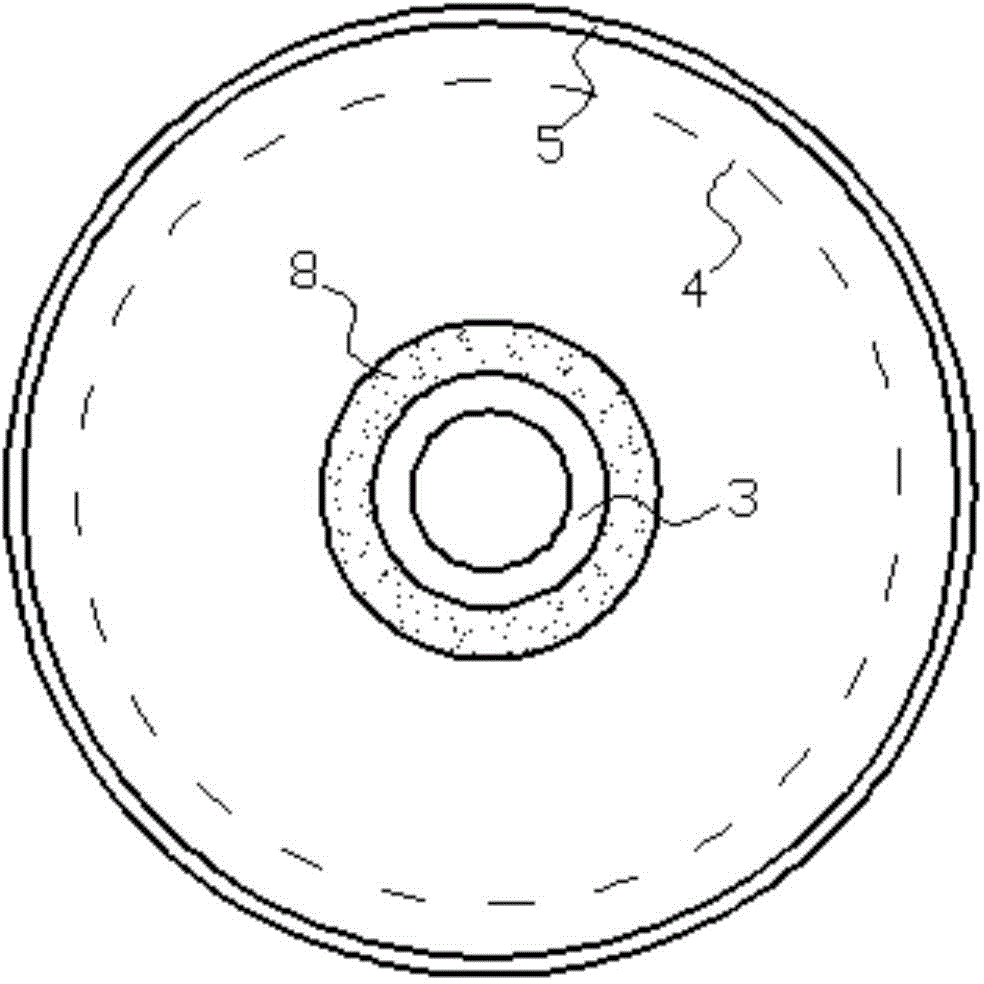

Tandem continuous ball mill and ball milling method

The invention discloses a tandem continuous ball mill and a ball milling method and belongs to the technical field of equipment for producing ceramic products and ball milling technologies. A feeding device (1) is communicated with a feeding end of a first-stage ball milling tank (4), wherein a plurality of second-stage ball milling tanks (7) are connected in series; the length of the first-stage ball milling tank (4) is 1.5-3 times that of one second-stage ball milling tank (7); an inner cavity of the first-stage ball milling tank (4) has a taper of which the diameter is gradually reduced from the feeding end to the discharging end. The tandem continuous ball mill can be used for materials with different sizes; the discharging mode is changed from the traditional overflow into flow extraction; in the ball milling method, materials with different particle sizes are pertinently added; after materials of which the particle sizes are 0.5-15mm are pulped, the pulped materials are directly added in each second-stage ball milling tank (7) through a connecting device (3); after materials of which the particle sizes are 0.1-0.5mm are pulped, the pulped materials are directly added in the tail-end second-stage ball milling tanks (7) through the connecting devices (3), so that the grinding efficiency is greatly improved.

Owner:GUANGDONG EDING IND

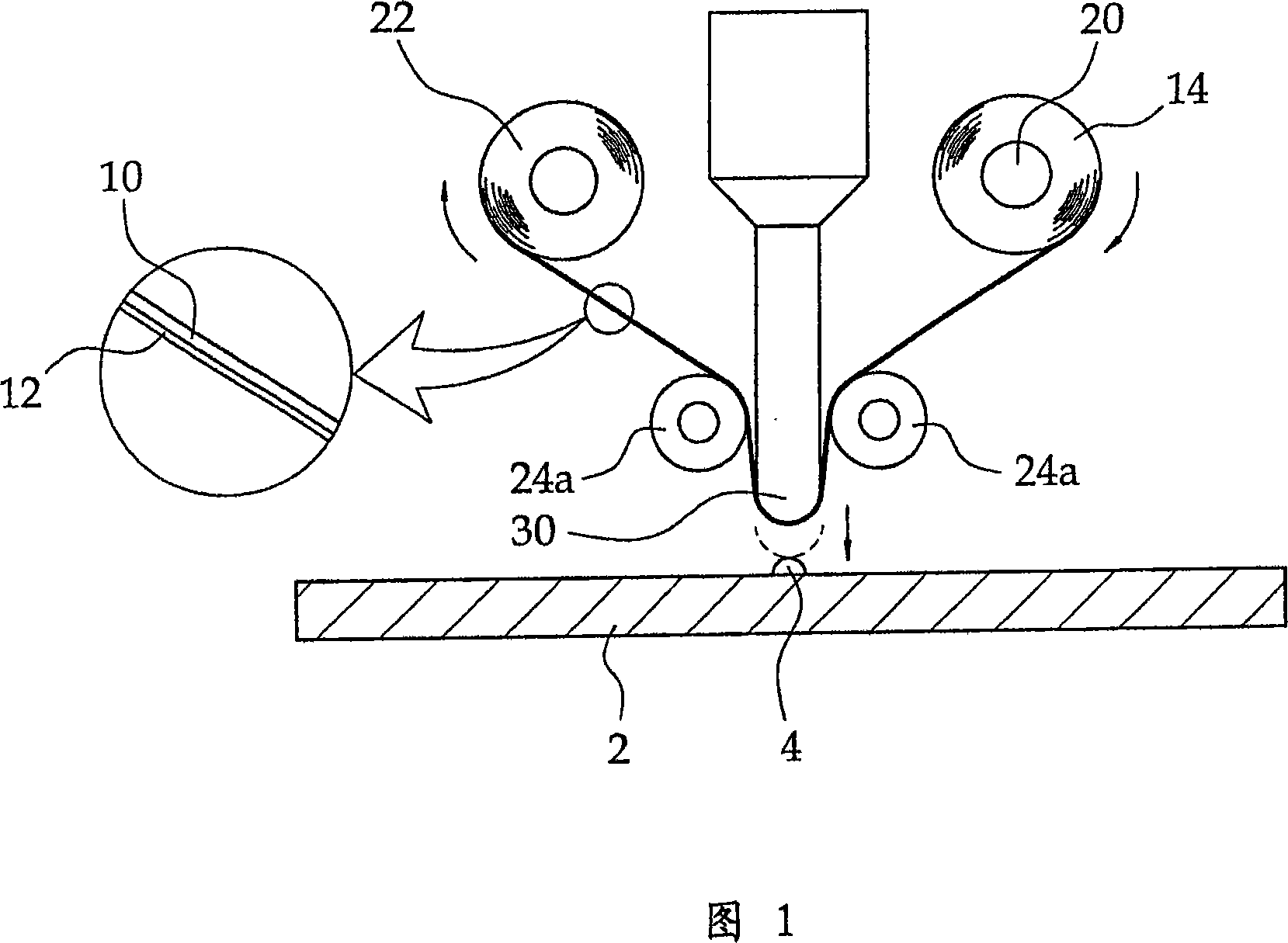

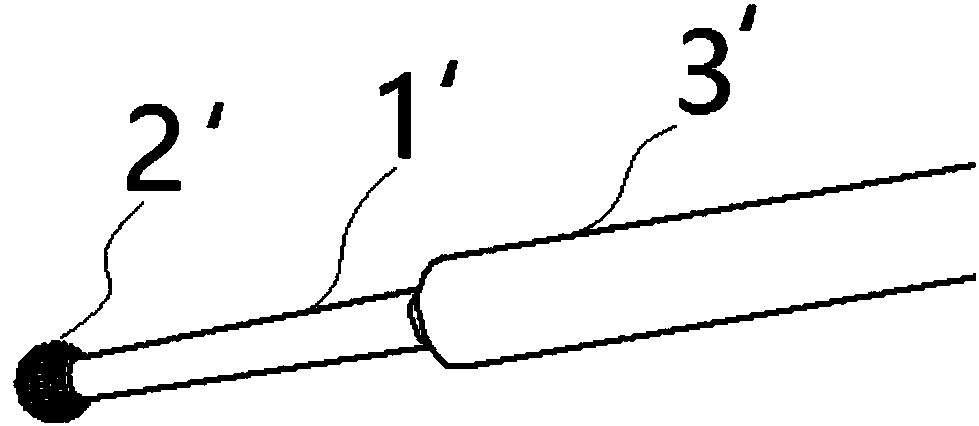

Substrate repairing device and method

InactiveCN101085508AQuick grindingCorrectly control the amount of grindingOptical surface grinding machinesBelt grinding machinesContact typeMechanical engineering

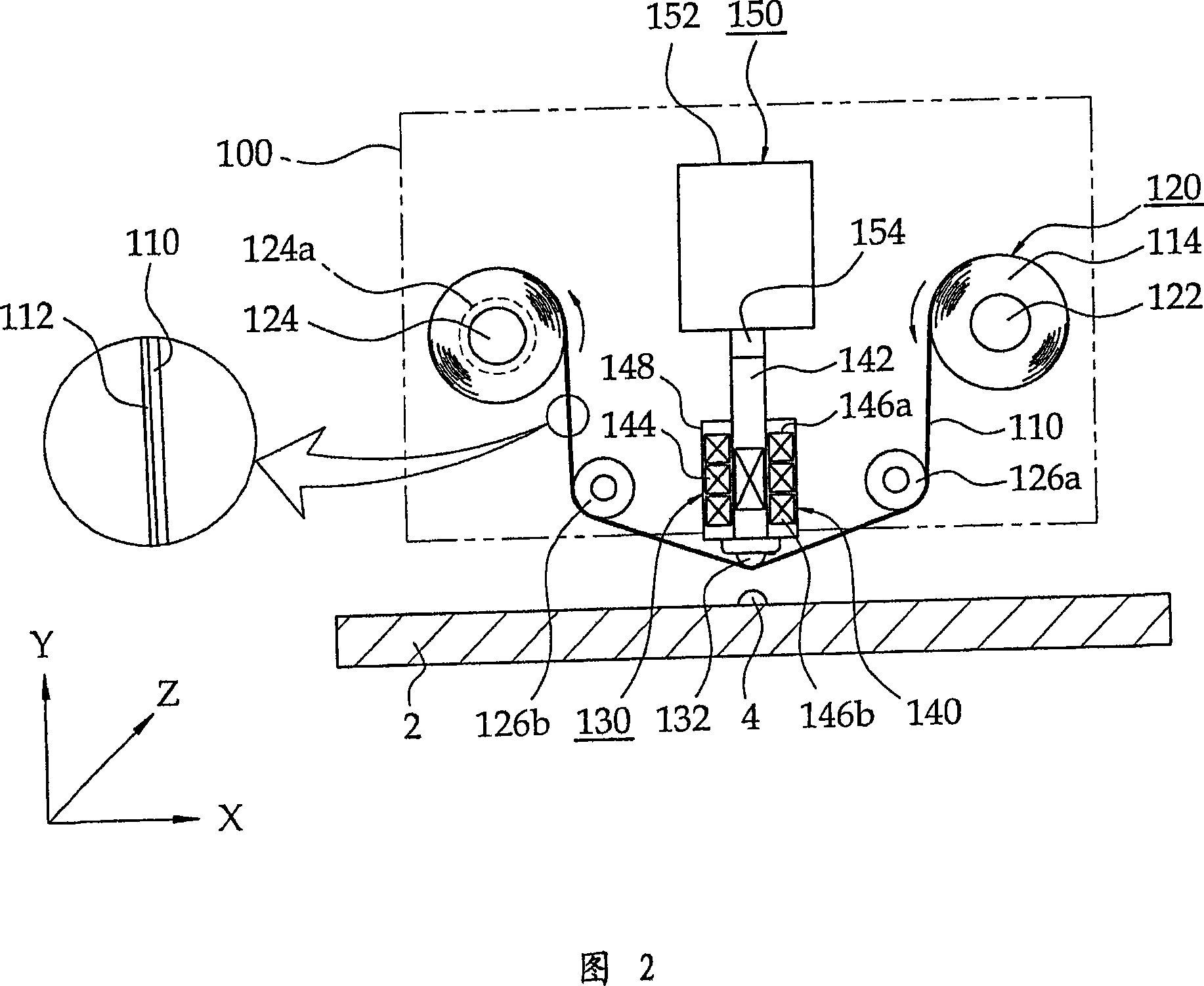

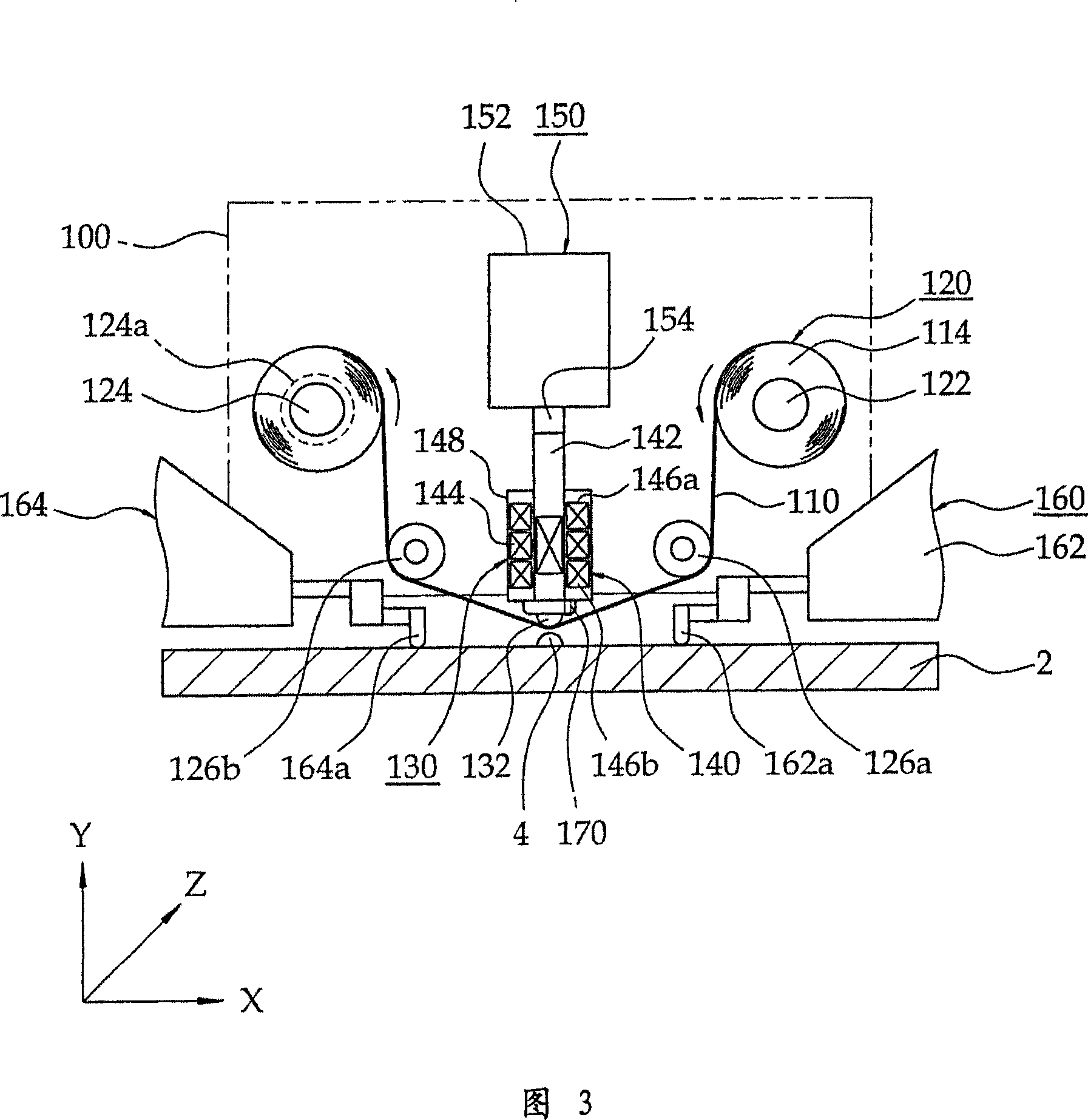

This invention relates to a repair (repair) device of a substrate, and a method for the same, which can remove in more detail the projection which exists as a defect of a substrate correctly by polish. A carriage currently installed on said substrate so that it can exercise along the X-axis, a Y-axis, and Z shaft orientations to a projection projected to a substrate. An abrasive tape feeding means which transports an abrasive tape in which said carriage is equipped and an abrasive layer is applied to the surface above said projection. A contact type displacement sensor which said carriage is equipped with so that it may be located in the upper part of said abrasive tape transported by said abrasive tape feeding means, and is provided with a presser which presses a rear face of said abrasive tape and contacts said abrasive layer to said projection, and detects said pressor displacement. A repairing device of a substrate containing a displacement control machine which controls said pressor displacement so that said pressure which it is equipped with so that it may be connected that it is pressor, and is given to said projection by said pressor press is controlled by said carriage.

Owner:SNU PRECISION CO LTD

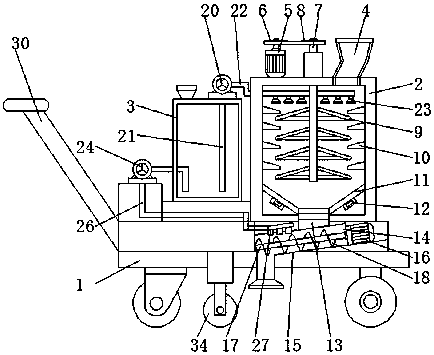

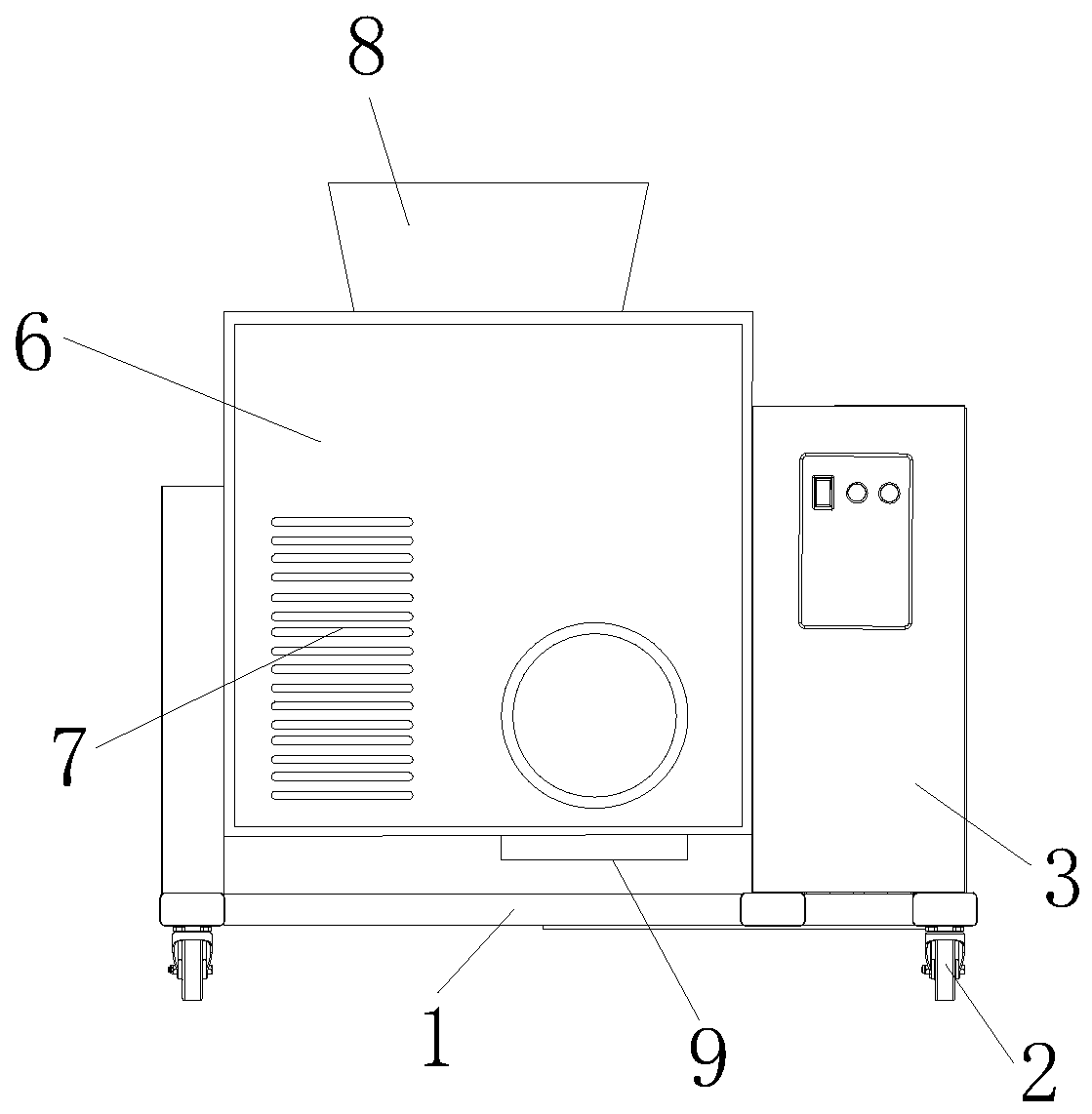

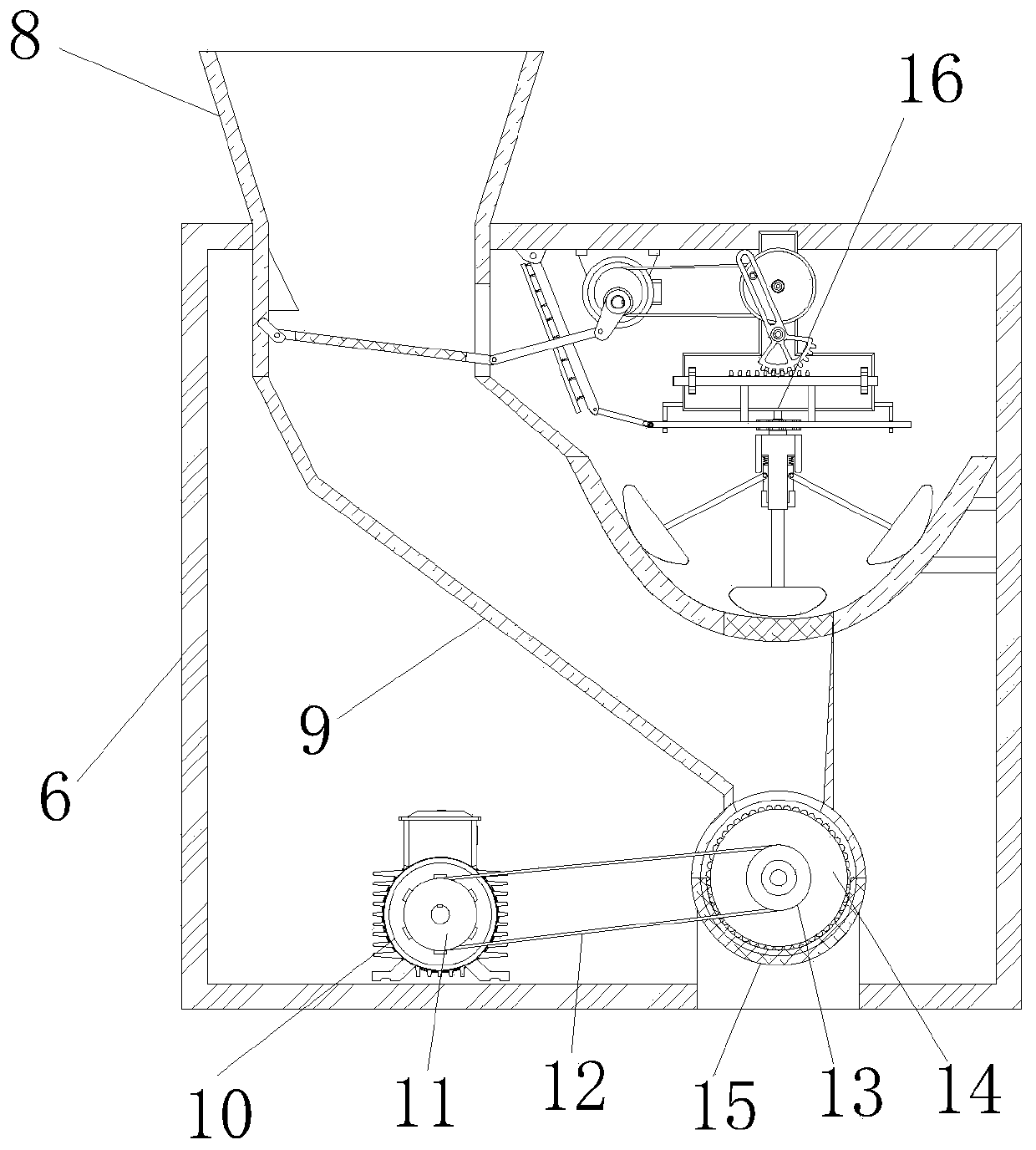

Quantitative crushing and grinding device for Chinese herbal medicines

InactiveCN108514946ANo need to add frequentlyGuaranteed qualityGrain treatmentsMedicinal herbsEngineering

The invention discloses a quantitative crushing and grinding device for Chinese herbal medicines. A working box is fixedly arranged at the top of a base through a bracket; a sieve plate is arranged atthe middle position in the working box; a grinding seat is further arranged at the bottom in the working box; the grinding seat is located below the sieve plate; a first rotary shaft is further arranged at the central position in the working box; a grinding roller and crushing blades are mounted on the first rotary shaft; supporting plates are arranged at left and right sides of the base; a medicinal material box is fixedly arranged at the tops of the supporting plates through brackets; a discharging pipe is arranged at the bottom of the medicinal material box; the discharging pipe is locatedabove a feeding funnel; a speed reducing motor is further arranged at the top of the base; a discharging disc is mounted on a motor shaft of the speed reducing motor; the top of the discharging discis fitted to the bottom of the discharging pipe. According to the quantitative crushing and grinding device disclosed by the invention, discharging is automatically controlled through rotating the discharging disc so that the amount of medicinal materials processed each time is relatively fixed and the medicinal materials do not need to be frequently added, and furthermore, the working efficiencyis improved; the medicinal materials are crushed through the crushing blades; the crushed medicinal materials are sieved and then are ground through the grinding roller, so that the quality of the medicinal materials is ensured.

Owner:童振锴

Ceramic raw material fast grinder applied to 3D printing

ActiveCN106423391AImprove grinding effectQuick grindingAdditive manufacturing apparatusGrain treatmentsMaterials scienceRaw material

The invention relates to a ceramic raw material grinder applied to 3D printing, and in particular to a ceramic raw material fast grinder applied to 3D printing. The invention aims to solve a technical problem and provide a ceramic raw material fast grinder applied to 3D printing with a better grinding effect, a simple structure and high working efficiency. In order to solve the technical problem, the invention provides the ceramic raw material fast grinder applied to 3D printing; the ceramic raw material fast grinder applied to 3D printing comprises a base plate, a left frame, a right frame, a first supporting rod, a first sliding rail, a second supporting rod, a third supporting rod, a fourth supporting rod, a collecting frame, a fifth supporting rod and the like, wherein the left frame, the first supporting rod, the first sliding rail, the second supporting rod, the third supporting rod, the fourth supporting rod, the collecting frame, the fifth supporting rod and the right frame are sequentially arranged at the top of the base plate from left to right. The ceramic raw material fast grinder applied to 3D printing achieves effects of the better grinding effect, the simple structure and high working efficiency, can fast grind ceramic raw materials, and improves working efficiency of enterprises; furthermore, the fast grinder is rationally provided with an air blower.

Owner:易加三维增材技术(杭州)有限公司

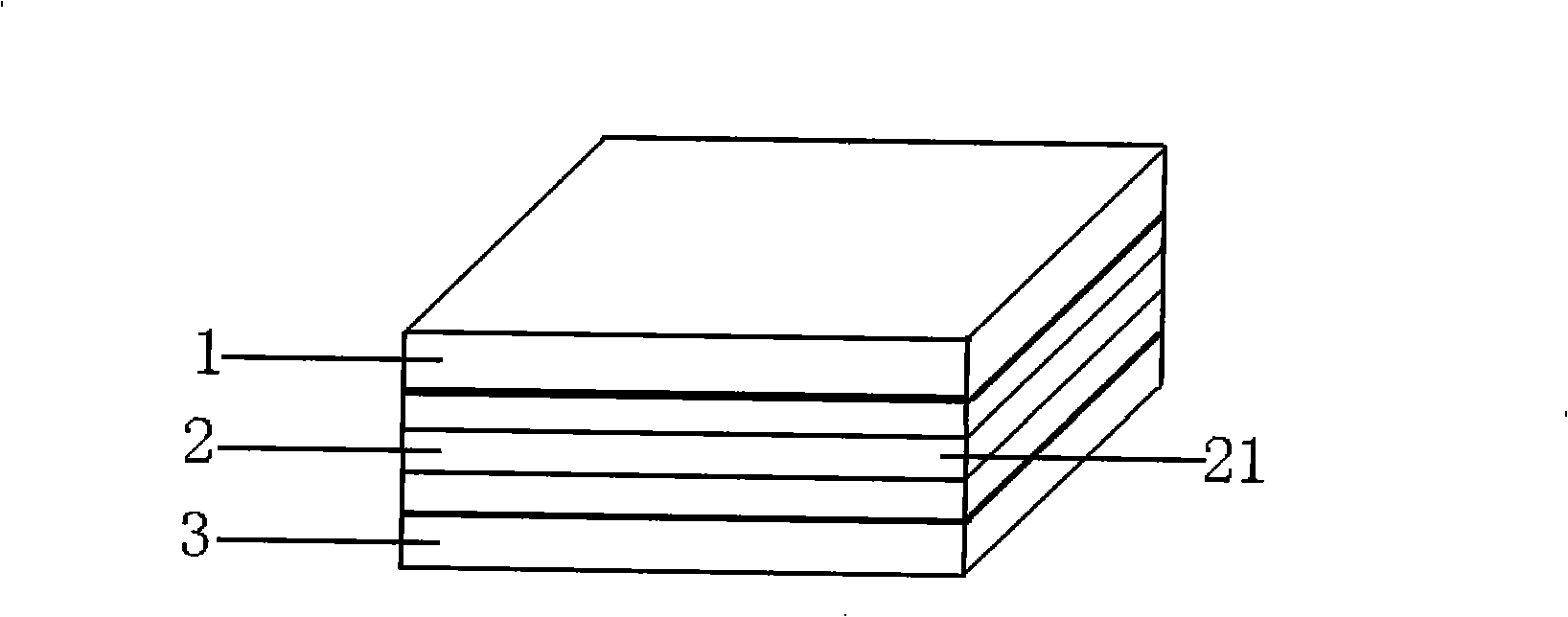

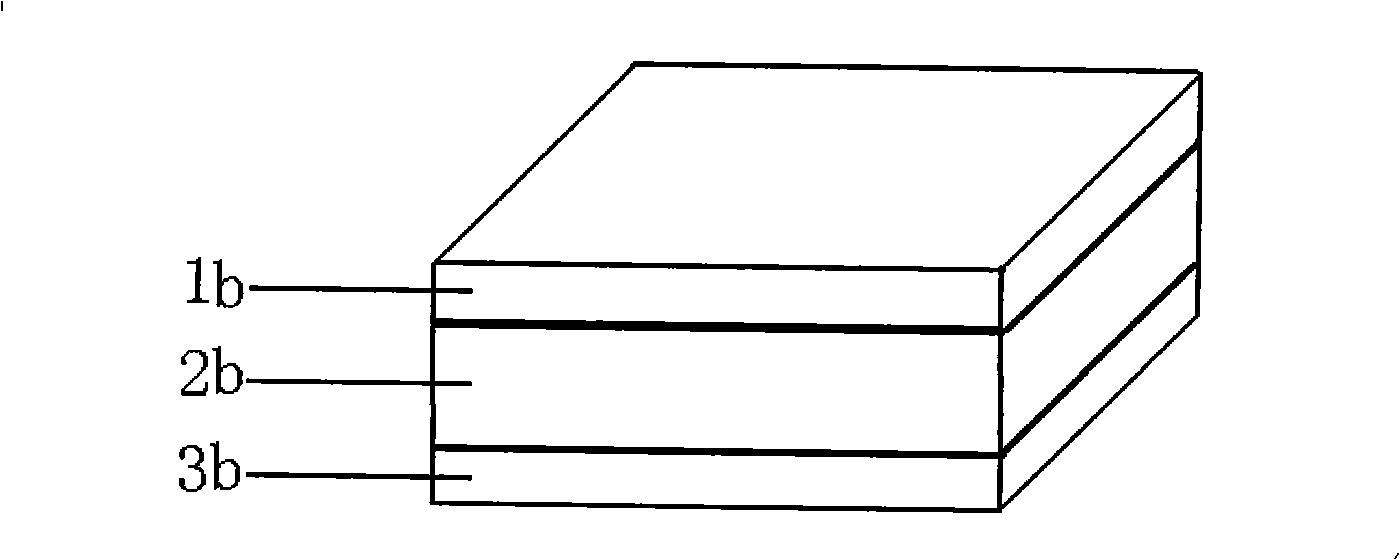

Whole bamboo high strength composite industrial floor

The invention relates to a full-bamboo and high strength composite industrial floor board, which is characterized in that auxiliary materials (offcut materials of semi-finished products) of bamboos (of any variety), bamboo treetop, bamboo branches, waste trifling and waste strips are adopted to make into medium density (more than 750kg / m<3>) or high density (more than 850kg / m<3>) full-bamboo fiber board for manufacturing the core board by the steps of cleaning, softening, burnishing, adhering by modified urea formaldehyde or modified phenolic resin adhesives, and processing at high temperature and high pressure. As result of long length and good flexibility, the bamboo fibers are crosswise rearranged and adhered during the softening, burnishing, adhering and thermally pressing molding processes, the indexes of static bending strength and elastic modulus of longitudinal and transverse texture, and the shearing force are also increased and the characteristics of the bamboo are optimized. Therefore, the composite industrial floor board is an ideal full-bamboo core board material and improves the comprehensive utilization ratio of the full bamboo (the utilization rate is more than 95 percent).

Owner:葛会龙 +1

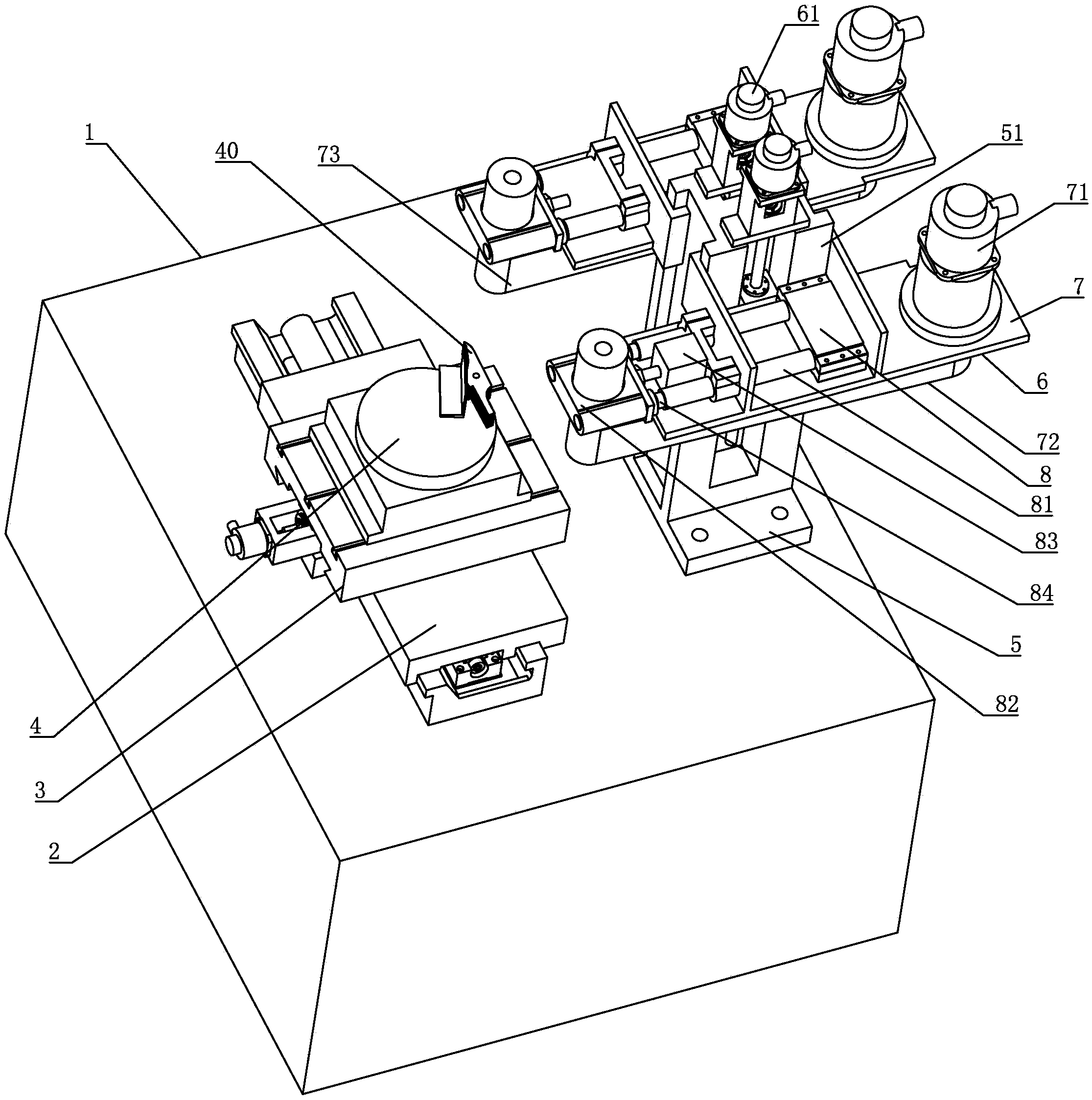

Belt sander

ActiveCN103659477AQuick grindingGuaranteed grinding qualityBelt grinding machinesOther manufacturing equipments/toolsCircular discSander

The invention discloses a belt sander. The belt sander comprises a base, wherein an X-axis workbench and a Y-axis workbench are arranged on the base, a rotating disk used for fixing a workpiece is arranged on the Y-axis workbench, more than one station is arranged on the rotating disk, a Z-axis support is arranged on the base, more than one sliding rail is vertically arranged on the Z-axis support, a Z-axis machining device is further installed on the Z-axis support and comprises a servo motor installed on the Z-axis support and a supporting table driven by the servo motor to move up and down on the sliding rail, a motor, a driving wheel driven by the motor, and a driven wheel driven by the driving wheel are installed on the supporting table, and the driven wheel is driven to rotate by the driving wheel through a sand belt. According to the belt sander, four-shaft linkage can be achieved, workpieces can be flexibly machined, a large part of side faces of the workpieces can be machined, machining efficiency is high, and the workpieces can be machined very conveniently.

Owner:江门杰能刀剪装备科技有限公司

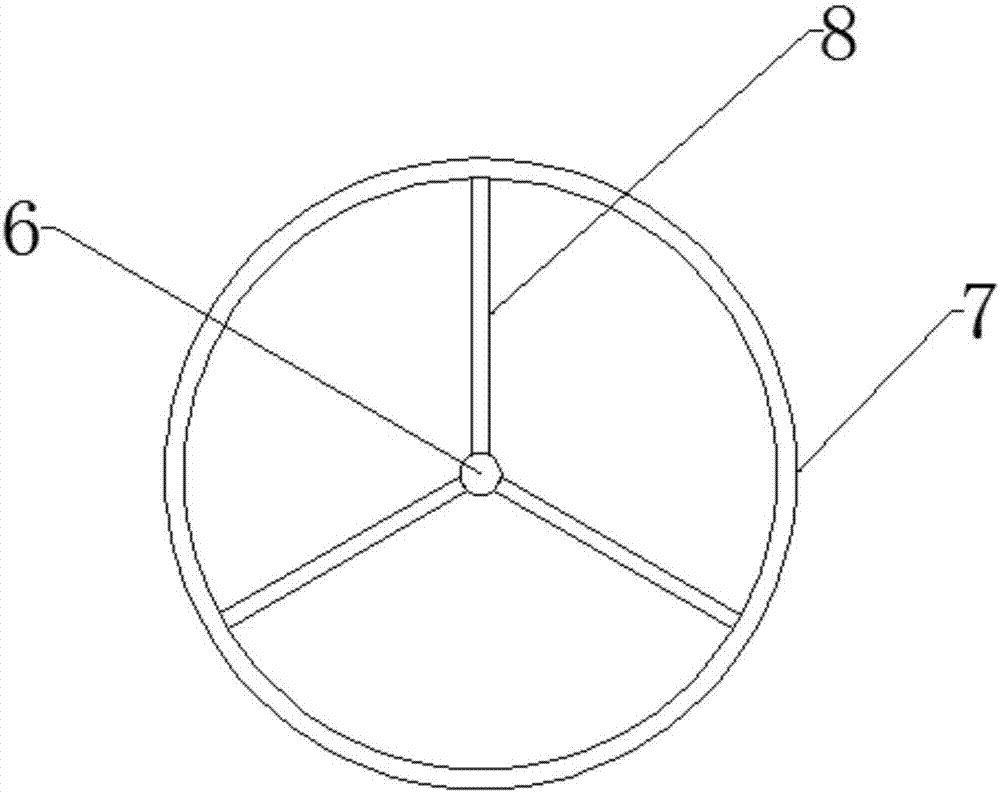

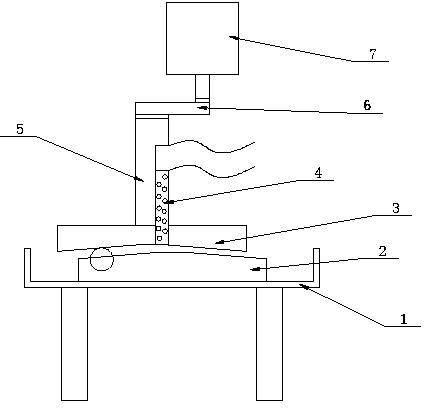

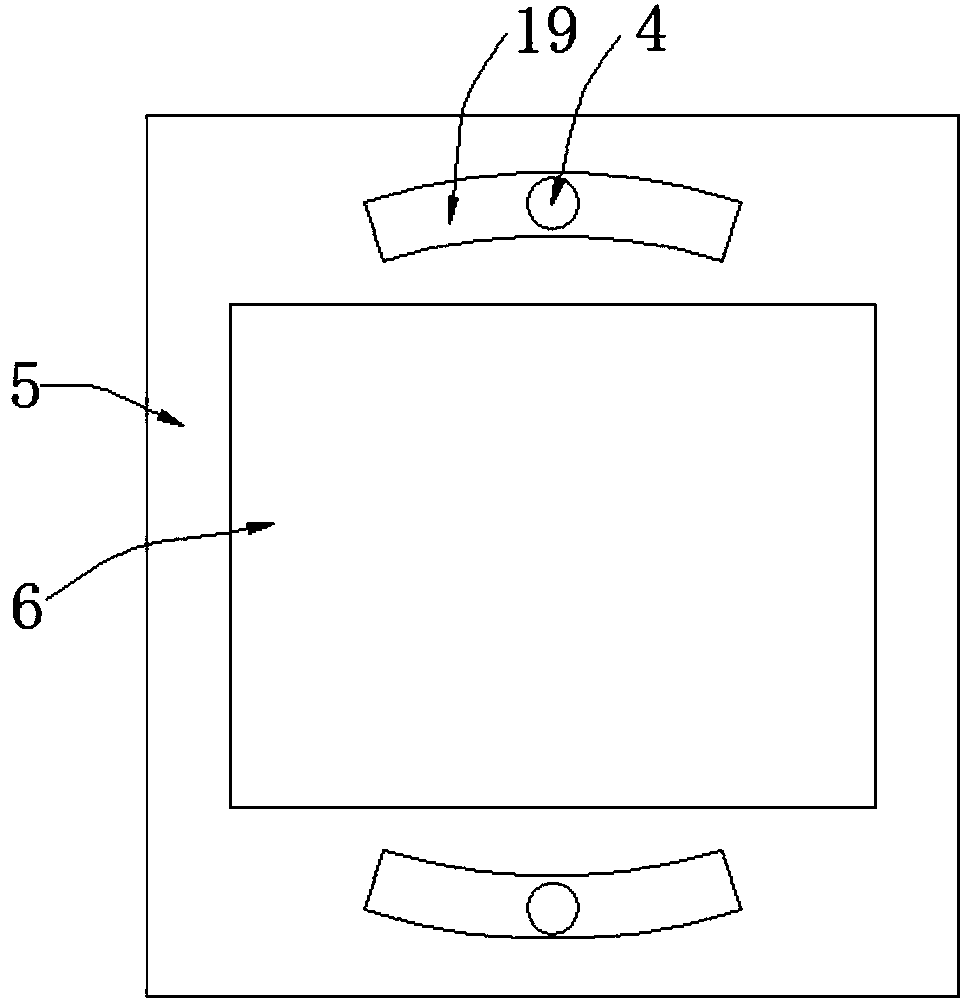

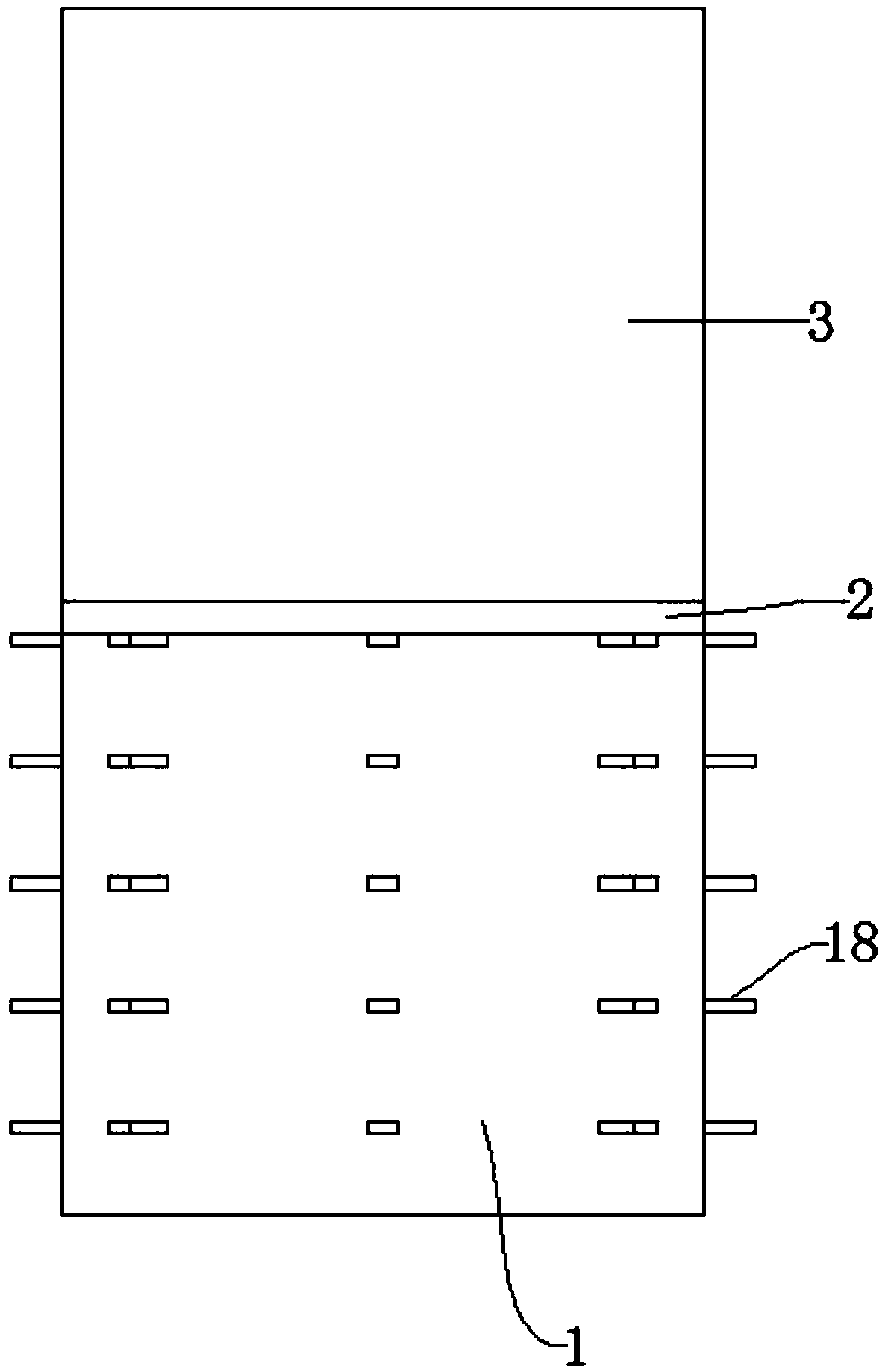

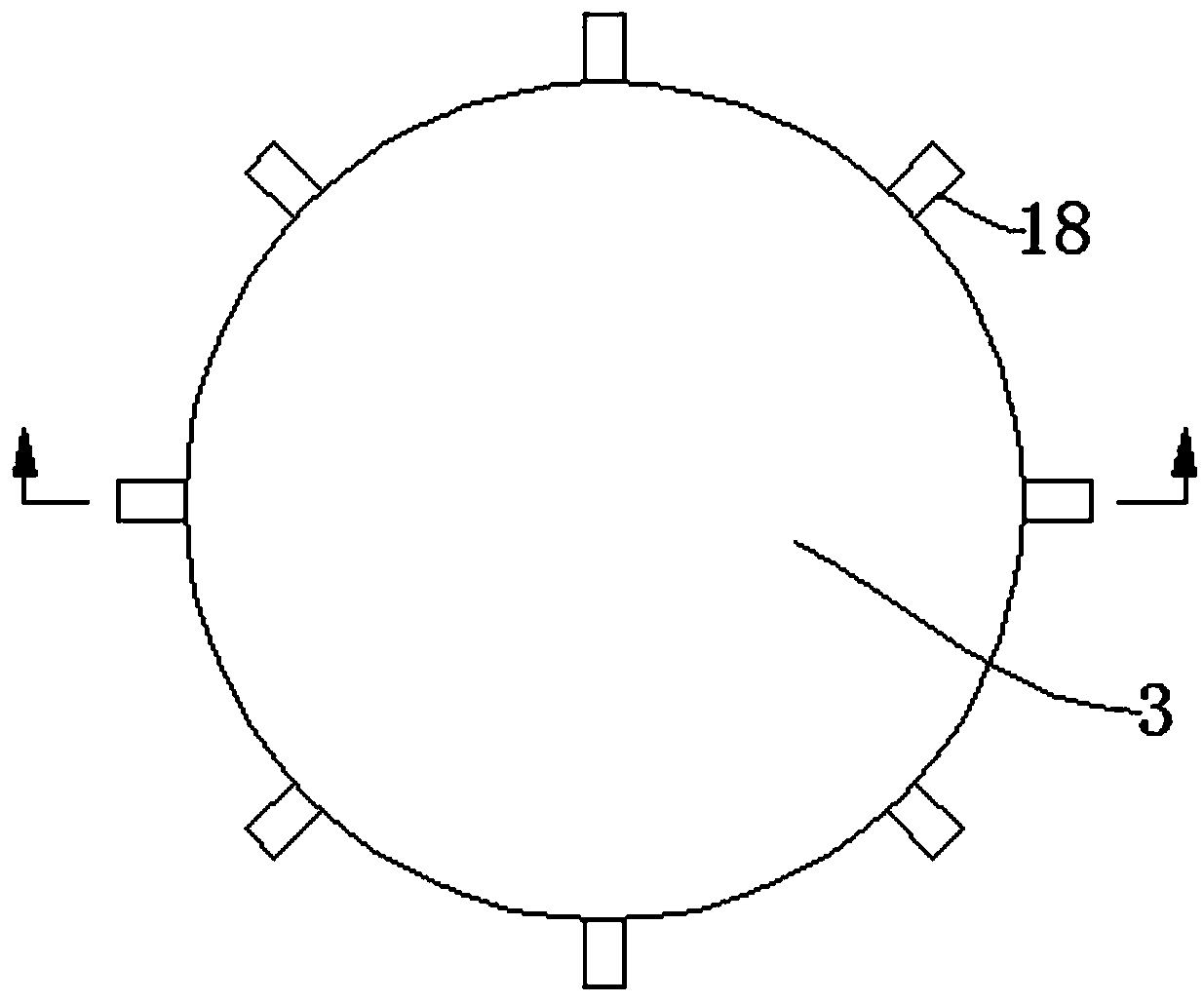

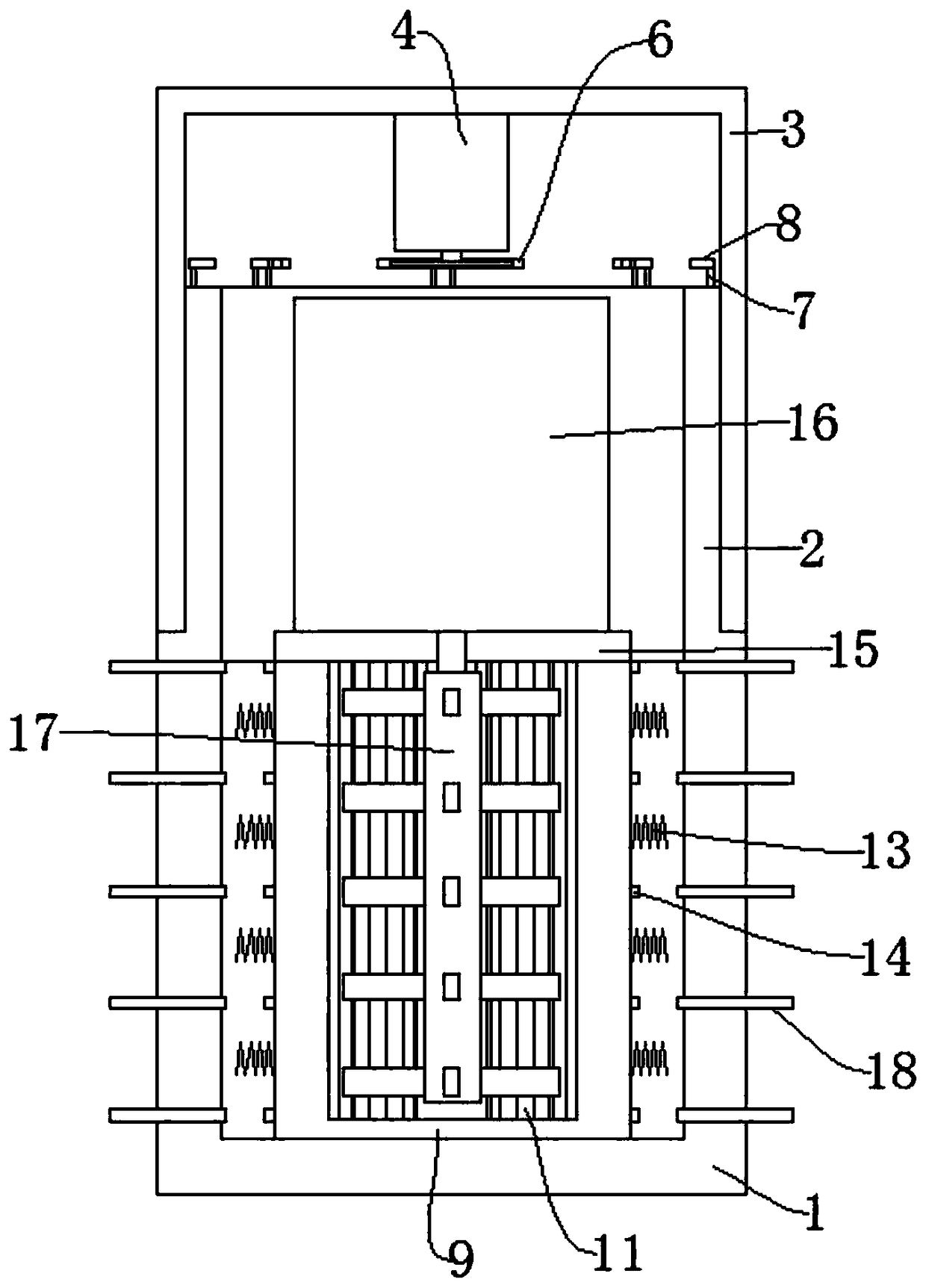

Novel eccentric powder grinding device

The invention relates to a novel eccentric powder grinding device, which relates to the technical field of granulating and grinding devices. A lower grinding disc (2) is fixedly arranged in the middle of the upper end of a powder collection hopper (1), the upper end of the lower grinding disc (2) is provided with an upper grinding disc (3), a central transmission shaft (4) is fixed on the upper end of the upper grinding disc (3), one side of the central transmission shaft (4) is provided with a hollow feeding pipe (5), the hollow feeding pipe (5) extends to the bottom of the upper grinding disc (3), the upper end of the central transmission shaft (4) is connected with an eccentric disc (6), and the eccentric disc (6) is connected with a drive motor (7). The novel eccentric powder grinding device is simple in structure, and the eccentric principle is cooperated with a double-grinding device, so that the granular crystals can be rapidly ground, the grinding efficiency is high, and the cost is low.

Owner:NANTONG AUXIN ELECTRONICS TECH

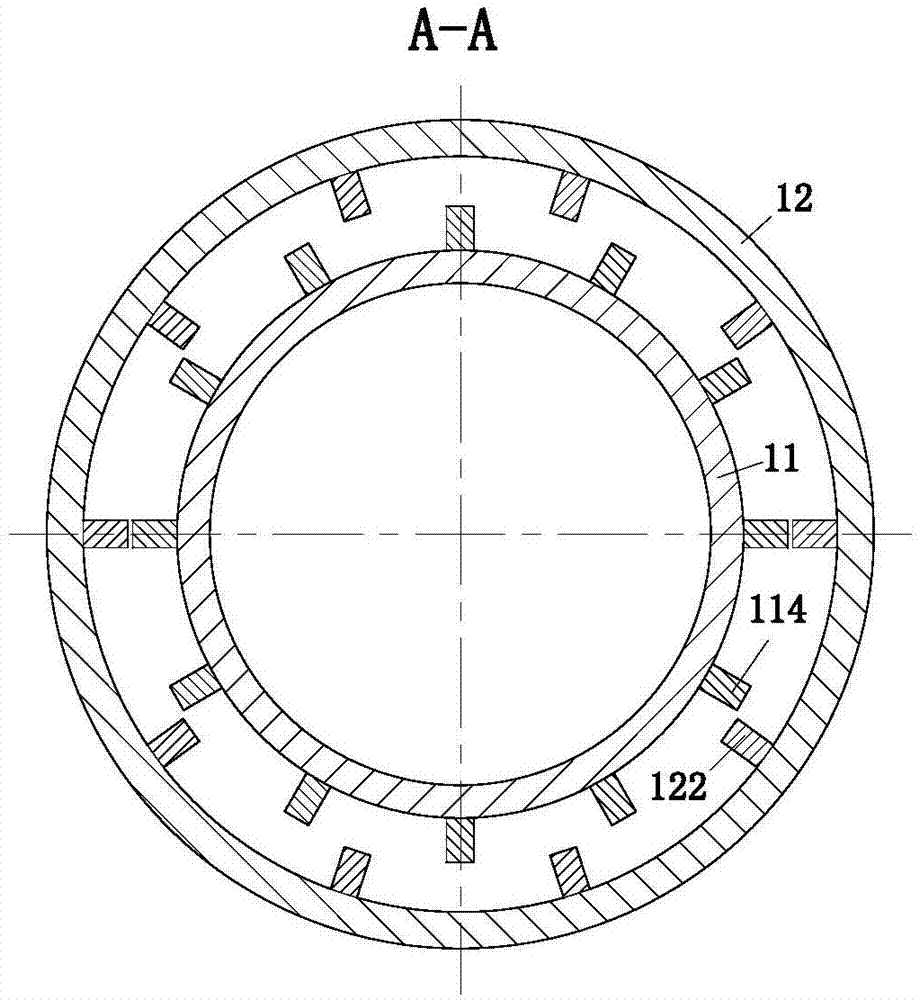

Elastic piece ball mill

The invention relates to an elastic piece ball mill which mainly comprises a rack, a driving motor, a bearing, a tank body, a casing and a grinding medium, wherein the tank body is wrapped with the casing arranged on the rack; the casing is connected to the bearing through a shaft, and can rotate along the bearing; elastic mechanisms are arranged on the inner peripheral wall of the tank body; each elastic mechanism comprises an elastic piece and a lifting rod; strong magnetic pieces are arranged at the bottoms of the lifting rods; strong magnets opposite to the strong magnetic pieces one to one are arranged on the lower half cylindrical surface of the inner wall of the casing; the magnetism of each strong magnet forms homopolar repulsion or heteropolar attraction with that of the strong magnetic piece opposite to the strong magnet. According to the ball mill, the grinding medium can be actively ejected to increase impact force after reaching a certain height, and in addition, materials can be completely dispersed to be ground more completely; the materials can be ground at higher speed.

Owner:SUBEI COUNTY BOLUN MINING DEV CO LTD

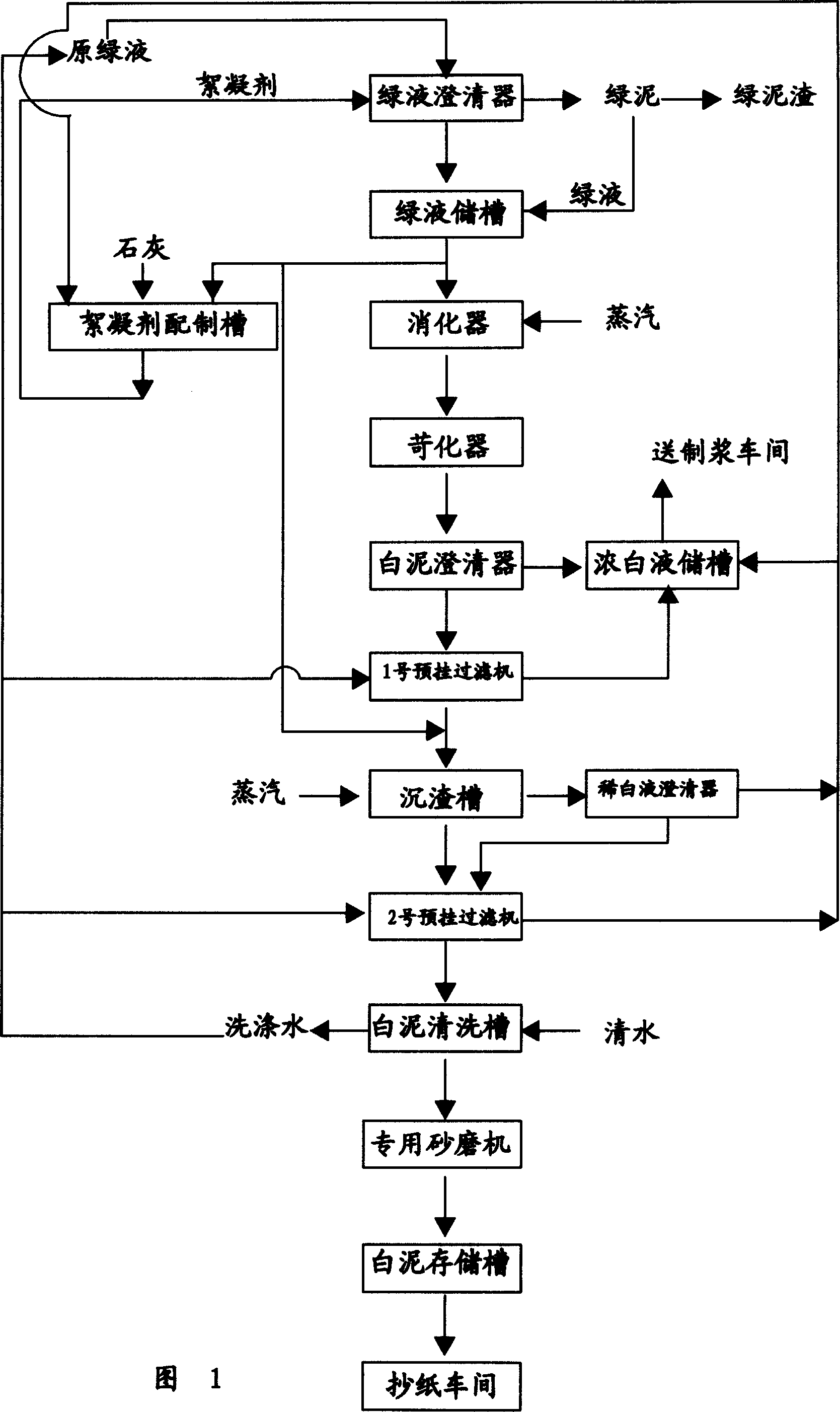

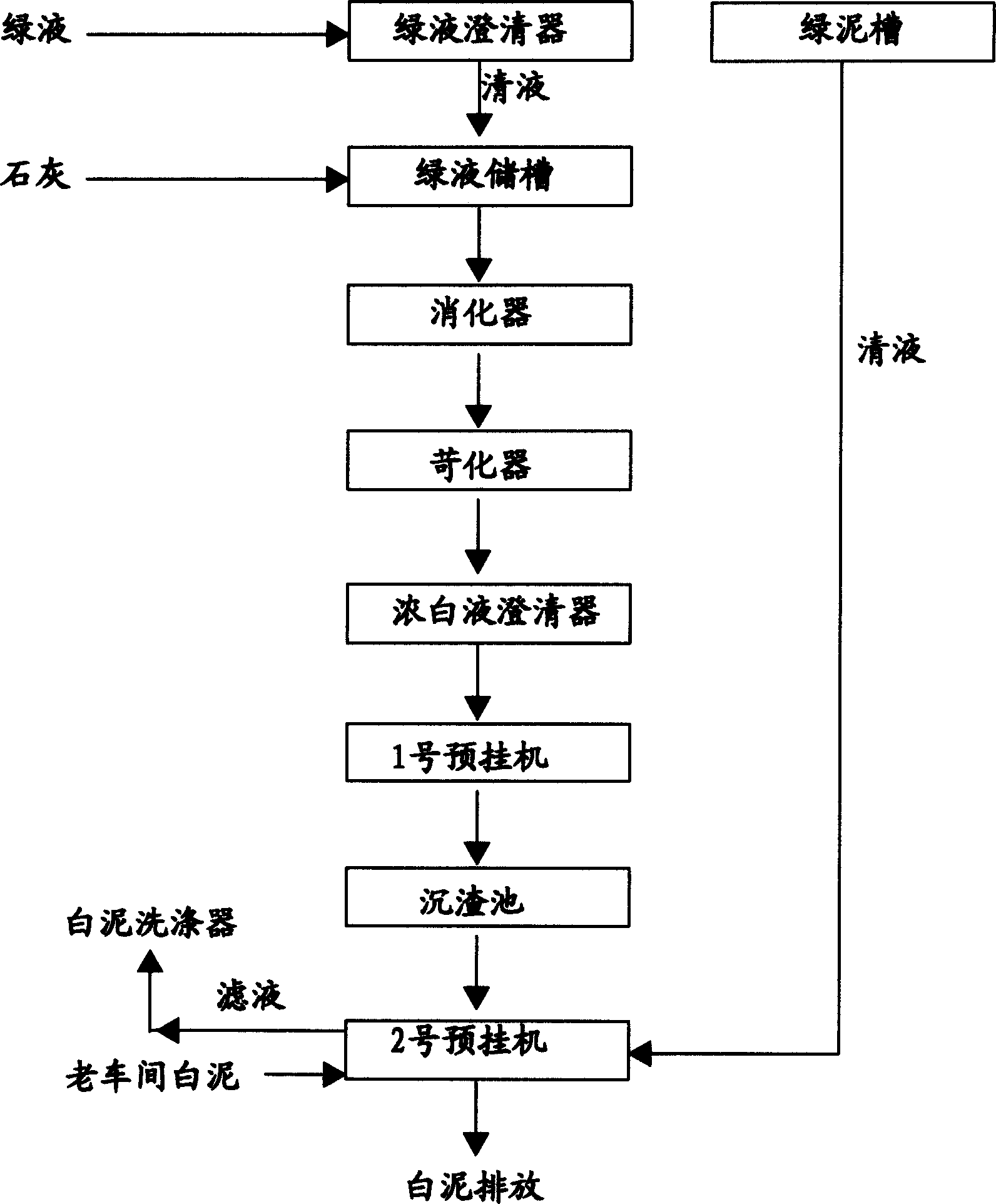

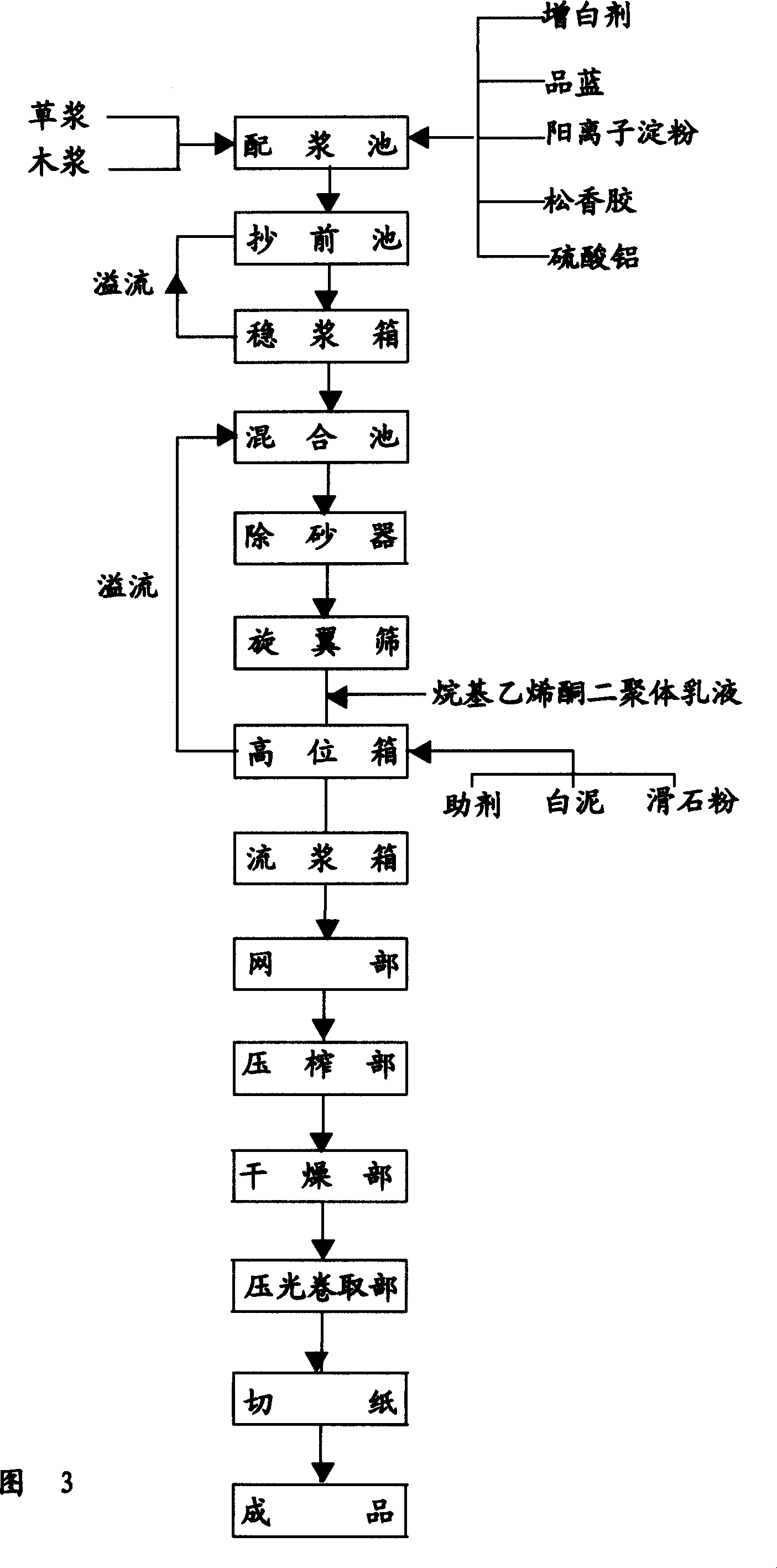

Improved lime mud recovering process and its application for producing neutral glue blending paper

ActiveCN1546789AIncrease washing residual alkaliQuick grindingPulp liquor regenerationSolid waste disposalIonEmulsion

The invention is a kind of improved white clay reclaiming process and its application in neutral glue executing paper production. The original green liquid in flocculation: lime cream=30:1-1.2; they are stirred under 90-100 degrees for 20-40 minutes; when in assisting causticization, the white clay: clear green liquid =5-8:1; 90-100 degrees; rinses the residual alkali, the white clay: water =1:8-10; the white clay is grinded into particle with radius smaller than 20-30 micro meter. The density is 12-18%w / w; the white degree is 80-95%; the residual alkali is less than 0.5%; the active CaO is less than 0.5%; the pH value is from 9 to 11; the deposited volume in ten minutes is 3-10 ml / g; the dust degree is less than 0.5mm2 / g; 325 items residual is less than 0.055; when filling, the absolute dry pulp: talc powder: reclaimed white clay: positie ion starch=1;0-0.2:0.15-0.4:0.015-0.02, the AKD emulsion quantity is 15-18 kg / T paper.

Owner:SHANDONG BOHUI PAPER INDUSTRY CO LTD

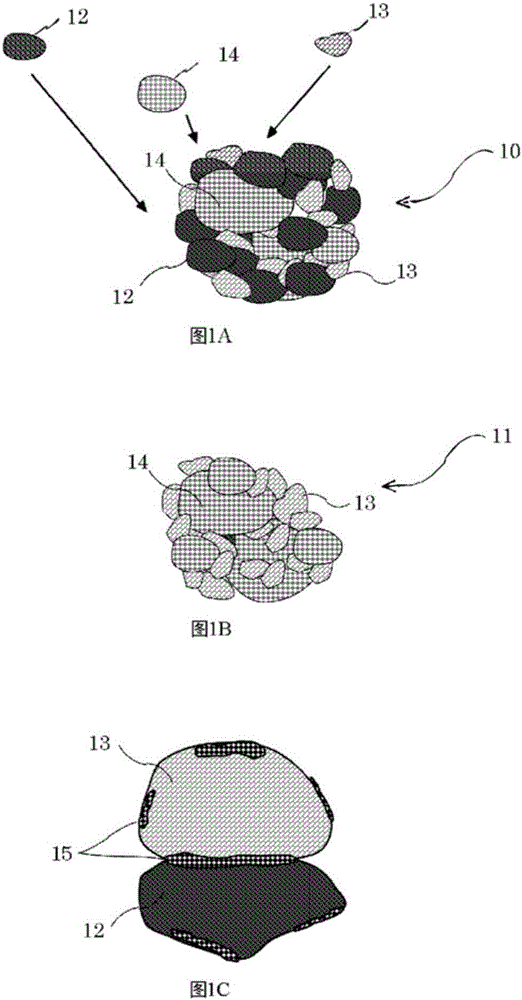

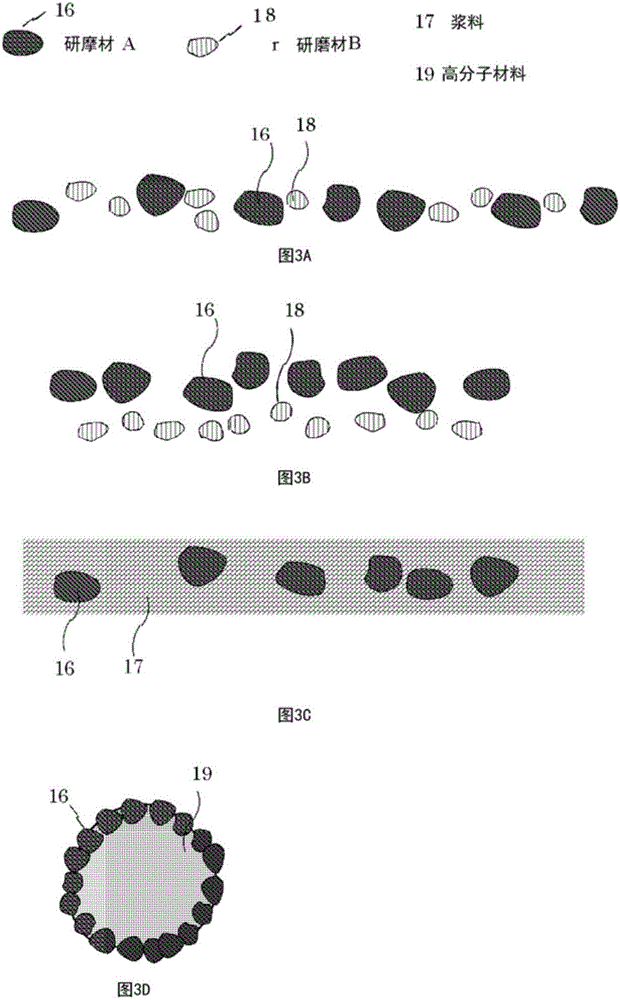

Polishing abrasive particle, production method therefor, polishing method, polishing device, and slurry

ActiveCN105940076AChemical abrasive action promotesFacilitates chemical abrasive actionOther chemical processesSemiconductor/solid-state device manufacturingLiquid wasteSlurry

[Problem] To polish the surface of an object material at a high removal rate and into a high-quality surface. [Solution] The object material is polished by wet polishing. A slurry comprises polishing abrasive particles dispersed in pure water. Each of the polishing abrasive particles comprises a component that exerts a mechanochemical action, a component that reacts to a frictional heat generated when polishing the object material, and the like, integrated into a particle as a whole. The components are bonded directly to one another by mechanical alloying while each retains the inherent properties of the substances in the individual component. Using this slurry in a lapping process for sapphire, silicon carbide, gallium nitride, and the like, allows the polishing time to be much shorter than conventionally, and allows the processing costs to be reduced significantly. The quality of the polished surface is high. The polishing abrasive particle can be used repeatedly for polishing. As the pH of the slurry is on the order of 3 to 9, there is no impact on the environment of the polishing work area, and processing of liquid waste is simple.

Owner:ASAHI CHEM IND CO LTD

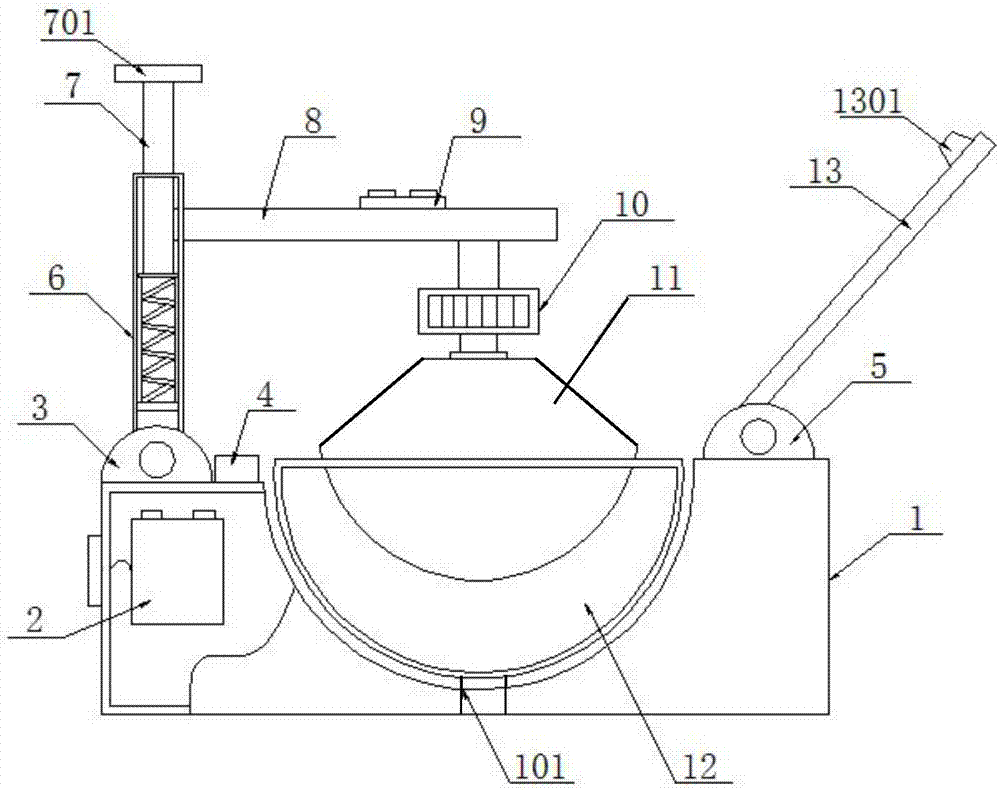

Multifunctional molecular biology experiment specimen grinding device

The invention discloses a multifunctional molecular biology experiment specimen grinding device, and relates to the field of grinding devices. The multifunctional molecular biology experiment specimengrinding device comprises an enclosure, wherein the side surface of the enclosure is equipped with a fan and is equipped with an air inlet tube in a penetrating mode; the air inlet tube is connectedto the fan; a grinding mechanism is arranged inside the enclosure; the grinding mechanism comprises a hemi-spherical grinding block; a circular table shaped connecting block is fixedly arranged on thetop of the hemi-spherical grinding block; the top of the circular table shaped connecting block is fixedly equipped with an upper rotary rod; the bottom of the hemi-spherical grinding block is equipped with a grinding base; a hemi-spherical grinding slot is formed in the top of the grinding base; grinding teeth are arranged at each of the outer side of the hemi-spherical grinding block and the inner side of the hemi-spherical grinding slot; a groove is formed in the bottom of the hemi-spherical grinding block; a blocking cover plate is fixedly arranged on the bottom of the groove; and the blocking cover plate is fixedly connected to the inner wall of the hemi-spherical grinding slot. In practical use, material recycling is not required, so that operation steps are effectively reduced, grinding efficiency is improved, and the practical use effect is better.

Owner:HUNAN UNIV OF CHINESE MEDICINE

Graded traditional Chinese herb grinding system

The invention discloses a graded traditional Chinese herb grinding system which comprises a base, a grinding ball and a grinding bowl. A half-circle limit groove is arranged in the surface of the base; a first rotating shaft is arranged at the top of the base and is rotatably connected with a branch pipe; a pressure lever and a spring are connected to the interior of the branch pipe in a sleeved manner; a bottom plate is welded to the bottom end of the spring; a sliding chute is arranged in the branch pipe; a support rod is welded to the side wall of the pressure lever, and a rotary motor is connected to the bottom of the support rod; the rotary motor is detachably connected with the grinding ball; the lower portion of the grinding ball is of a half-circle structure, the middle portion of the grinding ball is of a truncated cone-shaped structure, the upper portion of the grinding ball is provided with a connecting shaft, and the grinding ball is of a hollow-out structure; the grinding bowl is right under the grinding ball and is placed in the limit groove, the grinding bowl is of a half-circle structure, and the top of the grinding bowl extends upwards to form a ring wall. The grinding system is mainly used for grinding of traditional Chinese herbs, the traditional Chinese herbs can be crushed and ground by grade, and overall time in grinding is shortened; the graded traditional Chinese herb grinding system has the advantages of simpleness in structure and convenience in operation.

Owner:安徽普仁中药饮片有限公司

Efficient boron carbide grinding fluid and method for preparing same

InactiveCN105505231AImprove flatnessQuick grindingOther chemical processesPolishing compositions with abrasivesWater basedAlcohol

The invention discloses efficient boron carbide grinding fluid and a method for preparing the same, and relates to the field of technologies for grinding sapphire. The efficient boron carbide grinding fluid comprises, by weight, 5-25 parts of boron carbide micro-powder, 1-2 parts of dispersing agents, 0.5-1 part of water-based thickeners, 0.5-1 part of anti-settling agents, 0.5-5 parts of synergists, 0.5-1 part of antirust agents and 65-92 parts of substrate fluid. The substrate fluid can be one of pure water, isopropyl alcohol and polyhydric alcohol or a mixture of the pure water, the isopropyl alcohol and the polyhydric alcohol, and various components of the substrate fluid have equal weight parts or other proportions when the substrate fluid comprises the mixture of the pure water, the isopropyl alcohol and the polyhydric alcohol. The efficient boron carbide grinding fluid and the method have the advantages that the efficient boron carbide grinding fluid is long in service life, good in stability and applicable to rough grinding for processing sapphire wafers, the A-direction and M-direction sapphire grinding rates can be increased, processed products are good in surface flatness, and the like.

Owner:HUNAN HAOZHI TECH

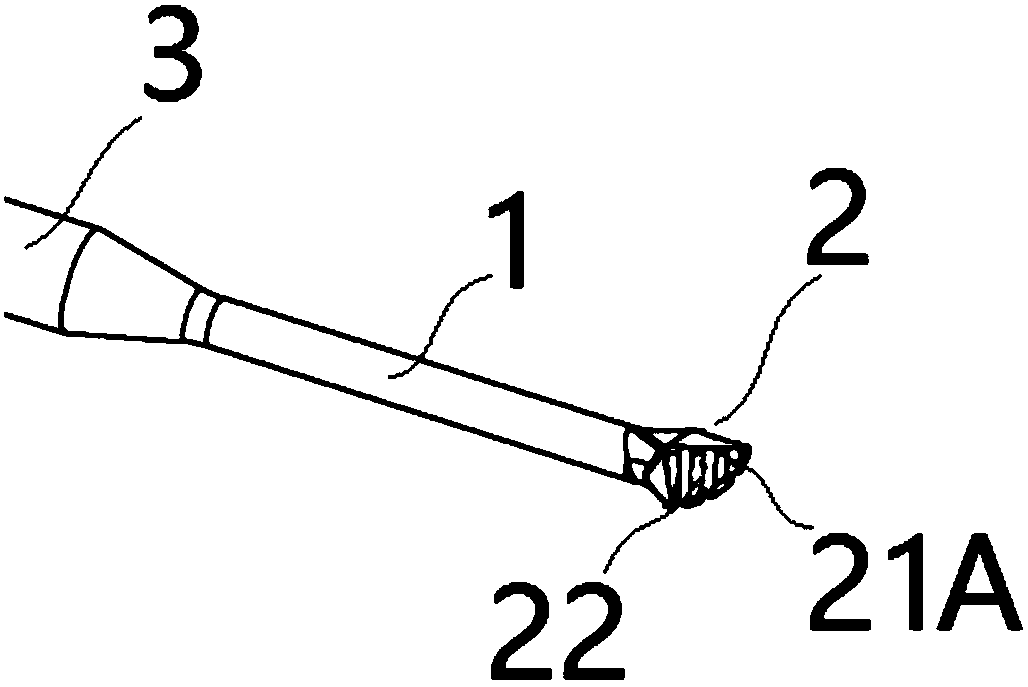

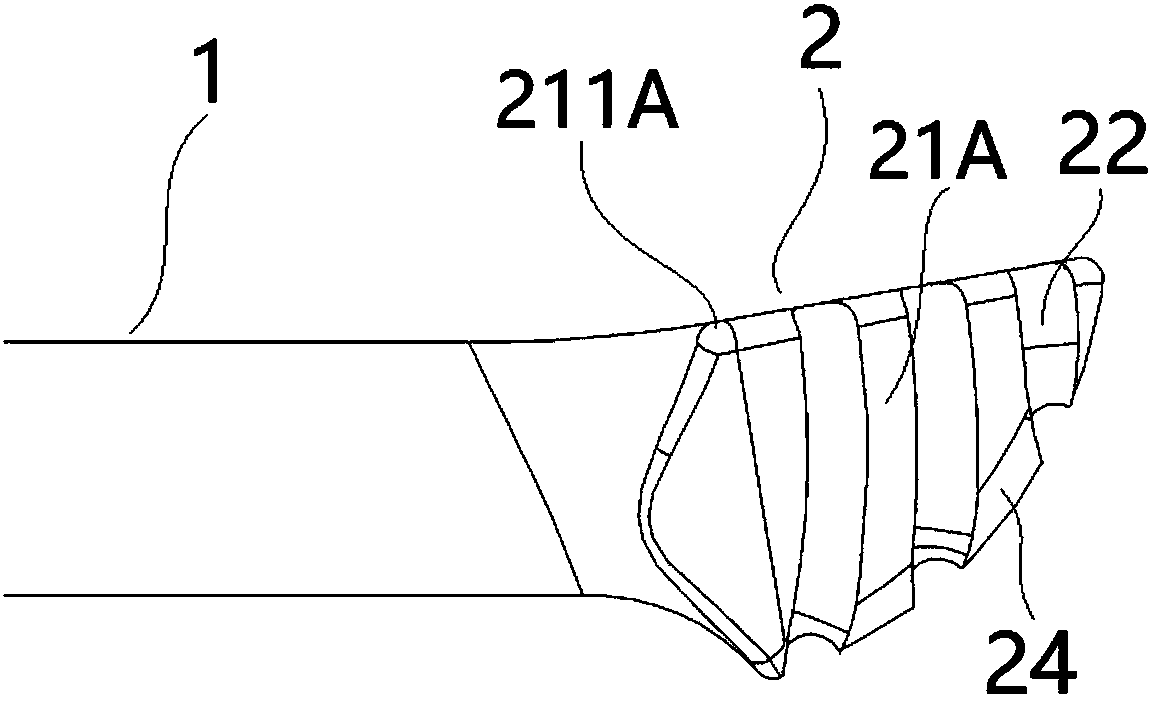

Piezosurgery head

The invention discloses a piezosurgery head. The piezosurgery head comprises a bar, a body and a head grinding part located at the front end of the piezosurgery head; the head grinding part is in a triangular pyramid shape, the bottom surface of the triangular pyramid is the rear end of the head grinding part, and the top tip, right facing the bottom surface, of the triangular pyramid is the frontend of the head grinding part; one end of the bar is connected with the rear end of the head grinding part, and the other end of the bar is connected with the body; two side faces in the three side cone faces of the triangular pyramid serve as a first grinding face and a second grinding face respectively. By means of the piezosurgery head, normal bone grinding operation can be completed; meanwhile, as the front end of the piezosurgery head is small in area, the grinding speed is high, and as the rear end is large, a good visual field can be provided for doctors; meanwhile, by the unique full-V structure design, doctors can guarantee that door-spindle-side bone grooves formed after grinding can be fully-closed V grooves at any operation angle, the wound incision area is reduced, use convenience is brought to doctors, and the surgery efficiency is improved.

Owner:BEIJING SMTP TECH CO LTD

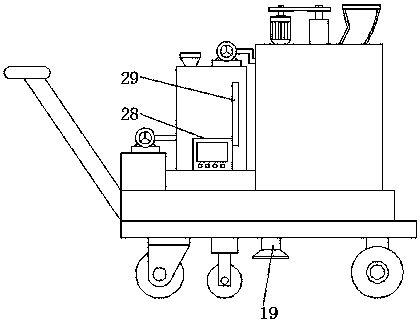

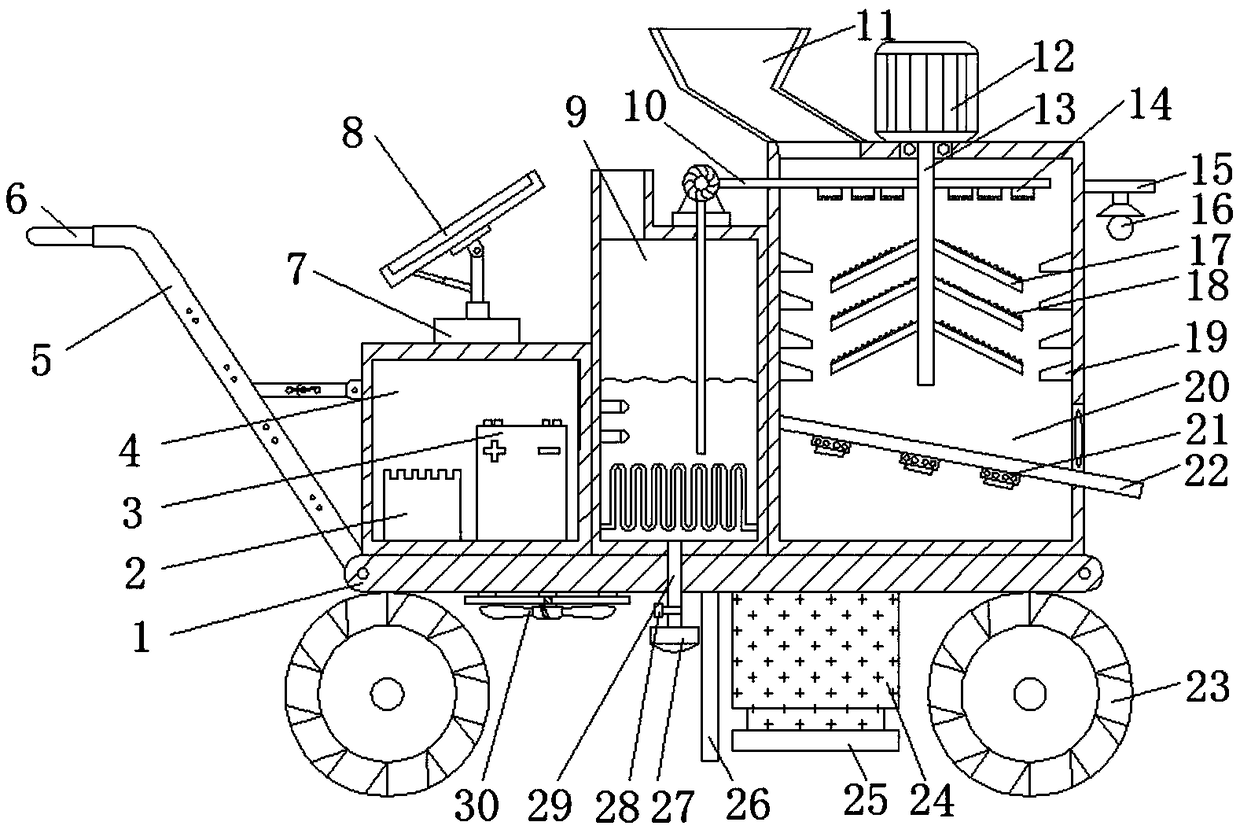

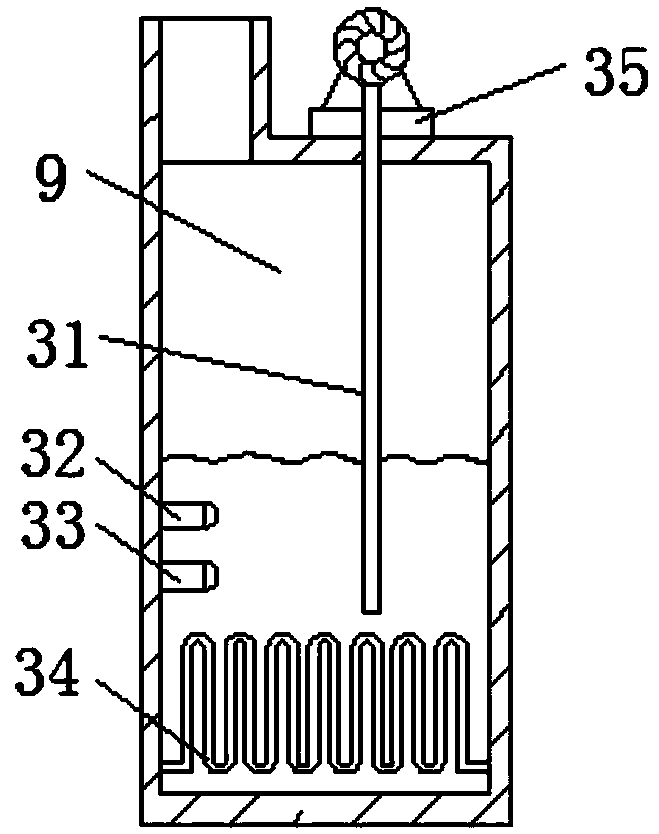

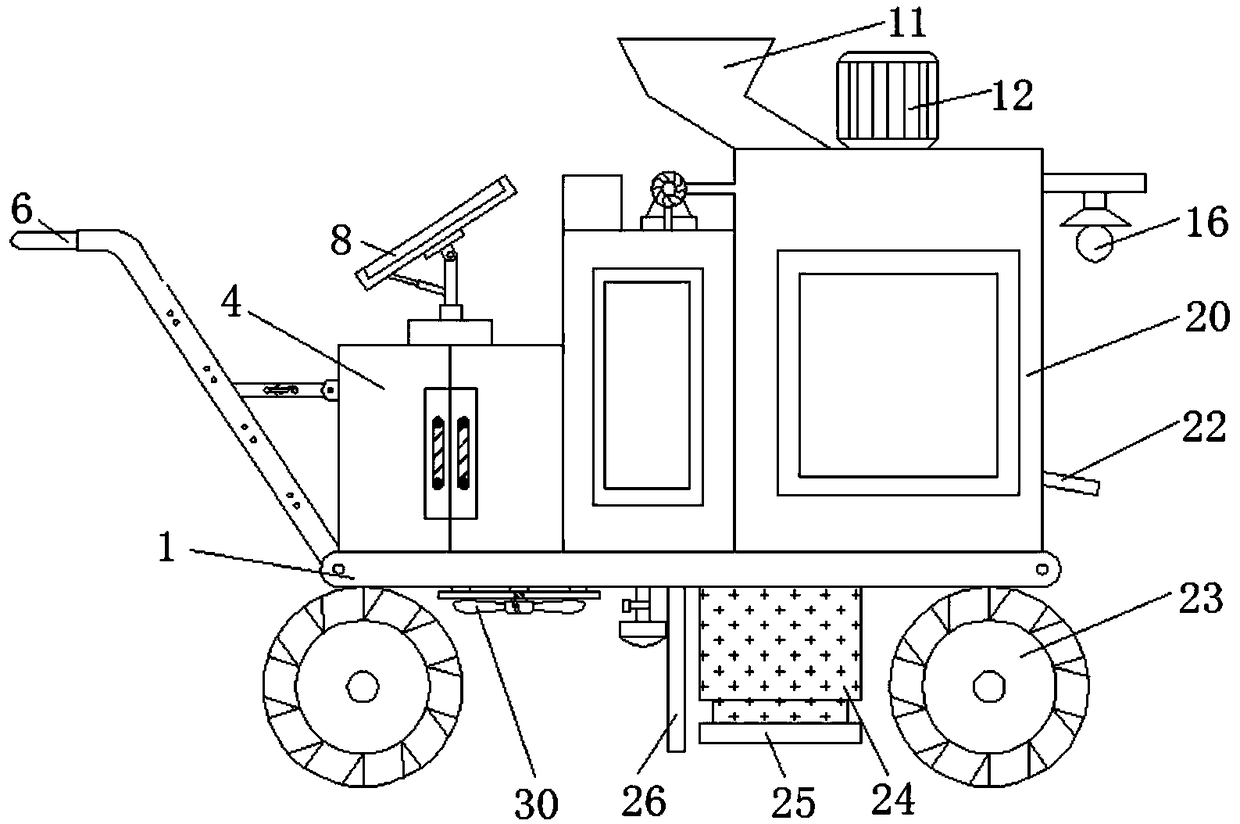

Pavement patching device for road engineering

InactiveCN110004809AEasy temperature controlImprove stirring efficiencyRoads maintainenceRoad engineeringWater storage tank

The invention discloses a pavement patching device for road engineering. The pavement patching device comprises a vehicle body. A stirring box and a water storage tank are arranged at the top of the vehicle body. A feeding port is formed in the top of the stirring box, and a first motor is arranged on one side of the feeding port. An output shaft of the first motor is connected with a first belt pulley in a sleeving mode. A stirring shaft is vertically arranged on the inner side of the stirring box. The upper end of the stirring shaft penetrates through the stirring box and is connected with asecond pulley in a sleeving mode, a plurality of stirring blades are fixed to the outer surface of the lower end of the stirring shaft equidistantly, a plurality of fixed blades are equidistantly distributed on the inner surface of the stirring box, a guiding hopper is arranged at the bottom of the inner side of the stirring box, vibrators are symmetrically distributed at the bottom of the guiding hopper, a discharging pipe is arranged at the center of the bottom of the guiding hopper in a penetrating mode, and a squeezing mechanism is arranged at the bottom of the discharging pipe. The pavement patching device is convenient to use, the efficiency of cement stirring is greatly improved, the quality of cement stirring is improved, the vibrators accelerate the falling of the cement, blockage is avoided, the practicability of the device is improved, the grinding of the patched pavement is accelerated, and the paving of the pavement is ensured.

Owner:卢光再

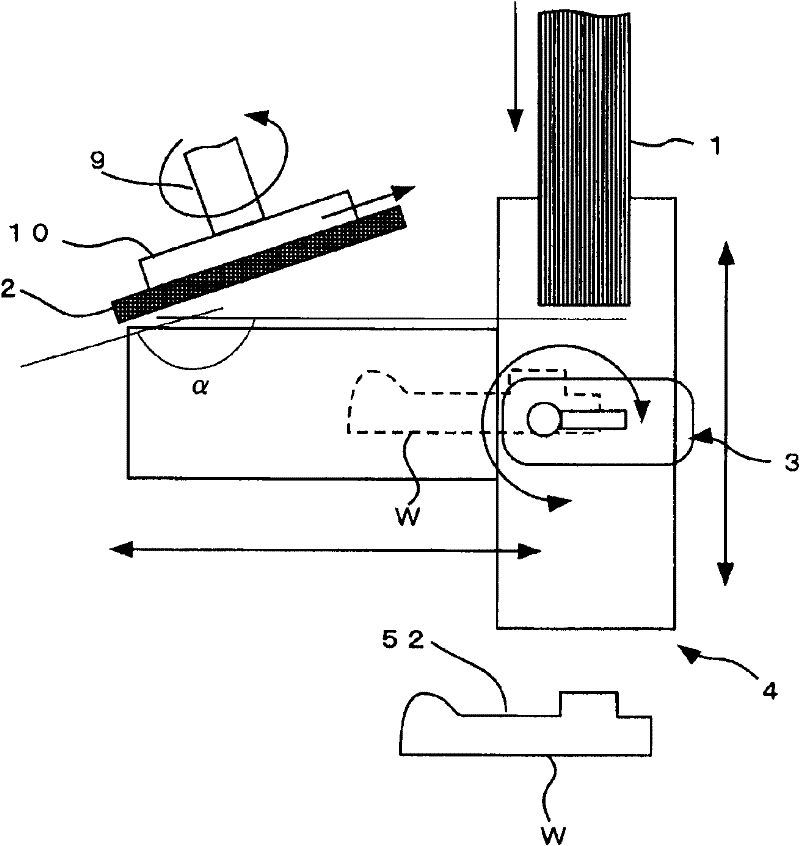

Grinding Device Of Parting Line Of Resin Molding And Grinding Method

ActiveCN102371523AGrinding fasterContinuous grindingBelt grinding machinesEngineeringPerpendicular direction

The invention provides a grinding device of a parting line of a resin molding and can grinding resin moldings having different shapes quickly. The grinding device of the parting line of the resin molding is composed of an annular grinding belt (1) rotating along a generally perpendicular direction and grinding burrs or jumps of the parting line (52) of the resin molding (W); a push and press pulley (21) capable of moving freely and provided with the grinding belt (1) on the back for pushing and pressing a part of the grinding belt and forming an inclining angle of an incline face of the grinding belt (1); a grinding plate (2) used for fine grinding and having a smaller thickness a low rigidity than the grinding belt (1); and a work piece holding tool (3) carrying the resin molding (W) in a dismountable manner to make the parting line (52) in a generally horizontal direction.

Owner:KAKIHARA KOGYO CO LTD

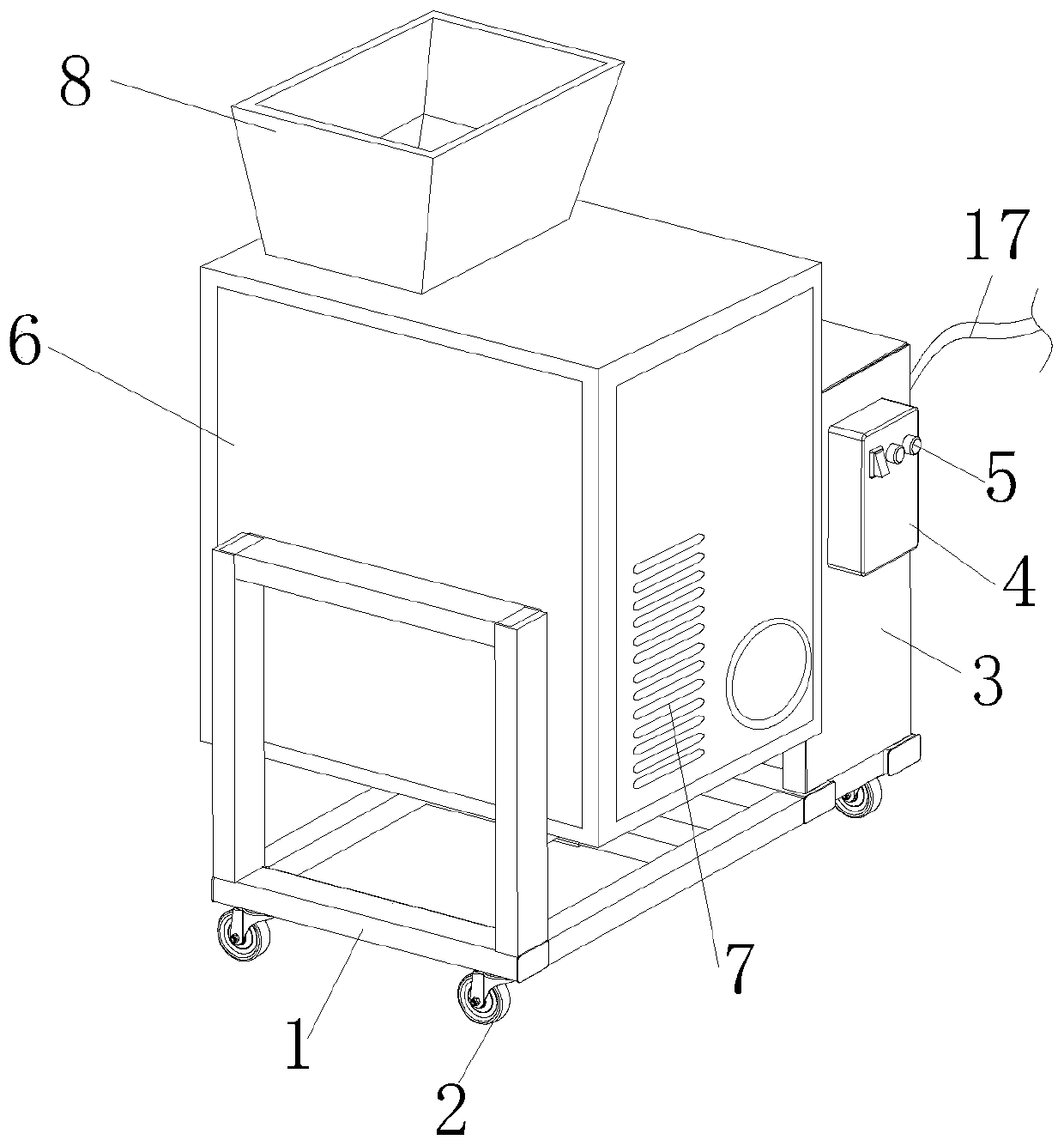

Powder grinding equipment for cosmetics

ActiveCN110961216AQuick grindingPrimary grinding up toGrain treatmentsVibration suppression adjustmentsGear driveCrank

The invention discloses powder grinding equipment for cosmetics, which comprises a fixing frame, a powder grinding frame, a heat dissipation groove, a feeding hopper, a discharging hopper, a first motor, a powder grinding cylinder and a screening and grinding device. The screening mechanism is arranged in the powder grinding frame, the second motor is power-on for work, a driving belt wheel and adriving handle are driven to rotate through a rotor arranged at the front end, the driving handle drives a filtering frame to swing at the upper end of the connecting handle through a crank, and therefore the filtering frame screens materials discharged through the feeding hopper, and the advantage that cosmetic materials can be screened and ground into powder is achieved. A primary grinding mechanism is arranged in the powder grinding frame, a second rack moves to drive a gear to rotate, so that the gear drives a rotating shaft and a rotating rod to rotate, the rotating rod drives a second grinding block and a first grinding block at the upper end of a connecting roller to be matched with a grinding plate to grind cosmetic materials, and the advantage that large-particle materials can beprimarily ground is achieved.

Owner:浙江百姿化妆品股份有限公司

Novel pediatric tablet cutting and grinding device

InactiveCN107440911AEasy to operateFlexible adjustmentOral administration deviceArchitectural engineering

The invention discloses a novel pediatric tablet cutting and grinding device, which comprises a No. 1 shell and a No. 2 shell. The bottom of the No. 1 shell is hinged with a plastic cover. The top of the No. 1 shell is provided with a cavity, and A metal grinding disc is clamped in the cavity. The top of the No. 1 shell is screwed to the bottom of the No. 2 shell. There is a mounting hole on the outer wall of the top of the No. 2 shell, and a metal sleeve is inserted into the mounting hole. The outer wall of the metal sleeve is provided with a limit ring, the inner wall of the metal sleeve is welded with a metal partition, and the bottom end of the metal partition is fixed with a motor through a bolt, and the bottom end of the output shaft of the motor is fixed with a grinding head through a bolt. The battery plate is fixed on the top of the separator by bolts, the top of the metal sleeve is sleeved with a plastic cap, and a push switch is clamped in the middle of the top of the plastic cap. The invention can cut the tablets into different sizes to meet the demands of dispensing medicines in different doses, and is convenient to operate, more time-saving and labor-saving, and more hygienic.

Owner:YANCHENG XINANZHOU PHARMA

Preparation method of meal replacement powder

ActiveCN113198564AScientific and reasonable structureEasy to useGrain huskingGrain polishingMeal replacementProcess engineering

The invention discloses a preparation method of meal replacement powder. The preparation method comprises the steps of S1, cereal crushing; S2, cereal sterilization; S3, dry-wet separation; S4, water milling and screening; S5, product collection; S6, quick freezing of the product. The cereals are beaten and crushed, bran remaining on the surfaces of the cereals is removed, and large cereals are rapidly crushed, so that the surfaces of the cereals are clean. Meanwhile, the situation that a discharging port is blocked due to accumulation of large particles is avoided, the bacteria-free condition of subsequent production of the product is guaranteed through continuous sterilization, dry-wet separation is conducted on the sterilized product, a large amount of water is prevented from rapidly entering the grinding position, and therefore the concentration of a powder solution is guaranteed, and the situation that the drying efficiency is affected due to too low concentration is avoided. Dust raising and wet powder accumulation caused by too dry powder are avoided through water milling, normal production of the product is guaranteed, and in addition the production quality of the product is guaranteed.

Owner:东莞市霖鑫牛食品科技有限公司

Ball-milling process for superfine ceramic powder

The invention discloses a ball-milling process for superfine ceramic powder. The ball-milling process comprises the following steps of proportionally feeding ceramic powder, water and primary grinding ball stones into a first section of ball-milling tank, mixing the added ceramic powder, water and primary grinding ball stones with stirring by virtue of the first section of ball-milling tank, and performing primary medium-fineness crushing on the ceramic powder in a stirring mixing process by virtue of the primary grinding ball stones; pumping slurry out after the feed liquid is stirred for a long time by the ball-milling tank and the ceramic powder in the slurry is ground to medium fineness, simultaneously filtering the primary grinding ball stones in the slurry, and feeding the filtered slurry into a second section of ball-milling tank; adding secondary grinding ball stones into a second section of ball-milling tank according to a certain proportion, stirring the slurry within a preset time, and secondarily and finely grinding the ceramic powder in the slurry by virtue of the secondary grinding ball stones in the second section of ball-milling tank until final fineness is achieved.

Owner:佛山市阳光陶瓷有限公司

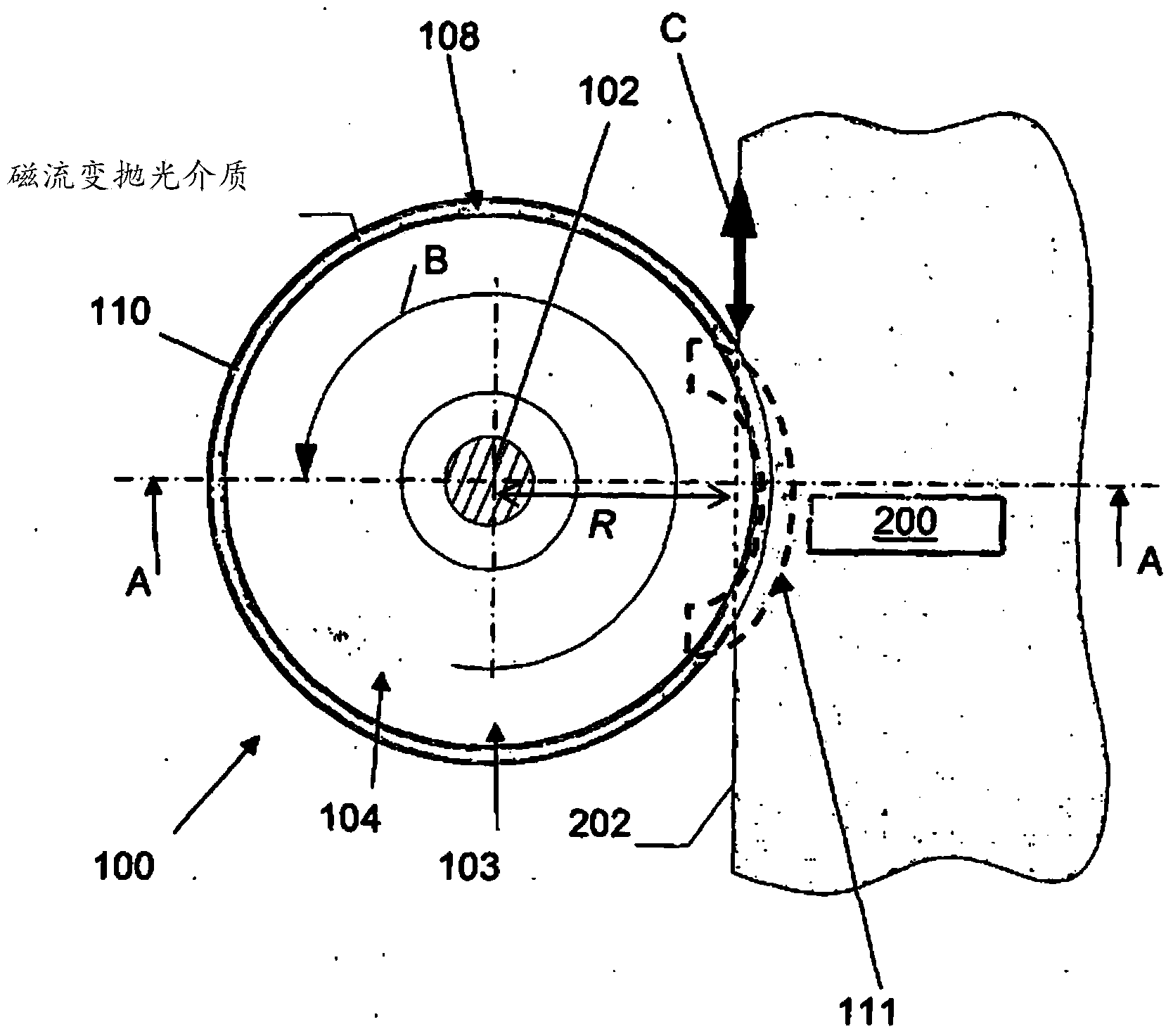

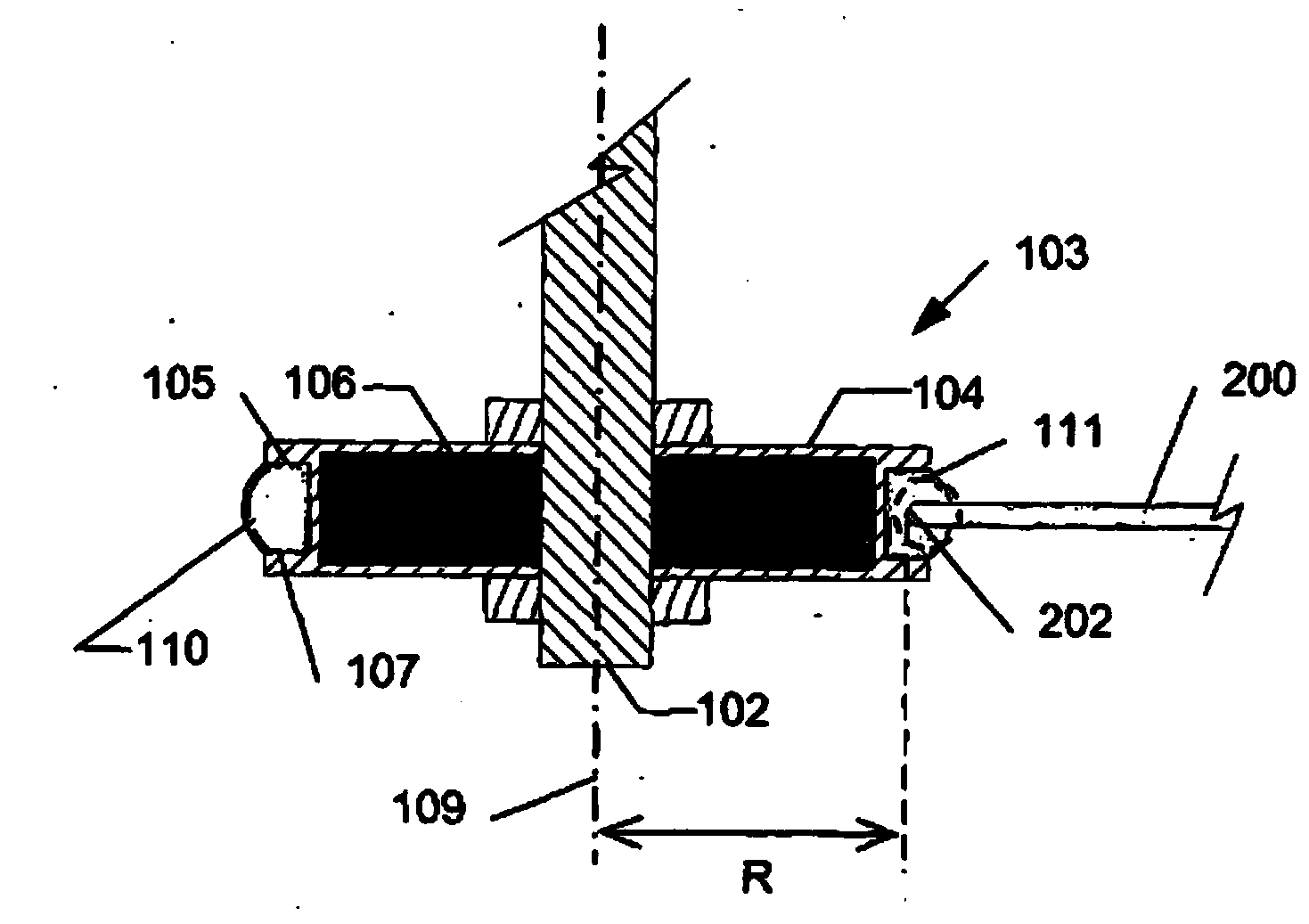

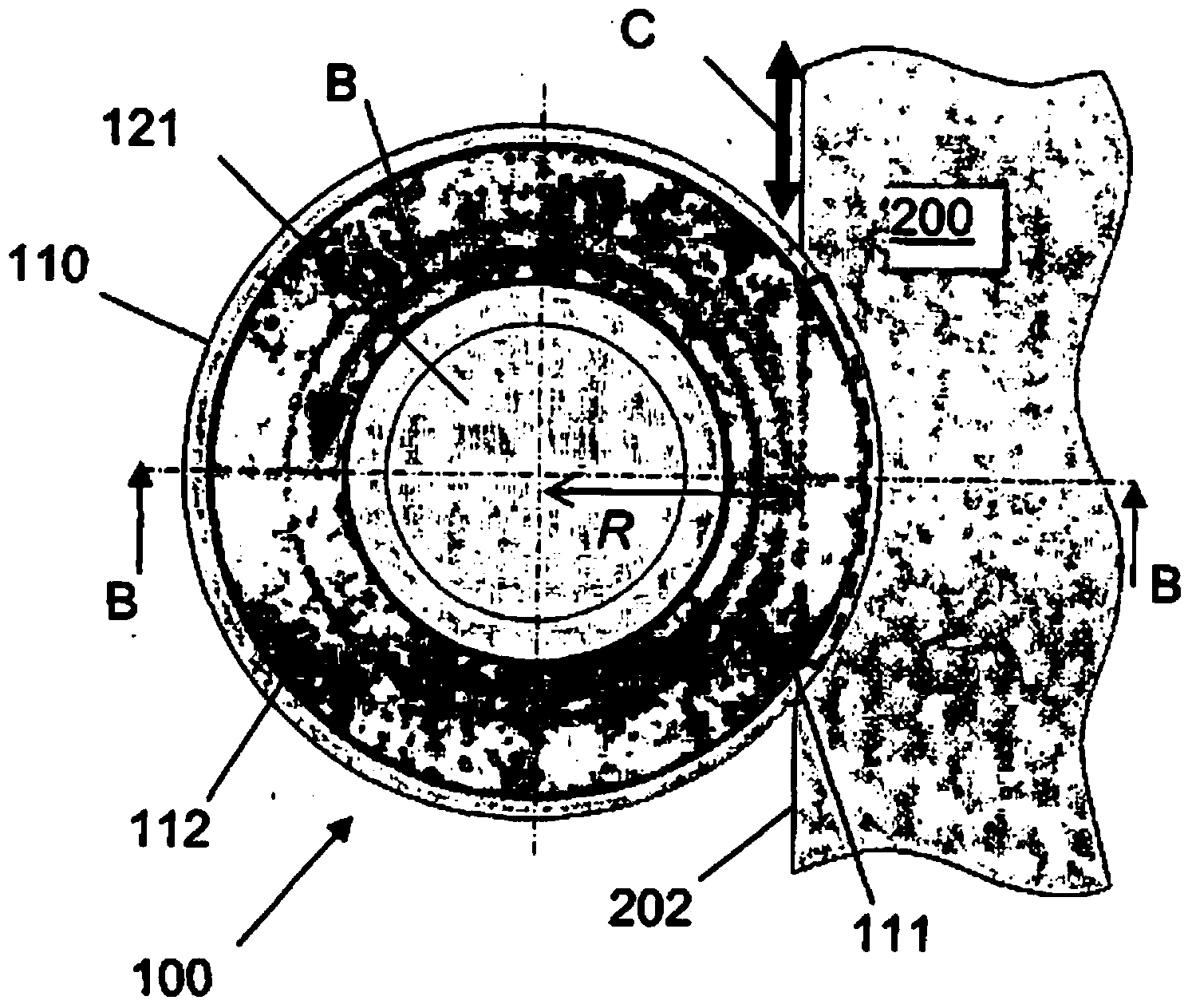

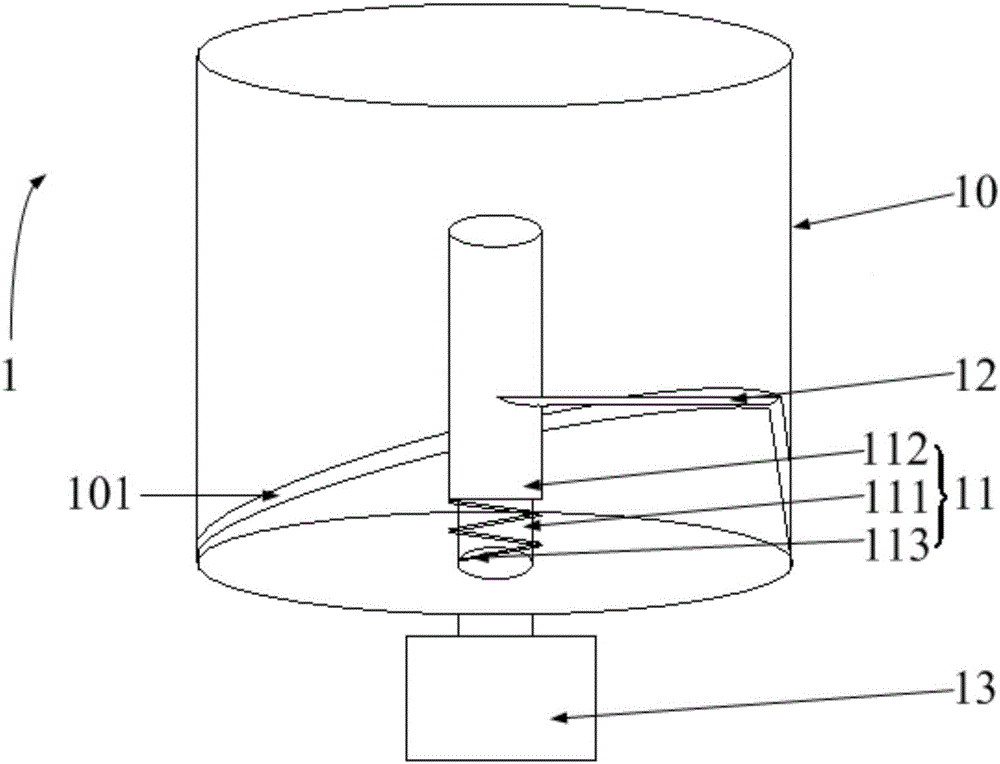

Apparatus and method for polishing an edge of an article using magnetorheological (MR) fluid

InactiveCN103402704AImprove removal rateShorten polishing timeEdge grinding machinesSuperfinishing machinesRelative motionEngineering

Disclosed is a method and apparatus for polishing an edge of an article involving providing at least one carrier including: first and second opposing surfaces defining a groove, the first and second opposing surfaces being spaced apart in a first direction to receive the edge; and magnetic field generator configured to provide a magnetic field in the groove to stiffen magnetorheological (MR) fluid disposed in the groove to provide at least one polishing zone; receiving the edge in the polishing zone; and driving relative motion between the at least one carrier and the edge in a second direction substantially transverse to the first direction.

Owner:AGENCY FOR SCI TECH & RES

Special compound grinding agent for valve flange and preparation method of special compound grinding agent

InactiveCN104610879AStable in natureProtectiveOther chemical processesPolishing compositions with abrasivesCalcium silicateManufacturing technology

The invention discloses a special compound grinding agent for a valve flange and a preparation method of the special compound grinding agent, and relates to the technical field of valve manufacture. The special compound grinding agent is prepared from raw materials in percentage by mass as follows: 60%-65% of boron carbide, 5%-8% of diatomaceous earth, 3%-5% of carborundum, 3%-5% of chromium oxide, 2%-3% of white carbon black, 2%-3% of putty powder, 1%-2% of calcium silicate, 1%-2% of polyvinyl alcohol, 0.5%-1% of gelatin, 0.5%-1% of starch, 2%-3% of oleic acid, 5%-10% of ethanol and 5%-10% of water. Boron carbide is taken as a main abrasive, appropriate quantities of auxiliary abrasives and dispersing agents are added, and the prepared grinding agent is powdery, has stable performance and is convenient to store and transport; during use, all that is required is to add an appropriate amount of water to a mixture, the mixture is blended to be thick, a to-be-ground flange is coated with the thick product, the grinding process can be accelerated, the grinding effect is enhanced, and the grinding agent has a certain protection function on a grinding tool.

Owner:ANHUI SRILL VALVE CO LTD

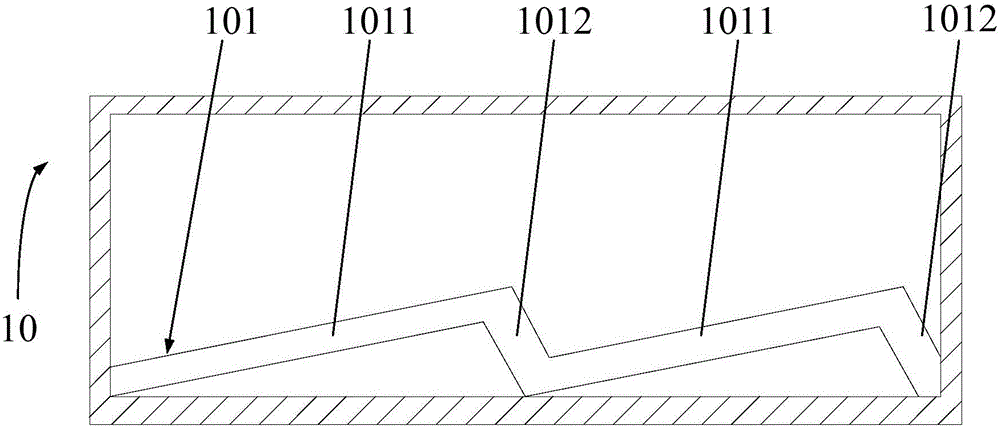

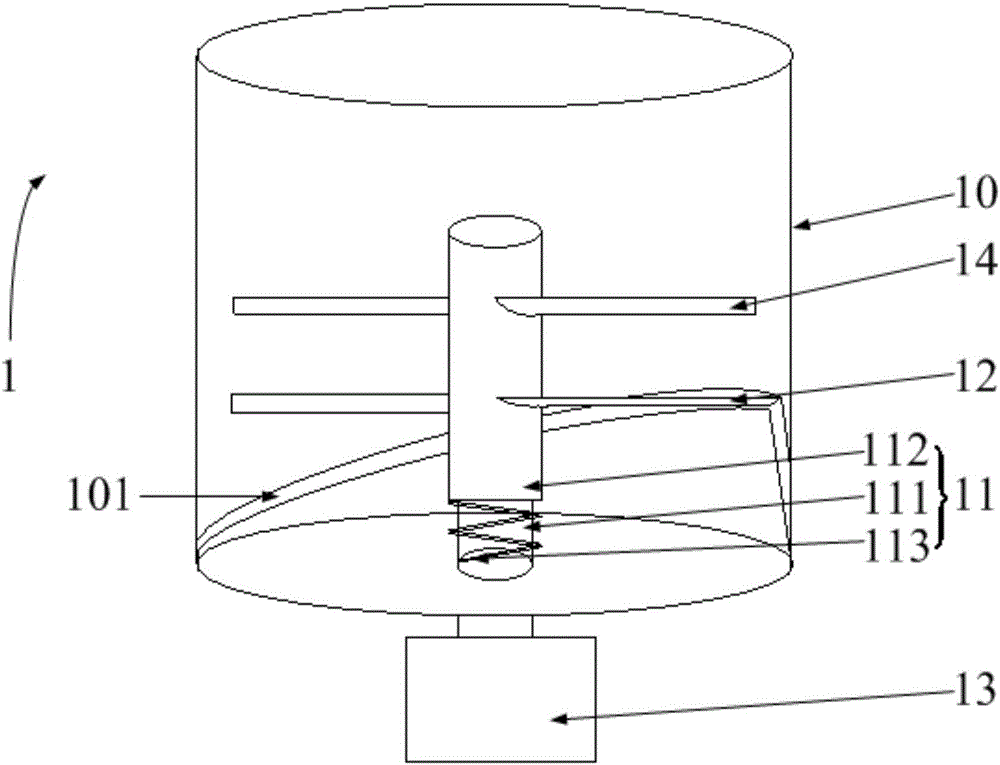

Material drying device and conditioning machine

ActiveCN106037526AFully automatedIncreased flexibility of useBeverage vesselsElectric machineryEngineering

The invention provides a material drying device and a conditioning machine, wherein the material drying device comprises a drying cavity, a stirring shaft and a stirring motor; a guide groove, which has a predetermined track, is formed in the inner sidewall of the drying cavity in a peripheral direction; the stirring shaft is arranged in the drying cavity and is provided with a first stirring blade; one end of the first stirring blade is connected to the stirring shaft, and the other end of the first stirring sheet extends towards the inner sidewall of the drying cavity and is located within the guide groove; the stirring motor is connected to the stirring shaft; and by virtue of the stirring motor, the stirring shaft is driven to do circumferential rotation and the first stirring sheet is driven to do circumferential rotation along the predetermined track of the guide groove and simultaneously to do an axial motion. According to the technical scheme, by virtue of the first stirring blade and the guide groove which are matched, materials are stirred in a horizontal direction, and meanwhile, the materials are also stirred in a vertical direction,so that the materials in the drying cavity are fully stirred and a drying efficiency is improved; and in addition, drying uniformity is guaranteed, and user's using satisfaction is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Municipal anti-blocking cement road surface repairing device

InactiveCN108755367AImprove stirring efficiencySave time at workRoads maintainenceRoad surfaceWater level

The invention belongs to the technical field of municipal engineering equipment and especially relates to a municipal anti-blocking cement road surface repairing device. Aiming at the problems that warming to preventing block cannot be achieved and stirring is simple, the municipal anti-blocking cement road surface repairing device is disclosed. The municipal anti-blocking cement road surface repairing device comprises a bottom plate, wherein a tool box is welded with an outer wall of the top of the bottom plate, a water tank is welded with the outer wall of the top of the bottom plate and atthe position close to the tool box, a stirring box is welded with the outer wall of the top of the bottom plate and at the position close to the water tank, a first installation hole is arranged on one side of an outer wall of the top of the stirring box, and a feeding hopper is welded with an outer wall of one side of the first installation hole. According to the municipal anti-blocking cement road surface repairing device disclosed by the invention, control on a water temperature and a water level in the water tank is improved, a cement stirring efficiency is greatly quickened, work time oflabor personnel is shortened, a contact area between the box body and cement is increased by the stopping plate, cement stirring is quickened by rotary cutting of blades, cement falling is quickened by a vibrator, block is avoided, practicability of the device is improved, grinding to the repaired road surface is quickened, and flat pavement of the road surface is ensured.

Owner:张磊

Wood end buffering and grinding equipment capable of synchronously removing dust

InactiveCN107538295AFast grindingWith safety protectionPlane surface grinding machinesGrinding/polishing safety devicesArchitectural engineeringPulley

The invention discloses a synchronous dust-removing wood end buffering and smoothing device, which comprises a dust-removing box, a frame, an installation shell and a base. The frame is installed and fixed on the base. A large pulley is installed on the right side of the drum, and the large pulley is connected with the small pulley on the output shaft of the drive motor through a V-belt. Mounting plate, a grinding plate is installed on the right side of the mounting plate, multiple support springs are provided on the outer ring of the mounting plate, a dust removal box is installed on the outside of the left end of the drum, and an air duct is connected to the left side wall of the dust removal box. A cooling fan is installed, and the other end of the air pipe is connected with a ring pipe arranged on the right side of the installation housing, and a plurality of air blowing heads are installed on the inner side of the ring pipe. The present invention can carry out fast wood grinding operation, and can remove dust synchronously during processing, so as to prevent the dust from flying everywhere to pollute the environment and endanger the health of workers.

Owner:NINGBO ZHENHAI XIUYANG ADVERTISEMENT DECORATION

Grinding device for unshaped refractory production

The invention discloses a grinding device for unshaped refractory production. The grinding device comprises a device body, the device body is of a cavity structure, the two sides of the device body are provided with placing openings, the inner wall of the bottom of the device body is provided with a machining plate, positioning sliding rods are vertically arranged on the two sides of the machiningplate correspondingly, a horizontally-arranged sliding pressing plate is connected between the two positioning sliding rods in a sliding mode, the bottom of the sliding pressing plate is provided with a grinding plate corresponding to the machining plate, a fixed base is welded to the middle position of the top of the sliding pressing plate, the top of the fixed base is rotationally provided witha movable block, a reinforcing base is welded to the inner wall of one side of the device body, a horizontally-arranged thread rotating rod is rotationally connected to one side of the reinforcing base, and two oppositely-arranged adjusting blocks are connected to the thread rotating rod through threads. The grinding device is reasonable in design and easy to operate, achieves the purpose of rapidly grinding unshaped refractory, is good in grinding effect, low in cost and easy to popularize and saves trouble and labor.

Owner:浙江康斯迪冶金科技有限公司

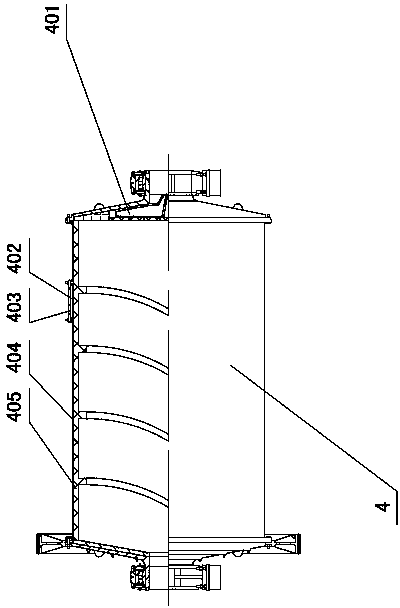

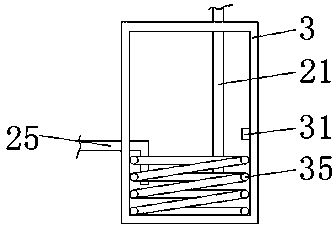

Efficient vertical agitating ball mill for cemented carbide production and manufacture

ActiveCN109201214AQuick grindingImprove grinding efficiencyGrain treatmentsElectric machineryEngineering

The invention discloses an efficient vertical agitating ball mill for cemented carbide production and manufacture. The efficient vertical agitating ball mill comprises a grinding outer cylinder, a machine cylinder is installed at the upper end of the grinding outer cylinder in a disassembled mode, and a cylinder cover is tightly arranged at the upper end of the machine cylinder in a covered mode.An electric rotating machine is vertically and fixedly mounted at the center of the top surface of the inner side of the cylinder cover, a mounting bracket is mounted on an output shaft at the lower end of the electric rotating machine, and a conductive arc is mounted at the end, away from the electric rotating machine, of the mounting bracket. The efficient vertical agitating ball mill has the beneficial effects that the efficient vertical agitating ball mill for cemented carbide production and manufacture can realize fast and efficient grinding of cemented carbide powder, has high grinding efficiency, can achieve a better grinding effect without long-time grinding, and has good practicability.

Owner:蓬莱市超硬复合材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com