Polishing abrasive particle, production method therefor, polishing method, polishing device, and slurry

A technology of abrasive grains and slurry, which is applied in the direction of grinding equipment, grinding machine tools, manufacturing tools, etc., and can solve the problem that diamond abrasive grains cannot be reused

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

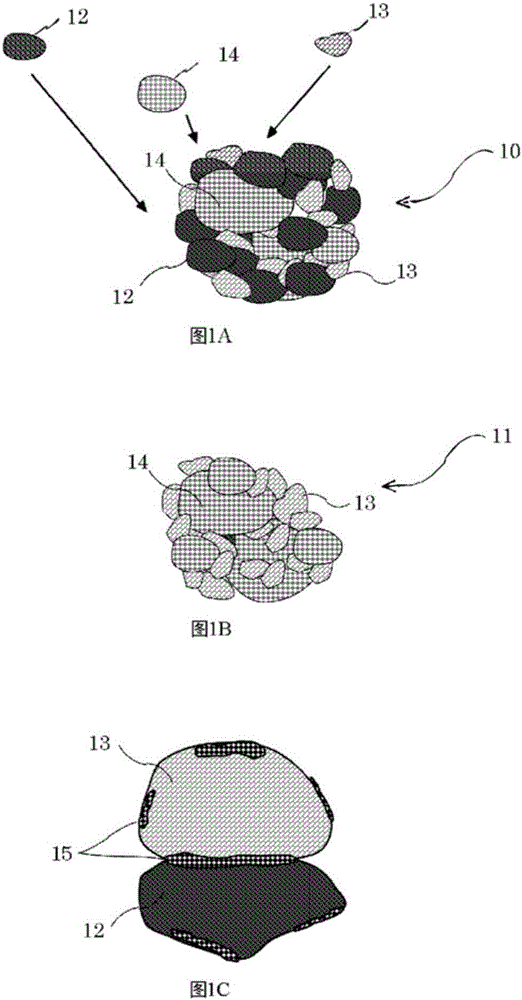

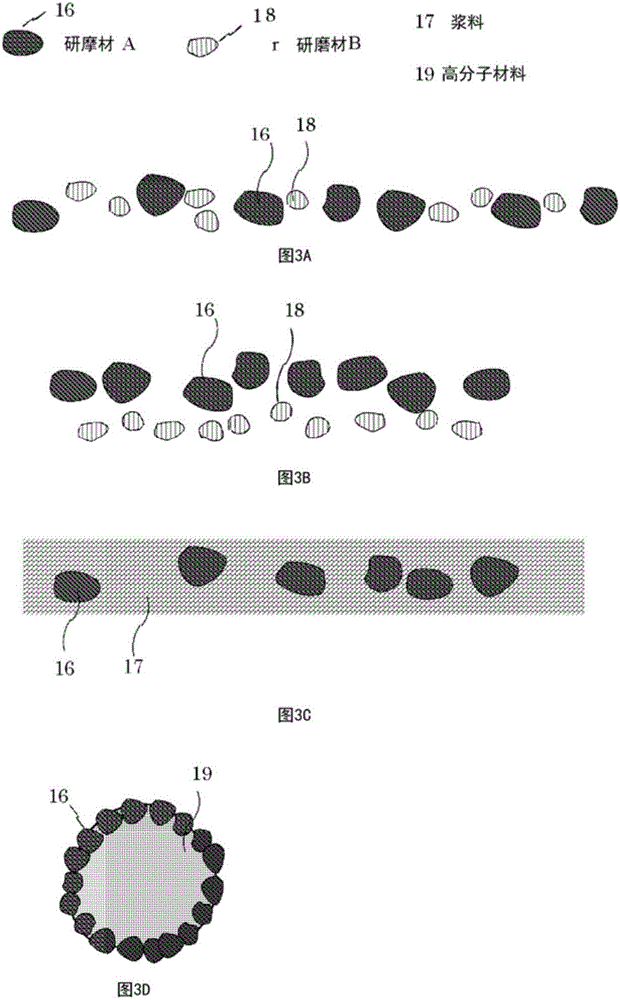

[0194] [Structure and function of abrasive grains for grinding]

[0195] Figure 4 A and Figure 4 B is a micrograph of the abrasive grains for grinding of the present invention, Figure 4 A The following is an explanatory diagram of its grinding effect.

[0196] Figure 4 A is a micrograph showing the polishing abrasive grains of Example 1. FIG. Since the latter has just been integrated, abrasive grains of various sizes are mixed. Those with an average particle size of 5 to 6 μm and a particle size of about 1 μm are mixed. Figure 4 B is an enlarged view of its part. This is a photograph of one abrasive grain with an outer diameter of approximately 6 μm. Three types of components that have been pulverized in advance are mixed and strongly connected to each other. The three types of components are all integrated into particles while maintaining their inherent physical and chemical properties. The abrasive grains for polishing of the examples are integrated with such a...

Embodiment 2

[0217] [Verify the effect of the first component]

[0218] Figure 7 It is a comparative graph of the polishing rate when polishing SiC with the first component replaced.

[0219] The portion denoted Sample 1-1 shows the use of Al in the grinding of SiC 2 o 3 with MnO 2 and CaCO 3 The result of integrated abrasive grains for grinding.

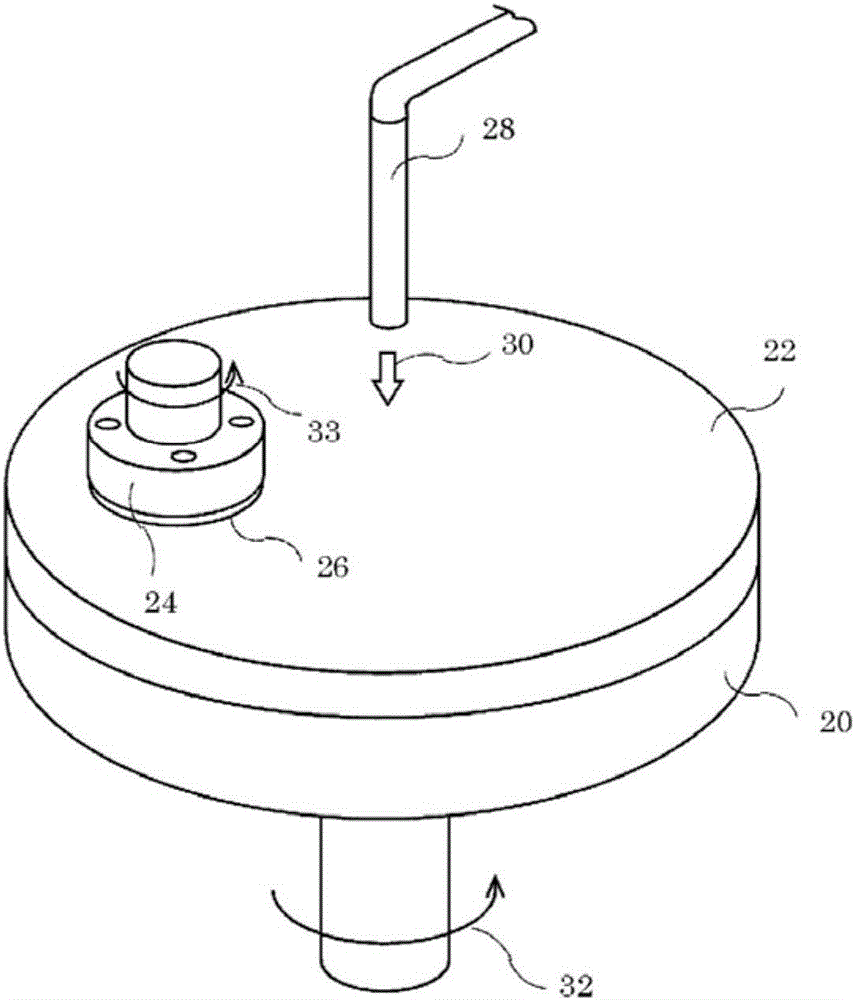

[0220] In this embodiment, the operating conditions of the grinding device are that the number of revolutions of the grinding platen 20 is set at 50 revolutions per minute (rpm), the number of revolutions of the holding device 24 is set at 100 revolutions per minute, and the holding device 24 moves the material to be ground 26 toward The grinding pressure pressed in the direction of the grinding platen 20 is set as 160 grams (g / cm2) per 1 square centimeter. 2 ). The abrasive grains for polishing were mixed in pure water in an amount of 15% by weight. The thus adjusted slurry was supplied onto the polishing pad 22 from the liquid injecto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com