System and method for treating waste acid gas

A waste gas treatment and acid gas technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to achieve the effect of small footprint, low operating cost and simple operation

Active Publication Date: 2013-02-06

美景(北京)环保科技有限公司

View PDF6 Cites 49 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, various Claus+ reduction absorption and its improved processes use new patented solvents to capture and recycle the tail gas from liquid sulfur degassing, and use pre-enrichment and enrichment for low-concentration acid-poor gas to impro

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

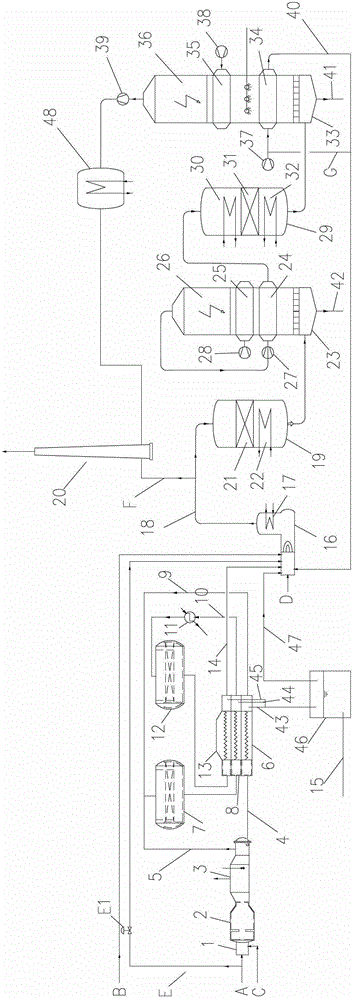

The invention provides a system and a method for treating waste acid gas. The system for treating the waste acid gas comprises a rich acid gas thermal reaction treating unit, a claus treating unit, a claus tail gas and poor acid gas burning unit, a burnt tail gas catalytic oxidation acid-making unit, a secondary conversion acid-making unit and a tail gas reheating unit. According to the system for treating the waste gas, the sulfur recovery rate of the whole system for treating the acid gas reaches above 99.99%, the concentration of SO2 in the tail gas emitted to atmosphere is less than 100mg/m<3>, the conversion rate and the emission concentration can meet the highest emission limit standards in the industry, and no waste liquid is discharged from the system.

Description

technical field [0001] The invention relates to an acid gas waste gas treatment system and treatment method. Background technique [0002] In petrochemical, coal chemical and other production processes, the sulfur in raw materials is finally converted into high-concentration acid gas containing tens of percent hydrogen sulfide in the process of processing. Hydrogen sulfide is a very harmful substance to safety and the environment. Must be treated or recycled before discharge. For large-scale sulfur recovery (greater than several thousand tons / year), in order to facilitate product sales, storage and transportation, the Claus sulfur recovery process is usually used to convert hydrogen sulfide into sulfur. [0003] The conventional Claus sulfur recovery process is composed of a thermal reaction section and several catalytic reaction sections. Contains H 2 The acid gas of S is incompletely burned with air in the combustion furnace, and the air volume is strictly controlled to...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C01B17/80C01B17/04

CPCY02P20/129

Inventor 胡惊雷

Owner 美景(北京)环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com