Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about How to "Speed up crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

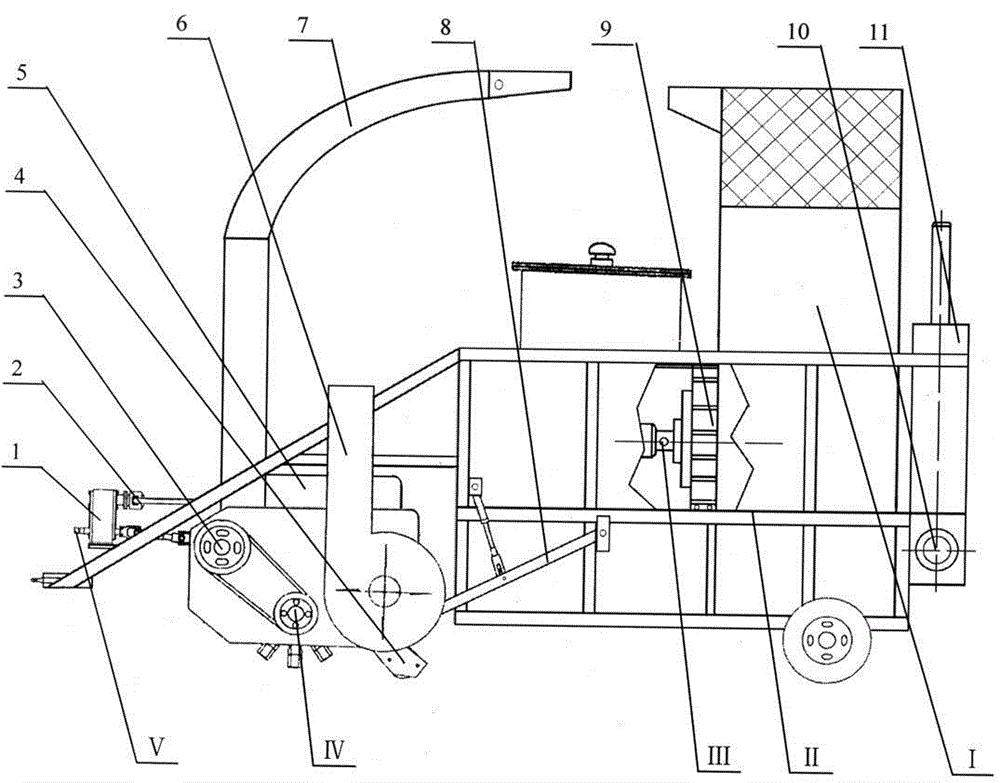

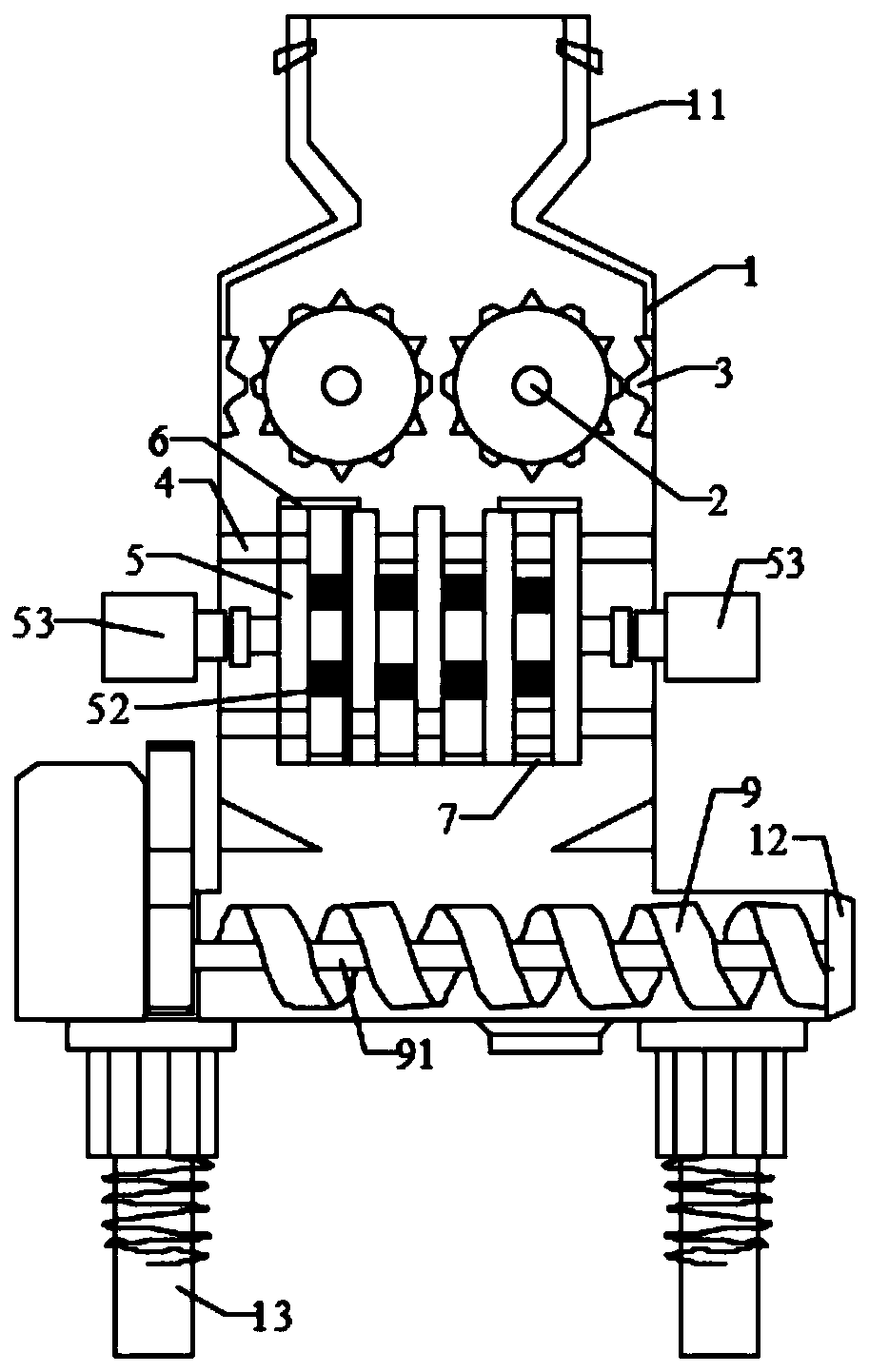

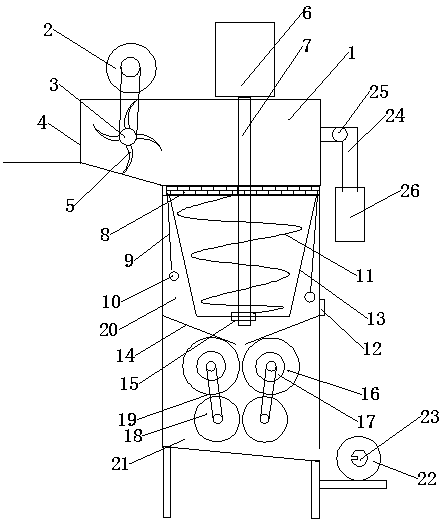

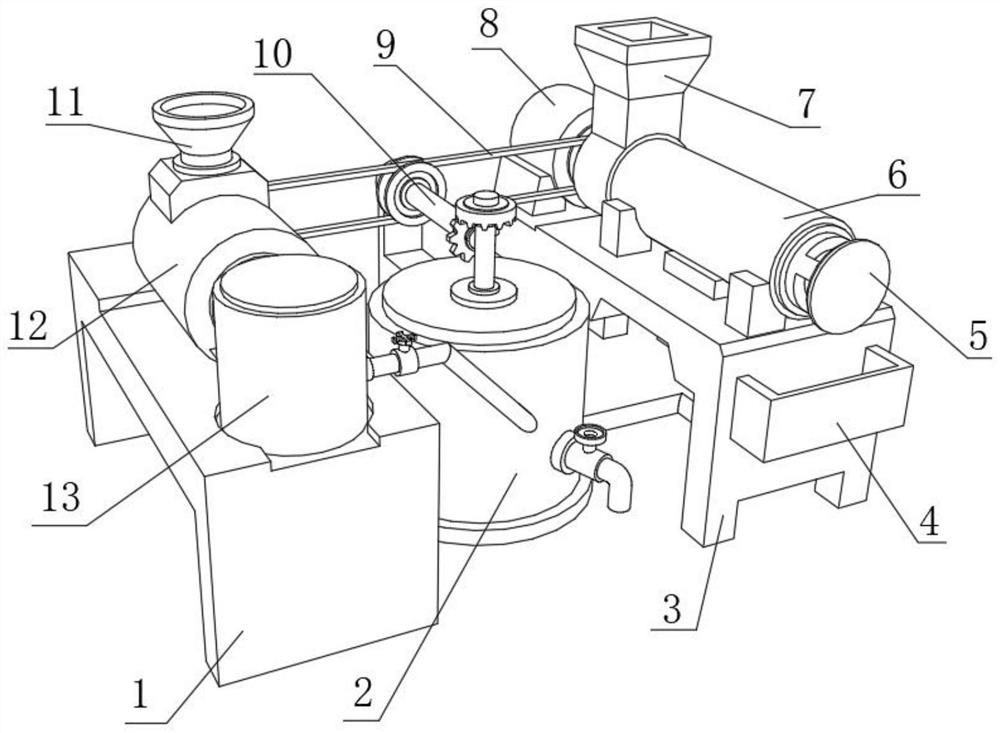

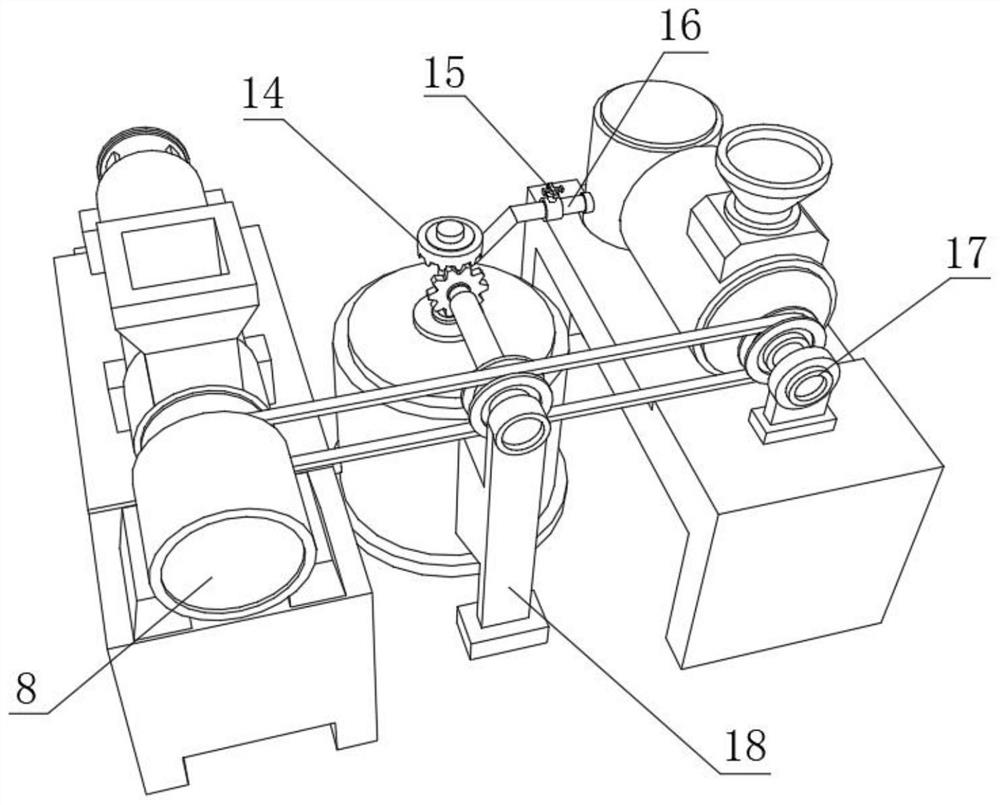

Pull-type picking, kneading, bundling and bagging machine for straw feed

ActiveCN104904437AGood rigidityGood precise shape and position benchmarkLoadersBalingGrazingEngineering

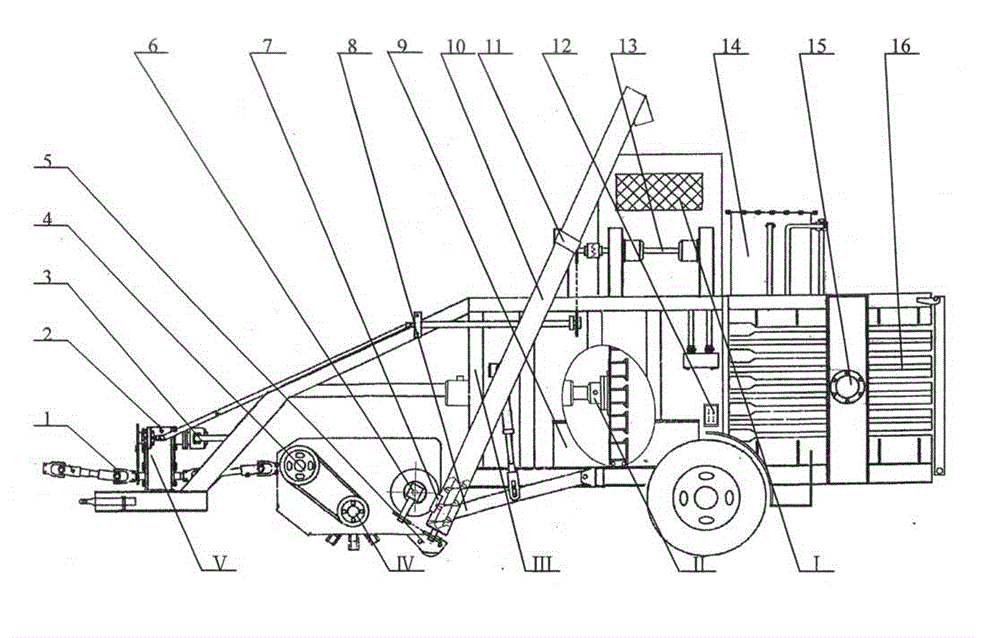

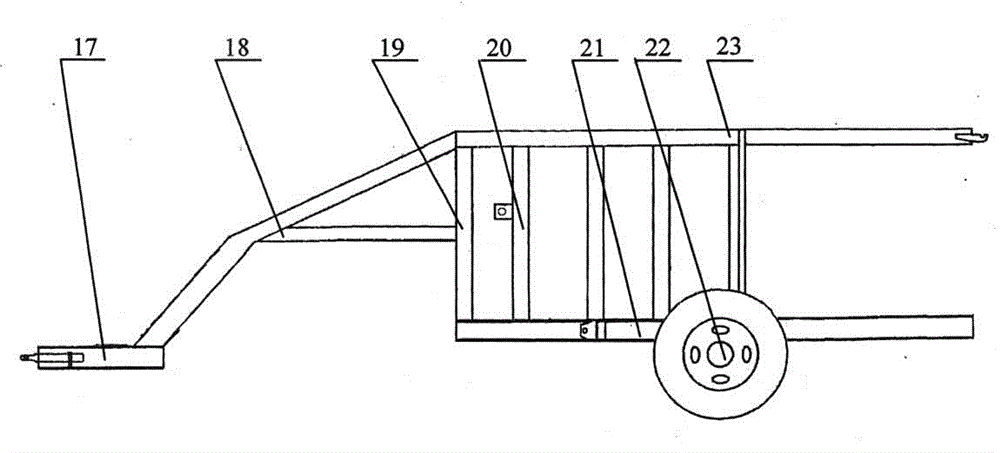

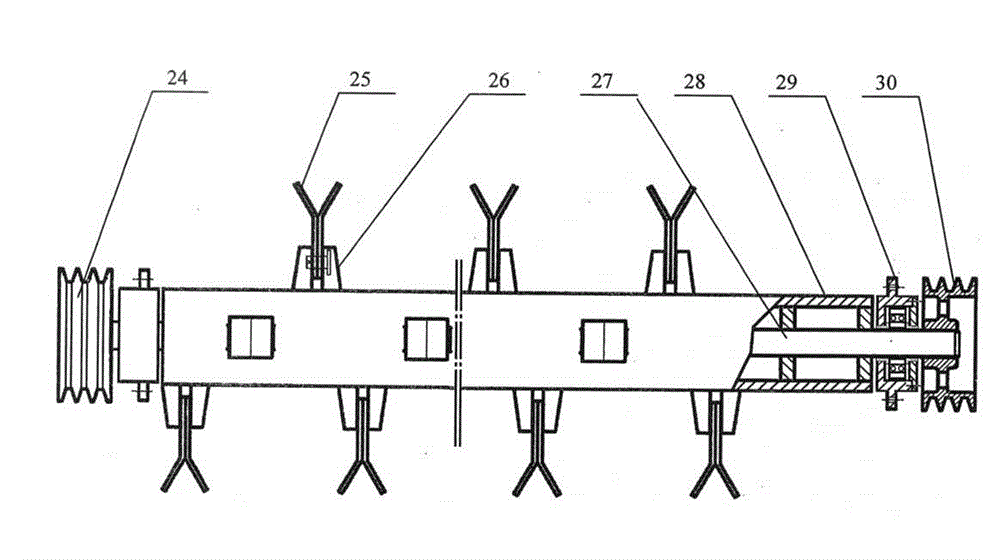

The invention discloses a pull-type picking, kneading, bundling and bagging machine for straw feed. The pull-type picking, kneading, bundling and bagging machine comprises an integral rack, a picking, kneading and transporting device, a straw smashing filling bin, a straw compacting, bundling and bagging device and a powder transmission system. The innovative technologies such as the picking kneading and transporting device being front-arranged to suspend and hydraulically lift, deep tearing, kneading and smashing processing conducted on coarse hard section head and dense surface of corn straw, straw smashing three-direction hydraulic strong compaction and bundling to transport, straw compaction bundling, automatic packing after manual bagging are adopted, and combination processes of picking and smashing, compacting and bundling, bagging and packing are conducted on corn straw in the field. And the pull-type picking, kneading, bundling and bagging machine for the straw feed has the advantages that the technology is advanced, the structure is reasonable, the production efficiency is high, and the working quality is good. Straw feed compaction bales made by the machine has good sealing environment, microbial fermentation action can also occur in a natural condition, the slaking degree is improved, the nutrition ingredient is increased, and the palatability, the grazing rate and the digestion and absorption rate are improved when cattle and sheep are fed.

Owner:四平市顺邦农机制造有限公司

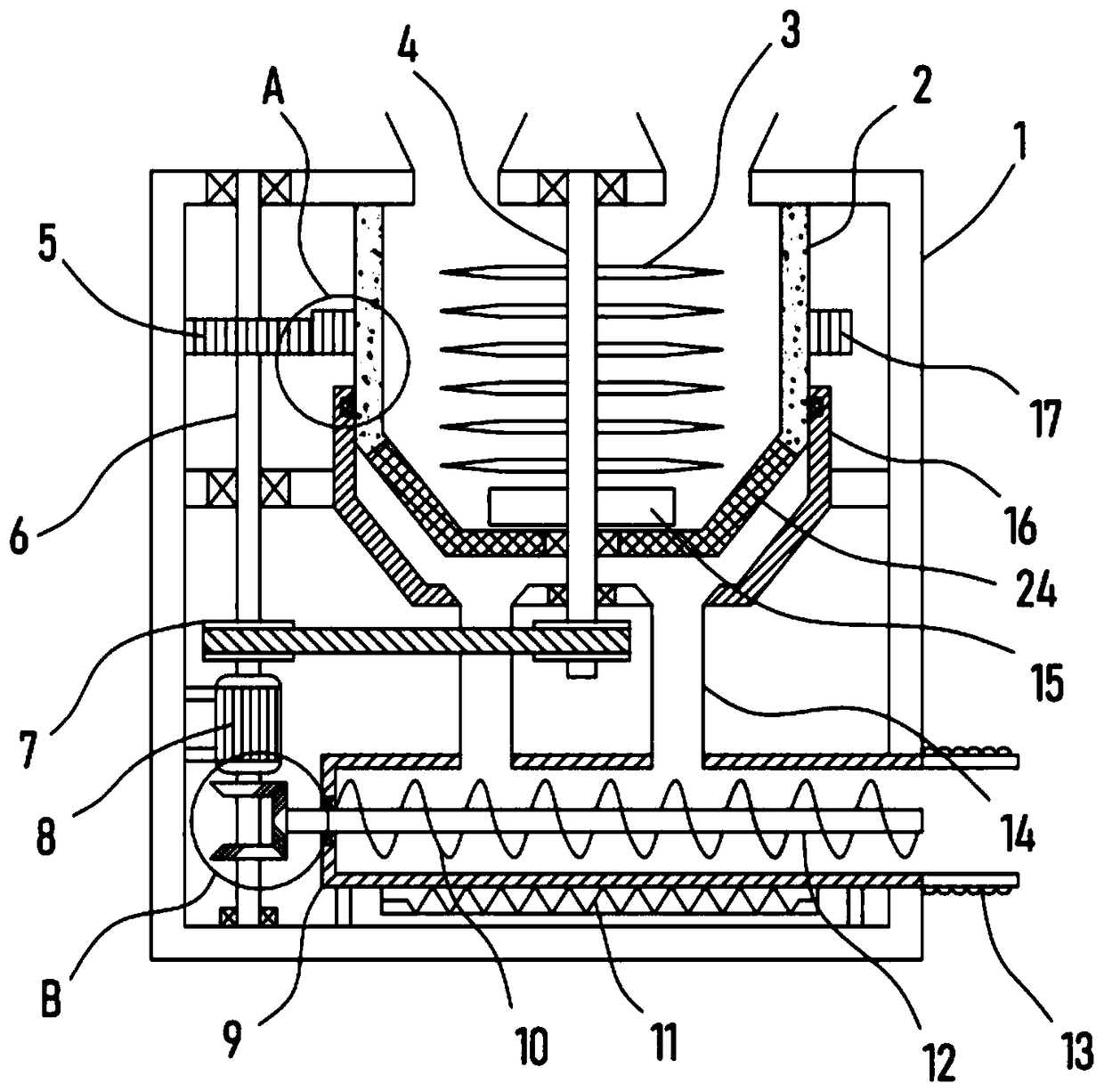

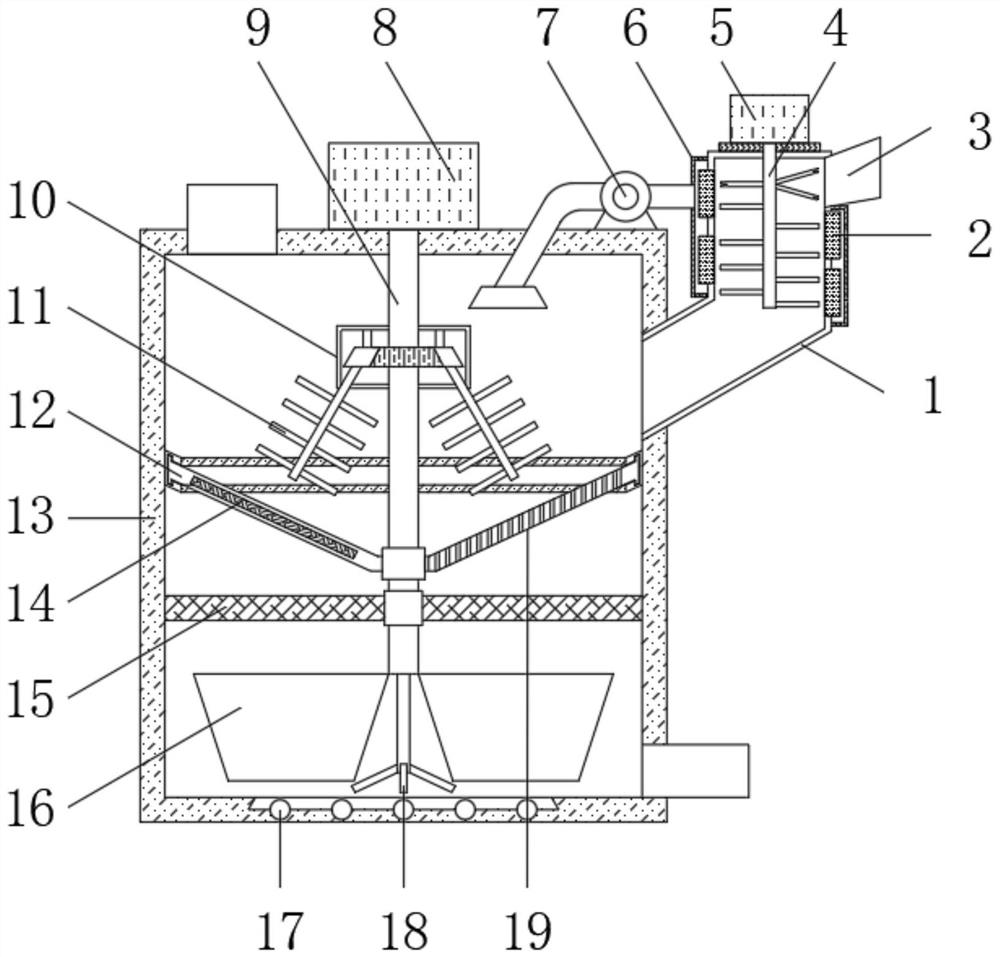

Mixing and discharging device for pharmaceutical chemical engineering

InactiveCN109433066ARealize the rotary crushing effectImprove refinementRotating receptacle mixersTransportation and packagingHelical bladeDrive shaft

The invention discloses a mixing and discharging device for pharmaceutical chemical engineering, and relates to the technical field of discharging devices. The mixing and discharging device comprisesa fixed rack, wherein a rotating groove is fixedly formed in the fixed rack, a driven shaft is rotationally mounted in the rotating groove, a plurality of breaking blades are uniformly fixed on the driven shaft at equal intervals, a horizontal conveying barrel is mounted at the lower end of a delivery pipe in a communicated manner, a conveying shaft is rotationally mounted in the conveying barrel,and a helical blade is fixed on the surface of the conveying shaft. Raw materials in the rotating groove can be rotationally broken by rotation of the breaking blades under driving of the driven shaft, refining of raw materials promoted, the rotating groove can rotate in the direction opposite to that of the breaking blades, sufficient and uniform mixing of the materials is guaranteed while smashing of the raw materials is promoted, the helical blade can rotate clockwise and anticlockwise along the conveying shaft, on one hand, the raw materials can move rightwards intermittently to realize discharging, and concentrated discharging of the raw materials is avoided, on the other hand, rotational mixing of the raw materials is promoted, and discharging quality is improved.

Owner:吴斌

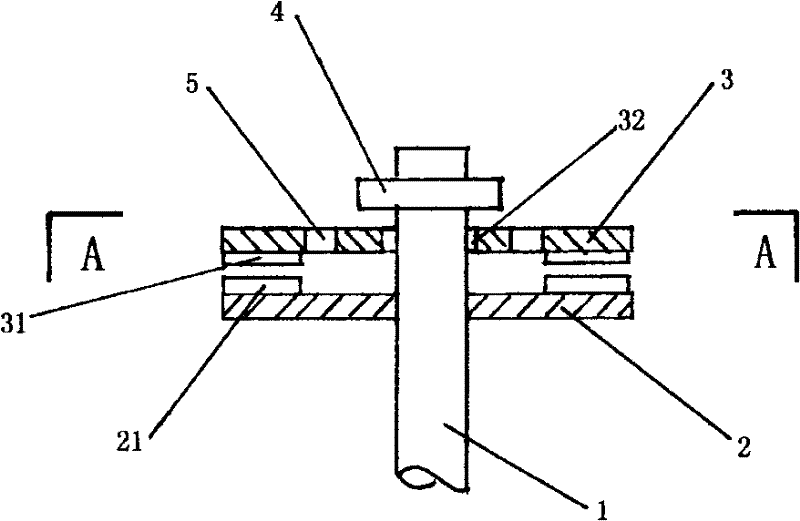

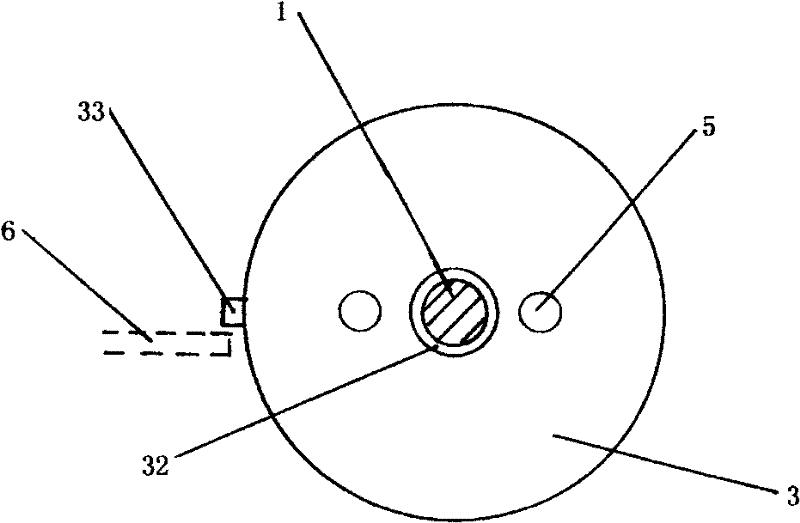

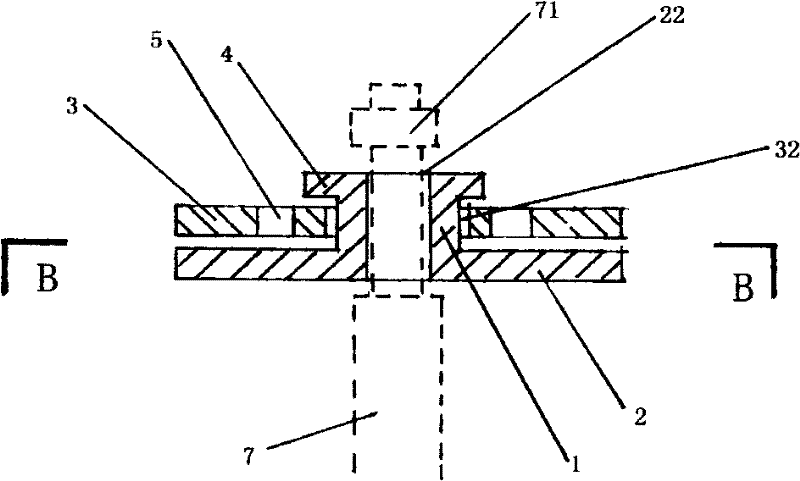

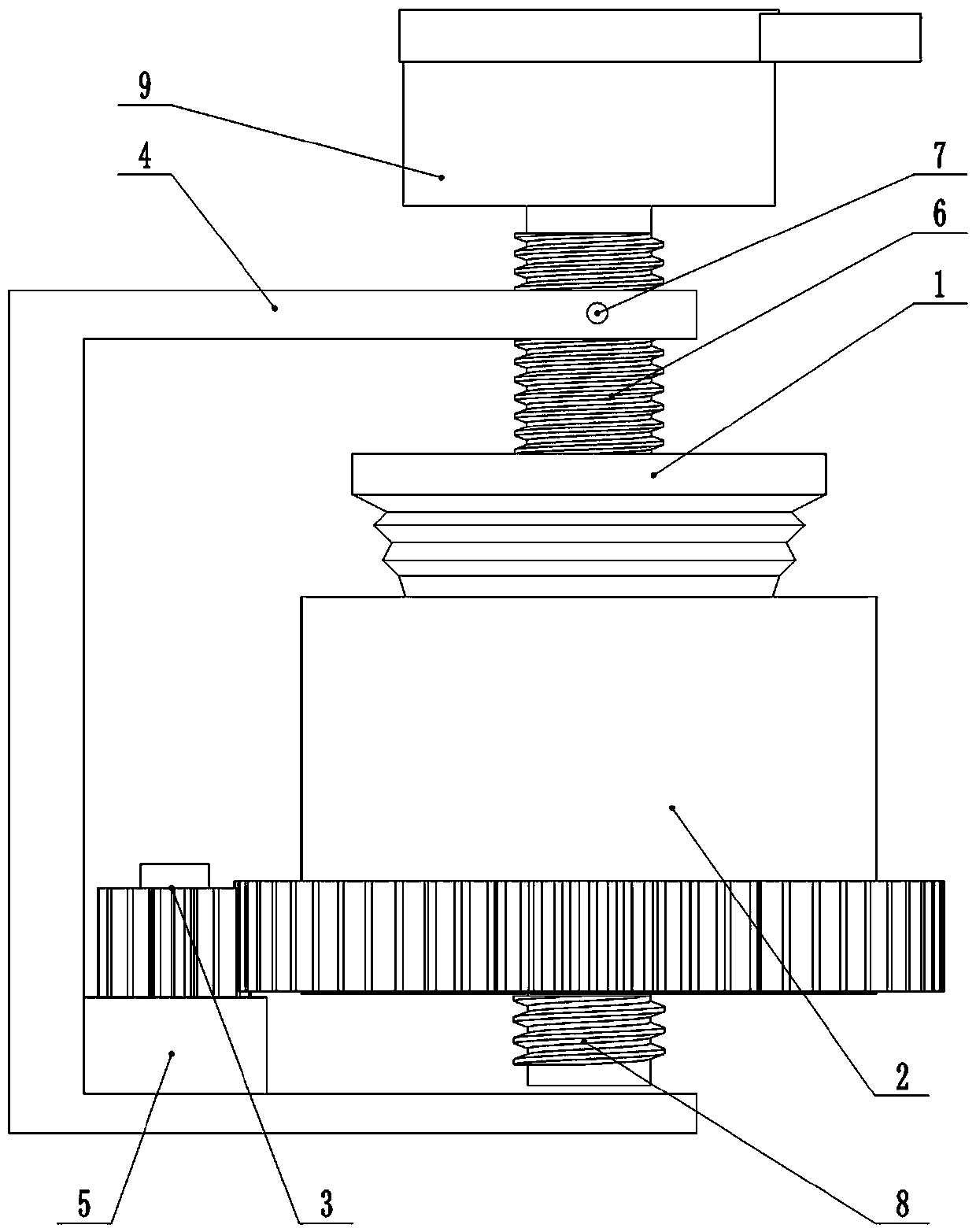

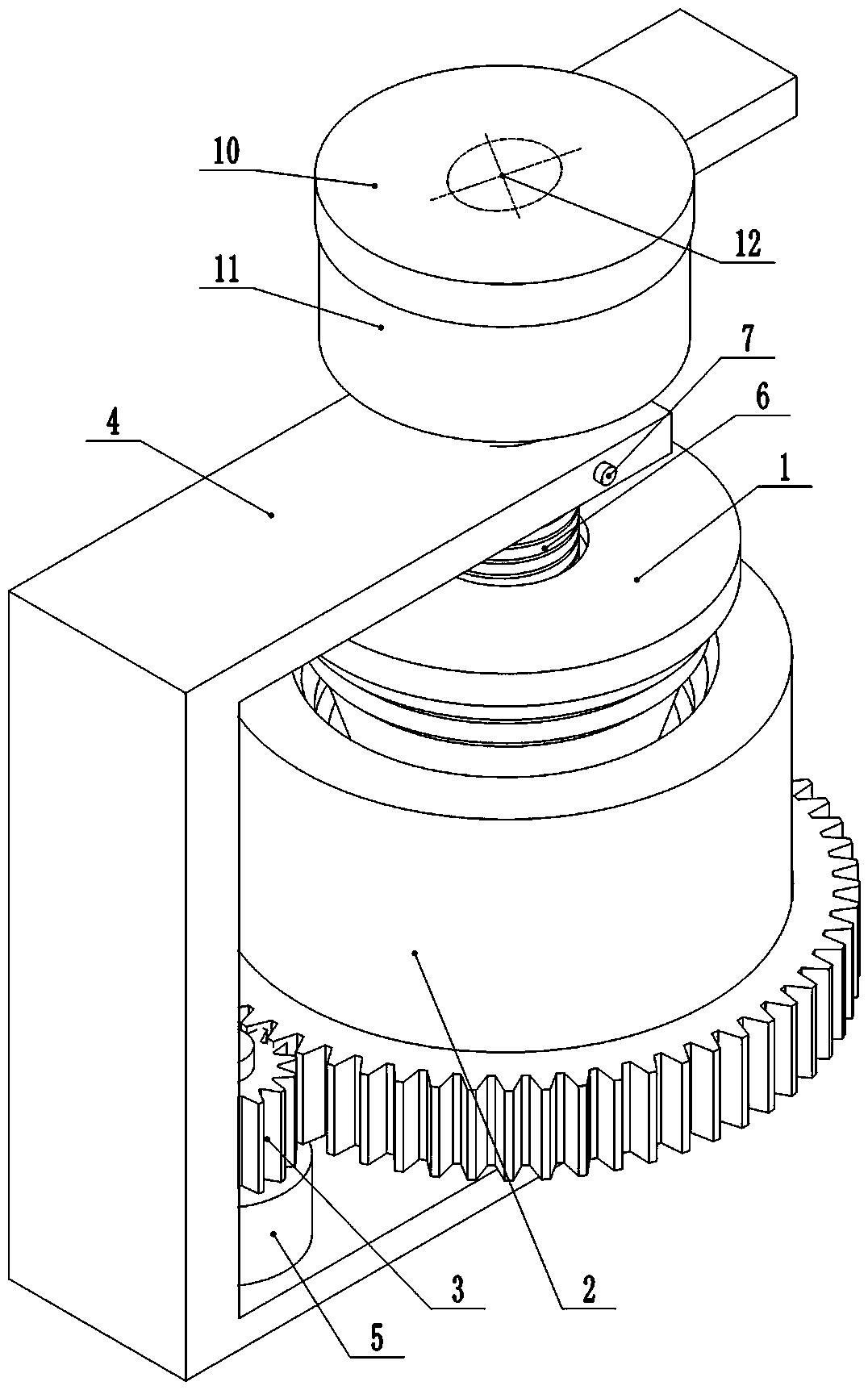

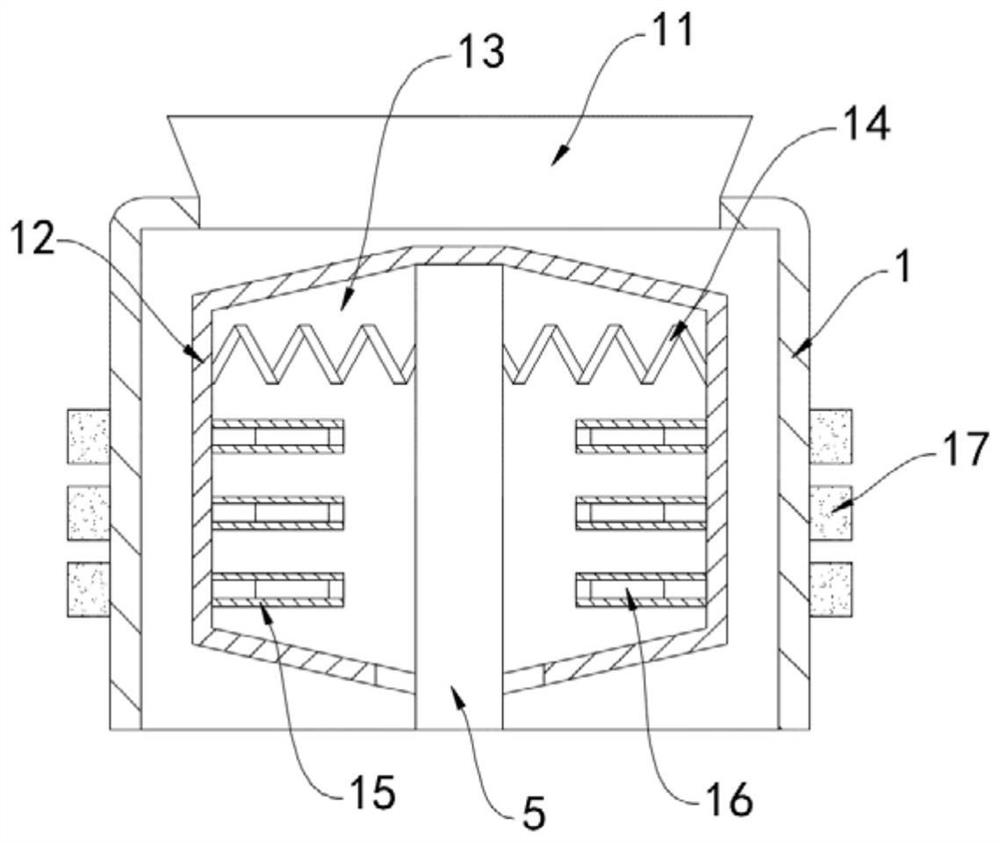

Coaxial interactive crushing device

The invention relates to a coaxial interactive crushing device of a foodstuff processor, mainly comprising a rotating shaft, a movable grinding head, a fixed grinding head, a positioning device and power shafts. The movable grinding head is arranged on the rotating shaft, and is in static connection with the rotating shaft through a mounting hole; the rotating shaft is connected with a motor shaft or other power shaft of the foodstuff processor directly or through a shaft coupling; and the movable grinding head or the fixed grinding head is equipped with a fluid director. The movable grindinghead and the fixed grinding head are arranged on the same rotating shaft, the positions and the axial movements of the movable grinding head and the fixed grinding head on the rotating shaft are limited by the positioning device to keep normal working gap (0mm<L<= 2mm)between the abrasive surfaces of the movable grinding head and the fixed grinding head, thereby avoiding the counterforce(through the fixed grinding head) to be delivered to the other parts of the foodstuff processor, avoiding other parts to be destroyed, debasing the strength requirement to the other parts of the foodstuff processor and reducing the cost. The coaxial interactive crushing device has accuracy positioning between the movable grinding head and the fixed grinding head, and high precision crushing. Moreover, the coaxial interactive crushing device is convenient to clean, and the crushing effect is promoted substantially.

Owner:王晓东

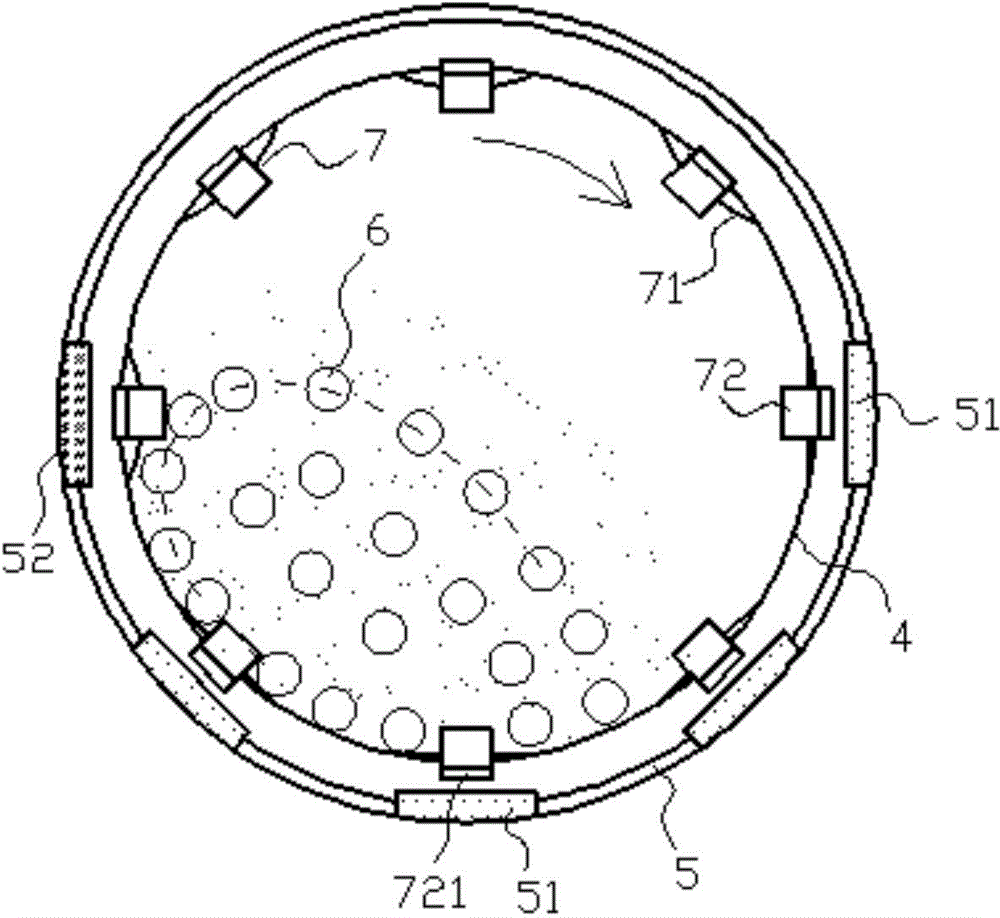

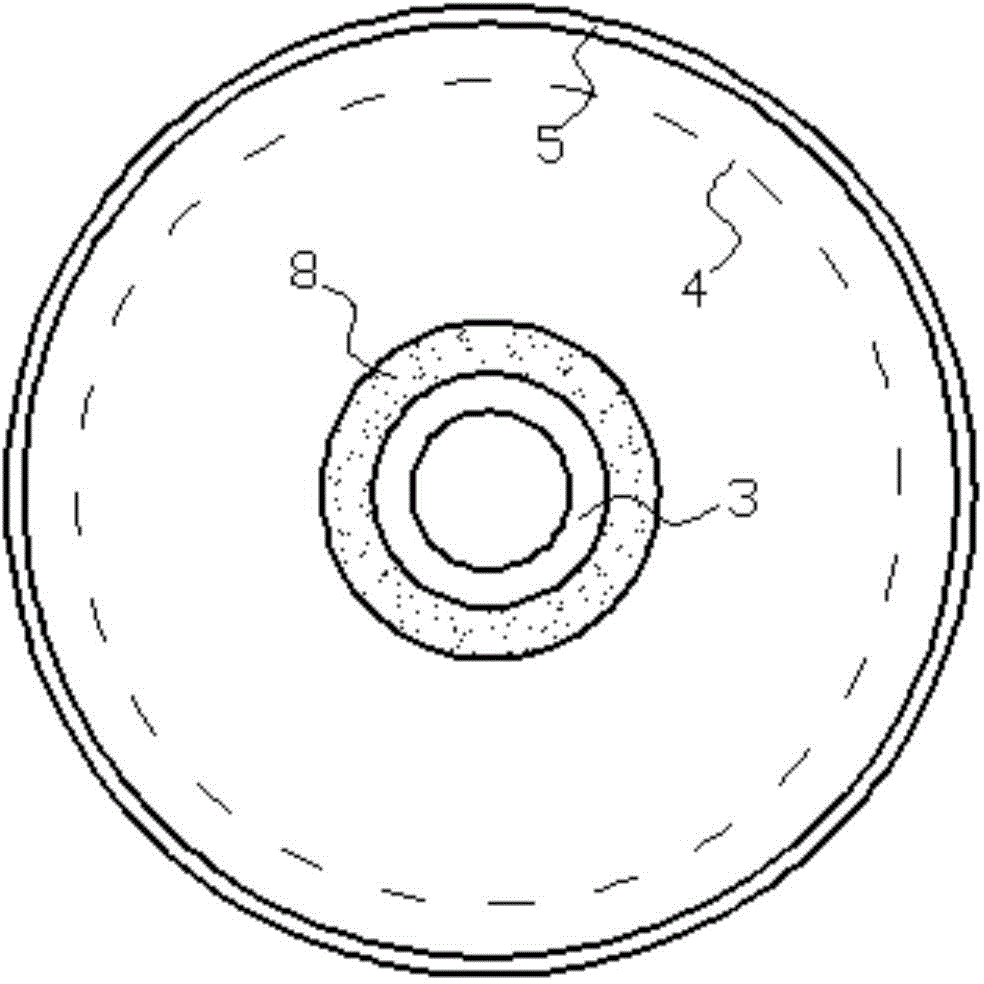

Elastic piece ball mill

The invention relates to an elastic piece ball mill which mainly comprises a rack, a driving motor, a bearing, a tank body, a casing and a grinding medium, wherein the tank body is wrapped with the casing arranged on the rack; the casing is connected to the bearing through a shaft, and can rotate along the bearing; elastic mechanisms are arranged on the inner peripheral wall of the tank body; each elastic mechanism comprises an elastic piece and a lifting rod; strong magnetic pieces are arranged at the bottoms of the lifting rods; strong magnets opposite to the strong magnetic pieces one to one are arranged on the lower half cylindrical surface of the inner wall of the casing; the magnetism of each strong magnet forms homopolar repulsion or heteropolar attraction with that of the strong magnetic piece opposite to the strong magnet. According to the ball mill, the grinding medium can be actively ejected to increase impact force after reaching a certain height, and in addition, materials can be completely dispersed to be ground more completely; the materials can be ground at higher speed.

Owner:SUBEI COUNTY BOLUN MINING DEV CO LTD

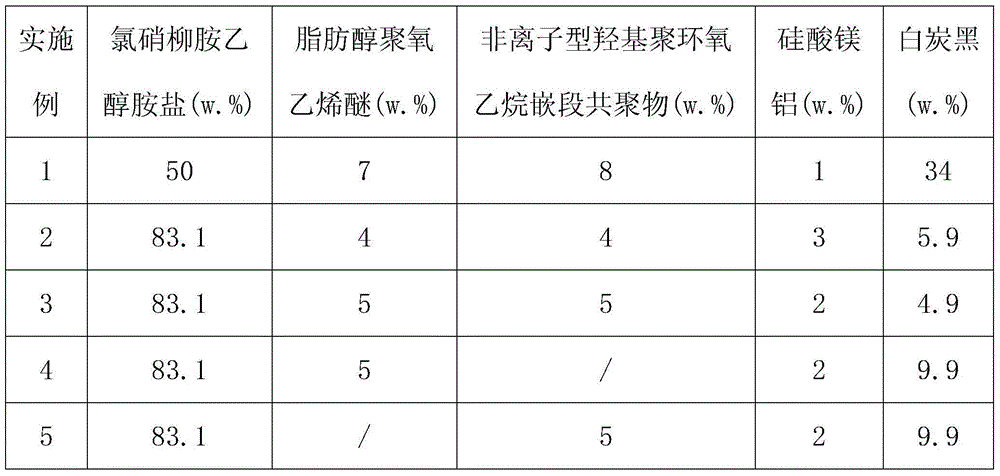

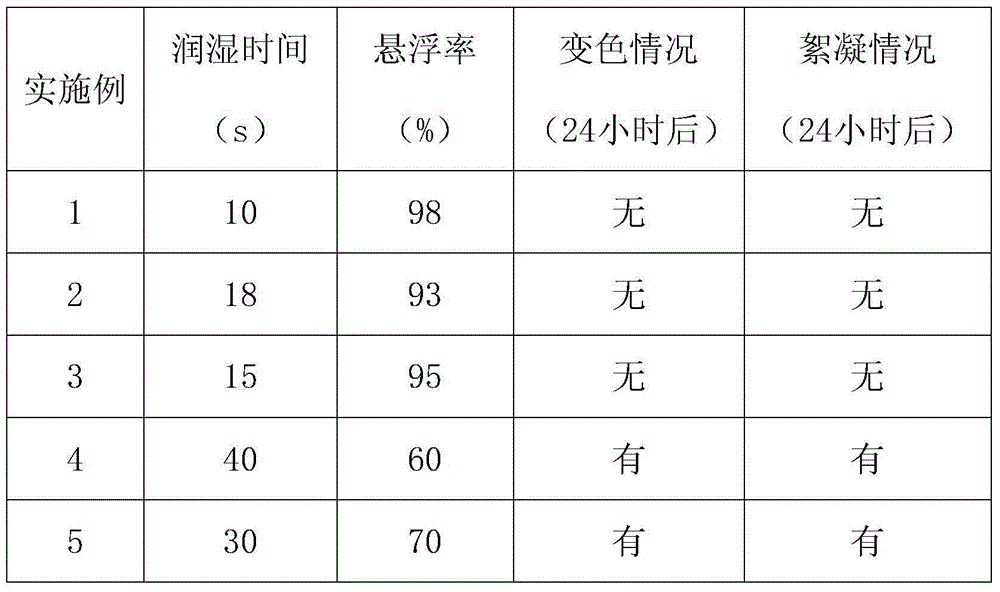

Niclosamide ethanolamine salt wettable powder as well as preparation method and application thereof

ActiveCN104430338AEvenly dispersedHigh suspension rateBiocideMolluscicidesPolyethylene oxideNon ionic

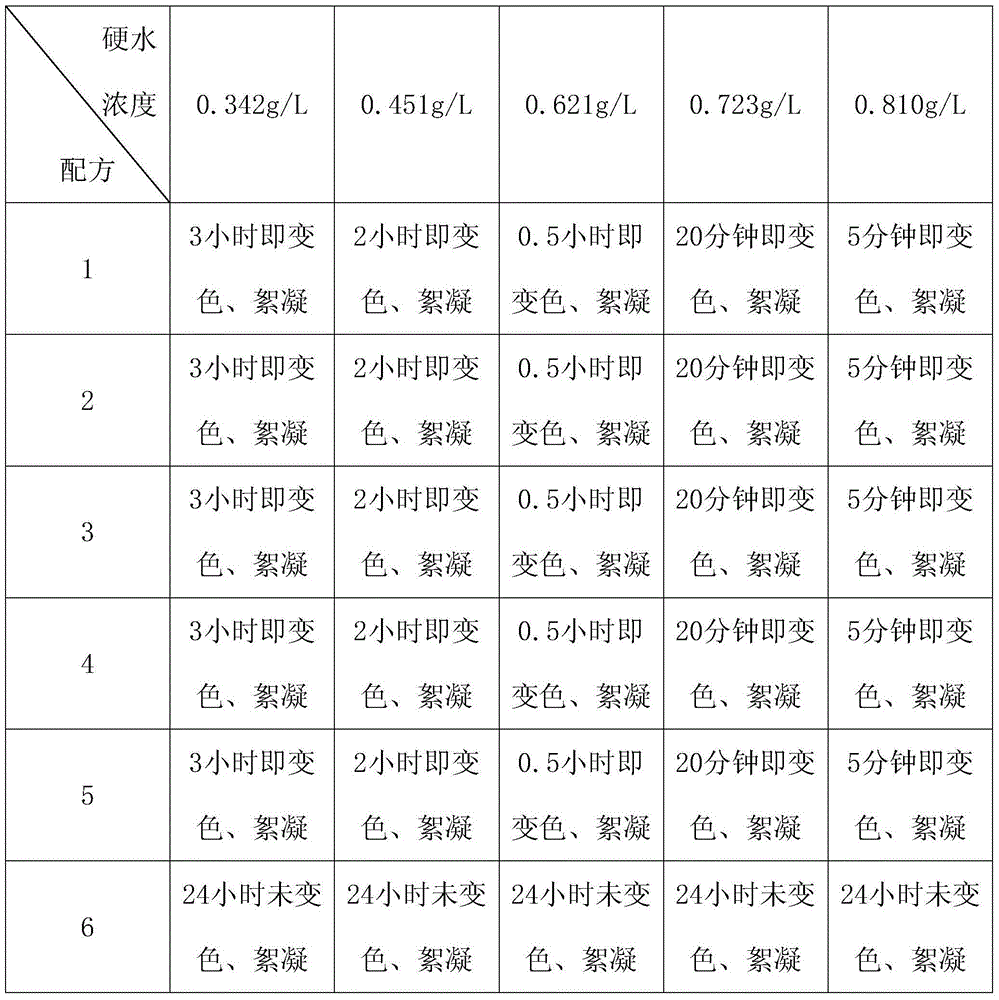

The invention provides niclosamide ethanolamine salt wettable powder as well as a preparation method and application thereof. The wettable powder is prepared from niclosamide ethanolamine salt, a dispersing and wetting agent, a suspension aid and an anti-caking agent, wherein the dispersing and wetting agent is a compound mixture of fatty alcohol-polyoxyethylene ether and a non-ionic hydroxyl polyethylene oxide block copolymer, and the use amount of the dispersing and wetting agent accounts for 8-15% of the total weight of the raw materials. By using the compound mixture of the fatty alcohol-polyoxyethylene ether and the non-ionic hydroxyl polyethylene oxide block copolymer as the dispersing and wetting agent, a unique steric hindrance effect is provided in the system, so that the stability of the system is effectively kept and the problems of slow wetting, color change and flocculation are solved; the wettable powder is short in wetting time, uniform in dispersion effect, relatively small in particle size distribution, capable of rapidly reaching a target site, free from flocculation for a long time and free from particle aggregation, so that the wettable powder has long-lasting efficacy and applicable to hard water. The wettable powder disclosed by the invention is applicable to the preparation of molluscicidal products and is good in molluscicidal effect.

Owner:JIANGSU ESSENCE AGROCHEM

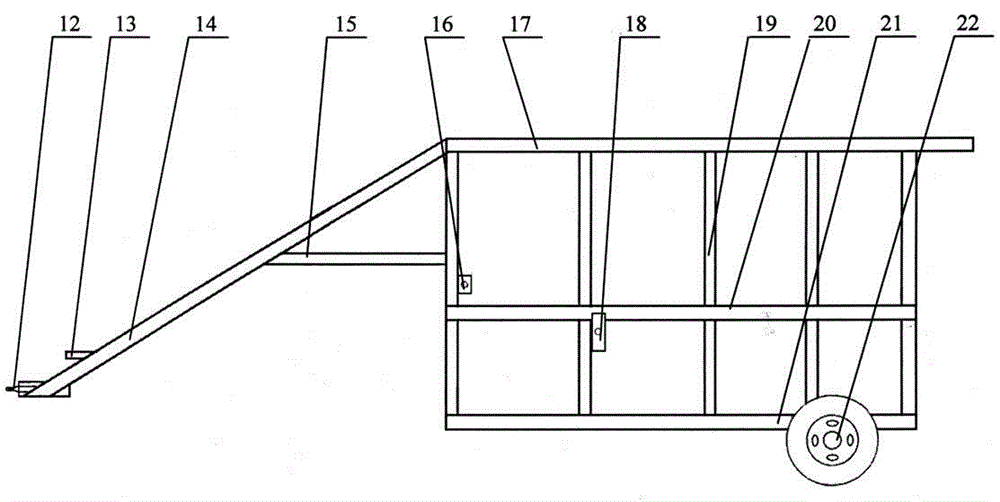

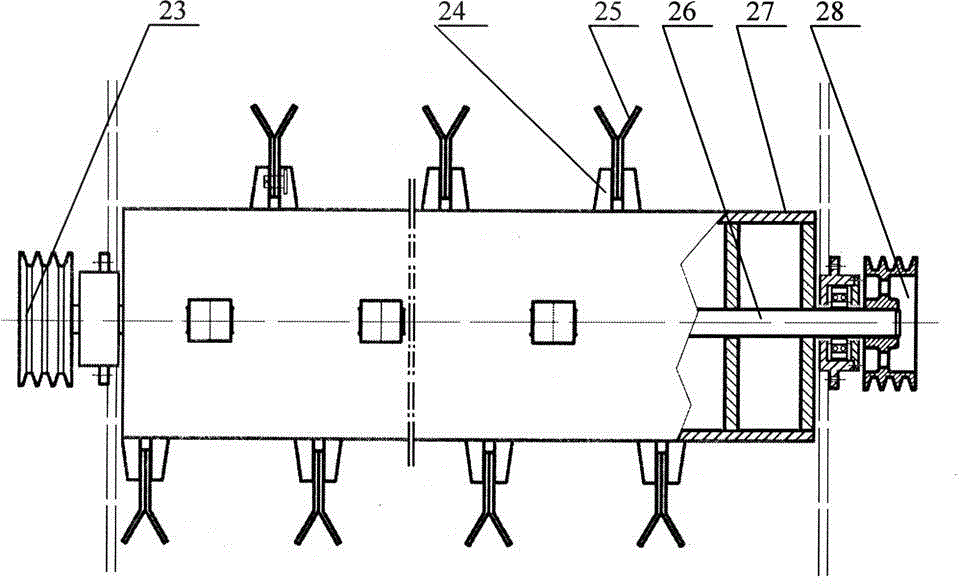

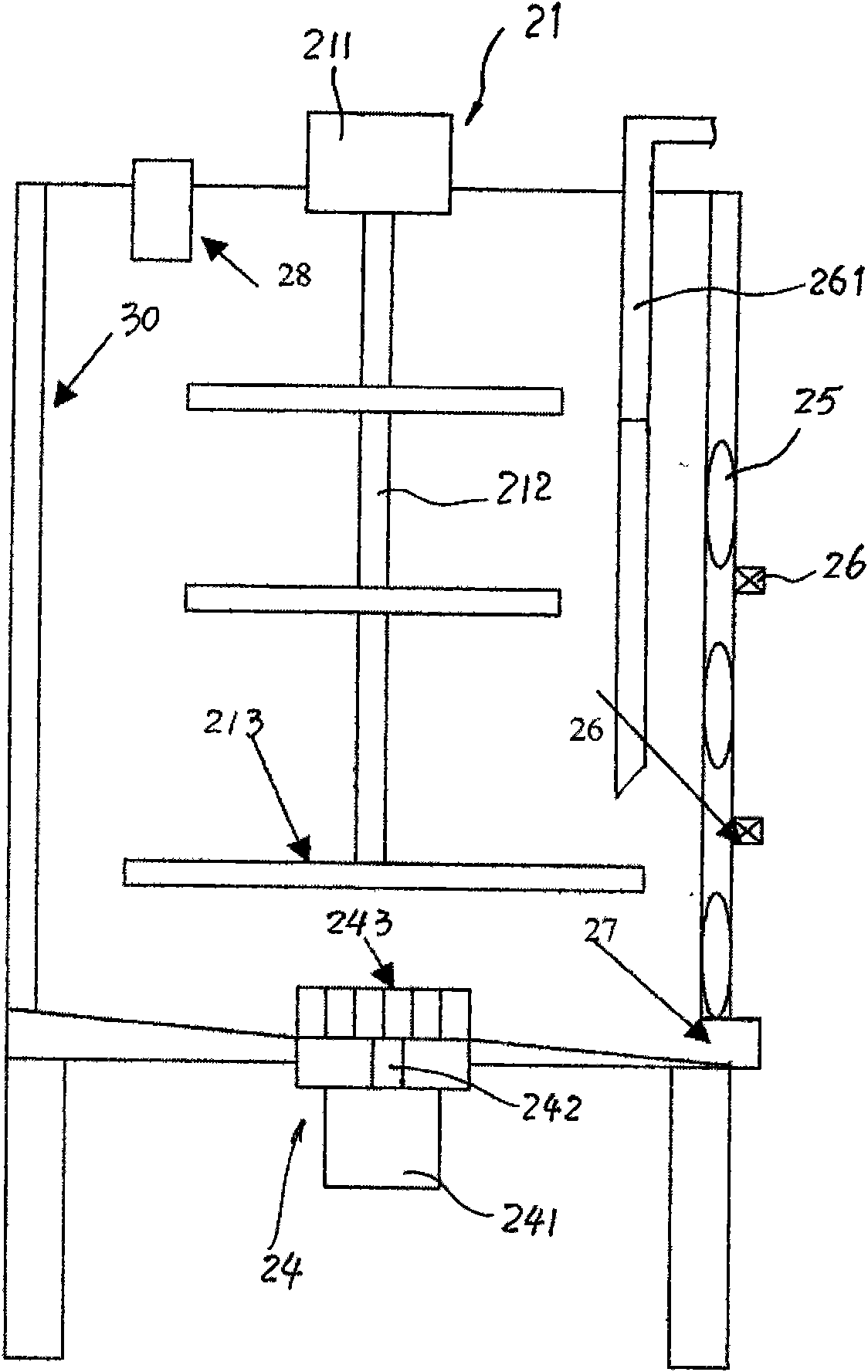

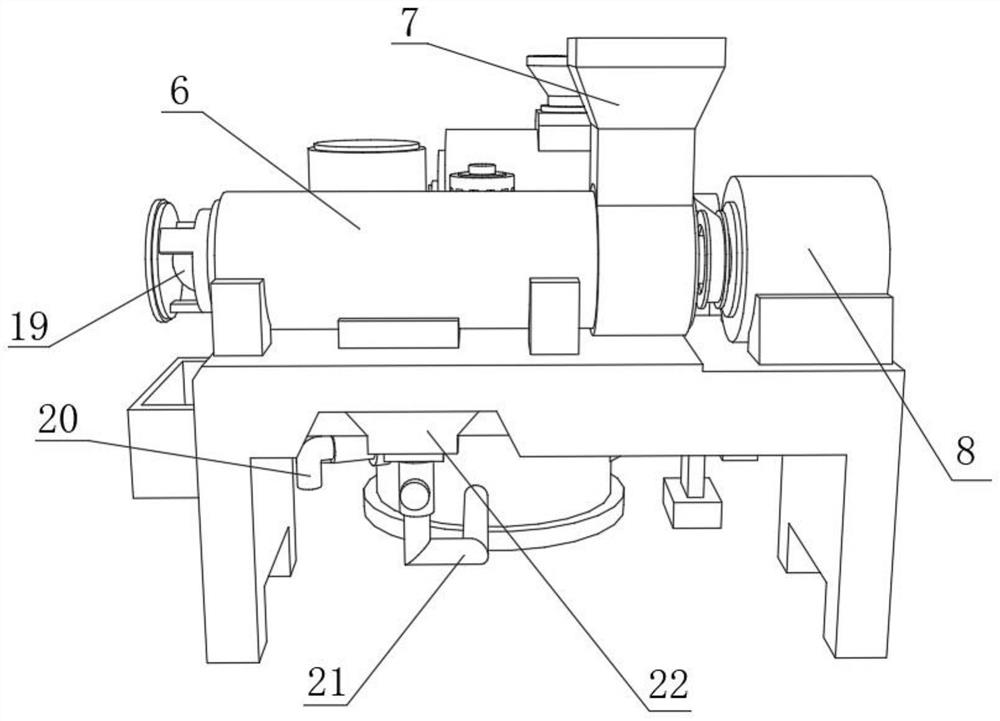

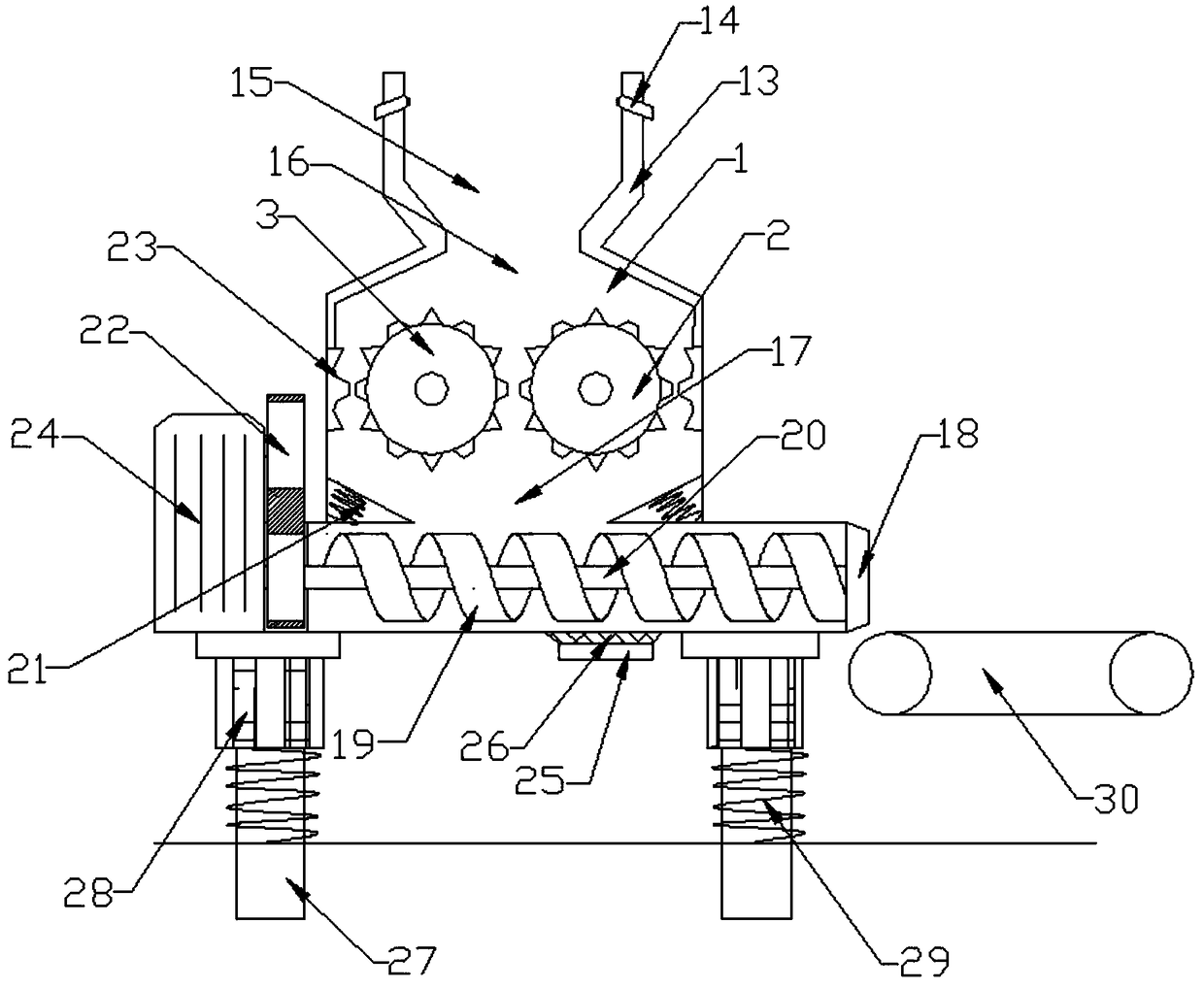

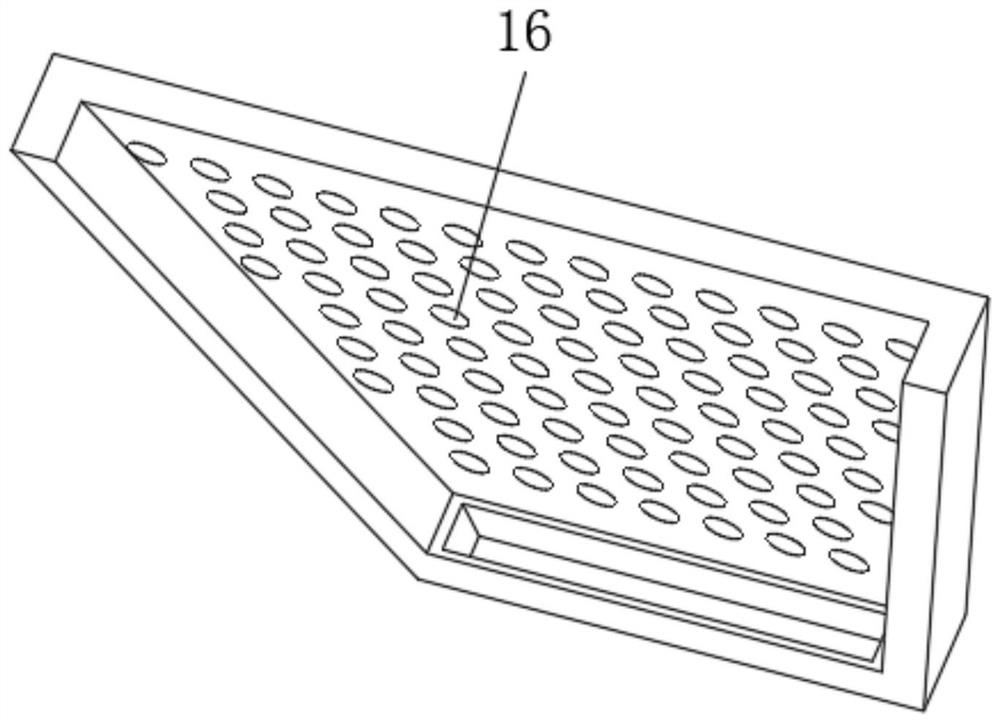

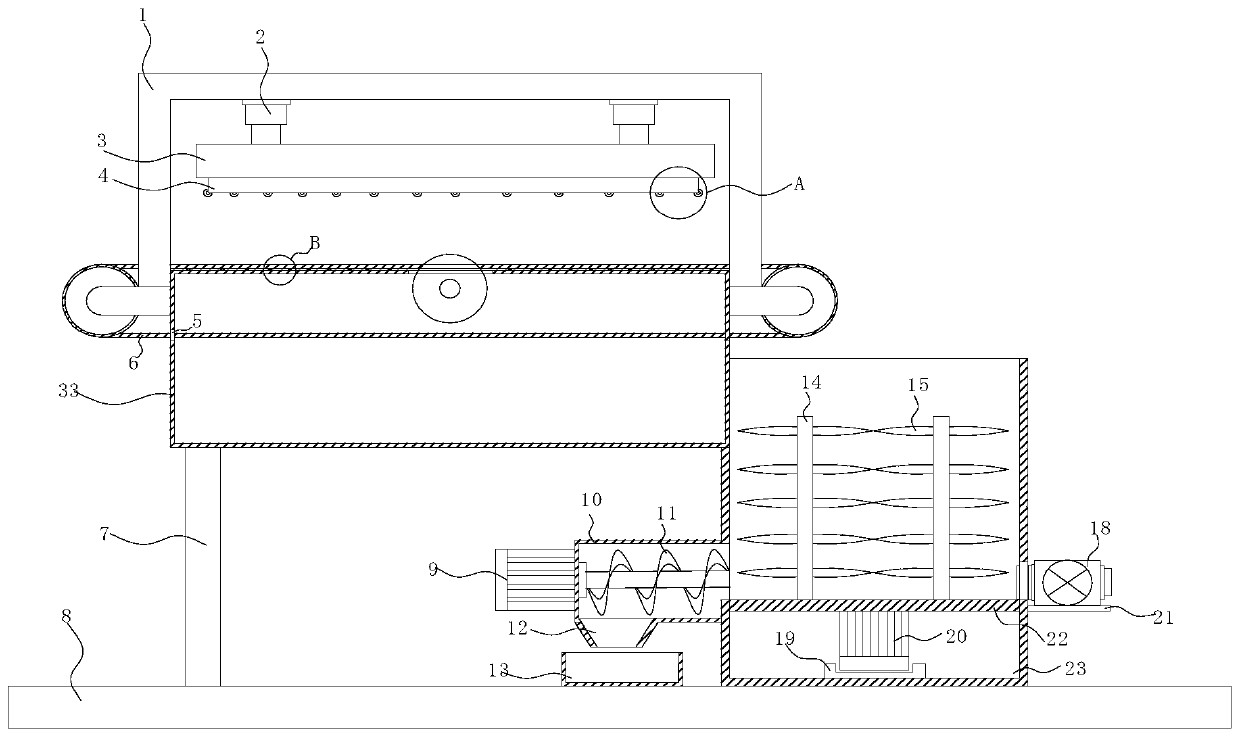

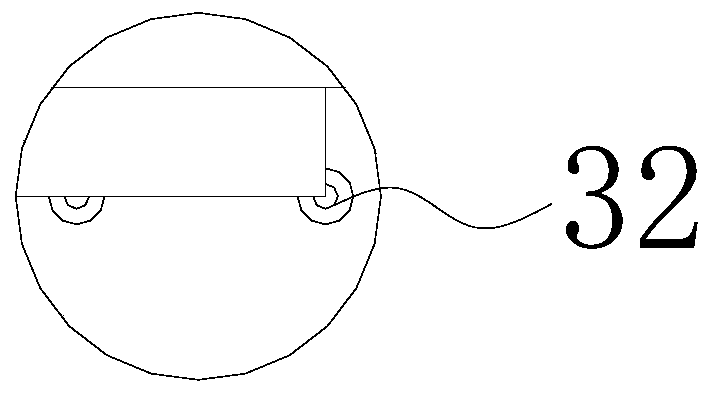

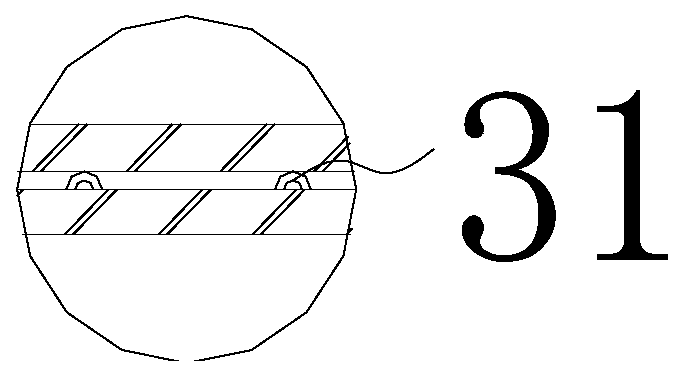

Trail-type straw collecting, smashing and bundling machine

ActiveCN104686098AIncrease productivityExpand the scope of collectionLoadersBalingEngineeringSorghum

The invention discloses a trail-type straw collecting, smashing and bundling machine. The machine is composed of a complete machine frame, a collecting, smashing and conveying device, a smashed straw filling device, a straw compacting and bundling device and a power transmission system. The machine well overcomes the technical problems like pre-hydraulic lifting of the collecting, smashing and conveying device, connecting and conveying of vertical and horizontal auger rollers, intermittent and fast and smooth filler dragging, piston-type strong compressing of straw, artificial tying and bundling of stringing driven by hydraulic pressure, adjustment of bundling bale density by clamping a side wall, and removing and top squeezing of straw bundling bales by adopting a plurality of innovative technologies in the aspects of layout and arrangement of overall structure, integration and conformity of functional parts for operation, matching and selection of transmission power, etc. According to the invention, the machine has the outstanding features of advanced technology, reasonable structure, high production efficiency, good operation quality, wide application range, etc.; and the machine is suitable for combined operation of collecting, picking, smashing, conveying, compacting and bundling of straws of crops like standing or spread-or-strip windrowing corns, wheat, beans, sorghum, cotton and oilseed rapes.

Owner:四平市顺邦农机制造有限公司

Stone crusher

InactiveCN111013720ASpeed up crushingAvoid cloggingUsing liquid separation agentDirt cleaningCrushed stoneEngineering

The invention relates to the technical field of stone treatment equipment, in particular to a stone crusher which comprises a shell, a crushing roller, a fixing rod, extrusion plates, an upper baffle,a lower baffle and a dust collection box. The stone crusher can cut and crush stone large in size, crushing of edge materials is improved through auxiliary crushing teeth on the inner wall, and the crushing efficiency is improved. A discharge elastic plate prevents a discharging port from being blocked, a supporting column and a damper improve the damping effect of the device, and therefore the high using effect is achieved; in the crushing process, dust can be effectively prevented from drifting out from the top end of the position between the extrusion plates, then the dust can be preventedfrom drifting out, meanwhile, the dust enters the dust collection box through a communication pipe in the extrusion crushing process, and therefore the dust can be effectively collected and preventedfrom drifting around, the body health of people is guaranteed, and high practicability is achieved.

Owner:福建省磊鑫环保科技有限公司

Purification method for quartz sand

InactiveCN106082238AReduce devitrificationImprove thermal propertiesSilicaPurification methodsQuenching

The invention discloses a purification method for quartz sand. The purification method comprises the following steps: crushing raw quartz ore, adding water, carrying out blending, then adding a grinding aid and successively carrying out ball milling, magnetic separation and drying so as to obtain a material A; subjecting the material A to heating, heat preservation, chlorination water and quenching and then carrying out filtering and drying so as to obtain a material B; and adding the material B into a mixed acid solution, carrying out ultrasonic treatment at 35 to 65 DEG C for 3 to 8 h and then successively carrying out filtering, washing until a pH value is 7, and drying so as to obtain purified quartz sand. The purification method for quartz sand is simple in steps, and the obtained quartz sand is high in purity and good in stability and can be applied to a plurality of fields.

Owner:安徽晶晶石英科技有限公司

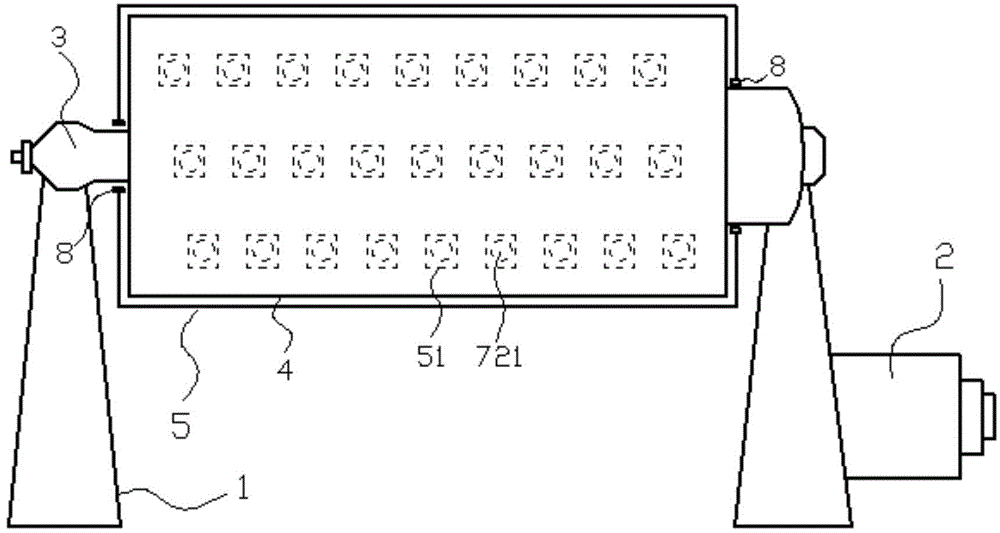

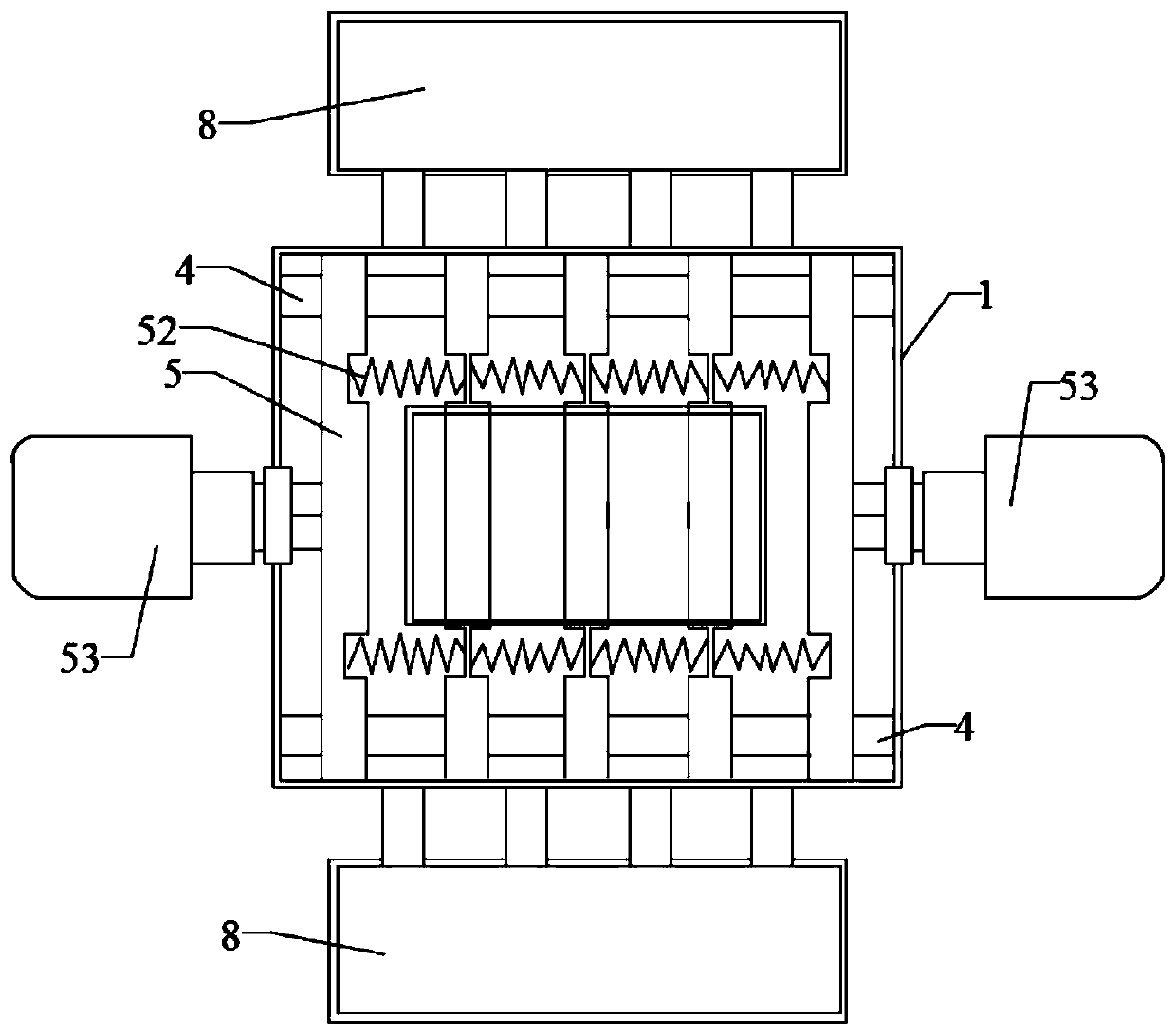

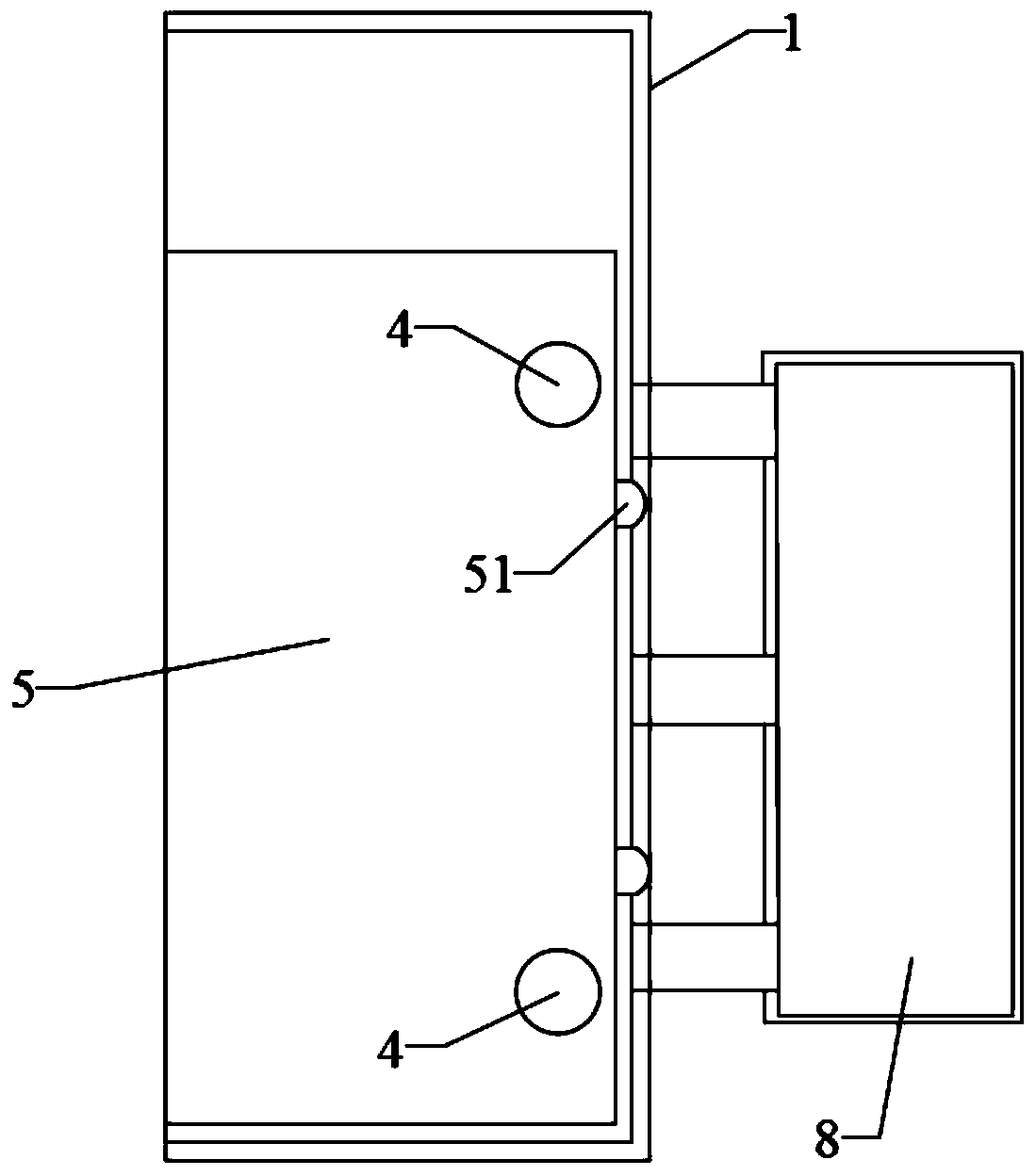

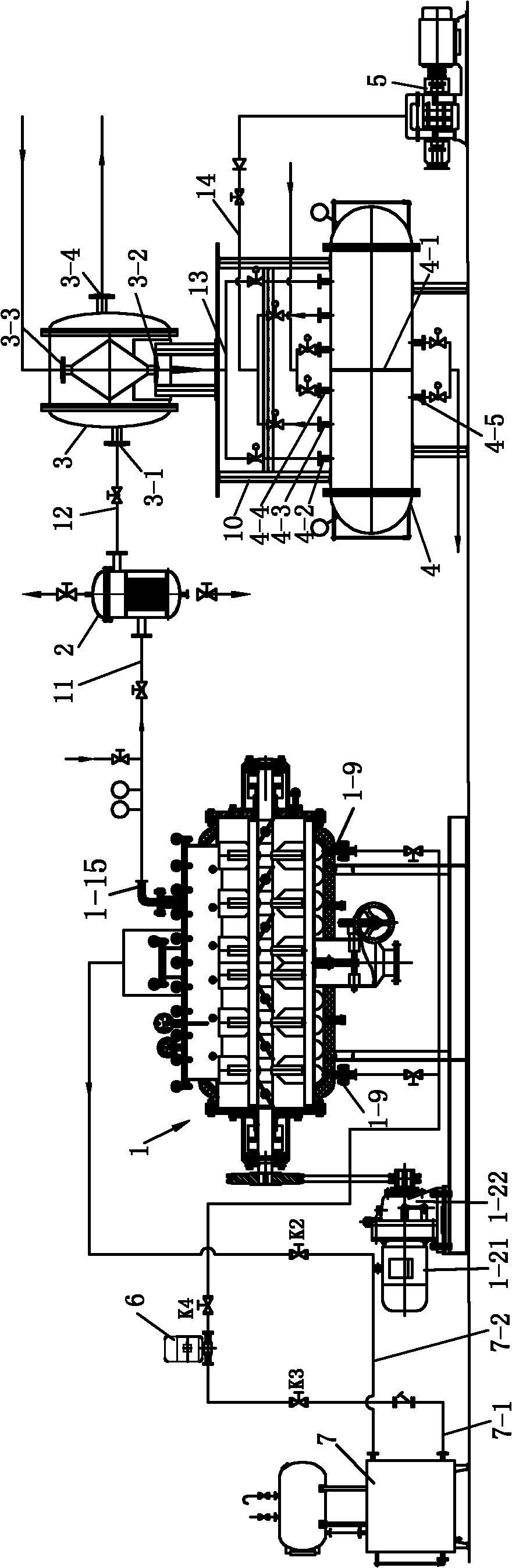

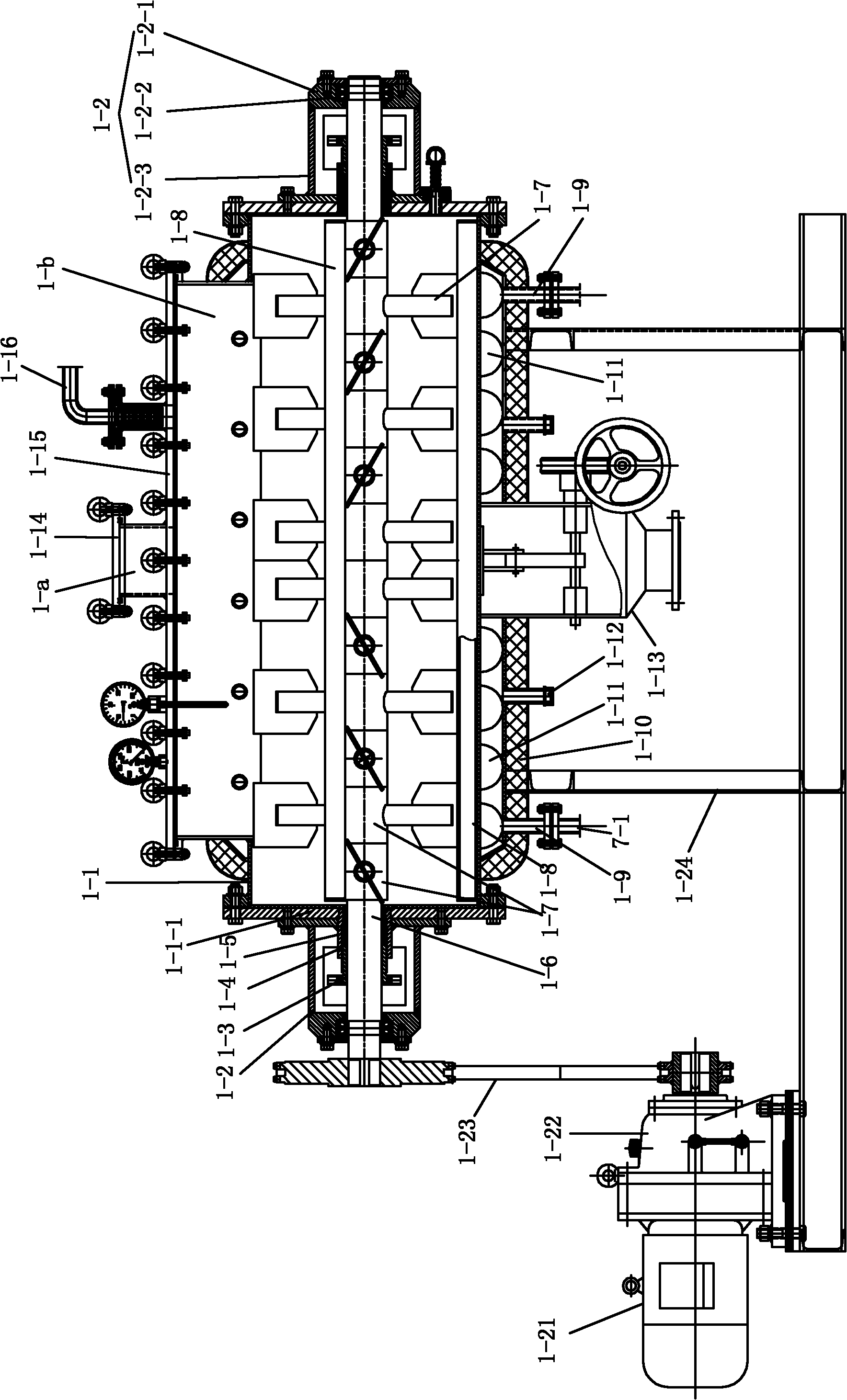

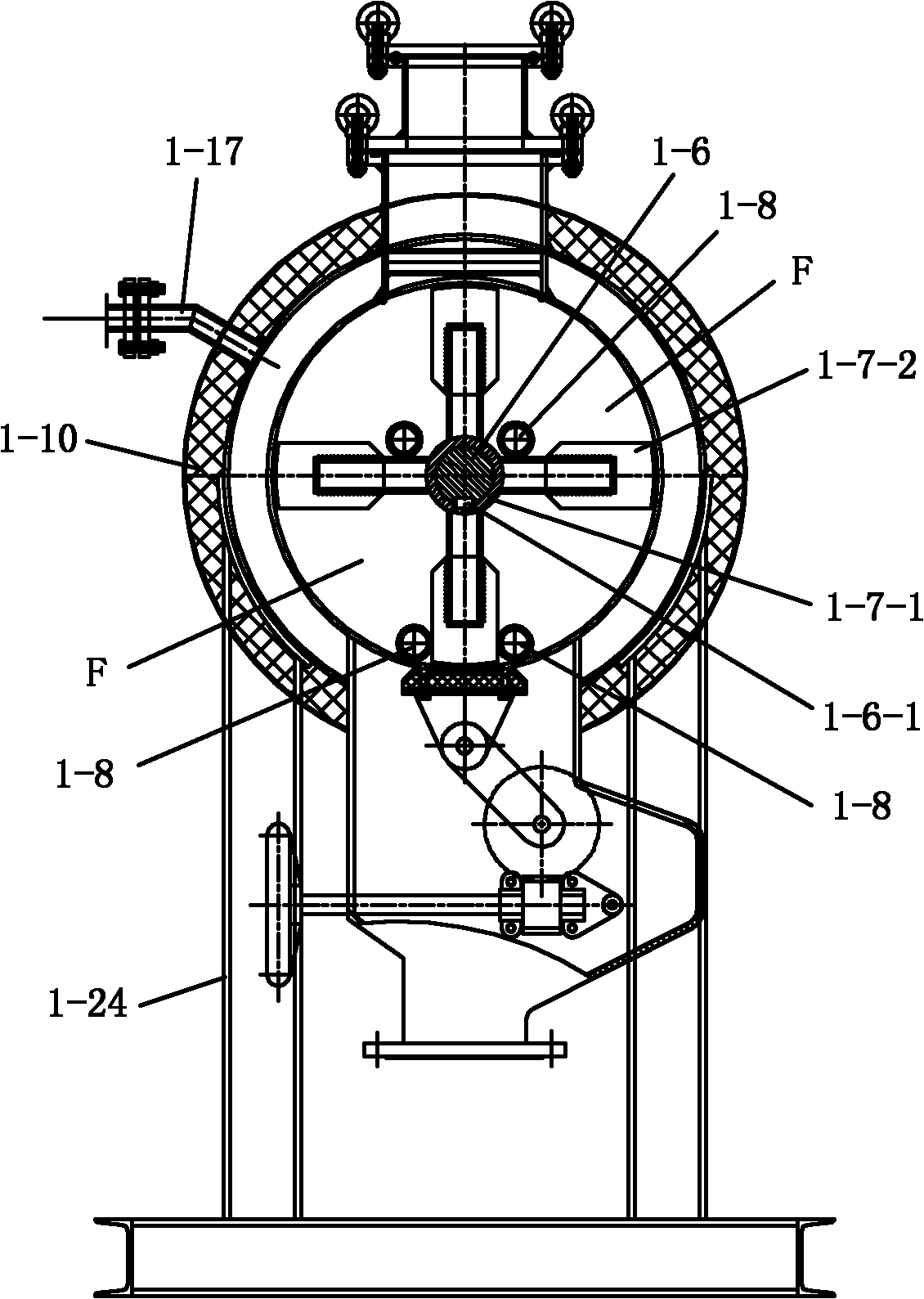

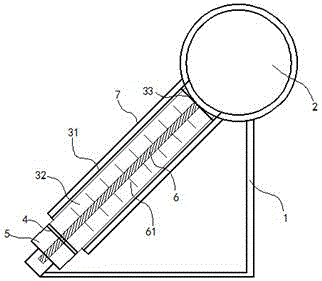

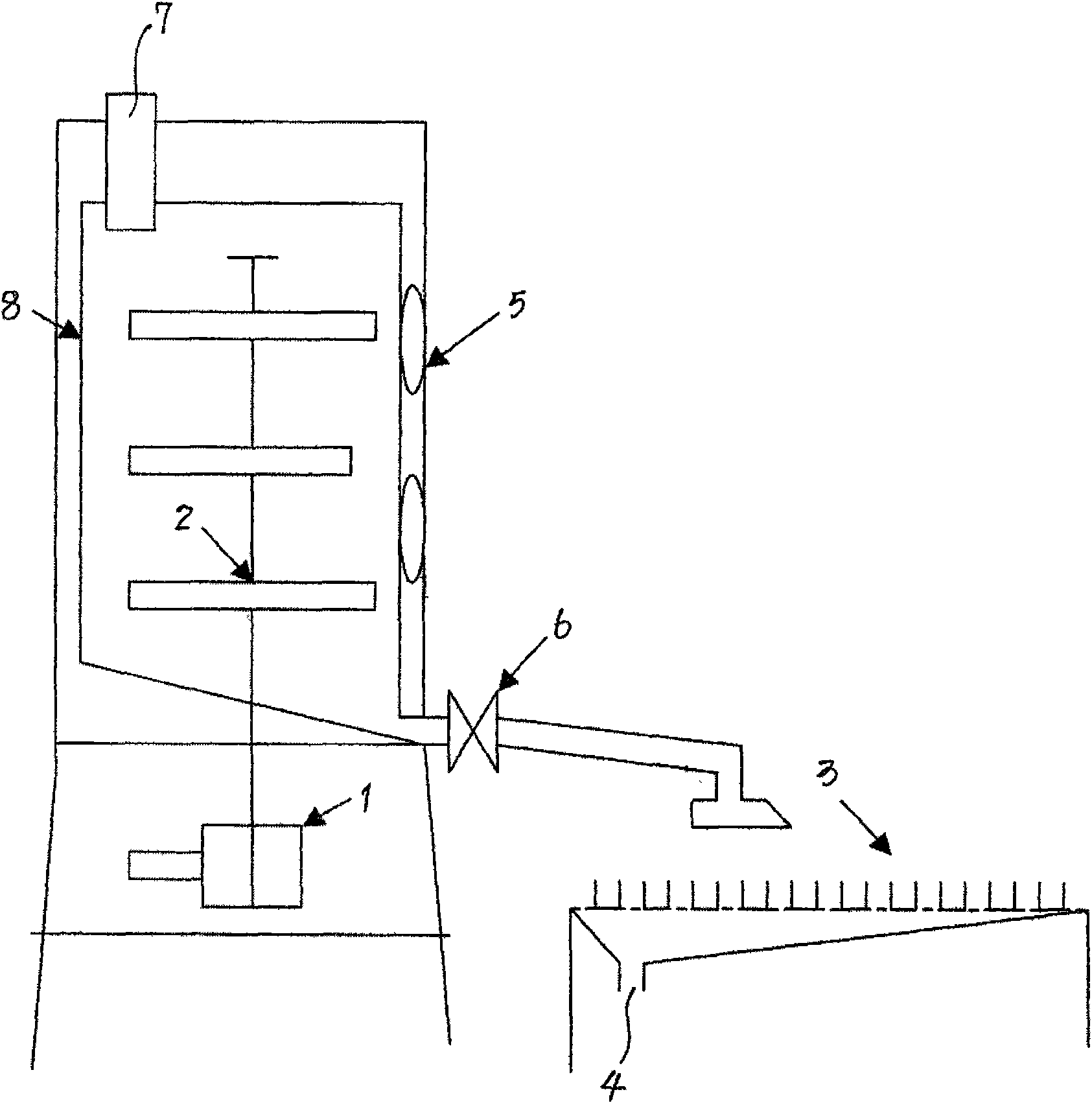

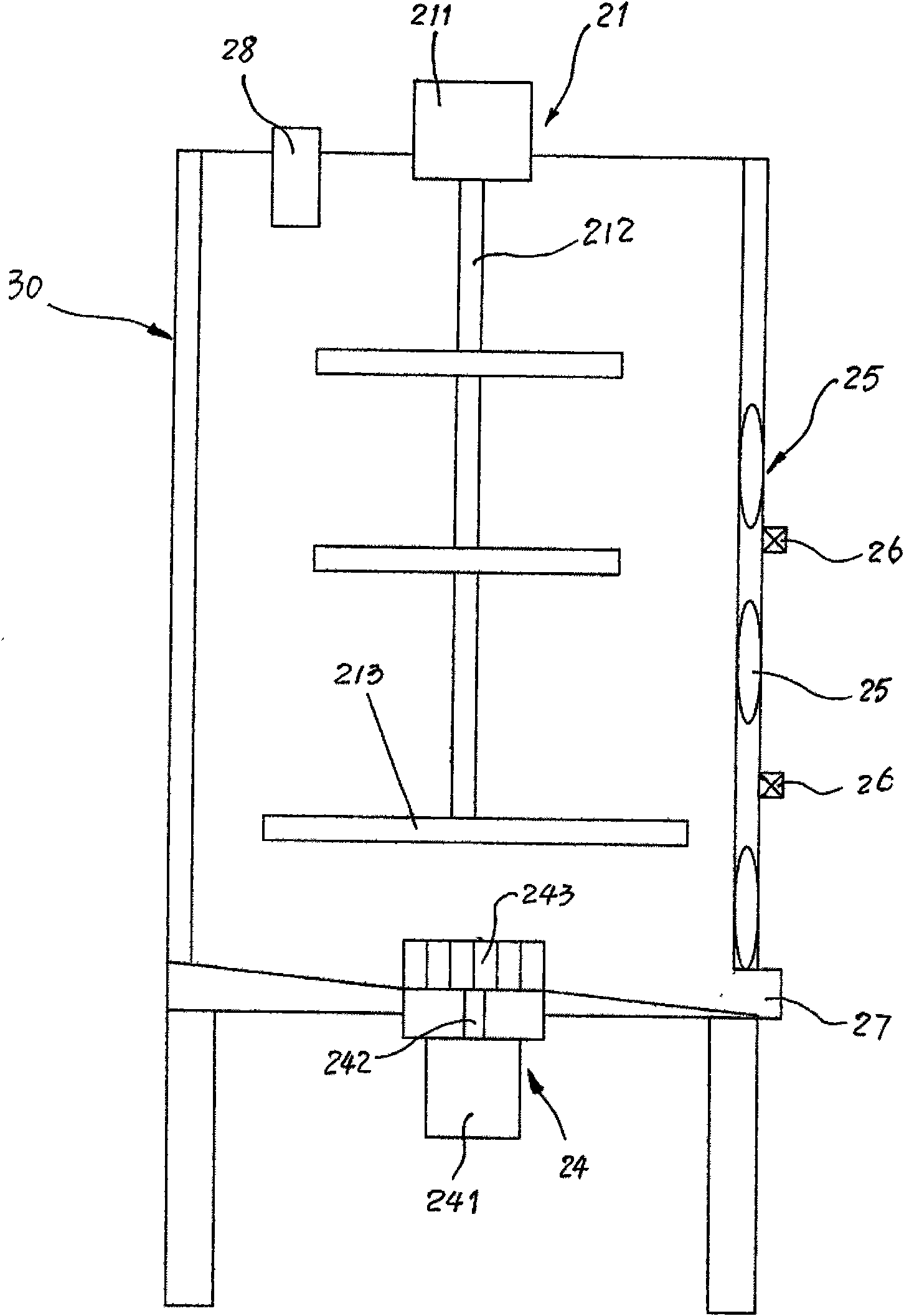

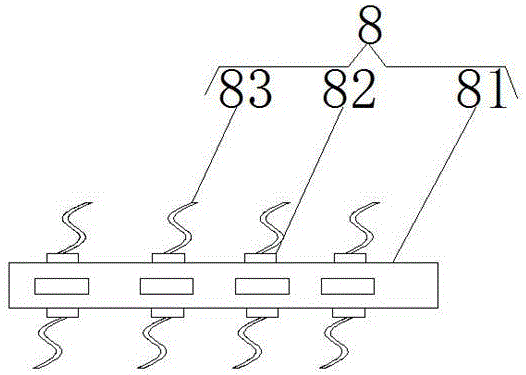

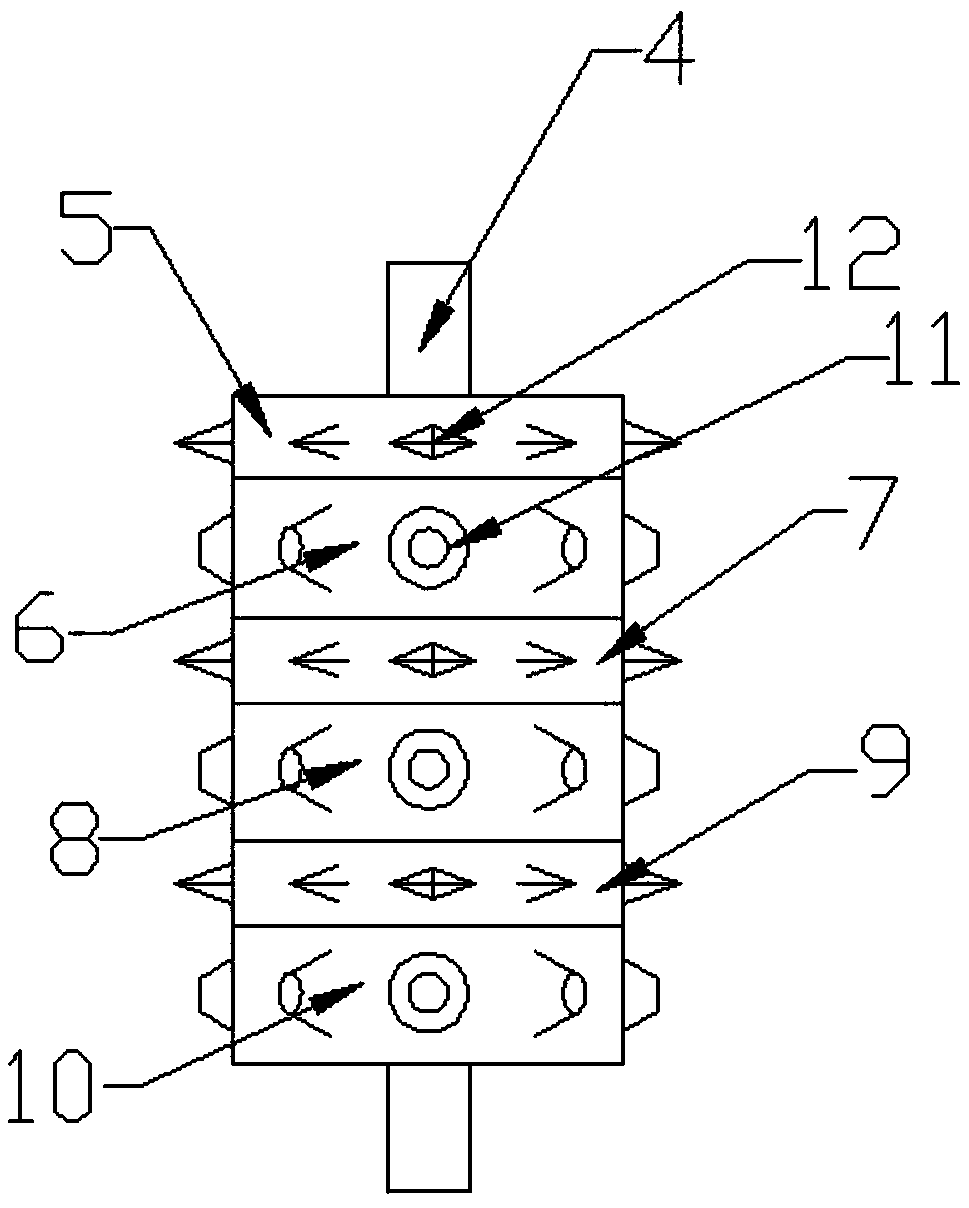

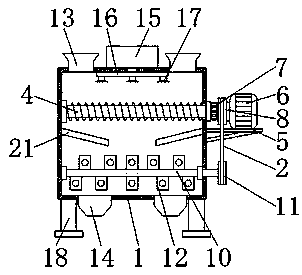

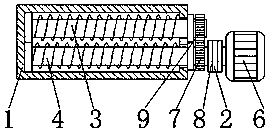

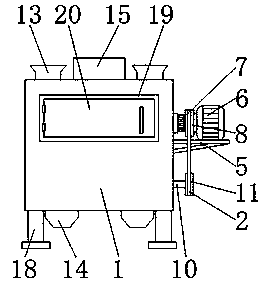

Rake type vacuum drying system

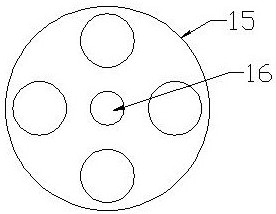

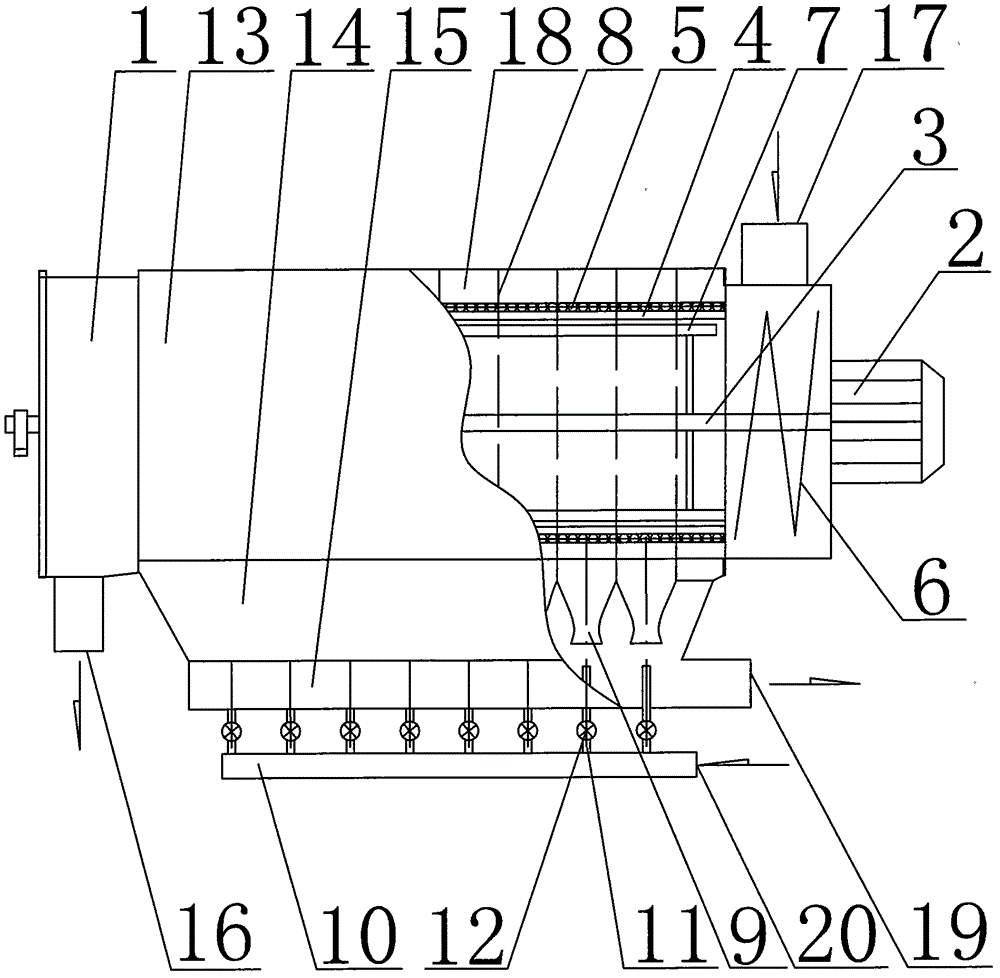

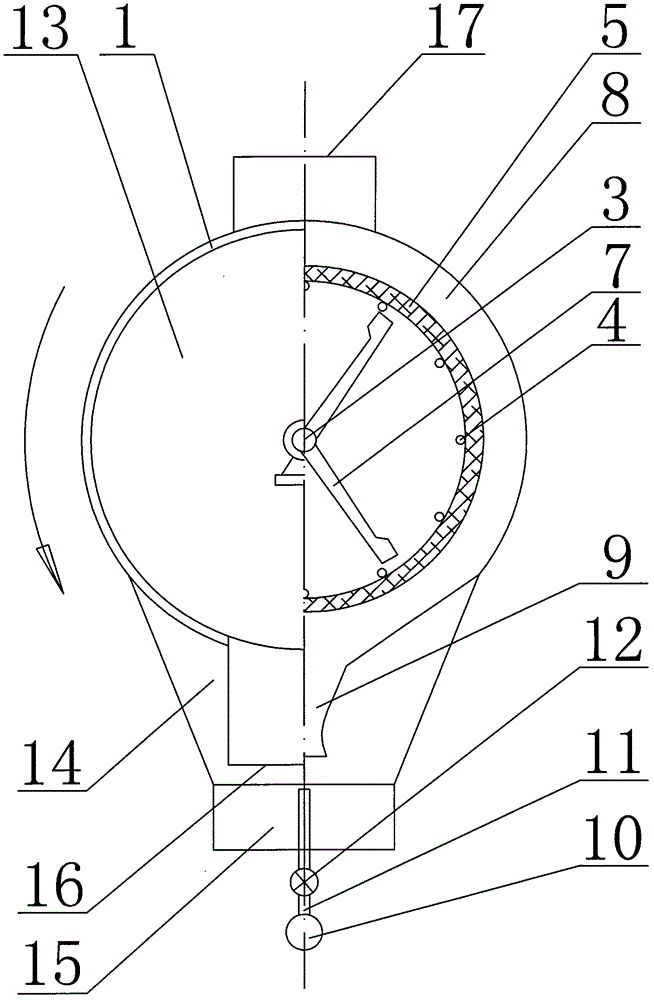

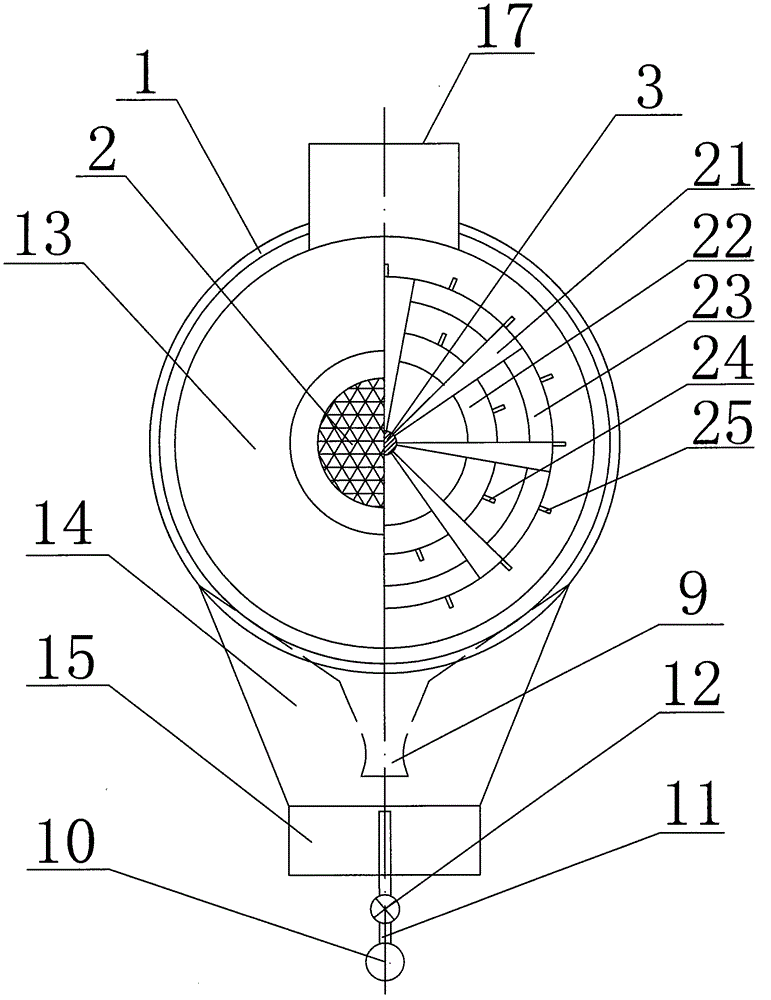

ActiveCN102183126ASpeed up crushingLarge specific surface areaDrying machines with non-progressive movementsDrying solid materialsVapor–liquid separatorLithium iron phosphate

The invention provides a rake type vacuum drying system, which comprises a rake type vacuum drying host machine, a bag type filter, a condenser, a gas-liquid separator, a vacuum pump, an oil pump and a hot oil tank, wherein a main shaft of the rake type vacuum drying host machine is a solid main shaft; a plurality of rake tooth components are arranged on the main shaft; each rake tooth component comprises a sleeve shaft and four solid rake teeth uniformly distributed on the sleeve shaft in a fixed manner, and is connected on the main shaft through a sleeve shaft key; the rake teeth of the respective rake tooth components face towards the same direction, so that four passageways are formed in a tank body; and striking rods are respectively arranged in respective passageways or in spaced passageways. In the invention, materials inside the tank body of the drying host machine are struck continuously by using the striking rods, so that the crushing of the materials is accelerated, the materials can obtain larger specific surface areas, the drying process is accelerated, and finished products have uniform fineness and low water content; thus, the rake type vacuum drying system is suitable for drying lithium iron phosphate materials, and the product quality and drying efficiency are improved; moreover, the system is used for recovering solvents through the condenser and the gas-liquid separator, and is beneficial to reduction of the cost.

Owner:JIANGSU XIANFENG DRYING ENG

Efficient waste glass breaking treatment device

InactiveCN108525741ASpeed up crushingImprove crushing efficiencyGrain treatmentsPulp and paper industry

Owner:赵晓晨

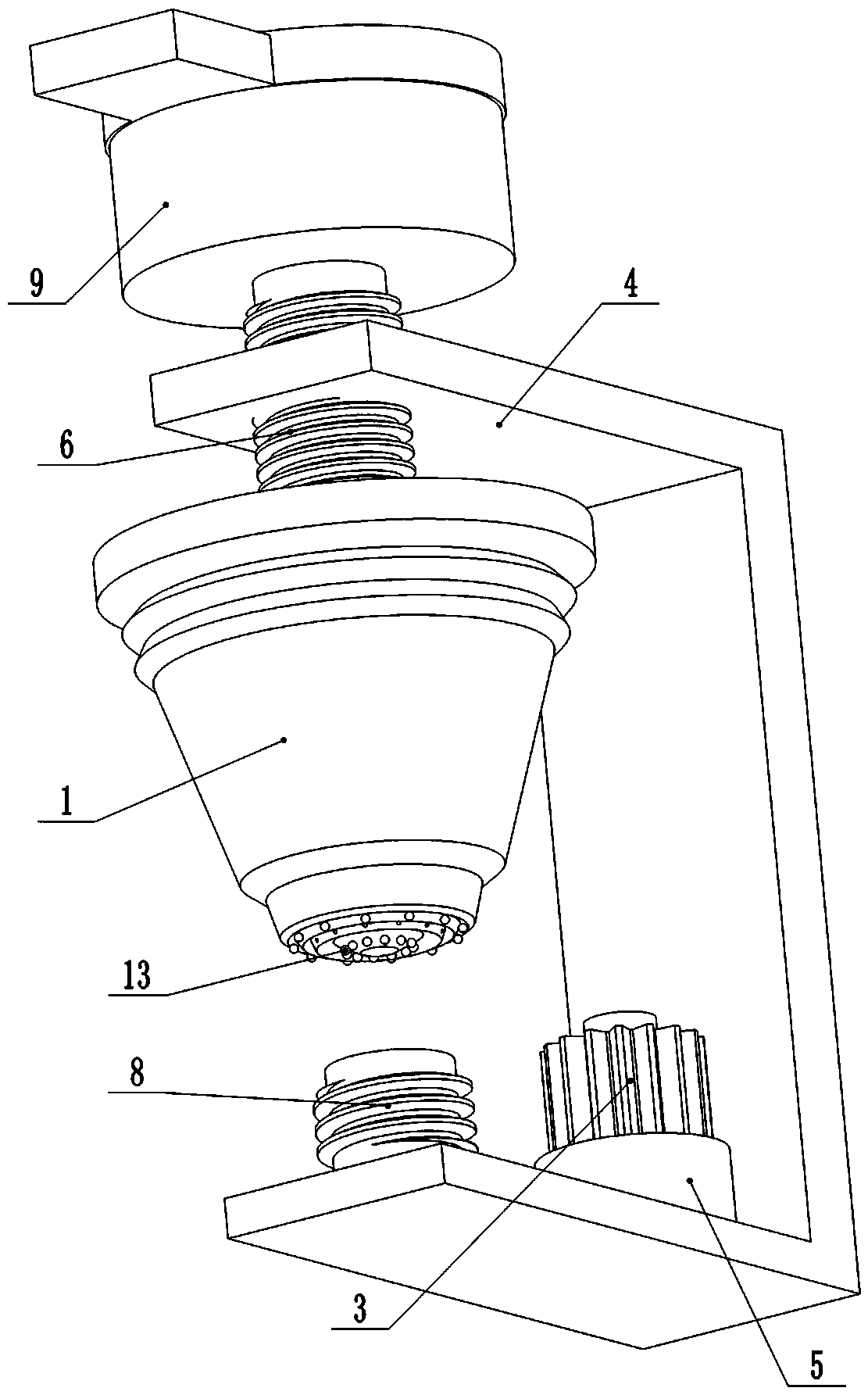

Portable automatic oral medicine grinding machine

PendingCN110124827AIncrease frictionMilling speed is fastOral administration deviceGrain treatmentsOral medicineSpherical shaped

The invention relates to a portable automatic oral medicine grinding machine comprising an upper mold, a lower mold, a transmission structure and a fixing base. The lower surface of the upper mold isin a convex spherical shape, a cone shape or a column shape, the lower surface of the upper mold is matched with the concave upper plane of the lower mold, the upper mold or the lower mold is fixed tothe output end of the transmission structure and can be rotated or moved along with the output end of the transmission structure, that is, the lower mold or the upper mold relatively fixed on the corresponding end of the fixing base is rotated or moved so that tablets located between the upper mold and the lower mold can be extruded and rubbed one time or many times to form granular powder, the transmission structure is driven by a gear motor to start or stop a power supply to control operation of the grinding machine, and the fixing base can limit the positions of the upper mold, the lower mold and the transmission structure. By means of the design, the portable automatic oral medicine grinding machine has the beneficial effect that the upper mold can be moved or rotated relative to thelower mold to grind the tablets between the upper mold and the lower mold, manpower is not needed for grinding the tablets into the powder, the motor is directly used for driving for grinding the tablets, and time and labor are saved; and the motor can repeatedly rotate positively and negatively to achieve repeated grinding, the grinding effect is better, and the tablets can be ground to be finerand more even.

Owner:THE FIRST AFFILIATED HOSPITAL OF WENZHOU MEDICAL UNIV

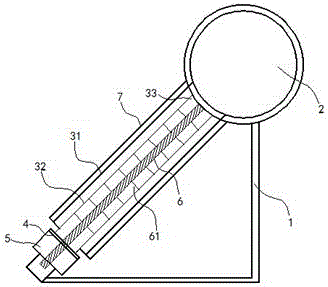

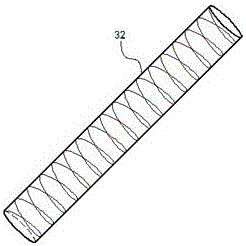

Water heater capable of being descaled

The invention relates to a water heater capable of being descaled. The water heater capable of being descaled comprises a support, a water storage tank, transparent pipes and heat collection pipes. Each heat collection pipe is divided into an inner layer and an outer layer. Each outer layer is a heat absorbing pipe made from a hard material. Each inner layer is a spiral pipe formed by spiraling and curling a long-strip elastic piece. The heat absorbing pipes extend into the water storage tank. The upper end of each spiral pipe is fixed to the water storage tank, and the lower end of each spiral pipe is installed on a rotary plate. Through holes are formed in the rotary plates. A scale accumulation cavity is further fixed to the lower portion of each rotary plate. A smashing rod is further arranged on the axis of each heat collection pipe. One end of each smashing rod is installed on the water storage tank, and the other end of each smashing rod is installed on the support. Smashing pins extending in the radial direction of the smashing rod are further distributed on the periphery of each smashing rod. The length of the smashing pins is smaller than the radius of the corresponding heat collection pipe. The water heater capable of being descaled is ingenious in structure and capable of being descaled completely and efficiently, and meanwhile water pipe blockage and human body harms are not caused.

Owner:佛山市史麦斯卫厨电器有限公司

Device for de-sugaring and processing dairy product

InactiveCN101623030ASignificant positive effectCurd effectRotary stirring mixersTransportation and packagingLow speedEngineering

The invention discloses a device for de-sugaring and processing a dairy product, which comprises a tank body. The tank body is provided with a feeding hole and a discharge hole and provided with observation devices; and a low-speed stirring device is fixedly placed in the tank body. The tank body is also fixedly provided with a high-speed shearing device at least; and a supernatant discharge hole is formed at the middle lower part of the tank body. The device has the advantages of reasonable structure, convenient operation and high production efficiency. At the early stage, enzyme and milk are evenly mixed by the low-speed stirring device to play a role of milk curd; and at the later stage, the low-speed stirring device cooperates with the high-speed shearing device to improve the effects of mixing, crushing and emulsifying. The milk clear liquid after the milk curd flows out from the supernatant discharge hole on the lateral surface from a high position to a low position in turn, and the milk curd precipitation effect is not influenced. Steps of de-sugaring and reducing and the like of the liquid milk are carried out in one tank body; a group of observation devices are convenient to observe and control the liquid; and the operation time is shortened and the pollution is reduced. The device of the invention is mainly used for processing sugar-free cow or sheep milk products, and also can be used for manufacturing cheese and reconstituted milk.

Owner:SHANGHAI SHANGLONG DAIRY

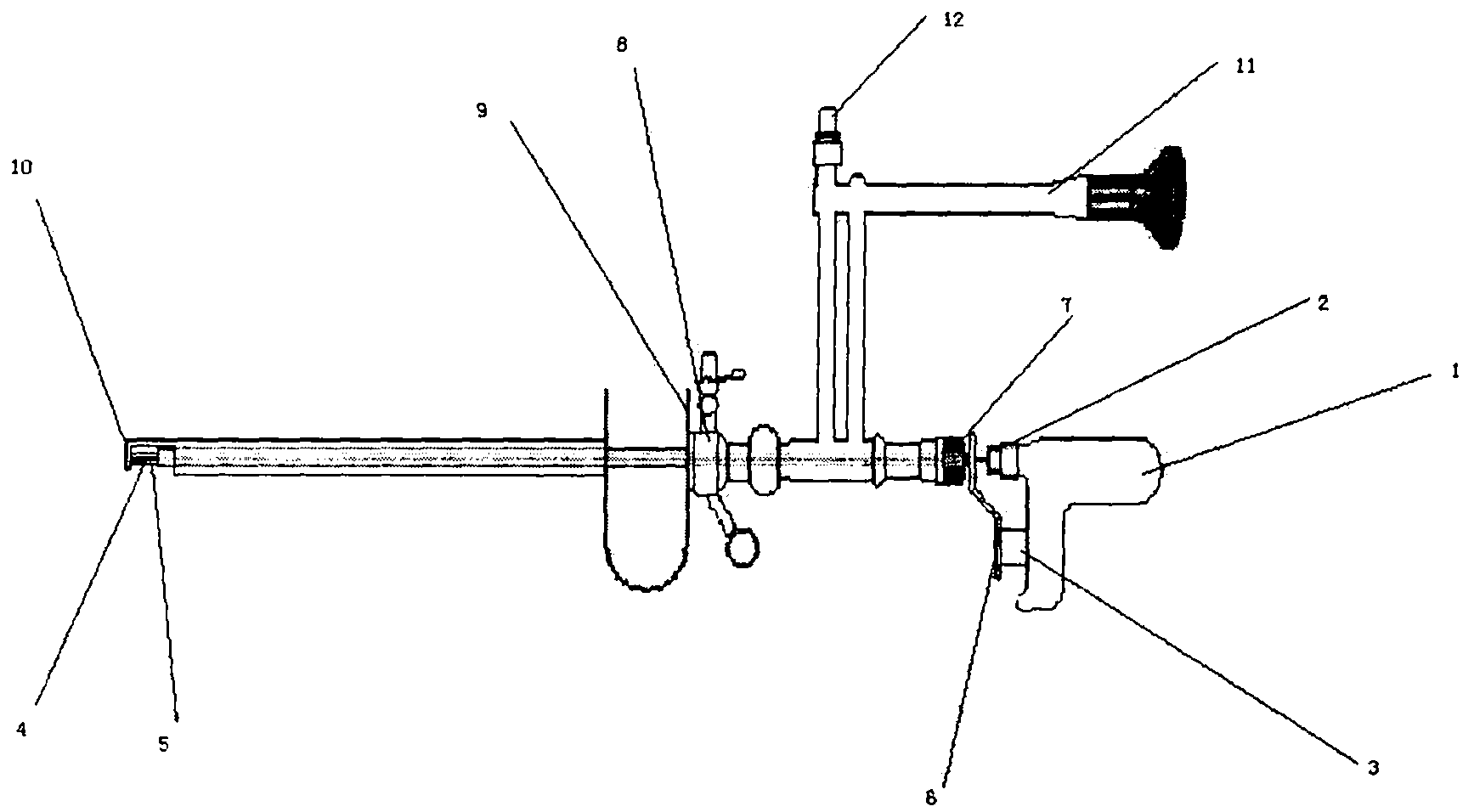

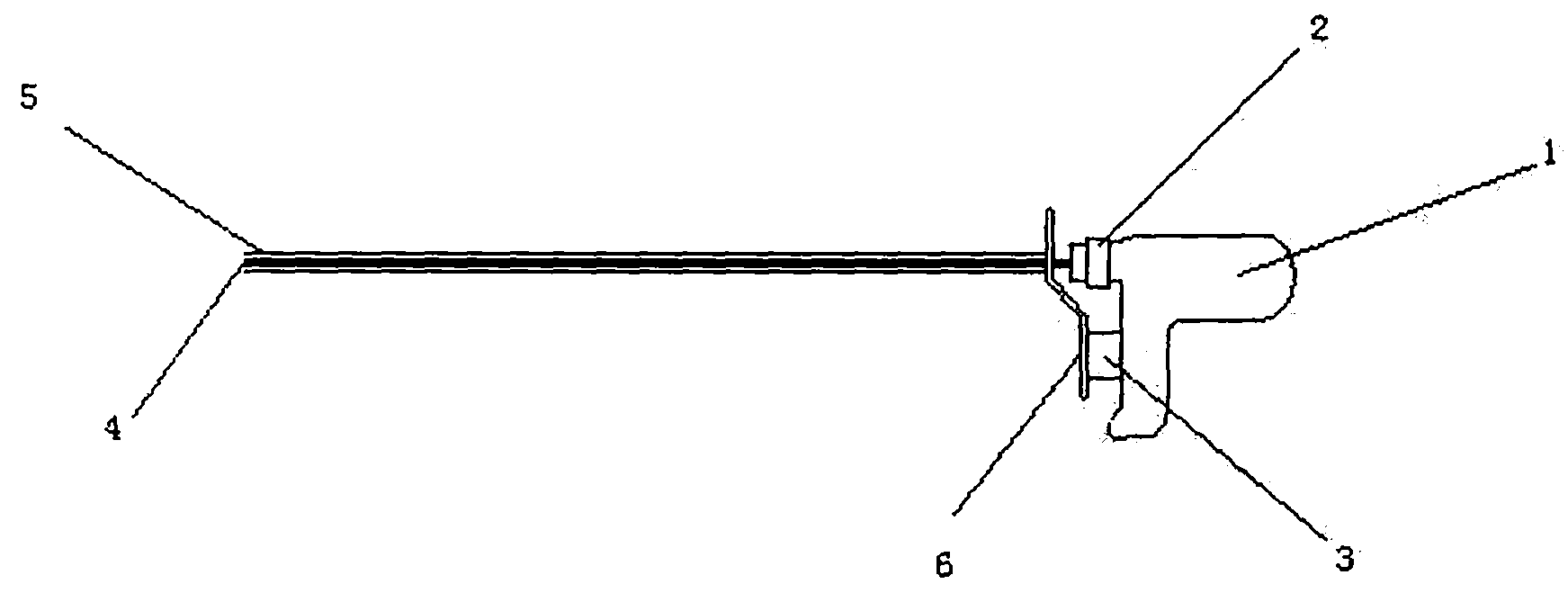

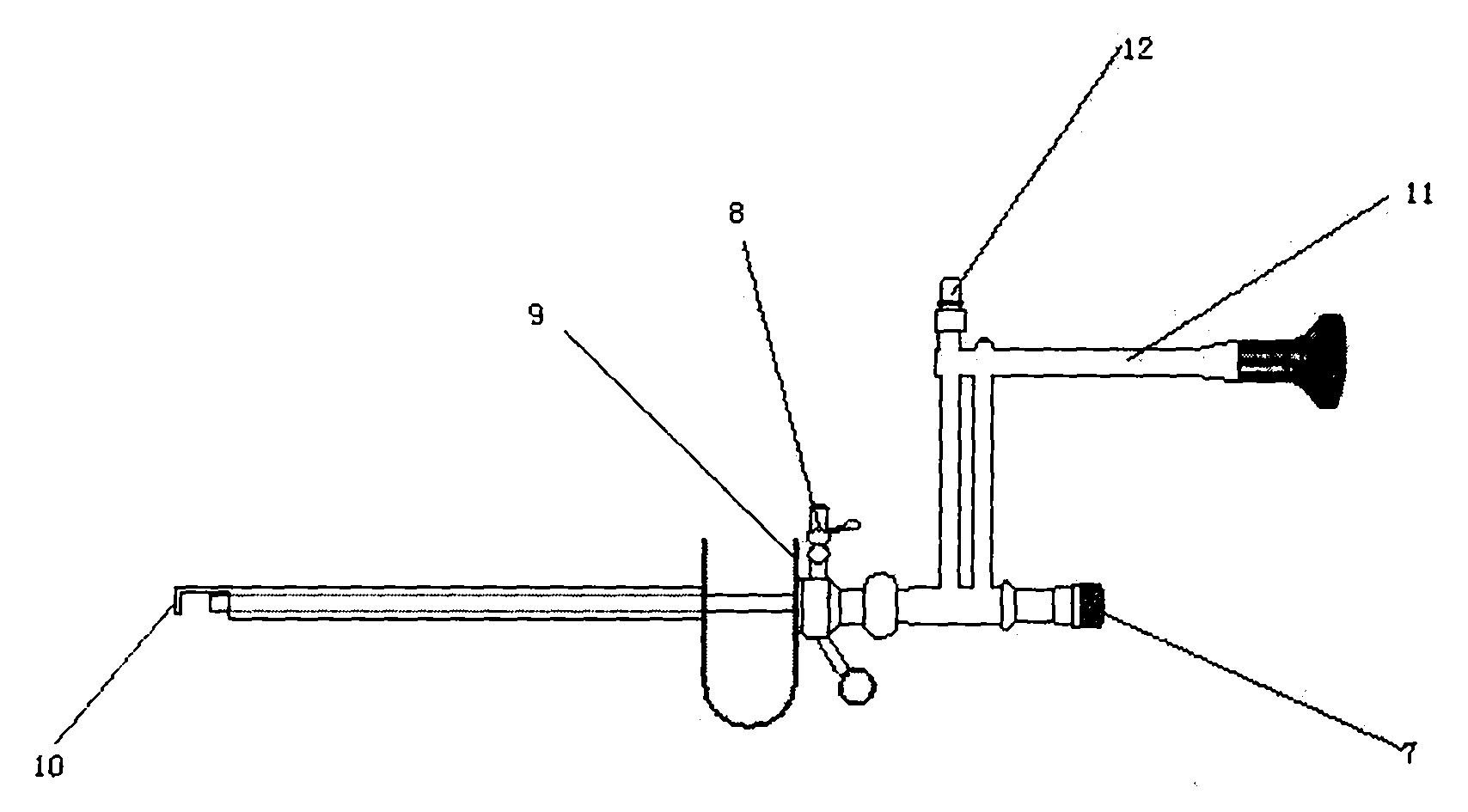

Intracavitary lithotripter for treating upper urinary tract calculi

InactiveCN101889887ASpeed up crushingImprove stone crushing efficiencySuture equipmentsInternal osteosythesisPerioperativeMathematical Calculus

The invention discloses an intracavitary lithotripter for treating upper urinary tract calculi. The lithotripter comprises an electric hammer host machine, a drill probe rod, a protective sheath, a protective sheath handle and an endoscope, wherein the electric hammer host machine is connected and fixed with the tail end of the drill probe rod through a screw on a front end interface; a sliding shaft is sleeved between the rear end of the protective sheath and the drill probe rod to ensure that the clearance distance between the protective sheath and the drill probe rod is constant; the handle at the tail end of the drill probe rod is fixed with an electric hammer switch through a clamping groove; a fixing device is sleeved in a nephroscope body, and an elastic handle on the tail part of the nephroscope body is fixed with the front end of a water inlet through the clamping groove, stretches out of a jaw of the calculus fixing device, and forms the clamping groove with the front end of the nephroscope; and the drill probe rod and the protective sheath of the lithotripter are externally embedded into an operation channel of the nephroscope. The lithotripter has the advantages of obviously shortening operation time, reducing the incidence rate of complications in perioperative period, breaking and picking large and hard complex calculi primarily, along with simple structure, convenient use and high calculi breaking efficiency.

Owner:张茨

Efficient pulverizer

The invention discloses an efficient pulverizer. The efficient pulverizer comprises a pulverizing box, wherein the bottom of the pulverizing box is fixedly connected with support legs, the top of the pulverizing box is fixedly connected with a grinding box, one side surface of the pulverizing box is fixedly connected with a first motor box, a first motor is fixedly connected in the first motor box, and an output shaft of the first motor is fixedly connected with a rotating shat through a coupling. According to the efficient pulverizer, an arranged grinding device carries out first pulverization on objects through the cooperation use of an electric telescopic rod and a grinding block, a second motor of the grinding device drives the grinding block and a friction block to rotate, and accelerating pulverization can be realized on the objects, so that the pulverizing speed is increased, and the pulverizing time is saved; and an arranged pulverizing device carries out second pulverization on the objects through the cooperation of the first motor, a connecting rod, a fixing plate and a pulverizing blade, so that the pulverizing effect is optimal.

Owner:唐山三发普林饲料有限公司

Straw smashing and recovering device for agricultural machinery

InactiveCN110603967ASpeed up crushingAchieve recyclingDispersed particle filtrationCuttersEconomic benefitsAgricultural engineering

The invention relates to a straw smashing and recovering device for agricultural machinery. The straw smashing and recovering device comprises a cut-off chamber, a smashing chamber and an extrusion chamber. A cutting motor is fixedly arranged above the cut-off chamber, a cut-off rotating shaft is jointly arranged on front and rear walls of the cut-off chamber, cutting blades are arranged on the outer side of the cut-off rotating shaft, and the smashing chamber is positioned on the right side of the cut-off chamber. A rotating rod is arranged under a smashing motor which is fixedly arranged above the smashing chamber, a filter screen is arranged on the rotating rod, a plurality of suspension ropes are arranged around the upper end of the filter screen, and impact beads are connected to lower portions of the suspension ropes respectively. The extrusion chamber is arranged below the smashing chamber, discharging retaining plates are fixedly arranged on upper left and right sides of the extrusion chamber, and second extrusion rollers are arranged under first extrusion rollers which are arranged under the discharging retaining plates respectively. A collection motor is arranged at an outlet of the extrusion chamber and provided with a collection roller. The straw smashing and recovering device has advantages of structural simplicity, effectiveness in smashing and recovering and increase of economic benefits.

Owner:禹州市植物保护植物检疫站

Self-cleaning waste water pipe rack

InactiveCN107830304AAvoid cloggingIncrease intensityPipe heating/coolingPipe elementsFixed bearingWastewater

The invention discloses a self-cleaning waste water pipe rack. A stirring main shaft in the pipe rack drives a main stirring disc and secondary stirring discs to longitudinally stir sewage and waste water, such that pollutants are smashed and dispersed, meanwhile, a gas pipe rotates around a fixed bearing to drive and overturn a hollow body and vertical discs to transversely stir the sewage and the waste water, such that the smashing and dispersing effects of the pollutants are enhanced. In addition, overturning air pores and pipe air pores can outward spray gas during rotation to enhance a stirring capacity for the pollutants, water passing holes can reduce the resistance of the sewage during movement, and cross-shaped reinforcing ribs can avoid blockage of the water passing holes by thepollutants. The self-cleaning waste water pipe rack in such design not only can perform longitudinal and transverse stirring and has higher stirring and smashing functions, but also can realize dispersing by heating, is better in dispersing and uniformizing effects and is favorable for re-discharging the processed sewage and waste water.

Owner:李秀青

Suaeda salsa tea beer and brewing process thereof

PendingCN111826248AEffective in liver protectionHas the effect of protecting the liverBeer fermentationBiotechnologyChaptalization

The invention discloses Suaeda salsa tea beer and a brewing process thereof, relates to the technical field of Suaeda salsa tea beer brewing and aims to solve the problem of nutritional components inthe brewing of Suaeda salsa tea beer. The brewing process of the Suaeda salsa tea beer includes the following steps: dividing the prepared Suaeda salsa into two parts and putting the two parts into juicing equipment and milling equipment respectively to prepare Suaeda salsa juice and Suaeda salsa powder for later use; putting selected malt and rice into crushing equipment, placing the crushed maltand starch auxiliary materials into a gelatinization pot and a saccharification pot respectively for saccharification, filtering the saccharified raw materials by a filter, then putting the filteredmaterial into a boiling pot for heating, and then, putting hops to blend the wort concentration of 6%-20%. The Suaeda salsa is dopped into the Suaeda salsa tea beer brewing process, internal nutrientsin the Suaeda salsa tea beer are effectively improved, Suaeda salsa has a liver protecting function, and the Suaeda salsa tea beer brewed with the Suaeda salsa can effectively diminish inflammation and reduce swelling.

Owner:碱蓬先创科技(盘锦)有限公司

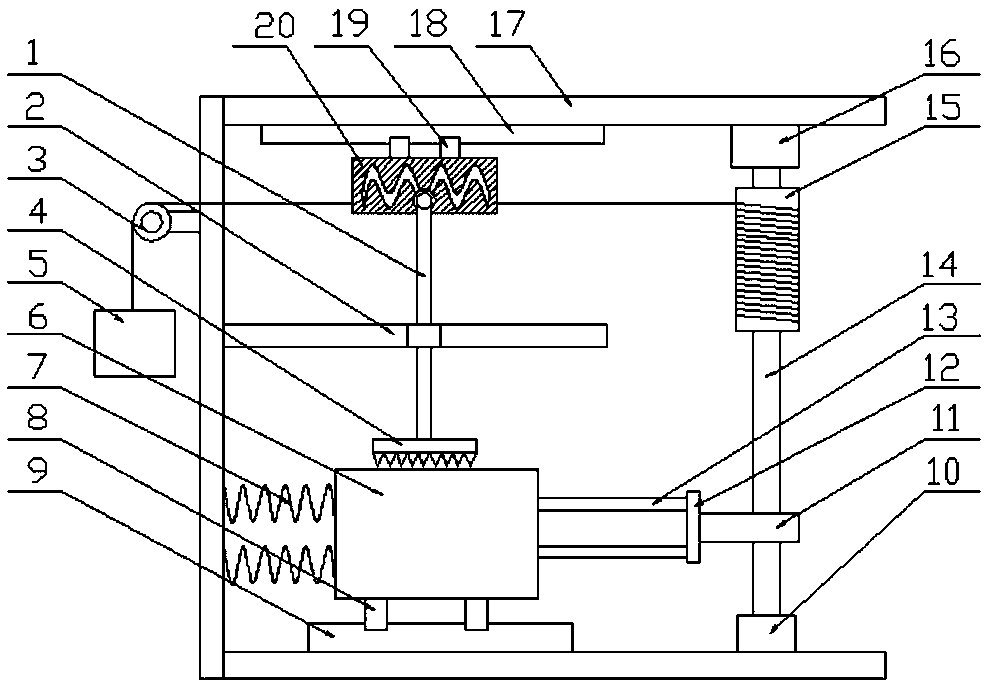

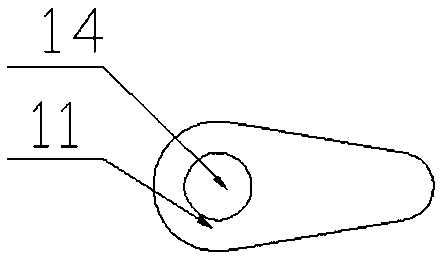

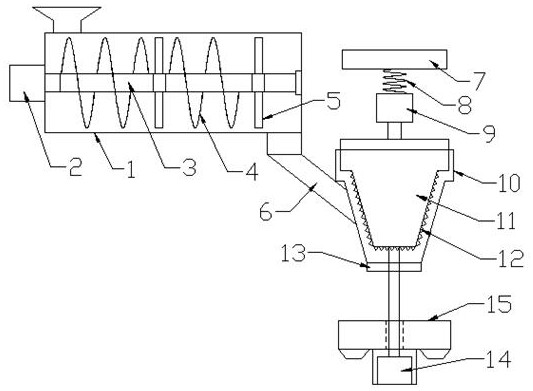

Raw material crushing and mixing device for automatic food production

InactiveCN112076861APlay the effect of primary crushingImprove mixing efficiencyGrain treatmentsElectric machineryStructural engineering

The invention discloses a raw material crushing and mixing device for automatic food production. A pre-crushing machine is arranged, a middle shaft is arranged in the pre-crushing machine, crushing blades are arranged on the middle shaft, and spiral conveying blades are arranged outside the middle shaft so that a conveying effect can be achieved through the spiral conveying blades, and a preliminary crushing effect on raw materials is achieved through the crushing blades. Meanwhile, the raw material mixing efficiency can be improved. A crushing barrel is arranged, a pressing block is arrangedin the crushing barrel, a motor is arranged above the pressing block, a compression spring is arranged at the top end of the motor, an air cylinder is arranged below the crushing barrel, the tail endof a piston rod of the air cylinder is fixed to the lower end face of the pressing block, the air cylinder works to drive the pressing block to move upwards, and therefore the materials are guided into the crushing barrel. Meanwhile, the motor works to drive the pressing block to rotate, and the materials can be further crushed through rotation of the pressing block. Teeth are arranged on the outer side of the pressing block so that crushing of the materials can be accelerated through the teeth outside the pressing block, and crushing is facilitated.

Owner:XIAN LANXIN IND AUTOMATION ENG CO LTD

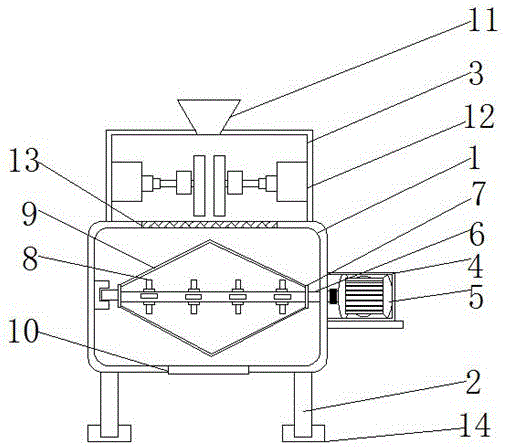

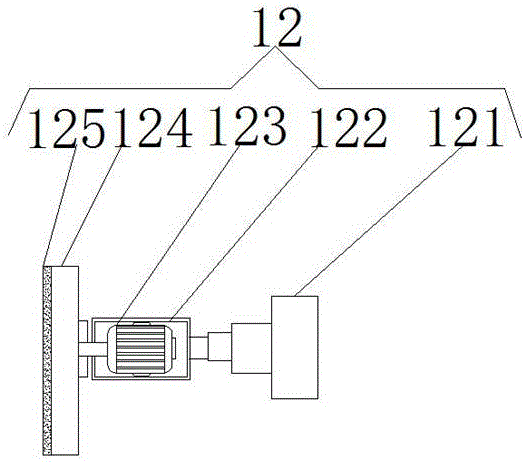

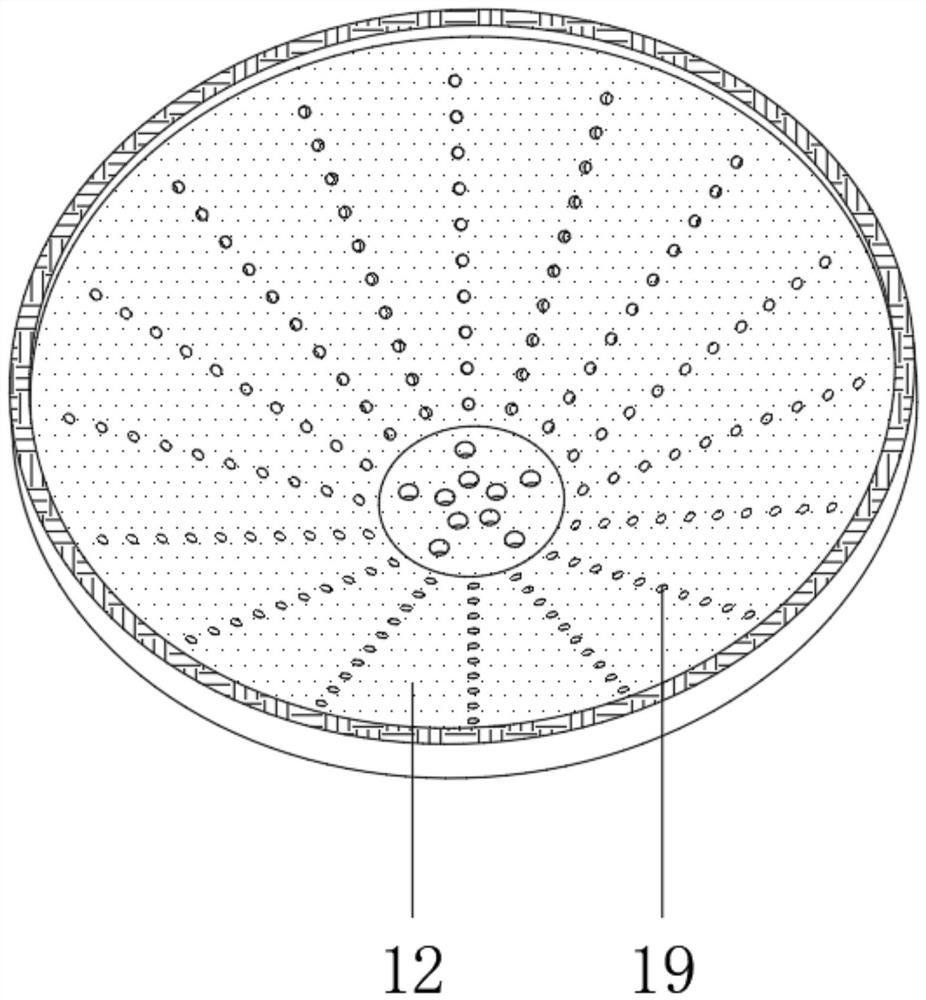

Pulse-jet screening machine

InactiveCN104923474ADisperse impactExtended service lifeSievingScreeningElectromagnetic pulseEngineering

The invention discloses a pulse-jet screening machine. The pulse-jet screening machine comprises a machine shell, a motor, a main rotating shaft, a net rack, a screen cloth, an atomization component, a rotational flow hammer, a jetting cabin clap board, a venturi-tube, a main pipe for compressed air, a jetting pipe for the compressed air and an electromagnetic pulse valve. The machine shell comprises a screening portion, an arrangement portion for the venturi-tube and an arrangement portion for the jetting pipe for the compressed air from top to bottom. The atomization component comprises an atomization paddle, an inner support component, an outer support component, an auxiliary smashing tooth and a main smashing tooth. The pulse-jet screening machine has the advantages of being reasonable in structure, high in screening efficiency and good in screening efficiency; on the one hand, fake capsule diameters which are collaborative due to an adsorption force can be damaged, and the yield is improved; on the other hand, the screen can be renewed, the changing time of the screen cloth is reduced greatly, the cost is saved, and the phenomenon of super-diameter level mixing can be prevented from generating effectively.

Owner:SHAOXING RENFEI CARBON BLACK

Ore pulverizer

The invention discloses an ore pulverizer. The ore pulverizer comprises a pulverizer case, a No.1 crushing cutter group is arranged at one end of the pulverizer case, a No.2 crushing cutter group is arranged at one end of the No.1 crushing cutter group, a rotating shaft is arranged at one end of the No.1 crushing cutter group, an A-type cutter blade is arranged at one end of the rotating shaft, anA-type crushing blade is arranged at one end of the A-type cutter blade, a B-type cutter blade is arranged at one end of the A-type crushing blade, a B-type crushing blade is arranged at one end of the B-type cutter blade, a C-type cutter blade is arranged at one end of the B-type crushing blade, and a C-type crushing blade is arranged at one end of the C-type cutter blade. The ore pulverizer iscapable of cutting and crushing large-volume mineral aggregate, employs cutters with different specifications for cutting the mineral aggregates with different volumes, reasonable resource utilizationis reduced, cutter damage is reduced, an inner-wall auxiliary crushing tooth is used for increasing crushing of the edge material, and the crushing efficiency is increased.

Owner:芜湖遥帆电子科技有限公司

Efficient asphalt melting device for road construction

InactiveCN112458831AImprove melting efficiencySpeed up crushingRoads maintainenceElectric machineryElectric heating

The invention belongs to the technical field of road construction, and particularly relates to an efficient asphalt melting device for road construction. Aiming at the problem that the melting rate isreduced due to the fact that the area of existing solid asphalt is larger, the efficient asphalt melting device comprises a shell, a crushing cylinder is fixedly inserted into the upper end of the outer wall of one side of the shell, a crushing motor is installed at the top end of the crushing cylinder through bolts, a crushing roller is rotatably installed at the bottom end of the crushing motorthrough a shaft coupling, and a scraping rod is fixedly installed at the upper end of the circumferential outer wall of the crushing roller. The crushing motor, the crushing roller, the scraping rodand the crushing rod are arranged in the crushing cylinder to crush large-size solid asphalt, semiconductor chilling plates are inserted into the outer wall of the crushing cylinder at equal intervals, crushing of the solid asphalt is accelerated in an assisted mode according to low-temperature brittleness and hardness of the asphalt, a first stirring frame, a crushing hopper, a second stirring frame, a third stirring frame and an electric heating filter screen are arranged on the outer wall of the circumference of the stirring shaft, solid-liquid mixed asphalt is centrifugally separated, heated and mixed, and the melting efficiency of the asphalt is greatly improved.

Owner:李好宣

High-efficiency pasture pulverizer for livestock breeding

InactiveCN109328676ASpeed up crushingIncrease productivityFeeding-stuffTransportation and packagingLivestock breedingEngineering

The invention discloses a high-efficiency pasture pulverizer for livestock breeding. The high-efficiency pasture pulverizer for livestock breeding comprises a box body and a belt, wherein the front end and rear end of the top of an inner cavity of the box body are movably connected with a first pulverizing rod and a second pulverizing rod through bearings respectively, the right side of the firstpulverizing rod and the right side of the second pulverizing rod both penetrate through the inner cavity of the box body and extend to the outside of the box body, the ends, located at the outside ofthe box body, of the first pulverizing rod and second pulverizing rod are movably connected with the right side of the box body through bearings, and the top of the right side of the box body is fixedly connected with a supporting plate. The high-efficiency pasture pulverizer for livestock breeding has the advantages that through the cooperative use of the box body, the belt, the first pulverizingrod, the second pulverizing rod, the supporting plate, a motor, a driving gear, a first belt disc, a driven gear, a transmission rod, a second belt disc, stirring blades, a feeding hopper and a discharging pipe, the mixing efficiency of pasture and fodder is improved while the pasture is efficiently pulverized, so that the production efficiency of the pasture is improved, and great benefits are brought to enterprises.

Owner:王超

A pipeline spraying equipment

Owner:东台市高科技术创业园有限公司

Suaeda glauca tea beer and brewing process thereof

PendingCN114075488AEffective in liver protectionHas the effect of protecting the liverBeer fermentationBiotechnologyChaptalization

The invention discloses suaeda glauca tea beer and a brewing process thereof, and relates to the technical field of brewing of suaeda glauca tea beer. The invention aims to solve the problem of nutritional ingredients in brewing of suaeda glauca tea beer. The suaeda glauca tea beer brewing process comprises the following steps: dividing prepared suaeda glauca into two parts, and respectively putting the two parts into juicing equipment and grinding equipment to prepare suaeda glauca juice and suaeda glauca powder for later use; putting the selected malt and rice into crushing equipment for crushing, respectively putting the crushed malt and starchy auxiliary materials into a gelatinization pot and a saccharification pot for saccharification, filtering the saccharified raw materials by a filter, putting the filtered raw materials into a boiling pot for heating, and adding hops between the filtered raw materials and the boiling pot, so as to prepare the wort with the concentration of 6-20%. According to the method, the suaeda glauca is doped into the suaeda glauca tea beer brewing process, so that the internal nutritional ingredients of the suaeda glauca tea beer are effectively improved, the suaeda glauca has the effect of protecting the liver, and the suaeda glauca tea beer brewed from the suaeda glauca can effectively resist inflammation and relieve swelling.

Owner:碱蓬先创科技(盘锦)有限公司

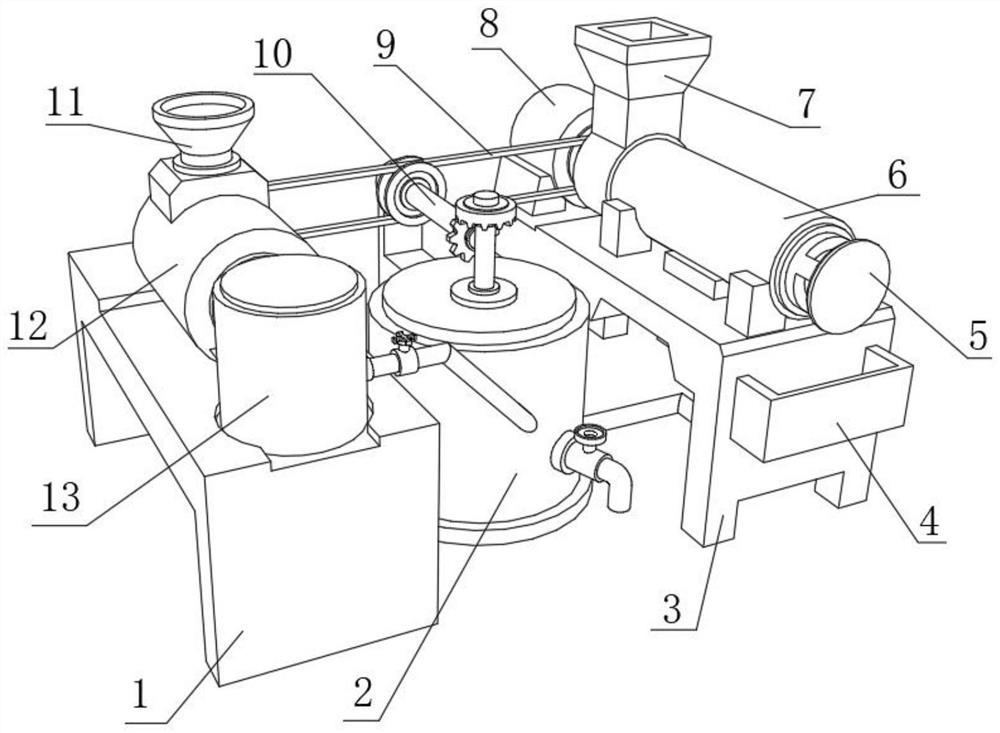

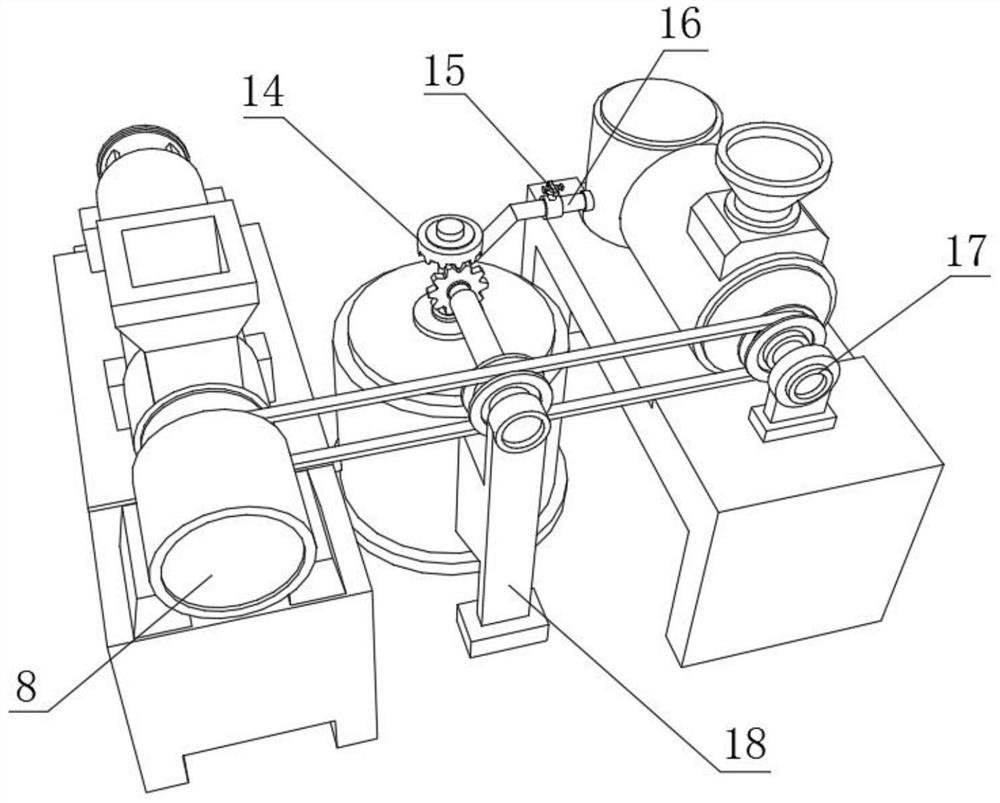

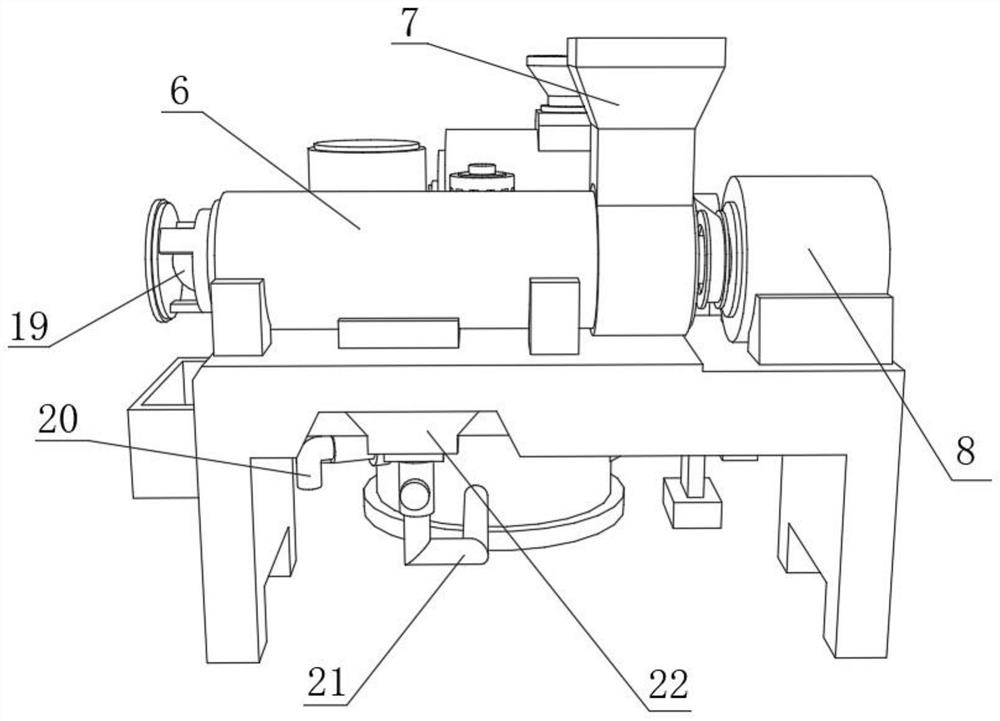

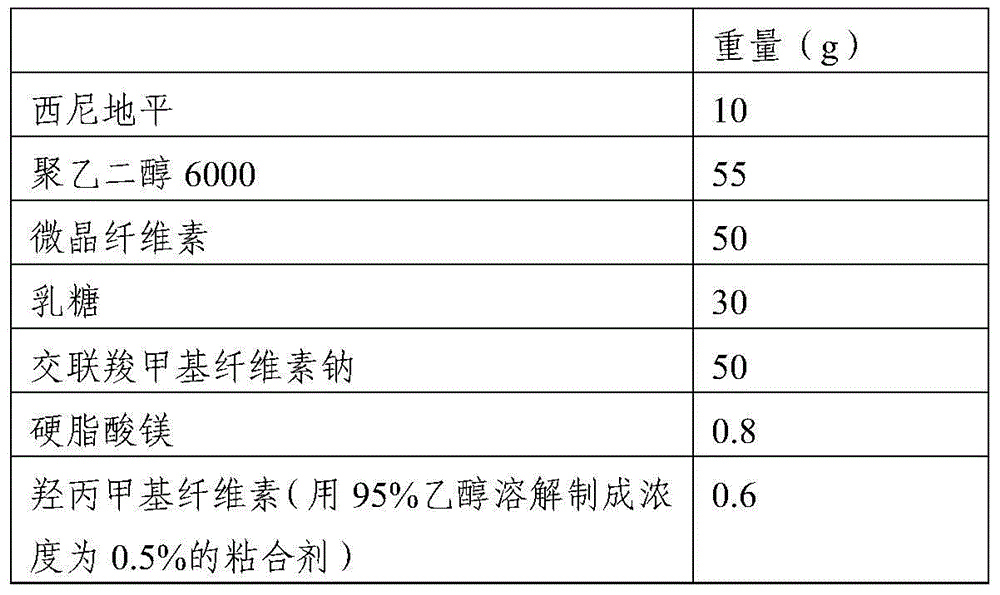

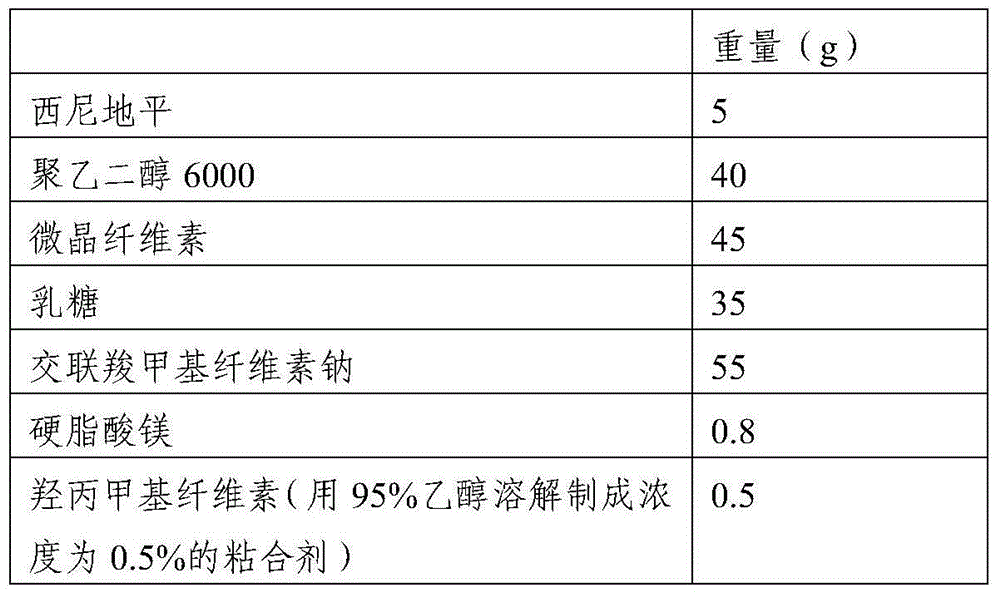

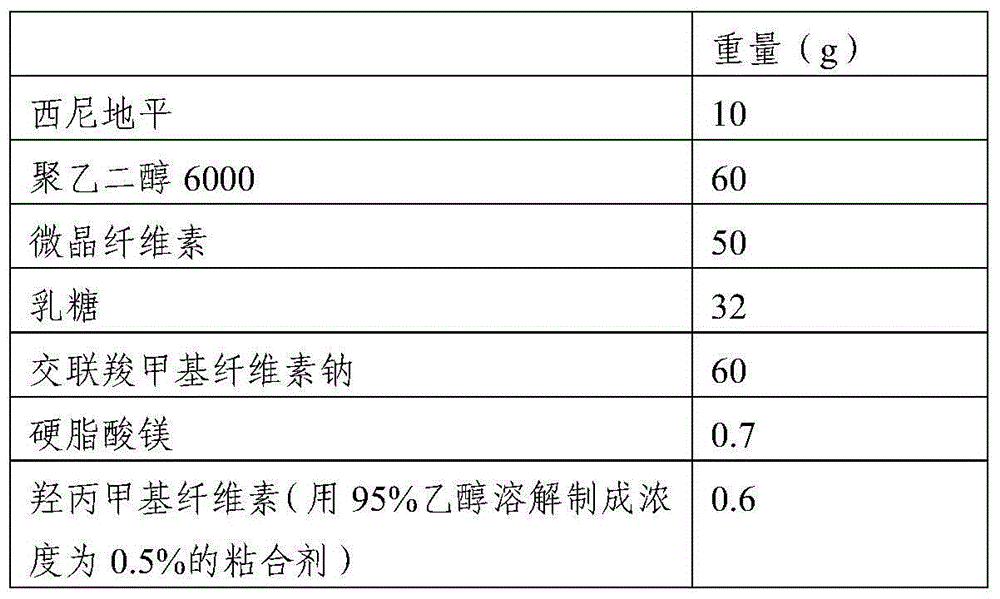

Solid dispersion of cilnidipine and preparation method thereof

InactiveCN104644558ASpeed up crushingGood water solubilityPowder deliveryOrganic active ingredientsPolyethylene glycolLactose

The invention relates to a solid dispersion of cilnidipine and a preparation method thereof. The solid dispersion is prepared from the following raw material components: cilnidipine, polyethylene glycol, microcrystalline cellulose, lactose, croscarmellose sodium, magnesium stearate and hydroxypropyl methylcellulose. The dissolution degree of the solid dispersion provided by the invention is not lower than 85%; the contents of related substances conform to the requirements; and the effect is superior to that of the prior art.

Owner:蚌埠丰原涂山制药有限公司

Method for performing normal-temperature rapid dip dyeing on seaweed non-woven fabric and enhancing ultraviolet resistance

ActiveCN106049101AImprove hydrophobicitySmall particle sizeLiquid/gas/vapor removalDyeing processUltraviolet lightsNonwoven fabric

The invention relates to a method for performing normal-temperature rapid dip dyeing on a seaweed non-woven fabric and enhancing ultraviolet resistance, in particular to a method for utilizing a copper phthalocyanine pigment to perform rapid dip dyeing on the seaweed non-woven fabric and enhance ultraviolet resistance, and belongs to the technical field of spinning dyeing and printing. According to the method, cationic surfactant cetyltrimethylammonium chloride is utilized to prepare the small copper phthalocyanine pigment stably dispersed in water, the normal-temperature rapid dip dyeing of the seaweed non-woven fabric is achieved, the ultraviolet light transmittance can be remarkably lowered, the ultraviolet protection factor (UPF) of the non-woven fabric is improved remarkably, and thus the ultraviolet resistance of the seaweed non-woven fabric can be enhanced obviously.

Owner:QINGDAO UNIV

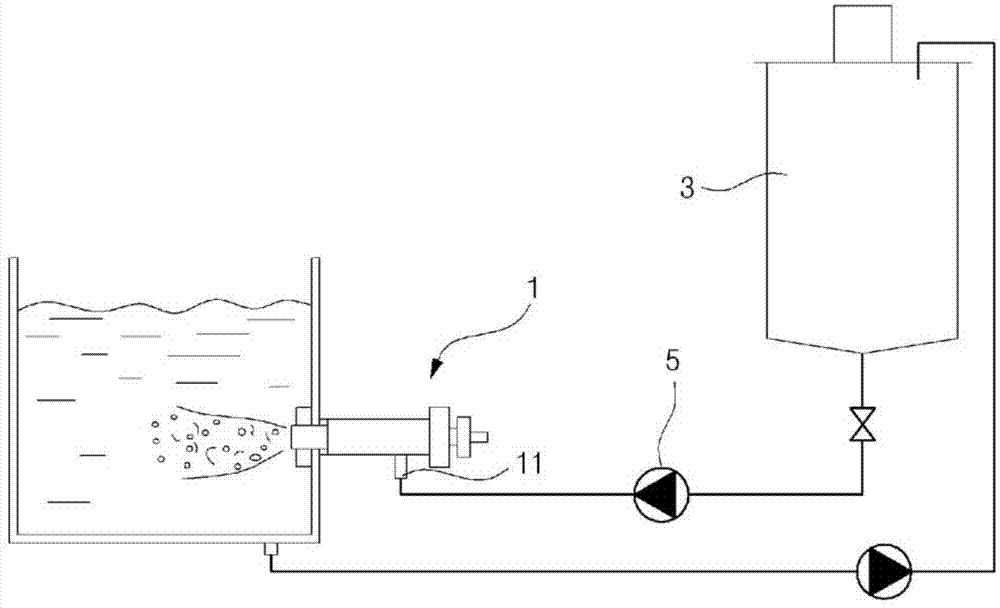

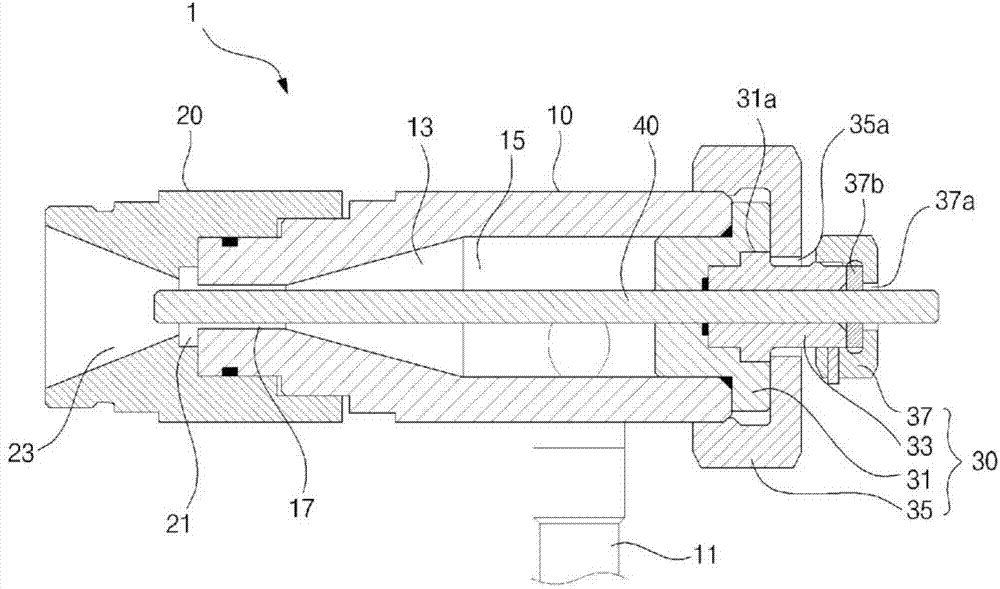

Hydrodynamic super-cavitation apparatus

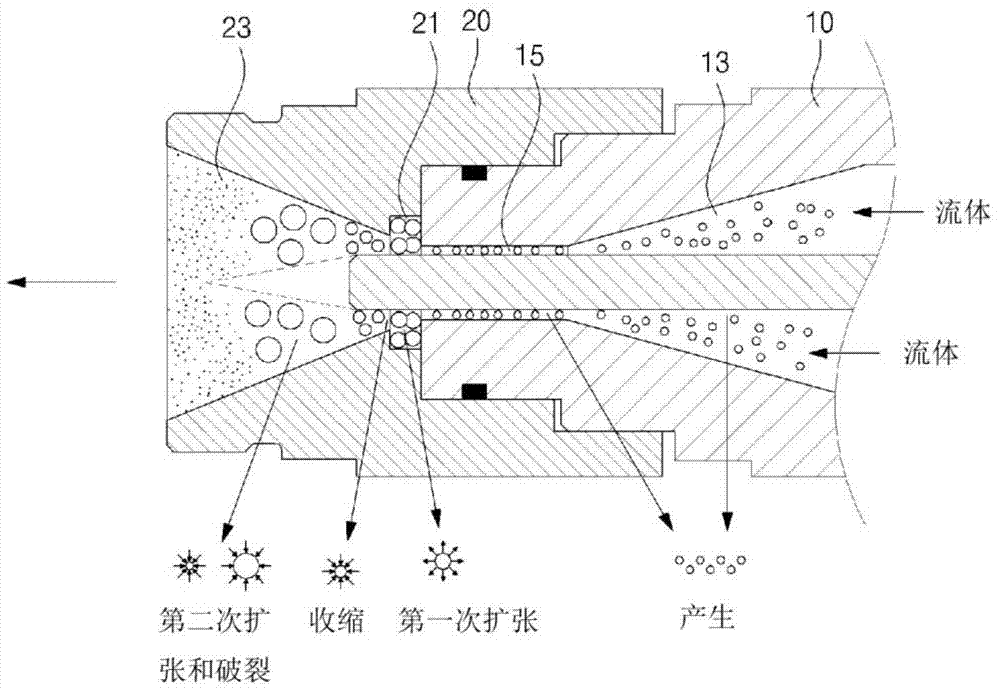

ActiveCN103596667AIncrease forceEasy to manufactureFlow mixersTransportation and packagingCavitationWater vapor

The present invention relates to a hydrodynamic super-cavitation apparatus in which effects of biodiesel production, emulsification, water treatment, descaling, and particle crushing or the like are doubled according to a significant increase in an acting force of an outlet side of the apparatus where a water vapor bubble-type cavitation collapses. The hydrodynamic super-cavitation apparatus according to the present invention comprises: a main body having one side connected to a fluid supply line for supplying fluid, and an interior having a cross-section decreasing space with a gradually decreasing transverse cross-section area, wherein the cross-section decreasing space has one side having a large space communicated to the fluid supply line and the other side having a small space; an outlet cap which is coupled to one end of the main body and which has an interior with one side having a first cross-section increasing space communicated to the small space of the main body and the other side having a second cross-section increasing space which gradually increases the transverse cross-section area beginning from a transverse cross-section area smaller than the first cross-section increasing space; a closing cap coupled to the other end of the main body in order to close the other end of the main body; and a center bar one end of which is supported by and coupled to the closing cap, and which passes through the interior of the main body so as to be extended to the second cross-section increasing space of the outlet cap.

Owner:KOREA CAVITATION +1

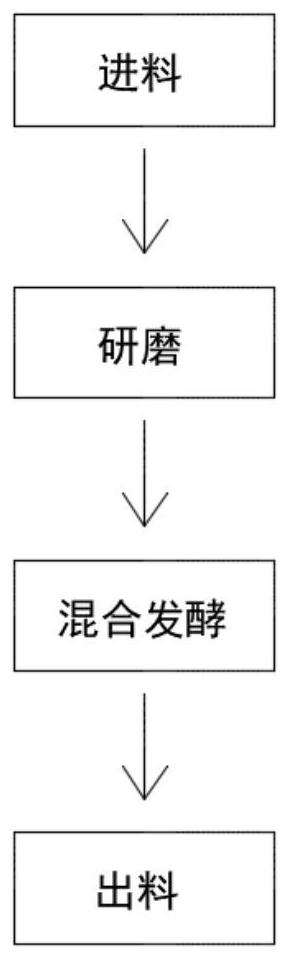

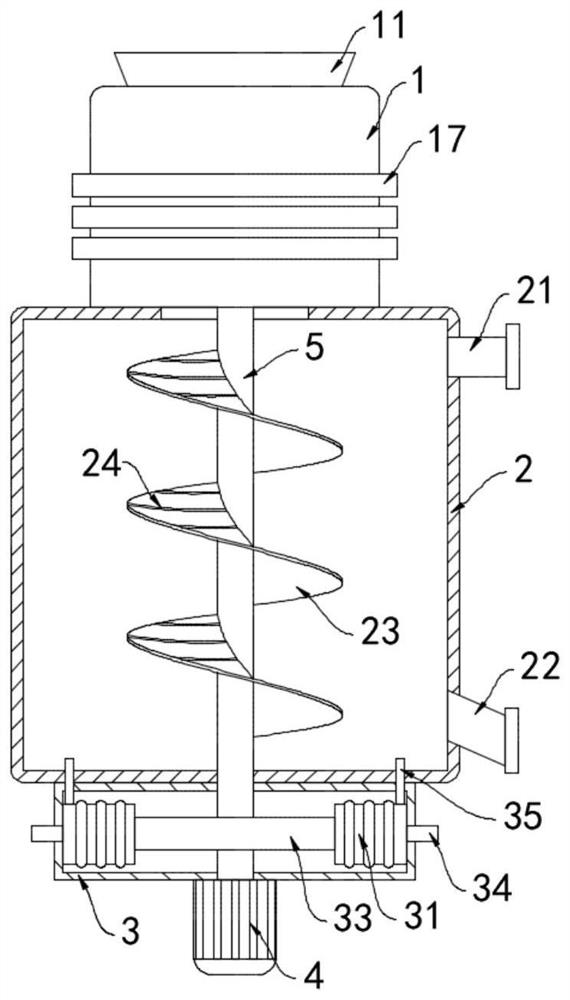

Production fermentation method of microbial fertilizer

ActiveCN112125719AIncrease profitReduce complexityBio-organic fraction processingFertiliser treatment heating/coolingAgricultural scienceAgricultural engineering

The invention belongs to the technical field of microbial fertilizer production, and relates to a production fermentation method of a microbial fertilizer. The method comprises the following steps of:S1, feeding: carrying out moisture content and carbon nitrogen ratio adjustment on microbial raw materials and fertilizers, and conveying the microbial raw materials and the fertilizers into a feeding funnel; S2, grinding: grinding and crushing the plurality of microbial raw materials and fertilizers with different particle sizes until the particle size range is 12mm-60mm; S3, mixed fermentation:feeding the ground and crushed microbial biomass raw materials and fertilizers into a fermentation tank for fermentation, maintaining the temperature within 35-40 DEG C, and continuously turning thematerials and fertilizers and performing ventilation; and S4, discharging: discharging the fermented microbial fertilizer through a discharging pipe, granulating, packaging, and transporting the fertilizer to a finished product area. According to the method of the invention, the vibration of a grinding head can form a vibration effect on the fertilizer, promote the crushing of the fertilizer and improve the grinding efficiency; in the rotation process of a spiral impeller, the mixing and exchange of the fertilizer at different positions are promoted, so that the fertilizer is in uniform contact with air, the turning effect is good, and the quality and fermentation efficiency of the microbial fertilizer are effectively improved.

Owner:清原满族自治县宏运有机肥有限公司

Waste cloth excess material recycling and packaging device for garment production

InactiveCN110947478AReduce laborSave energySolid waste disposalGrain treatmentsWork periodTransmission belt

The invention discloses a waste cloth excess material recycling and packaging device for garment production, and relates to the technical field of recycling and packaging. The waste cloth excess material recycling and packaging device for garment production comprises a workbench, wherein transmission rollers are fixedly arranged on the two side walls of the workbench, fourth motors are fixedly arranged on the rear side walls of the transmission rollers, output shafts of the fourth motors are fixedly connected with rotating shafts of the transmission rollers through couplers, seven groups of limiting grooves are arranged, and transmission belts are arranged in the seven groups of limiting grooves in a sleeved mode. According to the device, motors operate by manually operating switches, waste cloth is cut and crushed through the cooperative use of a first motor, a second motor, a third motor, the fourth motors, a hydraulic air cylinder, the transmission belts and an extrusion plate, andthe crushed waste cloth can enter a spiral discharging mechanism through the use of a fan so that the waste cloth can be rapidly crushed and packaged, the labor amount of workers is reduced to a certain extent, the physical strength of the workers is saved, and the working time of the workers is shortened.

Owner:浙江今日蓝纤科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com