Trail-type straw collecting, smashing and bundling machine

A traction-type, baler technology, applied in the field of traction-type straw collection, crushing and baling machines, which can solve the problems of large operating radius and long main machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

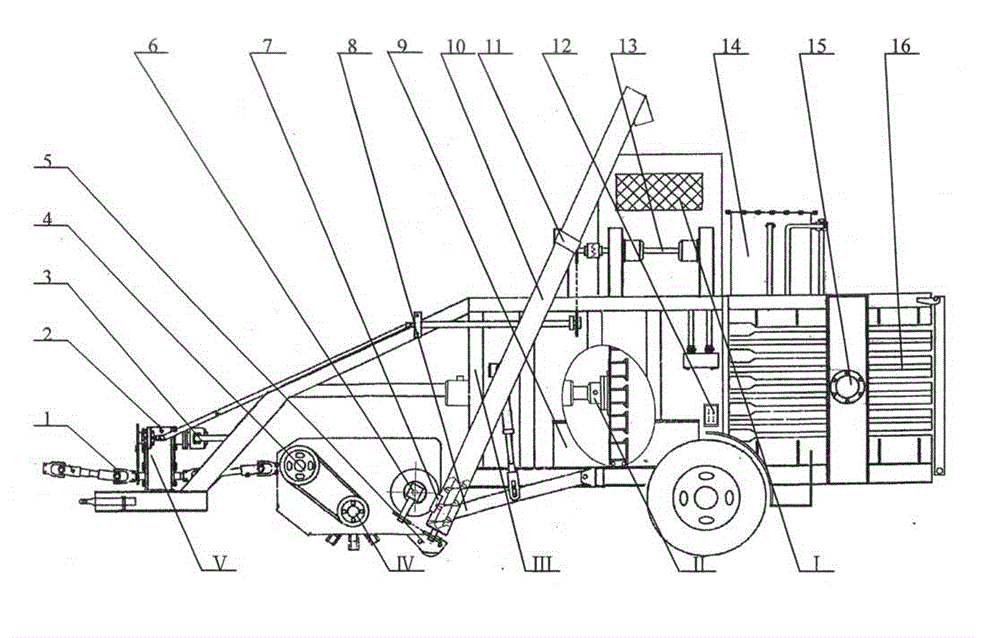

[0054] as attached figure 1 As shown, the traction-type straw collection, crushing and bundling machine designed by the patent research of the present invention includes a complete machine frame (Ⅲ), a collection and crushing conveying device (Ⅳ), a crushed straw filling device (Ⅰ), a straw compacting and bundling device ( Ⅱ), power transmission system (Ⅴ).

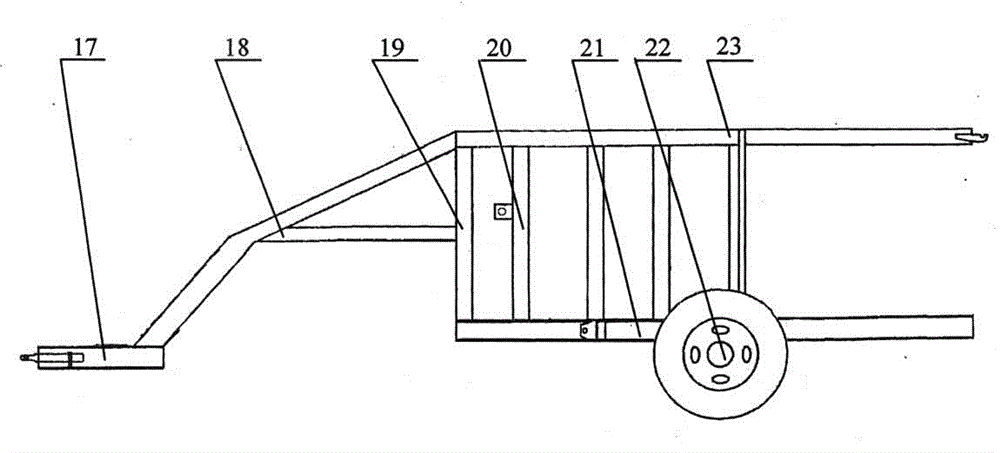

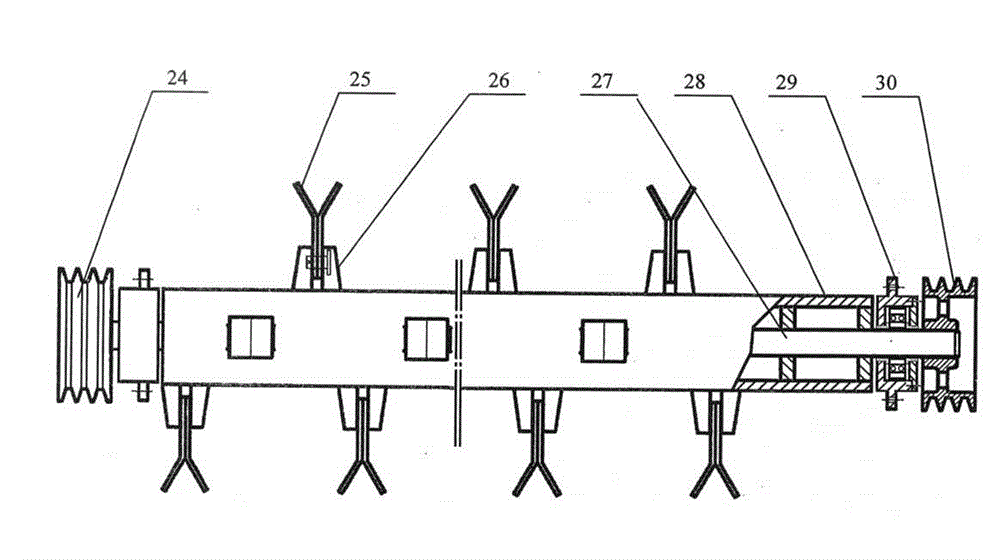

[0055] as attached figure 1 , attached figure 2 As shown, the complete machine frame (Ⅲ) includes the main machine frame (19), traction frame (18), and road wheels (22). The main frame (19) is a chassis (21) composed of a bottom beam (69) and a crossbeam, a top frame (23) composed of a top beam (59) and a crossbeam, and a frame structure formed by columns (20) on both sides , the above-mentioned beams and columns are all made of carbon steel profiles, and welded and fixed into a rigid whole in the form of a frame structure by a full-constraint welding method. The traction frame (18) is composed of a traction connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com