Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

148 results about "Tooth Component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

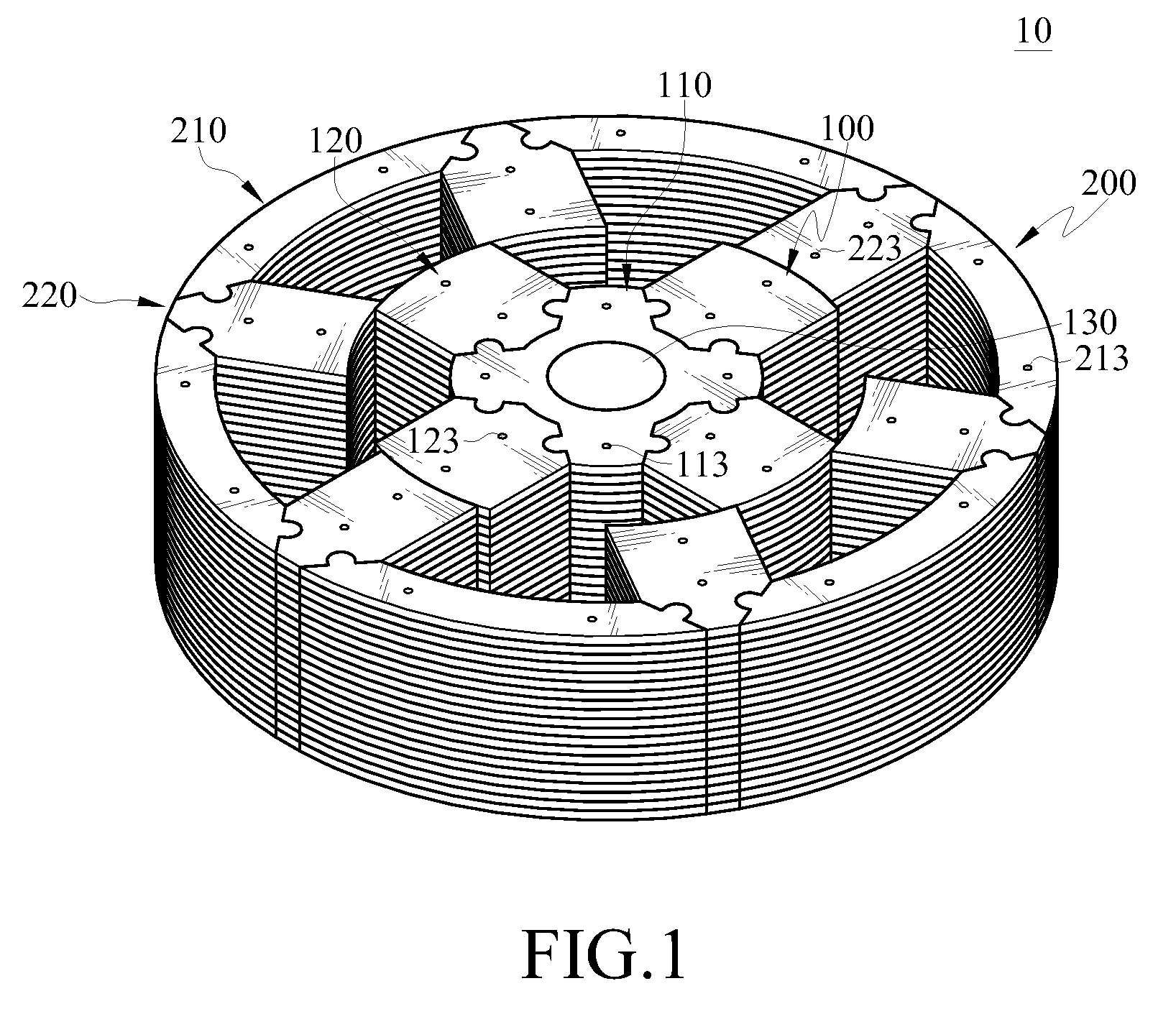

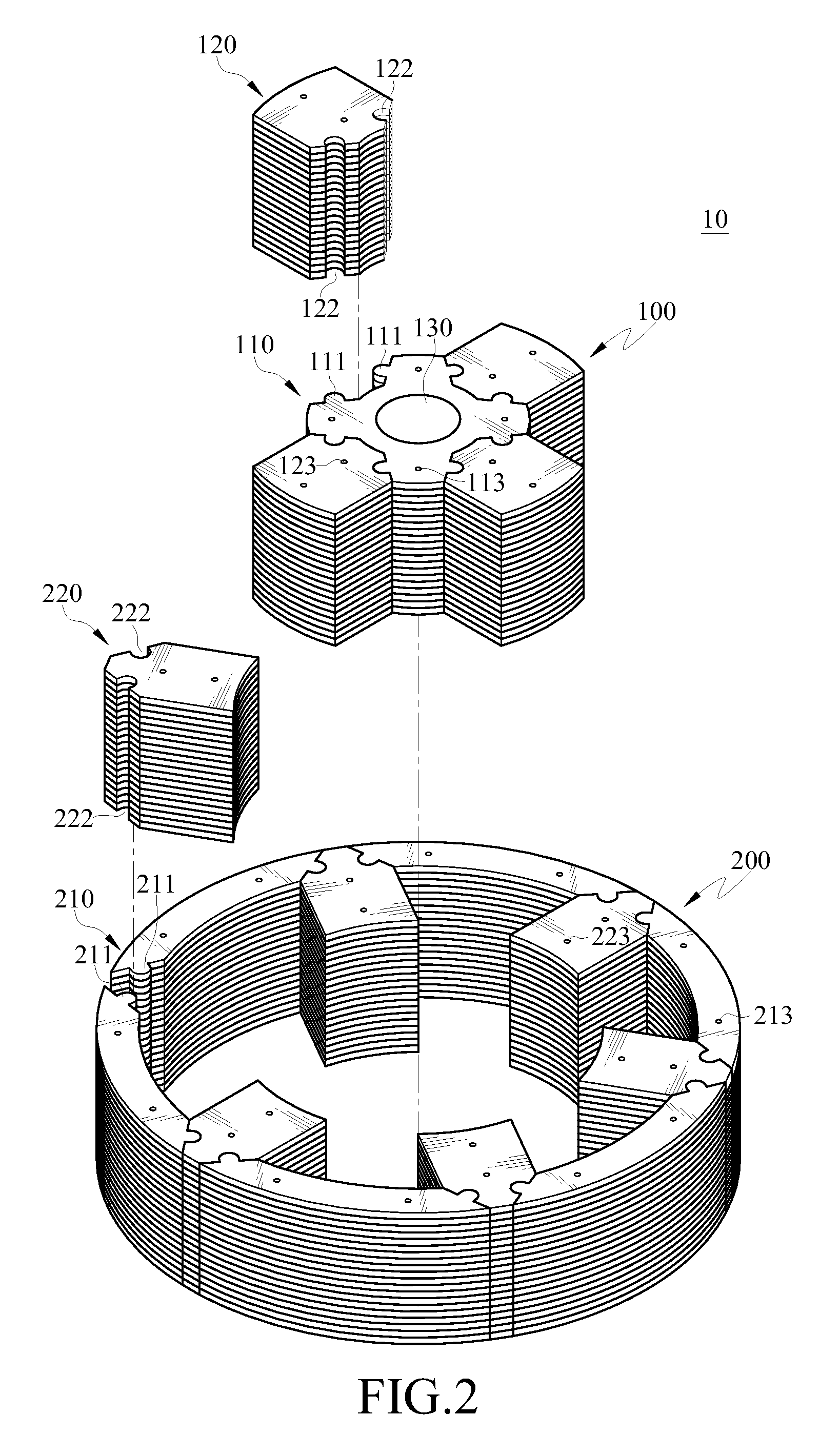

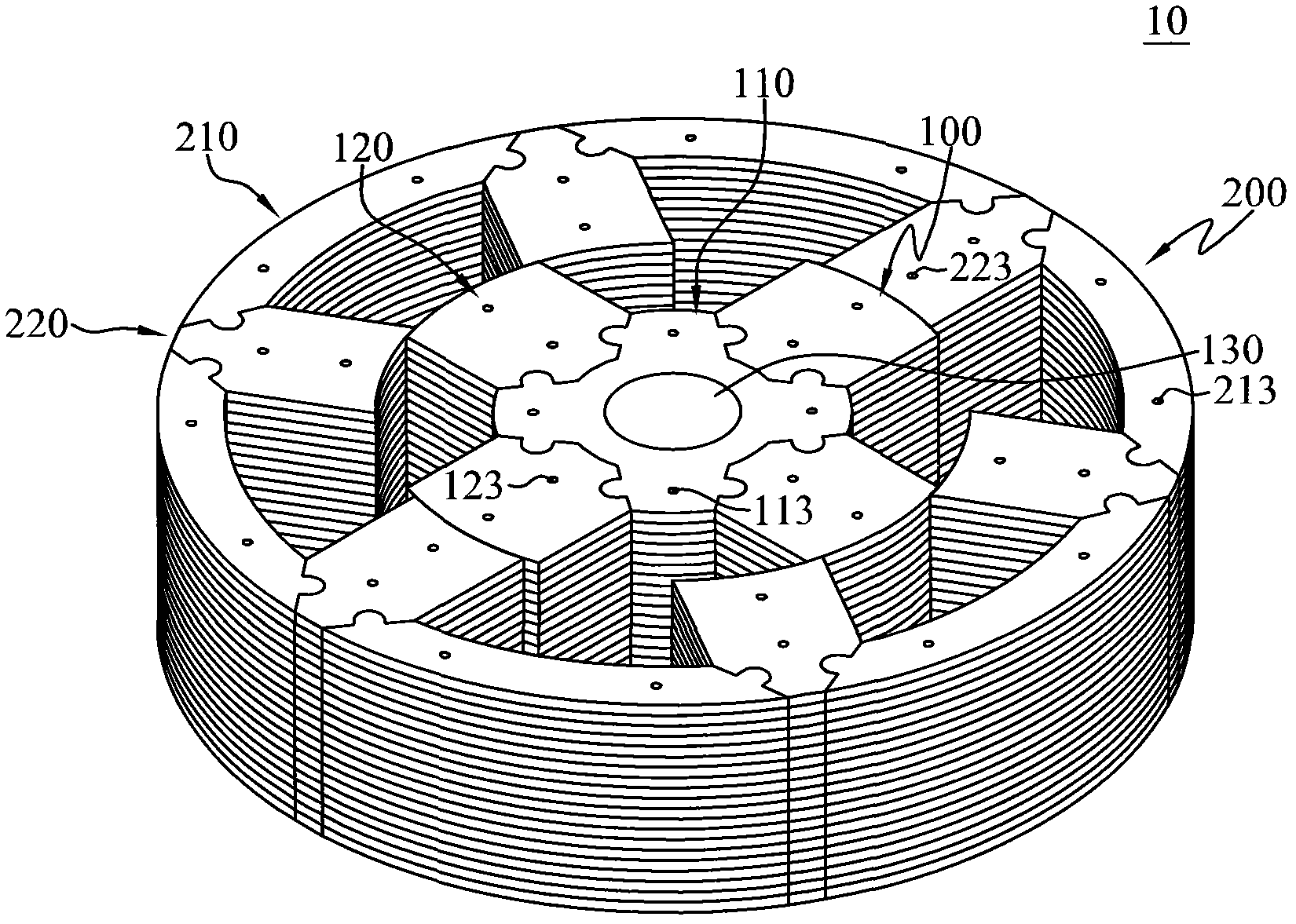

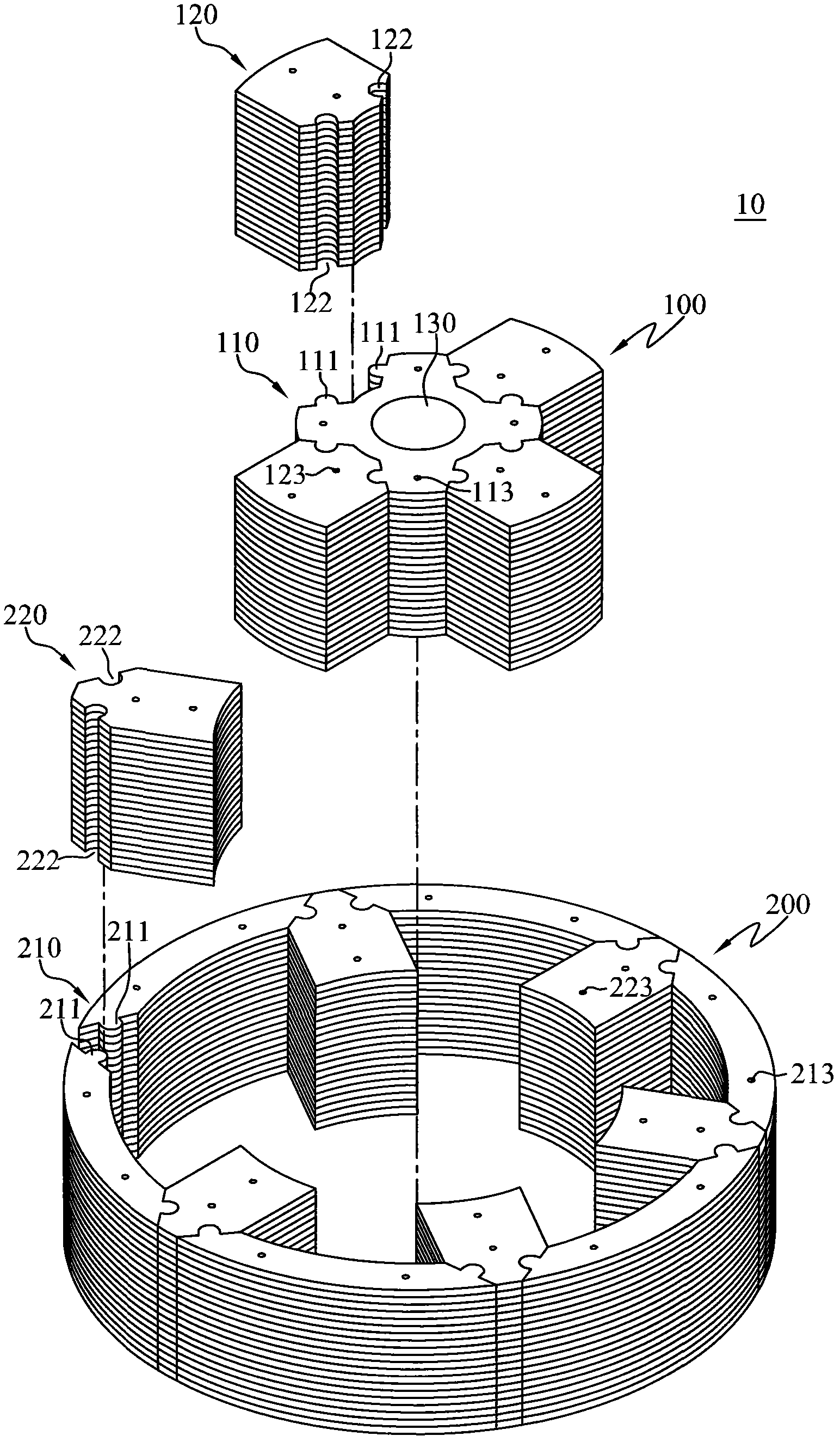

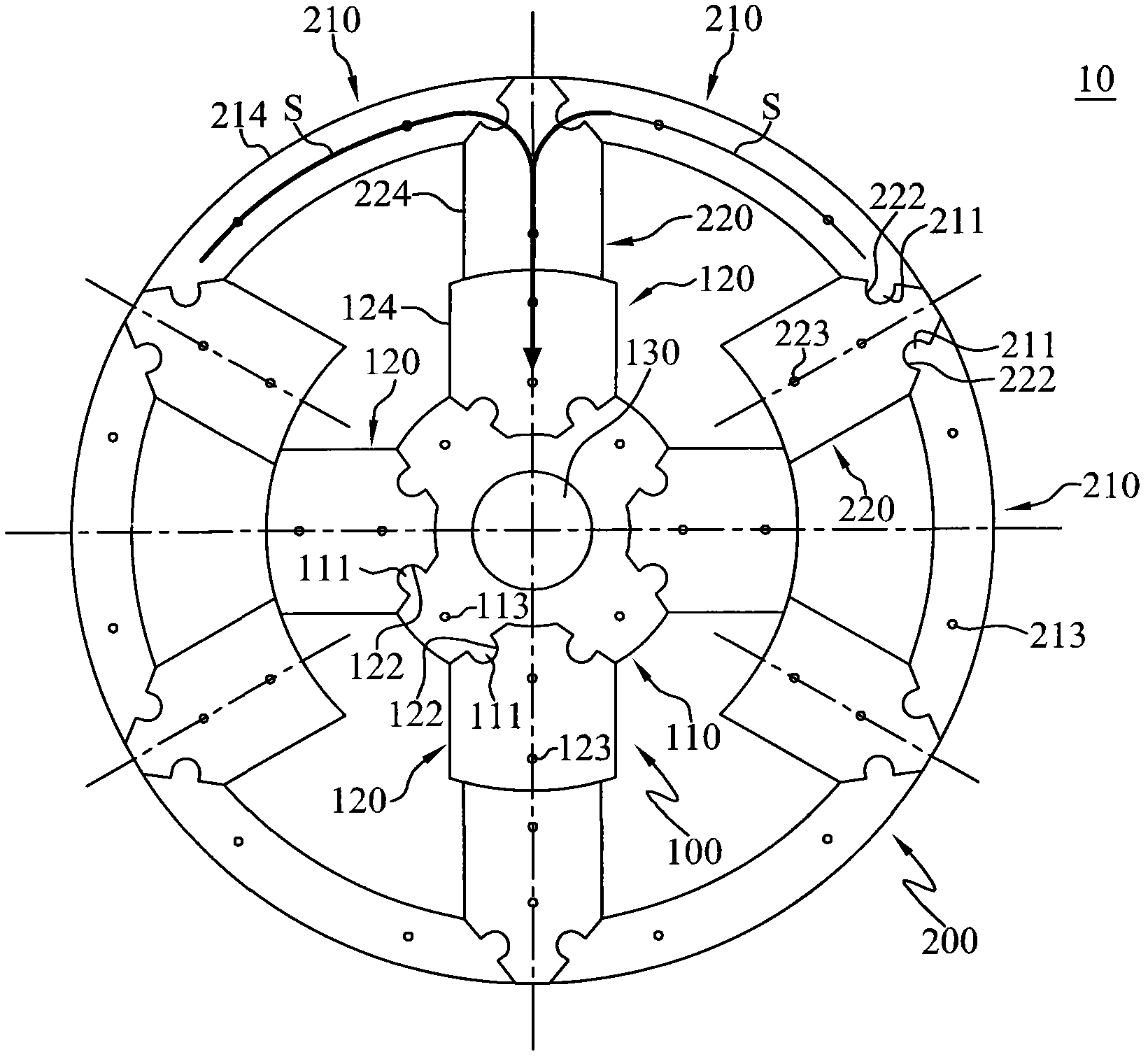

Segmented magneto-conductive structure applied in rotating machines

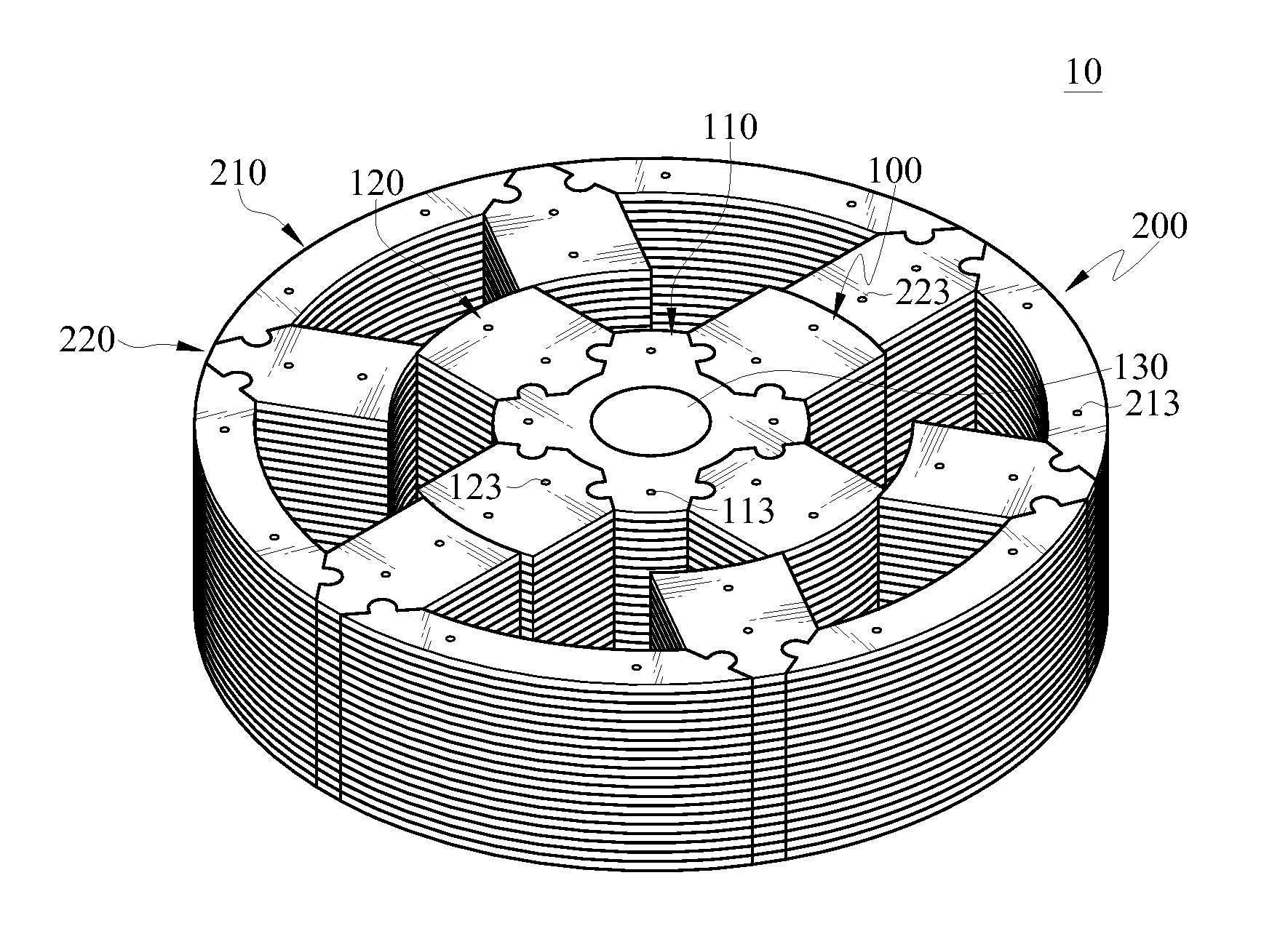

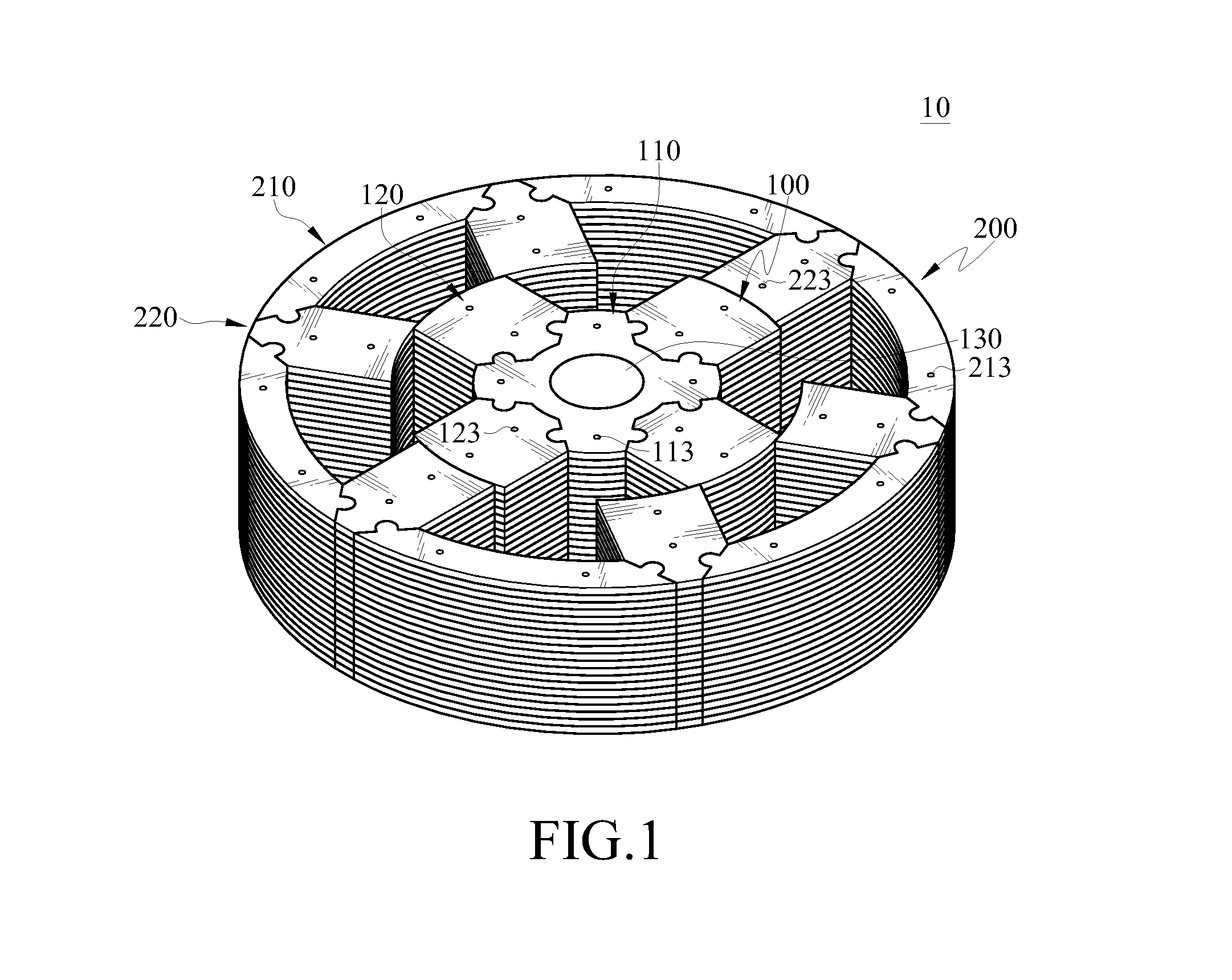

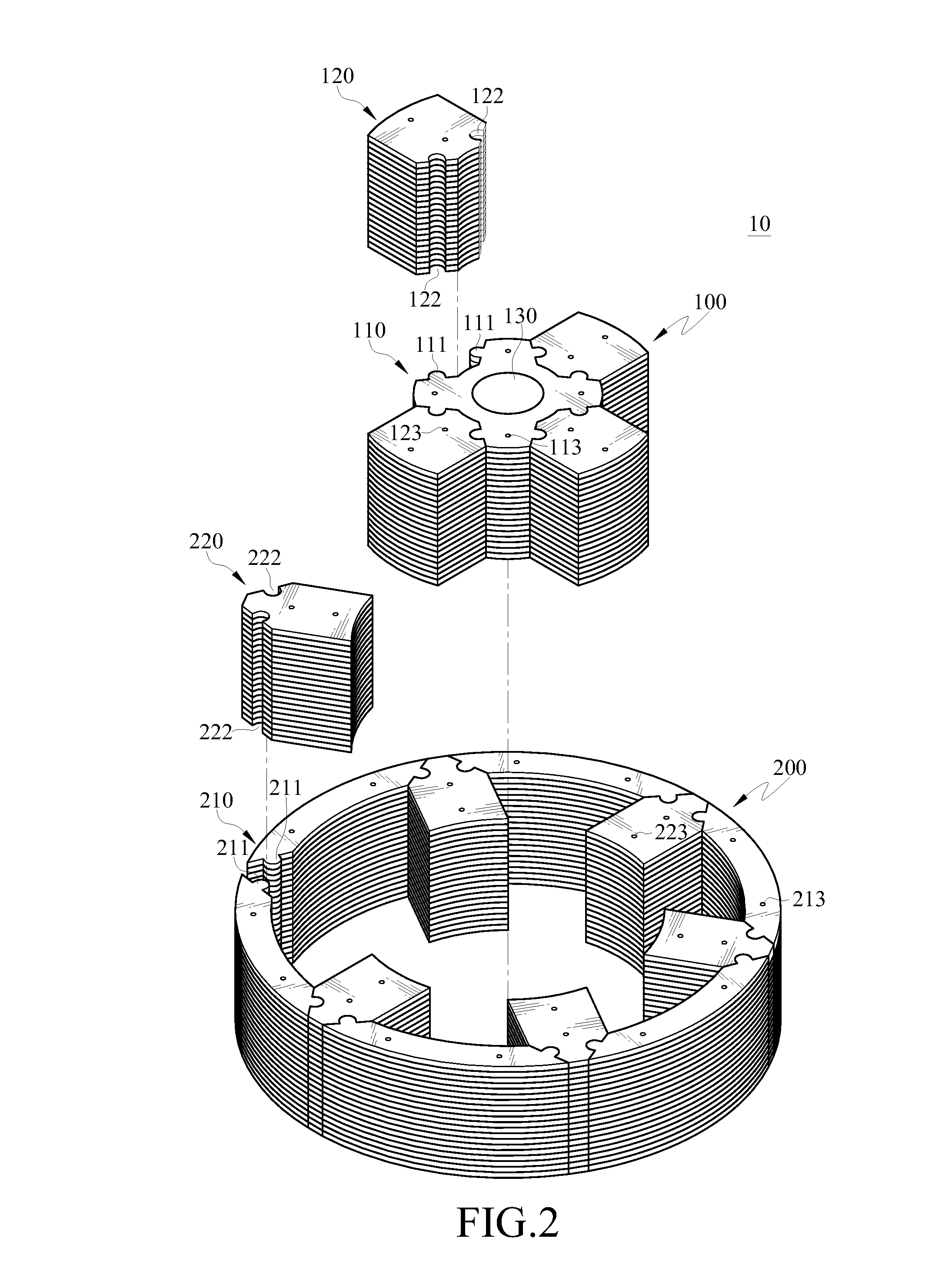

A segmented magneto-conductive structure applied in rotating machines comprises a rotor assembly and a stator assembly. The rotor assembly includes a rotor yoke component and a plurality of rotor teeth components. The rotor yoke component is made of non-oriented silicon steel. The rotor teeth components are made of grain-oriented silicon steel. The stator assembly includes a plurality of stator yoke components and a plurality of stator teeth components. The stator yoke components and the stator teeth components are made of grain-oriented silicon steel. Thereby, an operational efficiency of a motor applying the segmented magneto-conductive structure is enhanced.

Owner:IND TECH RES INST

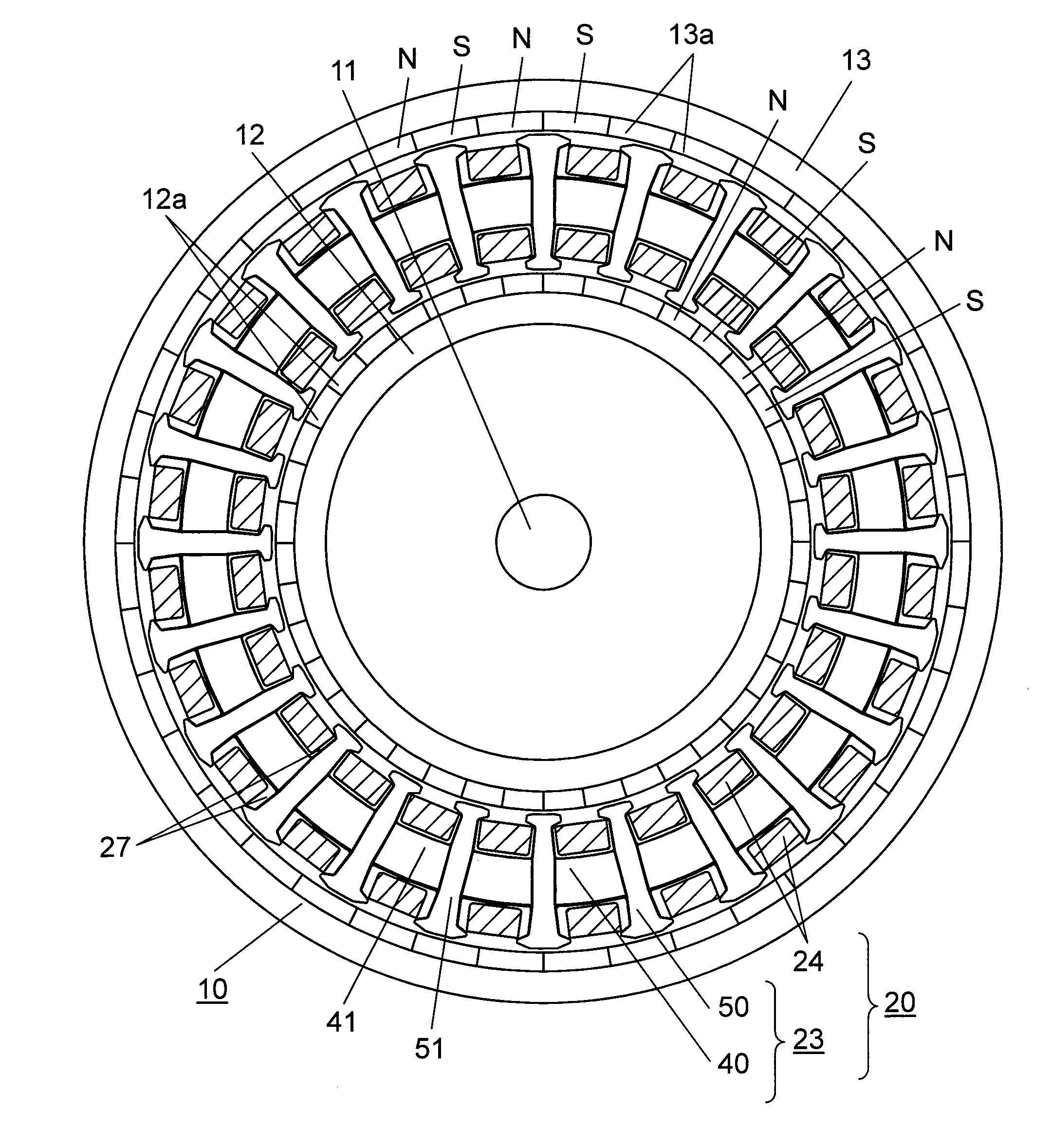

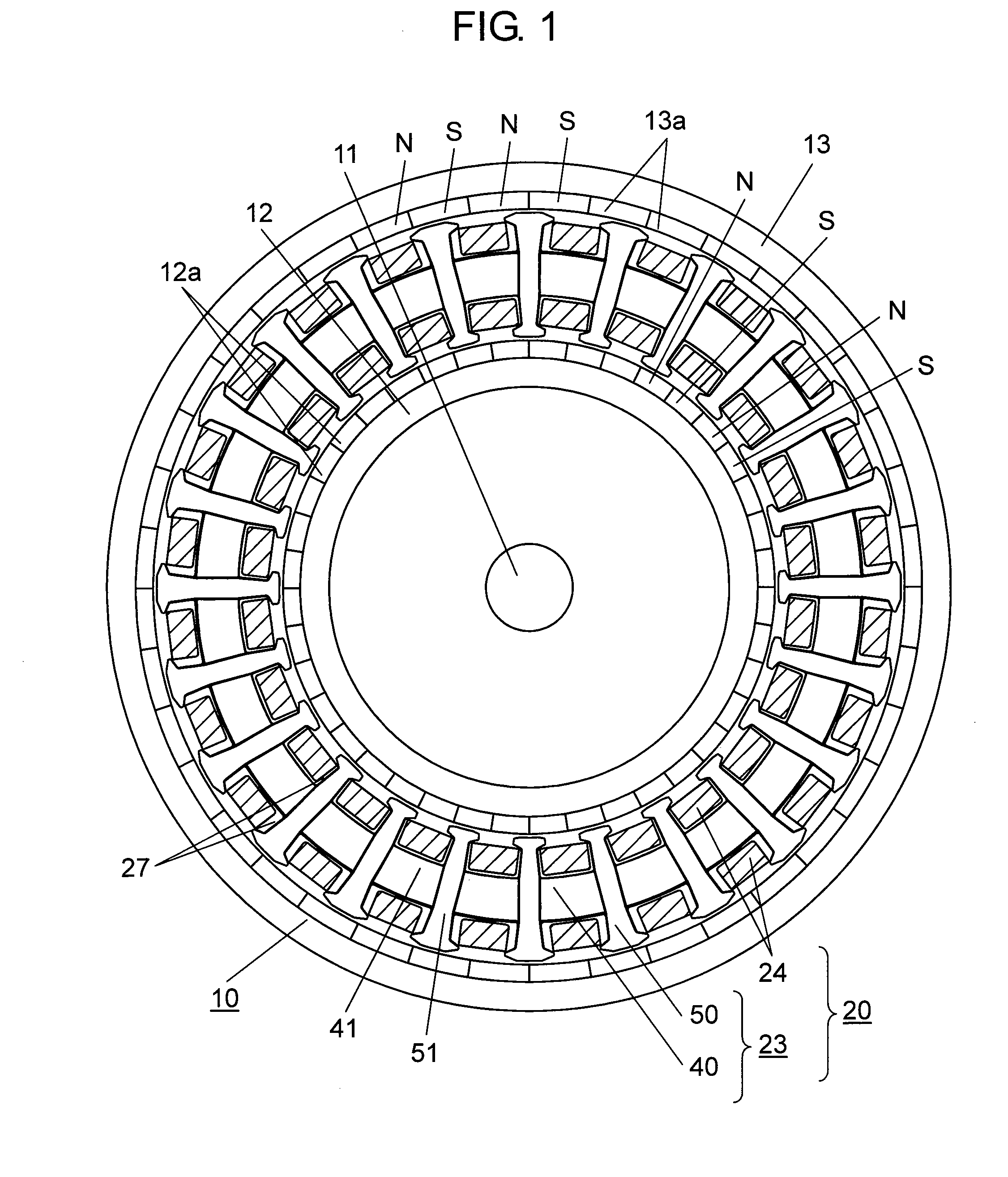

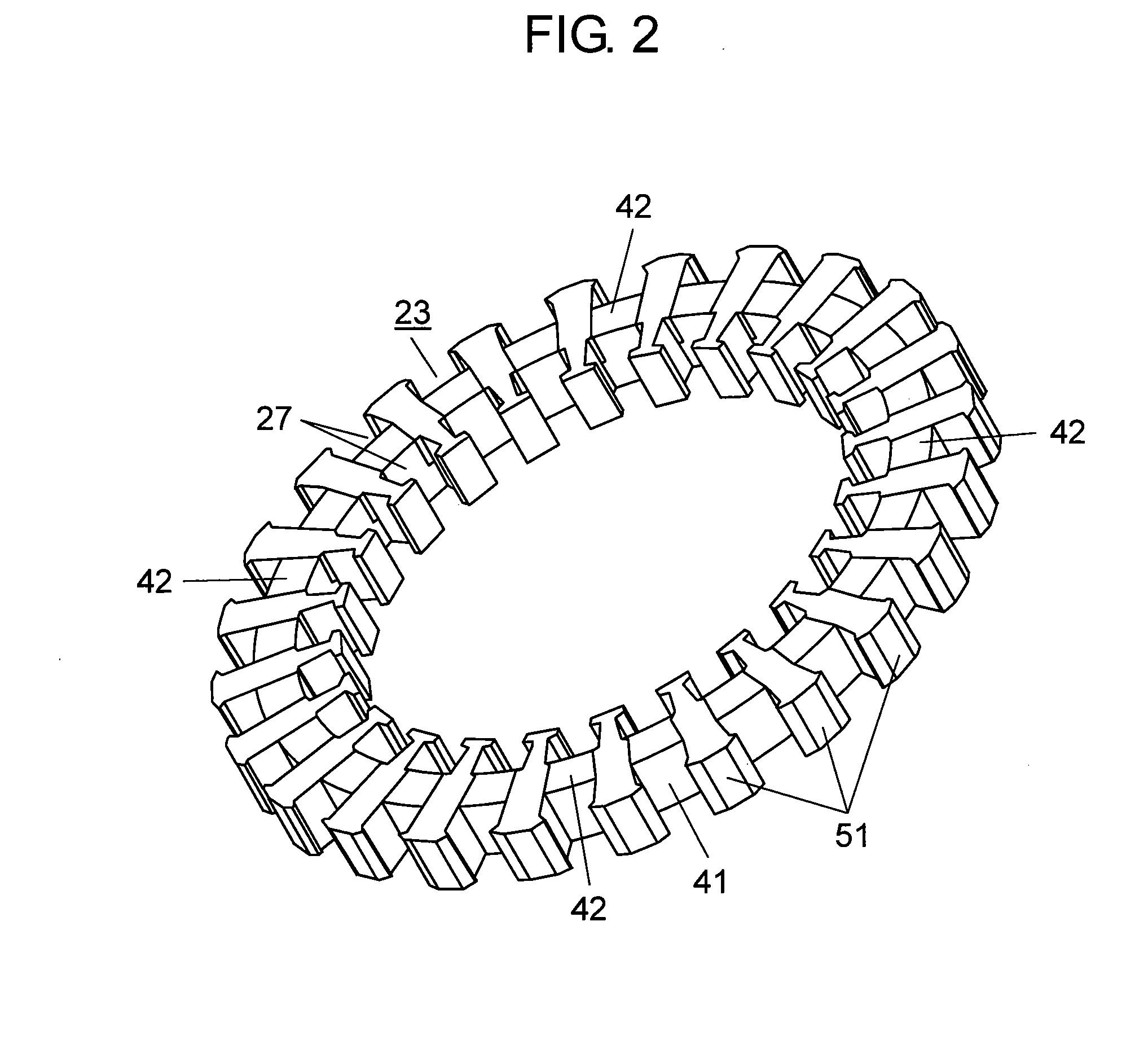

Dual-rotor motor and method of manufacturing the same

InactiveUS20110187222A1Keep the weight balancedEliminate needMagnetic circuit stationary partsManufacturing dynamo-electric machinesEngineeringTooth Component

A dual-rotor motor provided with a stator having a stator core including a yoke, a plurality of teeth and a coil wound around the stator core, an inner rotor and an outer rotor, wherein the stator core includes an annular yoke component forming the yoke, and a plurality of tooth components forming the teeth. The stator core is made by fitting the tooth components individually into the annular yoke component in a manner that one ends of the tooth components protrude from the inner peripheral side of the annular yoke component and the other ends protrude from the outer peripheral side of the annular yoke component.

Owner:PANASONIC CORP

Carburization-like overloading tooth component tooth surface laser cladding powder material and repairing method thereof

InactiveCN101100746AImprove repair qualityImprove performanceMetallic material coating processesLaser beam welding apparatusLaser power densityAlloy

A process for laser powder-melting onto the surfaces of the teeth parts that are of heavily loaded cemented steel to be repaired is disclosed herewith. The powder of grains = (-140-+260 mesh) comprises (mass%): C 0.80-1.10, Mn 7.50-9.00, Cr 0.90-1.30, Mo 0.20-0.35, B 2.00-3.50, Si 2.50-3.50, and balanced with Fe with impurities of P not more than 0.06 and S not more than 0.04. Laser power density is equal to 1.0 X 108W-109W / m2 per unit of time. The said powder has good re-melting property, self-enhancing and fatigue-resistance performances, so that it can be used to repair worn gears.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

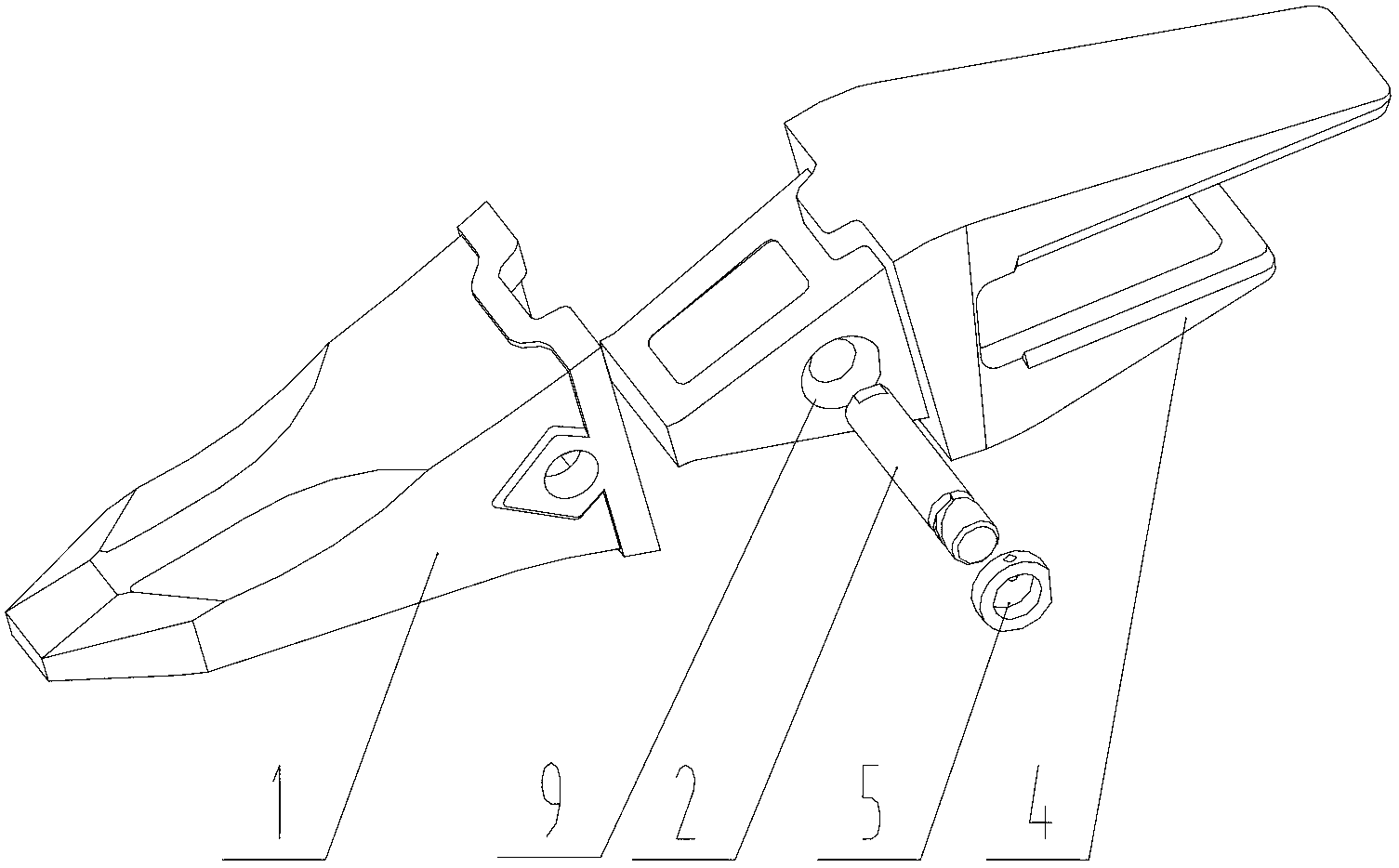

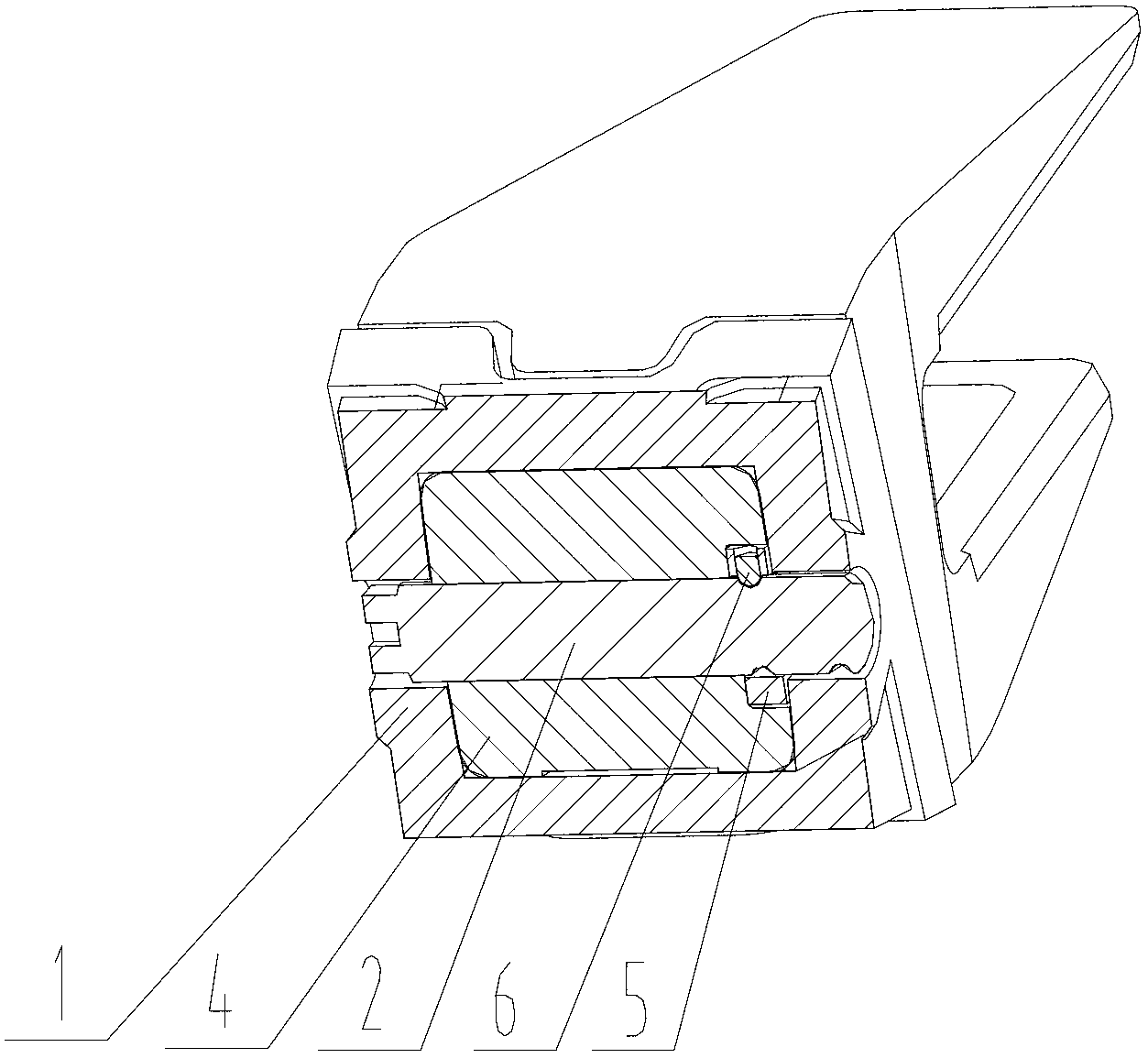

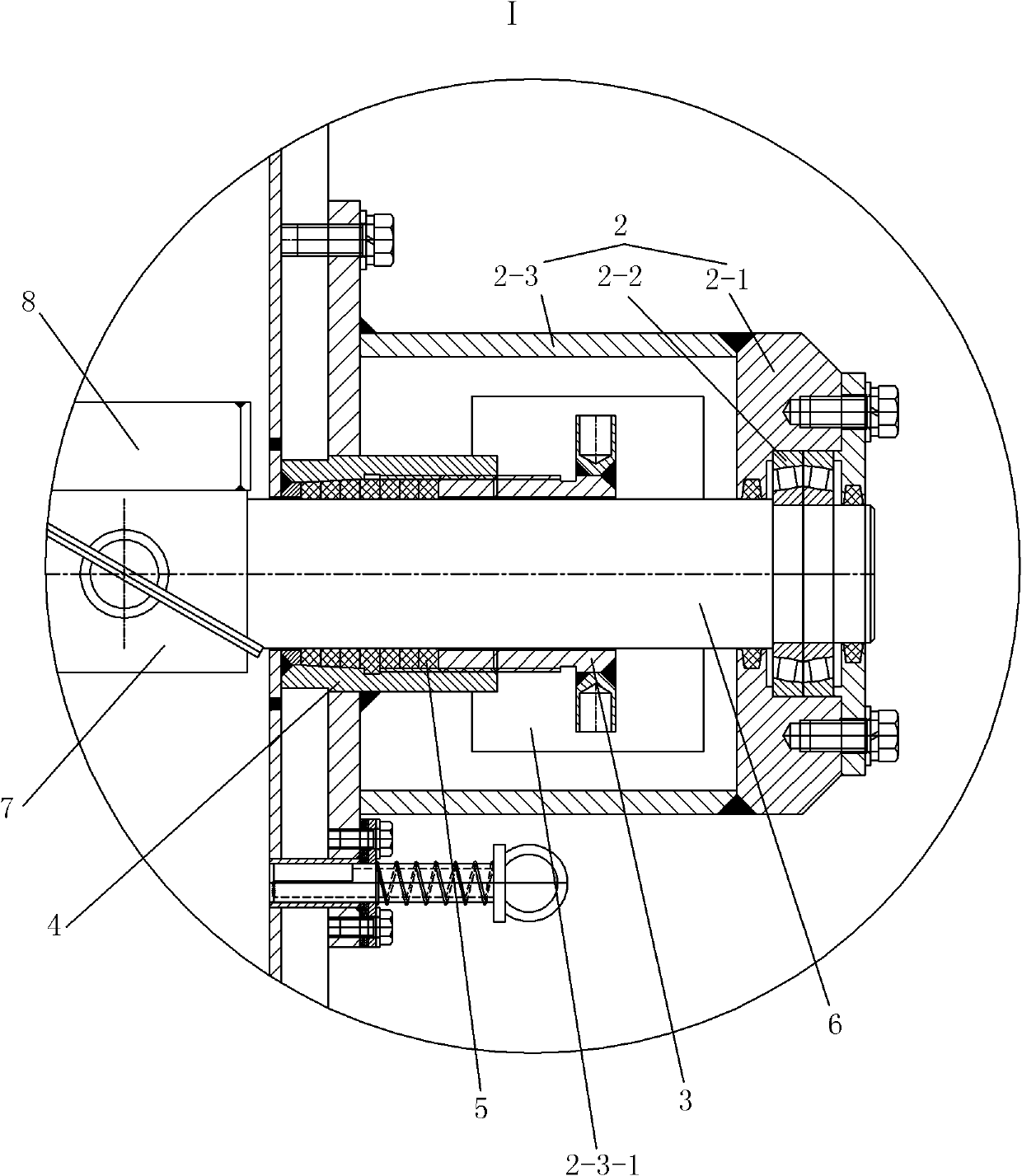

Tooth pin, excavation tooth component and excavating machine

InactiveCN102704529AFirmly connectedEasy to disassemble and installSoil-shifting machines/dredgersEngineeringWear resistance

The invention discloses a tooth pin, an excavation tooth component and an excavating machine, wherein the excavation tooth component comprises a bucket tooth, a toothholder and a connecting component; the bucket tooth and the toothholder are connected through the connecting component; the connecting component comprises the tooth pin and a block pin; pin holes that can accommodate the tooth pin are formed on the bucket tooth and the toothholder; a clamping groove and a guide groove are formed on the tooth pin; the clamping groove extends in the circumferential direction of the tooth pin; the guide groove integrally extends in the axial direction of the tooth pin from the clamping groove to one end of the tooth pin; the block pin is arranged on the toothholder; and the block pin is matched with the clamping groove so as to limit the axial movement of the tooth pin. The clamping groove and the guide groove both extending in the circumferential direction of the tooth pin are formed on the tooth pin, the block pin is arranged on the toothholder, the clamping groove formed on the tooth pin and the block pin can enter matching positions conveniently due to the adoption of the guide groove, the clamping groove and the block pin are matched so as to achieve the firm connection of the bucket tooth and the toothholder, the wearing resistance of the tooth pin is improved, and the bucket tooth and the toothholder can be disassembled and mounted conveniently.

Owner:SANY HEAVY MACHINERY

Telescopic positioning device and application thereof

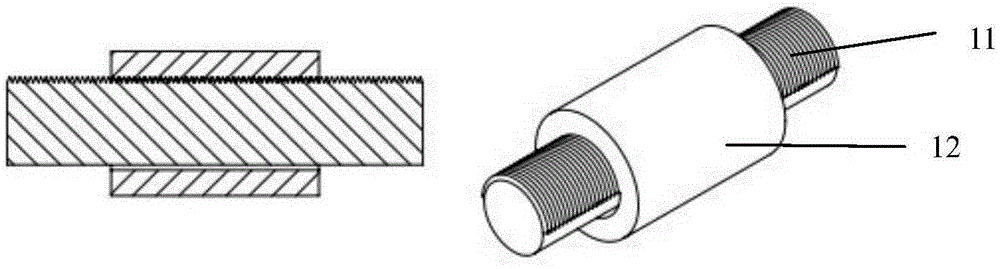

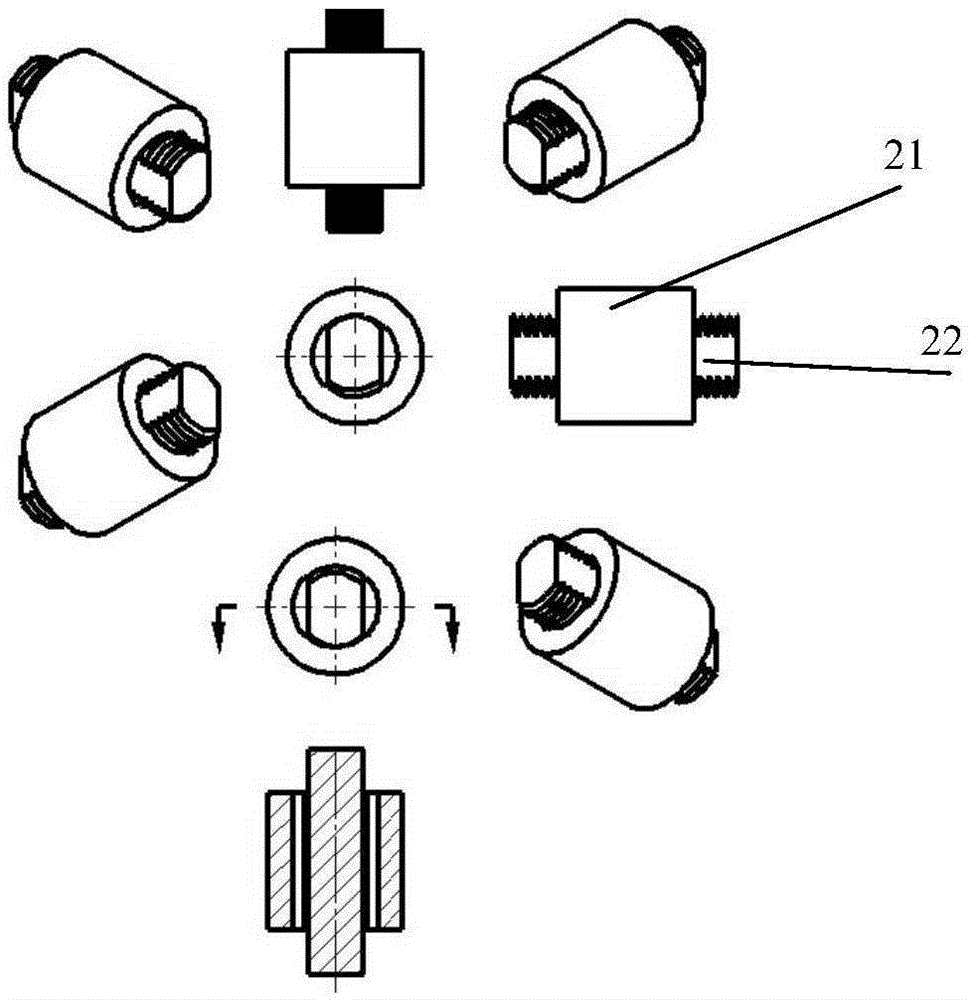

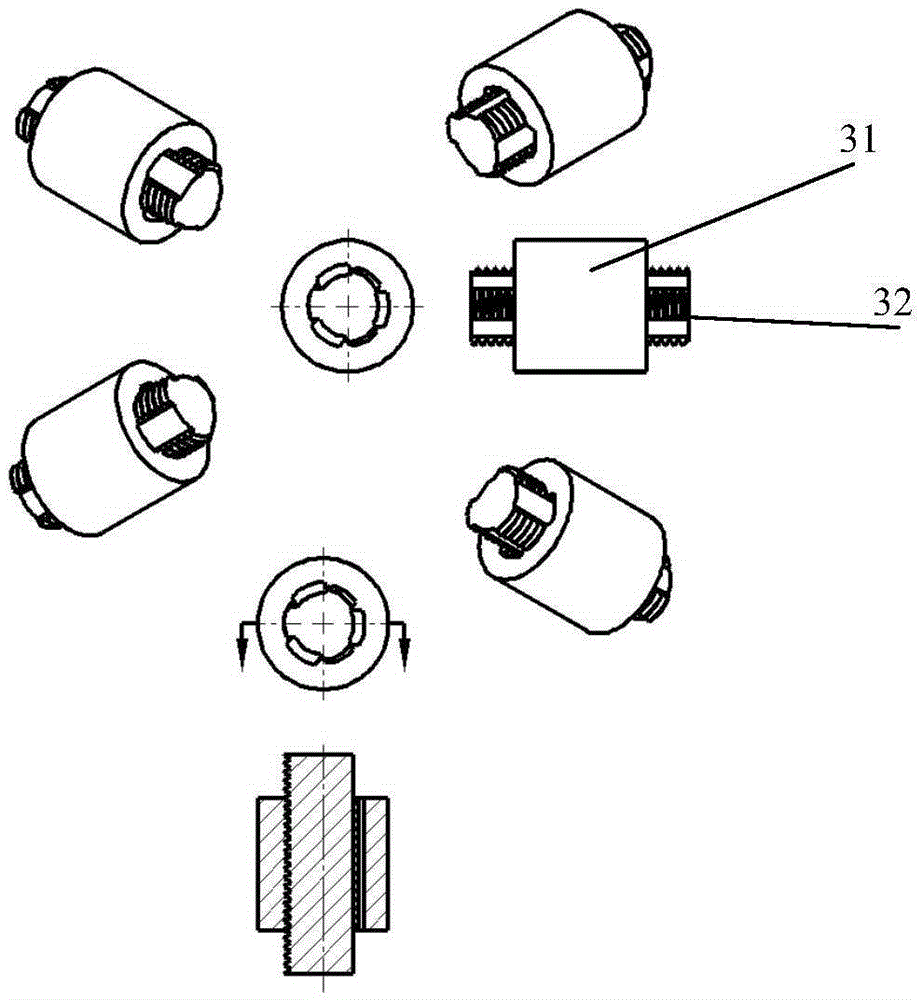

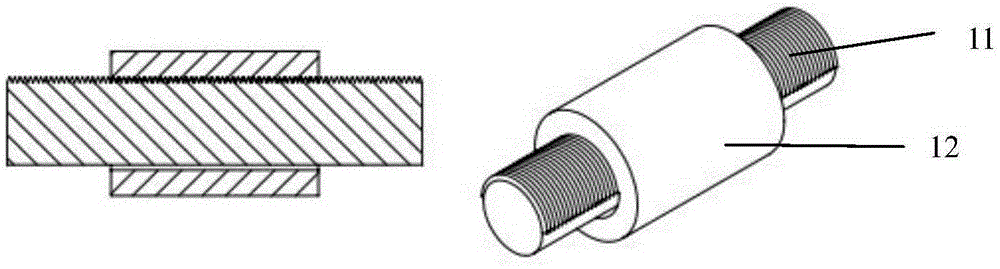

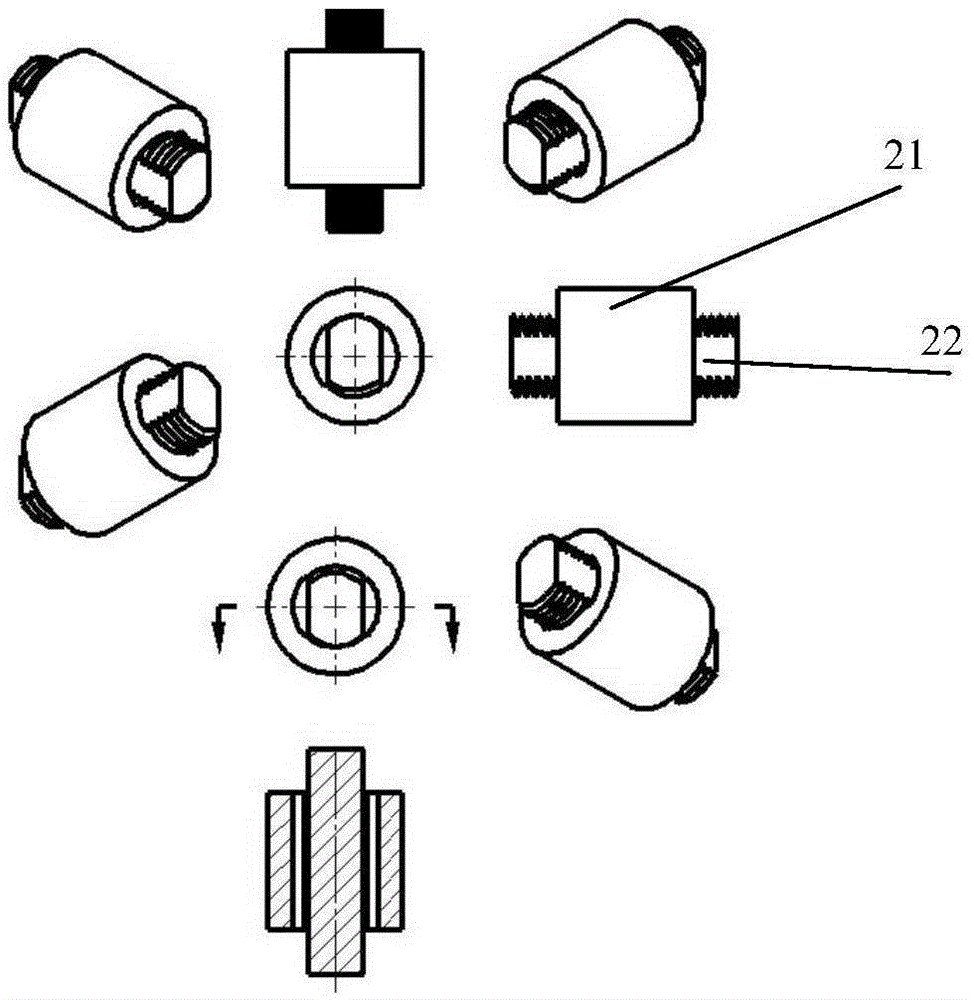

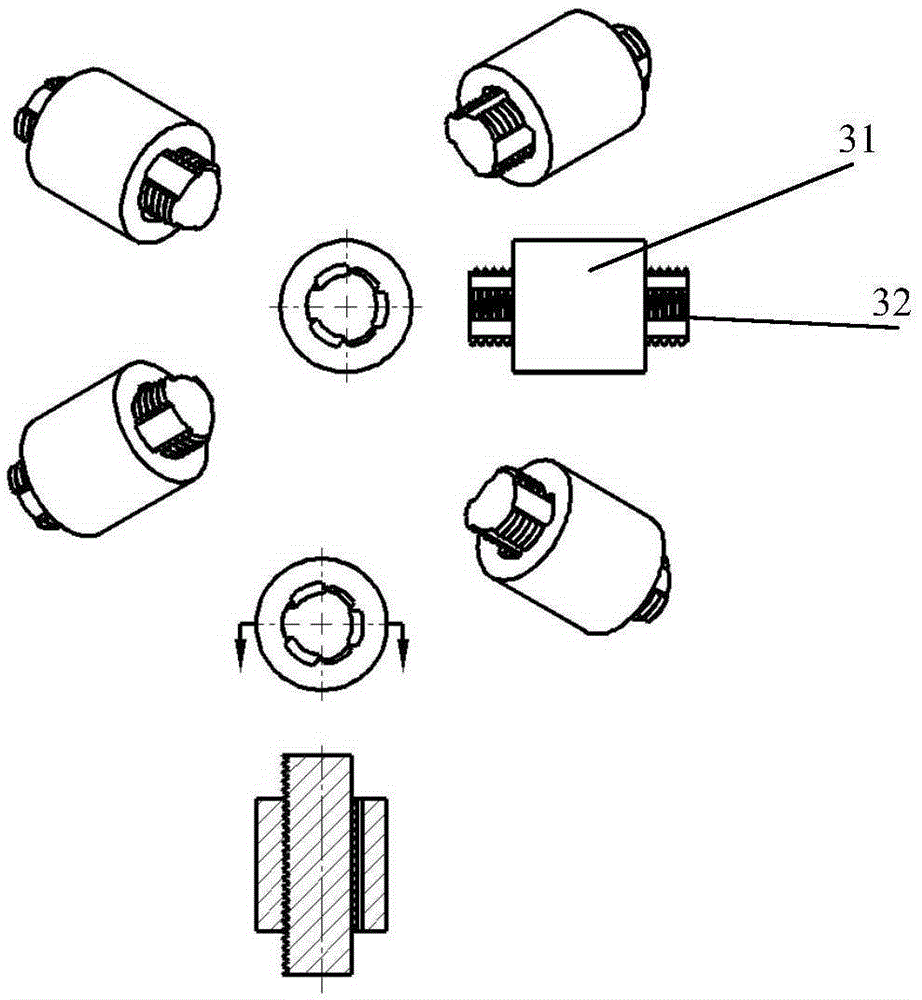

The invention discloses a telescopic positioning device and application thereof and belongs to the technical field of telescopic connection. Engaging positioning or separation telescopic type connection is achieved through convex and concave engaging mechanisms which are evenly and continuously distributed; each convex and concave engaging mechanism comprises a convex tooth component and a groove component engaged with or disengaged from the convex tooth component; the engaging portion of each convex tooth component is provided with at least one partition groove in the cross section perpendicular to the relative displacement direction so that the two parts can stretch out and draw back and can be positioned; the convex and concave engaging mechanisms comprise the rotating engaging mechanism of non-complete round threads, the wedge expansion engaging mechanism and the rotating engaging mechanism of a non-circular cross section cam shaft; and the rotating engaging mechanism of the non-complete round threads can be applied to functional mechanisms of lifting and folding position restoration of bike seats or bike handlebars. The telescopic positioning device achieves the fast telescopic adjusting, locking and positioning through the threads or a pawl mechanism. Compared with a similar hydraulic or pneumatic mechanism, the telescopic positioning device is easy to manufacture, low in weight and reliable in performance, and cost is substantially reduced.

Owner:戚善鸣

Excavating tooth component, tooth holder and bucket teeth

ActiveCN101768992AGuaranteed stabilityGuarantee the safety of useSoil-shifting machines/dredgersEngineeringTooth Component

The invention discloses an excavating teeth component, a tooth holder and bucket teeth. The excavating tooth component comprises the tooth holder, the bucket teeth, and a locking piece. The rear part of the bucket teeth is provided with a cavity and the front end of the tooth holder is provided with a tooth holder head. The cavity of the bucket teeth and the tooth holder head are firmly combined together through the locking piece. The upper part of the tooth holder head is provided with a first transition connecting surface, a first matching surface and a third matching surface, and the lower part of the tooth holder head is provided with a second transition connecting surface, a second matching surface and a fourth matching surface. The first matching surface and the third matching surface are connected through the first transition connecting surface, and the second matching surface and the fourth matching surface are connected through the second transition connecting surface. The first matching surface and the second matching surface form a predetermined angle with a central axis of the tooth holder head respectively, and the third matching surface and the fourth matching surface are parallel to the central axis of the tooth holder head respectively. An inner surface of the cavity of the bucket teeth is provided with a plurality of matching surfaces which are contacted with the matching surfaces.

Owner:NINGBO ZHEDONG PRECISION CASTING

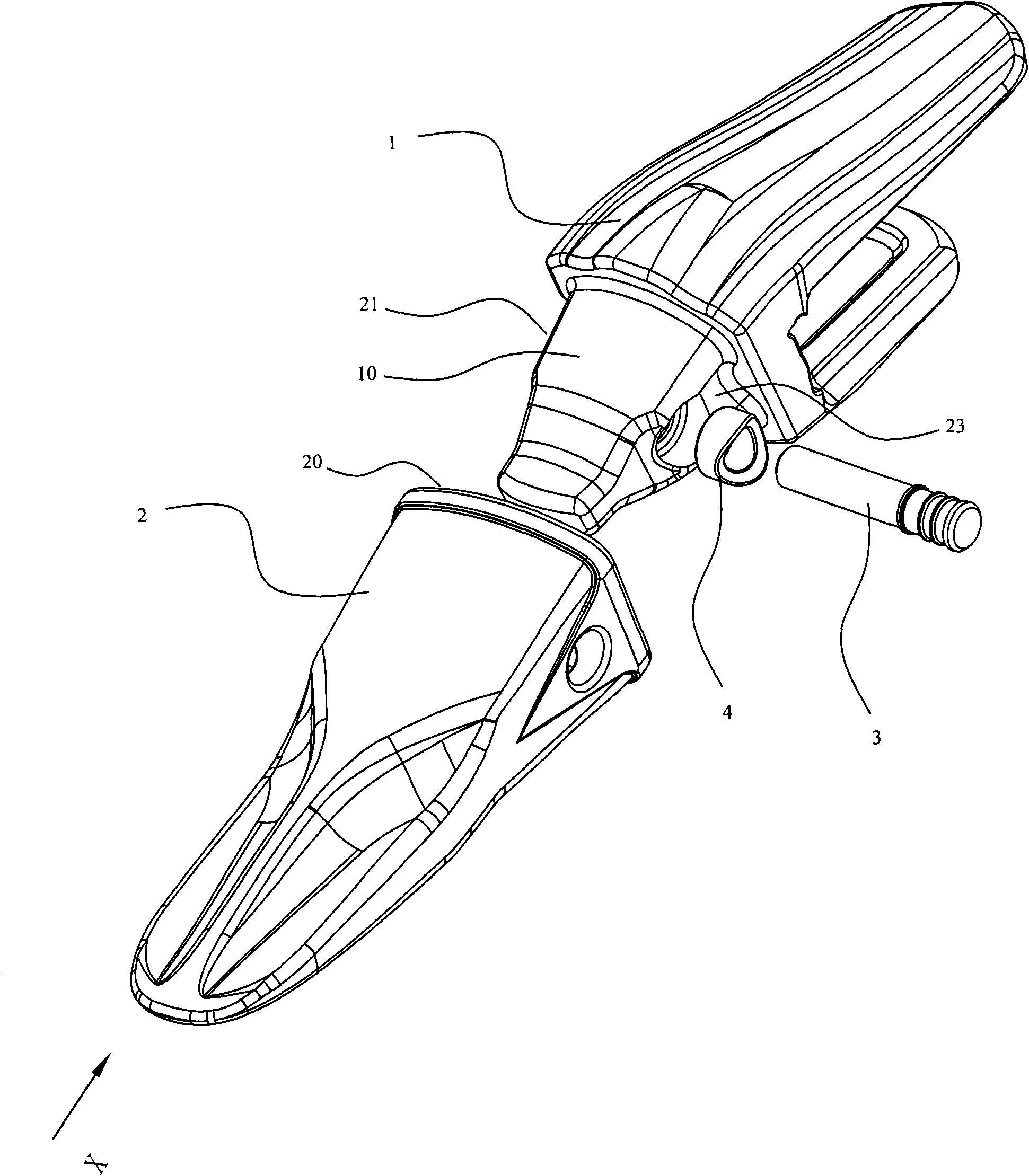

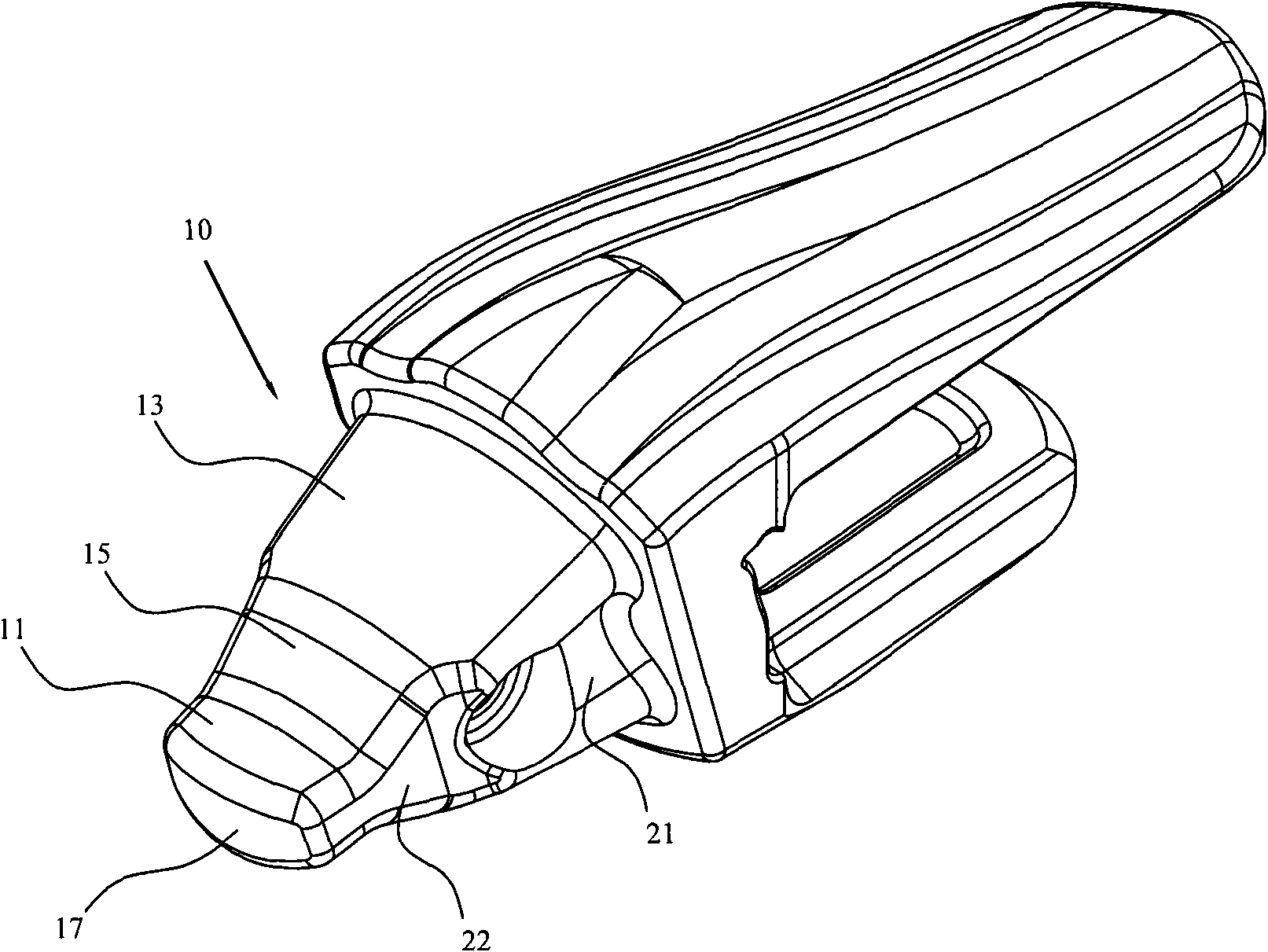

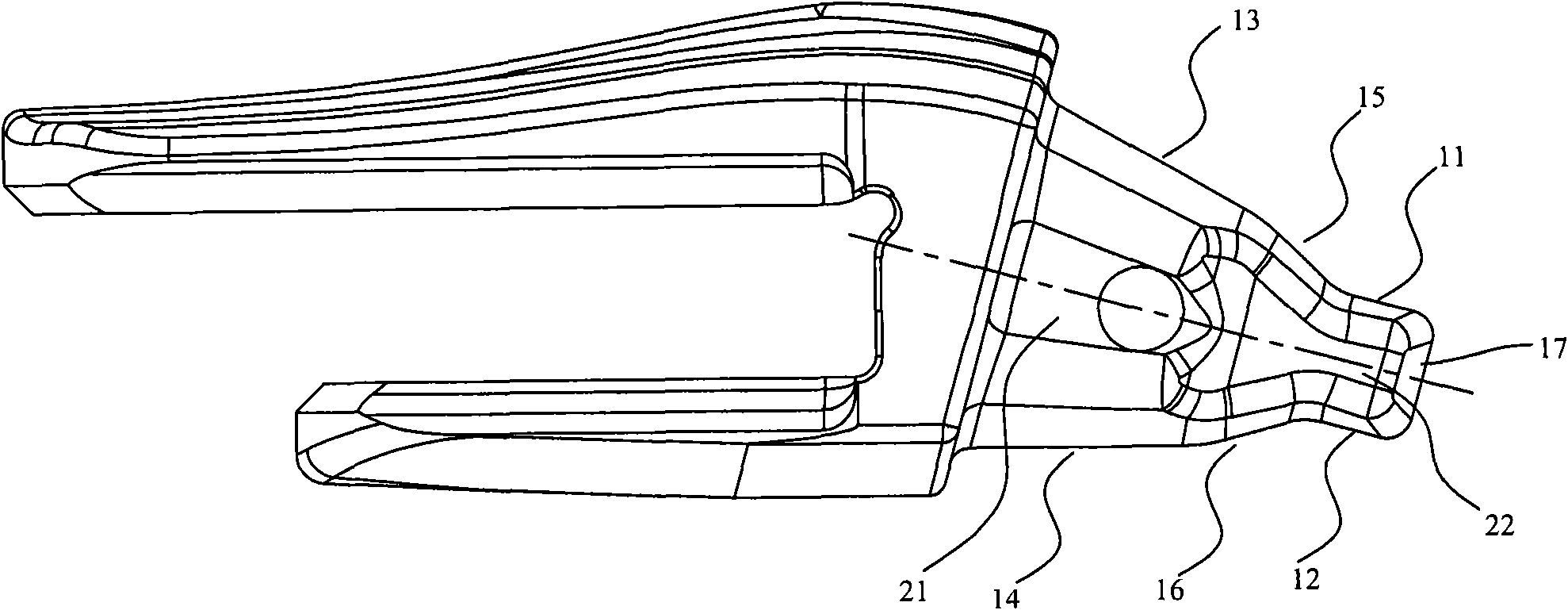

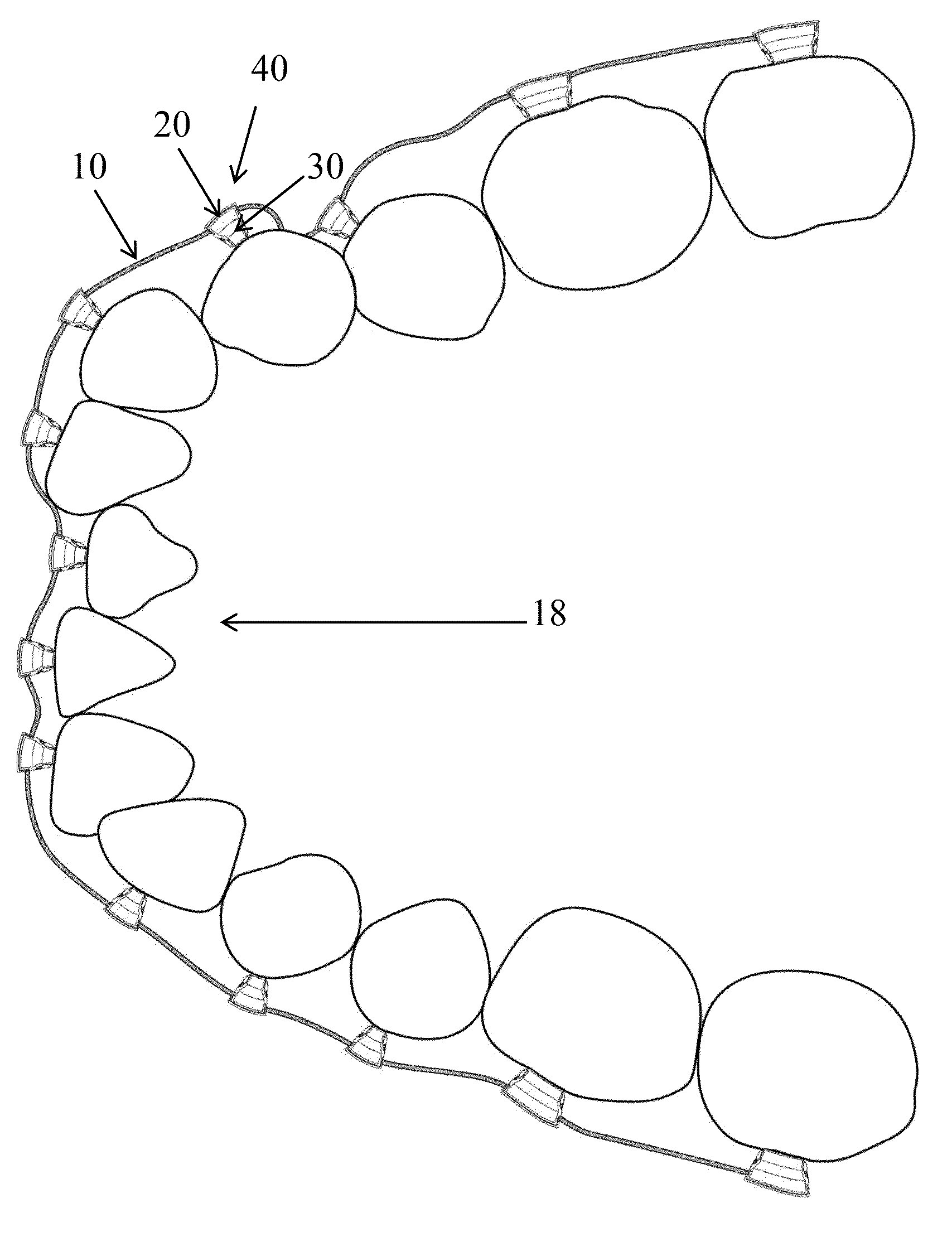

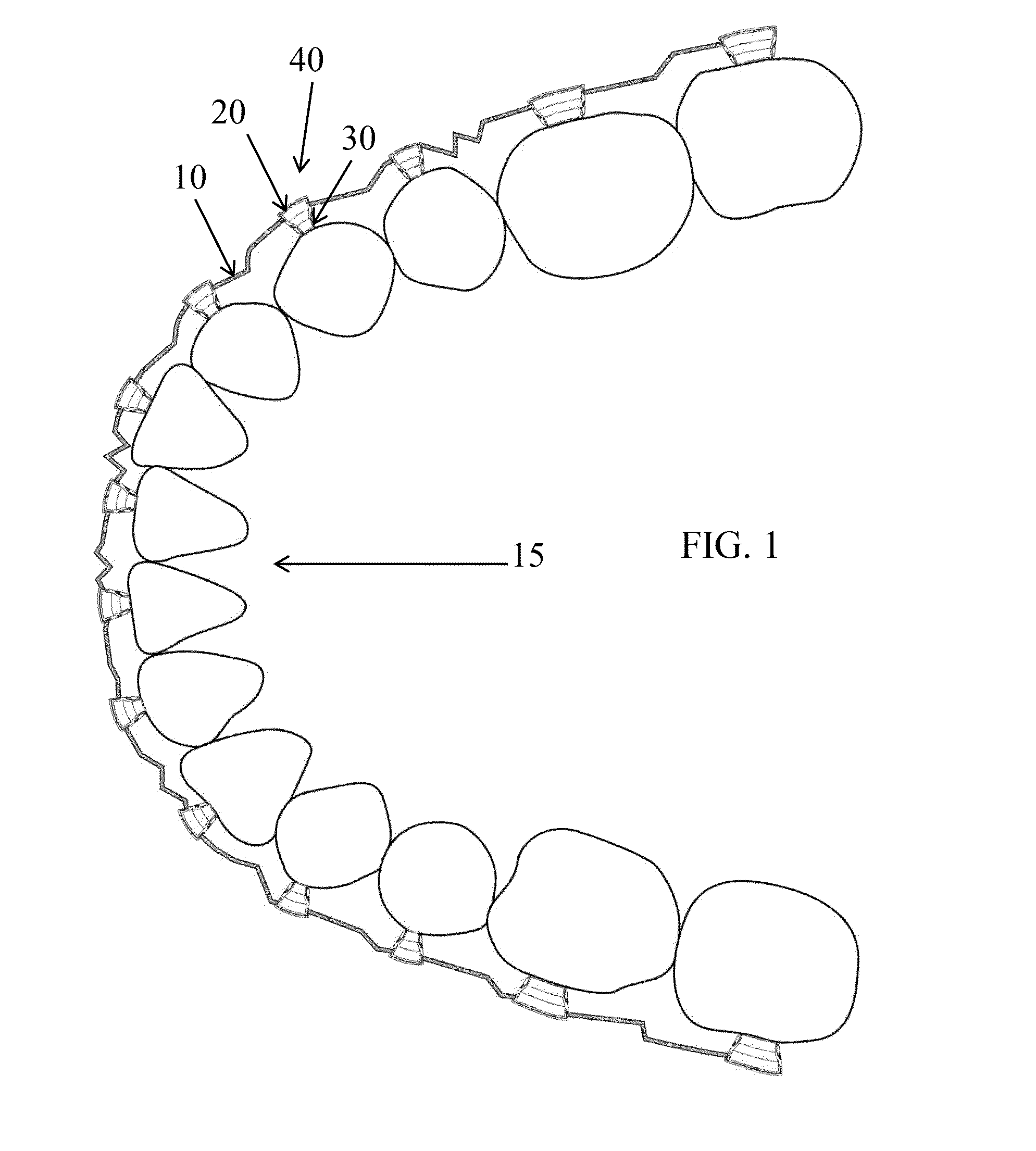

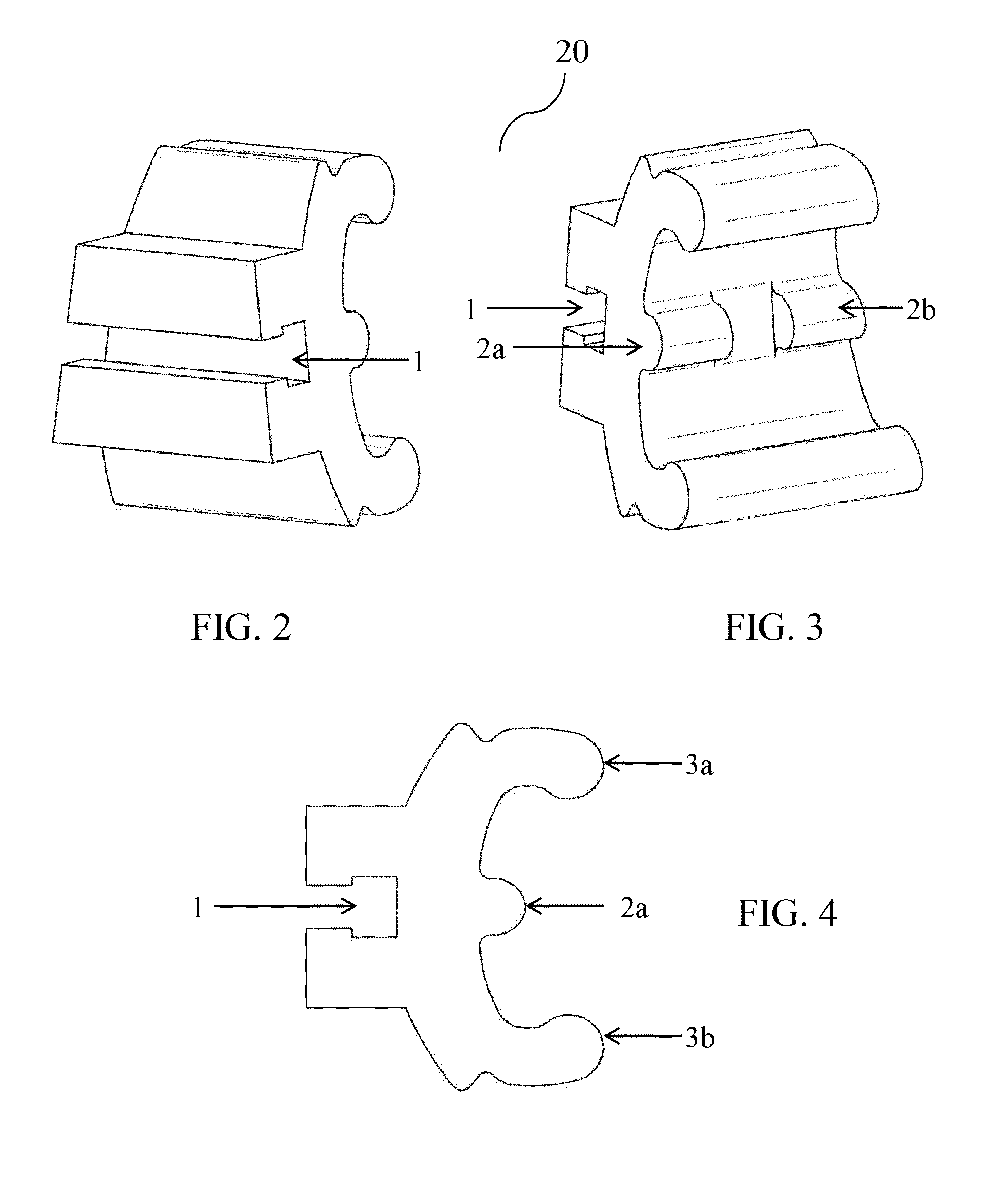

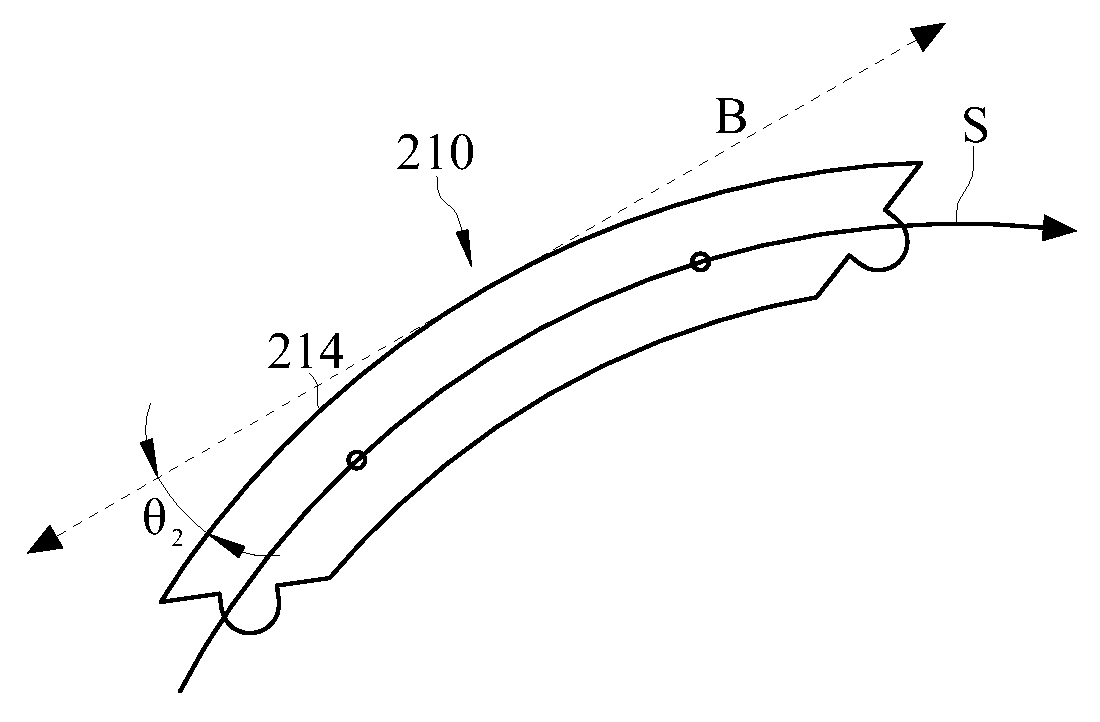

Orthodontic appliance

An orthodontic appliance consisting of a two-component bracket assembly and a customized wire where the tooth component of the bracket assembly is semi-permanently glued to the tooth surface and the wire component of the bracket assembly is securely attached to the customized wire. The customized wire has a configuration that is derived from characteristics of both the mal-aligned and aligned states of the teeth. The series of wire components of the bracket assembly are separated by an inter-bracket distance and are specifically oriented along the customized wire to form the customized wire-bracket device. When the wire component and the tooth component of the bracket assembly are engaged, the alignment of the teeth occurs due to the elastic recoil of the customized wire. The customized wire-bracket device is completely detachable and re-attachable to the tooth component of the bracket assembly as are the two components of the bracket assembly.

Owner:GAUTAM PAWAN

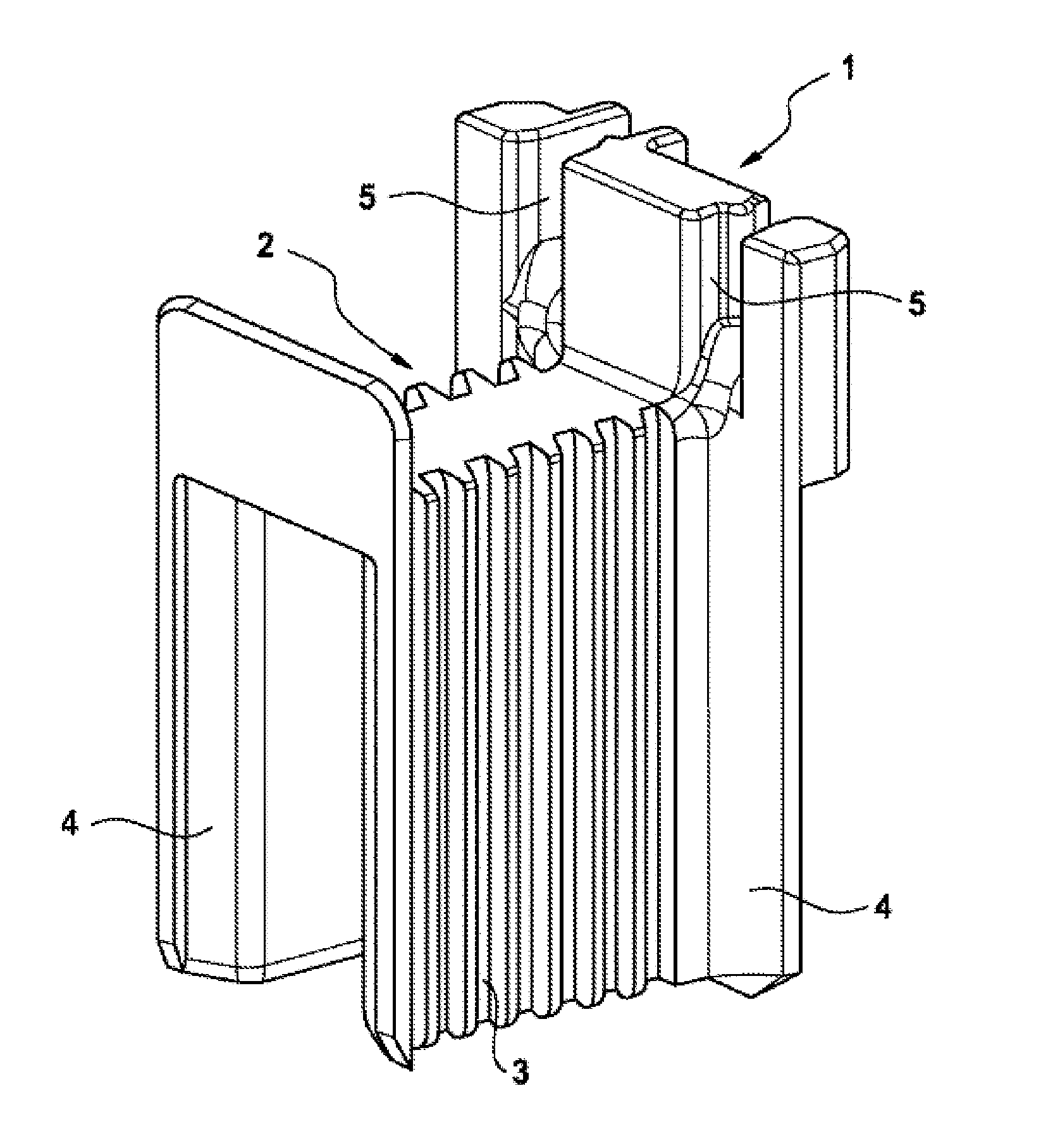

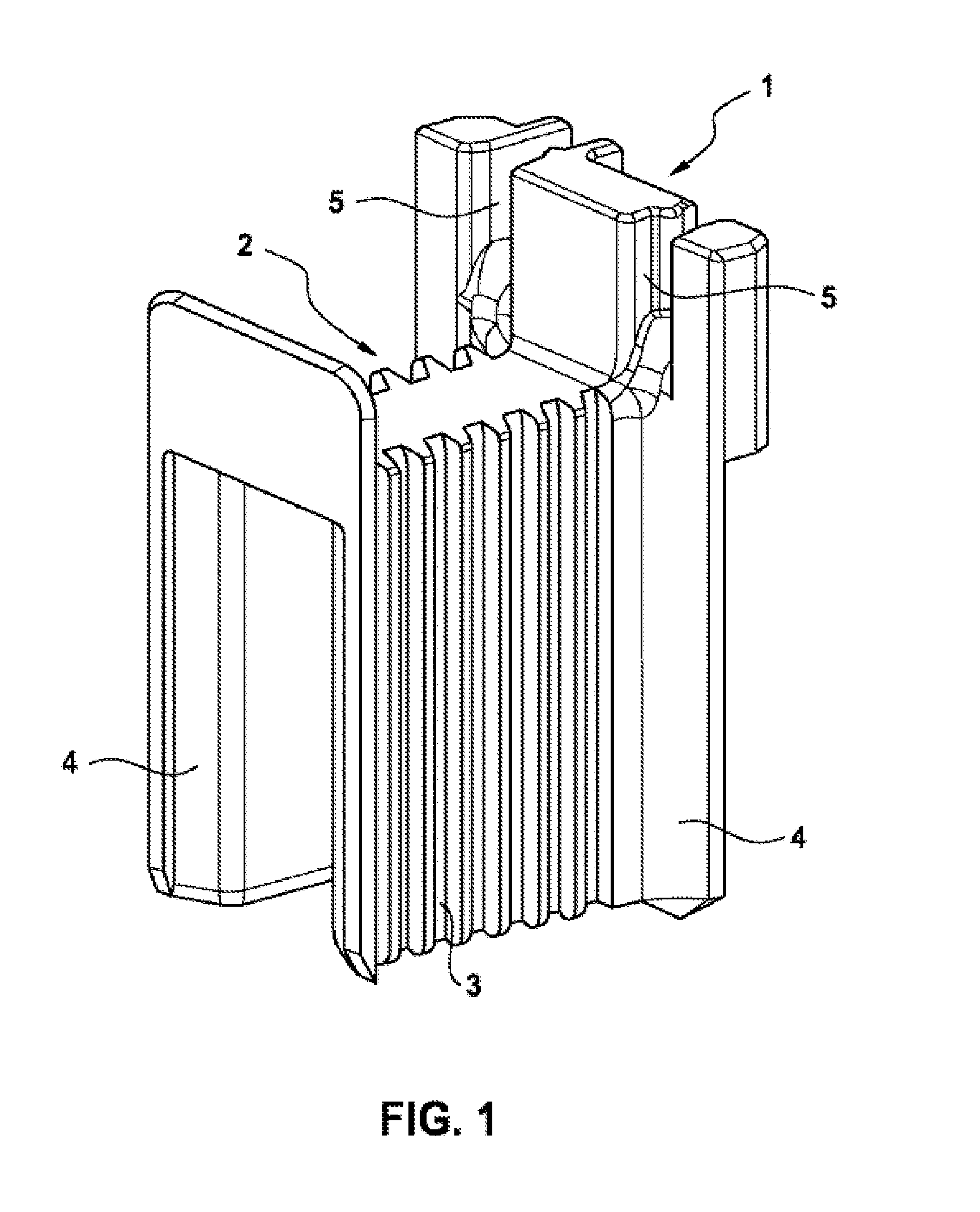

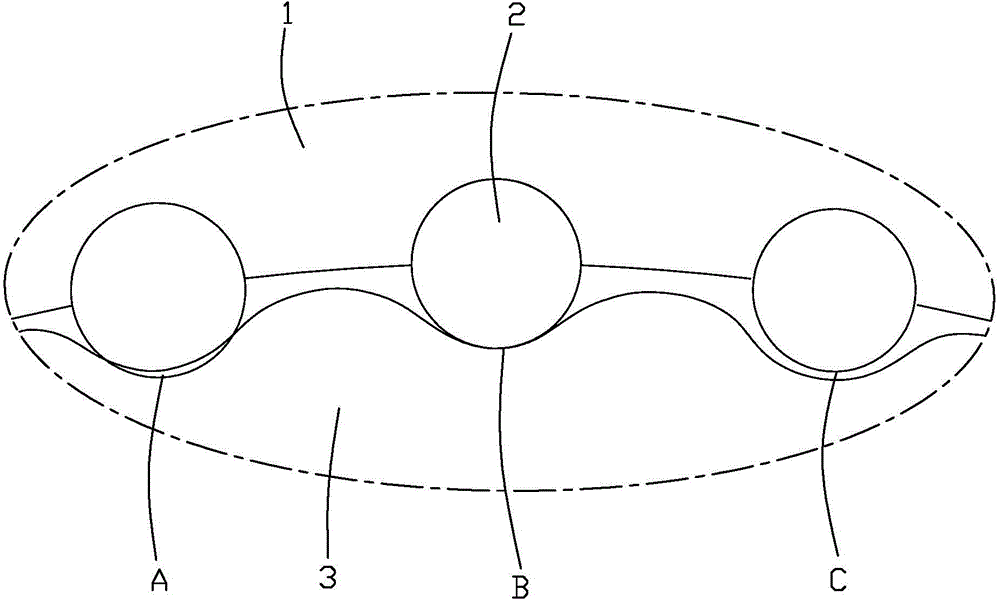

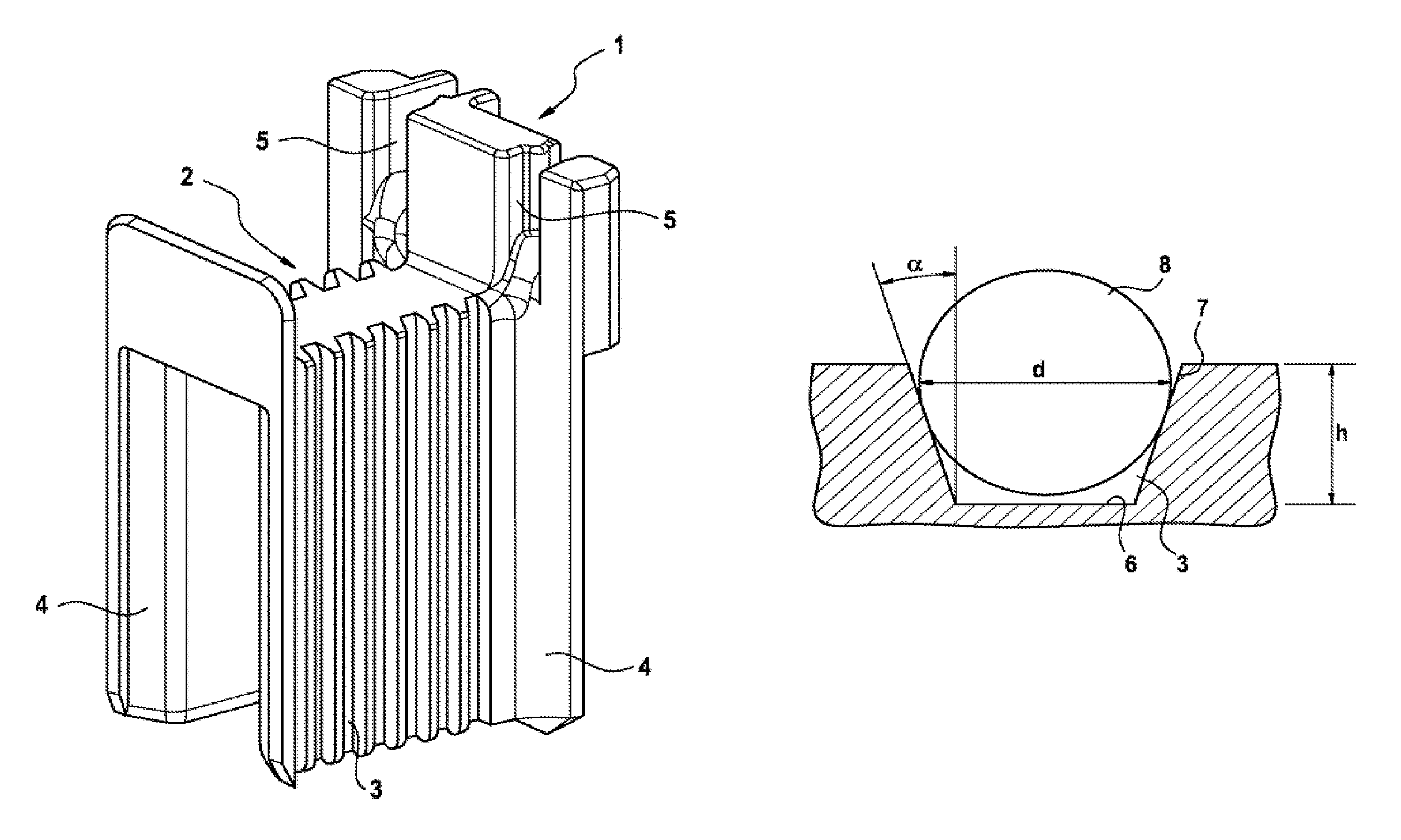

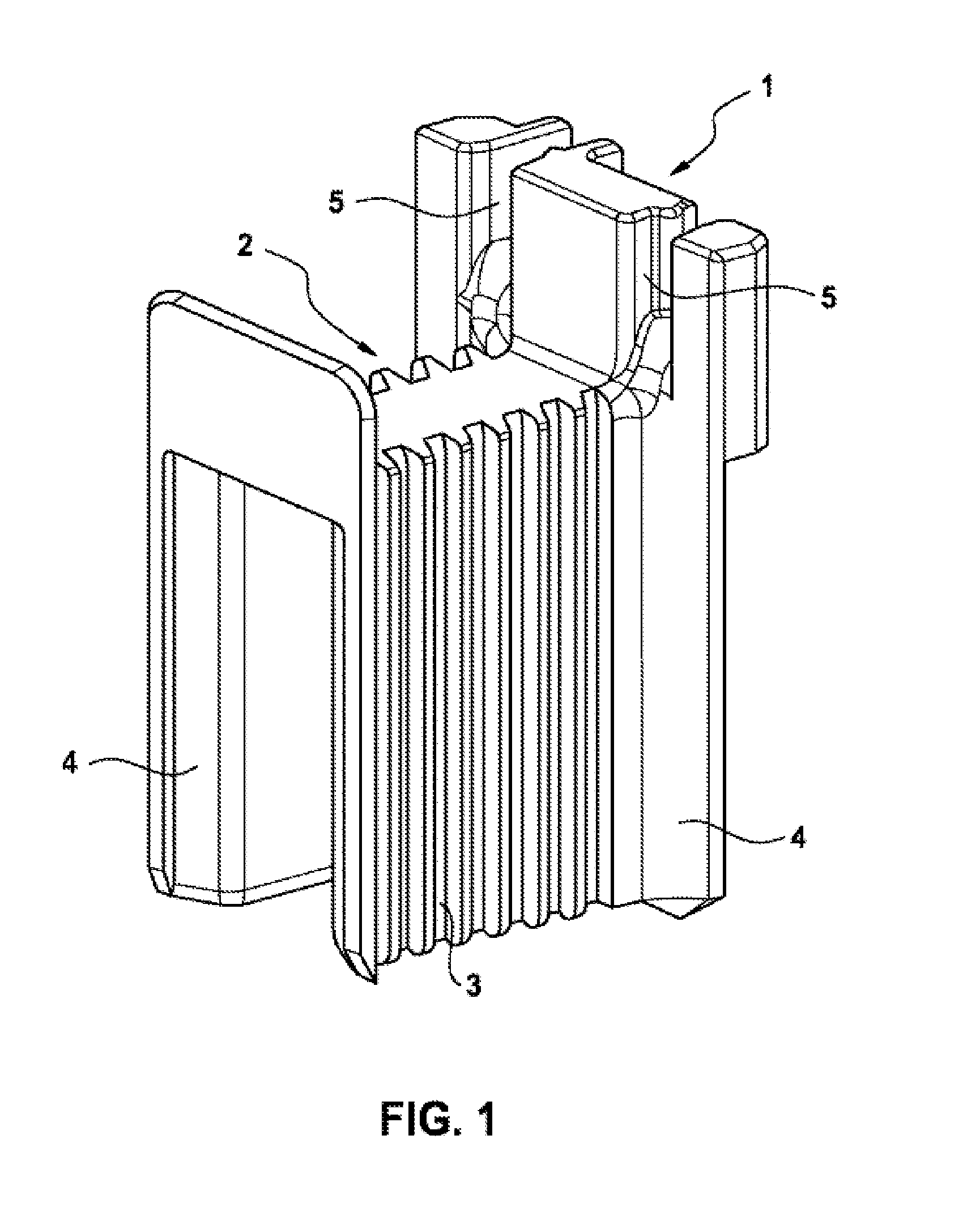

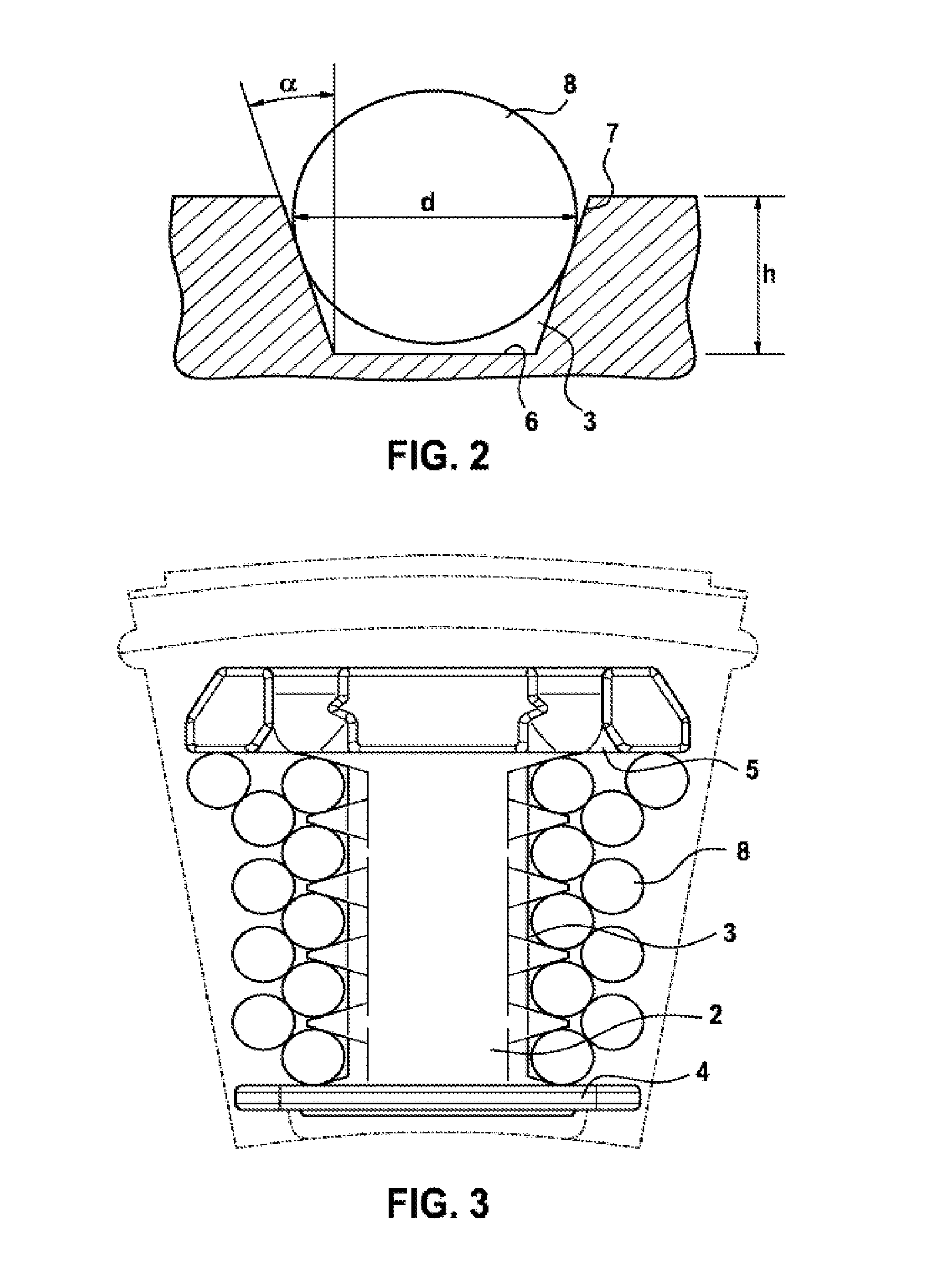

Winding carrier for use in an electrical machine and winding arrangement

ActiveUS20140327336A1Easy to manufactureImprove cooling effectWindings insulation shape/form/constructionElectric machineEngineering

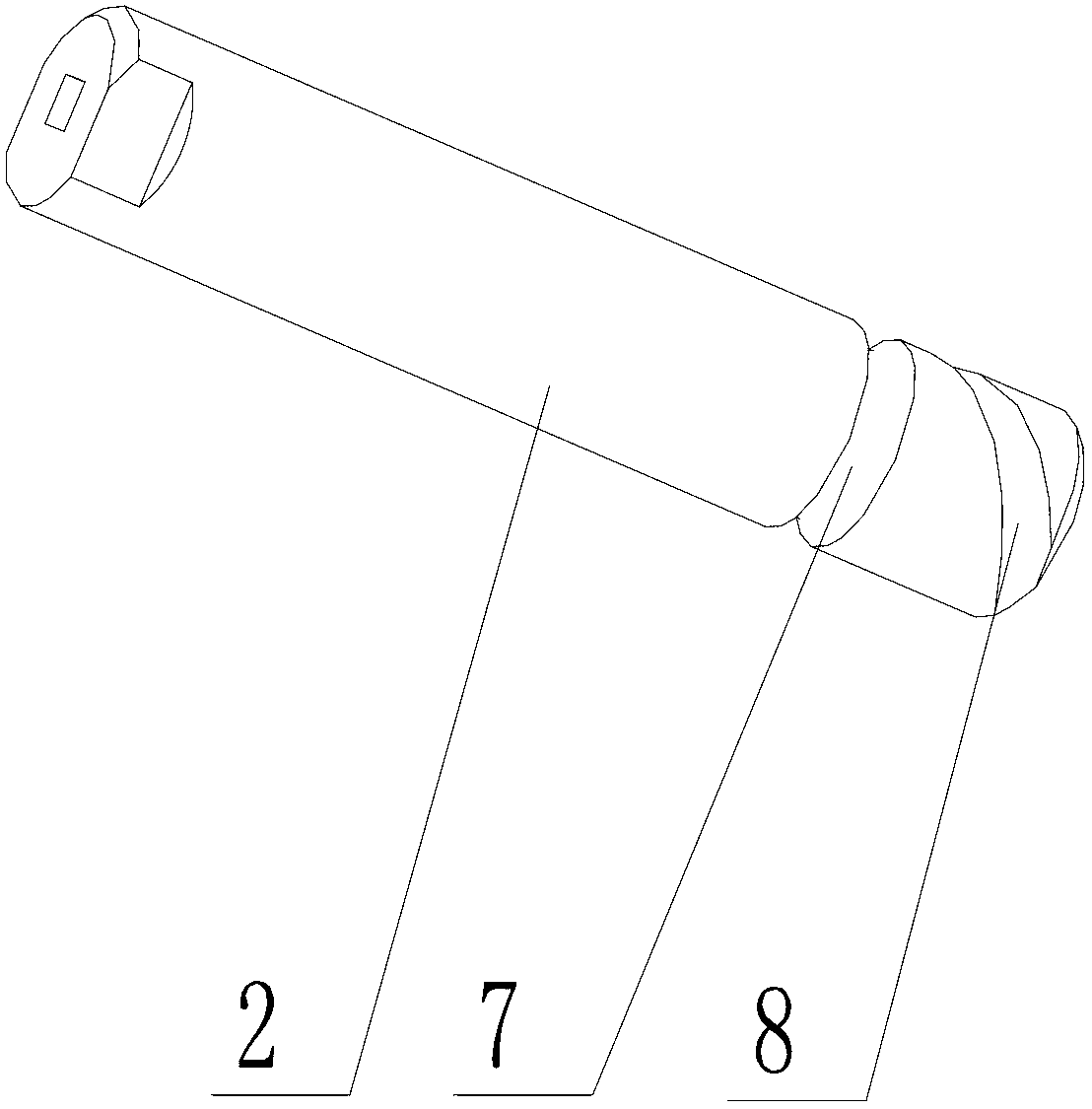

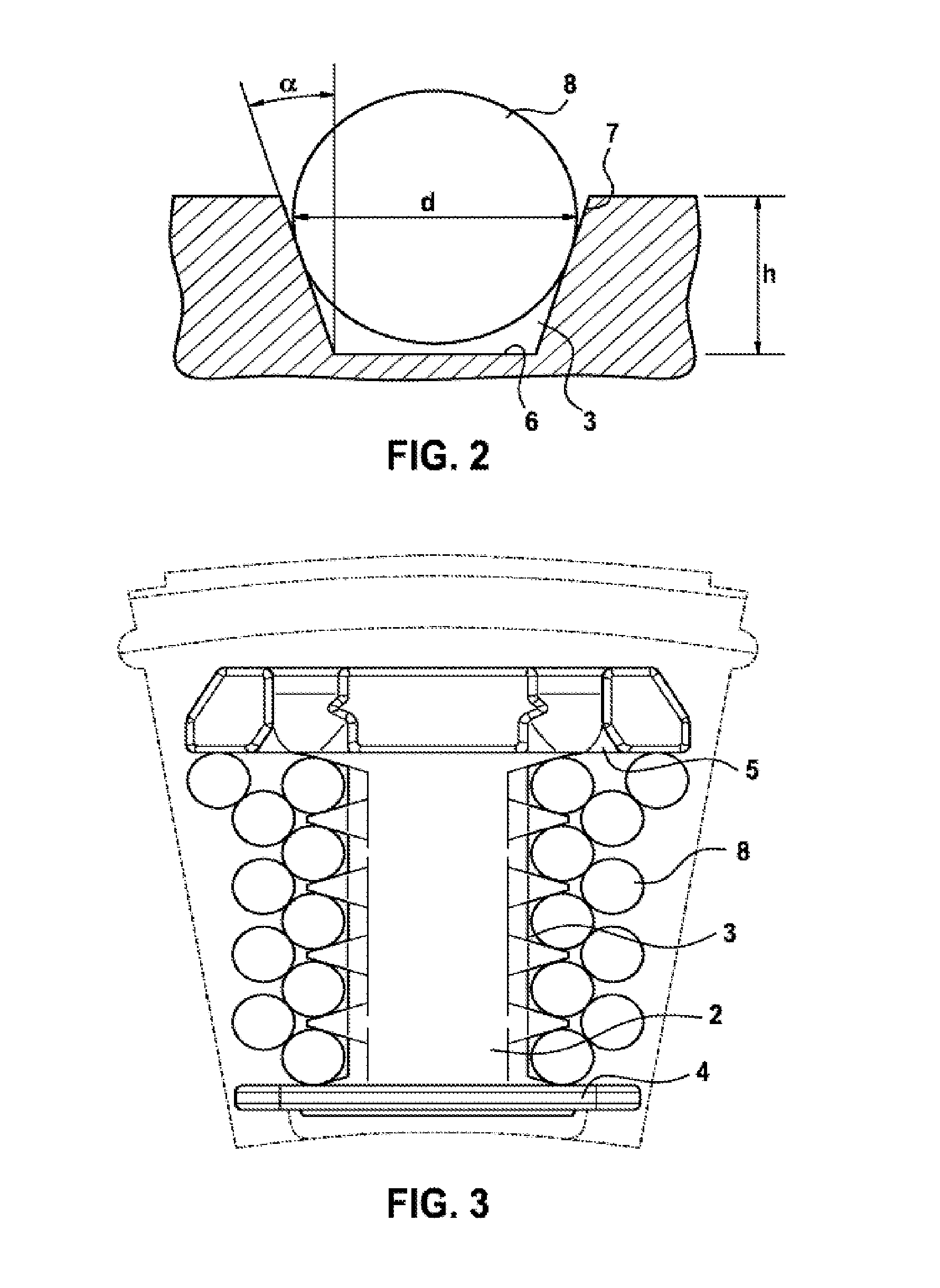

The invention relates to a winding carrier (1) for the defined application of a coil winding, comprising: a winding section (2) for placing onto a cylindrical tooth component; a groove structure (3), which is arranged in at least one region of the winding section and extends transversely to the winding axis in order to receive a winding wire; wherein the groove structure (3) has a cross section having two mutually opposite, preferably flat side faces (7), which taper in the direction of a bottom face (6) of the groove structure (3).

Owner:ROBERT BOSCH GMBH

Convex-concave engaging type telescopic positioning device

The invention provides a convex-concave engaging type telescopic positioning device and belongs to the technical field of telescopic connection. Engaging positioning or separated telescopic connection is formed through convex-concave engaging mechanisms which are evenly and continuously distributed. The convex-concave engaging mechanisms comprise convex tooth components and groove components engaged with or separated from the convex tooth components. At least one separation groove is formed in the sections, perpendicular to the relative displacement direction, of engaging positions on the convex tooth components, and then the convex tooth components and the groove components can conduct telescopic motion and positioning. The convex-concave engaging mechanisms comprise rotary engaging mechanisms with incomplete round threads, wedge-shaped expansion engaging mechanisms and non-circular section camshaft rotary engaging mechanisms. According to the device, engaging and separation of incomplete outer threads and inner threads are achieved through rotation or radial displacement, relative motion and locking and positioning of the parts in the axial direction are achieved, and no tool needs to be used during use. The device is safe, practical, easy to manufacture, low in weight and reliable in performance, the rapid telescopic function and the accurate positioning function can be achieved, and cost is greatly reduced.

Owner:戚善鸣

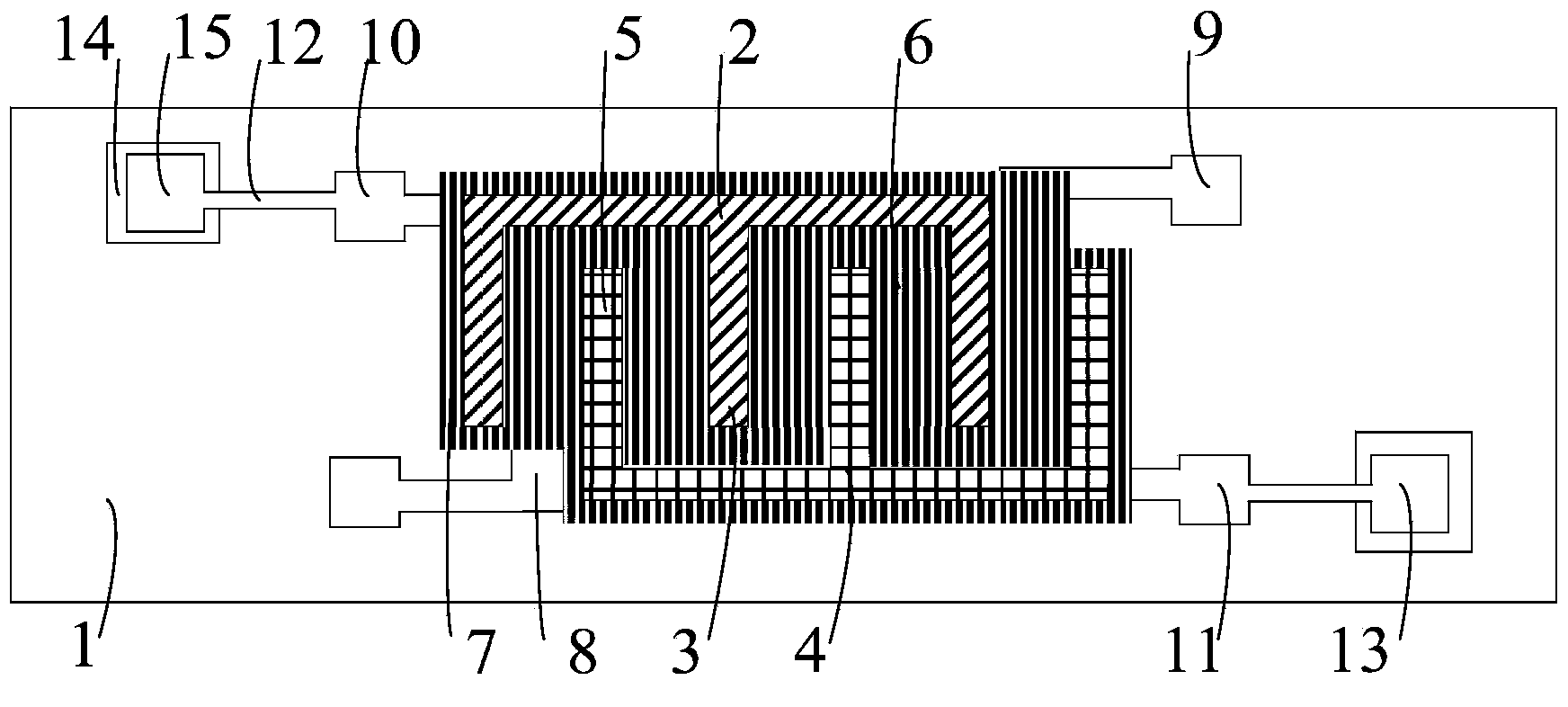

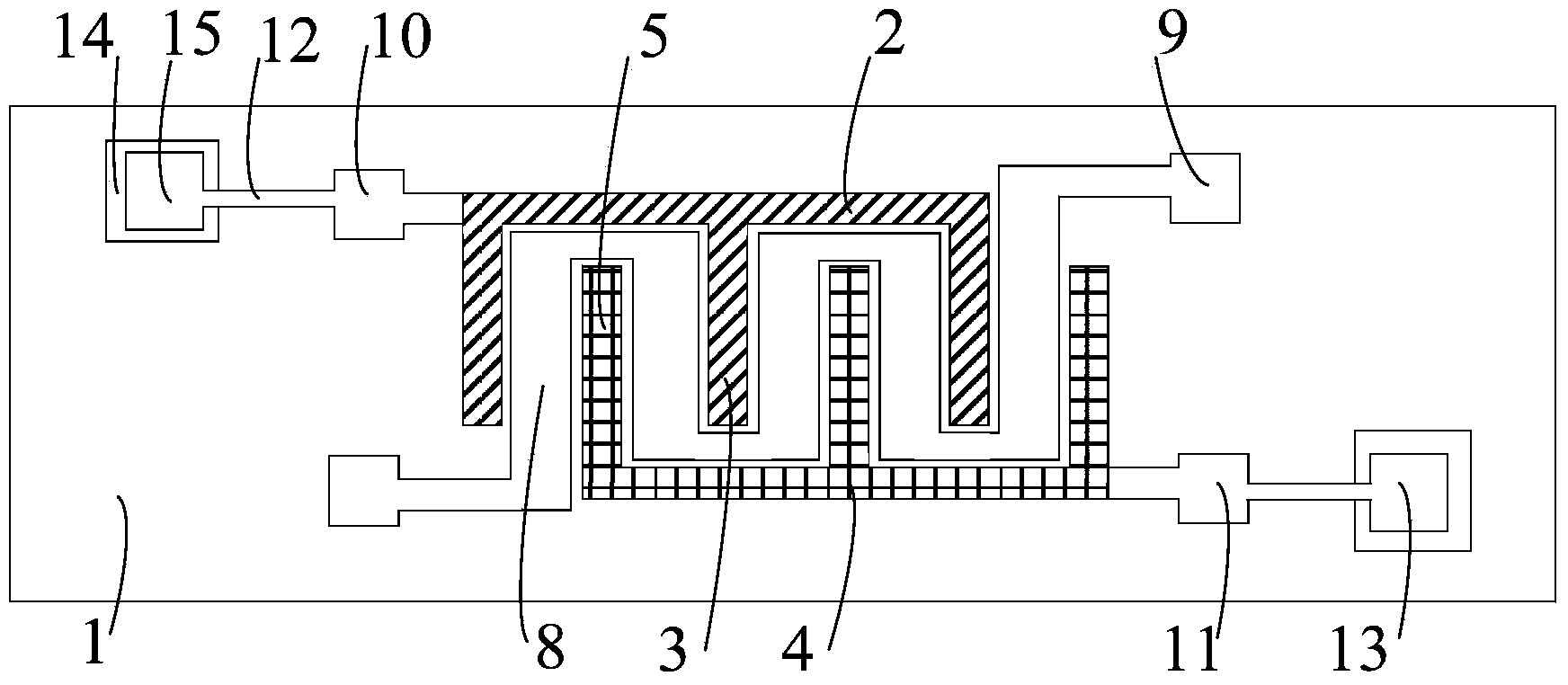

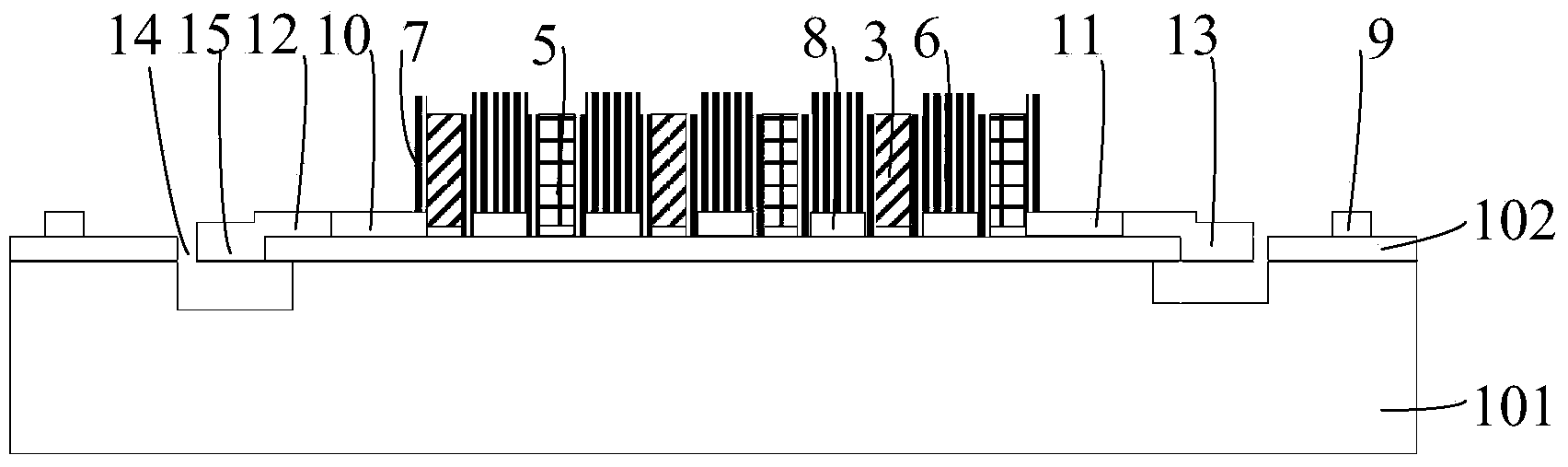

Micro-electromechanical system (MEMS) humidity sensor and preparation method thereof

ActiveCN103630582ATo achieve the purpose of humidity detectionSimple structureTelevision system detailsImpedence networksElectrical isolationTooth Component

The invention discloses a micro-electromechanical system (MEMS) humidity sensor and a preparation method thereof. The MEMS humidity sensor is designed to solve the problems that the existing humidity sensor has high cost and low precision. The MEMS humidity sensor comprises a supporting base, an electrical isolation layer arranged on the supporting base and comb tooth components arranged on the electrical isolation layer, wherein heating resistor strips are arranged between the comb tooth components. The invention also provides a preparation method of the MEMS humidity sensor. The MEMS humidity sensor provided by the invention is simple in structure, high in sensitivity, high in process compatibility, wide in application range, safe and reliable; the preparation process is simple and easy to implement; and integrated processing is facilitated.

Owner:中科芯未来微电子科技成都有限公司

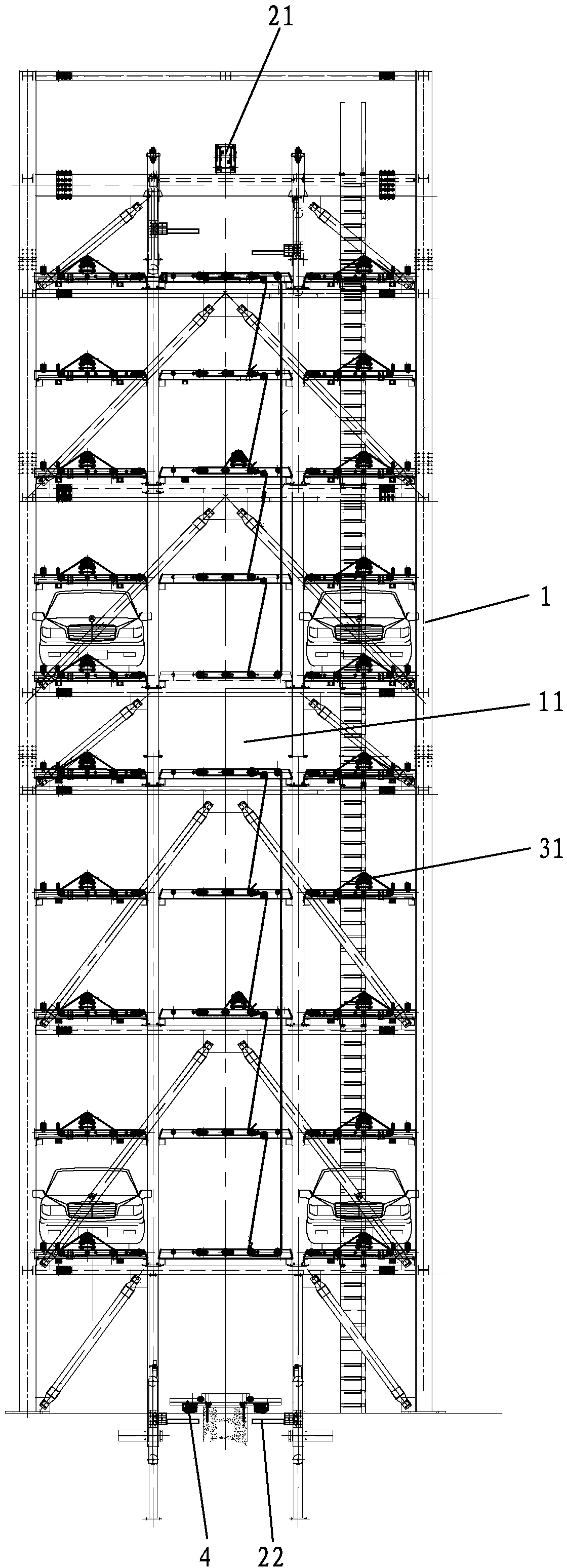

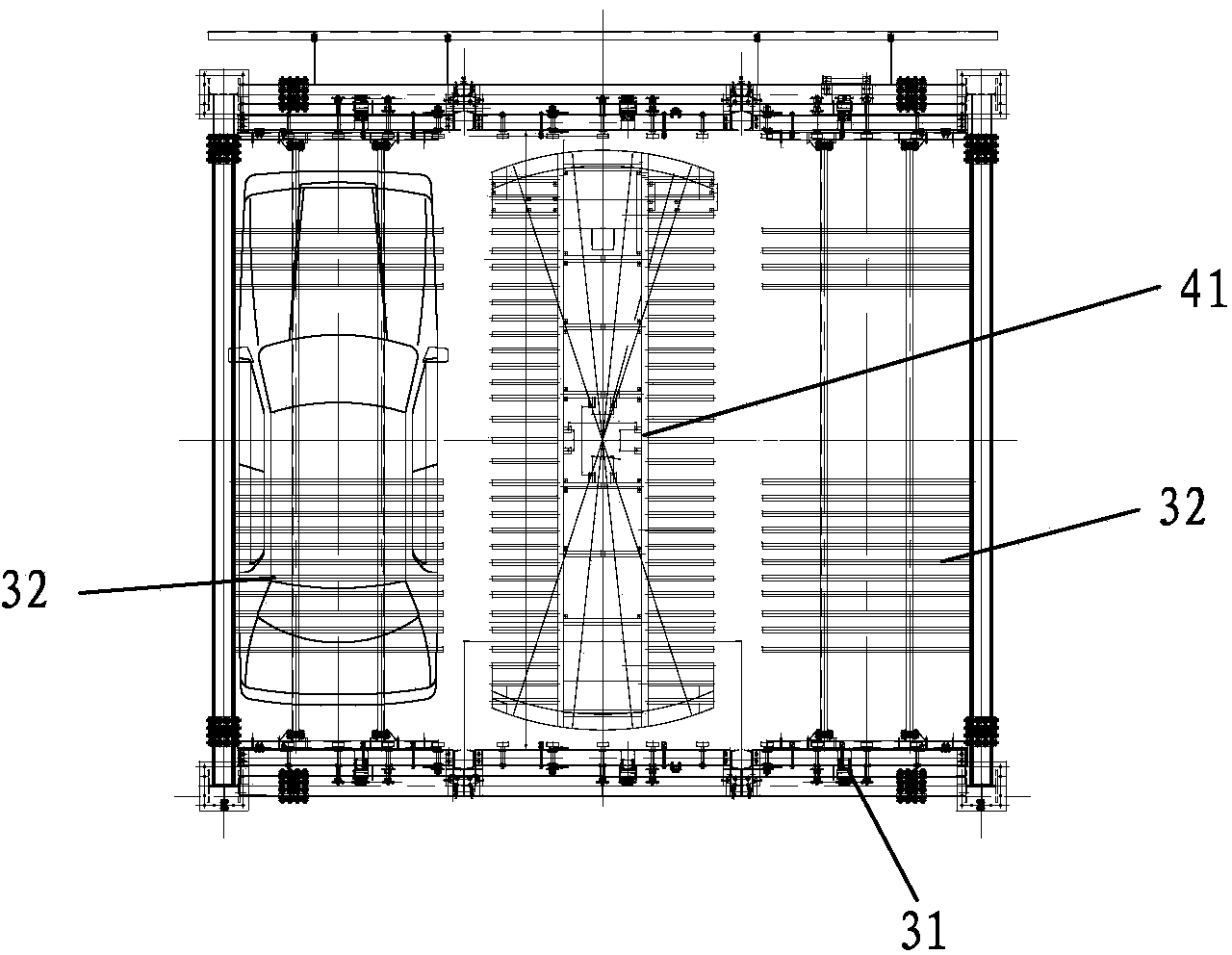

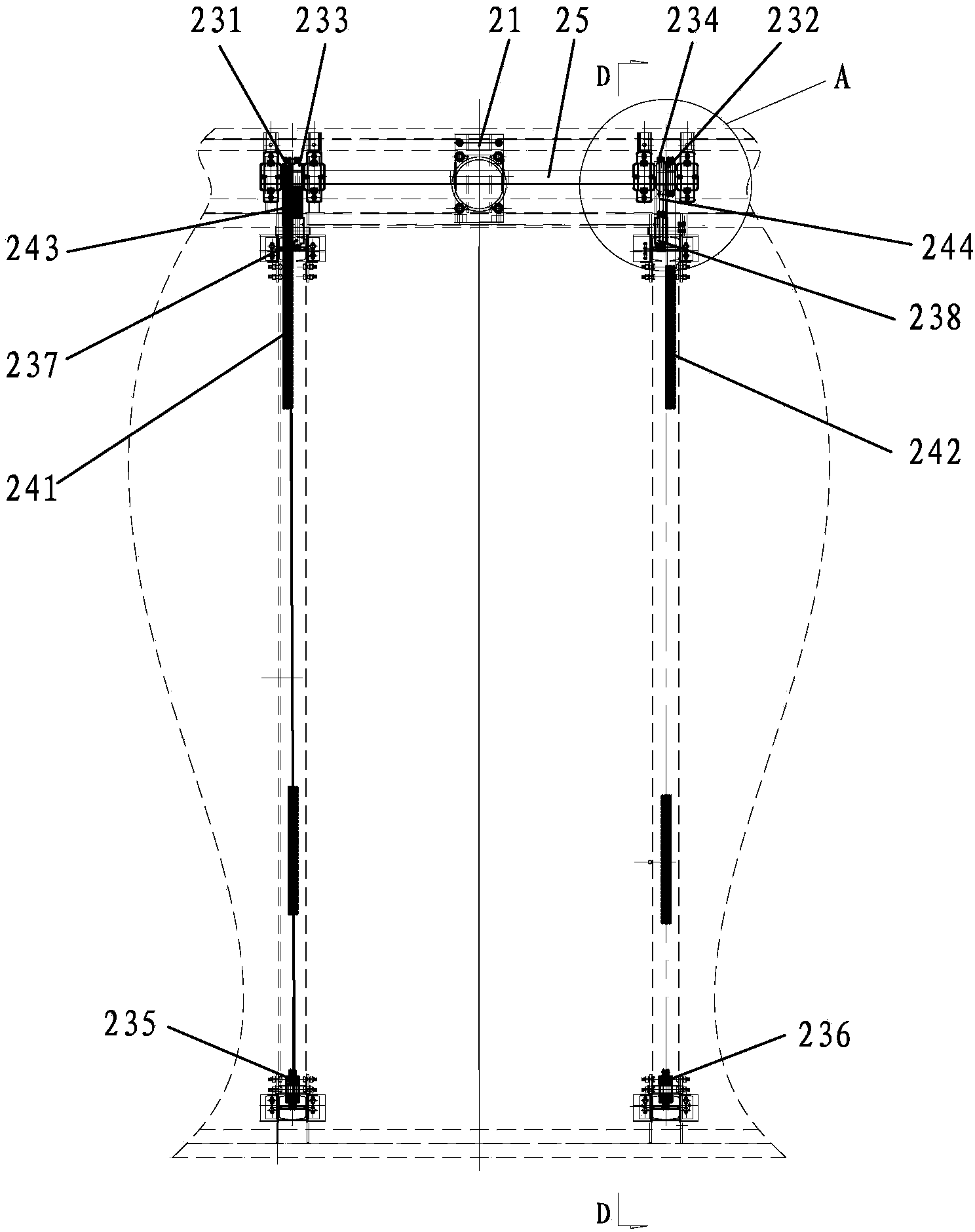

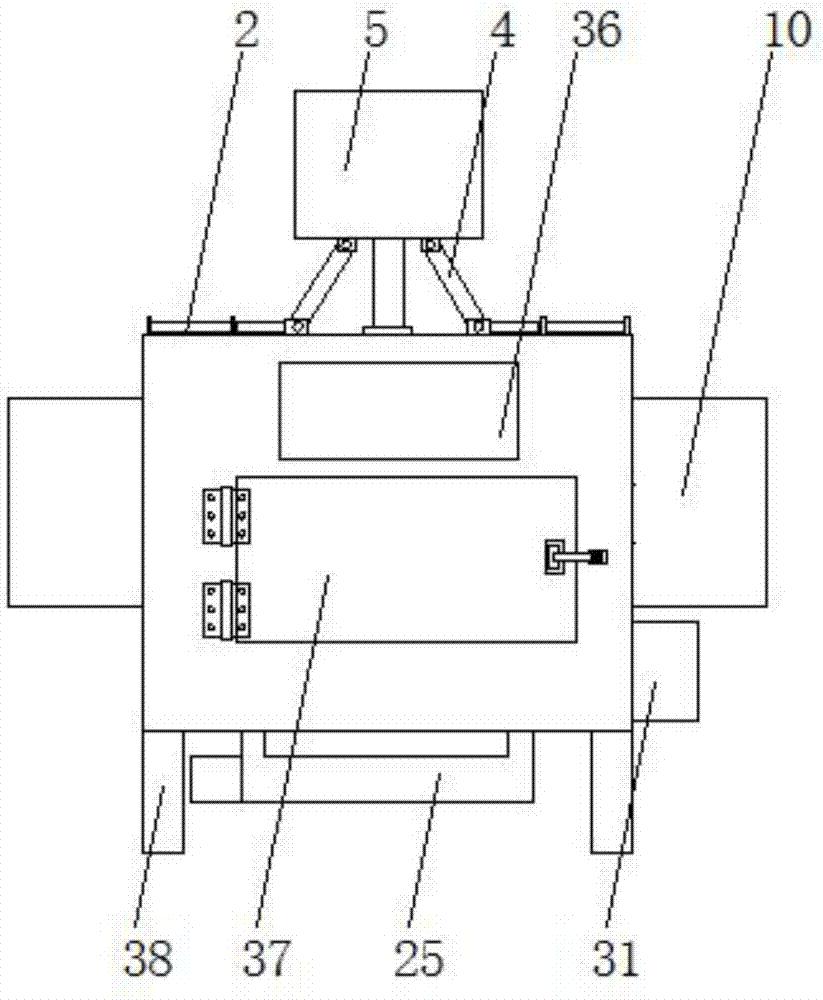

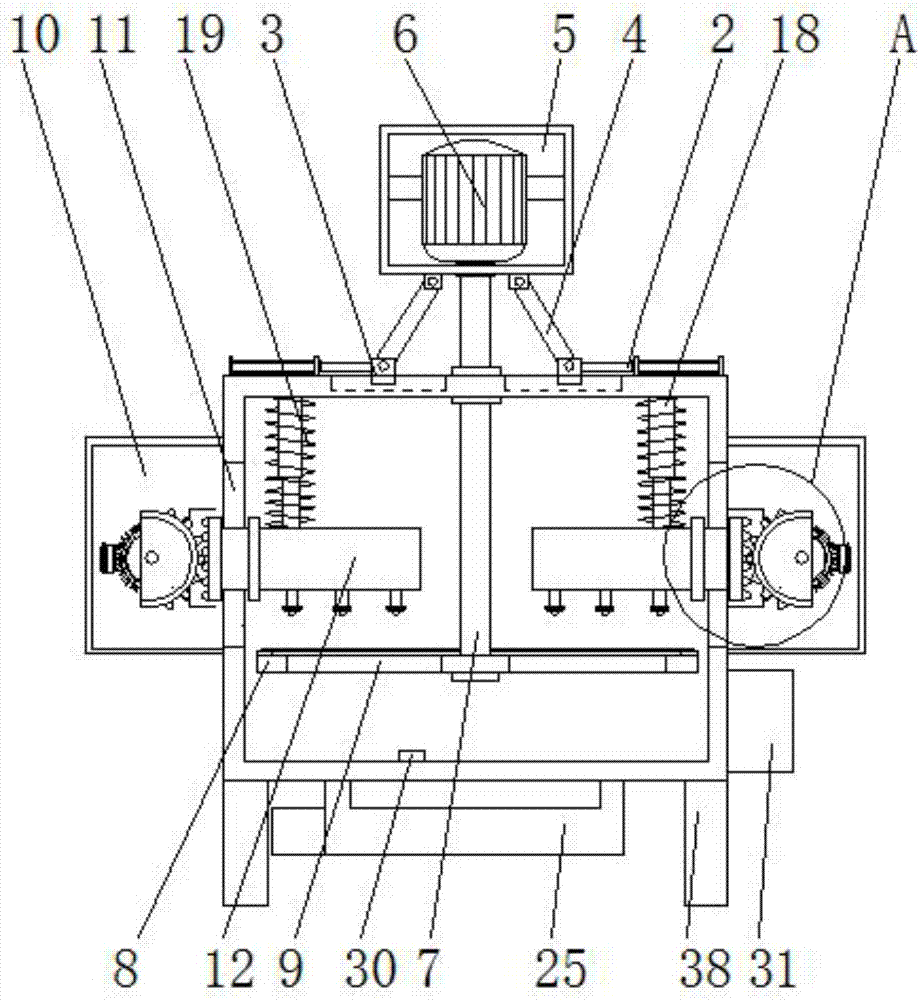

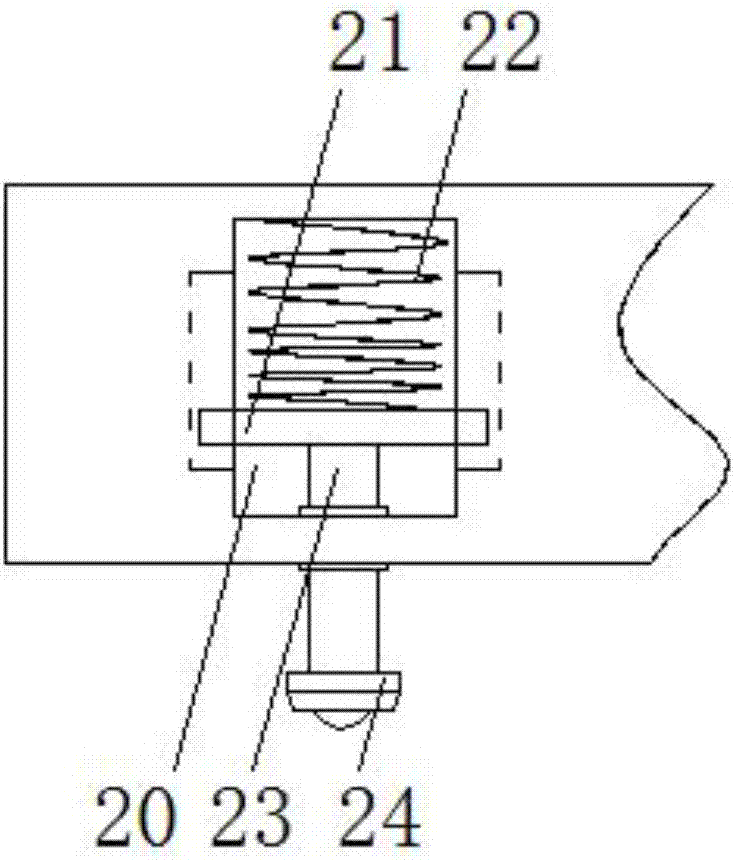

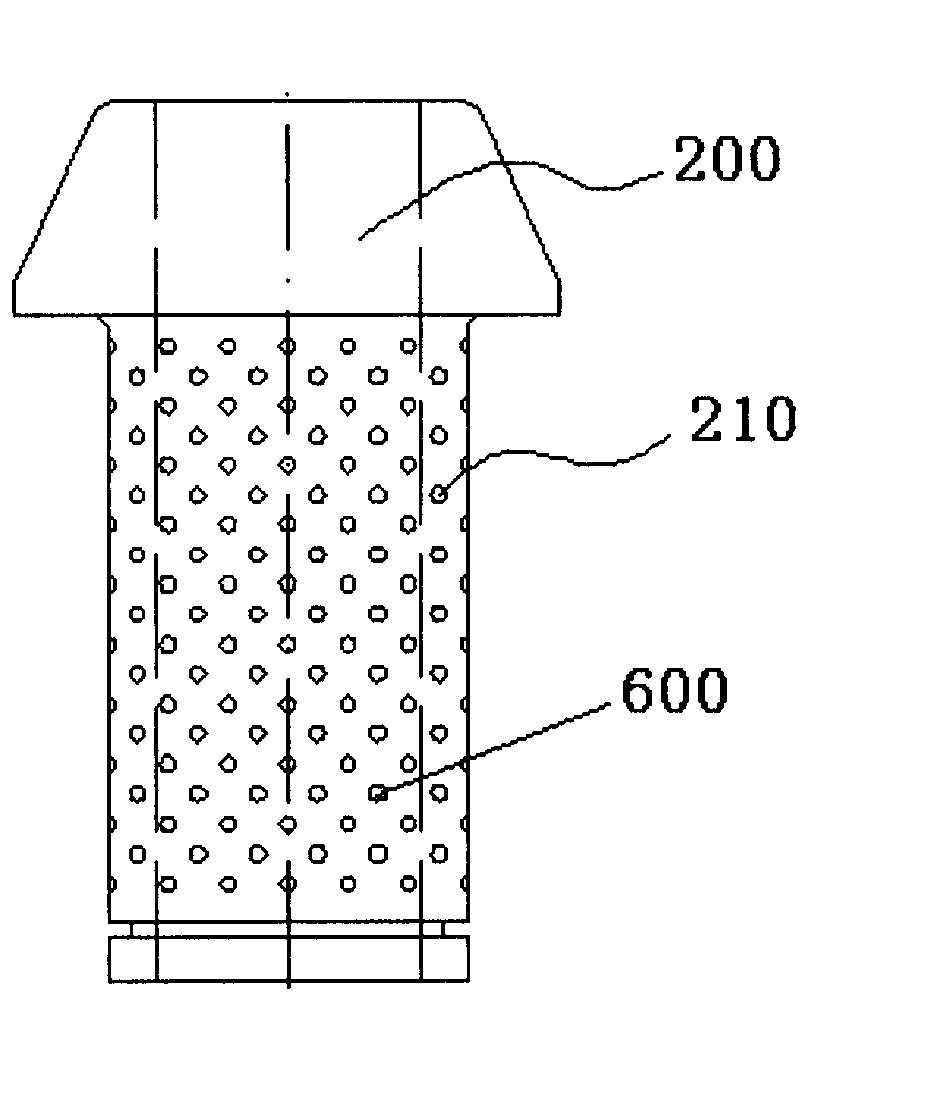

Comb-tooth type tower garage parking equipment

The invention discloses comb-tooth type tower garage parking equipment which comprises a supporting framework, a lifting device, a transverse moving device and a rotating device, wherein the supporting framework is provided with a plurality of layers of supports for parking, and a lifting roadway is formed in the middle of the supporting framework; the lifting device comprises a lifting motor, a lifting transmission component and a lifting comb-tooth component; the lifting motor is mounted at the top of the supporting framework and drives the lifting comb-tooth component to move up and down in the lifting roadway through the lifting transmission component; the transverse moving device comprises transverse movement power components and transverse moving comb-tooth components, the transverse movement power components and the transverse moving comb-tooth components are mounted on the supports, and the transverse movement power components drive the transverse moving comb-tooth components to transversely move; the rotating device is arranged on an equipment foundation at the bottom of the lifting roadway. The comb-tooth type tower garage parking equipment utilizes comb teeth to switch from parking to car fetching, and the operation of parking or car fetching is completed once when the lifting device moves up and down each time. The comb-tooth type tower garage parking equipment has the advantages of short time, high efficiency, less power consumption and energy conservation.

Owner:陈四海

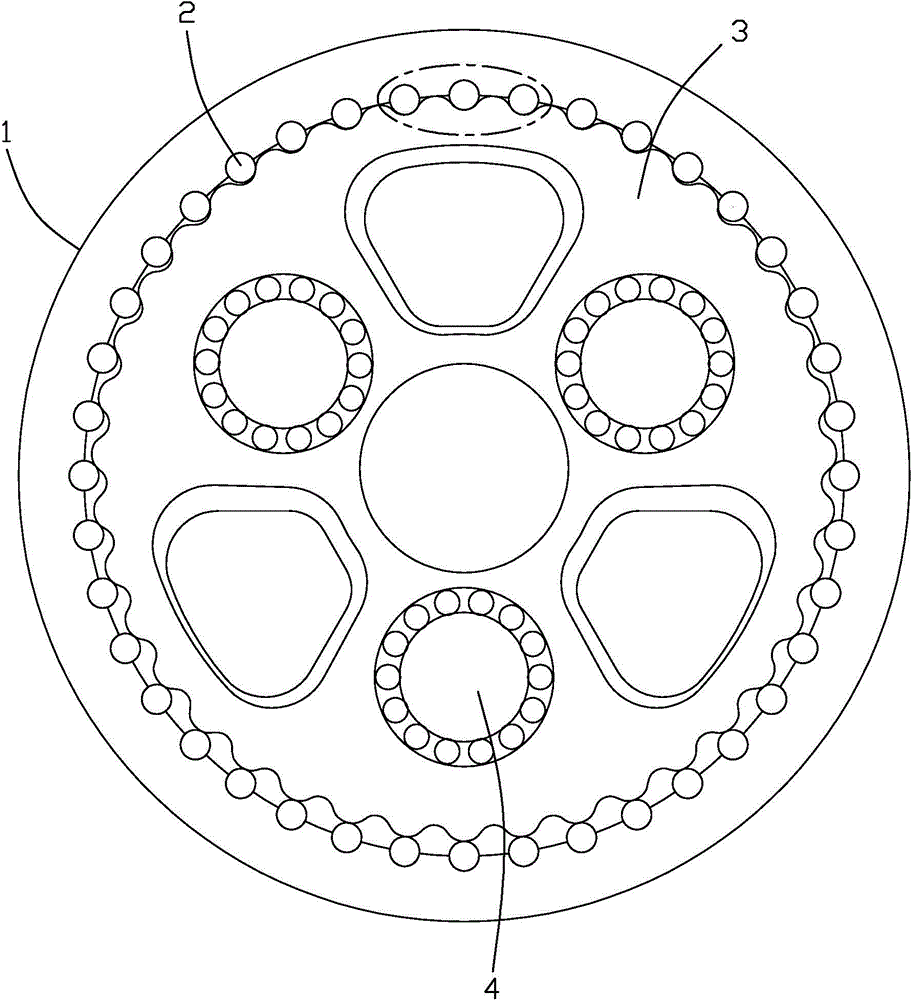

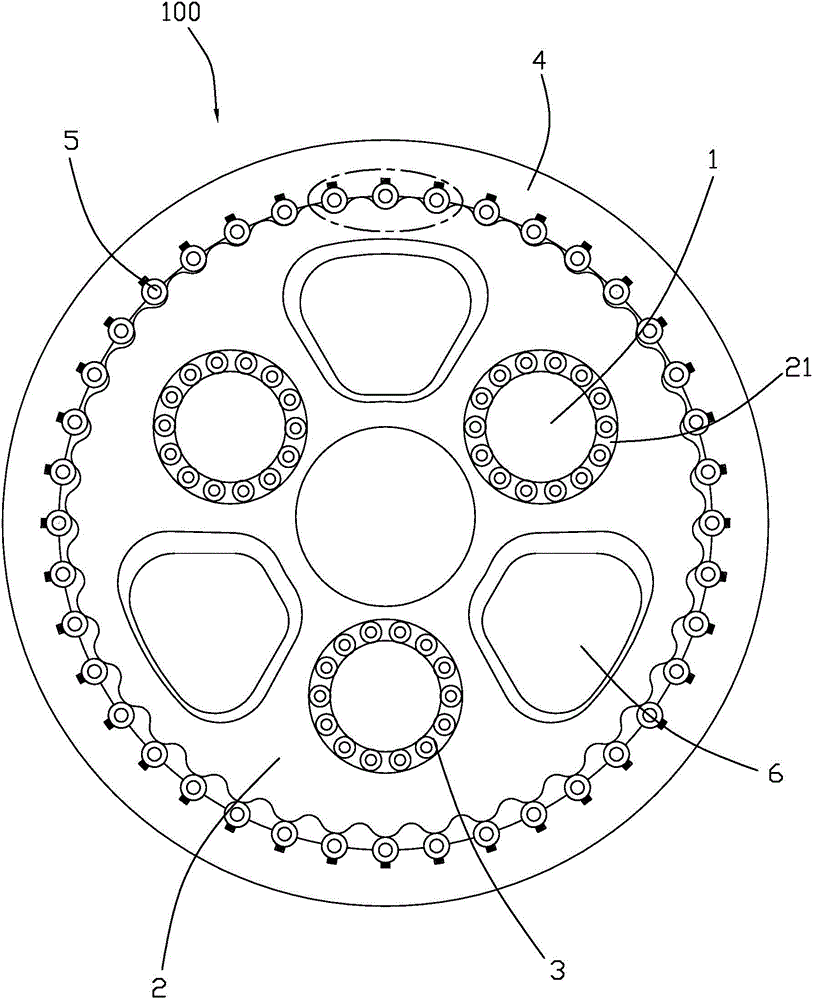

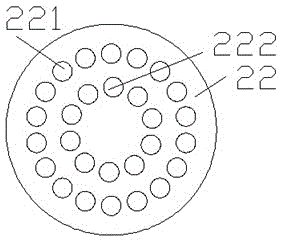

Needle tooth cycloid speed reducer

ActiveCN105299148AExtended service lifeReduce manufacturing precisionToothed gearingsPortable liftingReduction driveDentistry

The invention provides a needle tooth cycloid speed reducer. The needle tooth cycloid speed reducer comprises a cycloid disc, a needle tooth shell, and a needle tooth component clamped between the cycloid disc and the needle tooth shell. The needle tooth component comprises multiple elastic rolling column combinations uniformly distributed in the peripheral direction of the inner side of the needle tooth shell. The elastic rolling column combinations comprise elastic rolling columns, and elastic elements clamped between the elastic rolling columns and the needle tooth shell in the radial direction of the needle tooth shell.

Owner:QUANTA MACHINERY CO LTD

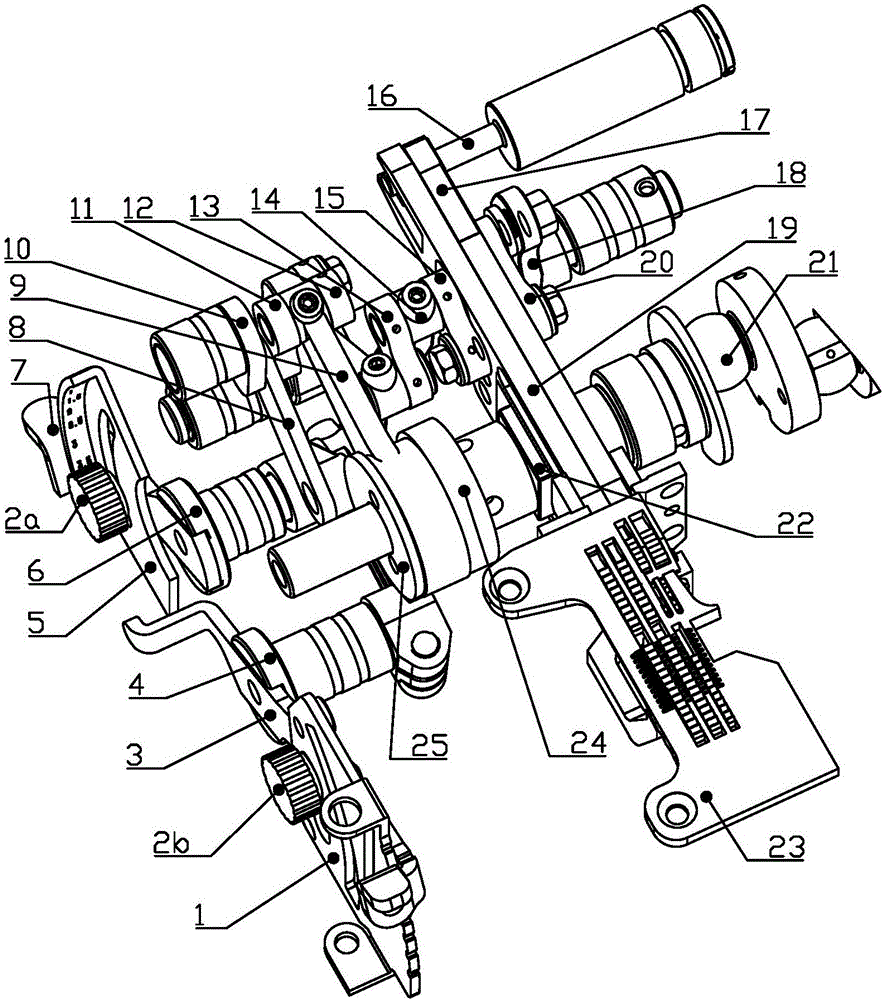

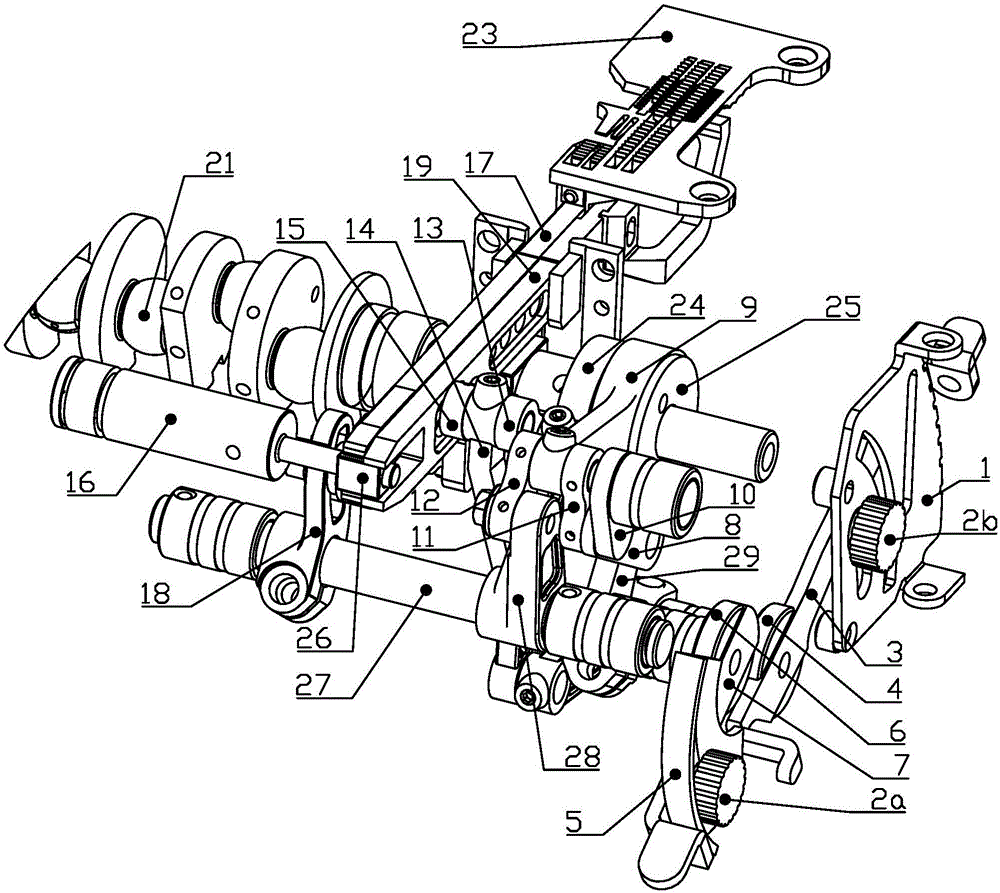

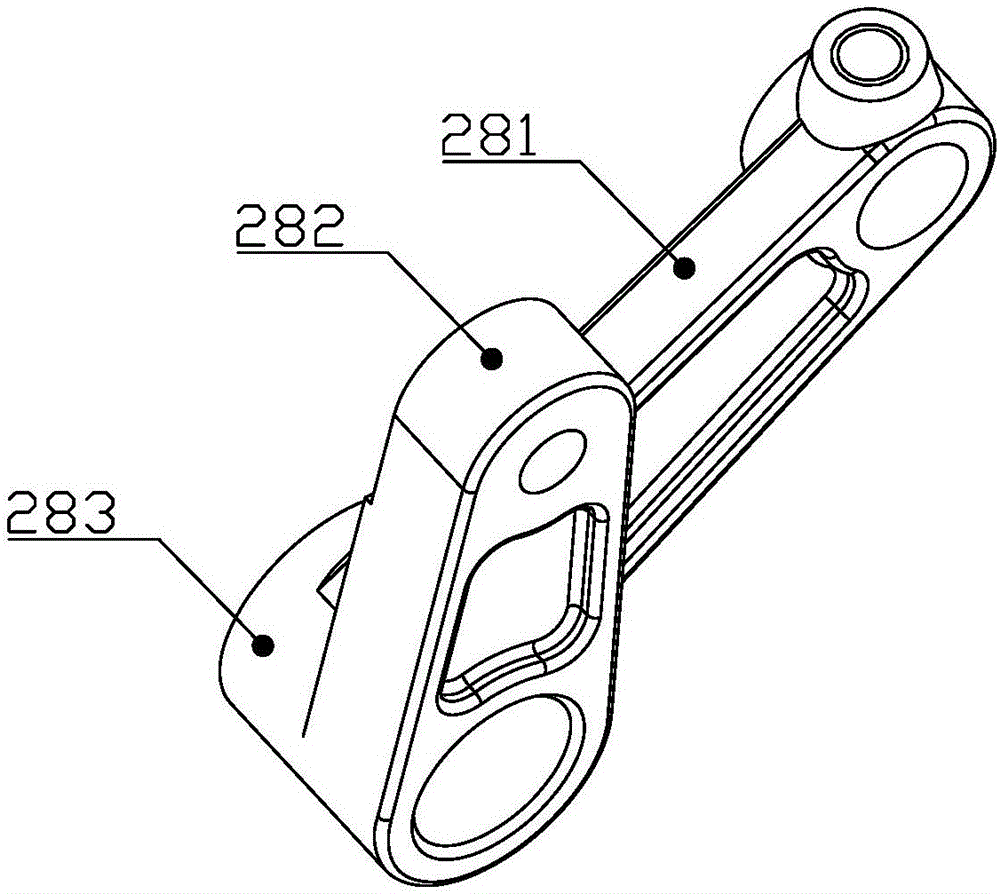

Stitch length and differential regulating mechanism and sewing machine

ActiveCN106012337AAdjust stitch sizeCompact structureSewing-machine control devicesNeedle barsControl theoryFixed position

The invention provides a stitch length and differential regulating mechanism and a sewing machine. The mechanism comprises a stitch length regulating part, a differential ratio regulating part and a differential cloth feeding crank, wherein the stitch length regulating part comprises a first manual regulating component, a first hinge point and a second hinge point; the first manual regulating component is connected with the first hinge point, so as to position the first hinge point; the first hinge point is linked with the second hinge point; the second hinge point is in transmission connection with the main shaft of the sewing machine; the differential ratio regulating part comprises a second manual regulating component and a third hinge point; the second manual regulating component is connected with the third hinge point, so as to position the third hinge point; the third hinge point is in transmission connection with a differential cloth feeding component; the differential cloth feeding crank comprises a first connecting arm and a second connecting arm which are crosswise arranged; a crosswise fixed position between the first connecting arm and the second connecting arm is fixedly connected with a cloth feeding shaft; the cloth feeding shaft is in transmission connection with an active cloth feeding tooth component; the first connecting arm is in transmission connection with the second hinge point; the second connecting point is in transmission connection with the third hinge point. The stitch length and differential regulating mechanism and the sewing machine are simple and compact in structure and high in regulation precision.

Owner:JACK SEWING MASCH CO LTD

Segmented magneto-conductive structure applied in rotating machines

A segmented magneto-conductive structure applied in rotating machines comprises a rotor assembly and a stator assembly. The rotor assembly includes a rotor yoke component and a plurality of rotor teeth components. The rotor yoke component is made of non-oriented silicon steel. The rotor teeth components are made of grain-oriented silicon steel. The stator assembly includes a plurality of stator yoke components and a plurality of stator teeth components. The stator yoke components and the stator teeth components are made of grain-oriented silicon steel. Thereby, an operational efficiency of a motor applying the segmented magneto-conductive structure is enhanced.

Owner:IND TECH RES INST

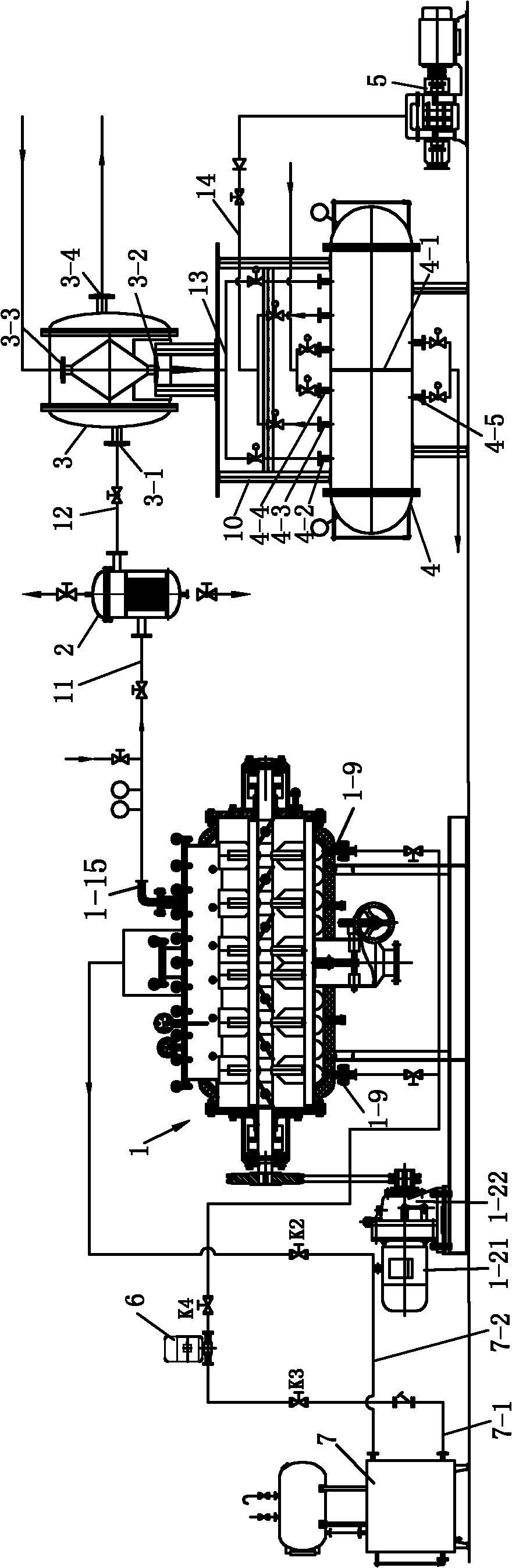

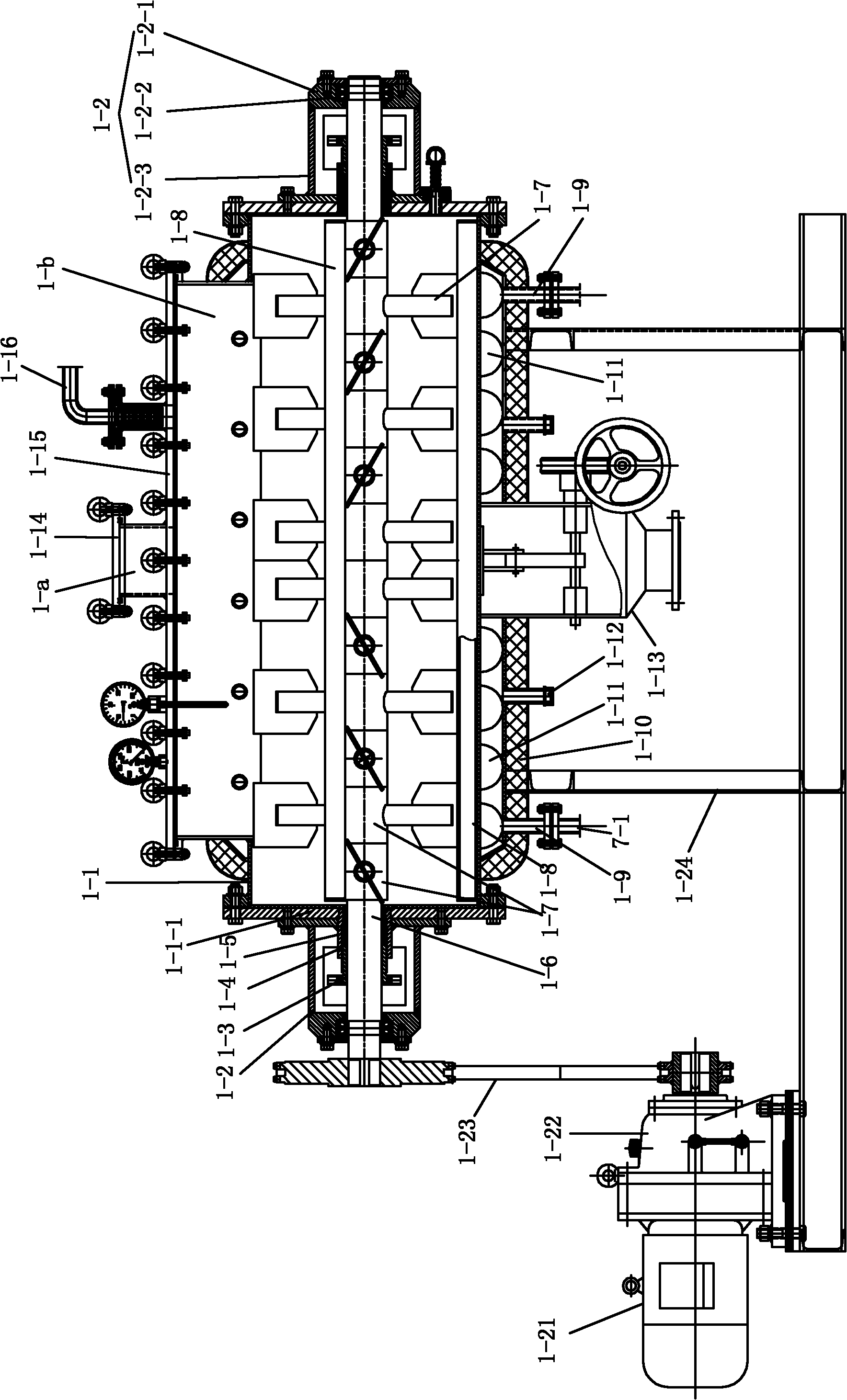

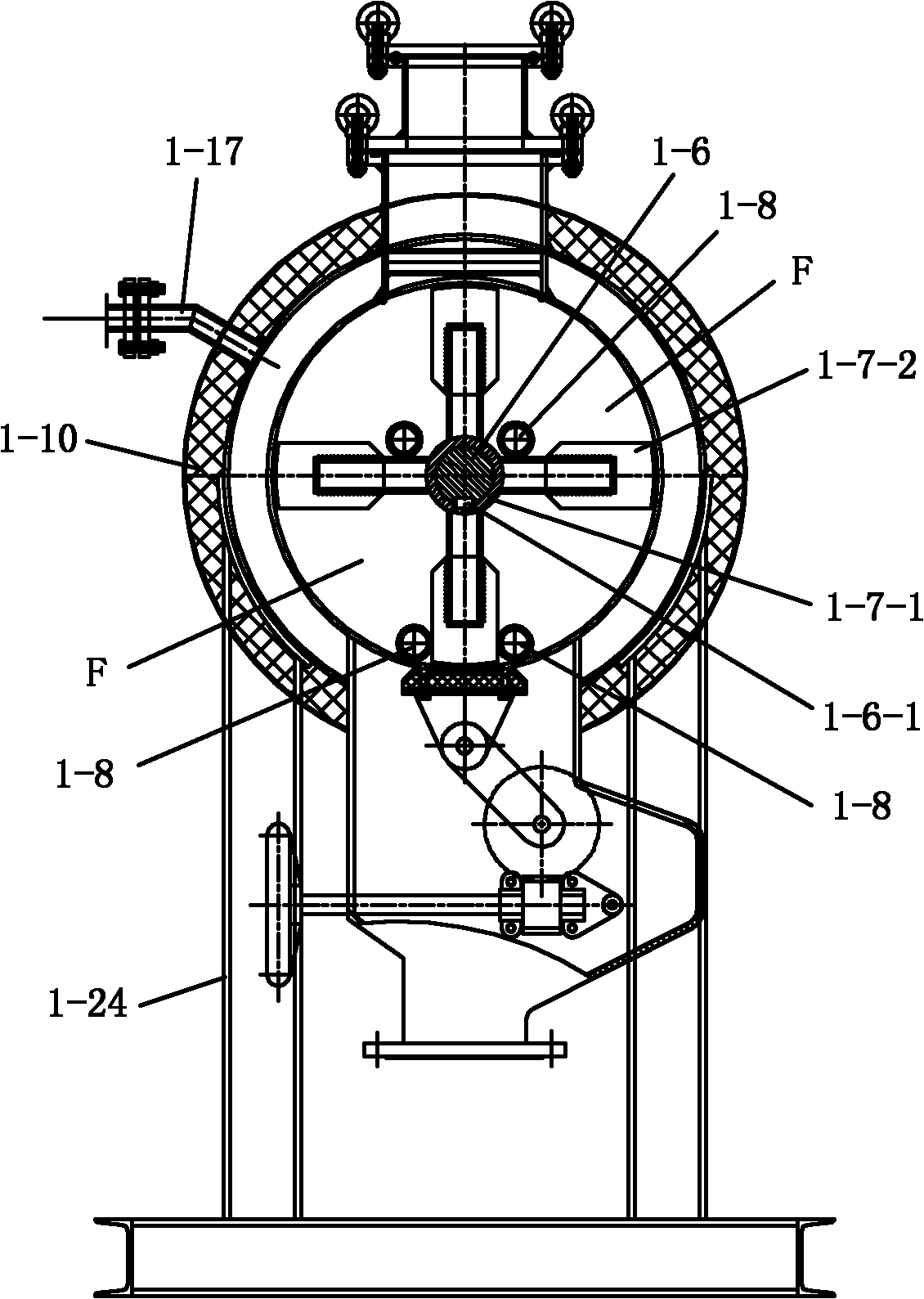

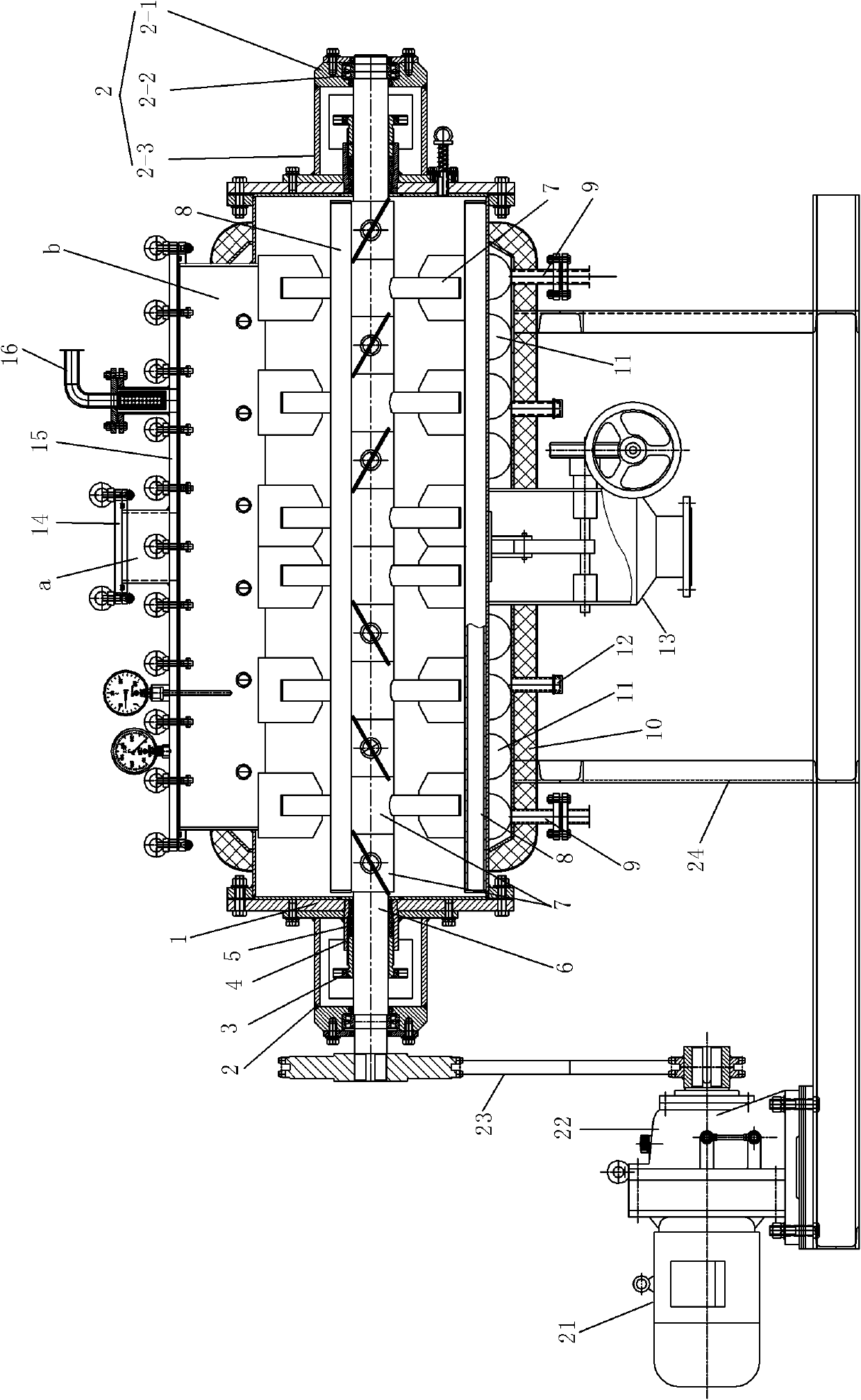

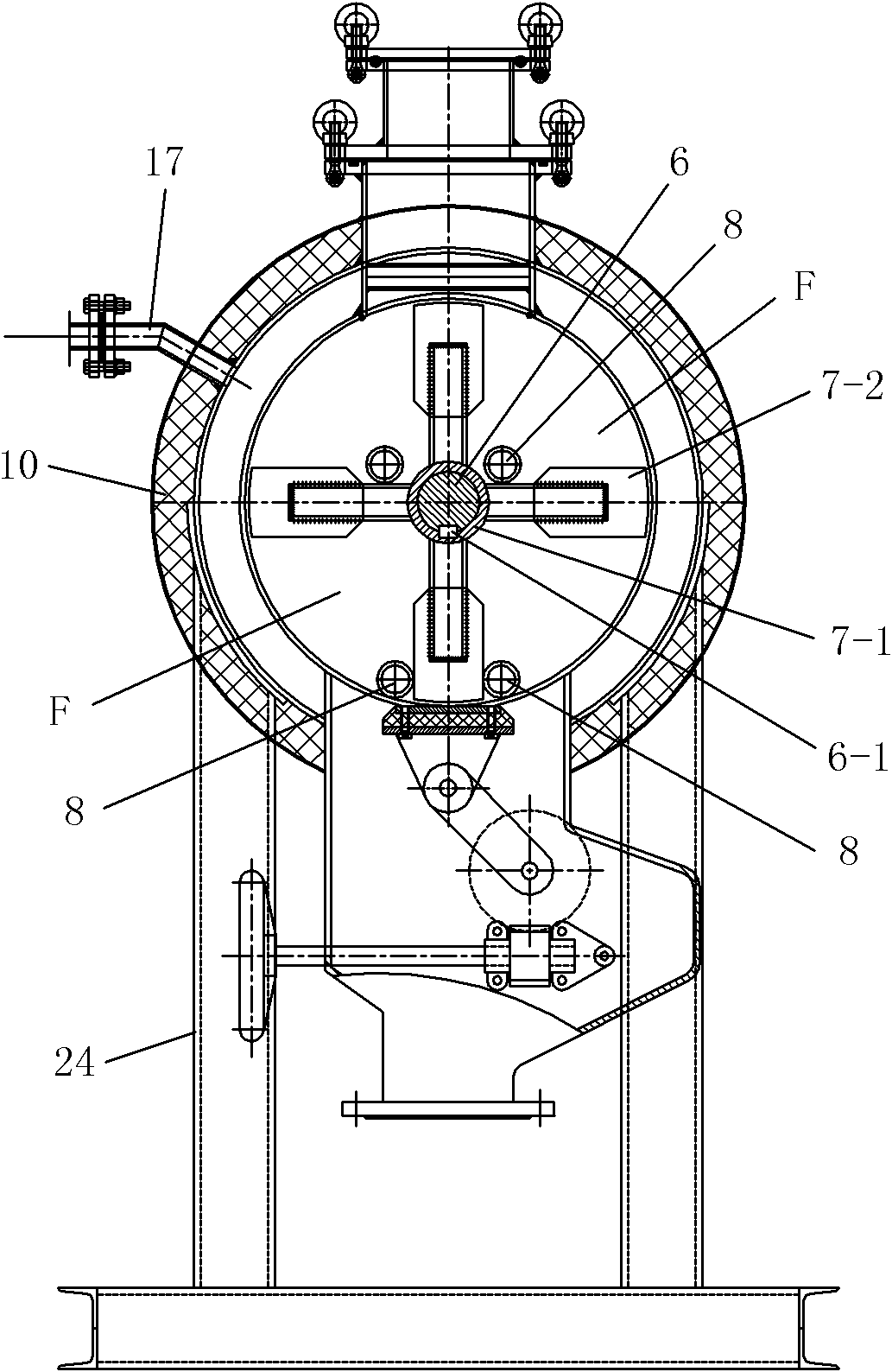

Rake type vacuum drying system

ActiveCN102183126ASpeed up crushingLarge specific surface areaDrying machines with non-progressive movementsDrying solid materialsVapor–liquid separatorLithium iron phosphate

The invention provides a rake type vacuum drying system, which comprises a rake type vacuum drying host machine, a bag type filter, a condenser, a gas-liquid separator, a vacuum pump, an oil pump and a hot oil tank, wherein a main shaft of the rake type vacuum drying host machine is a solid main shaft; a plurality of rake tooth components are arranged on the main shaft; each rake tooth component comprises a sleeve shaft and four solid rake teeth uniformly distributed on the sleeve shaft in a fixed manner, and is connected on the main shaft through a sleeve shaft key; the rake teeth of the respective rake tooth components face towards the same direction, so that four passageways are formed in a tank body; and striking rods are respectively arranged in respective passageways or in spaced passageways. In the invention, materials inside the tank body of the drying host machine are struck continuously by using the striking rods, so that the crushing of the materials is accelerated, the materials can obtain larger specific surface areas, the drying process is accelerated, and finished products have uniform fineness and low water content; thus, the rake type vacuum drying system is suitable for drying lithium iron phosphate materials, and the product quality and drying efficiency are improved; moreover, the system is used for recovering solvents through the condenser and the gas-liquid separator, and is beneficial to reduction of the cost.

Owner:JIANGSU XIANFENG DRYING ENG

Rake vacuum drying main machine

ActiveCN102168911ASpeed up crushingLarge specific surface areaDrying solid materialsDrying machines with non-progressive movementsLithium iron phosphatePulp and paper industry

The invention relates to a rake vacuum drying main machine, which comprises a tank body, wherein a main shaft of the main machine is solid, and a plurality of rake tooth components are arranged on the main shaft; each rake tooth component consists of a sleeve shaft and four solid rake teeth which are distributed and fixed on the sleeve shaft uniformly and is connected on the main shaft by a sleeve shaft key; the orientations of the rake teeth of all rake tooth components are the same, so that four channels are formed in the tank body; and a knocking rod is arranged in each channel or the spaced channel. In the rake vacuum drying main machine, materials are knocked continuously inside the tank body of the drying main machine by utilizing the knocking rods to accelerate the crushing of the materials, so that the materials have the large specific surface area, the drying process is accelerated, finished products are uniform in fineness and low in moisture; and the rake vacuum drying main machine is suitable for drying lithium iron phosphate materials, and improves the quality and drying efficiency of the products.

Owner:JIANGSU XIANFENG DRYING ENG

Segmented magneto-conductive structure applied in rotating machines

ActiveCN103107616ALow coercivityReduce iron lossMagnetic circuit rotating partsMagnetic circuit stationary partsSiliconMagneto

A segmented magneto-conductive structure applied in rotating machines comprises a rotor assembly and a stator assembly. The rotor assembly includes a rotor yoke component and a plurality of rotor teeth components. The rotor yoke component is made of non-oriented silicon steel. The rotor teeth components are made of grain-oriented silicon steel. The stator assembly includes a plurality of stator yoke components and a plurality of stator teeth components. The stator yoke components and the stator teeth components are made of grain-oriented silicon steel. Thereby, an operational efficiency of a motor applying the segmented magneto-conductive structure is enhanced.

Owner:IND TECH RES INST

Winding carrier for use in an electrical machine and winding arrangement

ActiveUS9455606B2Easy to manufactureImprove cooling effectWindings insulation shape/form/constructionElectric machineConductor Coil

The invention relates to a winding carrier (1) for the defined application of a coil winding, comprising: a winding section (2) for placing onto a cylindrical tooth component; a groove structure (3), which is arranged in at least one region of the winding section and extends transversely to the winding axis in order to receive a winding wire; wherein the groove structure (3) has a cross section having two mutually opposite, preferably flat side faces (7), which taper in the direction of a bottom face (6) of the groove structure (3).

Owner:ROBERT BOSCH GMBH

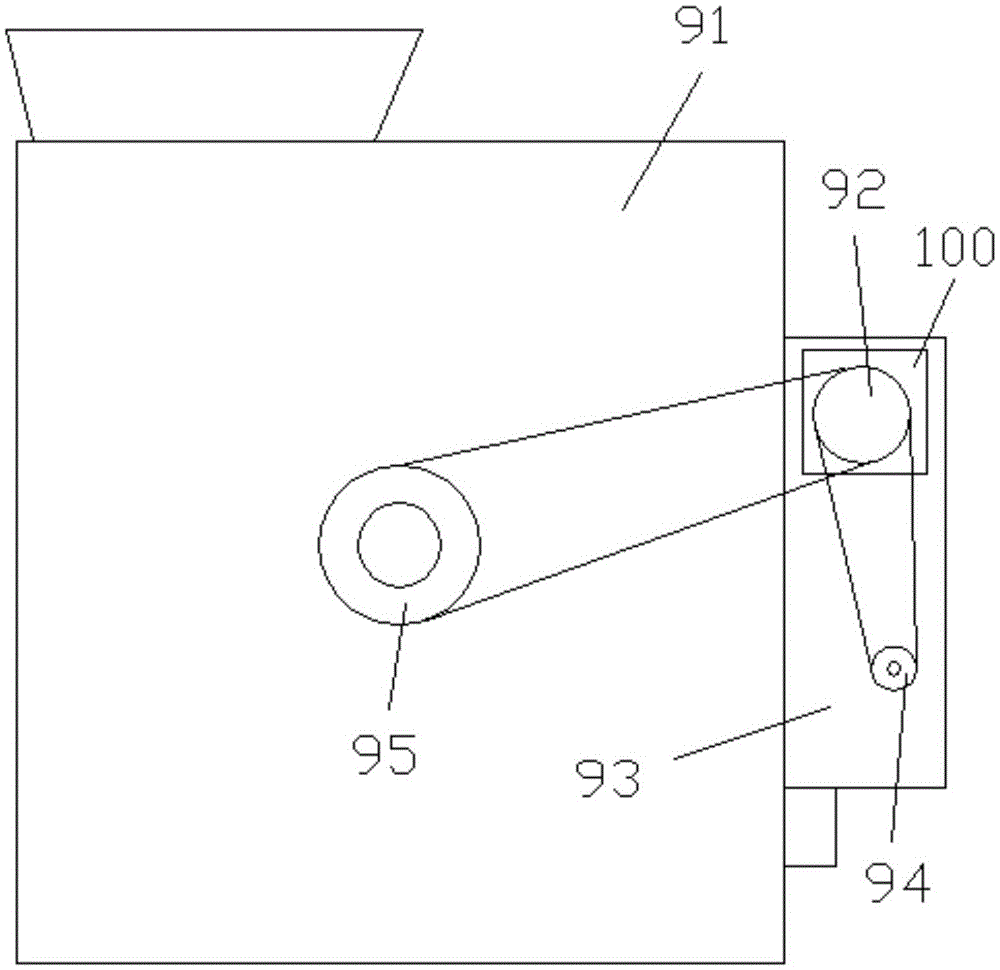

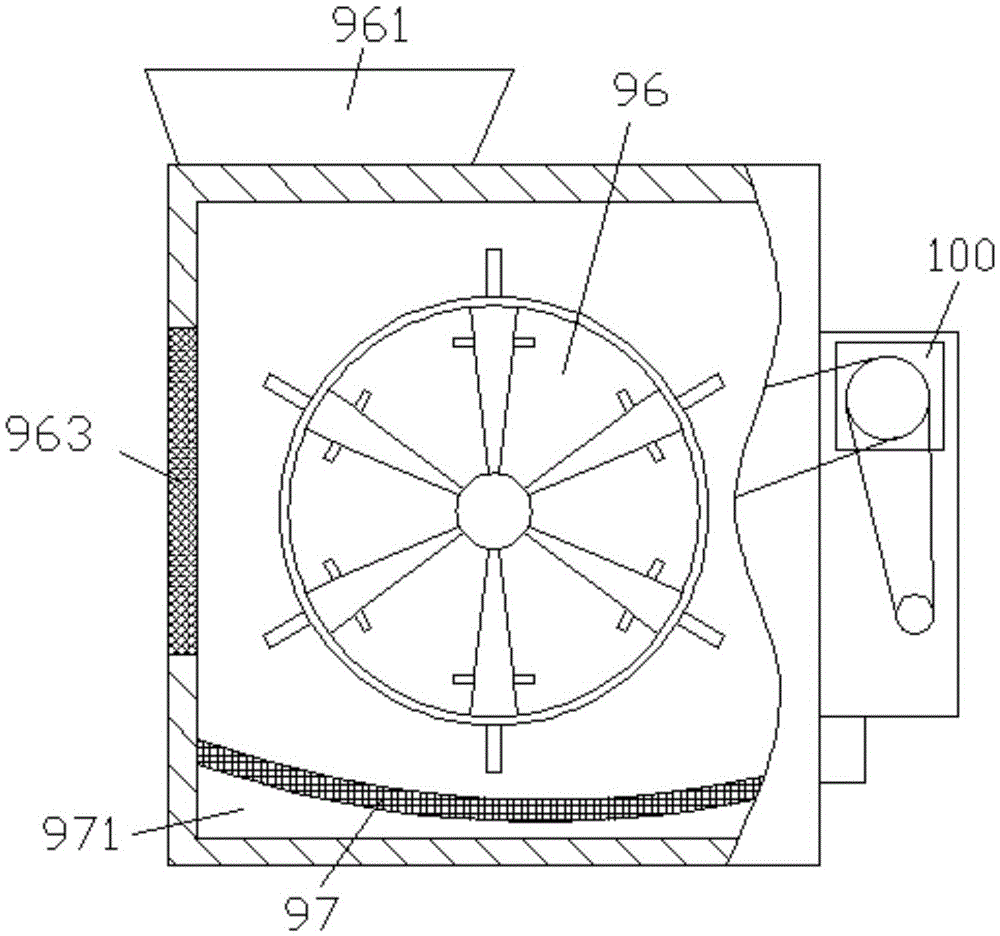

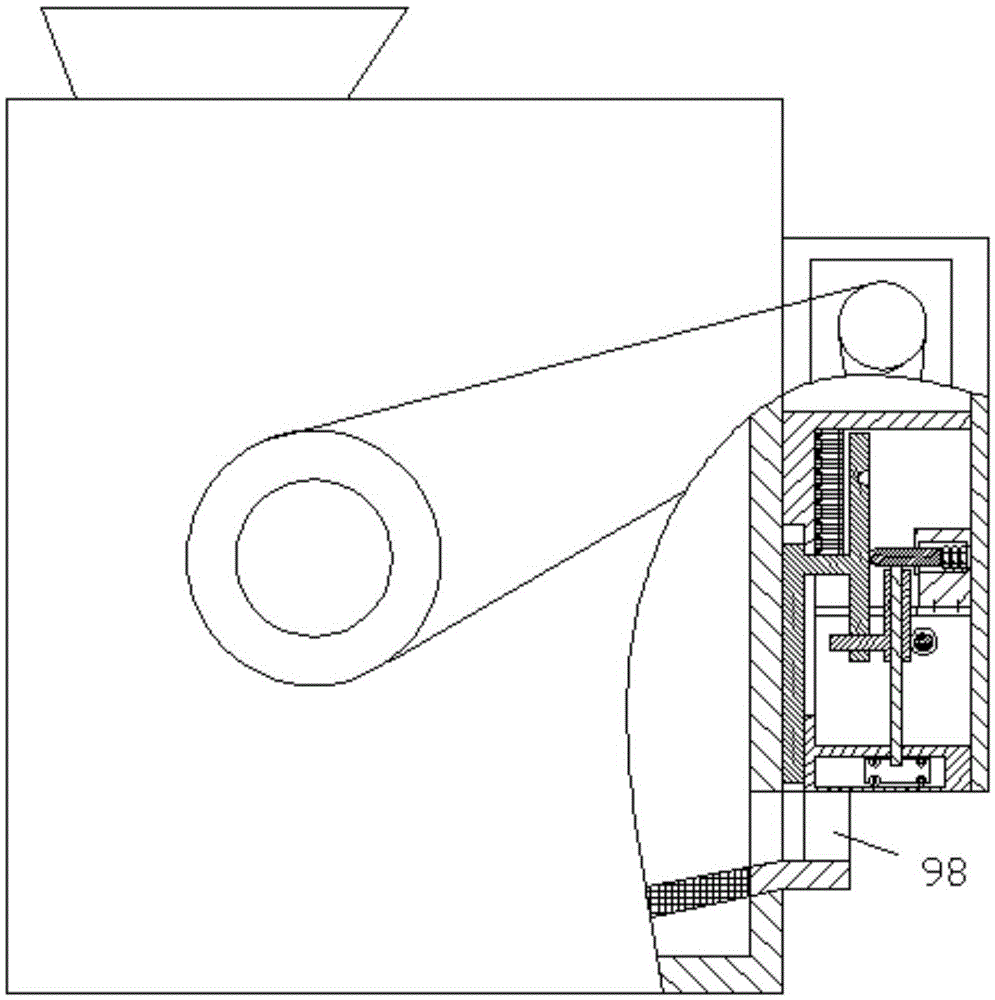

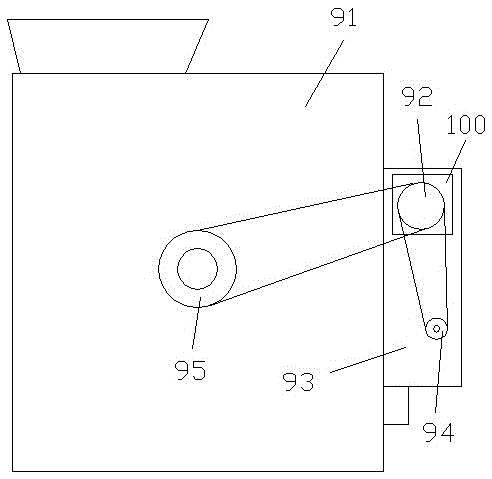

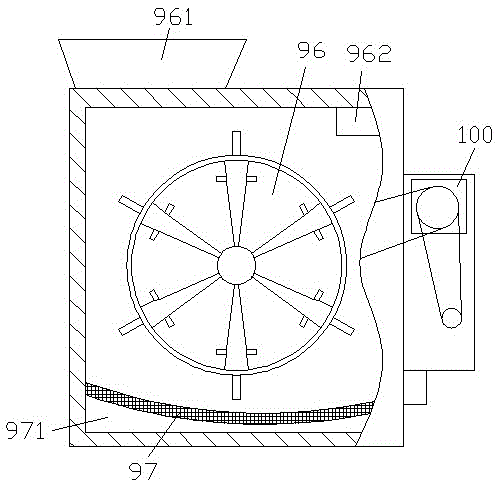

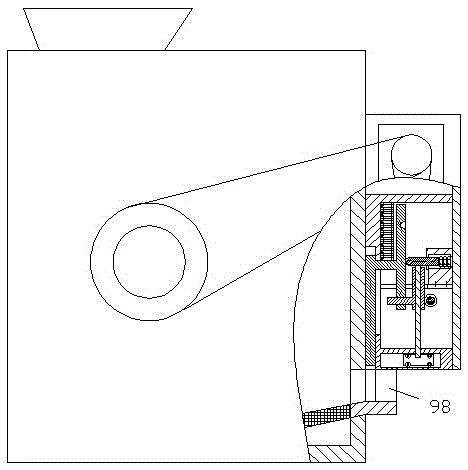

Agricultural material smashing equipment with visible window

Agricultural material smashing equipment with a visible window comprises a smashing executing box (91) and an additional box body (93), wherein the additional box body (93) is fixed on a side of the smashing executing box (91); a driving motor (100) is mounted on the upper part of the additional box body (93); a power wheel (92) and a slag outlet baffle driving wheel (94) are fixedly arranged on a driving shaft of the driving motor (100); the power wheel (92) is used for driving a smashing tooth belt pulley (95) through two belts; and the smashing tooth belt pulley (95) is coaxially connected with a smashing tooth component (96), and is used for smashing materials which are conveyed into the smashing executing box (91) through a feeding opening (961), and the smashed materials are sieved through a sieve plate (97) arranged at the bottom of the smashing executing box (91), drop into a smashed material discharging cavity (971), and then are discharged.

Owner:方志彦

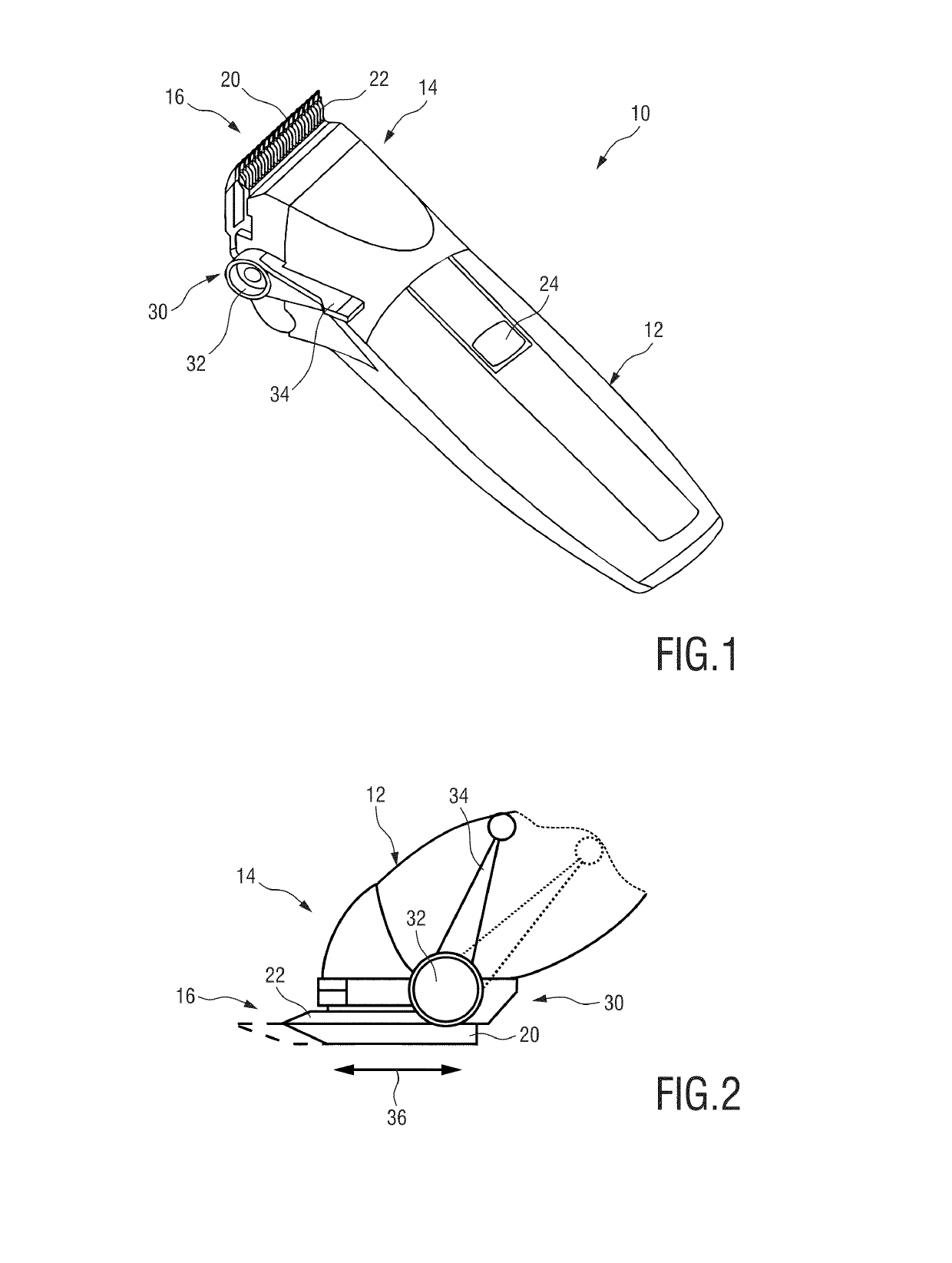

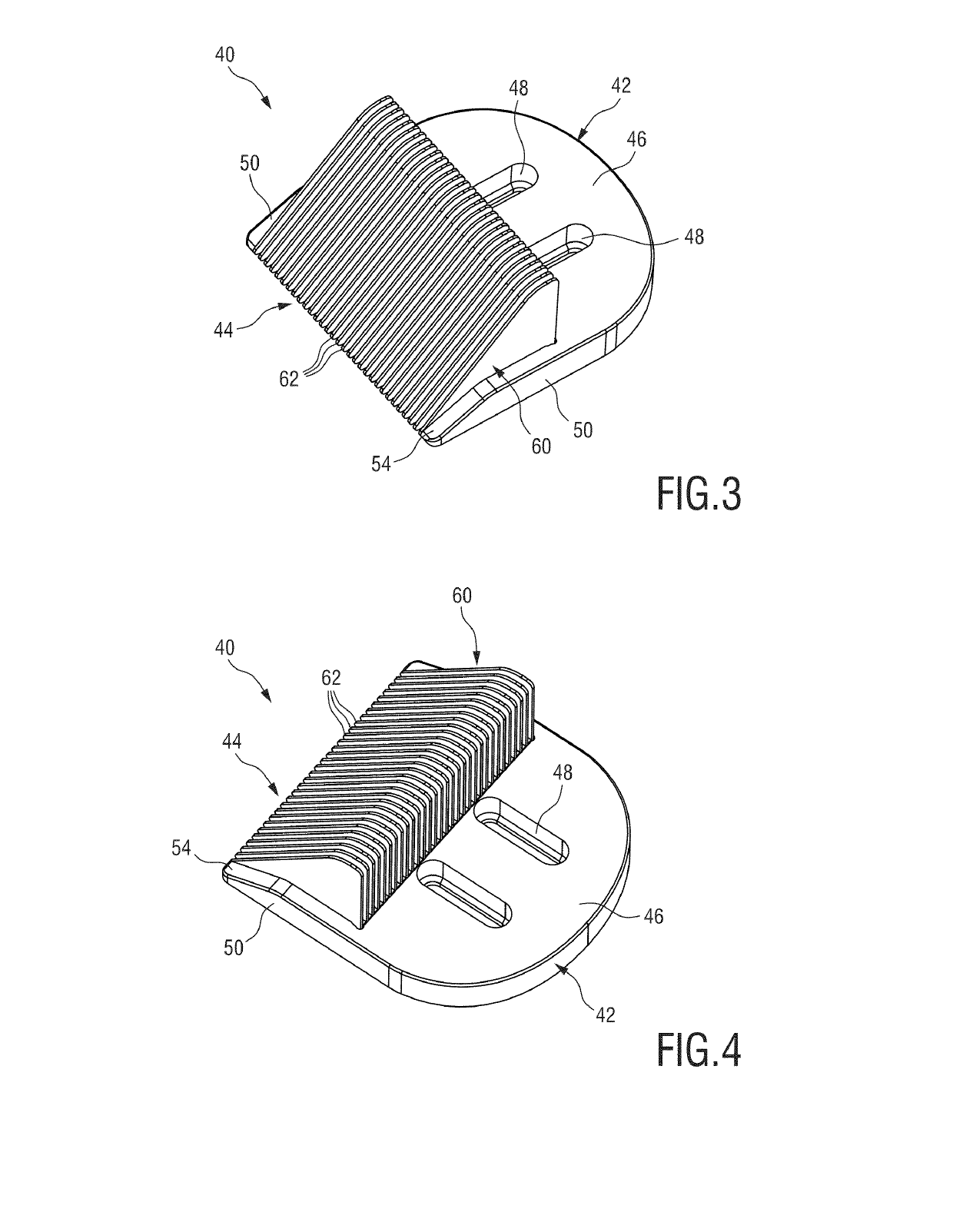

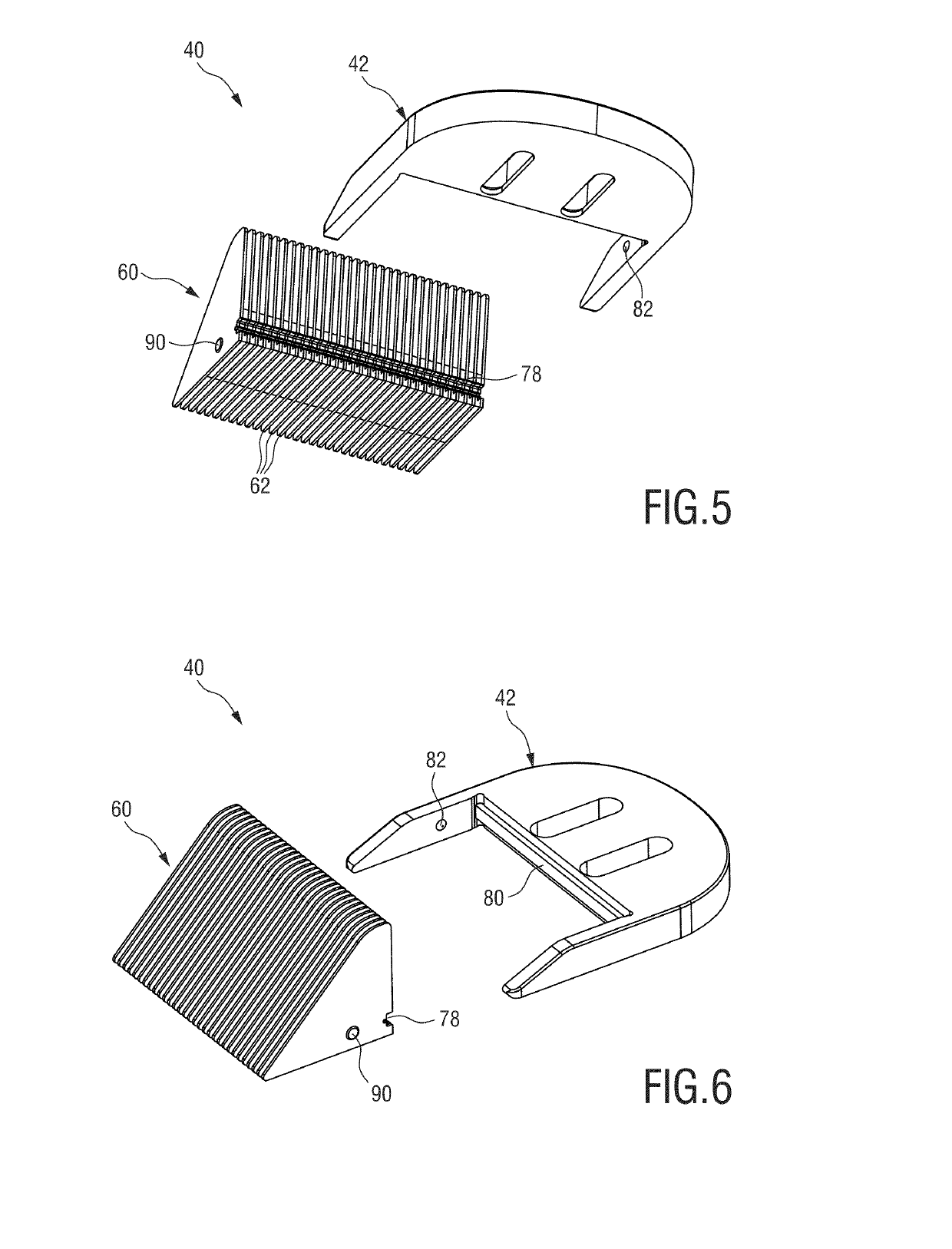

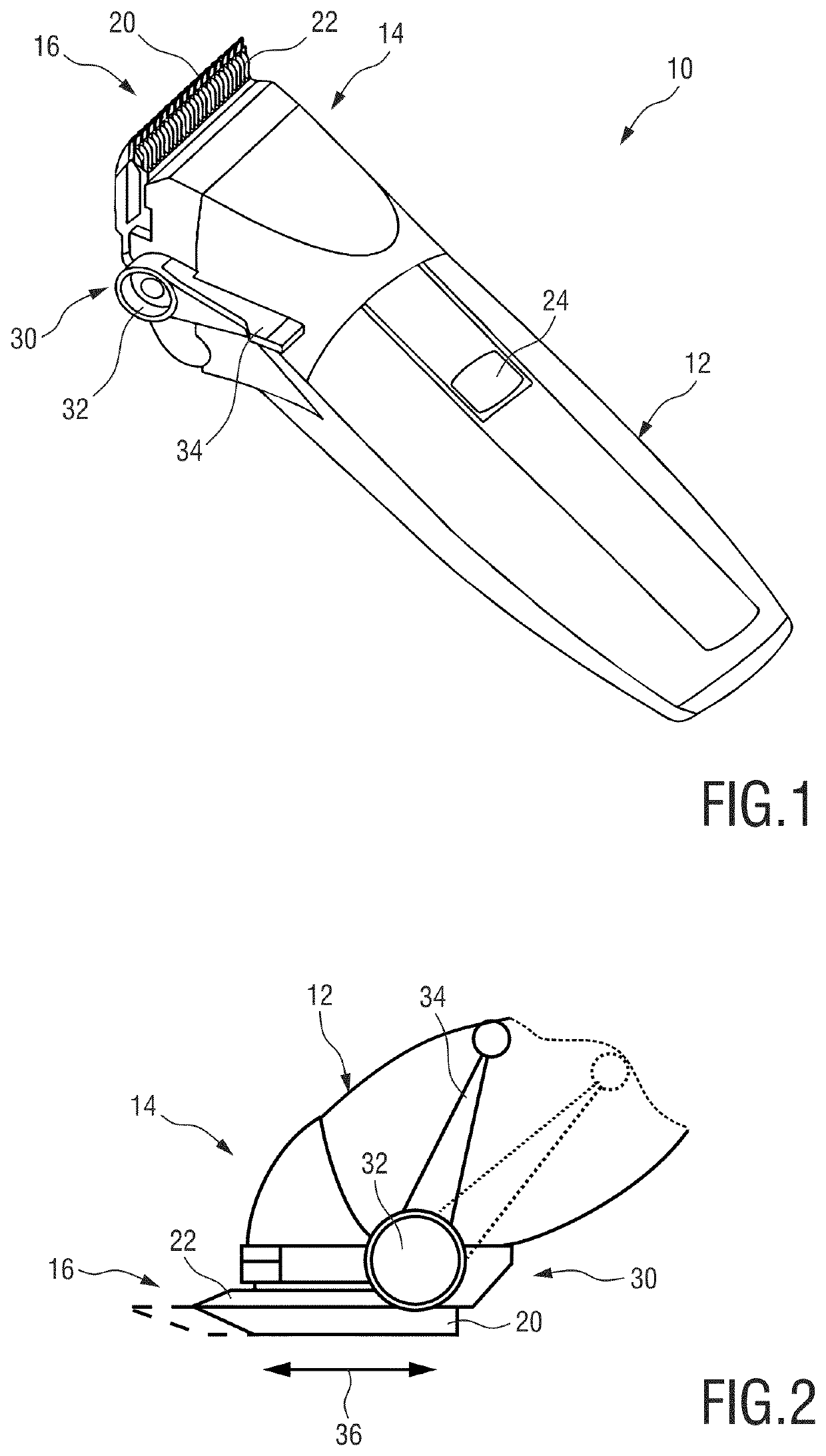

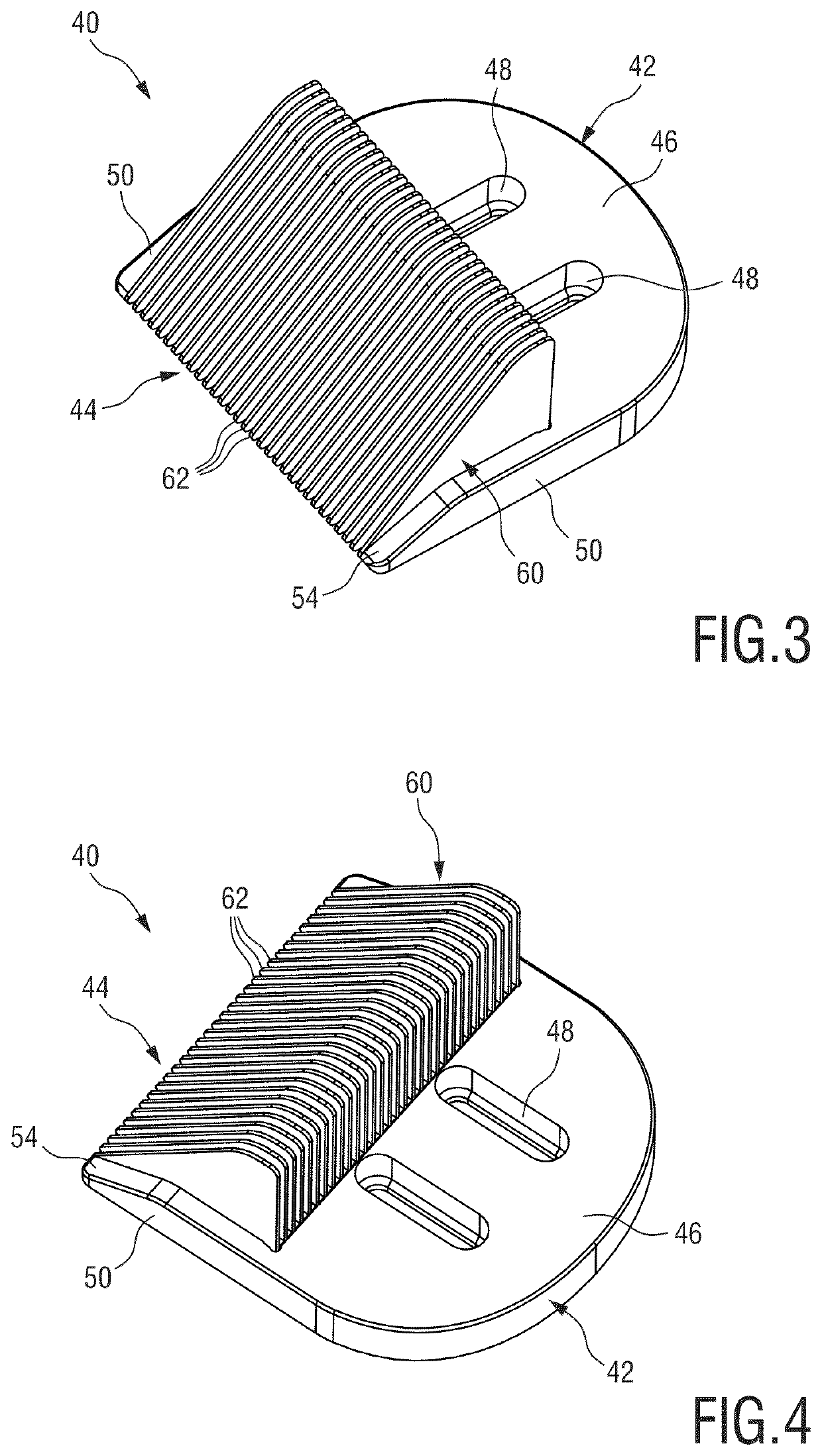

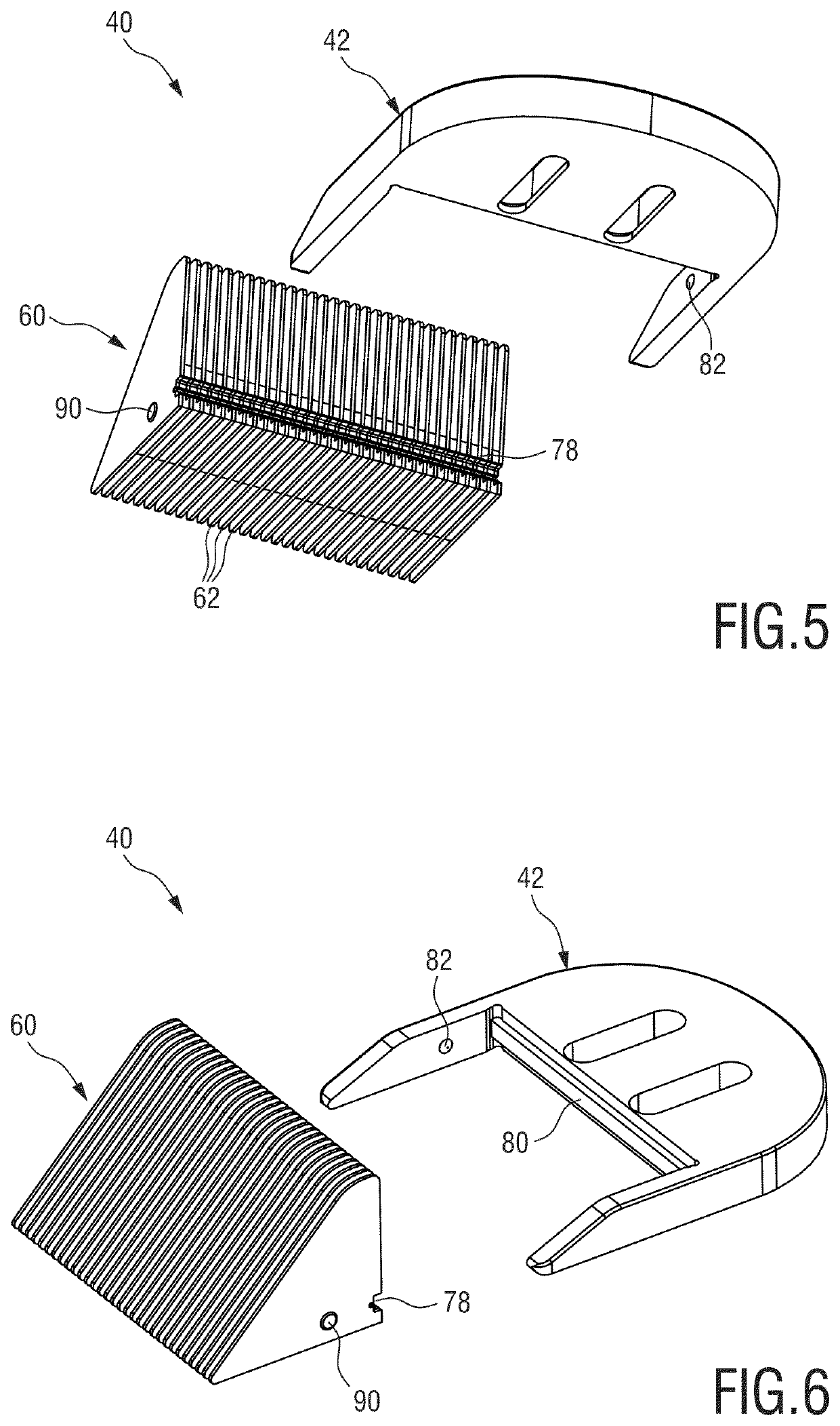

Blade set manufacturing method, blade set and hair cutting appliance

ActiveUS20190152076A1Improve business performanceExpand the adjustment rangeMetal working apparatusMetallic materialsEngineering

The present disclosure relates to a method of forming a stationary blade (40), to a stationary blade (40) for a hair cutting appliance (10) and to a hair cutting appliance (10). The method comprises providing a plurality of tooth components (64) obtained from metal material, the tooth components (64) being arranged in a substantially flat fashion and at least partially tapered towards a tip end (70) thereof, arranging the tooth components (64) in series, wherein neighboring tooth components (64) are arranged at an offset from one another, providing a blade base (42) acting as a support receptacle, arranged to receive the tooth components (64), and interconnecting the tooth components (64) and the blade base (42) in a direct or mediate fashion, thereby forming a plurality of teeth (62) of the stationary blade (40).

Owner:KONINKLJIJKE PHILIPS NV

Blade set manufacturing method, blade set and hair cutting appliance

ActiveUS10668635B2Expand the adjustment rangeImprove business performanceMetal working apparatusMetallic materialsKnife blades

A stationary blade for a hair cutting appliance and a method of forming the stationary blade includes providing tooth components obtained from metal material, where the tooth components are arranged in a substantially flat fashion and are at least partially tapered towards a tip end. The method further includes arranging the tooth components next to each other to form a series of spaced apart teeth, where neighboring tooth components are arranged at a distance from one another; providing a blade base acting as a support receptacle, arranged to receive the tooth components; and interconnecting the tooth components and the blade base in a direct or mediate fashion, thereby forming teeth of the stationary blade.

Owner:KONINKLJIJKE PHILIPS NV

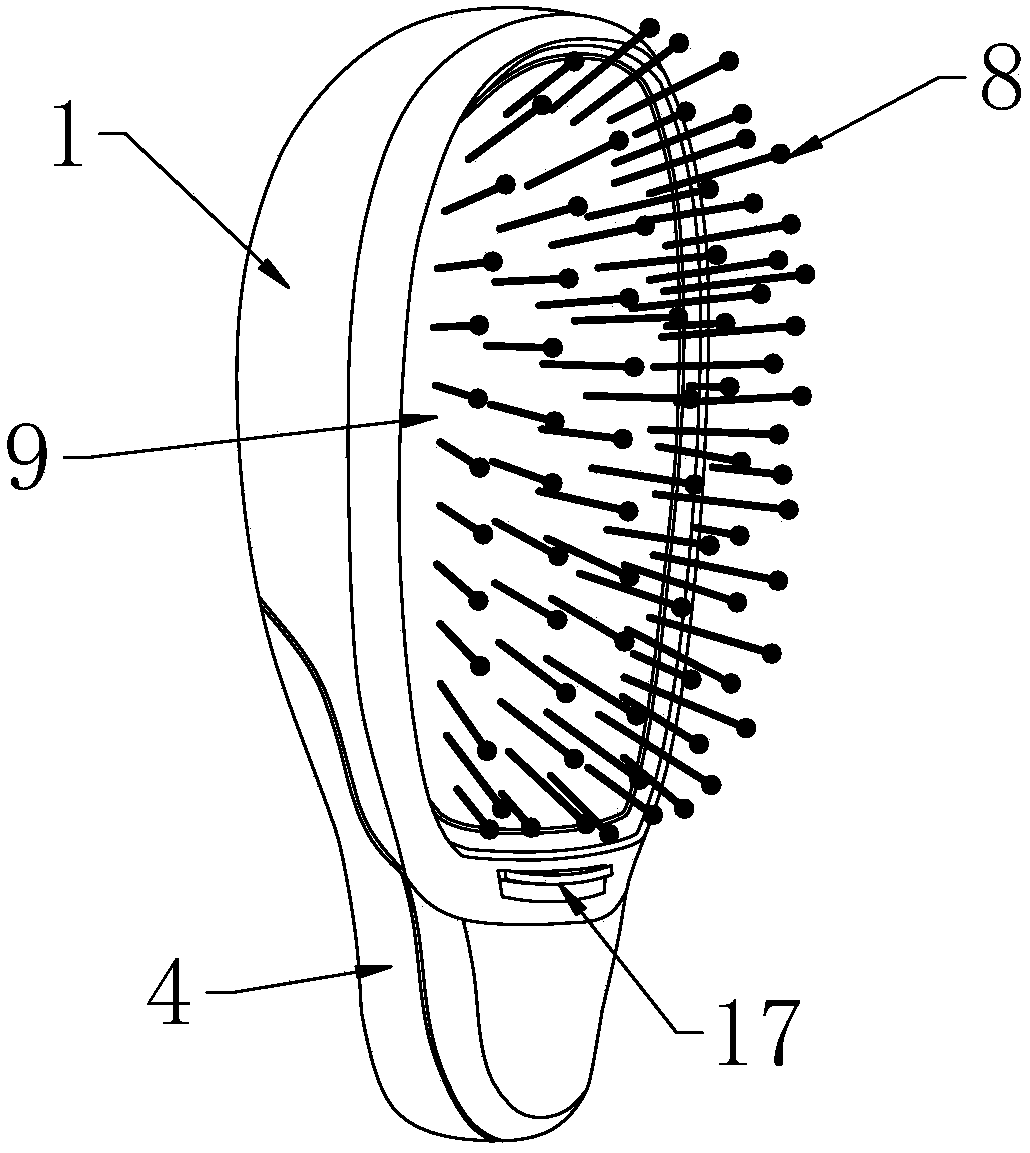

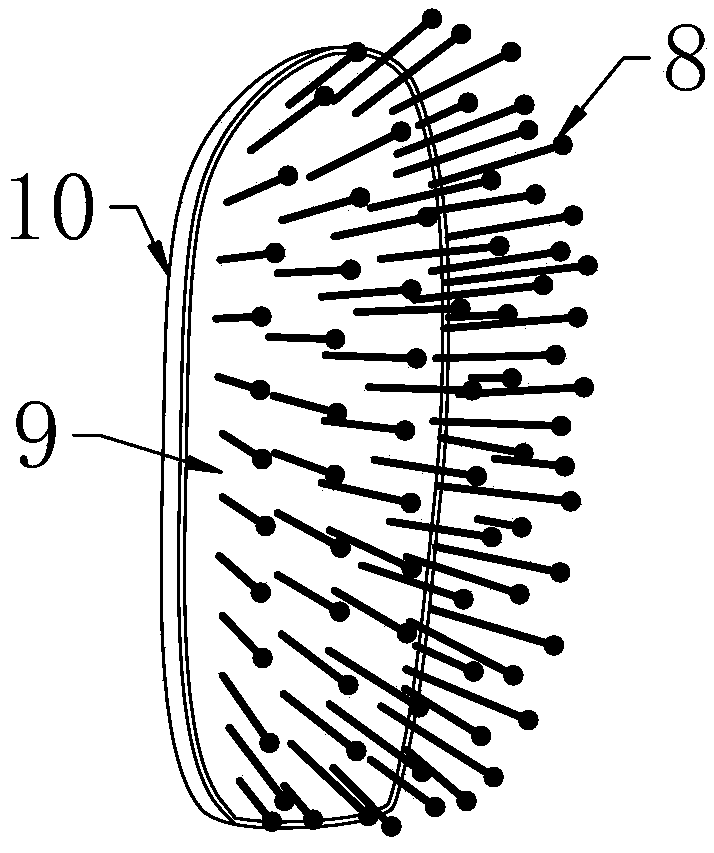

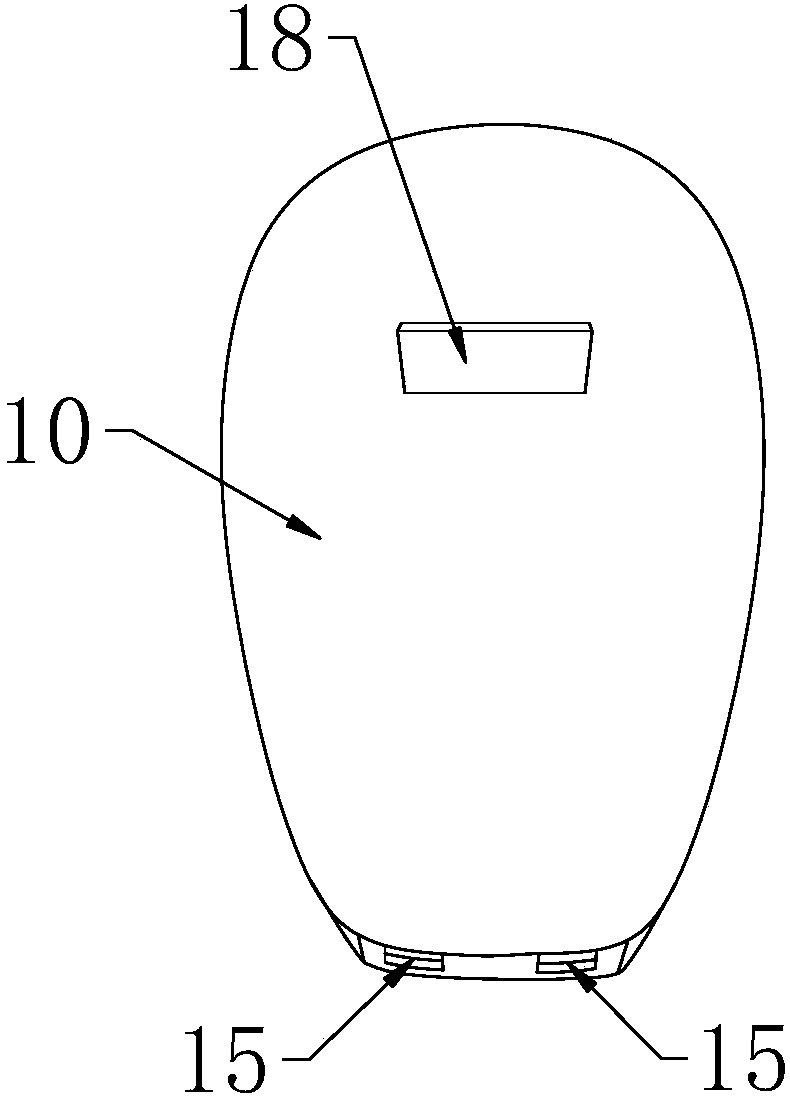

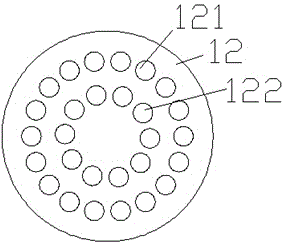

Plasma comb

The invention provides a plasma comb. The plasma comb comprises a comb body and a comb tooth component, wherein the back of the comb body forms a single hand controllable streamline; the comb body comprises a hollow cavity formed inside the comb body, a comb body groove formed in the front surface of the comb body and used for internal embedding the comb tooth component, a convex edge formed by the comb body groove, and a battery compartment arranged on the back of the bottom of the comb body; a miniature plasma generator is fixedly arranged in the hollow cavity; and a positive ion emitting opening and a negative ion emitting opening are formed in the inner wall of the convex edge. The plasma comb is based on the miniature plasma generator, and produces a large amount of positive ions andnegative ions, and the negative ions can ensure that hair is softer and conveniently cared; and the moment of positive and negative charge neutralization of the positive ions and the negative ions inthe air produces huge energy to be released, so that bacteria are died, and the germicidal effect is realized.

Owner:慈溪市香格电器有限公司

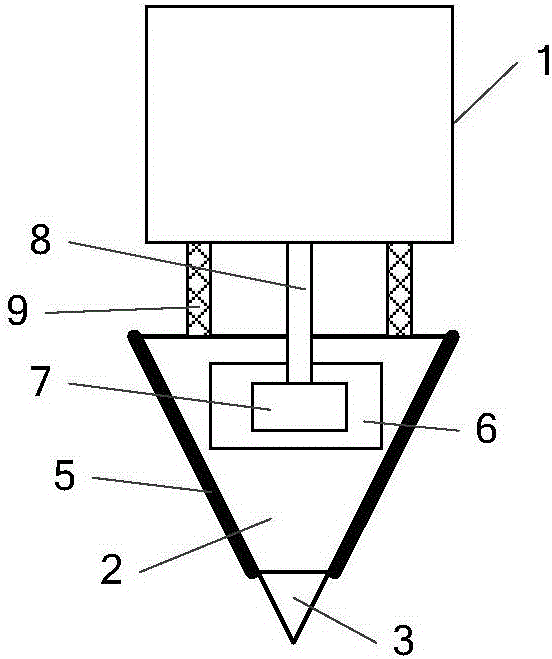

Garbage disposal device with heat dissipation function

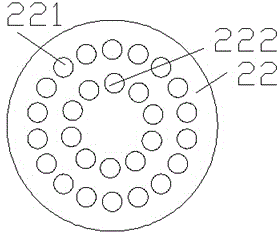

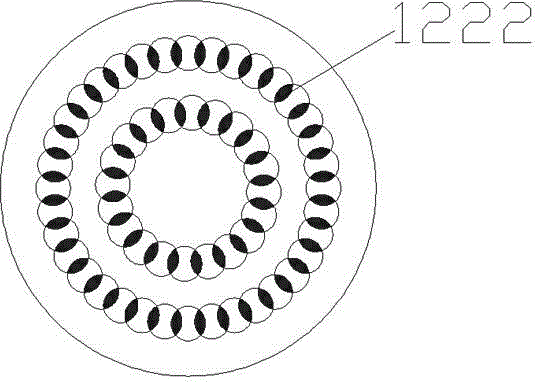

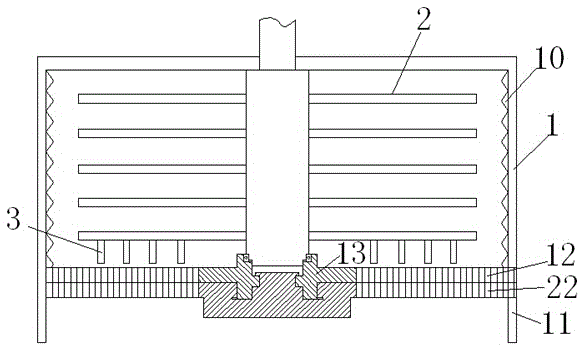

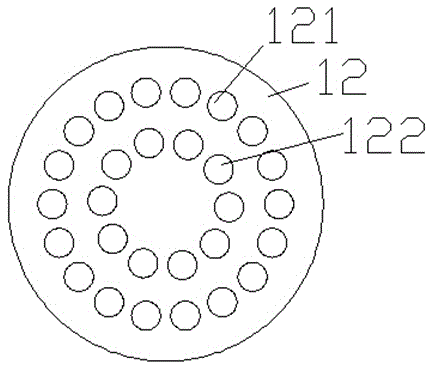

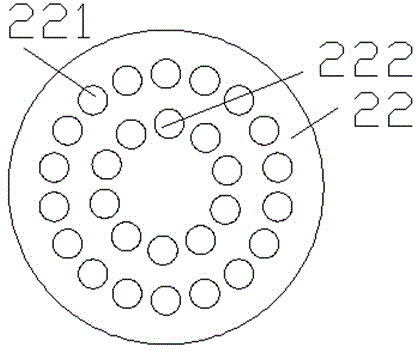

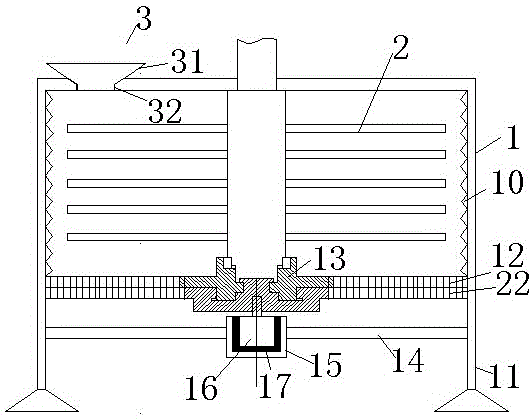

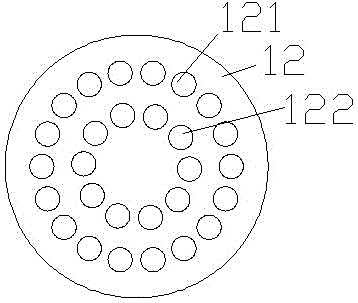

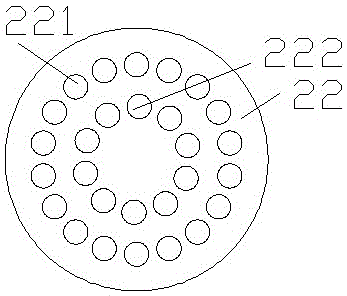

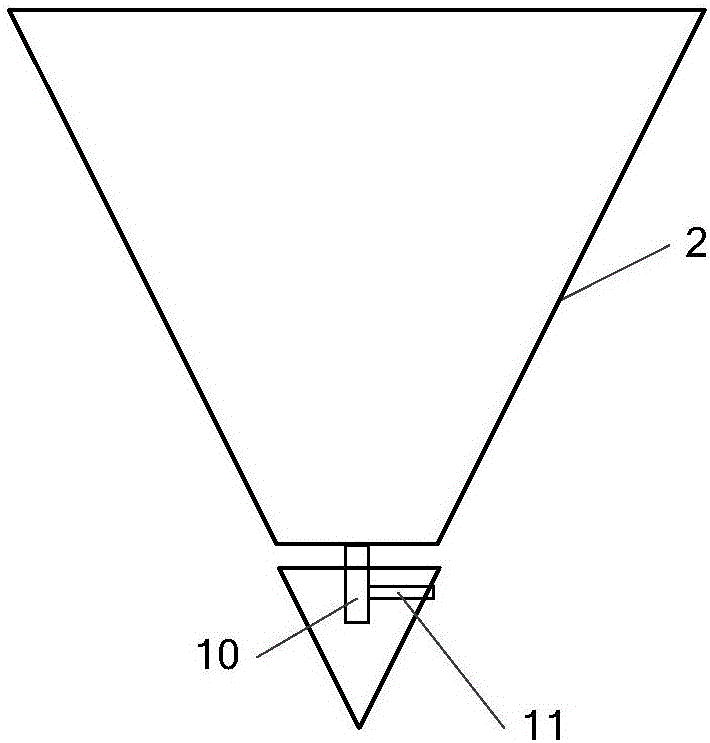

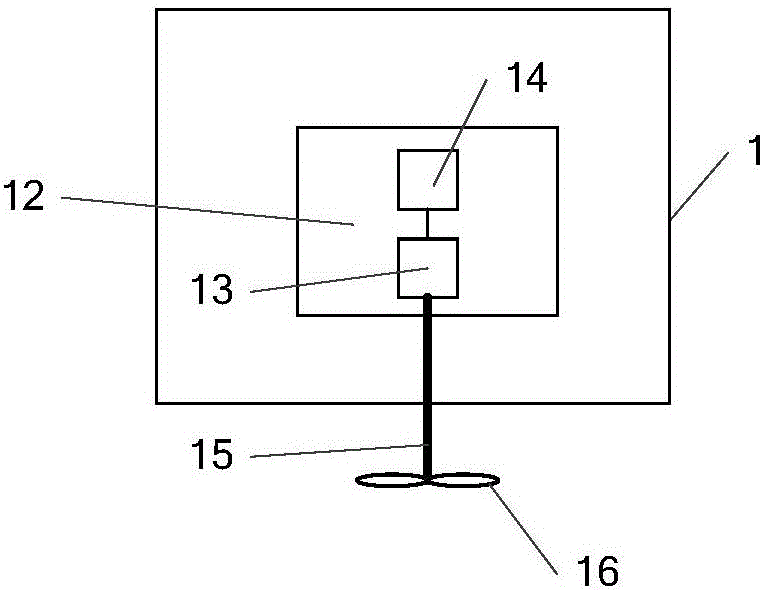

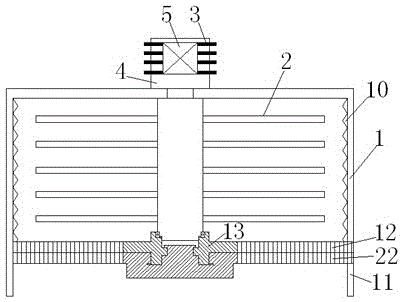

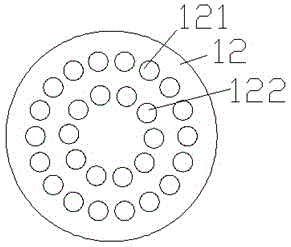

A garbage disposal device with a heat dissipation function is used for performing crushing process on garbage, and comprises a housing (1) of internal spurs (10) for smashing garbage during movement; an upper sieve plate (12) is fixed at the bottom of the housing (1); a centre bearing part (13) is arranged in the center of the upper sieve plate (12); the upper part of the centre bearing part (13) partially bears a crushing tooth component (2) in a rotary manner; the lower part of the centre bearing part (13) partially bears a lower sieve plate (22) in a rotary manner; a driving motor (4) is arranged in the center of the top part of the housing (1); the surface of the driving motor (4) is coated with radiating fins (3) used for absorbing and radiating heat generated by the driving motor (4) during running; the bottom of the driving motor (4) is in rotational connection with the crushing tooth component (2); a vertical frame (11) is fixedly arranged at the lower end of the housing (1), and is used for allowing the lower part of the lower sieve plate (22) to be overhead.

Owner:吴扬华

Garbage disposal device with stirring function

A garbage disposal device with a stirring function is used for pulverizing garbage and comprises a shell (1) which is provided with internal protruding tips (10) for smashing the garbage in the motion process, and an upper screen plate (12) is fixedly arranged at the bottom of the shell (1); a central bearing portion (13) is arranged at the central portion of the upper screen plate (12), and a pulverizing tooth component (2) is rotatably borne on the upper portion of the central bearing portion (13); a lower screen plate (22) is rotatably borne on the lower portion of the central bearing portion (13), and stirring teeth (3) are connected to the bottom of the pulverizing tooth component (2); the stirring teeth (3) are perpendicularly and fixedly connected with the pulverizing tooth component (2), and the stirring teeth (3) and the upper screen plate (12) are oppositely arranged in a suspension manner; and the number of the stirring teeth (3) is one or more, and a vertical frame (11) is fixedly arranged at the lower end of the shell (1) and is used for enabling the lower portion of the lower screen plate (22) to be aerial.

Owner:舒泳军

Low-vibration garbage crushing device

InactiveCN105080660AEasy to operateSimple structureSolid waste disposalGrain treatmentsEngineeringTooth Component

Owner:TONGXIANG CITY KENIER COMMODITY

Cloth dyeing device

ActiveCN107881684AImprove dyeing efficiencyThe purpose of efficient dyeingTextile treatment containersTextile treatment machine arrangementsHydraulic cylinderCoupling

The invention discloses a cloth dyeing device and relates to the technical field of textile processing. The cloth dyeing device comprises a case body, hydraulic cylinders are fixedly arranged on two sides on the top of the case body, sliding blocks are fixedly arranged at the output end of each hydraulic cylinder, the bottom of each sliding block is slidably connected with the top of the case body, a rotating rod is rotatably connected with the top of each sliding block, a motor box is rotatably connected with the tops of the rotating rods, a first rotating motor is fixedly arranged in the motor box, and a first rotating shaft is fixedly connected with an output shaft of the first rotating motor through a coupling. Cloths soaked with dyeing liquor at the bottom of the case body are delivered to the upper part of the dyeing liquor through a rotating plate, at the moment, a semi-gear is driven by a second rotating motor, a lifting plate is driven to ascend and descend by the semi-gear through tooth components, and when the semi-gear and teeth are separated, the lifting plate is driven to move downward by a first spring to perform hitting on the cloths, so that the dyeing liquor in the cloths seeps out, the cloths can absorb more dyeing liquor, and the design improves the dyeing efficiency of the cloths.

Owner:重庆稳稳科技有限公司

Lurking type composite solid lubrication cutting tooth component of coal cutter and lurking type composite solid lubrication cutting tooth component method

InactiveCN103174420AExtended service lifeSave manufacturing resourcesCutting machinesEngineeringLubrication

The invention relates to the technical field of coal mining, and in particular relates to a lurking type composite solid lubrication cutting tooth component of a coal cutter and a lurking type composite solid lubrication cutting tooth component method. The component comprises a cutter tooth, a cutter tooth sleeve and a cutter tooth base, wherein the upper end of the cutter tooth is a tapered body; the lower end of the cutter tooth is formed into a cutter tooth handle by a cylindrical body; the cutter tooth sleeve is sleeved at a cutter tooth handle end of the cutter tooth; the cutter tooth sleeve is located and assembled inside the cutter tooth base; and a gap coaxial body is formed by the cutter tooth, the cutter tooth sleeve and the cutter tooth base. The component is characterized in that at least one gap surface of the cutter tooth and the cutter tooth sleeve and a gap surface of the cutter tooth sleeve and the cutter tooth base are provided with lurking pits; and a waterproof, dustproof and long-acting composite solid lubricant special for a GR cutter tooth is filled into the gap between the cutter tooth and the cutter tooth sleeve and inside the lurking pits. The invention provides the lurking type composite solid lubrication cutting tooth component of the coal cutter and the lurking type composite solid lubrication cutting tooth component method, so that the problems that the parts between the cutter tooth and the cutter tooth sleeve and between the cutter tooth sleeve and the cutter tooth base are severely abraded in the prior art are solved, and the service lives are short.

Owner:西安奥奈特固体润滑工程学研究有限公司

Material crushing equipment used for agriculture and provided with LED illuminating lamp

The invention discloses material crushing equipment used for agriculture and provided with an LED illuminating lamp. The material crushing equipment comprises a crushing executing box (91) and an auxiliary box body (93) fixed to the lateral portion of the crushing executing box (91). A driving motor (100) is installed on the upper portion of the auxiliary box body (93). A power wheel (92) is fixedly arranged on a driving shaft of the driving motor (100) so as to drive a crushing tooth belt wheel (95) and a slag outlet baffle driving wheel (94) through two belts respectively. The crushing tooth belt wheel (95) is coaxially connected with a crushing tooth component (96), so that materials conveyed into the crushing executing box (91) through a feeding port (961) are crushed; in addition, the crushed materials are screened through a screen plate (97) arranged at the bottom of the crushing executing box (91) and fall into a crushed material output cavity (971), so that the crushed materials are output.

Owner:XIAMEN CITY WANJIACAN LIGHTING CO LTD

Excavator bucket tooth assembly convenient to replace

InactiveCN106759631AEasy to replaceReduce replacement costsSoil-shifting machines/dredgersEngineeringExcavator

The invention discloses an excavator bucket tooth assembly convenient to replace. The excavator bucket tooth assembly comprises a tooth base and a bucket tooth. The bucket tooth comprises a tooth tip, a tooth body and four tooth plates. The front surface, the back surface, the left side surface and the right side surface of the tooth body are each provided with a second fixing hole. Second fixing nails are inserted into the second fixing holes to fix the four tooth plates to the tooth body. The tooth body is internally provided with a first cavity. The first cavity is internally provided with a sliding block. A communicating hole is formed between the first cavity and the back end of the tooth body. One end of a connecting rod is connected with the tooth base. The other end of the connecting rod penetrates through the communicating hole and is connected with the sliding block. A buffer spring is connected between the tooth base and the tooth body. The technical effects that only parts of the bucket tooth components need to be replaced, replacing is convenient, the replacing cost is low, and damage is not prone to occurring are achieved.

Owner:永平县建达鑫鑫合金铸造有限公司

Garbage disposal device radiating through fan

InactiveCN105032551AEasy to operateSimple structureSolid waste disposalGrain treatmentsDrive motorEngineering

A garbage disposal device radiating through a fan is used for carrying out smashing treatment on garbage and comprises a shell (1) provided with internal protruding tips (10) used for smashing the garbage in the motion process, and an upper screen plate (12) is fixedly arranged at the bottom of the shell (1); a central bearing portion (13) is arranged at the central position of the upper screen plate (12), and a smashing tooth component (2) is rotatably borne on the upper portion of the central bearing portion (13); a lower screen plate (22) is rotatably borne on the lower portion of the central bearing portion (13), and a driving motor (4) is arranged in the middle of the top of the shell (1); the surface of the driving motor (4) is wrapped with radiating fins (3), and a radiating fan (5) is arranged on the radiating fins, and the bottom of the driving motor (4) is in transmission connection with the smashing tooth component (2); and a vertical frame (11) is further fixedly arranged at the lower end of the shell (1) and is used for enabling the lower screen plate (22) to be erected overhead.

Owner:吴扬华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com