Improved lime mud recovering process and its application for producing neutral glue blending paper

A white mud and process technology, applied in the white mud recycling process and its application in the production of neutral sizing paper, can solve the problems of light calcium carbonate not meeting the national standard quality requirements, cumbersome procedures, waste of resources, etc. Achieve significant social and environmental benefits, increase economic benefits, and reduce secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

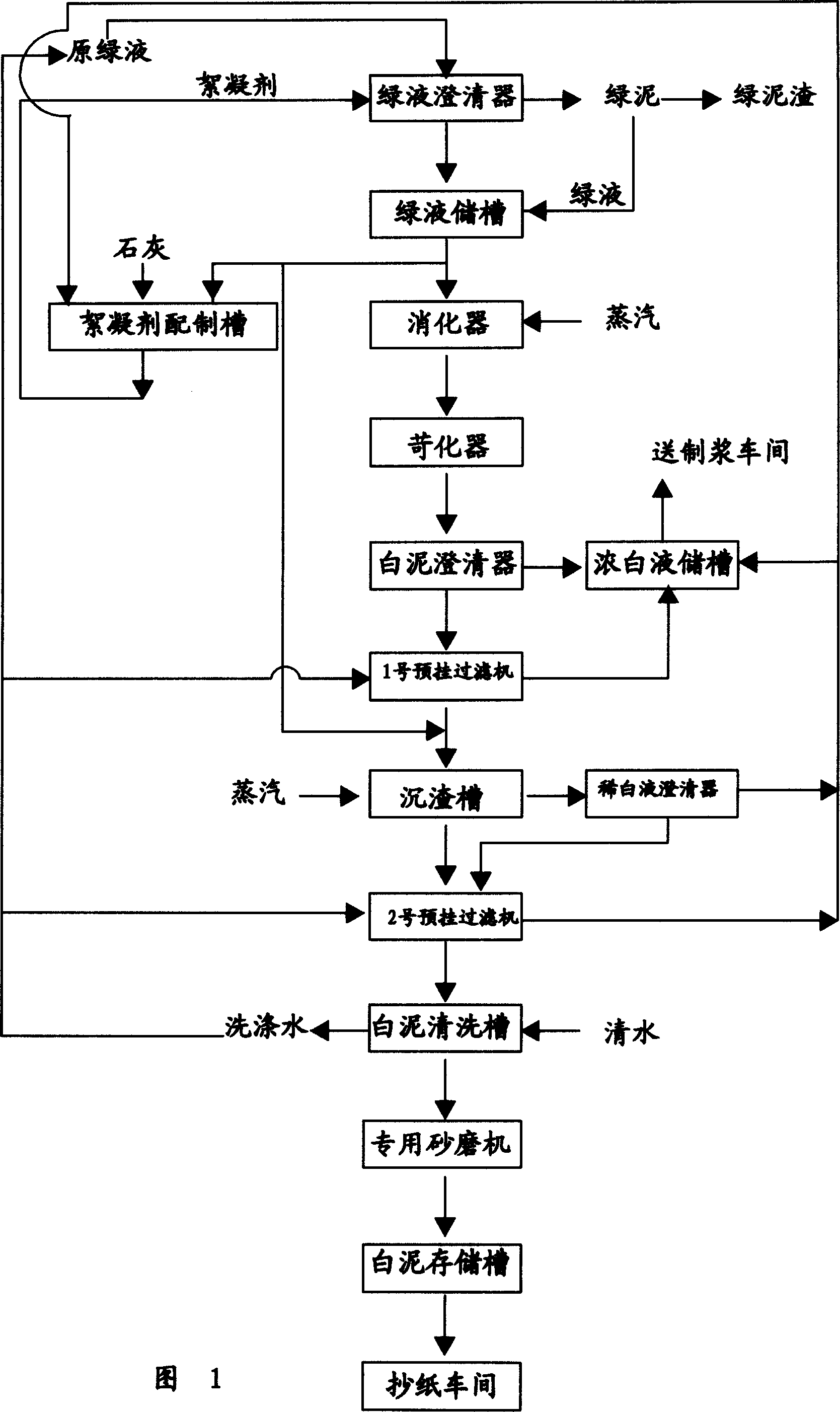

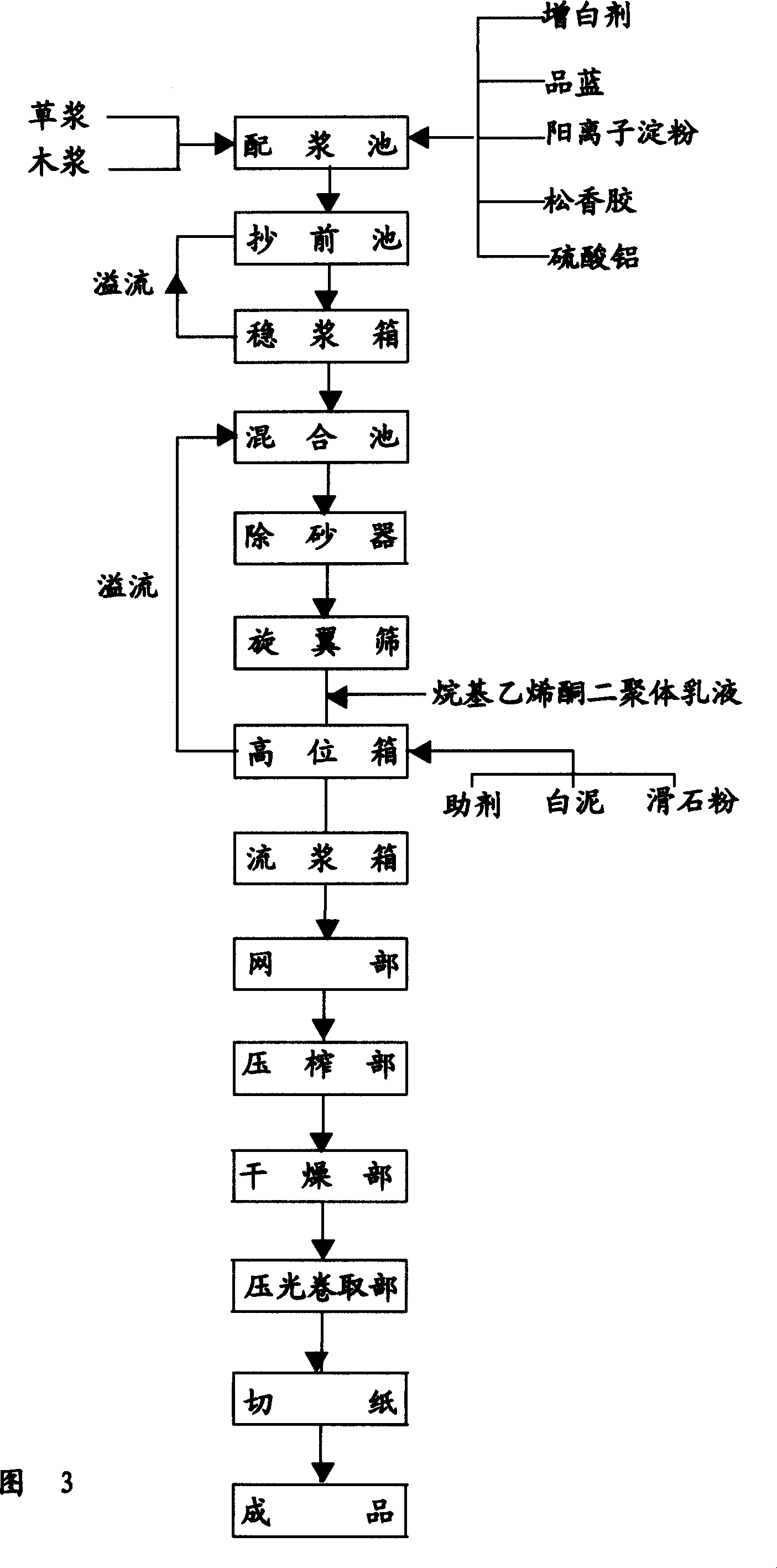

[0042] Embodiment 1 A kind of improved recycling lime mud process and its application in neutral sizing paper

[0043] That is to add a flocculation step in the clarification process of the original green liquor, the green liquor assists the causticizing step to the lime mud, and adds washing residual alkali and grinding and regularizing steps to the lime mud, wherein:

[0044] (1) Add milk of lime to its flocculation treatment in the original green liquor, the concentration of milk of lime is 8~10% w / w,

[0045] Its weight ratio is: former green liquid: milk of lime=30:1;

[0046] During flocculation treatment, the temperature is 90-100°C; stirring for 20-40 minutes; the treatment liquid is left to stand, and the green mud residue is separated for separate treatment;

[0047] (2) The clear green liquid that separation obtains assists causticizing to the white mud in the sedimentation tank, the white mud concentration is 30% w / w,

[0048]Its weight ratio is: white mud: clear...

Embodiment 2

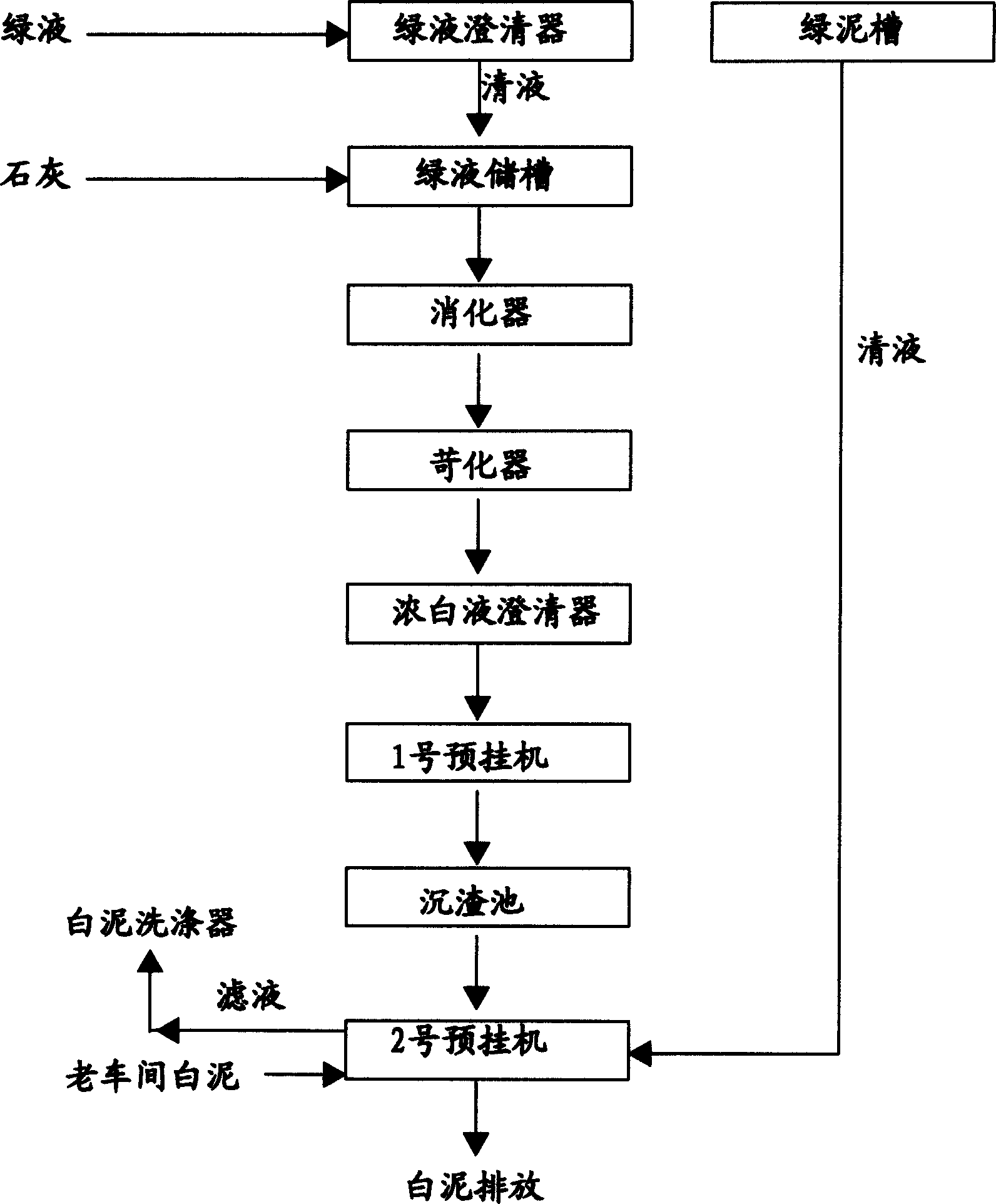

[0084] Recycling white mud process

[0085] (1) Add milk of lime to its flocculation treatment in the original green liquor, the concentration of milk of lime is 8~10% w / w,

[0086] Its weight ratio is: former green liquid: milk of lime=30: 1.2;

[0087] During flocculation treatment, the temperature is 90-100°C; stirring for 20-40 minutes; the treatment liquid is left to stand, and the green mud residue is separated for separate treatment;

[0088] (2) The clear green liquid that separates obtains assists causticizing to the white mud in the sedimentation tank, and the white mud concentration is 25% w / w,

[0089] Its weight ratio is: white mud: clear green liquor = 5:1; under conventional stirring, the auxiliary causticizing temperature is 90-100°C;

[0090] (3) Wash the residual alkali in the white mud with normal water, the weight ratio of water consumption and white mud is: white mud: water=1:8;

[0091] After stirring and washing, the residual alkali content is reduced...

Embodiment 3

[0099] Recycling white mud process

[0100] (1) Add milk of lime to its flocculation treatment in the original green liquor, the concentration of milk of lime is 8~10% w / w,

[0101] Its weight ratio is: former green liquid: milk of lime=30: 1.1;

[0102] During the flocculation treatment, the temperature is 90-100°C; stirring for 30 minutes; the treatment solution is left to stand, and the green sludge is separated and treated separately;

[0103] (2) The clear green liquid that separates obtains assists causticizing to the white mud in the sedimentation tank, and the white mud concentration is 28% w / w,

[0104] Its weight ratio is: white mud: clear green liquor = 6:1; under conventional stirring, the auxiliary causticizing temperature is 90-100°C;

[0105] (3) Wash the residual alkali in the white mud with normal water, the weight ratio of water consumption and white mud is: white mud: water=1:9;

[0106] After stirring and washing, the residual alkali content is reduced t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Sedimentation volume | aaaaa | aaaaa |

| Dust | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com