Belt sander

An abrasive belt machine and abrasive belt technology, applied in the field of abrasive belt machines, can solve the problems of troublesome belt replacement, low production efficiency, low grinding efficiency, etc., and achieve the effects of ensuring grinding quality, high processing efficiency, and rapid grinding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

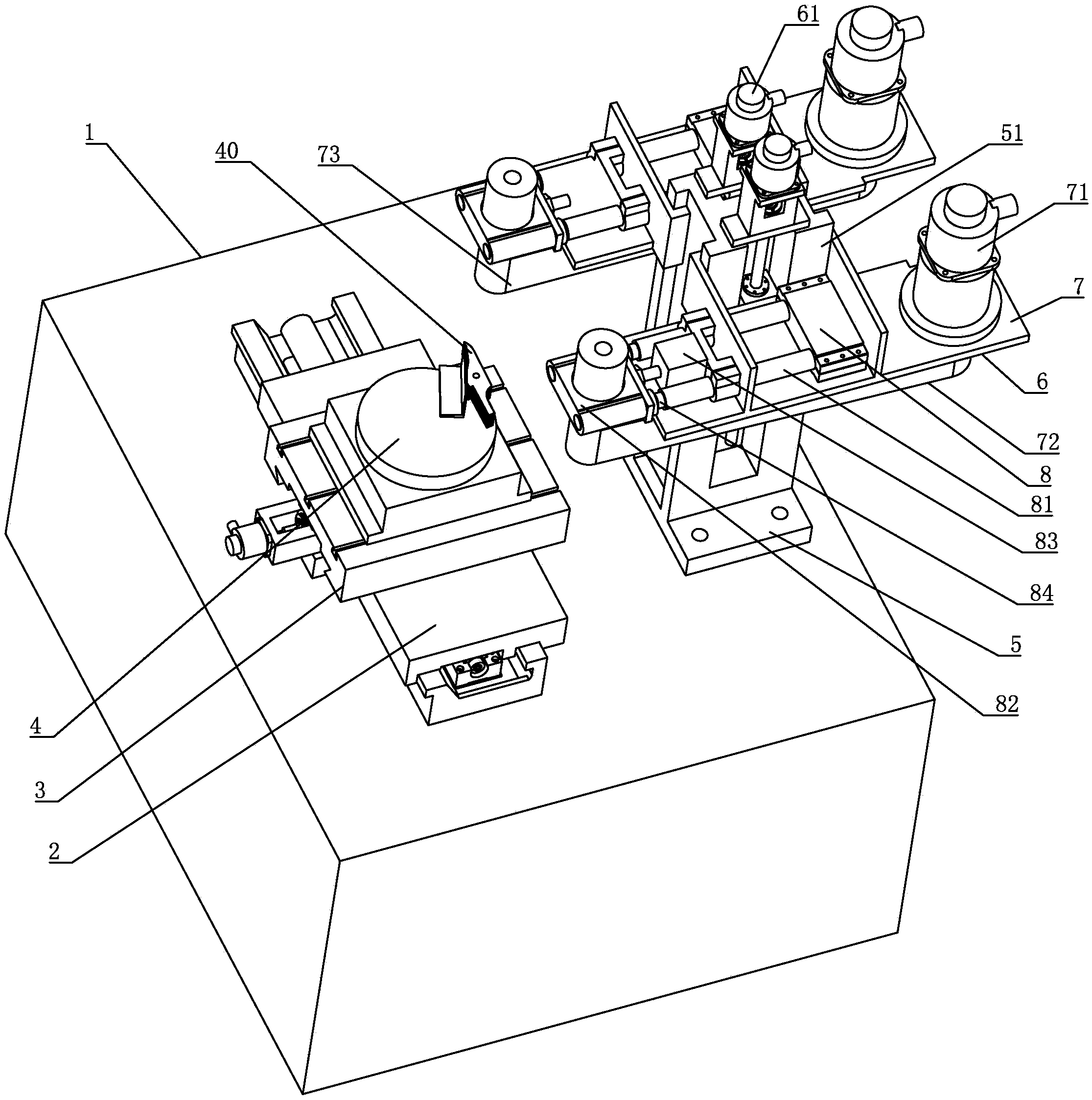

[0016] Such as Figure 1~Figure 2 As shown, a belt sander includes a base 1, on which an X-axis workbench 2 and a Y-axis workbench 3 are arranged, and the moving direction of the X-axis workbench 2 is perpendicular to the moving direction of the Y-axis workbench 3, The Y-axis table 3 is provided with a rotary disk 4 for fixing the workpiece 40, and the rotary disk 4 is provided with more than one station. After the workpiece 40 is placed on the rotary disk 4, the rotary disk 4 Send the workpiece 40 to the required position by rotating, so as to facilitate the processing of the workpiece 40. The base 1 is provided with a Z-axis support 5, and the Z-axis support 5 is vertically provided with two symmetrical slide rails 51, and the Z-axis support 5 is equipped with two symmetrical Z-axis processing devices 6, and the Z-axis The processing device 6 includes a servo motor 61 installed on the Z-axis support 5 and a support table 7 driven by the servo motor 61 to move up and down on...

no. 2 example

[0020] The difference between this embodiment and the first embodiment is that the guide rails 81 are square rails, and a slider is installed on the end of each guide rail 81 away from the fixed block 8, and the support base 82 is fixedly connected to the slider .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com