Whole bamboo high strength composite industrial floor

A composite floor, high-strength technology, used in manufacturing tools, wood processing appliances, wood veneer bonding and other directions, can solve the problem of small elastic modulus of horizontal grain, low static bending strength of horizontal grain, and low utilization rate of bamboo problems, to achieve the effect of easy softening, fast grinding, and comprehensive production cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

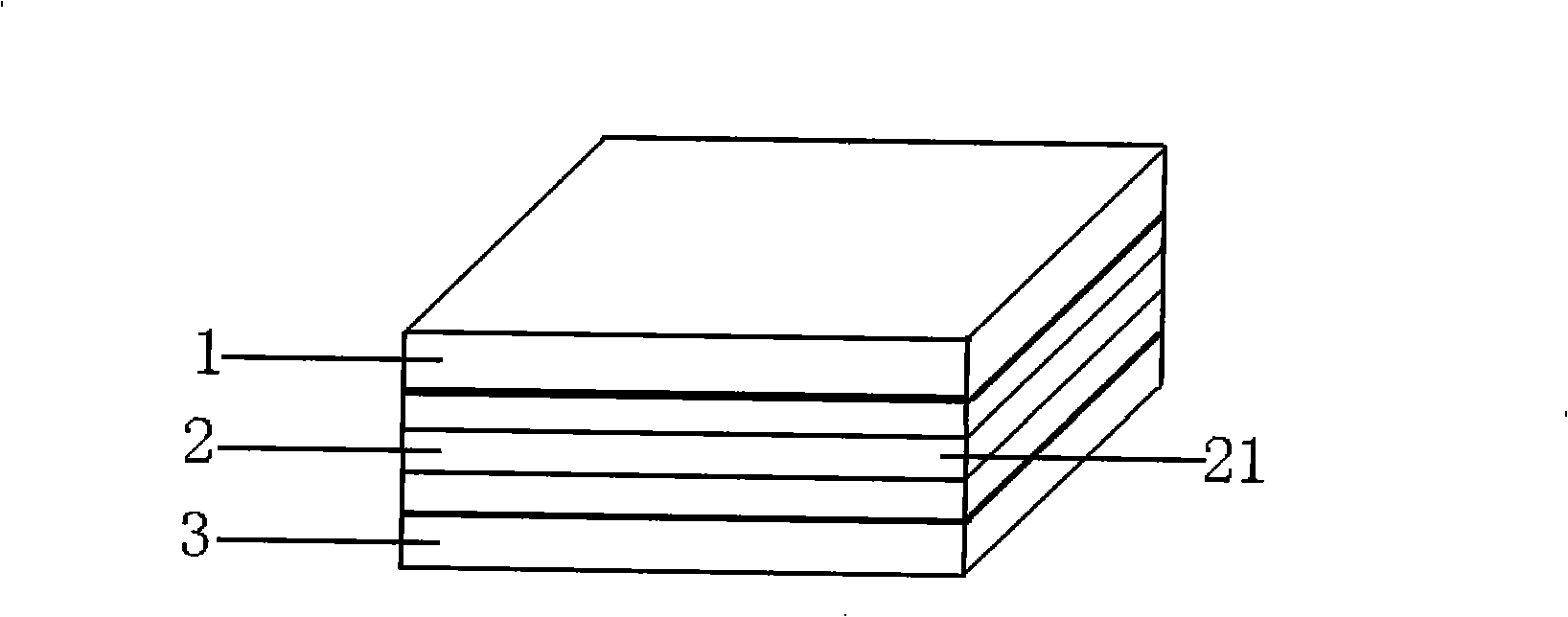

[0052] The panel 1a can be made of the radial surface of bamboo slices according to the functional requirements, and the panel is set off by multi-layer bamboo mats or bamboo curtains stacked vertically and horizontally, so that the natural attributes and characteristics of bamboo complement and strengthen the static bending strength of vertical and horizontal grains , longitudinal and horizontal grain elastic modulus and other indicators need.

[0053] The core board 2a can adopt full bamboo medium density fiberboard or high density fiberboard according to functional requirements.

[0054] The density core board can adopt double-core or single-core technology according to the strength index requirements. If the thickness is thick and the strength index is high, the double core can be stacked with multiple layers of vertical, horizontal and cross bamboo mats or bamboo curtains to balance and optimize the strength index.

[0055] The bottom plate 3a is set off by multi-layer b...

Embodiment 2

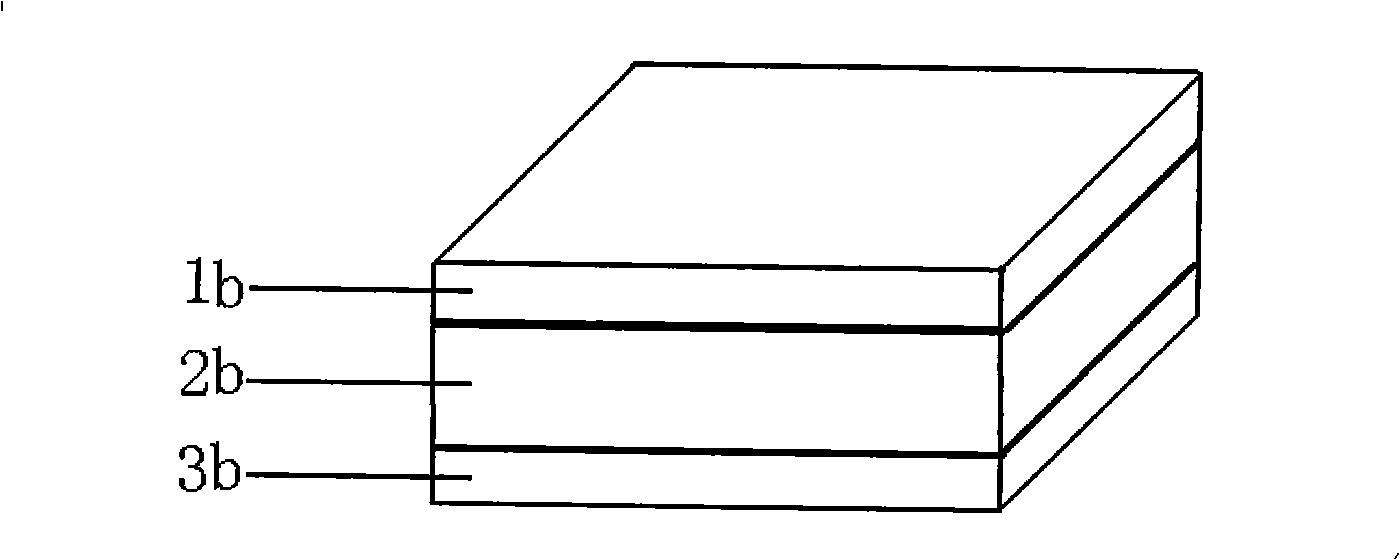

[0057] The panel 1b can be made of the chord surface of bamboo slices according to the functional requirements, and the panel is set off by multi-layered bamboo mats or bamboo curtains stacked vertically and horizontally, so that the natural attributes and characteristics of bamboo complement and strengthen the static bending strength of vertical and horizontal grains , longitudinal and horizontal grain elastic modulus and other indicators need.

[0058] The core board 2b can adopt full bamboo medium density fiberboard or high density fiberboard according to functional requirements.

[0059] The density core board can adopt double-core or single-core technology according to the strength index requirements. If the thickness is thick and the strength index is high, the double core can be stacked with multiple layers of vertical, horizontal and cross bamboo mats or bamboo curtains to balance and optimize the strength index.

[0060] The bottom plate 3b is set off by multiple lay...

Embodiment 3

[0062] The panel 1c can be made of the oblique surface of bamboo slices according to the functional requirements, and the panel is set off by multi-layer bamboo mats or bamboo curtains stacked vertically and horizontally, so that the natural attributes and characteristics of bamboo complement and strengthen the static bending strength of vertical and horizontal grains , longitudinal and horizontal grain elastic modulus and other indicators need.

[0063] The core board 2c can adopt full bamboo medium density fiberboard and high density fiberboard according to functional requirements.

[0064] The density core board can adopt double-core or single-core technology according to the strength index requirements. If the thickness is thick and the strength index is high, the double core can be stacked with multiple layers of vertical, horizontal and cross bamboo mats or bamboo curtains to balance and optimize the strength index.

[0065] The bottom plate 3c is set off by multi-layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com