Grinding Device Of Parting Line Of Resin Molding And Grinding Method

A resin forming and grinding device technology, which is applied in the direction of grinding machines, abrasive belt grinding machines, grinding/polishing equipment, etc., can solve the problems of parting line grinding and achieve the effect of rapid grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

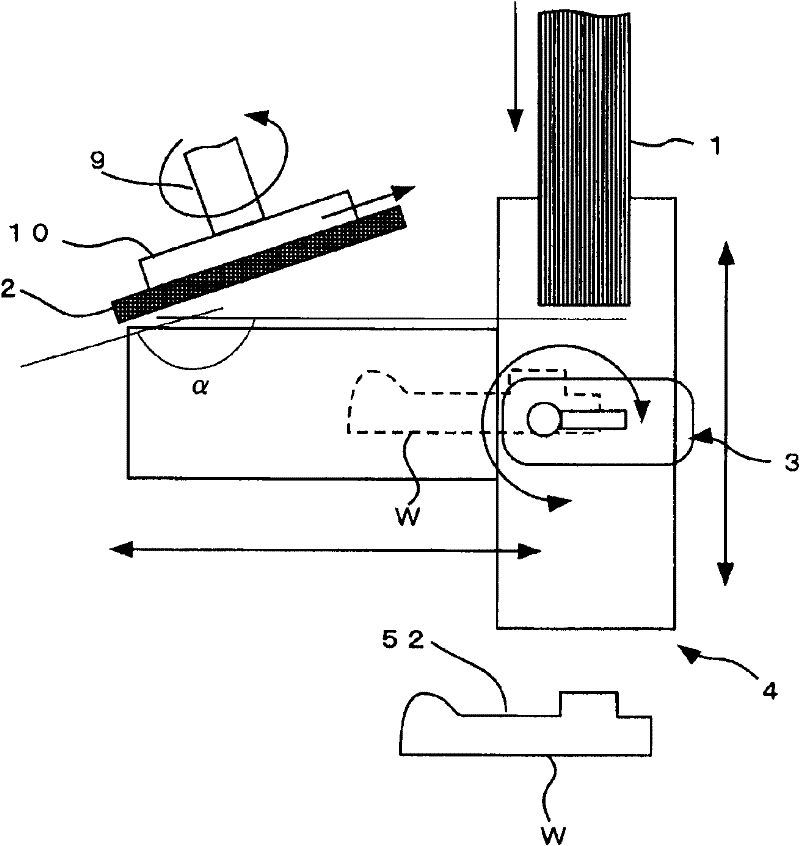

[0070] figure 1 It is a schematic perspective view showing the parting line polishing apparatus of the resin molded product of Example 1. figure 2 It is a schematic plan view showing the parting line polishing apparatus of the resin molded product of Example 1. image 3 It is a schematic side view showing the parting line polishing apparatus of the resin molded product of Example 1.

[0071] The parting line polishing apparatus of the present invention of Example 1 is provided with an endless belt-shaped polishing belt 1 that grinds the parting line 52 of the resin molded product W and travels in a substantially vertical direction, and adjacent to the polishing belt 1, a pair The polishing plate 2 on which the parting line 52 of the resin molded product W is subjected to finish polishing. The resin molded product W is carried using the workpiece holding tool 3 so...

Embodiment 2

[0102] Figure 8 Is an enlarged side view showing the belt pushing pulley of Example 2, Figure 8 (a) is the state of grinding the parting line of the upper corner, Figure 8 (b) is the state where the parting line of the lower corner is polished.

[0103] The belt pressing pulley 21 of the second embodiment replaces the structure in which the above-mentioned two pressing pulleys 22 advance and retreat, and is a structure by a seesaw method. The belt pressing pulley 21 is configured by attaching two pressing pulleys 22 freely advancing and retreating toward the back of the polishing belt 1 at both ends, and the intermediate position 32 of the connecting member 31 is rotated in a seesaw shape with an adjustment handle 33, which can be changed The inclination angle of the inclined surface of the polishing belt 1.

[0104] The parting line 52 formed on the upper corner of the resin molded product W is as Figure 8 As shown in (a), the belt pressing pulley 21 is inclined to grind the r...

Embodiment 3

[0108] Picture 9 It is a cross-sectional view showing the rotating plate of Example 3 provided with injection holes for removing the polishing slag of the polishing plate.

[0109] In the third embodiment, the rotating plate 10 is provided with injection holes 41 for removing the polishing slag adhering to the polishing plate 2. If the polishing plate 2 is used for a long period of time, the abrasive grains on the polishing surface of the resin molded product W will be clogged, and the polishing ability will decrease. Therefore, in the rotating plate 10 holding the polishing plate 2, a plurality of injection holes 41 are opened along the axial direction of the rotating shaft 9. By injecting compressed air from the injection hole 41, the polishing slag adhering to the polishing plate 2 can be removed in the state where the polishing plate 2 is mounted on the rotating plate 10. In the example shown in the figure, the supply of air to the injection hole 41 is a structure in which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com