Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Poor miscibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for making contact lenses

InactiveUS20070037897A1Quality improvementMinimizes entanglementOptical articlesLensFluid compositionPolymer chemistry

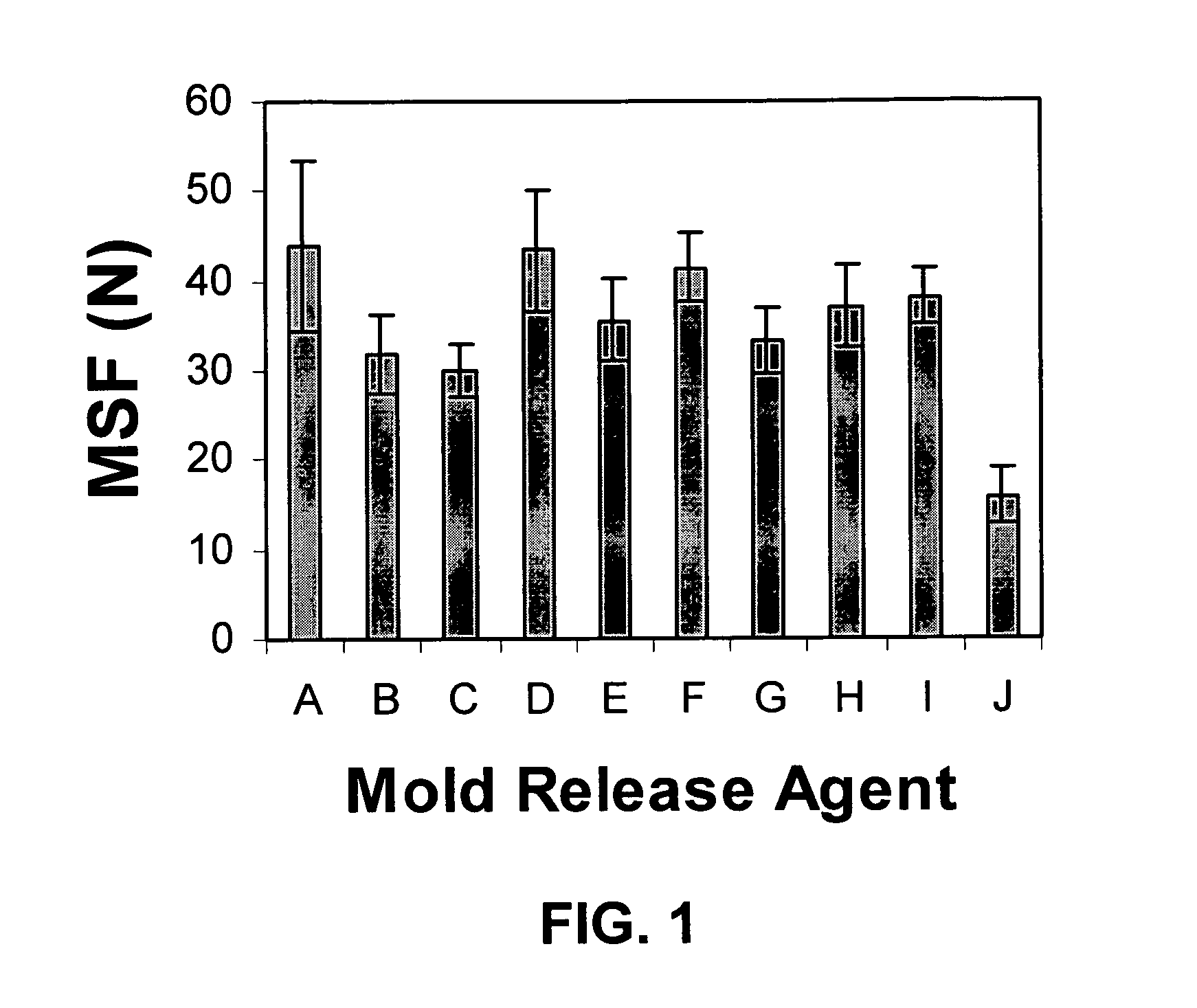

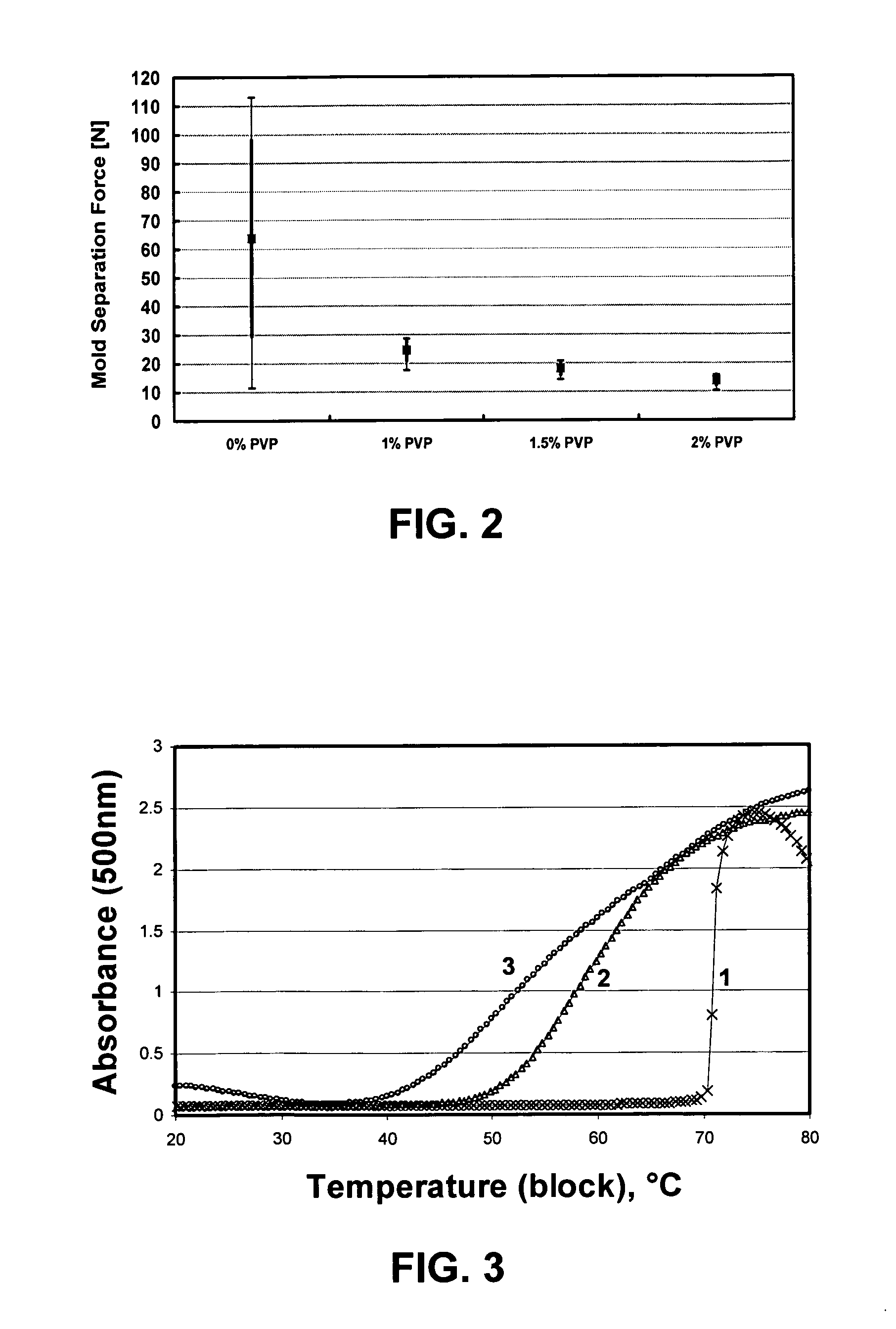

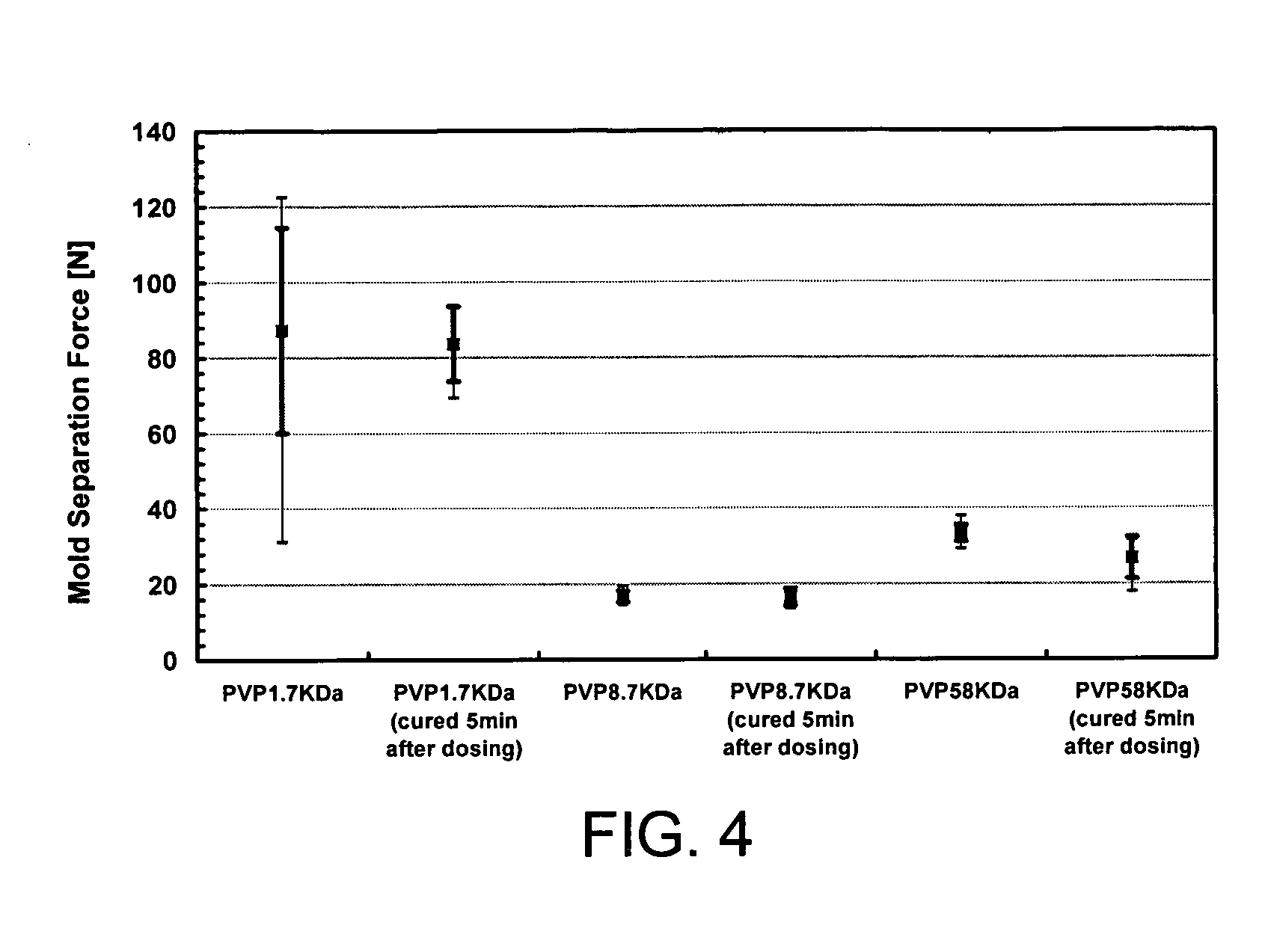

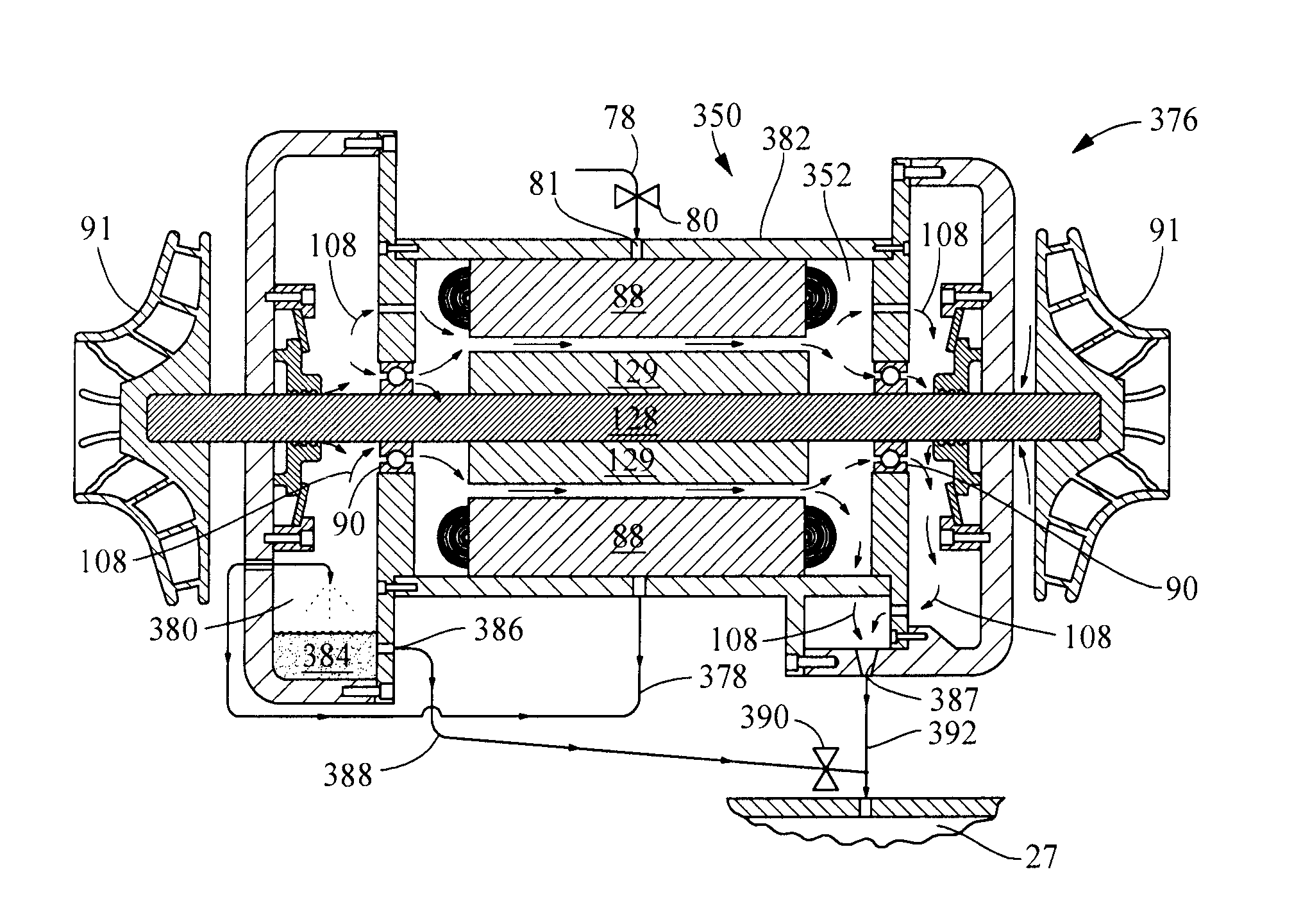

The instant invention pertains to a method and a fluid composition for producing contact lenses with improved lens quality and with increased product yield. The method of the invention involves adding a non-crosslinkable hydrophilic polymer into a fluid composition including a lens-forming material in an amount sufficient to reduce an averaged mold separation force by at least about 40% in comparison with that without the non-crosslinkable hydrophilic polymer and to provide a disparity of about 10 N or less in mold separation force. The non-crosslinkable hydrophilic polymer has a limited miscibility with the lens-forming material low enough to successfully and timely form an intact interfacial film with a sufficient thickness at an interface between the mold and the fluid composition therein, and has a structure that minimizes entanglement of the non-crosslinkable hydrophilic polymer in the interfacial film with the polymer matrix of the formed lens.

Owner:NOVARTIS AG

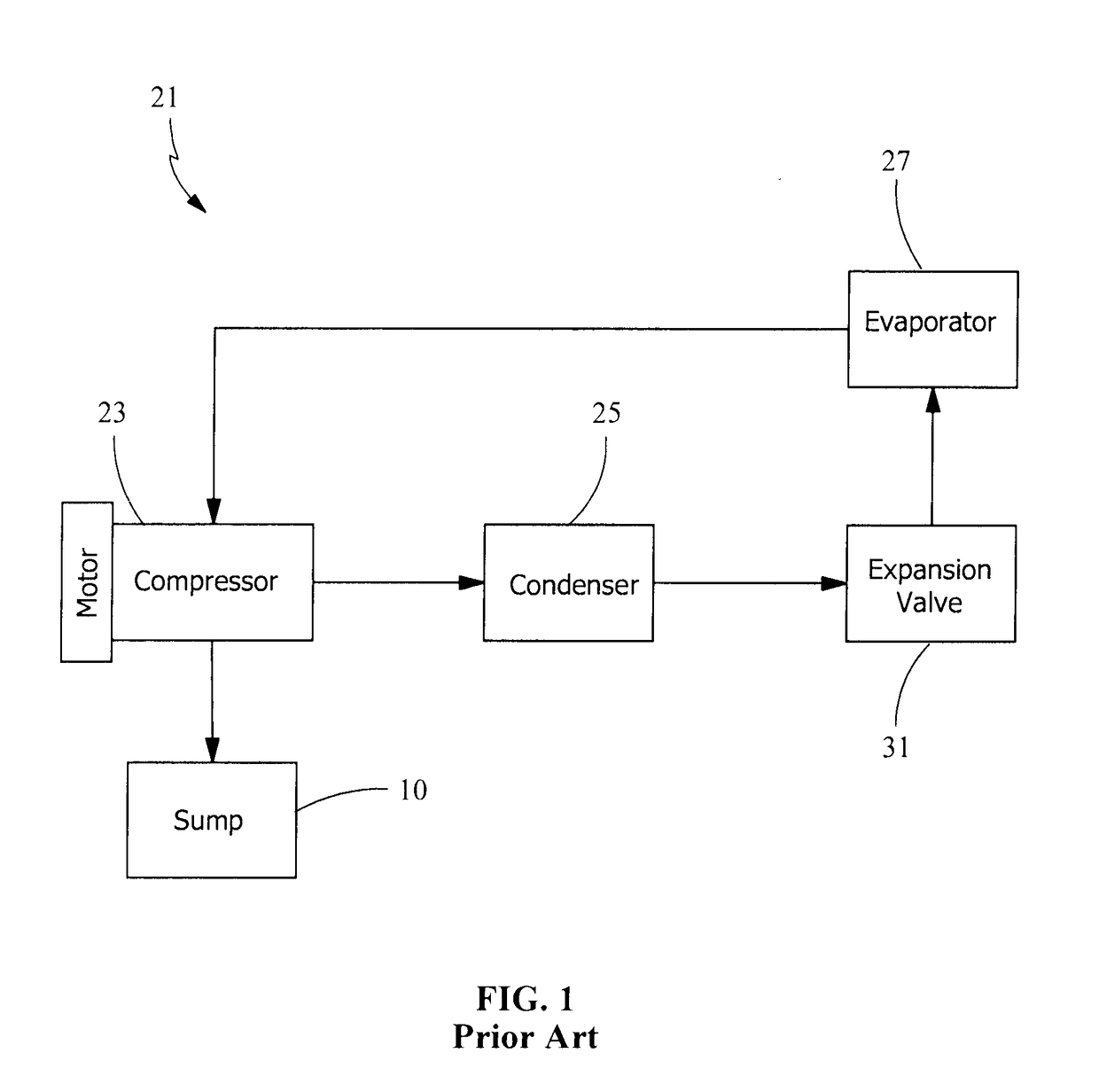

Lubrication and cooling system

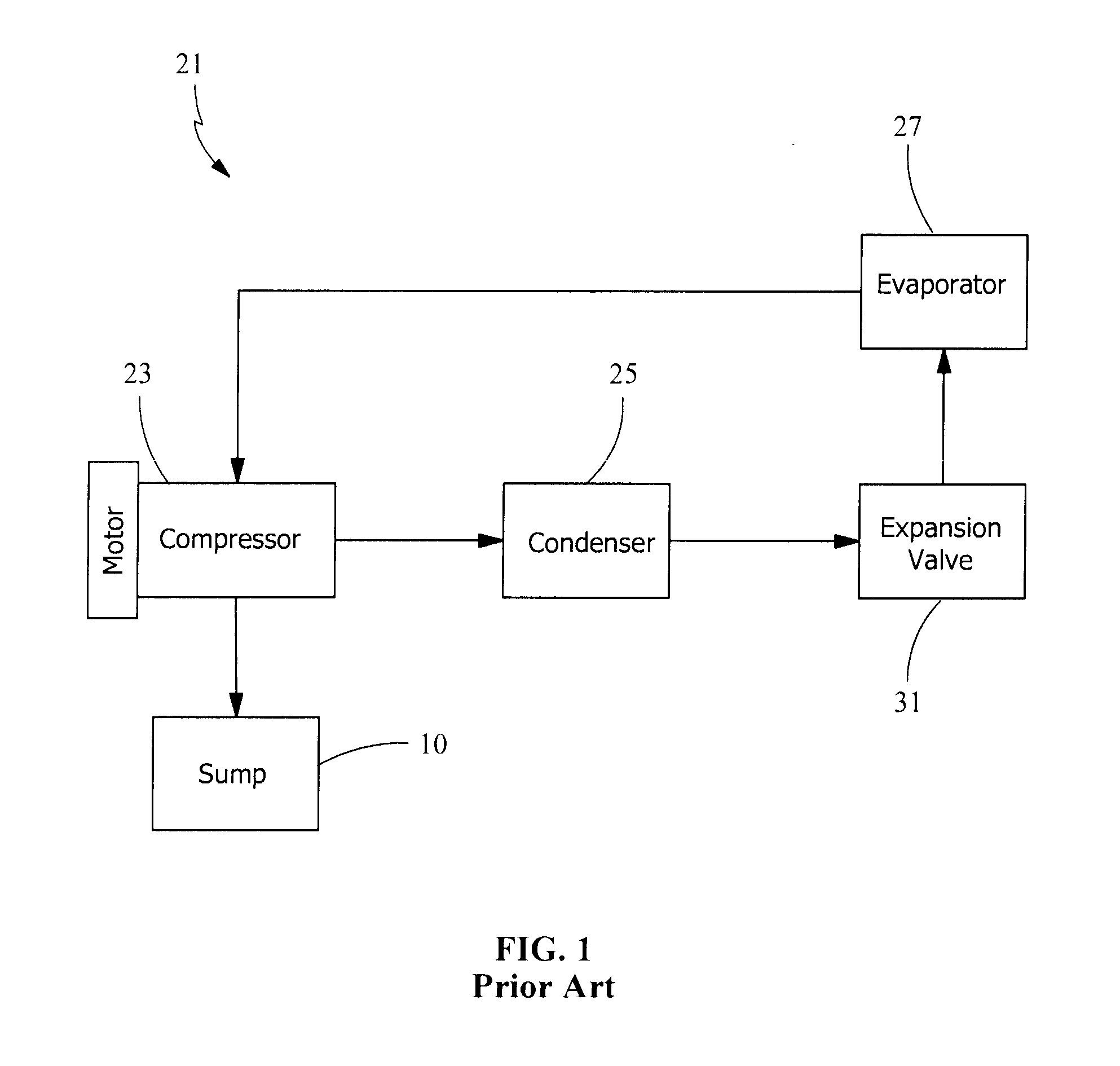

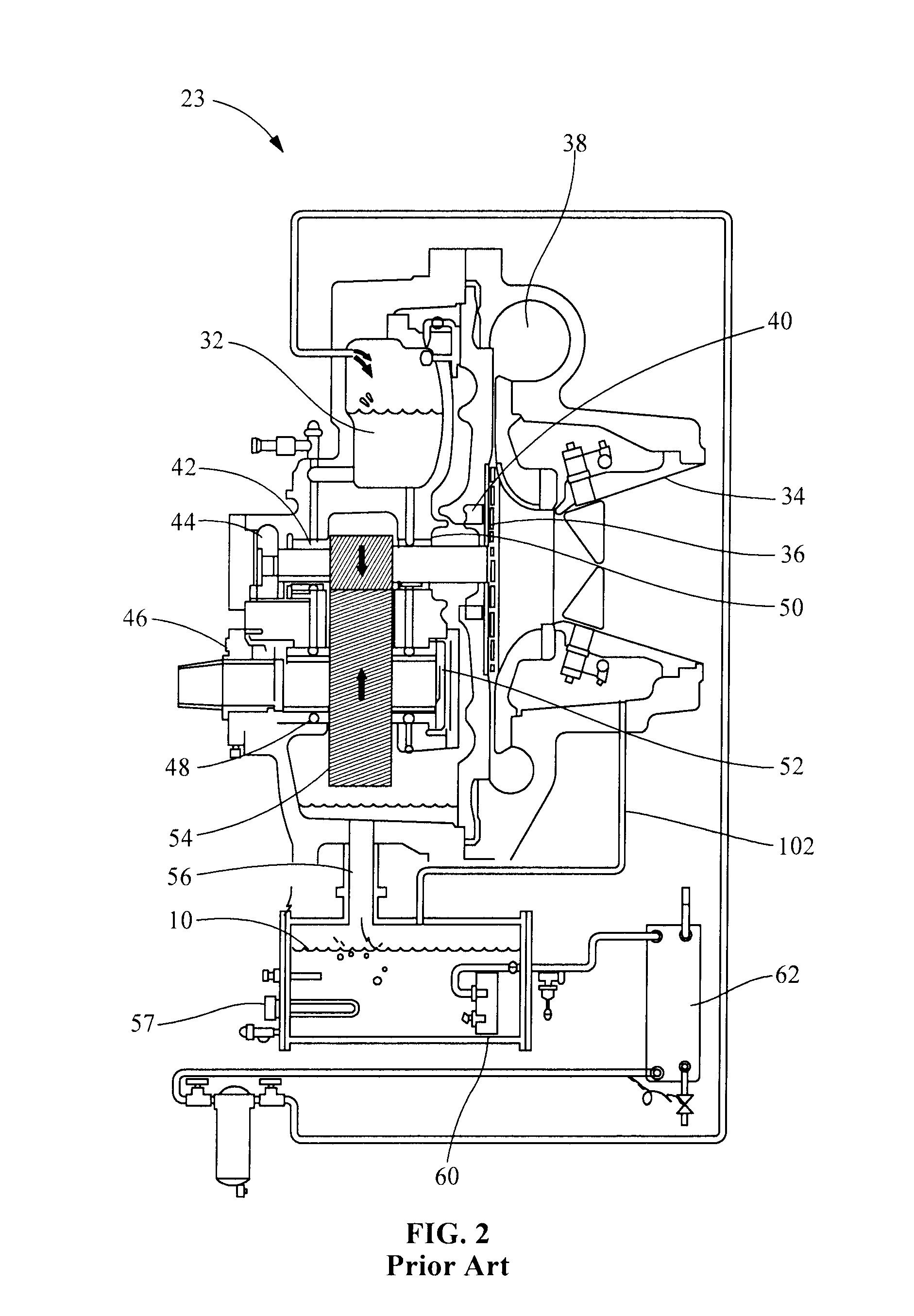

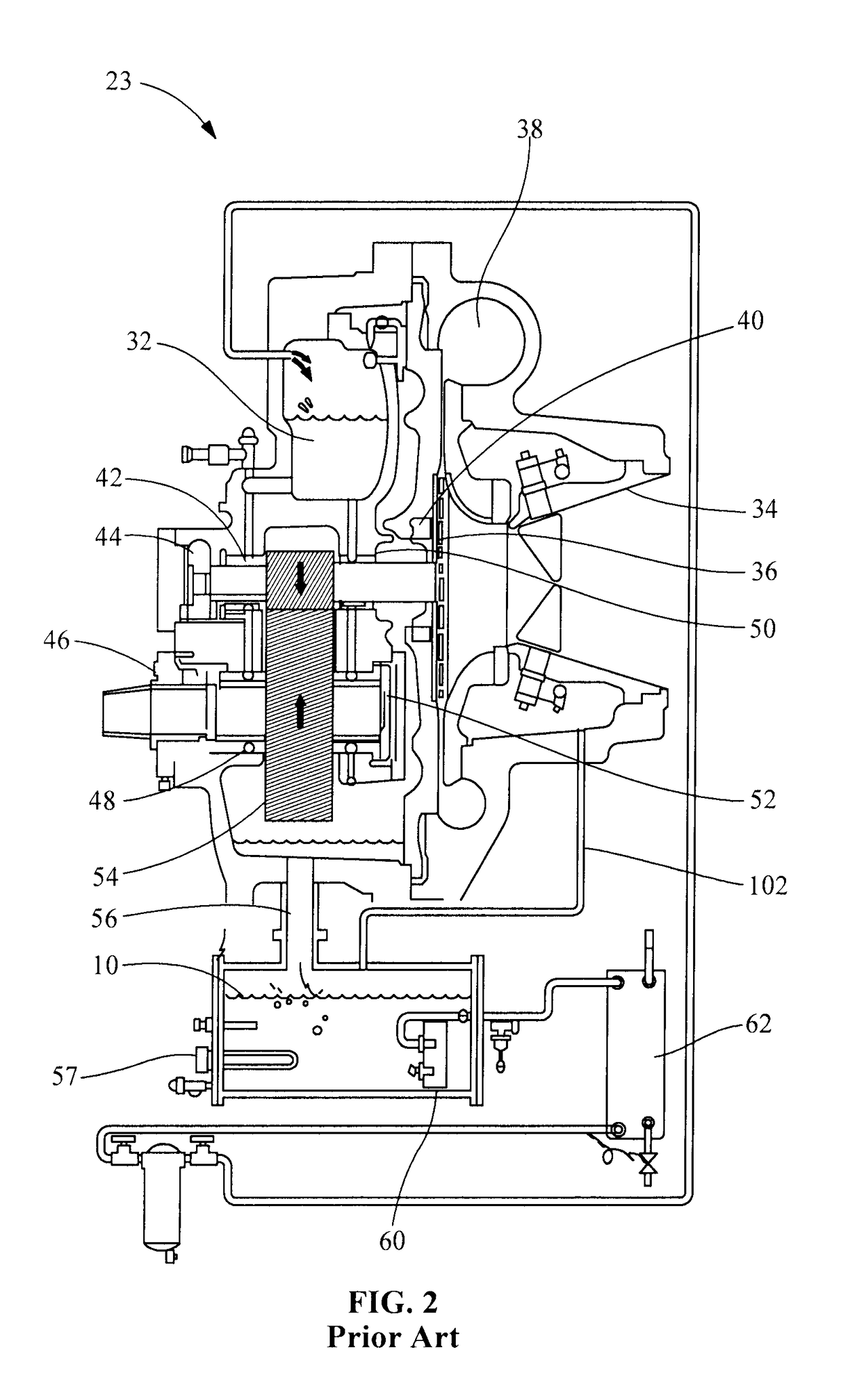

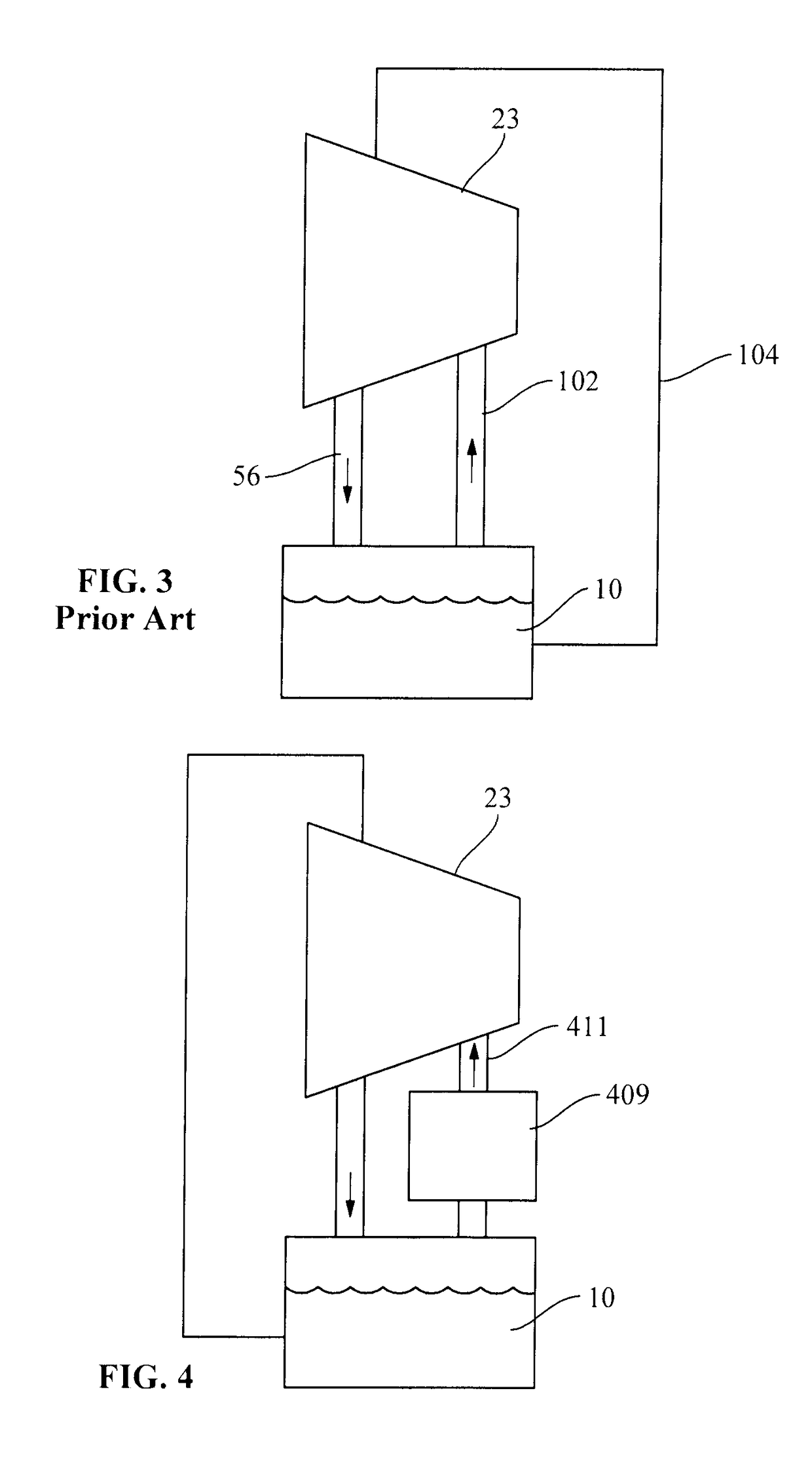

ActiveUS20160003510A1Reduce pressureSolve absorptionCompressorPump componentsLubricationAutomotive engineering

A system for reducing the refrigerant pressure in an oil sump (10) or in a cavity (352) of a housing. The invention is particularly useful for reducing pressure in a compressor (23) for heat pump applications that has been validated for water chiller operations or in turbine and generator systems in ORC systems generating electricity using refrigerant, the ORC systems essentially being a heat pump application operating in reverse. An auxiliary compressor (509), an auxiliary condenser (709) or an ejector pump (609) may be used to reduce pressure in the oil sump (10), to separate refrigerant from oil. The auxiliary compressor (509), the auxiliary condenser (709) or the ejector pump (609) may also be used to reduce the pressure of refrigerant in the housing of a compressor in heat pump applications at temperatures and pressures at which the compressor was validated for water chiller applications and of the turbine and generator in ORC applications.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

Process for production of etching or cleaning fluids

InactiveUS20060178282A1Good storage stabilityEasy to produceDetergent mixture composition preparationSemiconductor/solid-state device manufacturingHydrogen fluorideHydroxylamine

A method for producing an etching or cleaning solution comprising (1) at least one member selected from the group consisting of fluoride salts and bifluoride salts formed from at least one member selected from the group consisting of ammonia, hydroxylamines, aliphatic amines, aromatic amines, aliphatic quaternary ammoniums and aromatic quaternary ammoniums with hydrofluoric acid; (2) at least one heteroatom-containing organic solvent; and (3) water, the method comprising the steps of: Step 1: mixing an aqueous hydrofluoric acid solution with at least one heteroatom-containing organic solvent, and Step 2: mixing the mixture obtained in Step 1 with at least one member selected from the group consisting of ammonia, hydroxylamines, aliphatic amines, aromatic amines, aliphatic quaternary ammoniums, aromatic quaternary ammoniums, and fluorides thereof.

Owner:DAIKIN IND LTD

Resin for toner binder and toner composition

The present invention provides a resin for toner binders, which comprises two polyester resins (A) and (B), said resin (A) being a crosslinked modified polyester resin consisting of the reaction product from a crosslinked polyester resin (a) and a polyepoxide (c) and said resin (B) being an acid anhydride-modified linear polyester resin consisting of the reaction product from a linear polyester resin (b) and an acid anhydride (r).

Owner:SANYO CHEM IND LTD

Polyisocyanurate compositions and composites

InactiveUS7202302B2Good miscibilityPoor miscibilityOrganic chemistrySpecial tyresRoom temperaturePolyisocyanurate

Polyisocyanurate systems, pultrusion of those systems to produce reinforced polyisocyanurate matrix composites, and to composites produced thereby. The polyisocyanurate systems include a polyol component, an optional chain extender, and an isocyanate. The polyisocyanurate systems have extended initiation times of about 5 minutes to about 30 minutes at room temperature, and can be snap cured.

Owner:HUNTSMAN INT LLC

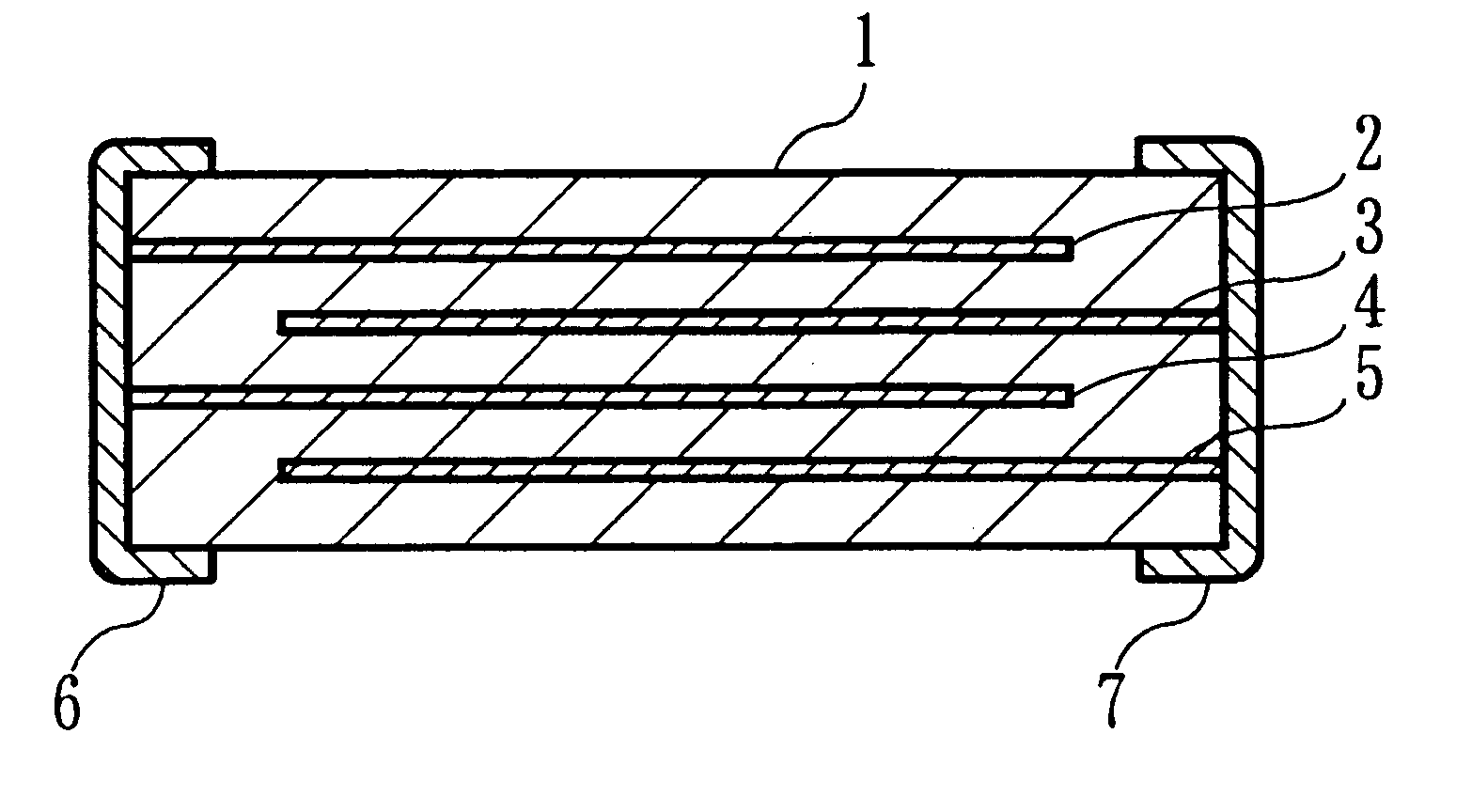

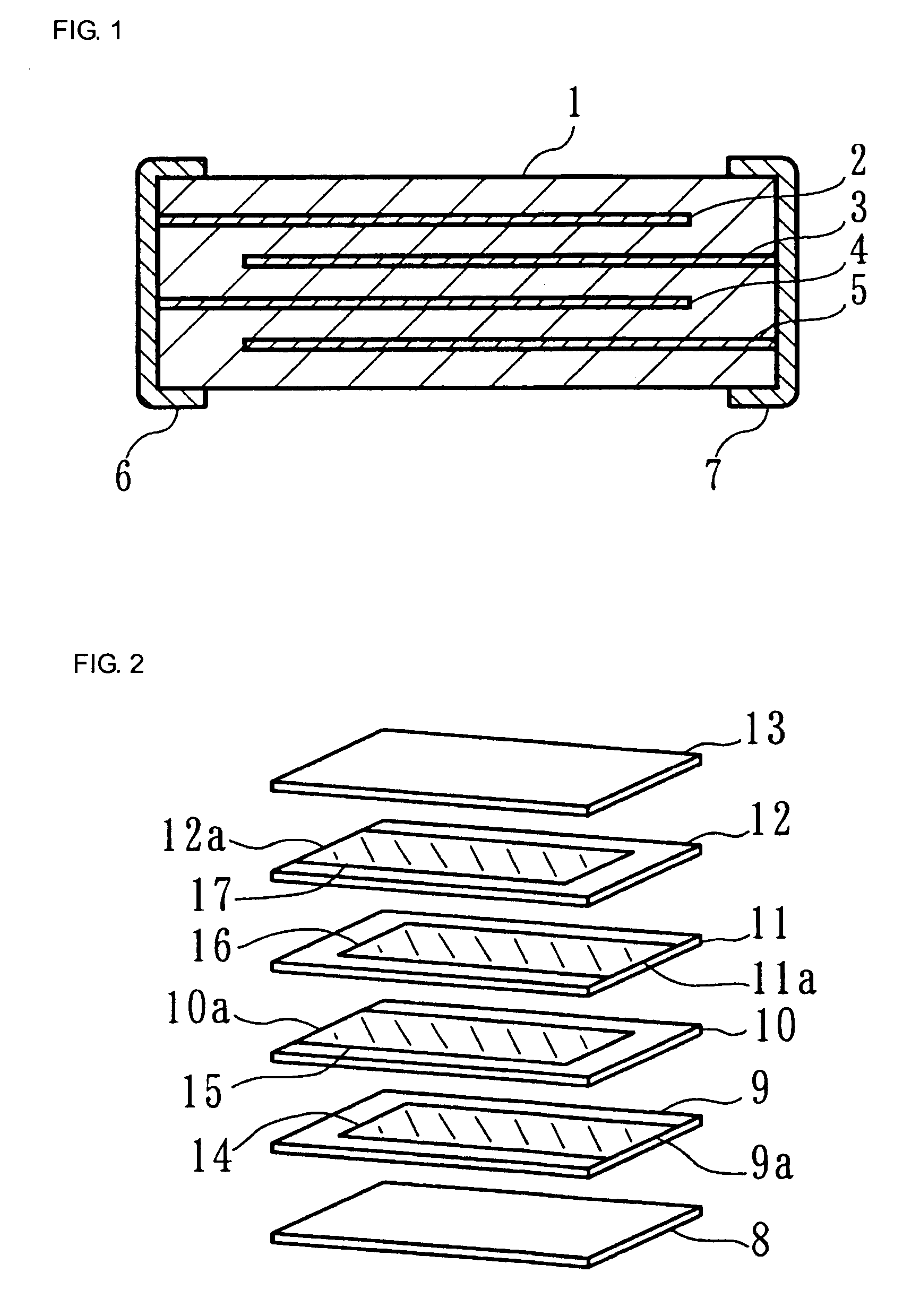

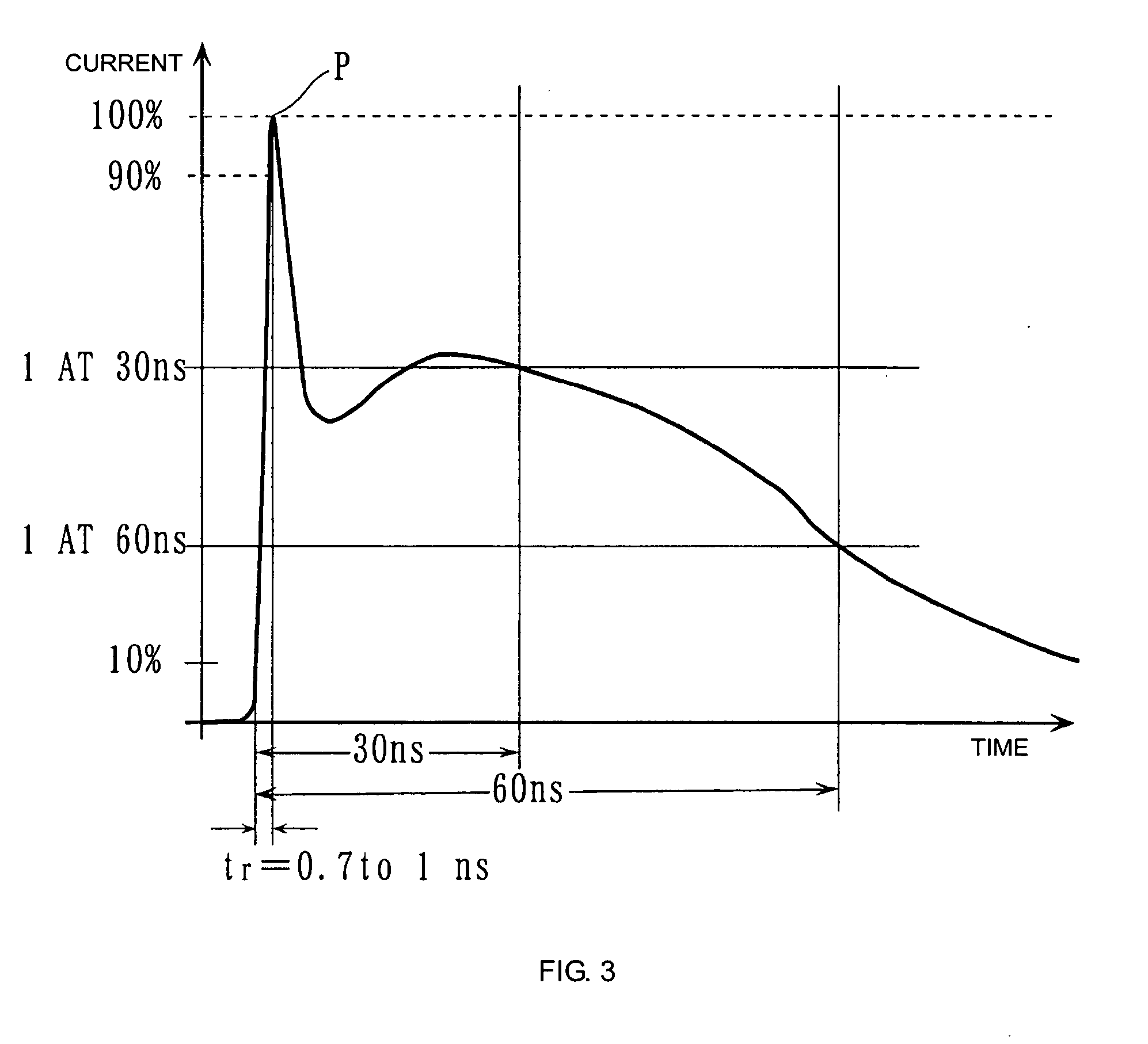

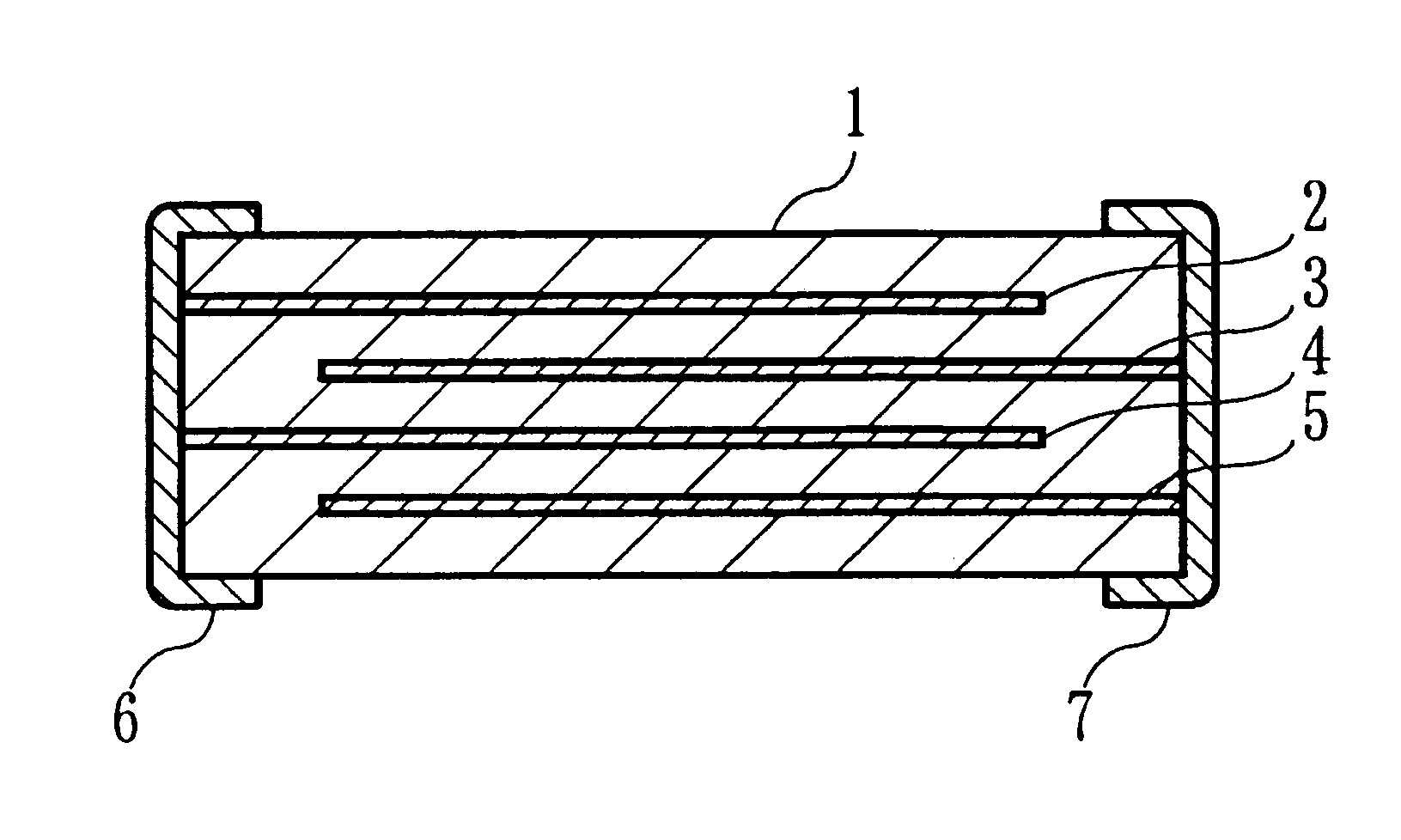

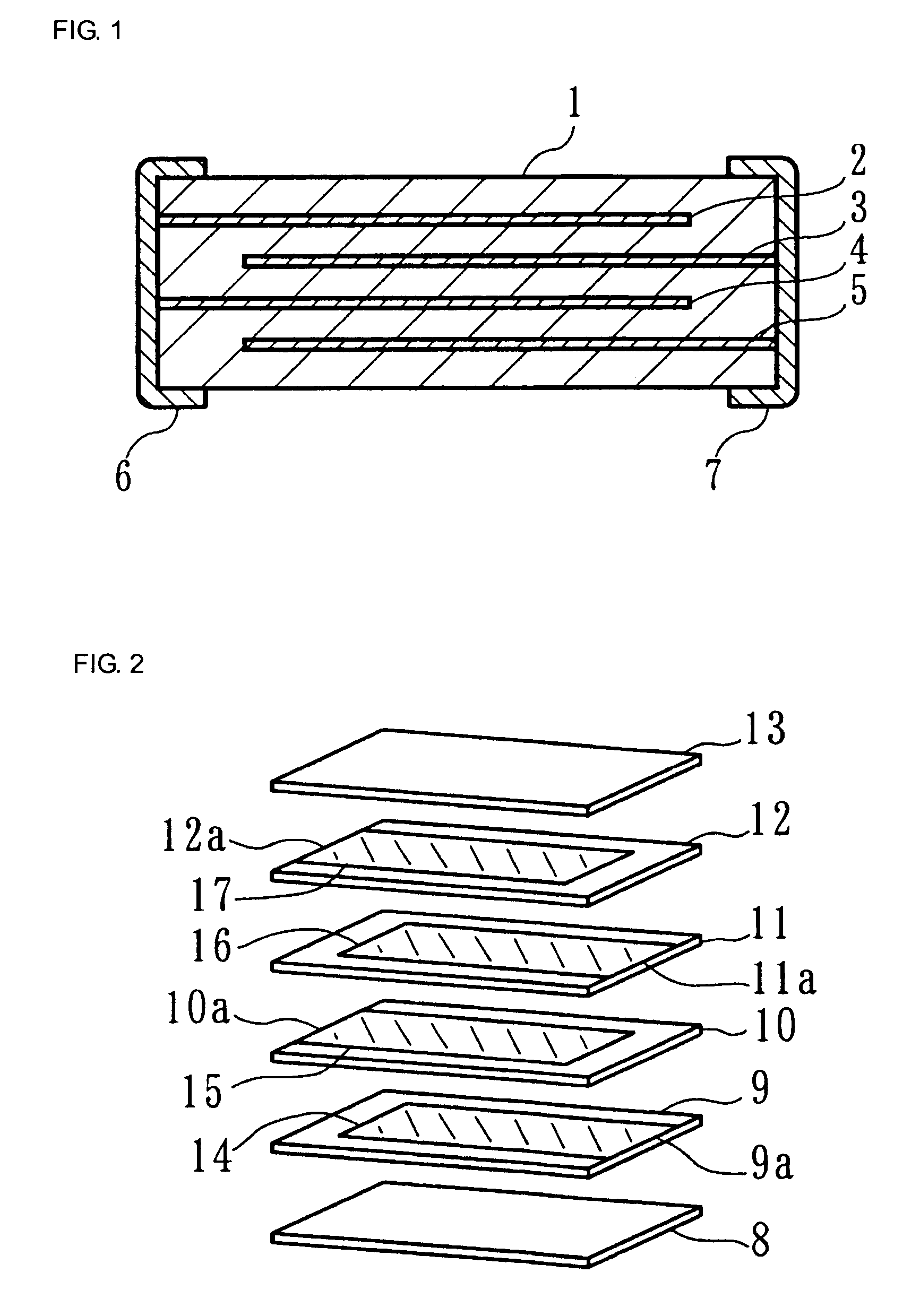

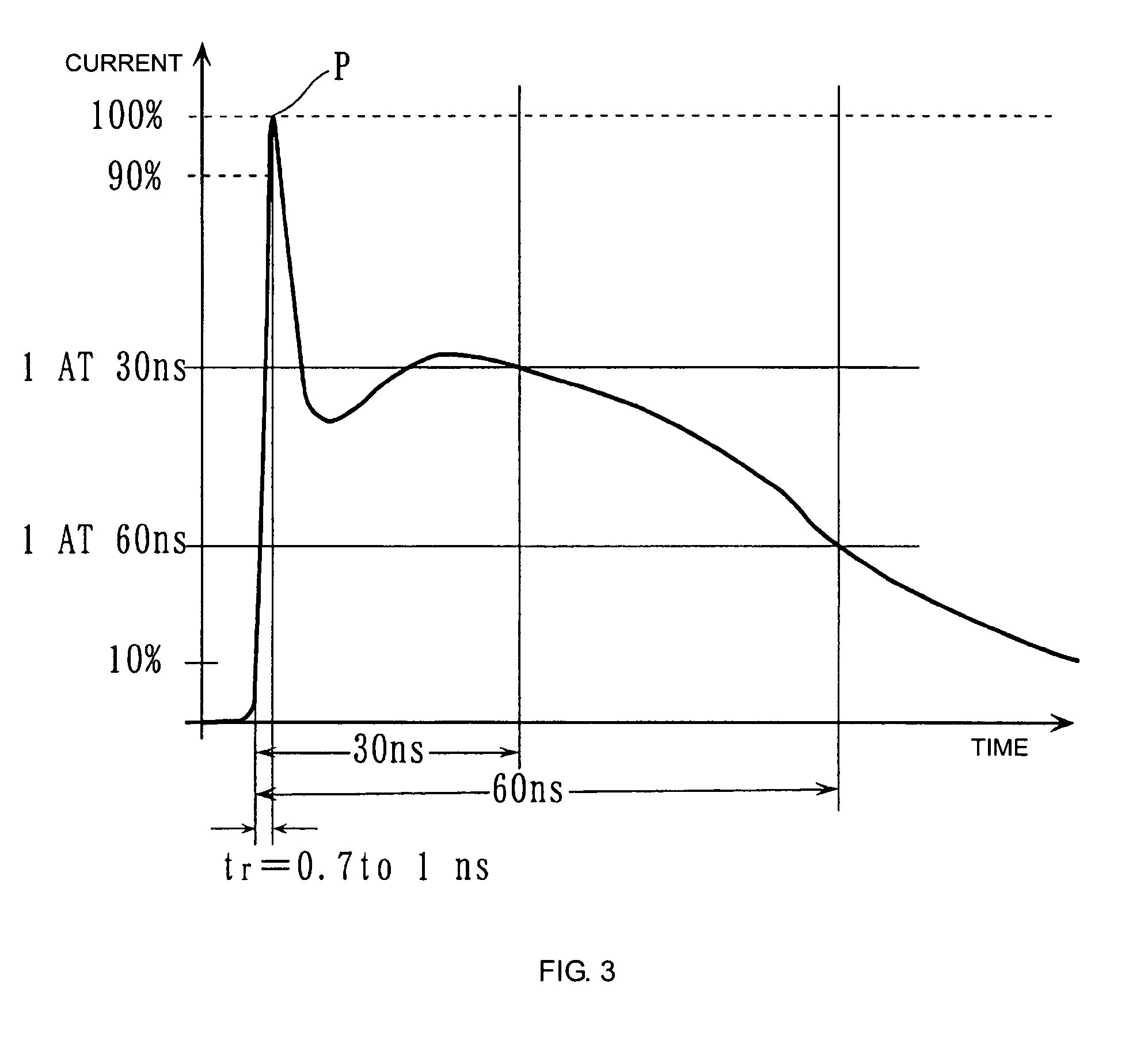

Method for manufacturing varistor and varistor

ActiveUS20040195734A1High viscosityPrevent aggregation and nonuniform precipitationLayered productsCeramic shaping apparatusPerchlorate saltPotassium

The raw material for a ZnO-Pr-based varistor is mixed with cobalt and potassium to prepare a ceramic raw material powder. Potassium, which is an alkali metal, is added in the form of KClO4, KHC4H4O6, PtCl6, or K2[Co(NO2)4]. The ceramic raw material powder is pulverized by a wet process while 0.1 to 5.0 wt % of polycarboxylate dispersant is added to the powder. Such a method can produce a reliable, high-quality varistor having excellent varistor characteristics, such as varistor voltage V1 ma and insulation resistance IR, and less variation in these characteristics.

Owner:MURATA MFG CO LTD

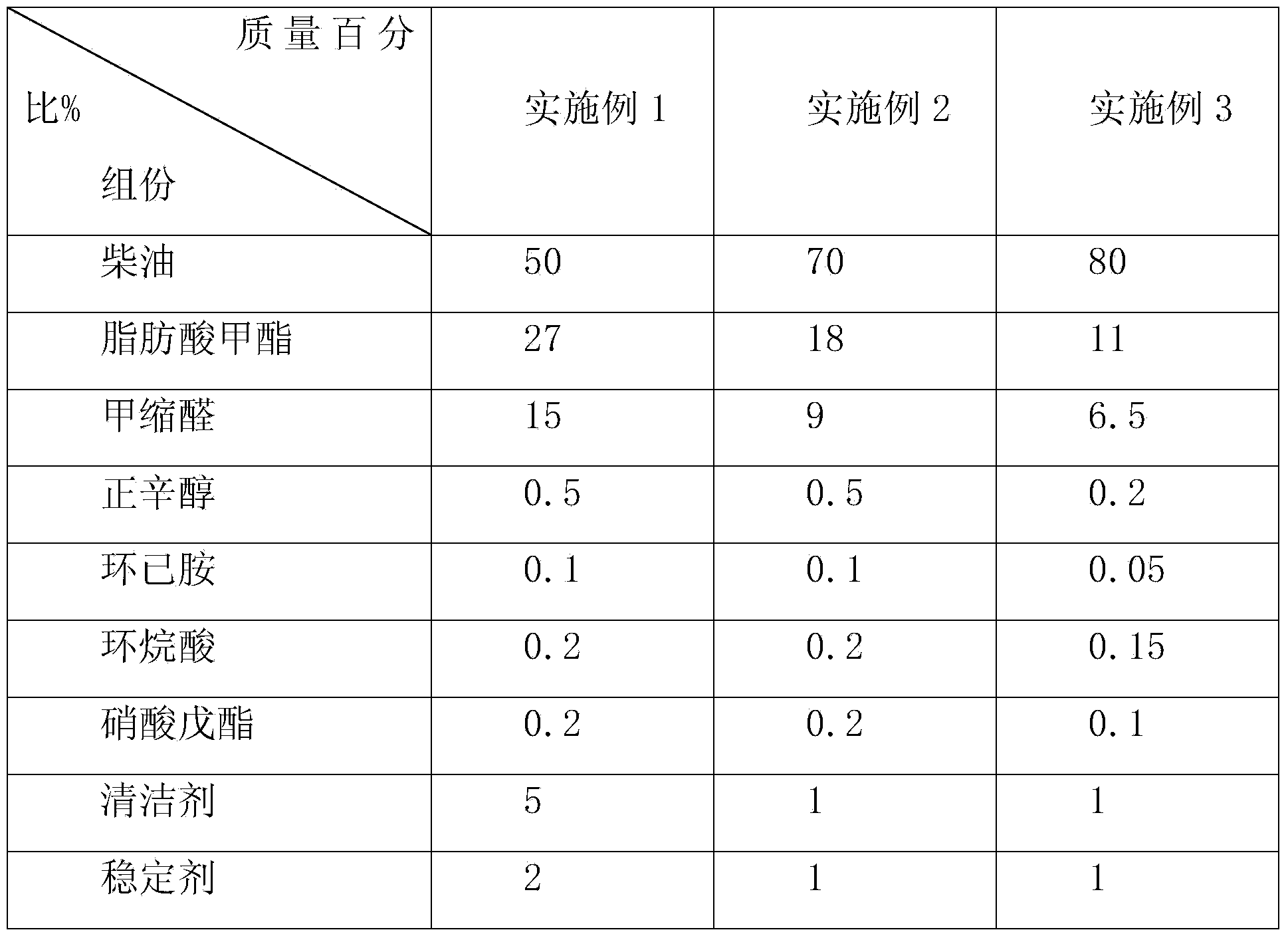

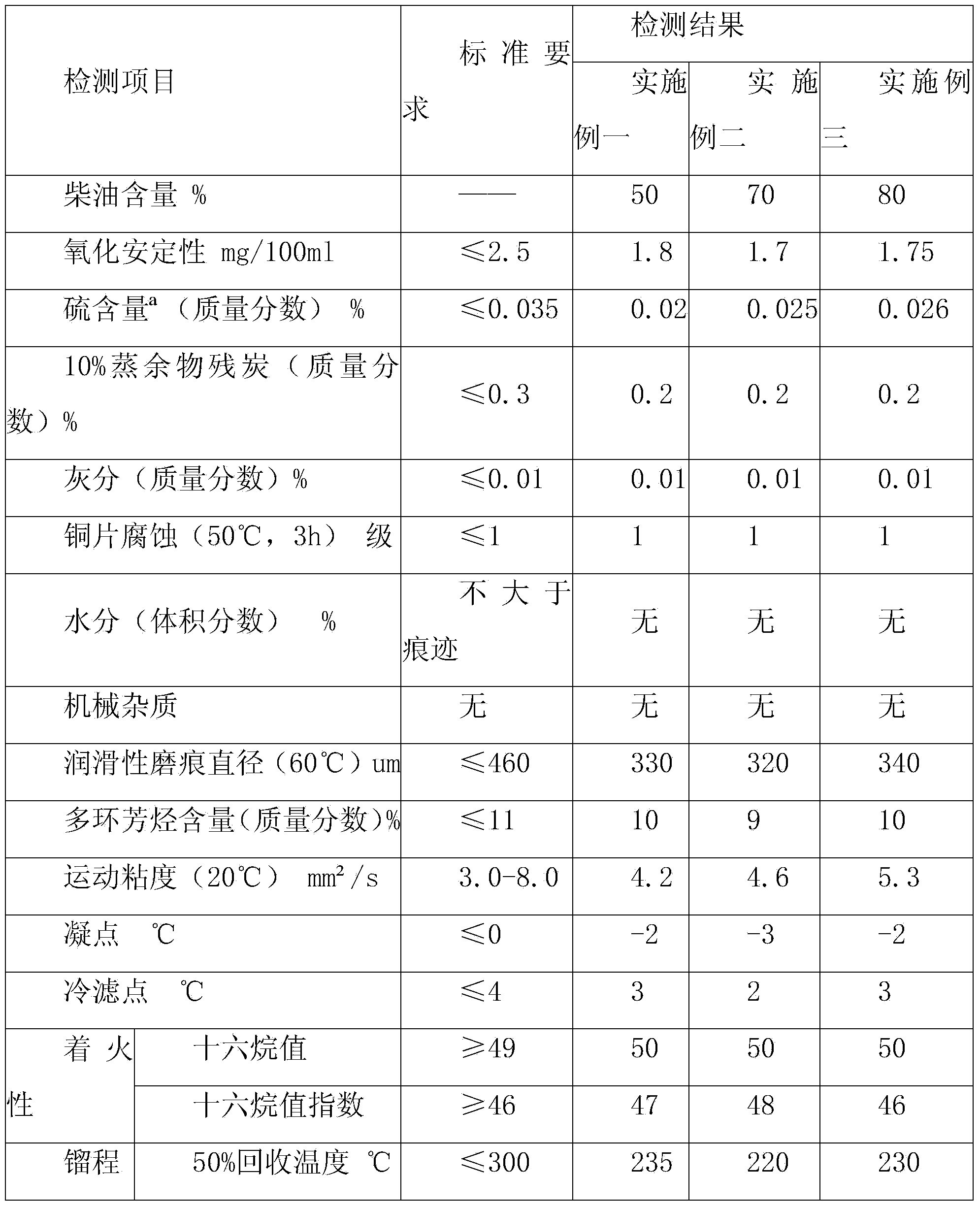

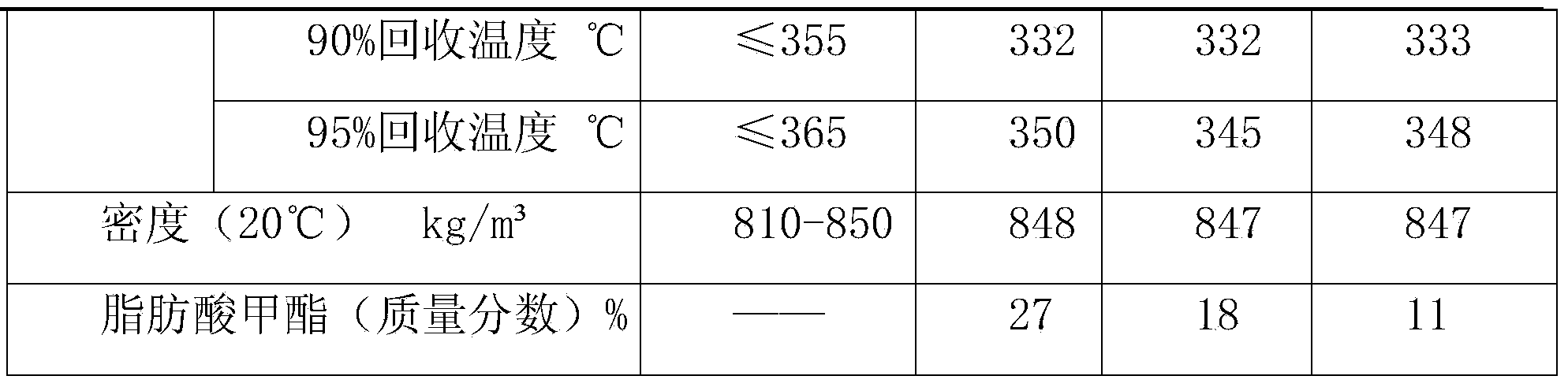

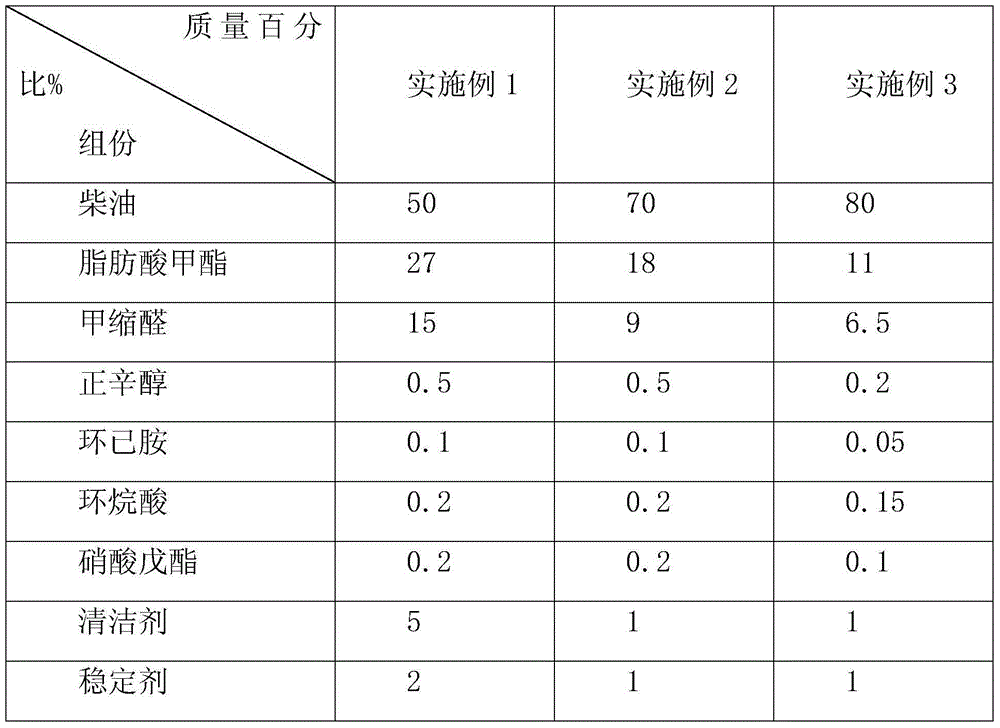

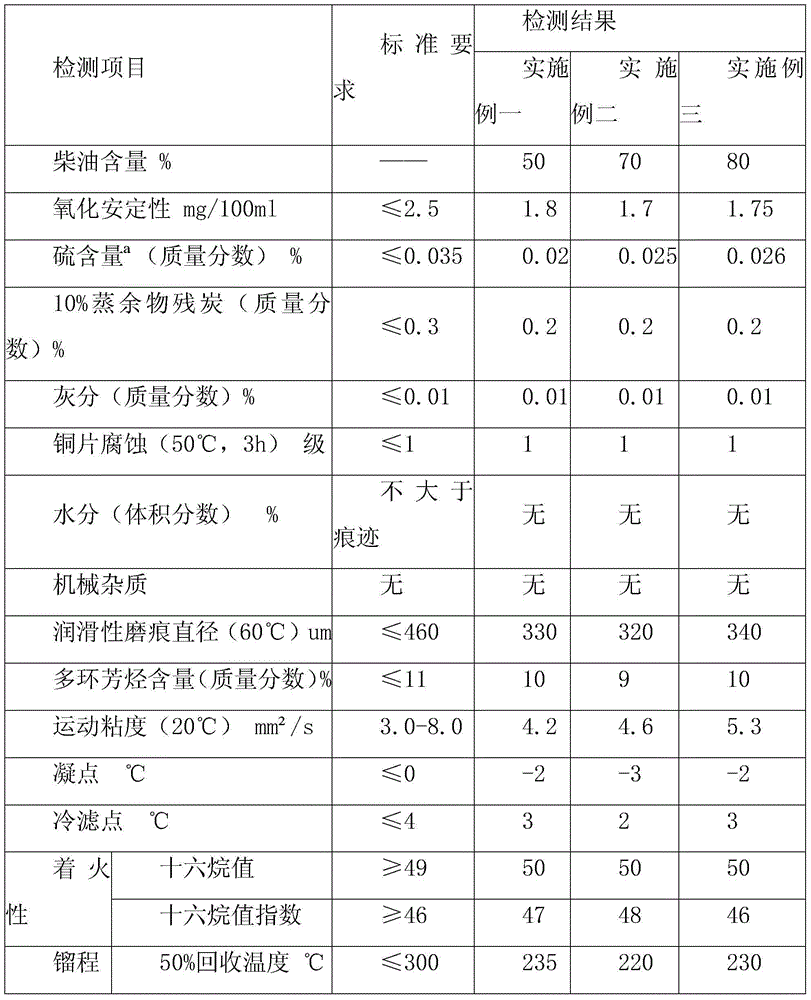

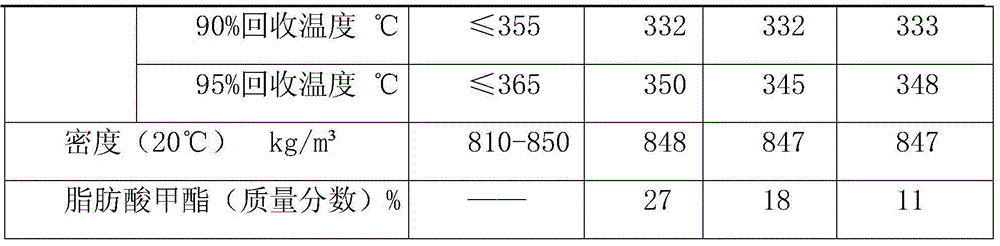

Methyl diesel

ActiveCN103865593ARich sourcesImprove performanceLiquid carbonaceous fuelsFuel additivesSulfurOctanol

The present invention discloses a methyl diesel. The methyl diesel comprises the components by mass percent of 50-80% of diesel, 11-27% of fatty acid methyl ester, 6-15% of methylal, 0.2-0.6 % of n-octanol, 0.05-0.2% of cyclohexylamine, 0.1-0.3% of naphthenic acid, 0.1-0.2% of amyl nitrate, 0.8-5% of detergent and 1-2% of stabilizer. The methyl diesel disclosed by the invention has good protective effect on the power system and fuel supply system of the vehicle; and dynamic performance, carbon deposits reduction, corrosion resistance, storage period, fuel consumption, micro metal emissions, sulfur emissions, miscibility, diesel air resistance meet or exceed the standard after the actual test is carried out.

Owner:常胜 +1

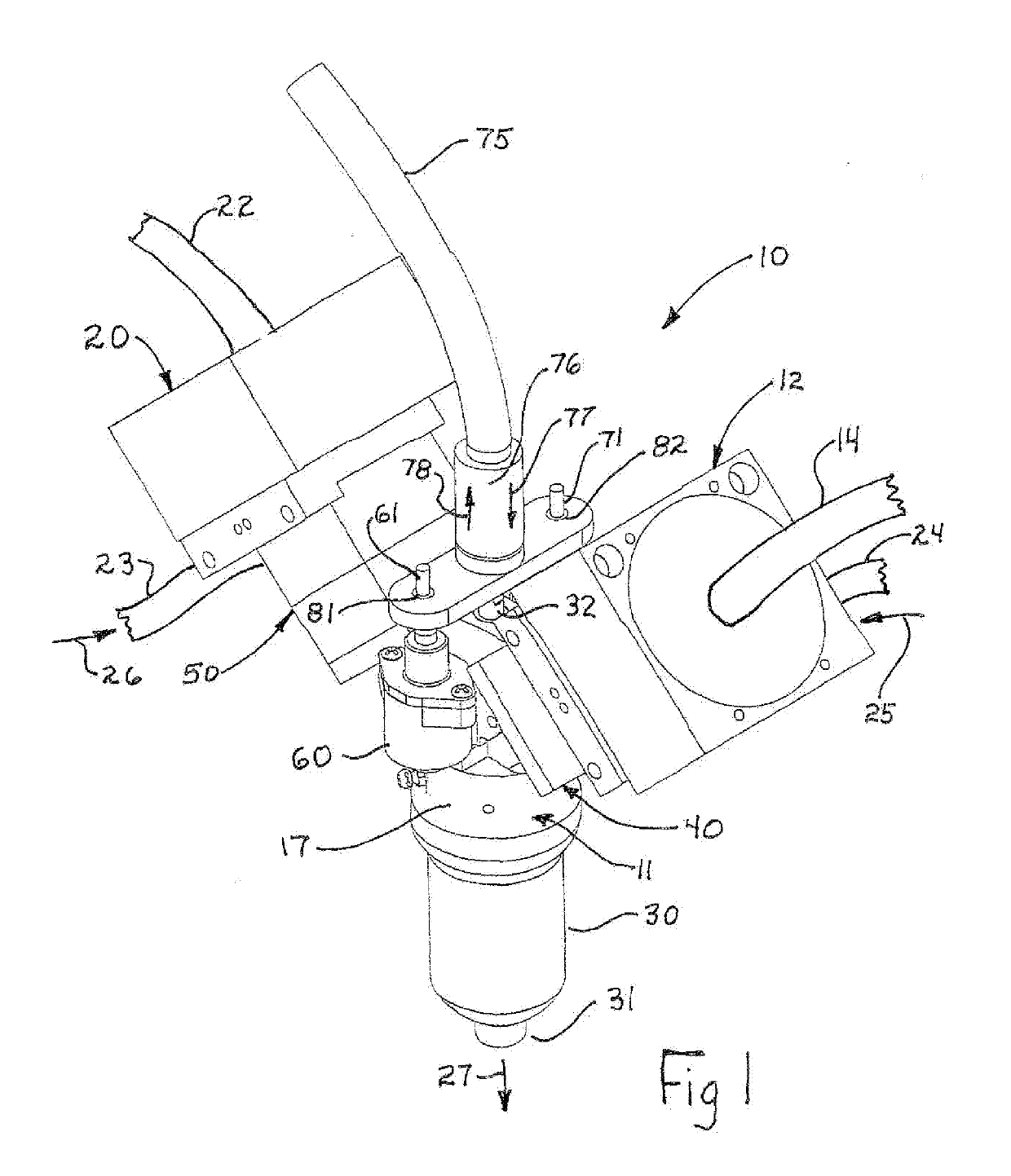

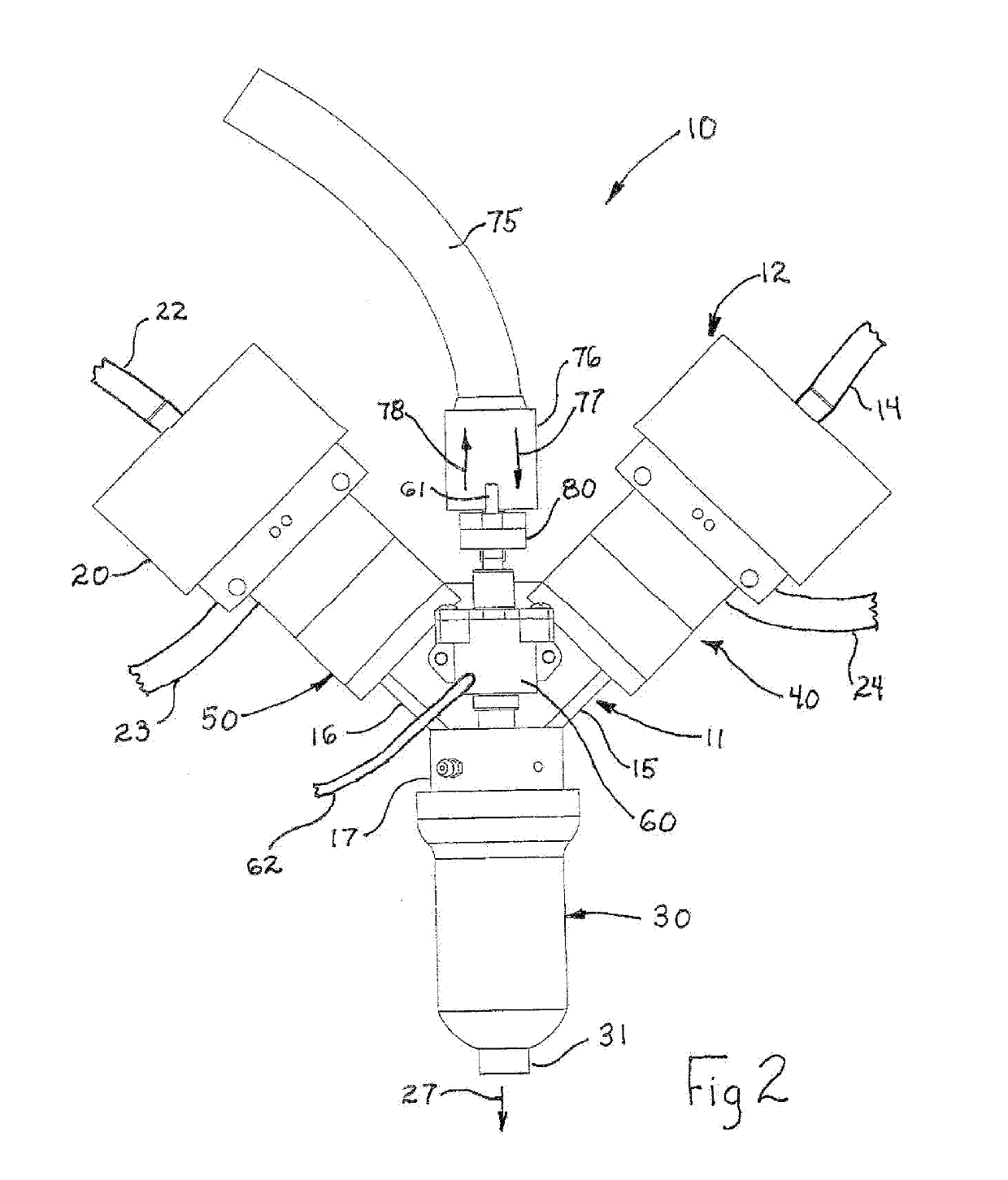

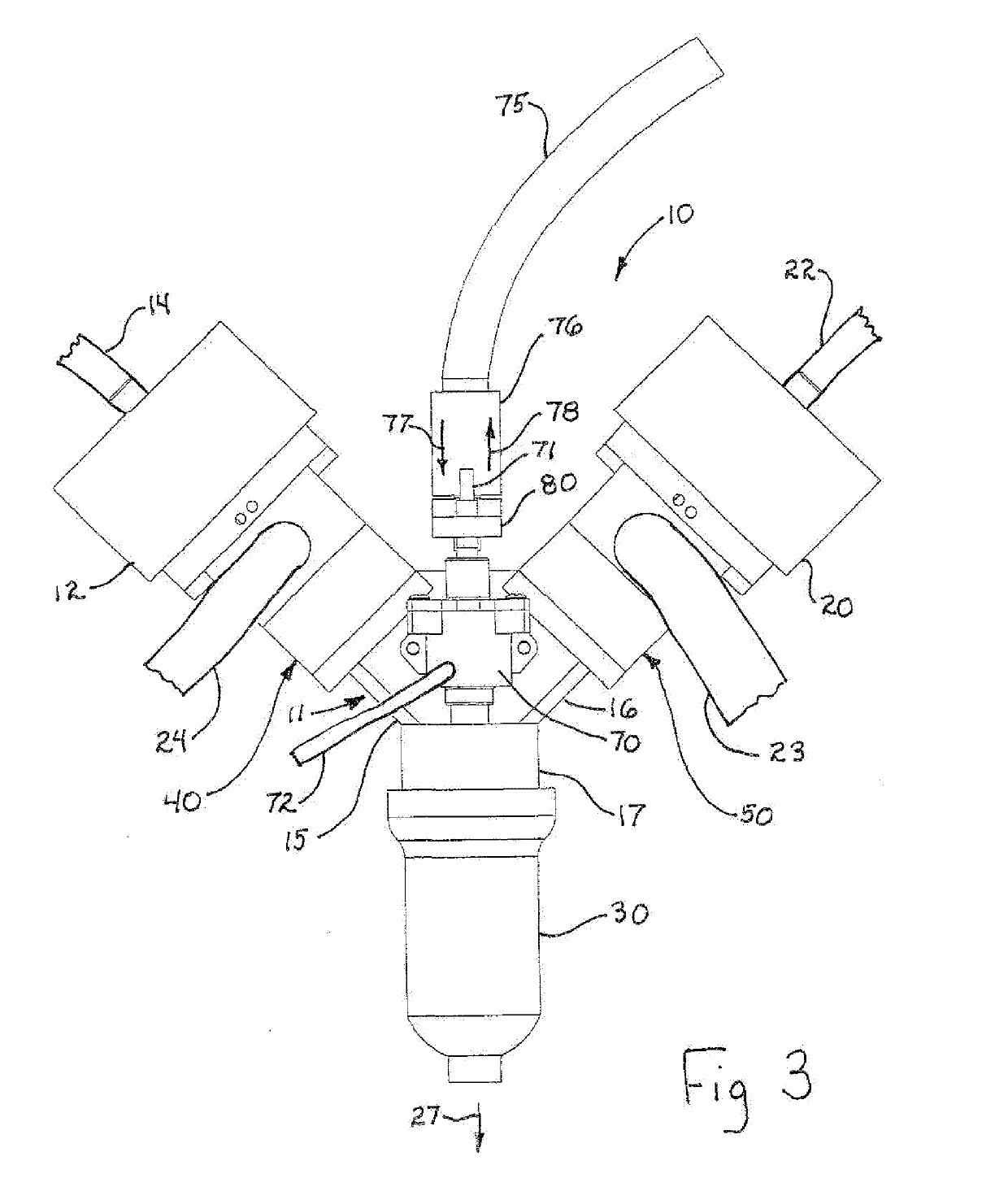

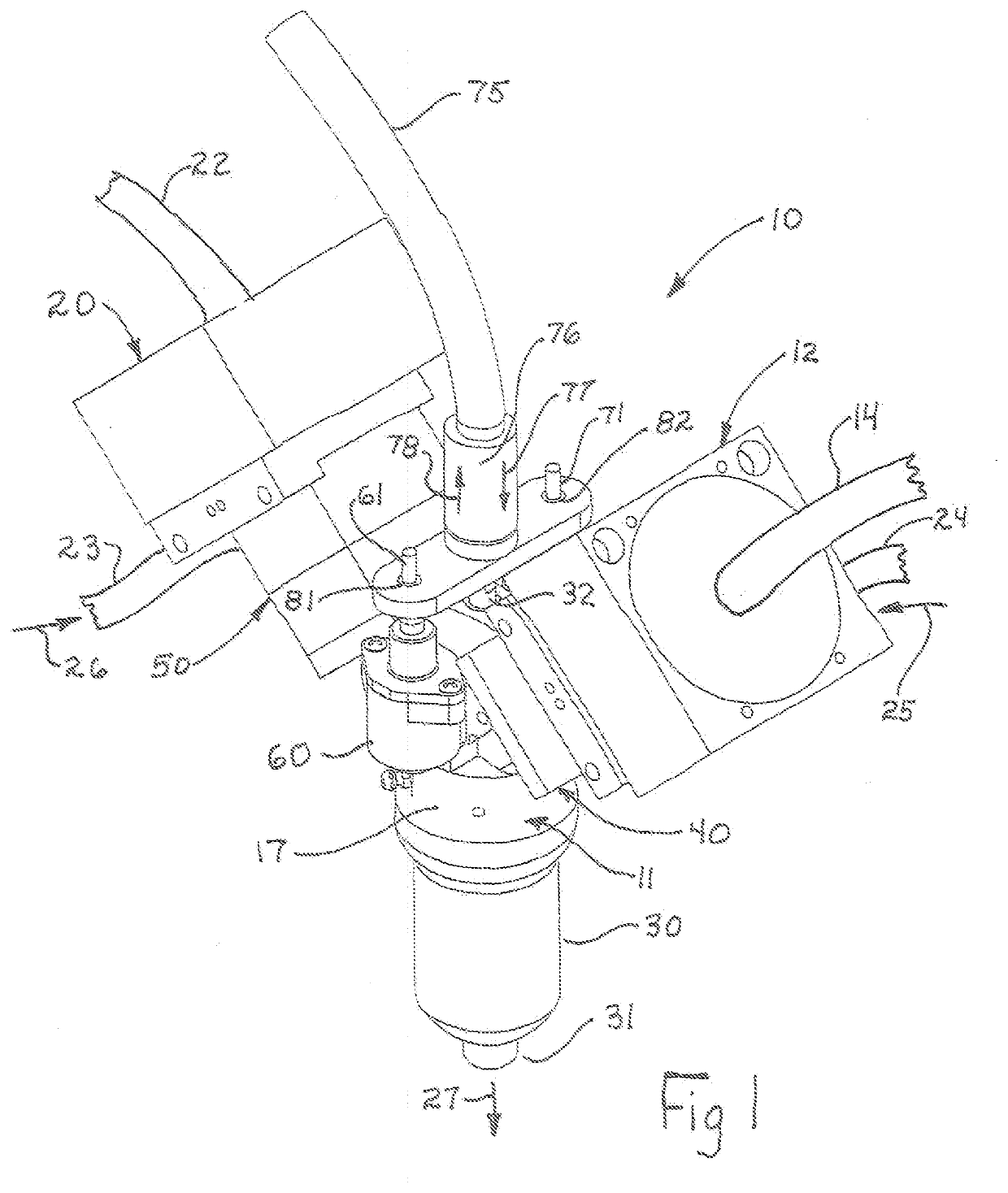

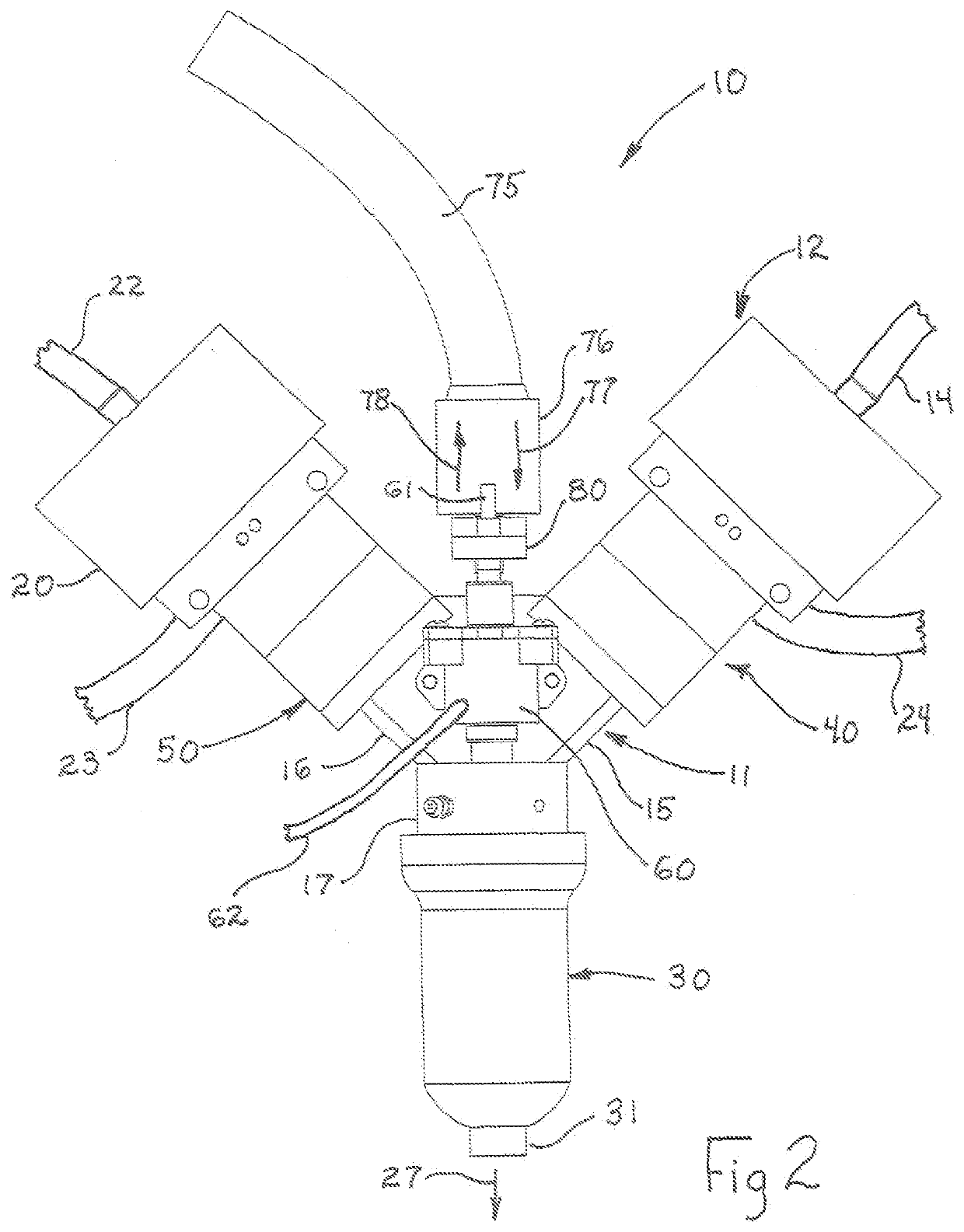

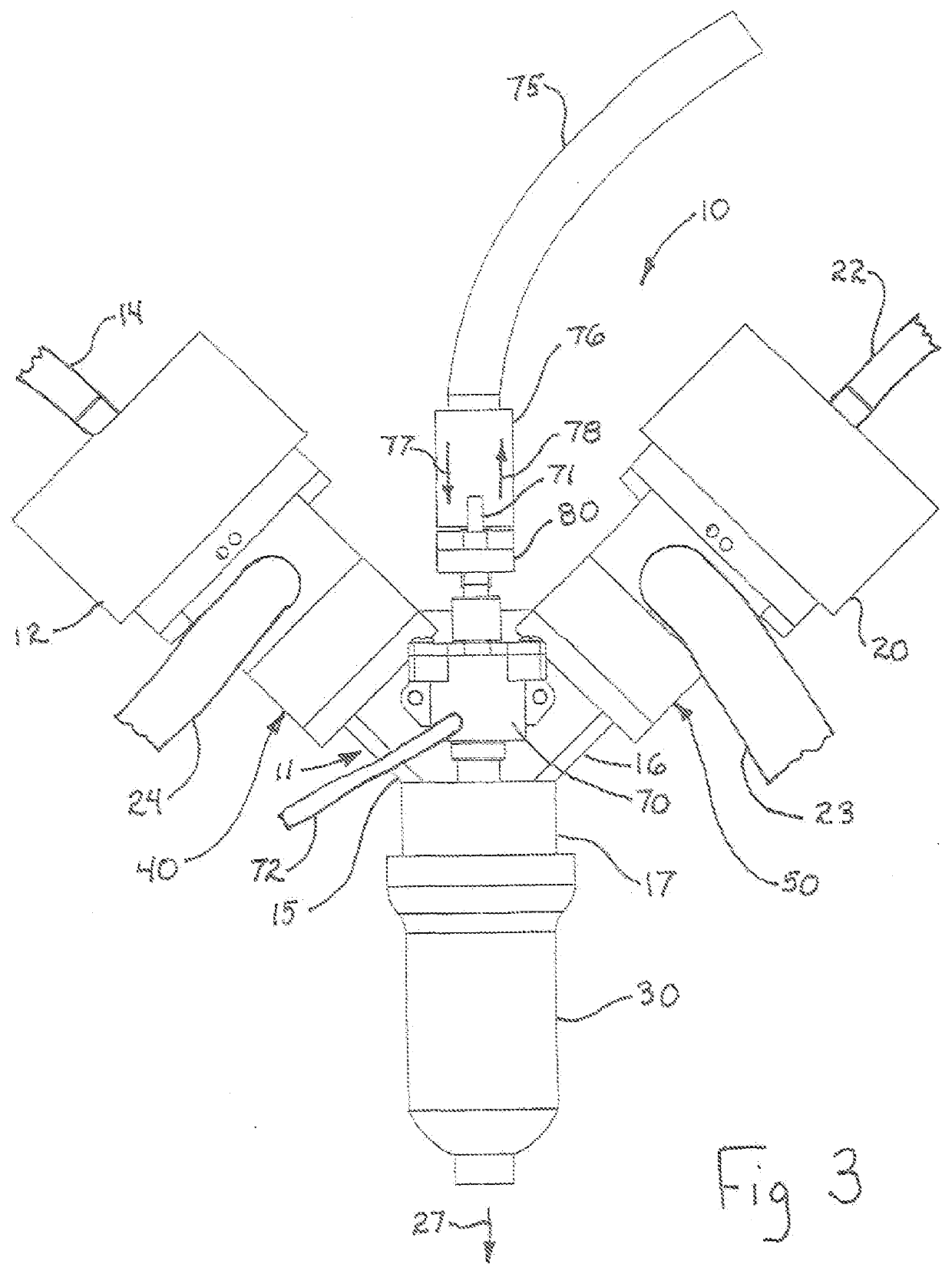

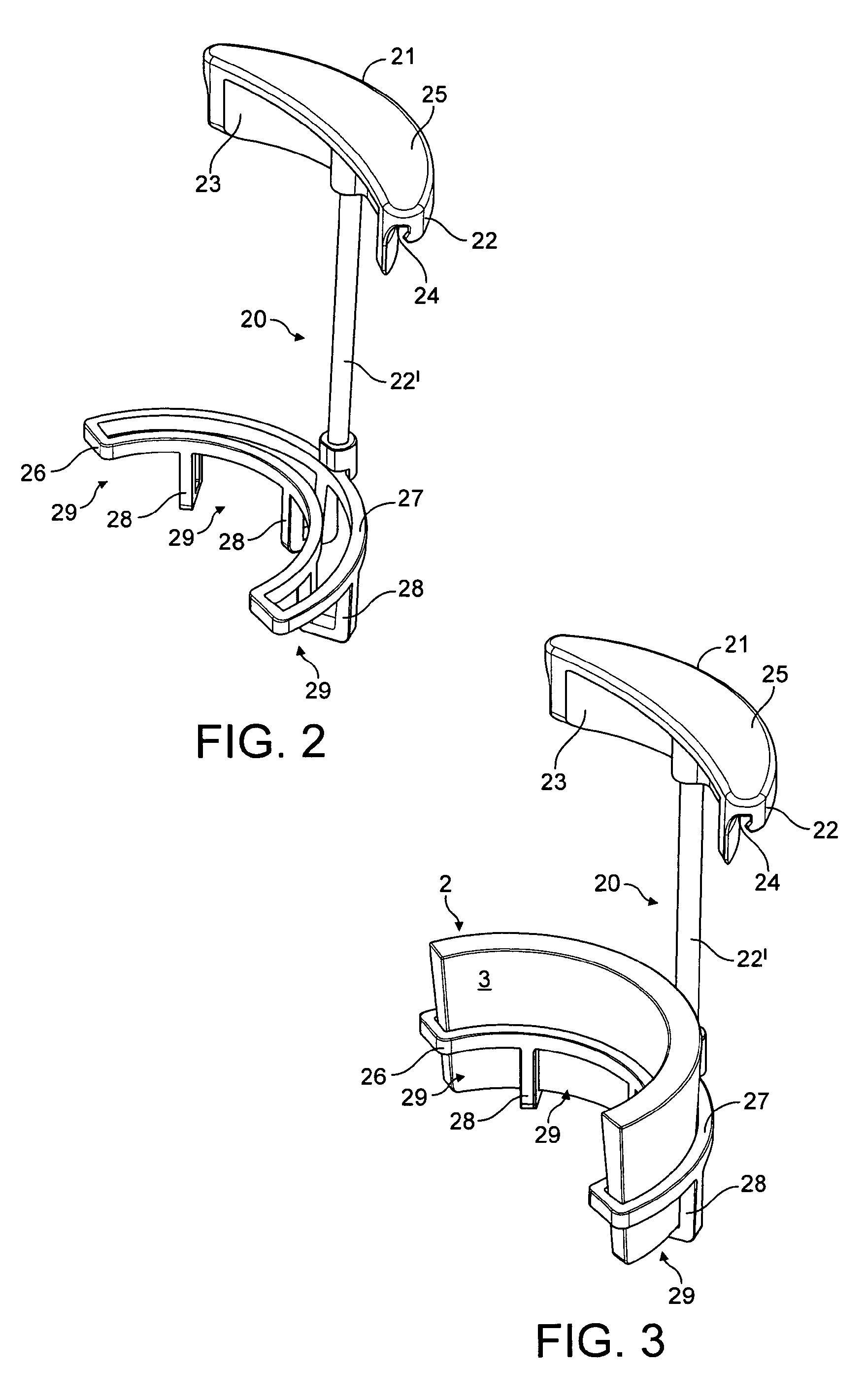

Dynamic mixer dispense valve for two-component high-viscosity high-ratio compounds

ActiveUS20190275482A1Easy to useHigh viscosityLiquid surface applicatorsRotary stirring mixersImpellerCompound a

A dynamic mixer dispense valve and metering apparatus suitable for use in mixing and applying high viscosity, disparate viscosity, high ratio and / or relatively immiscible two part compounds that exhibit short cure times includes a housing supporting a pair of valve assemblies each coupled to respective sources of base and accelerator components. A pair of pneumatic valve actuator s control the operation of the valve assemblies to control the flow of components into a mixing chamber. Within the mixing chamber a mixer impeller is rotatably supported and coupled to a source of rotational power. An additional pneumatic valve actuator combination operates a further flow control to prevent undesired material loss following a shot cycle.

Owner:MENK BRUCE H +1

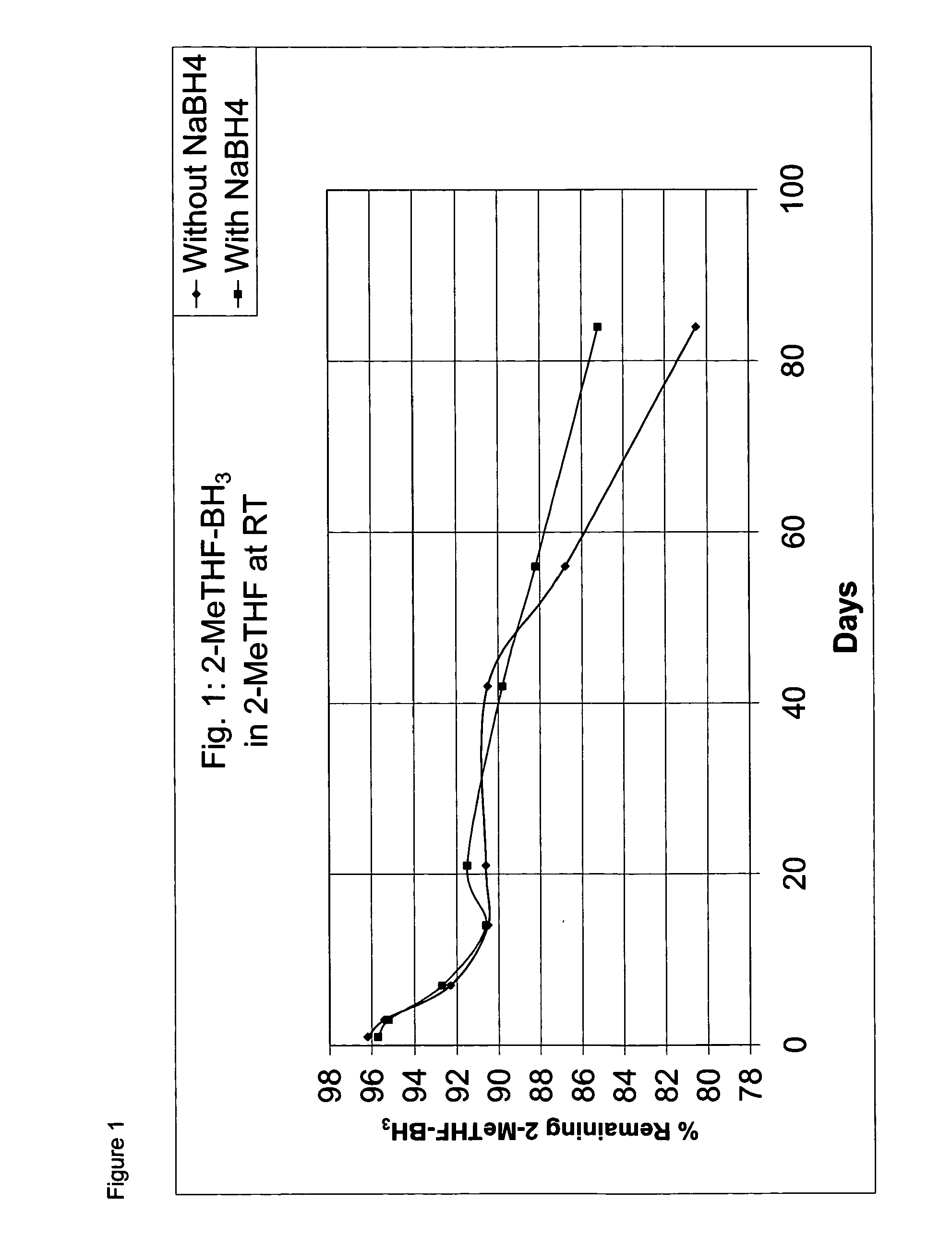

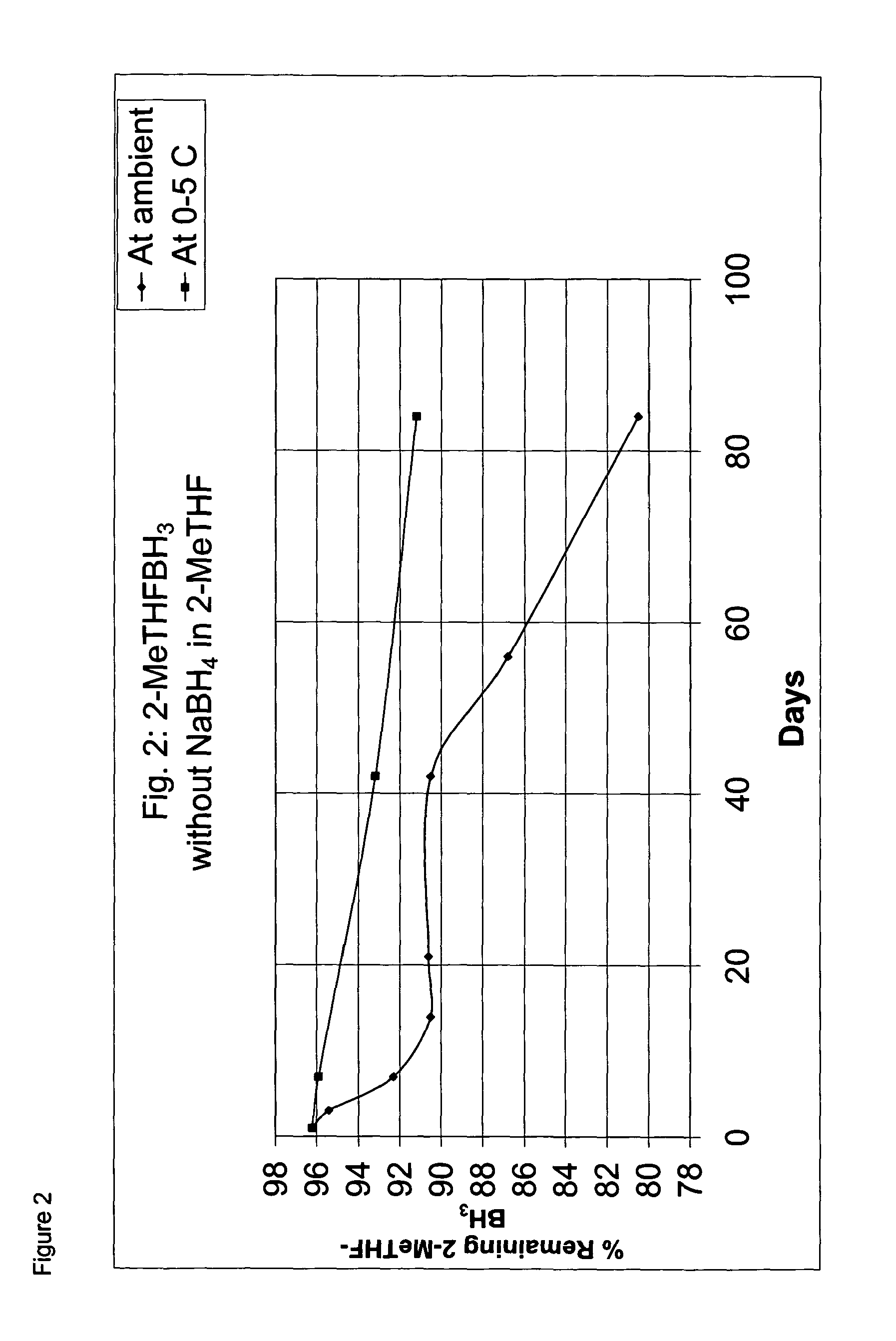

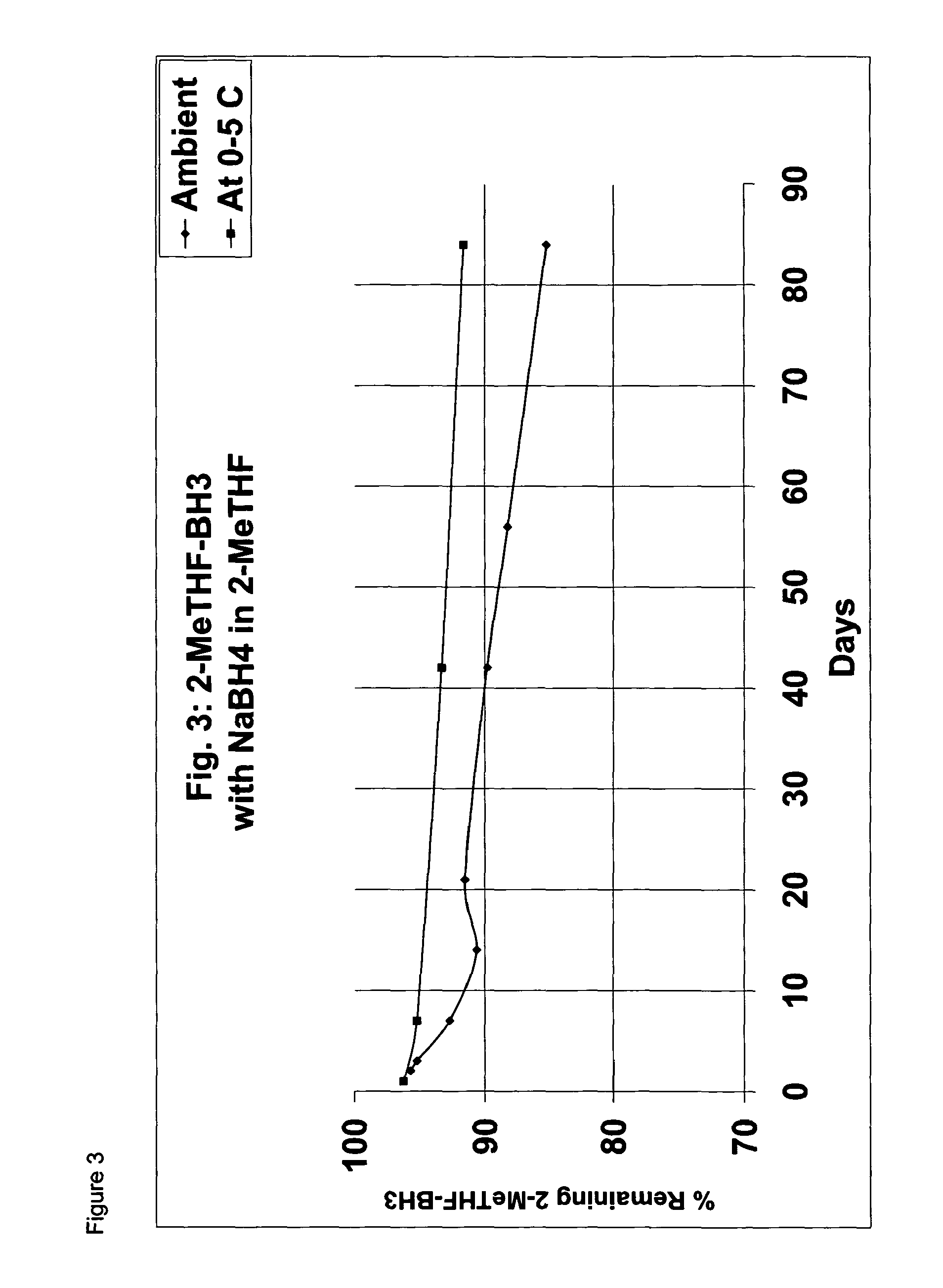

Borane ether complexes

InactiveUS20090278085A1Low flammability hazardLess polarOrganic compound preparationOther chemical processesEtherOrganic reaction

The present invention relates to a borane ether complex of the formula 1,whereinR1 to R4 represent independently from each other hydrogen, C1-C4-alkyl, C3-C6-cycloalkyl or a substituent of the formula CH2OR5, wherein R5 is C1-C4-alkyl or C3-C6-cycloalkyl,or two adjacent substituents R1 to R4 together are a divalent group selected from the group consisting of —CH2CH2—, —CH(CH3)CH2—, —CH2CH2CH2—, —CH(CH3)CH(CH3)—, —CH(CH2CH3)CH2—, —C(CH3)2C(CH3)2—, —CH2C(CH3)2CH2— and —(CH2)6— to form with the —CH—CH— moiety of the tetrahydrofuran ring a cyclic structure,with the provision that at least one of the substituents R1 to R4 is not hydrogen. The invention also relates to a method of using new borane complexes with substituted tetrahydrofuran ethers for organic reactions.

Owner:BASF AG

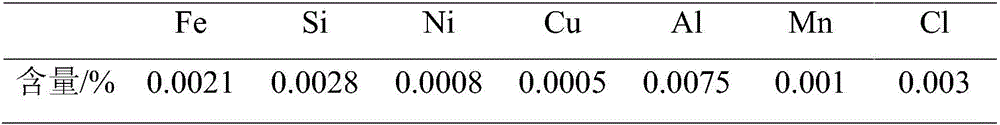

Magnesium reducing agent flux and preparation method thereof

The invention belongs to the field of non-ferrous metal metallurgy, in particular relates to a magnesium reducing agent flux and a preparation method thereof and aims at solving the problems that the impurity removing effect of a flux used by an existing magnesium reducing agent is poor and the quality of a refined magnesium reducing agent is still poor. The magnesium reducing agent flux provided by the invention comprises the following chemical ingredients: 15-20% of MgCl2, 30-40% of KCl, 10-25% of NaCl, 25-30% of CaCl2, 3.5-4.5% of CaF2, 1.5-2.5% of mixture of TiCl2 and TiCl3 and the balance of inevitable impurities. When the flux provided by the invention is adopted for treating a magnesium reducing agent obtained by a magnesium electrolysis technology, the quality of the magnesium reducing agent can be greatly improved, and a powerful support is provided for improvement of quality of subsequently produced sponge titanium. The flux provided by the invention has the advantages that raw materials are simple and easy to get, high design investment is not needed, and the feasibility is strong, so that the flux provided by the invention has stronger application and popularization prospects.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

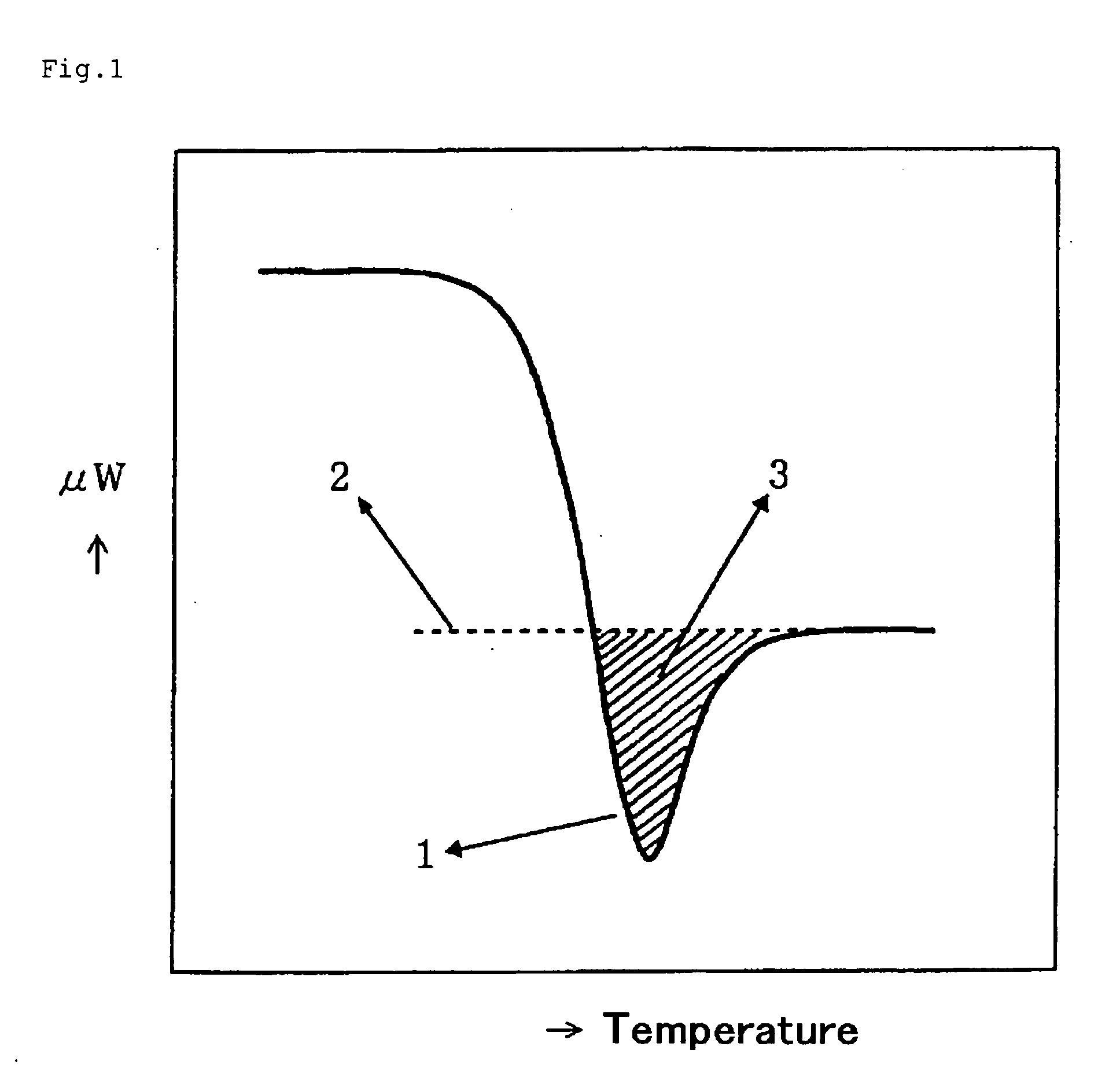

Hypromellose acetate succinate for use as hot-melt extrusion carrier, hot-melt extrusion composition, and method for producing hot-melt extrudate

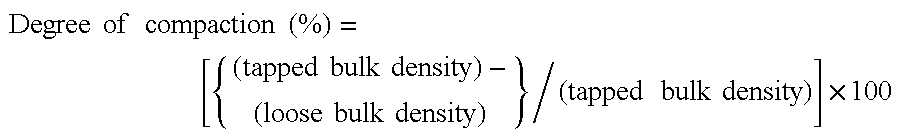

Provided are hypromellose acetate succinates (HPMCAS) for use as a hot-melt extrusion carrier having a volume average particle size (D50) of from 70 to 300 as measured by dry laser diffraction and a loose bulk density of from 0.25 to 0.40 g / cm3; and a hot-melt extrusion composition comprising the HPMCAS and a drug. Also provided is a method for producing a hot-melt extrudate including the steps of: hot-melting the hot-melt extrusion composition at a hot-melt temperature equal to or higher than a melting temperature of the HPMCAS, or at a hot-melt temperature equal to or higher than a temperature at which both of the HPMCAS and the drug become melt; and extruding the hot-melted composition.

Owner:SHIN ETSU CHEM IND CO LTD

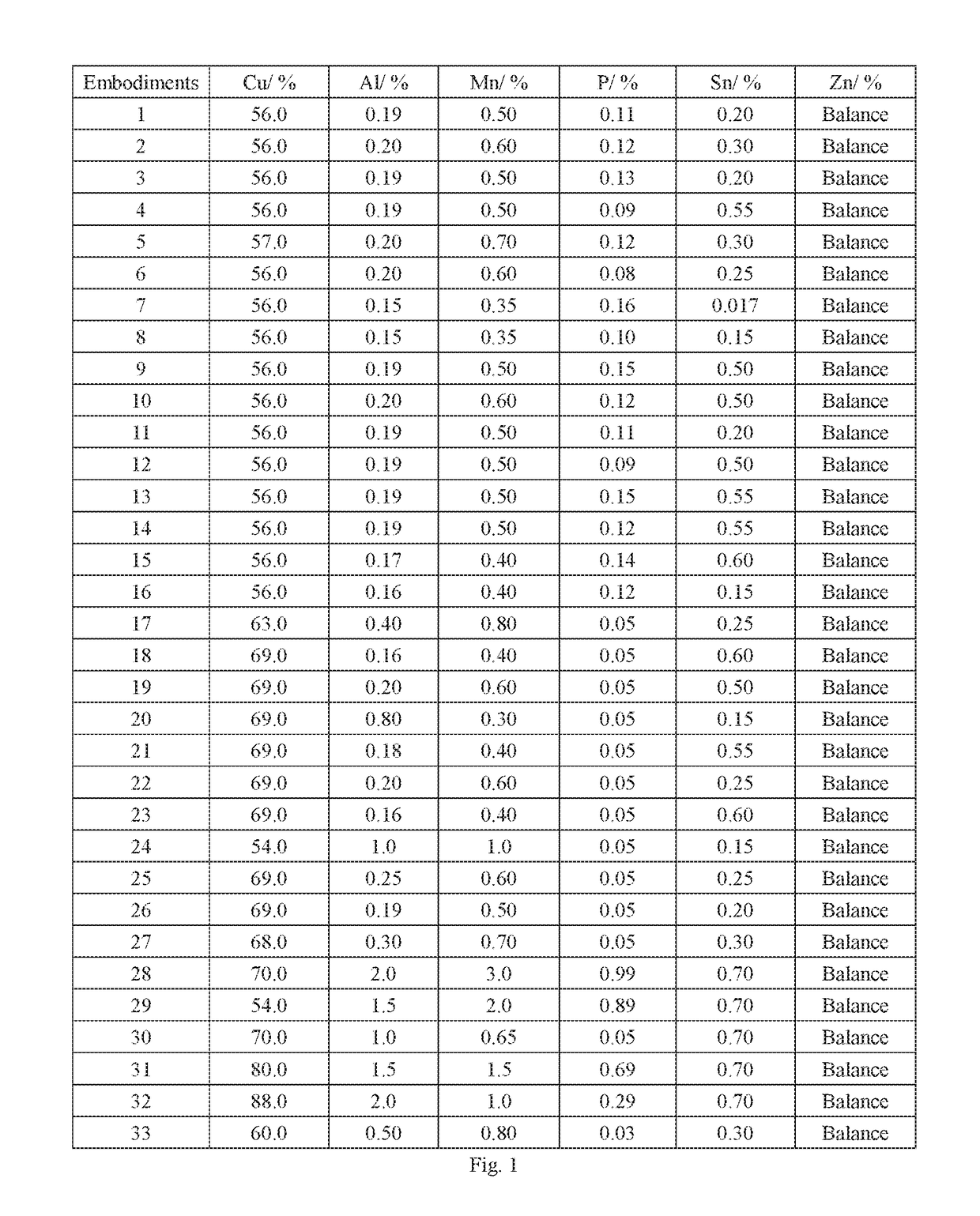

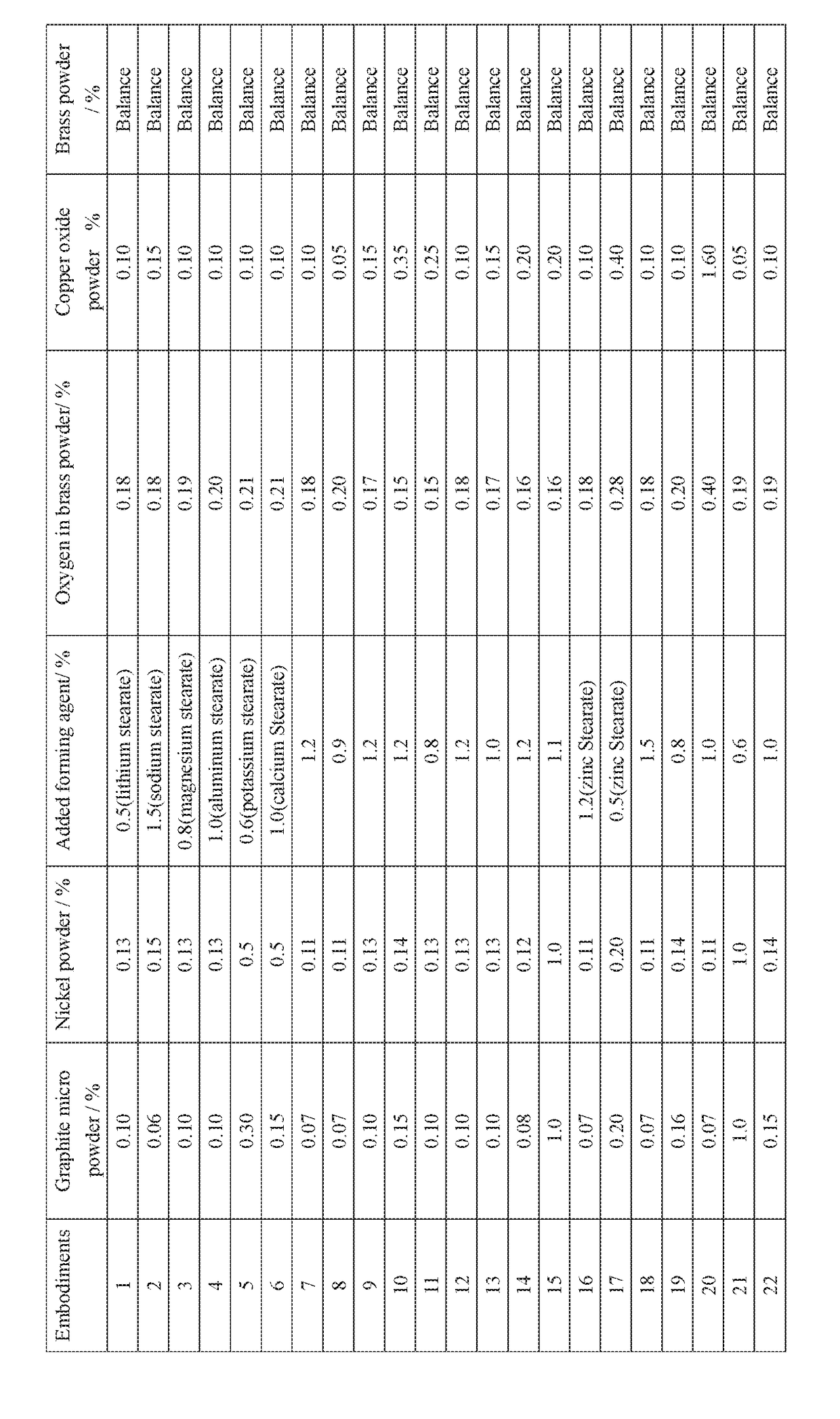

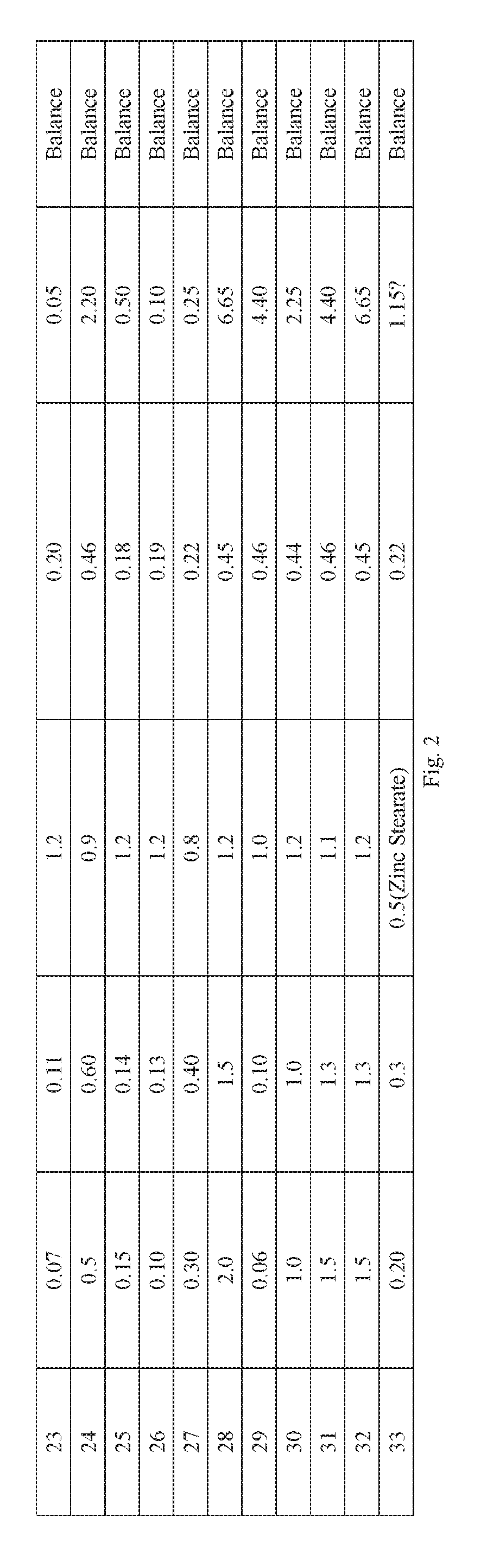

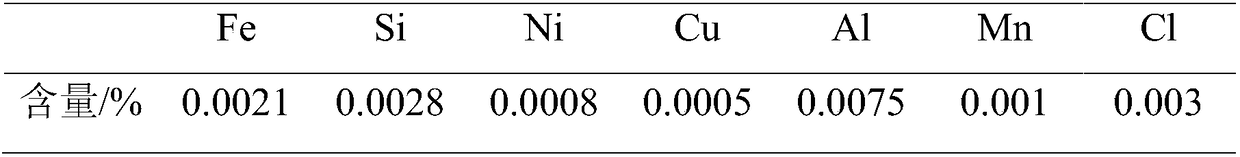

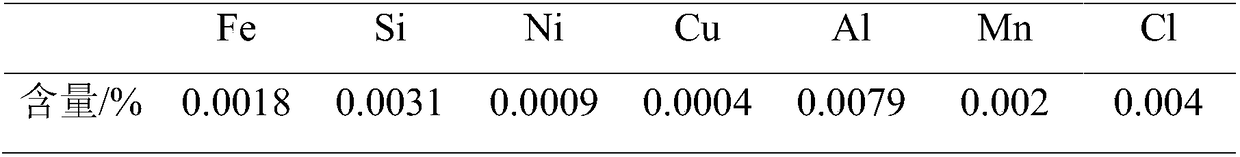

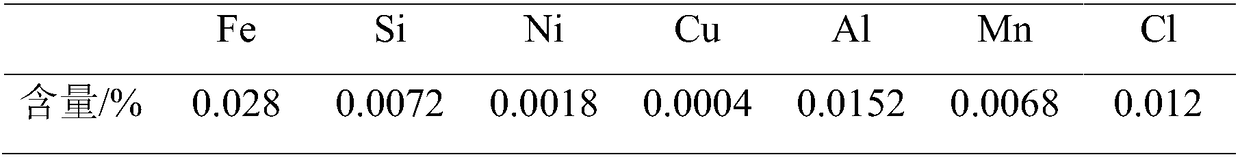

Oxide dispersion-strengthened alloy (ODS), lead-free and free-cutting brass and producing method thereof

ActiveUS20180355459A1Improve cooling effectImprove interface strengthTransportation and packagingMetal-working apparatusOxide dispersion-strengthened alloyManganese

Oxide dispersion-strengthened alloy (ODS), lead-free and free-cutting brass and producing method thereof The mass percent of components in the brass are: 52.0%-90.0% of copper, 0.001%-0.99% of phosphorus, 0.15%-0.70% of tin, 0.25%-3.0% of manganese, 0.15%-0.90% of aluminum, 0.10%-1.5% of nickel, 0.191%-0.90% of oxygen, and 0.06%-0.80% of carbon, the ratio of aluminum to oxygen not exceeding 27:24, with the balance being zinc and inevitable impurities, wherein lead is not more than 0.08%. The brass is produced by a powder metallurgy method: brass powder, copper oxide powder, and graphite micro powder are mixed evenly; 0.001%-1.5% of a forming agent is added and mixed evenly with the mixture; and then molded by compression, and sintering are performed before post-treatment.

Owner:HUNAN TERRY NEW MATERIALS COMPANY

Ink composition and printed article

InactiveUS20120156451A1Low transparencyDecrease in glossinessLayered productsDuplicating/marking methodsWaxTransmittance

The ink composition contains a glitter pigment and wax. In the case where an aqueous solution containing the wax of 0.1 weight % is prepared, the wax serves to satisfy the following relationship: a transmittance of at least 50% and less than 100% with respect to light having a wavelength of 450 nm; a transmittance of at least 60% and less than 100% with respect to light having a wavelength of 550 nm; a transmittance of at least 70% and less than 100% with respect to light having a wavelength of 650 nm; or a transmittance of at least 70% and less than 100% with respect to light having a wavelength of 750 nm.

Owner:SEIKO EPSON CORP

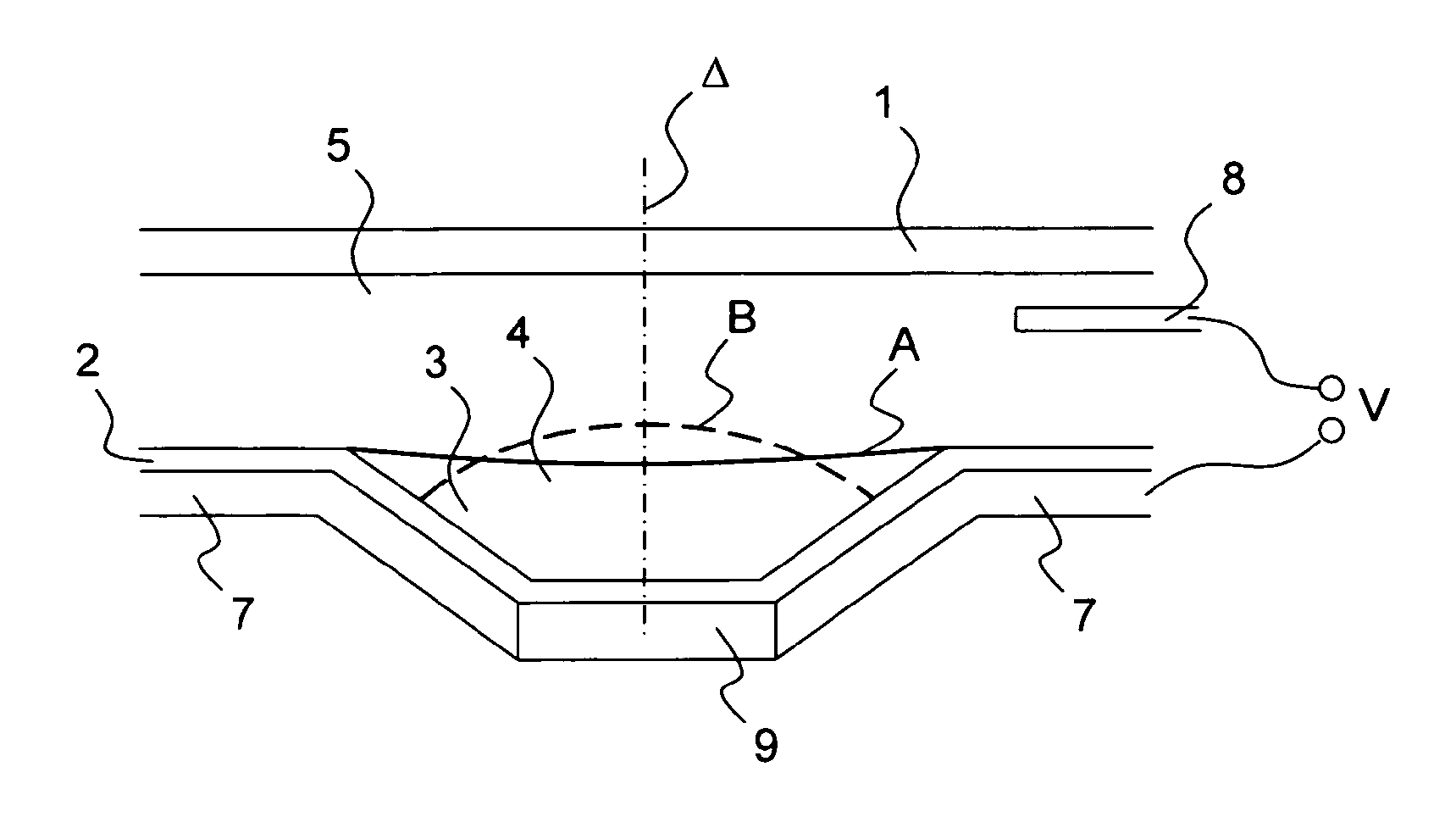

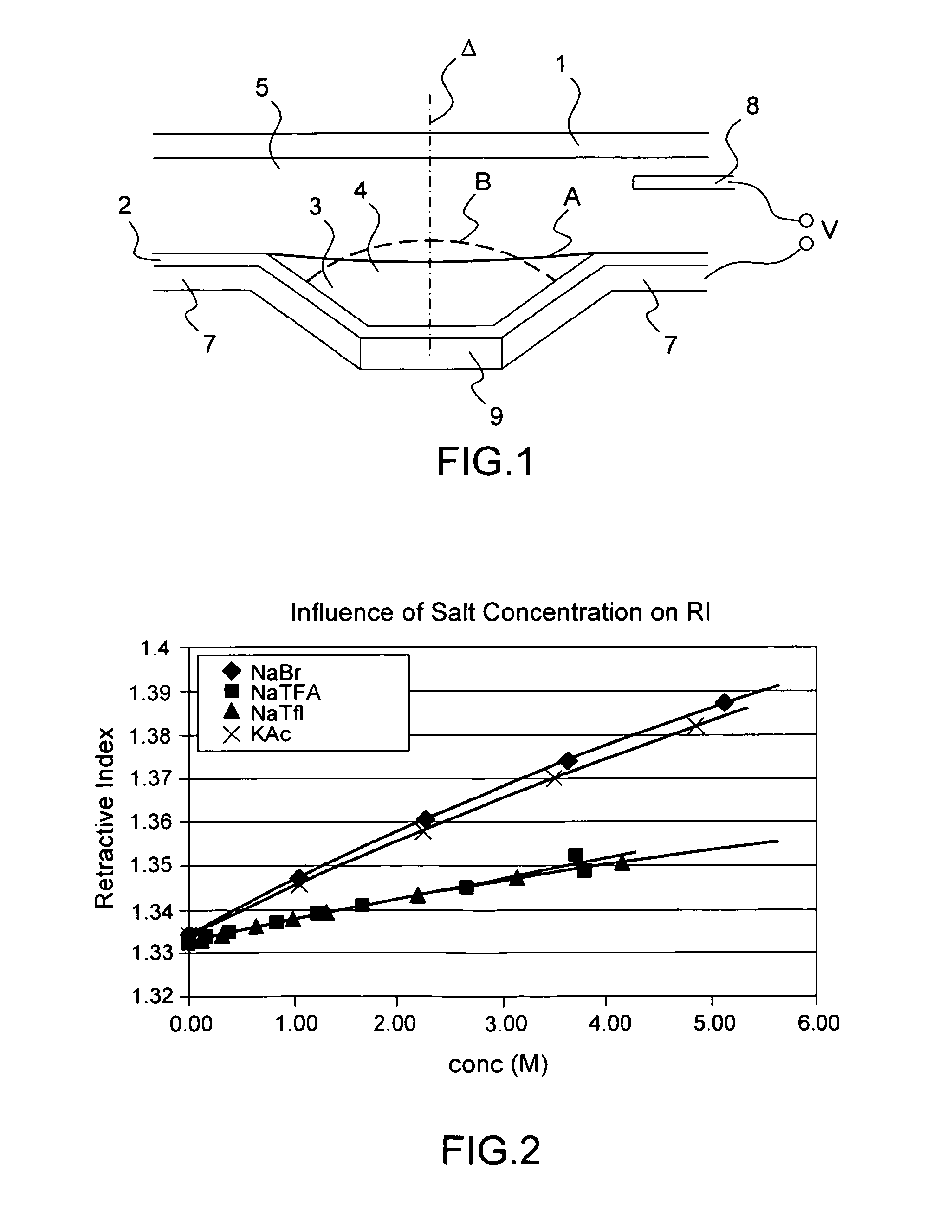

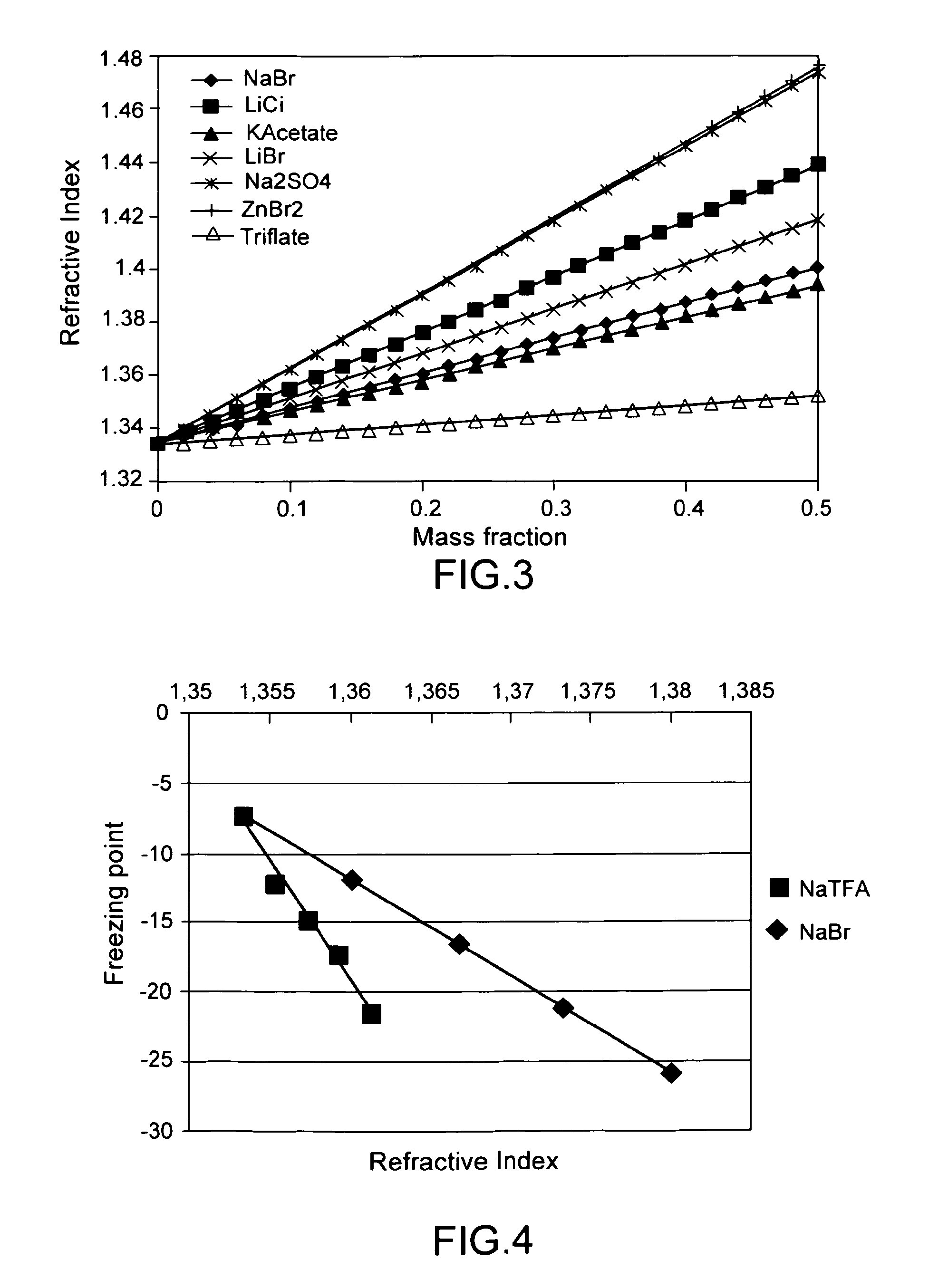

Electrowetting optical device

ActiveUS20130301109A1High densityNot compromise electrowetting device reliabilityLensRefractive indexChemistry

An electrowetting optical device is provided comprising a conductive liquid and a non-conductive liquid, the liquids being non miscible, having different refractive indices and forming an interface, wherein the conductive liquid comprises from 5% by weight of a fluorinated salt, based the total weight of the conductive liquid. An apparatus comprising said electrowetting optical device is described as well.

Owner:INVENIOS FRANCE SAS

Dynamic mixer dispense valvefor two-component high-viscosity high ratio compounds having quick change cartridge

PendingUS20210322939A1Easy to useHigh viscosityRotary stirring mixersTransportation and packagingImpellerEngineering

A dynamic mixer dispense valve and metering apparatus suitable for use in mixing and applying high viscosity, disparate viscosity, high ratio, and / or relatively immiscible two part compounds that exhibit short cure times includes a housing supporting a pair of valve assemblies each coupled to respective sources of base and accelerator components. A pair of pneumatic valve actuators control the operation of the valve assemblies to control the flow of components into a mixing chamber. Within the mixing chamber a mixer impeller is rotatably supported and coupled to a source of rotational power. An additional pneumatic valve actuator combination operates a further flow control to prevent undesired material loss following a shot cycle.Note

Owner:MENK BRUCE H +1

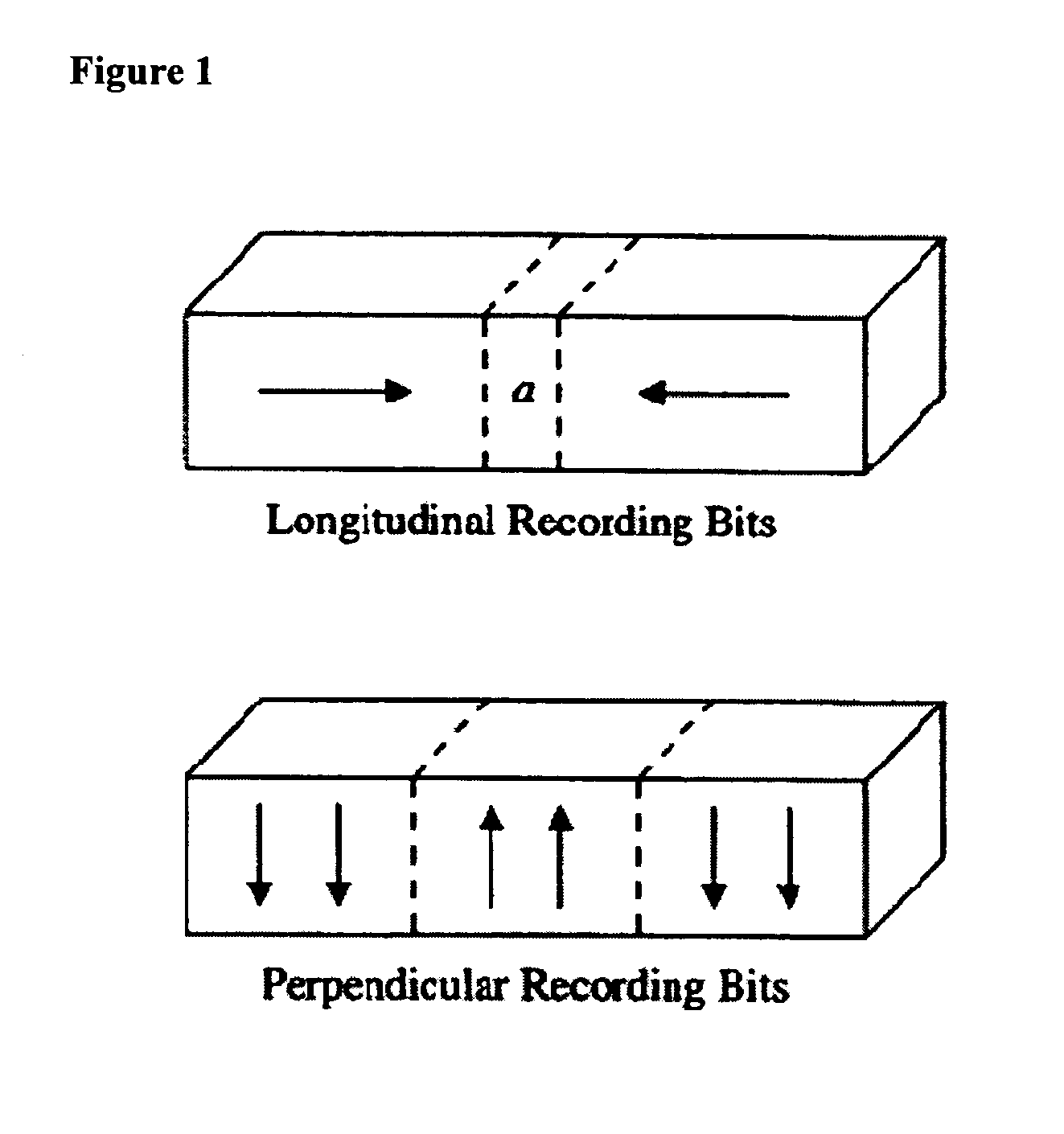

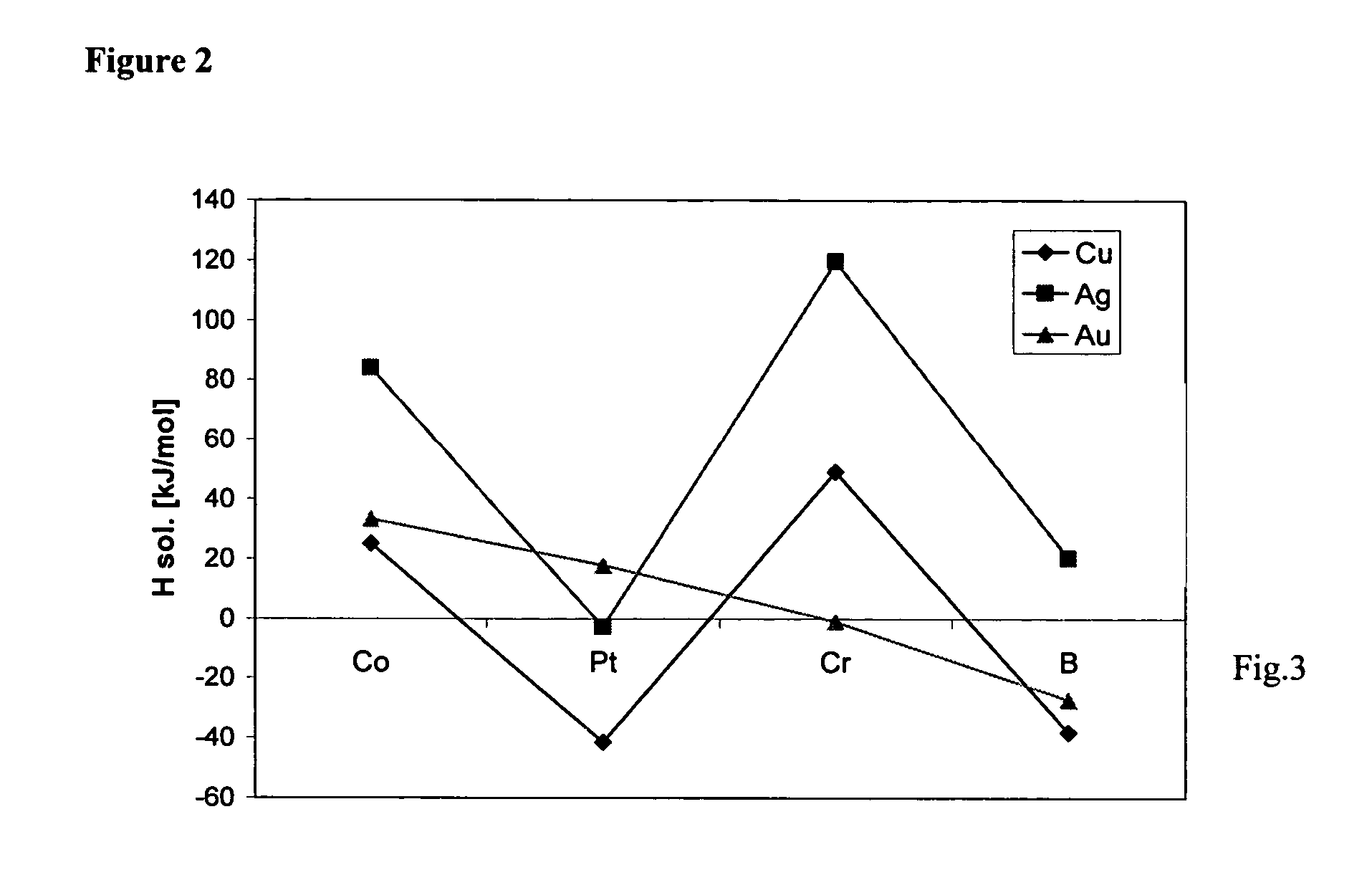

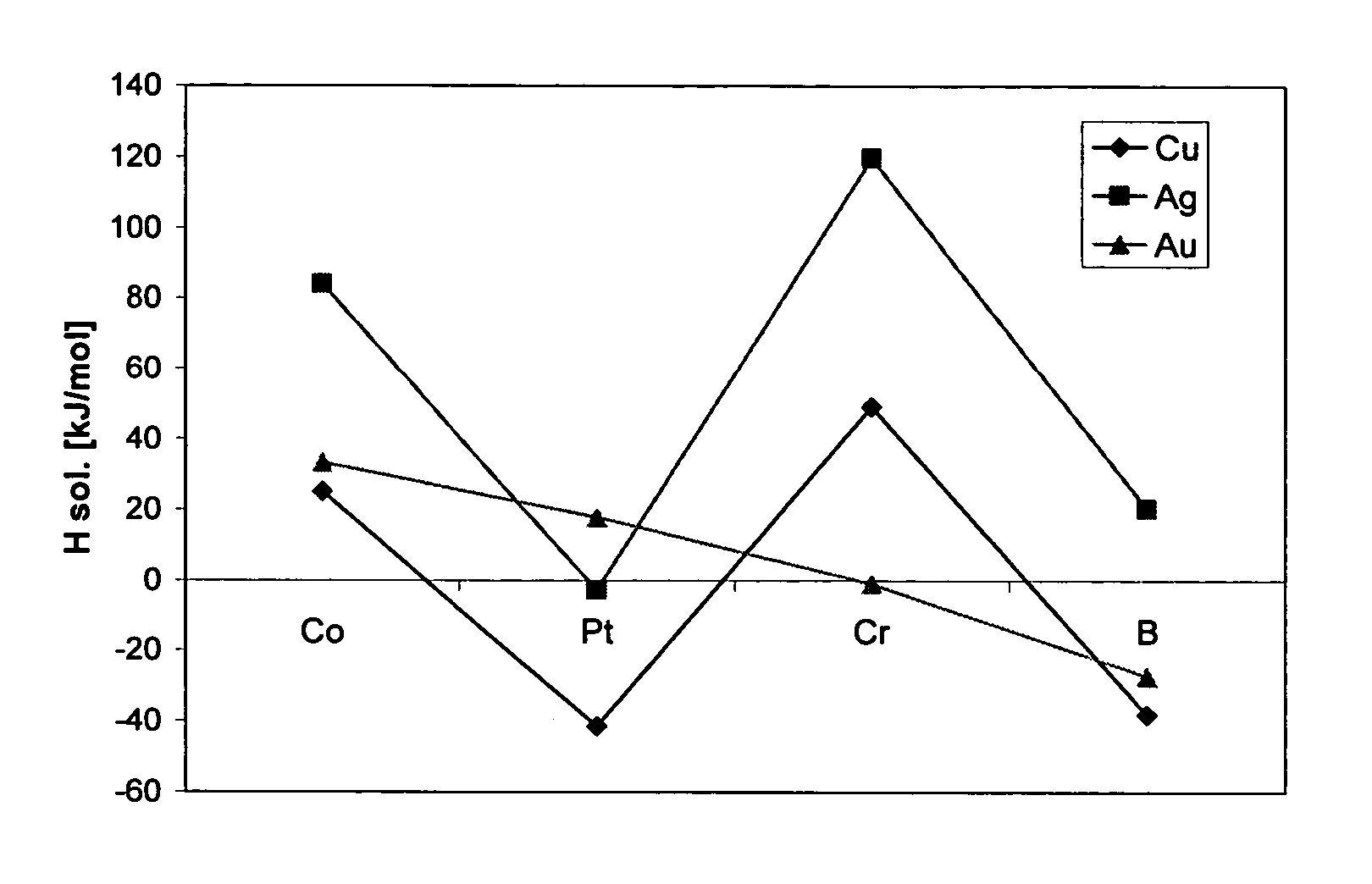

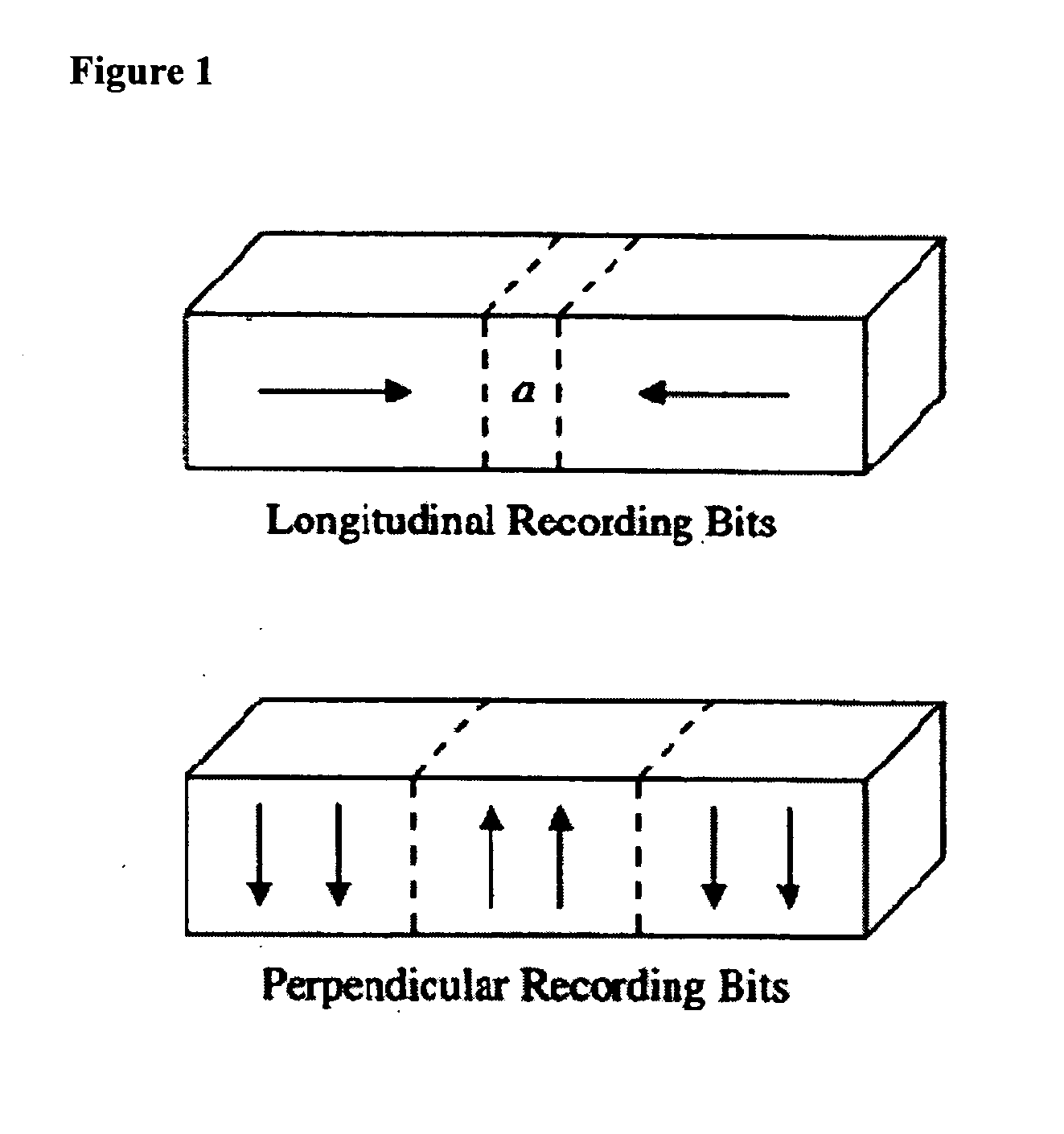

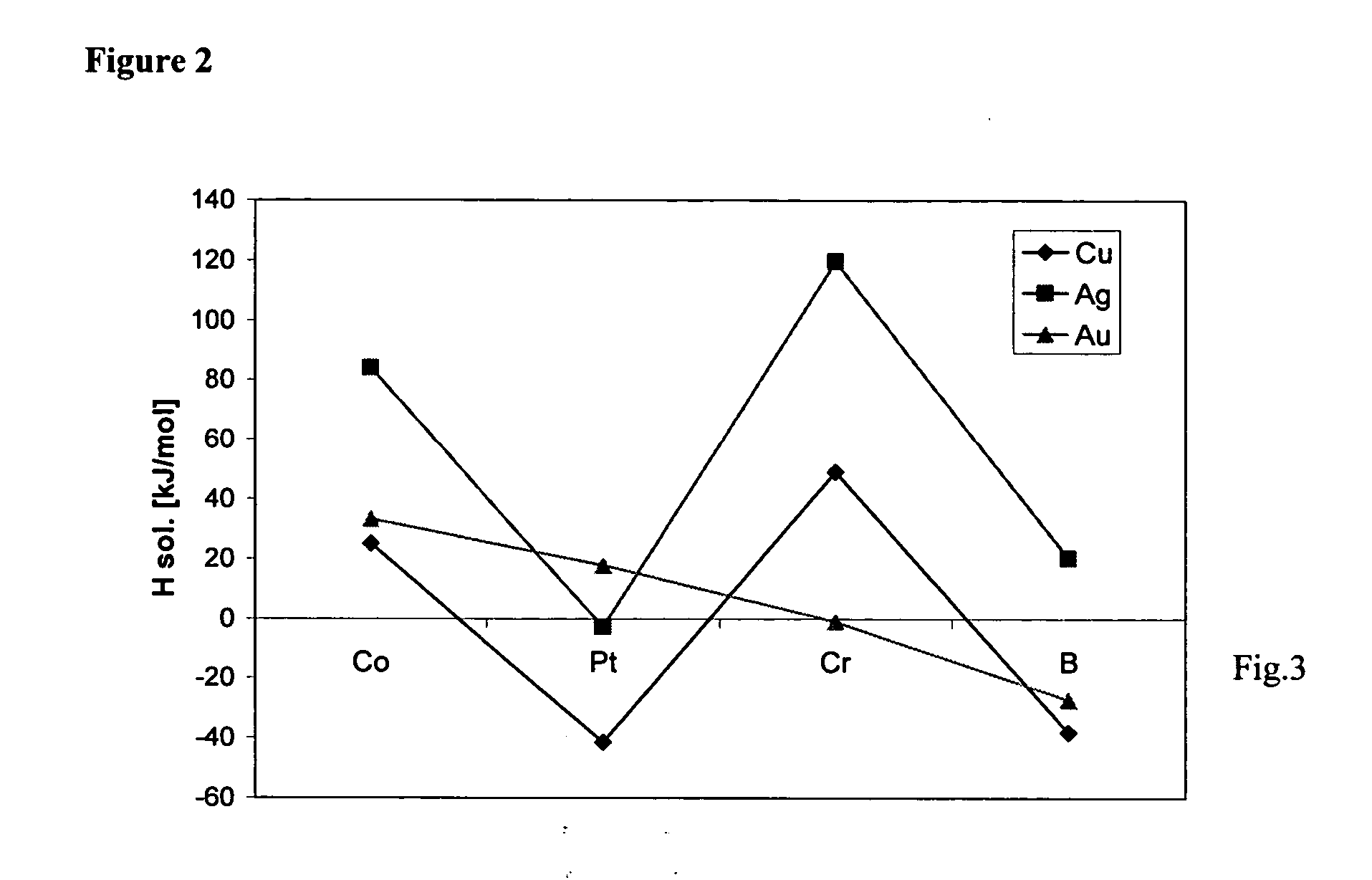

Magnetic storage media with Ag, Au-containing magnetic layers

InactiveUS7736766B2Improve isolationPoor miscibilityRecord information storageMagnetic recordingMagnetic storageGrain boundary

A magnetic recording medium having a Au, Ag-containing magnetic layer having Co, Cr, Ag and Au; the magnetic recording layer having Co-containing magnetic grains surrounded by substantially nonmagnetic Cr-containing grain boundaries; wherein said Ag and said Au are substantially immiscible in the Co-containing magnetic grains is disclosed.

Owner:SEAGATE TECH LLC

Method for manufacturing varistor

ActiveUS7300620B2High viscosityPrevent aggregation and nonuniform precipitationLayered productsCeramic shaping apparatusPotassiumCobalt

Owner:MURATA MFG CO LTD

Lubrication and cooling system

A system for reducing the refrigerant pressure in an oil sump (10) or in a cavity (352) of a housing. The invention is particularly useful for reducing pressure in a compressor (23) for heat pump applications that has been validated for water chiller operations or in turbine and generator systems in ORC systems generating electricity using refrigerant, the ORC systems essentially being a heat pump application operating in reverse. An auxiliary compressor (509), an auxiliary condenser (709) or an ejector pump (609) may be used to reduce pressure in the oil sump (10), to separate refrigerant from oil. The auxiliary compressor (509), the auxiliary condenser (709) or the ejector pump (609) may also be used to reduce the pressure of refrigerant in the housing of a compressor in heat pump applications at temperatures and pressures at which the compressor was validated for water chiller applications and of the turbine and generator in ORC applications.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

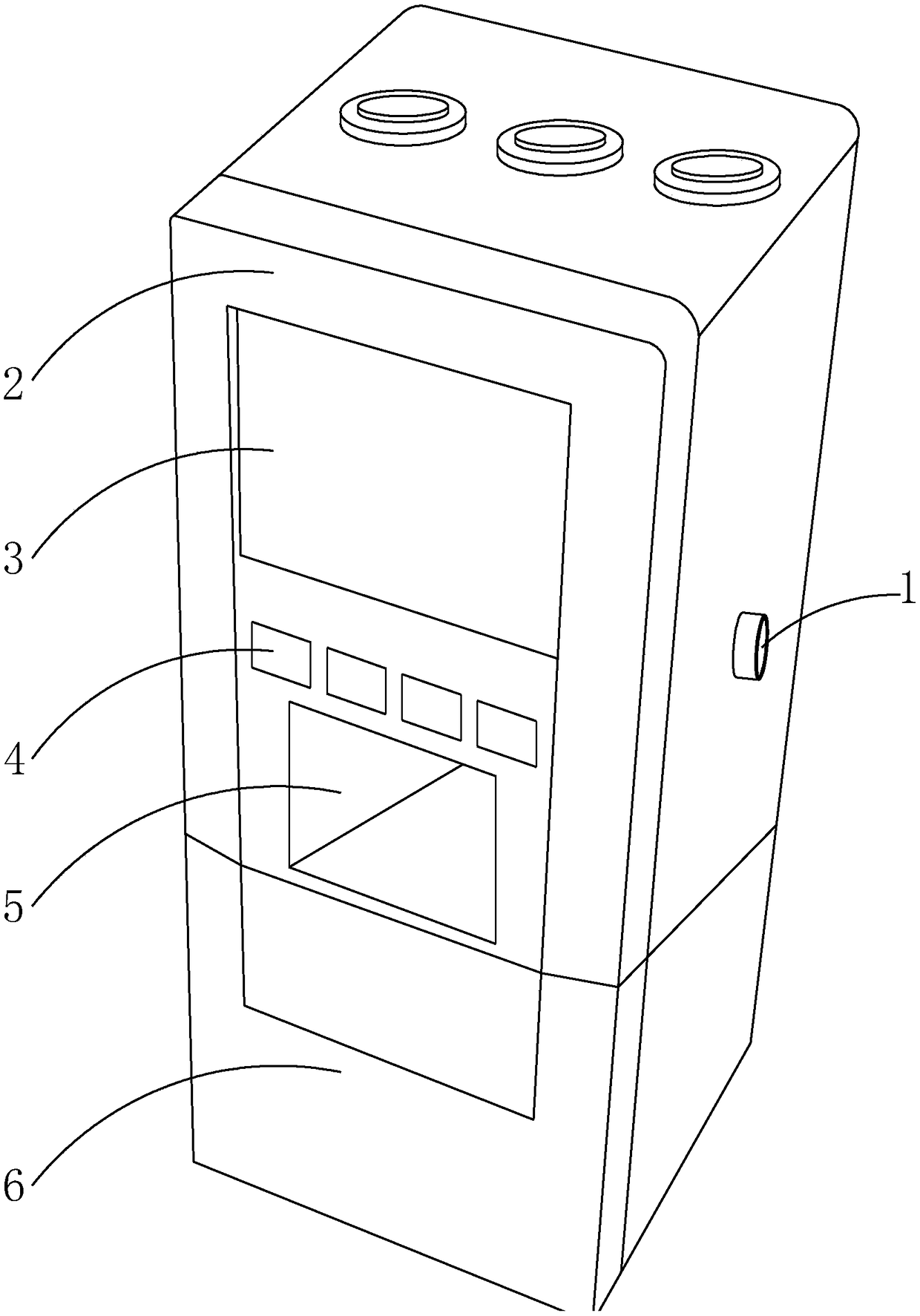

Spiral-guiding carbonated beverage layering device

The invention discloses a spiral-guiding carbonated beverage layering device, which comprises a syrup joint, a layering device, a window, buttons, a filling opening and a base, wherein the syrup jointis embedded in a side face of the layering device, the front surface of the layering device is provided with the window, the number of the buttons is four, and a sealing mechanism adopts double-layersealing to seal the top end of a feeding tube of a storage mechanism and a joint between a storage tank and the feeding tube. In this way, the loss of carbon dioxide inside a carbonated beverage during storage can be effectively prevented to ensure the taste of the carbonated beverage; a stirring paddle is rotated to stir by the gravity of the carbonated beverage, and then the carbonated beverageis injected into a holding cup through the spiral guiding mechanism, spiral guiding is performed through a spiral guiding spring to reduce the speed of the carbonated beverage injection, to prevent excessive bubbles, and to prevent the diffusion of the carbonated beverage through the spiral guiding, thereby reducing the mutual dissolution of the carbonated beverage and realizing more obvious layering.

Owner:南安墨潇工业产品设计有限公司

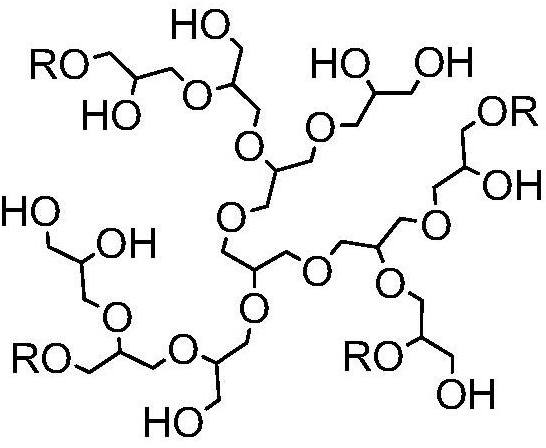

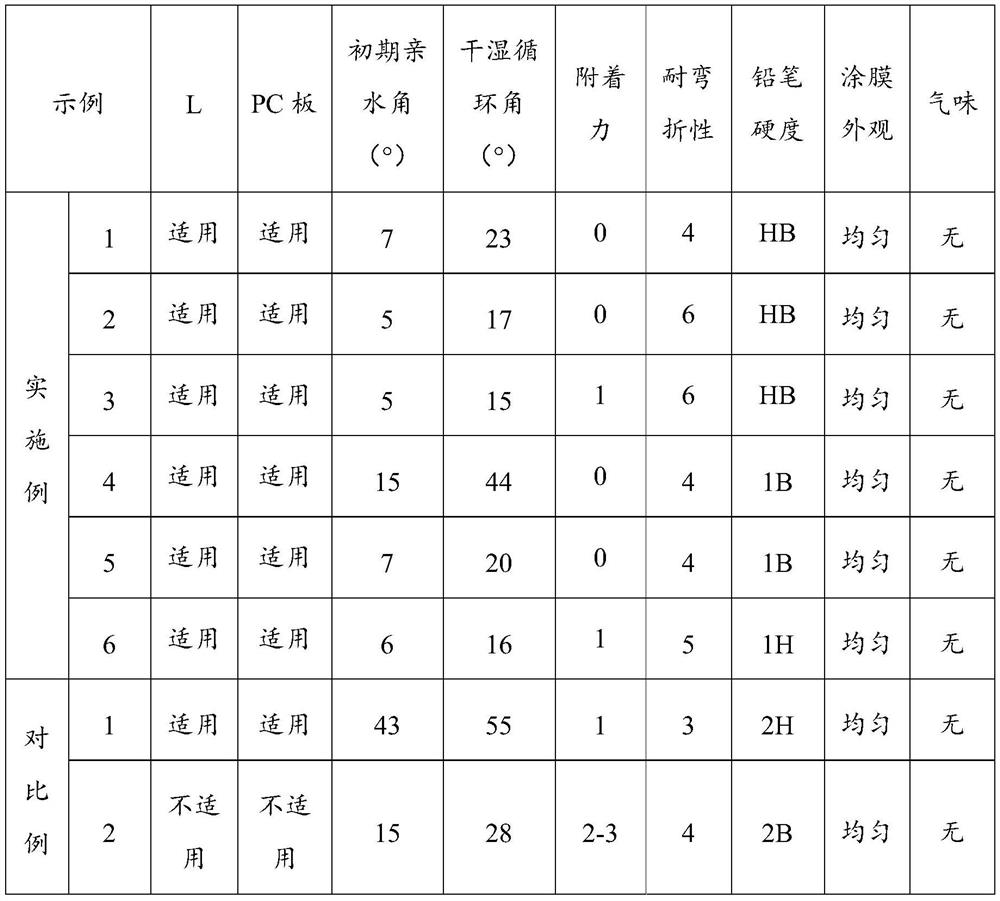

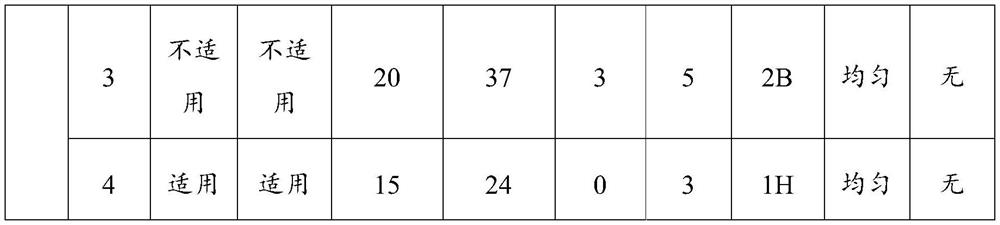

Photocureable coating as well as preparation method and application thereof

ActiveCN113185909AImprove hydrophilicityImprove adhesionChemical industryPolyurea/polyurethane coatingsPolymer scienceEther

The invention belongs to the technical field of coating preparation, and particularly relates to a photocureable coating as well as a preparation method and application thereof. The coating comprises the following raw materials in parts by weight: 5-20 parts of hyperbranched polyglycerol fatty acid ester, 10-50 parts of polyurethane acrylate, 10-50 parts of a reactive diluent, 0.5-8 parts of a photoinitiator and 0.1-2 parts of an auxiliary agent. When the hydrophilicity of the coating is improved, corrosive groups such as sulfonic acid and carboxylic acid do not need to be introduced, the hyperbranched polyglycerol fatty acid ester contains a large number of ether bonds and has good flexibility, and the hydrophilicity, the adhesive force and the bending resistance of the coating can be improved through the synergistic effect of the hyperbranched polyglycerol fatty acid ester and the polyurethane acrylate. The hyperbranched polyglycerol fatty acid ester with the saponification value of 50-300mg / g improves the hydrophilic effect of the coating on the premise of not influencing other properties of the coating.

Owner:佳化化学(抚顺)新材料有限公司

Organic reactions carried out in aqueous solution in the presence of a hydroxyalkyl(alkyl)cellulose or an alkylcellulose

ActiveUS11312668B2Poor miscibilityImprove solubilityUrea derivatives preparationCarbamic acid derivatives preparationCelluloseOrganic reaction

The present invention relates to a method of carrying out an organic reaction in aqueous solution in the presence of a hydroxyalkyl(alkyl)cellulose or an alkylcellulose.

Owner:ABBVIE INC +1

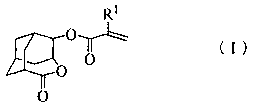

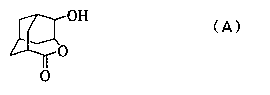

Homoadamantane derivatives, process for preparing same, and photoresist compositions

InactiveCN103038226AReduce roughnessReduce solubilityOrganic chemistryPhotosensitive materials for photomechanical apparatusCombinatorial chemistryPerylene derivatives

Owner:OSAKA ORGANIC CHEM INDS

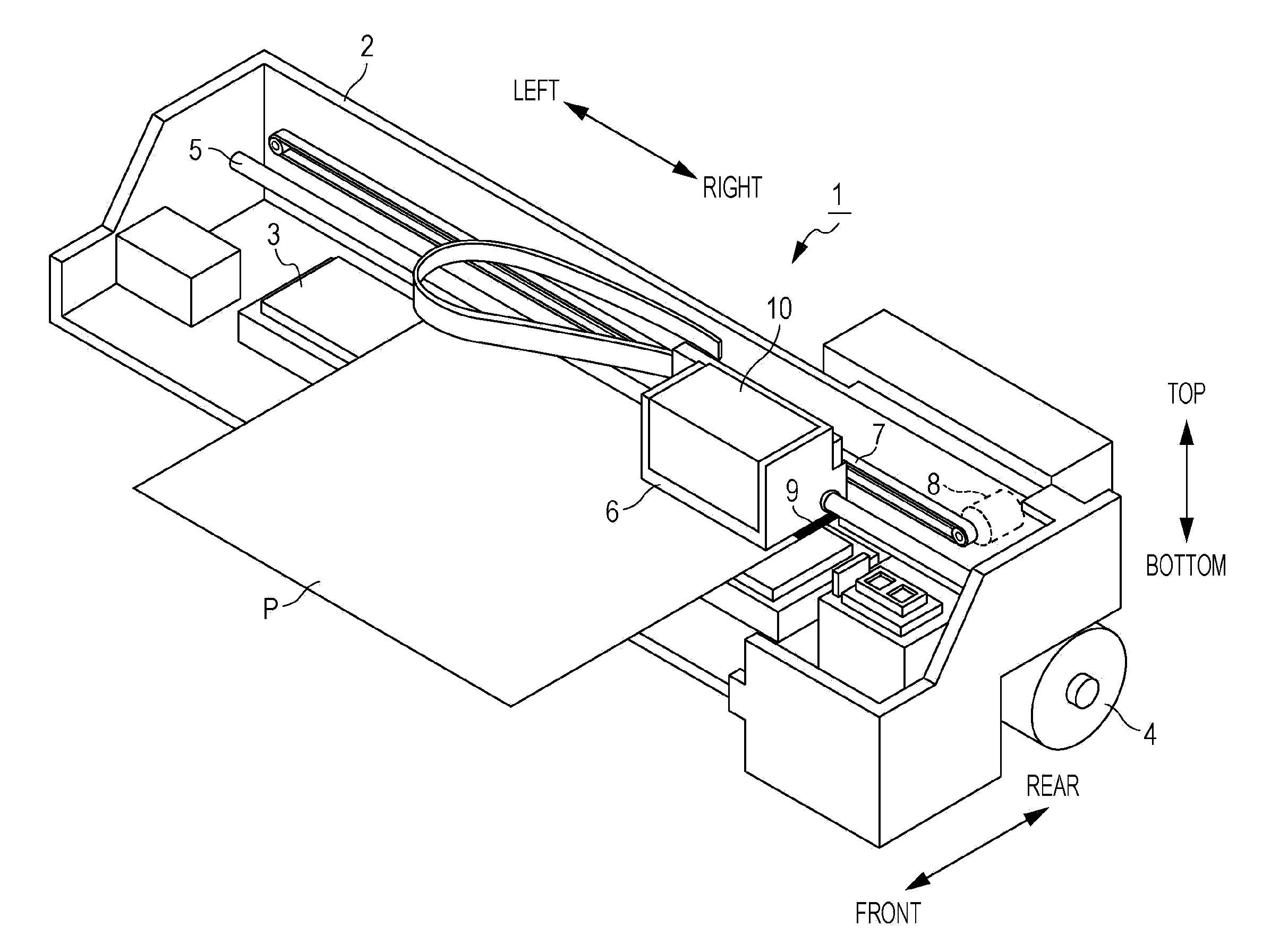

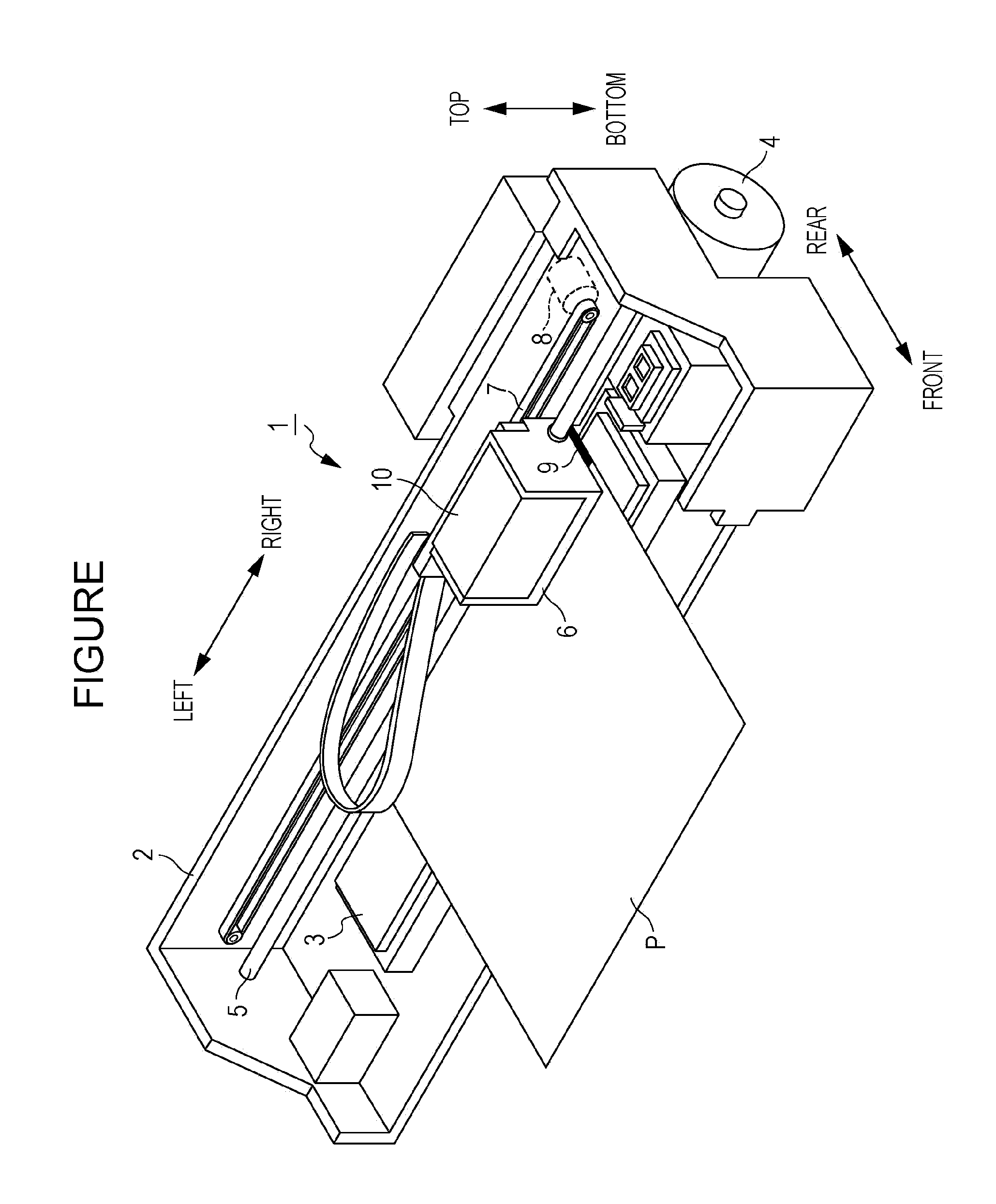

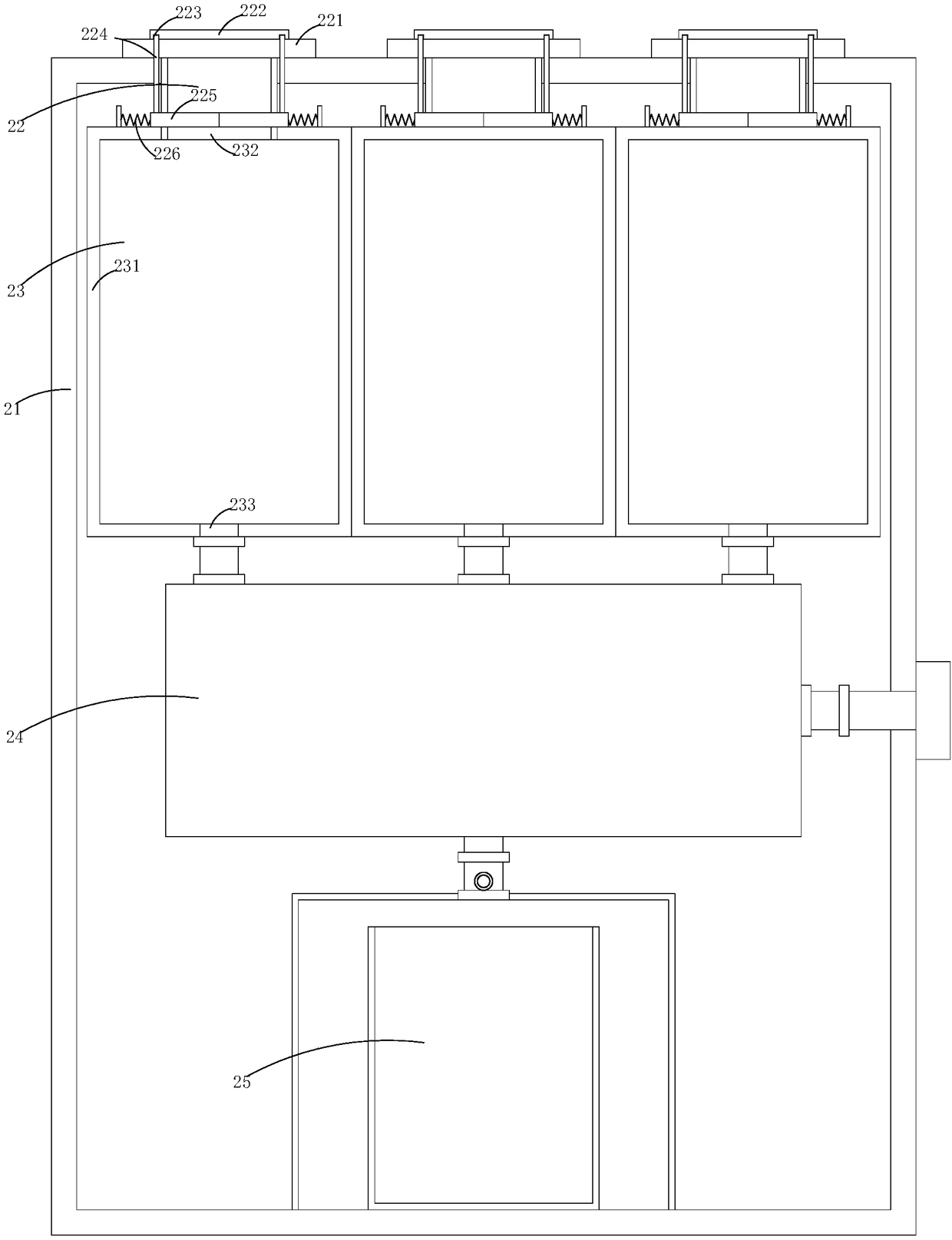

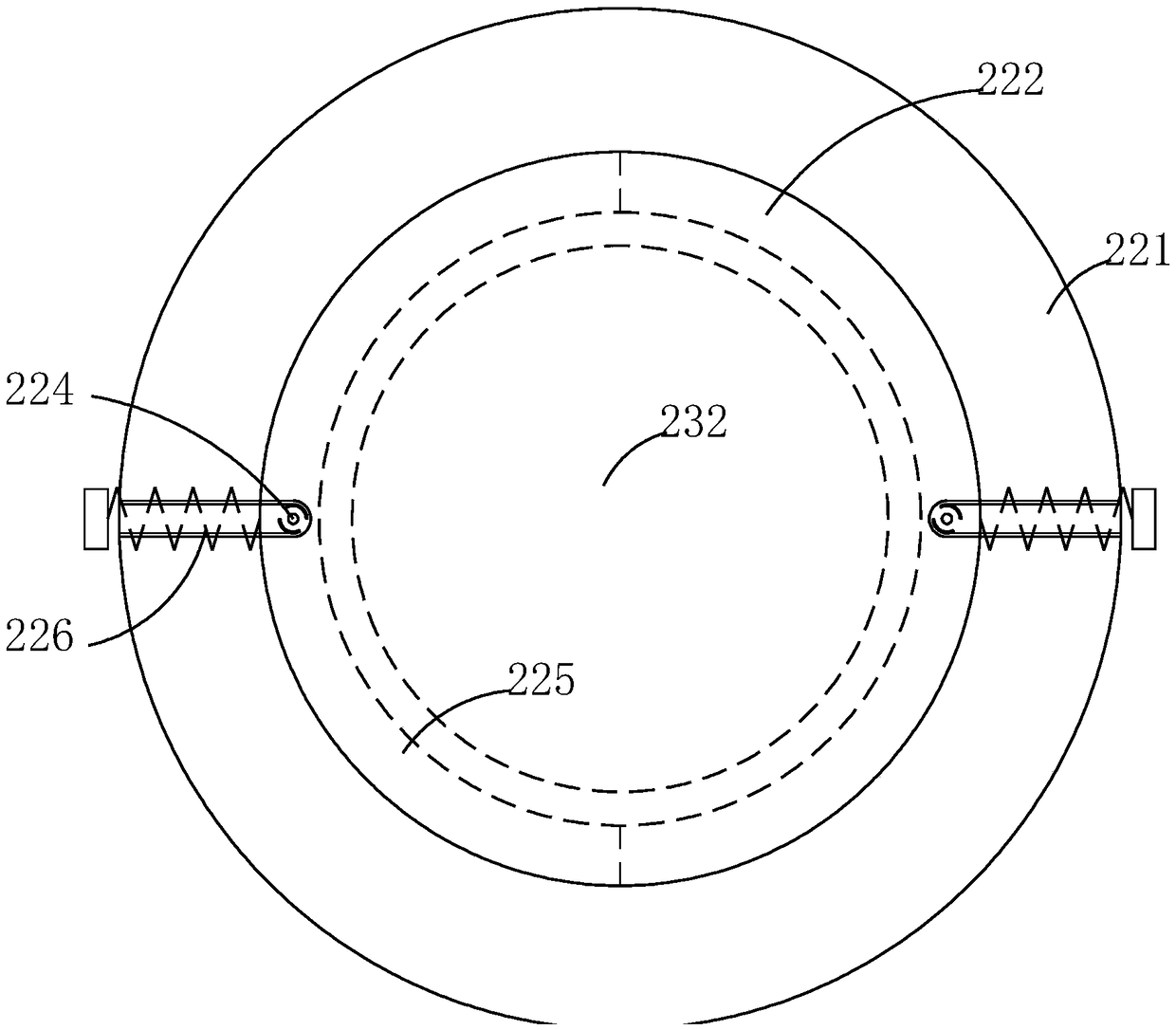

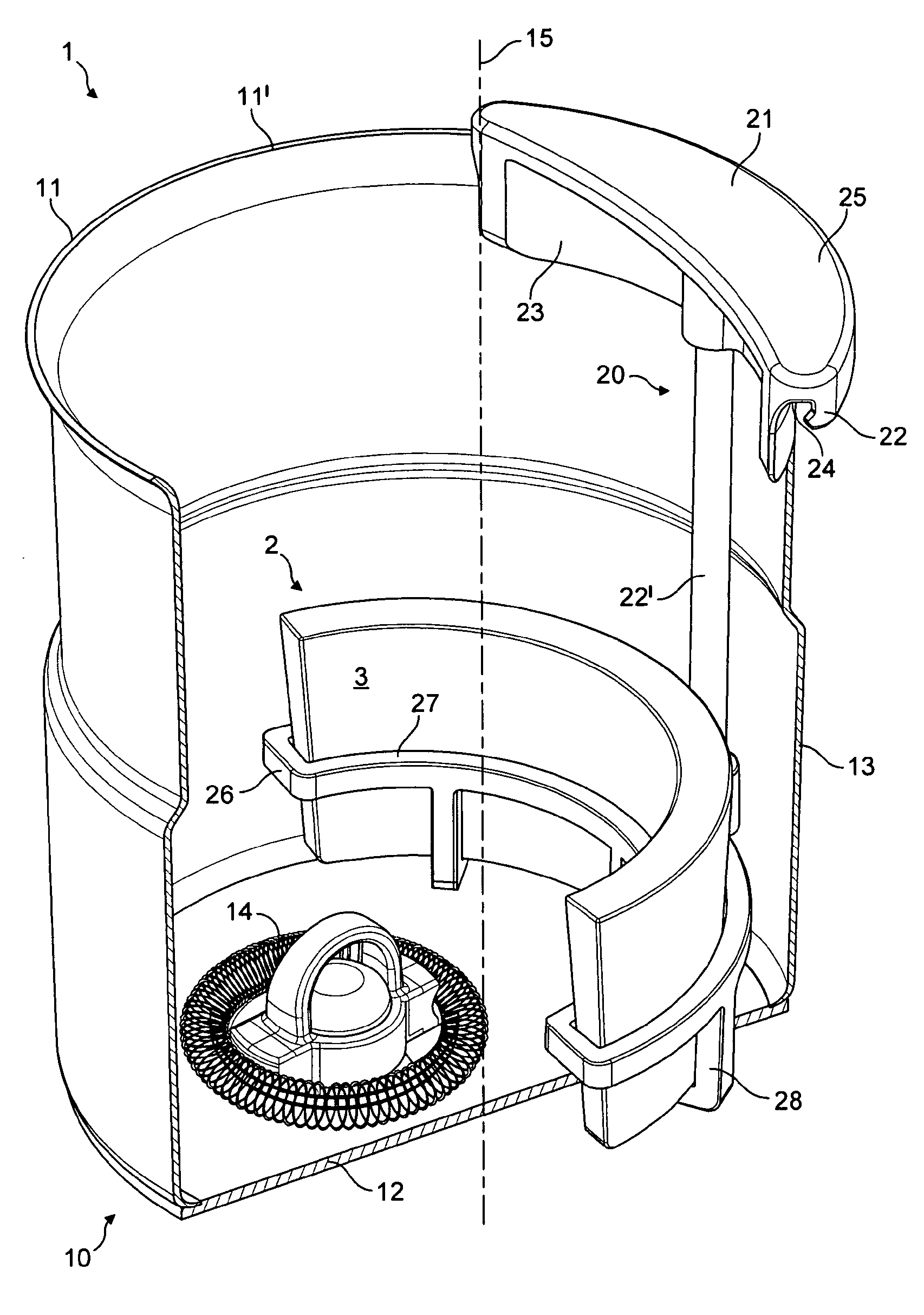

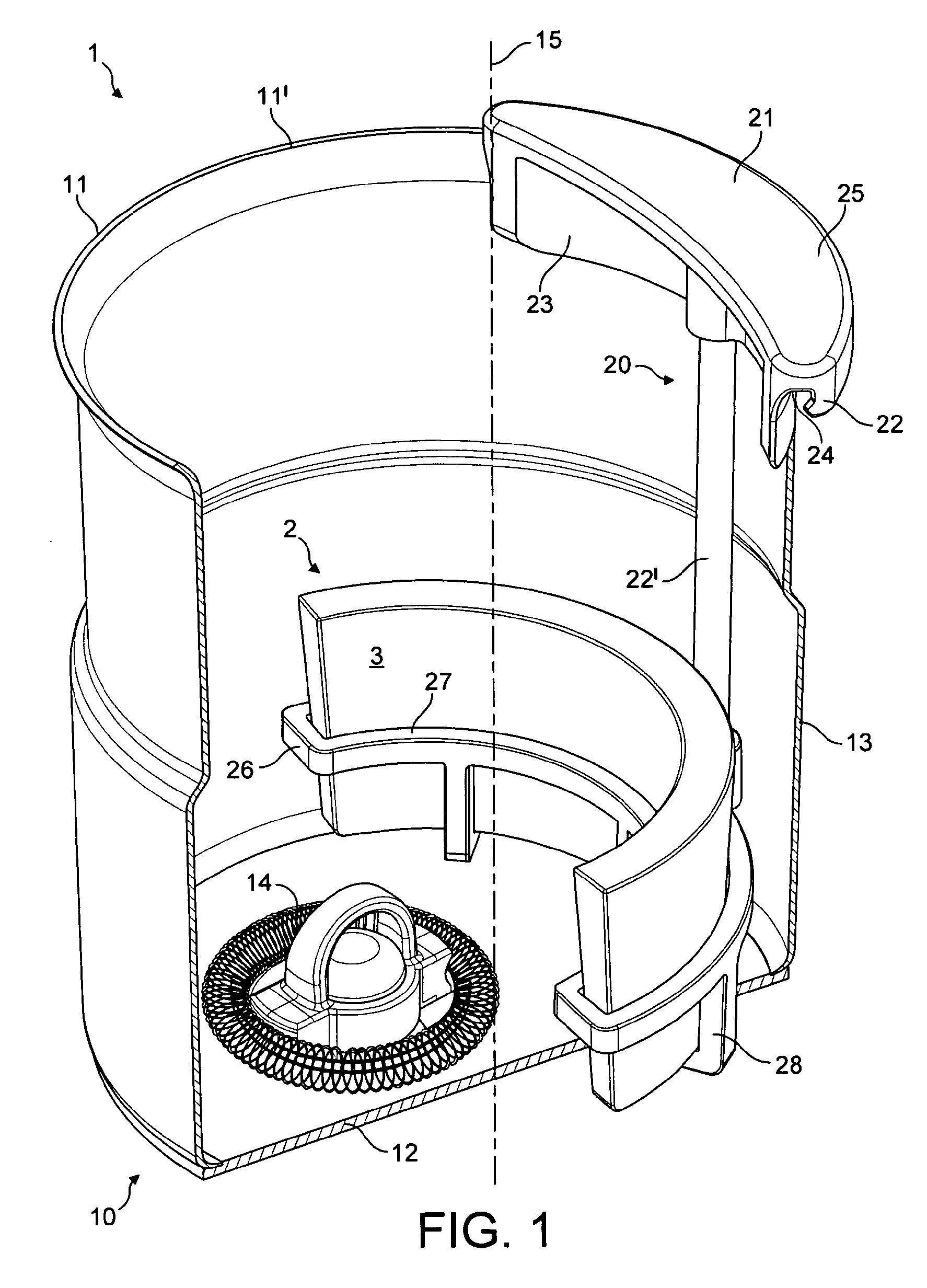

Arrangement for mixing a flavouring ingredient with a liquid carrier

InactiveUS20120189754A1Slow dispersionReduce solubilityMilk preparationBeverage vesselsImpellerEngineering

An arrangement (20,120,220,320,420,520,620,720,820,920) to hold a dissolvable and / or dispersible beverage flavouring ingredient in a liquid carrier (105,205,405,505) contained in a device (1,100,200,300,400,500,900) has: a tank (11) for containing this liquid carrier; and an impeller (14,214,214′,514,914) located in this tank for circulating this liquid carrier relative to this ingredient to promote dissolution and / or dispersion of this ingredient in the carrier. Such arrangement has means (26,126,226,326,426,526,626,726,826,926) for securing a self-sustaining body (2,102,202,302,402,502,602,702,802,902) of this ingredient and means (21,121,221,321,421,521,621,721,821,921) for positioning the securing means in this tank so as to secure a position of this self-sustaining body spaced apart from this impeller. The securing means is configured to allow substantially unrestricted flow of this relatively circulating liquid carrier to a main surface (3,103,203,303,403,503,603,703,803,903) of this self-sustaining body.

Owner:NESTEC SA

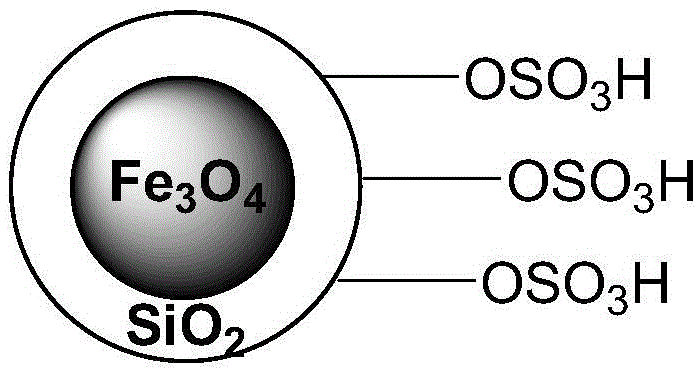

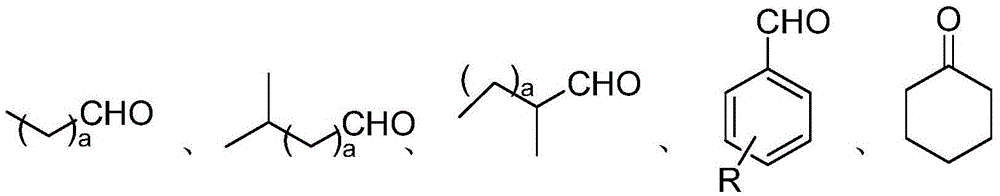

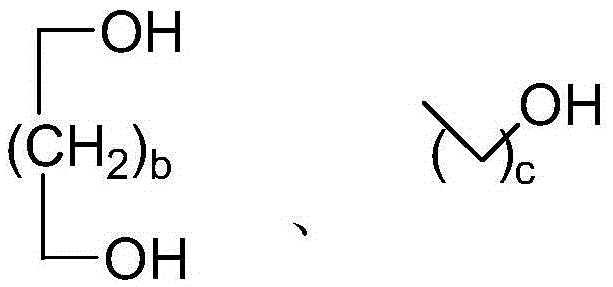

A method for preparing acetal (ketone) catalyzed by an acidic magnetic material containing -so3h

ActiveCN104327038BHigh catalytic activityHigh selectivityOrganic chemistryOrganic compound preparationAlcoholGas phase

The invention discloses a method for preparing acetal (ketone) by catalyzing an acidic magnetic material containing -SO3H, which belongs to the technical field of chemical material and preparation thereof. According to the invention, mol ratio of aldehyde or ketone to alcohol used in the preparation method is 1: (1-5), mole of the acidic magnetic material catalyst accounts for 8-10% of that of the used aldehyde or ketone by calculating -SO3H, reaction temperature is 110 DEG C, the reaction time is 0.5-3 hours, the reaction pressure is one atmospheric pressure, a cooling step is carried out to room temperature after reaction is completed, the catalyst is sucked by a magnet, and the conversion rate, selectivity and acetal(ketone) yield of the reaction raw material are detected by a reaction solution through a gas chromatograph. Compared with the preparation method of other catalysts, the method has the advantages of high reaction selectivity, simple separation of the catalyst and the product, the catalyst enables cycle usage without any treatment, the operation of whole preparation process is simple, the economic benefit is high, and the method is convenient for industrial large scale production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

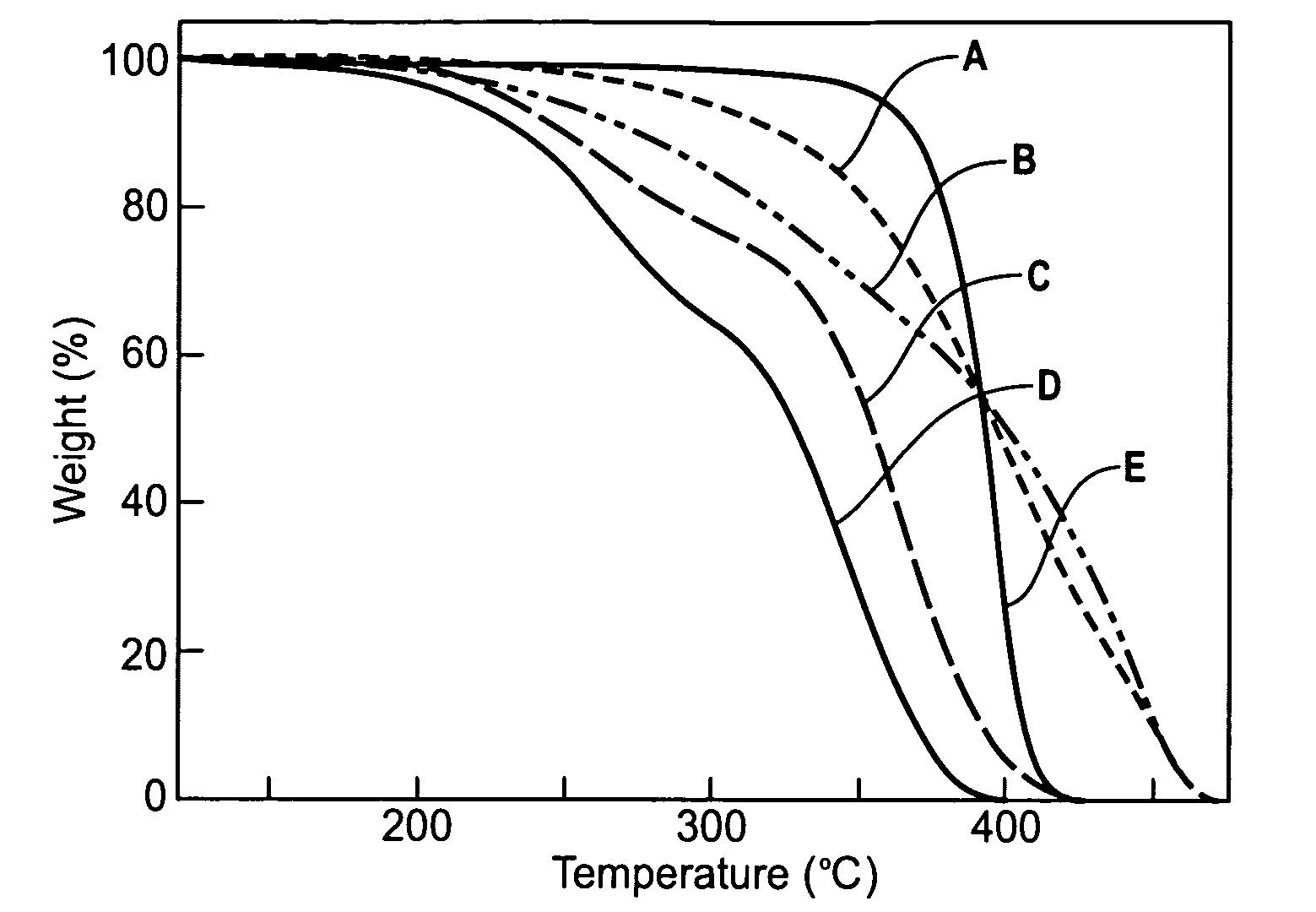

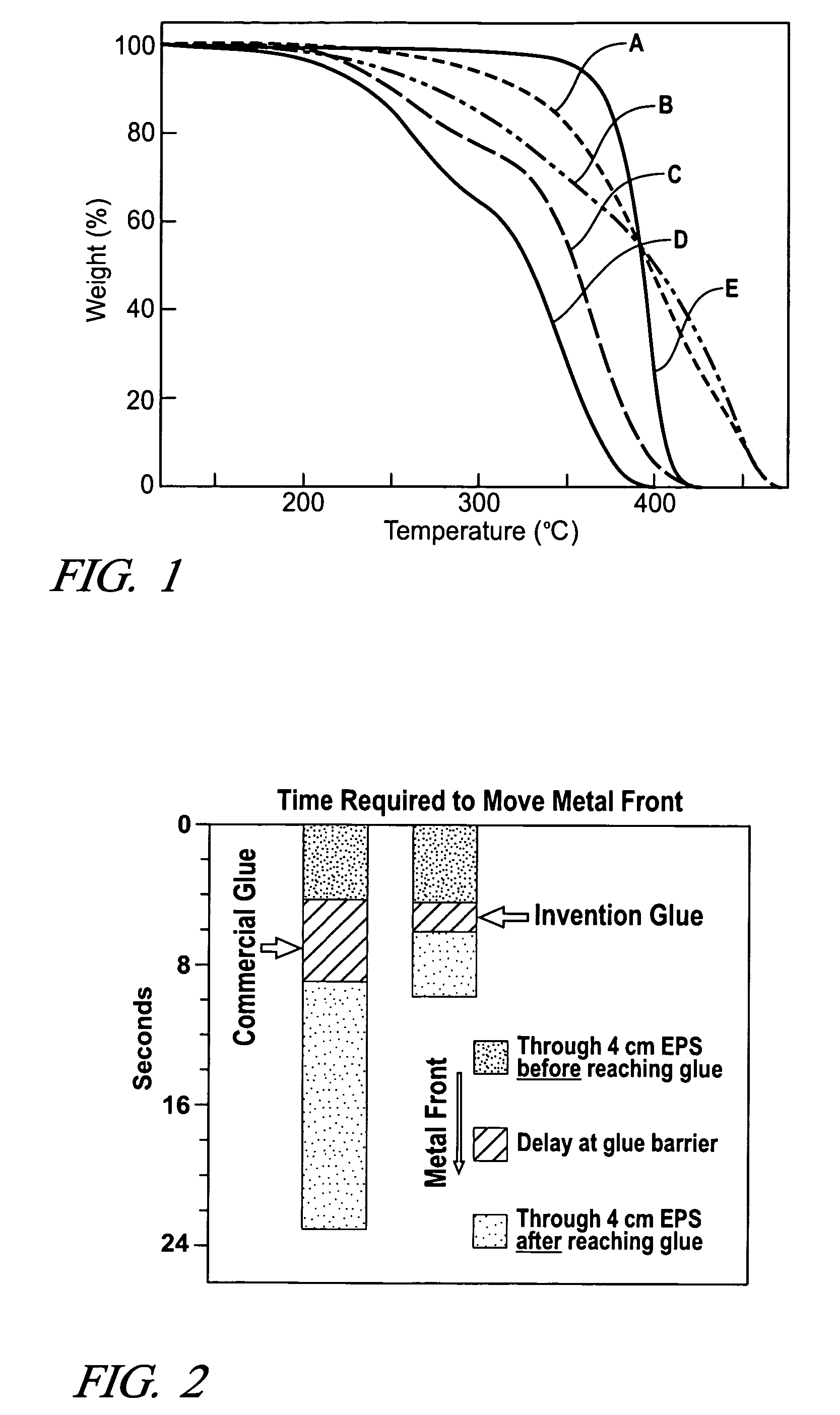

Glued lost foam casting pattern assembly

InactiveUS7318468B2Reduce formationPoor miscibilityFoundry mouldsVinyl aromatic copolymer adhesivesPlasticizerPolystyrene

Lost foam pattern assemblies formed by gluing together a plurality of EPS foam pattern segments with a polystyrene-like glue comprising an aromatic resin that has a molecular weight less than 10,000 and thermally degrades at temperatures no greater than said EPS. The glue contains sufficient first plasticizer, miscible with the resin, to impart a viscosity of about 0.1 to 5 PaS @ about 100-135° C. to the glue. The glue may optionally include a second, limited-miscibility, plasticizer to accelerate the hardening rate and increase the ultimate rigidity of the glue.

Owner:GM GLOBAL TECH OPERATIONS LLC

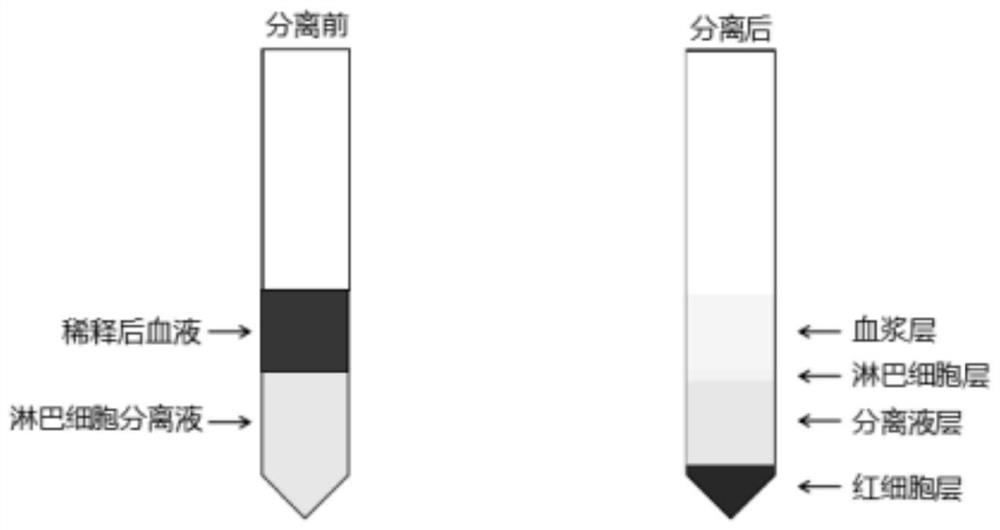

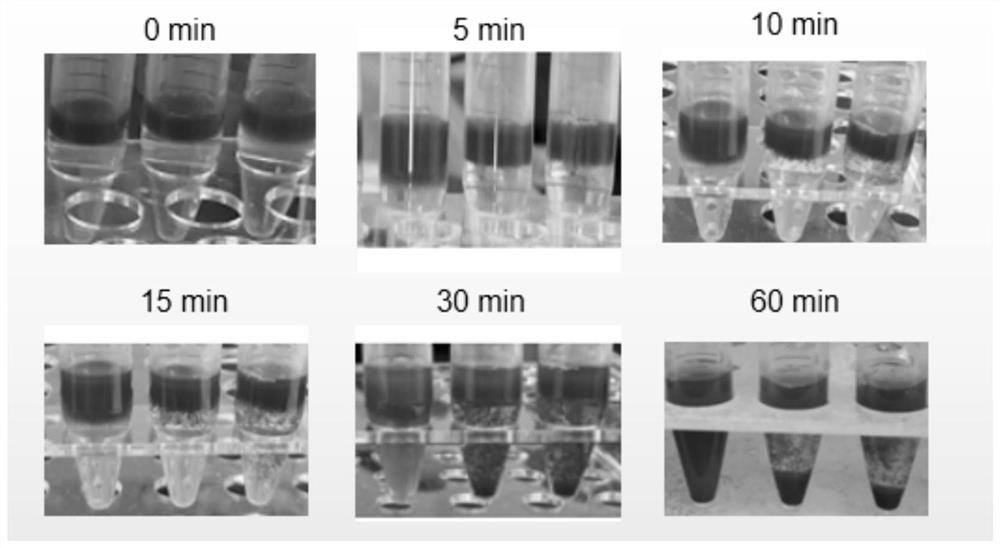

Peripheral blood lymphocyte separating medium and application thereof

The invention discloses a peripheral blood lymphocyte separating medium and application thereof. The peripheral blood lymphocyte separating medium is prepared from the following components in parts by mass: 102.8 to 110 parts of sodium diatrizoate, 10 to 30 parts of hydroxyethyl starch, 30 to 45 parts of polysucrose and 2.5 to 20 parts of polypropylene pyrrolidone. While sodium diatrizoate is adopted to replace expensive meglumine diatrizoate, other saccharide or non-saccharide macromolecules are introduced, so that the phenomenon that the separation effect is poor or unstable in the separation process of the mouse peripheral blood stranguria lysozyme is improved. The stability between the separating liquid and the blood can be maintained for a long time, the problem that the blood and the separating liquid are mutually mixed due to too long sample adding time or too large force can be prevented, and the phenomenon that the blood and the separating liquid are mutually dissolved is reduced. And the recovery efficiency, the purity and the motility rate are high, and the platelet pollution is less.

Owner:武汉赛维尔生物科技有限公司

methyl diesel

ActiveCN103865593BRich sourcesImprove performanceLiquid carbonaceous fuelsFuel additivesSulfurOctanol

The present invention discloses a methyl diesel. The methyl diesel comprises the components by mass percent of 50-80% of diesel, 11-27% of fatty acid methyl ester, 6-15% of methylal, 0.2-0.6 % of n-octanol, 0.05-0.2% of cyclohexylamine, 0.1-0.3% of naphthenic acid, 0.1-0.2% of amyl nitrate, 0.8-5% of detergent and 1-2% of stabilizer. The methyl diesel disclosed by the invention has good protective effect on the power system and fuel supply system of the vehicle; and dynamic performance, carbon deposits reduction, corrosion resistance, storage period, fuel consumption, micro metal emissions, sulfur emissions, miscibility, diesel air resistance meet or exceed the standard after the actual test is carried out.

Owner:常胜 +1

Magnesium reducing agent flux and preparation method thereof

The invention belongs to the field of non-ferrous metal metallurgy, in particular relates to a magnesium reducing agent flux and a preparation method thereof and aims at solving the problems that the impurity removing effect of a flux used by an existing magnesium reducing agent is poor and the quality of a refined magnesium reducing agent is still poor. The magnesium reducing agent flux provided by the invention comprises the following chemical ingredients: 15-20% of MgCl2, 30-40% of KCl, 10-25% of NaCl, 25-30% of CaCl2, 3.5-4.5% of CaF2, 1.5-2.5% of mixture of TiCl2 and TiCl3 and the balance of inevitable impurities. When the flux provided by the invention is adopted for treating a magnesium reducing agent obtained by a magnesium electrolysis technology, the quality of the magnesium reducing agent can be greatly improved, and a powerful support is provided for improvement of quality of subsequently produced sponge titanium. The flux provided by the invention has the advantages that raw materials are simple and easy to get, high design investment is not needed, and the feasibility is strong, so that the flux provided by the invention has stronger application and popularization prospects.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

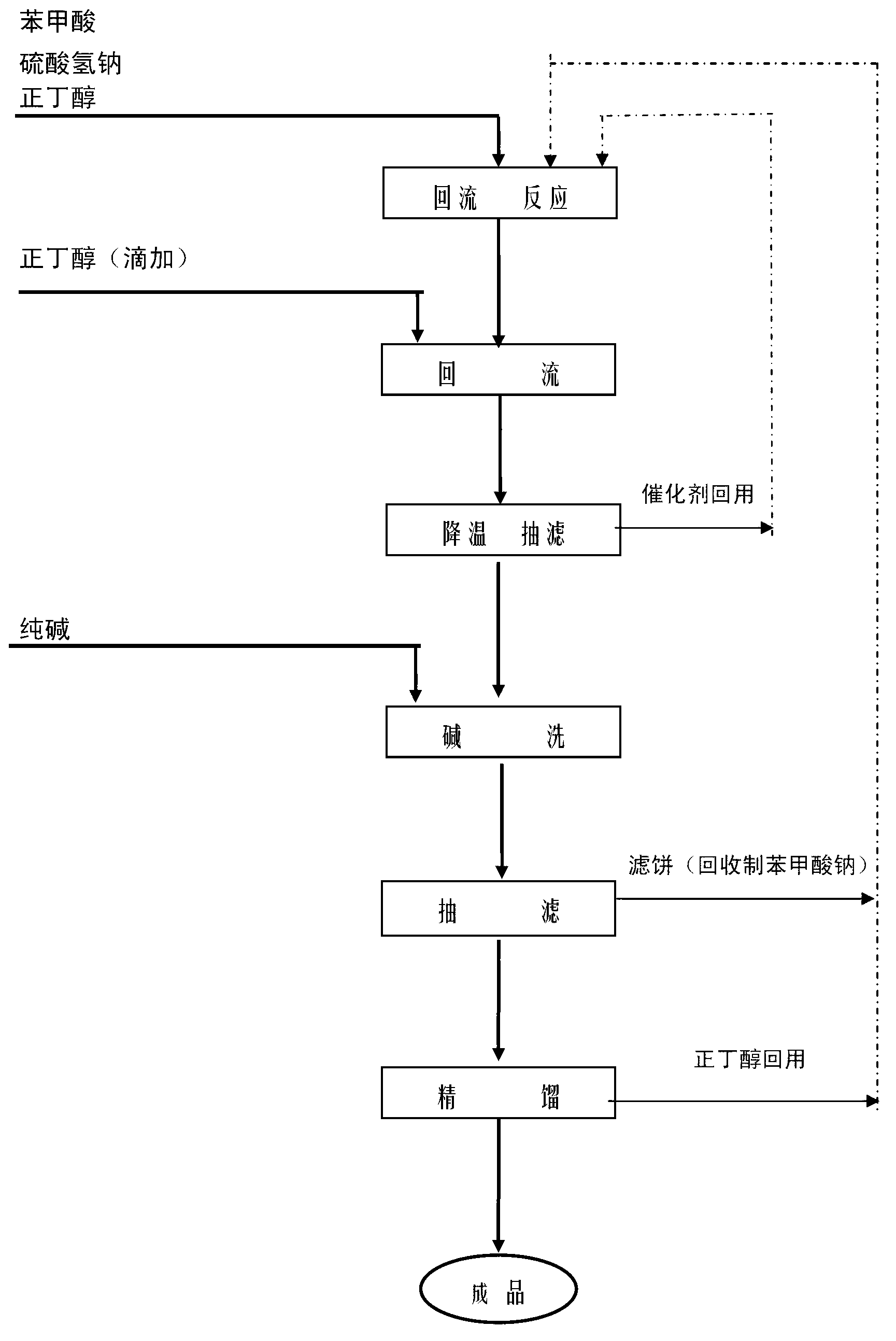

Preparation method of n-butyl benzoate

InactiveCN103012151AReduce corrosionImprove performanceOrganic compound preparationCarboxylic acid esters preparationBenzoic acidN-Butyl Alcohol

The invention discloses a preparation method of n-butyl benzoate. The preparation method mainly comprises the following steps of: taking benzoic acid as a raw material, enabling the benzoic acid to react with n-butyl alcohol under the existence of a solid acid catalyst to obtain a crude product, then neutralizing the crude product by using solid alkali, and then rectifying and purifying to obtain the finished product, namely the n-butyl benzoate. The preparation method disclosed by the invention is simple, convenient and stable in operation process, little in three-waste pollution and suitable for industrial production.

Owner:WUHAN YOUJI IND

Magnetic storage media with Ag, Au-containing magnetic layers

InactiveUS20070202363A1Improve isolationPoor miscibilityRecord information storageMagnetic recordingMagnetic layerMagnetic storage

A magnetic recording medium having a Au, Ag-containing magnetic layer having Co, Cr, Ag and Au; the magnetic recording layer having Co-containing magnetic grains surrounded by substantially nonmagnetic Cr-containing grain boundaries; wherein said Ag and said Au are substantially immiscible in the Co-containing magnetic grains is disclosed.

Owner:SEAGATE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com