Magnesium reducing agent flux and preparation method thereof

A technology of reducing agent and flux, which is applied in the field of magnesium reducing agent flux and its preparation, can solve the problems of poor quality of magnesium reducing agent and the achievement of magnesium reducing agent, and achieve the effect of reducing impurity content, removing impurities and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a kind of preparation method of above-mentioned magnesium reducing agent flux, comprises the following steps:

[0028] a, KCl, NaCl and CaCl 2 After heating and melting at 750-800°C, add MgCl 2 , then add CaF 2 powder, stir and mix to obtain mixed molten salt, so that MgCl in mixed molten salt 2 15-20%, KCl 30-40%, NaCl 10-25%, CaCl 2 25-30%, CaF 2 3.5~4.5%, TiCl 2 and TiCl 3 The mixture of 1.5 ~ 2.5%;

[0029] b, adding sponge titanium and TiCl to the mixed molten salt obtained in step a 4 , reacted to TiCl 2 and TiCl 3 When the content of the mixture accounts for 1.5-2.5% of the total weight of the solution, the magnesium reducing agent flux is obtained.

[0030] Magnesium reducing agent flux of the present invention adopts MgCl 2 As raw material, by adding CaCl 2 , MgCl 2and CaF 2 , and limit the impurity content of each raw material, so that the mixed molten salt composition is MgCl 2 15-20%, KCl 30-40%, NaCl 10-...

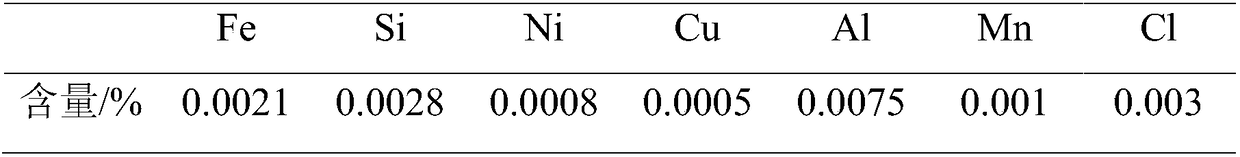

Embodiment 1

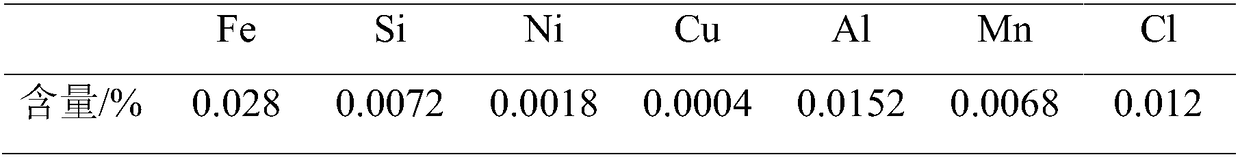

[0033] Embodiment 1 and Example 2 are the effects of refining with the magnesium reducing agent and flux of the present invention, and Comparative Example 1 is the effect of refining with the existing magnesium reducing agent and flux. In order to select a suitable concentration range of magnesium chloride, Comparative Example 2 and Comparative Example 3 were carried out. In order to select a suitable concentration range of calcium chloride, Comparative Example 4 and Comparative Example 5 were carried out. In order to select a suitable concentration range of low-valent titanium, Comparative Example 6 was carried out.

[0034] Embodiment 1 adopts flux of the present invention to refine magnesium reducing agent

[0035] Prepare magnesium reducing agent flux, concrete steps are as follows:

[0036] a, KCl, NaCl and CaCl 2 After heating and melting at 750-800°C, add MgCl 2 , then add CaF 2 Powder, stir and mix to mix the molten salt, to ensure the MgCl in the molten salt 2 1...

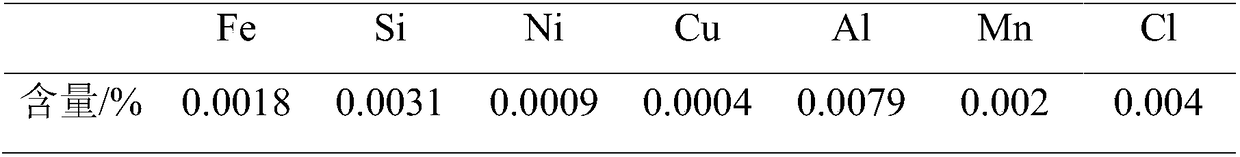

Embodiment 2

[0042] Embodiment 2 adopts flux of the present invention to refine magnesium reducing agent

[0043] Prepare magnesium reducing agent flux, concrete steps are as follows:

[0044] a, KCl, NaCl and CaCl 2 After heating and melting at 750-800°C, add MgCl 2 , then add CaF 2 Powder, stir and mix to mix the molten salt, to ensure the MgCl in the molten salt 2 18%, KCl 33%, NaCl 17%, CaCl 2 28%, CaF 2 4%;

[0045] b, adding sponge titanium and TiCl to the mixed molten salt obtained in step a 4 , reacted to TiCl 2 and TiCl 3 The content of the mixture accounts for 2% of the total flux, and the magnesium reducing agent flux is prepared.

[0046] The magnesium reducing agent flux composition prepared in Example 2 is: MgCl 2 17.5%, KCl 32.2%, NaCl 16.6%, CaCl 2 27.4%, CaF 2 3.8%, TiCl 2 and TiCl 3 The mixture is 2.2%, and the balance is impurities.

[0047] The above-mentioned magnesium reducing agent flux is used to refine the crude magnesium produced by the electrolys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com